Synergistic Effect of Nanofluids and Surfactants on Heavy Oil Recovery and Oil-Wet Calcite Wettability

Abstract

:1. Introduction

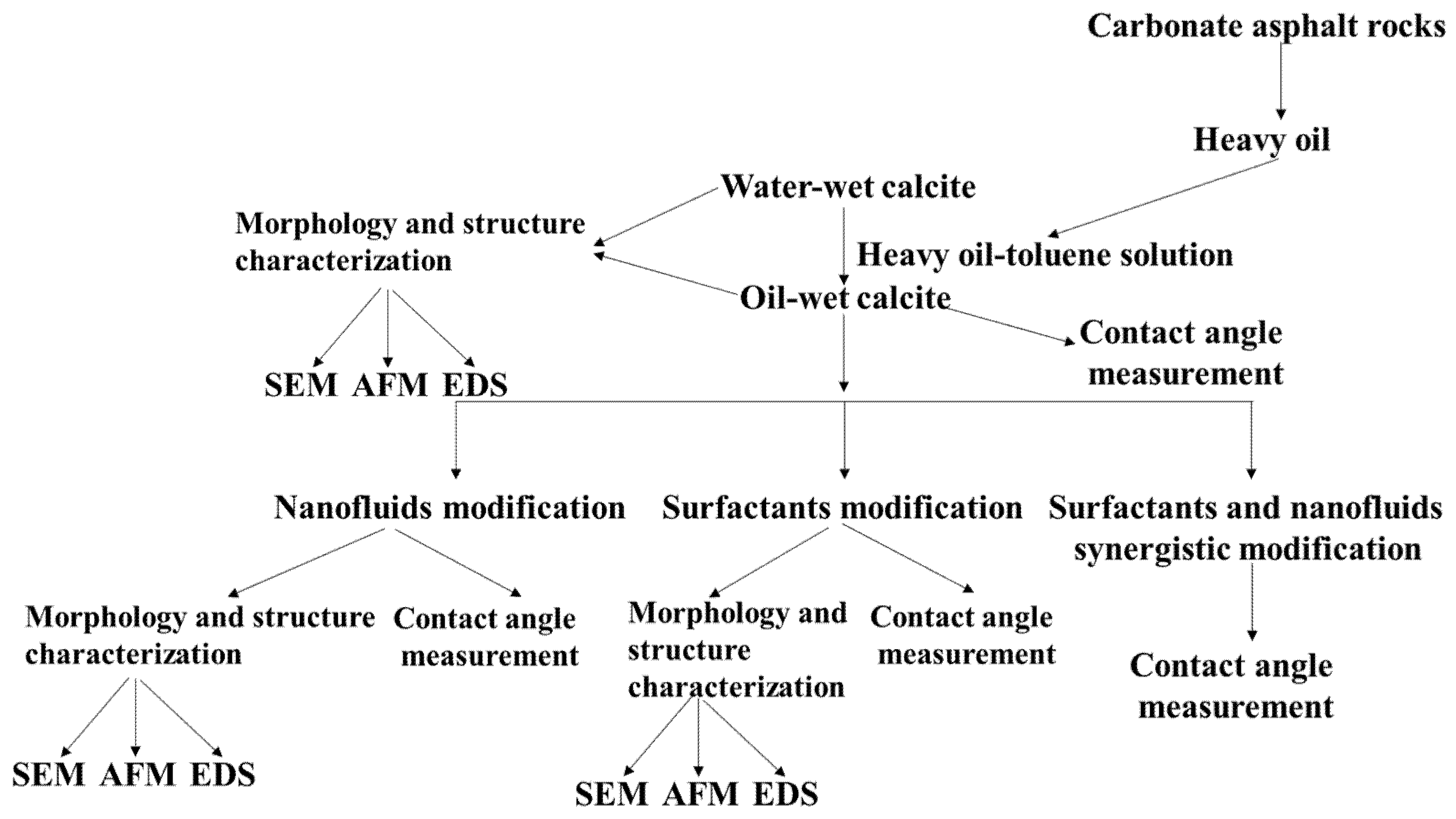

2. Materials and Methods

2.1. Materials

2.2. Heavy-Oil–Solid Separation Process

2.3. Wettability Alteration Experiment

2.4. Water-Wet Calcite Modification

2.5. Nanofluid-Treated Oil-Wet Calcite

2.6. Surfactant-Treated Oil-Wet Calcite

2.7. Synergistic Treatment of Oil-Wet Calcite with Surfactants and Nanofluids

2.8. Morphology Analysis by SEM–EDS and AFM

2.9. Zeta Potential Measurement

3. Results

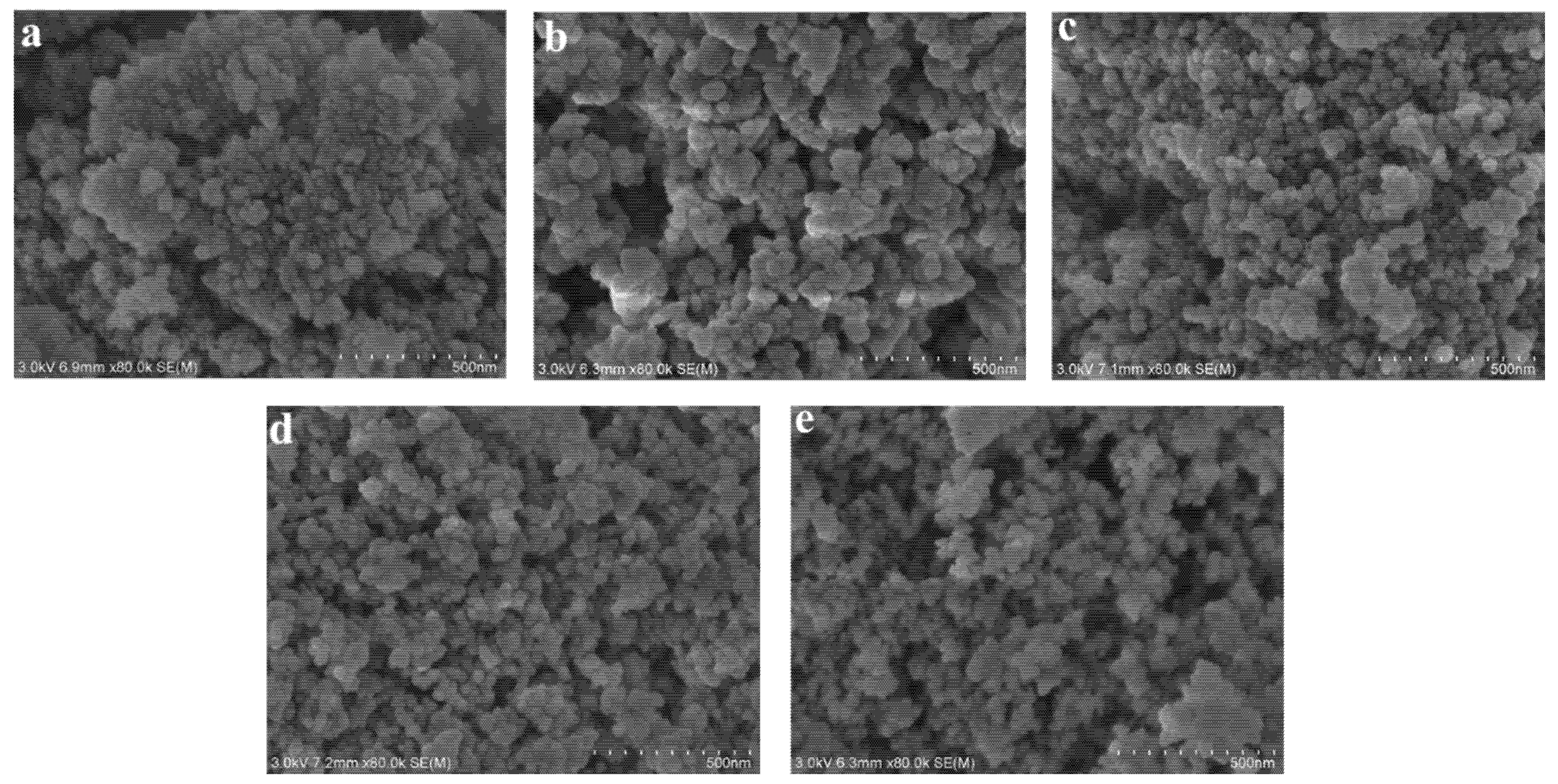

3.1. Nanoparticle Morphology Analysis

3.1.1. SEM Analysis

3.1.2. TEM Analysis

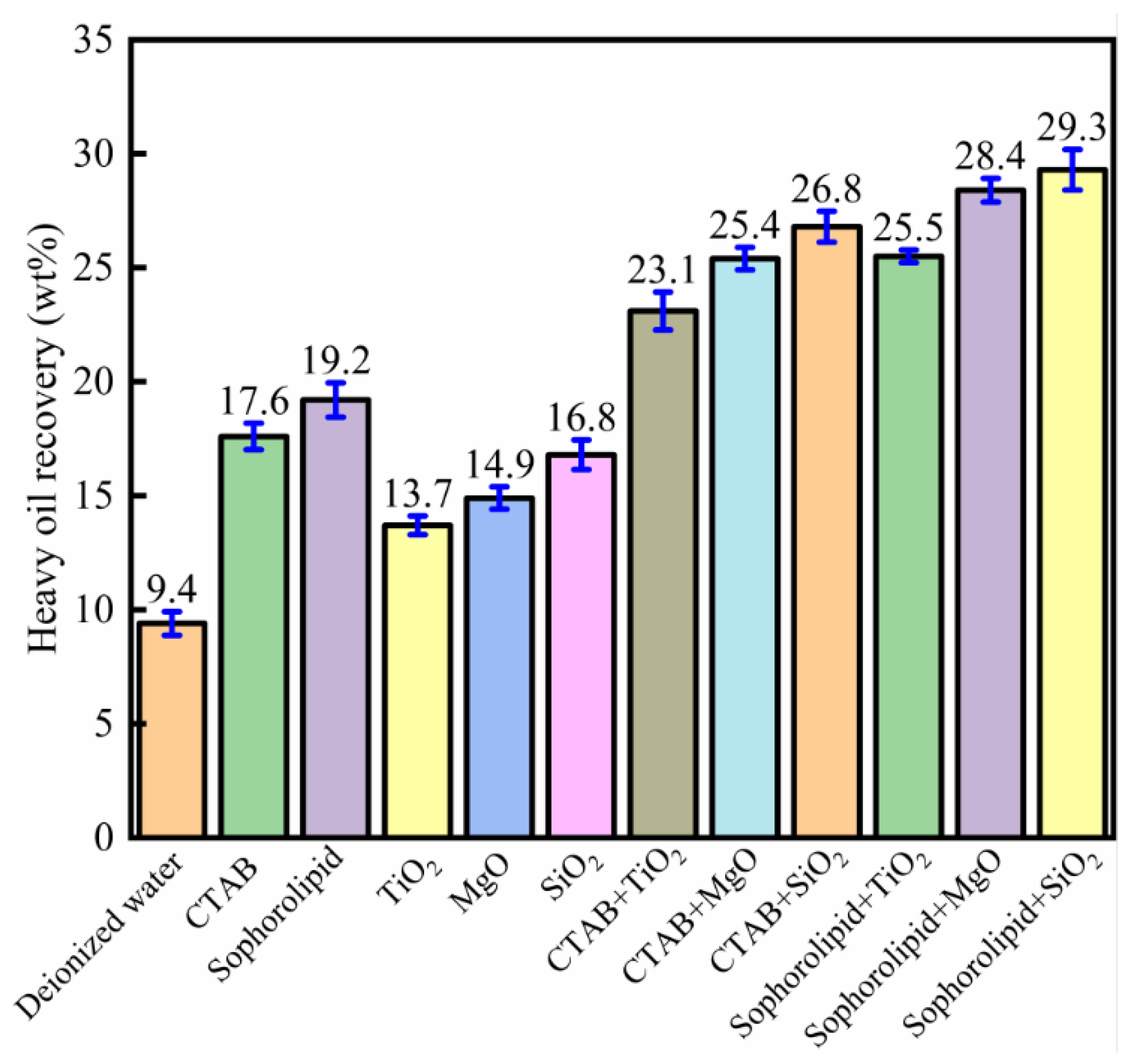

3.2. Synergistically Enhanced Oil–Solid Separation Using Surfactants and Nanofluids

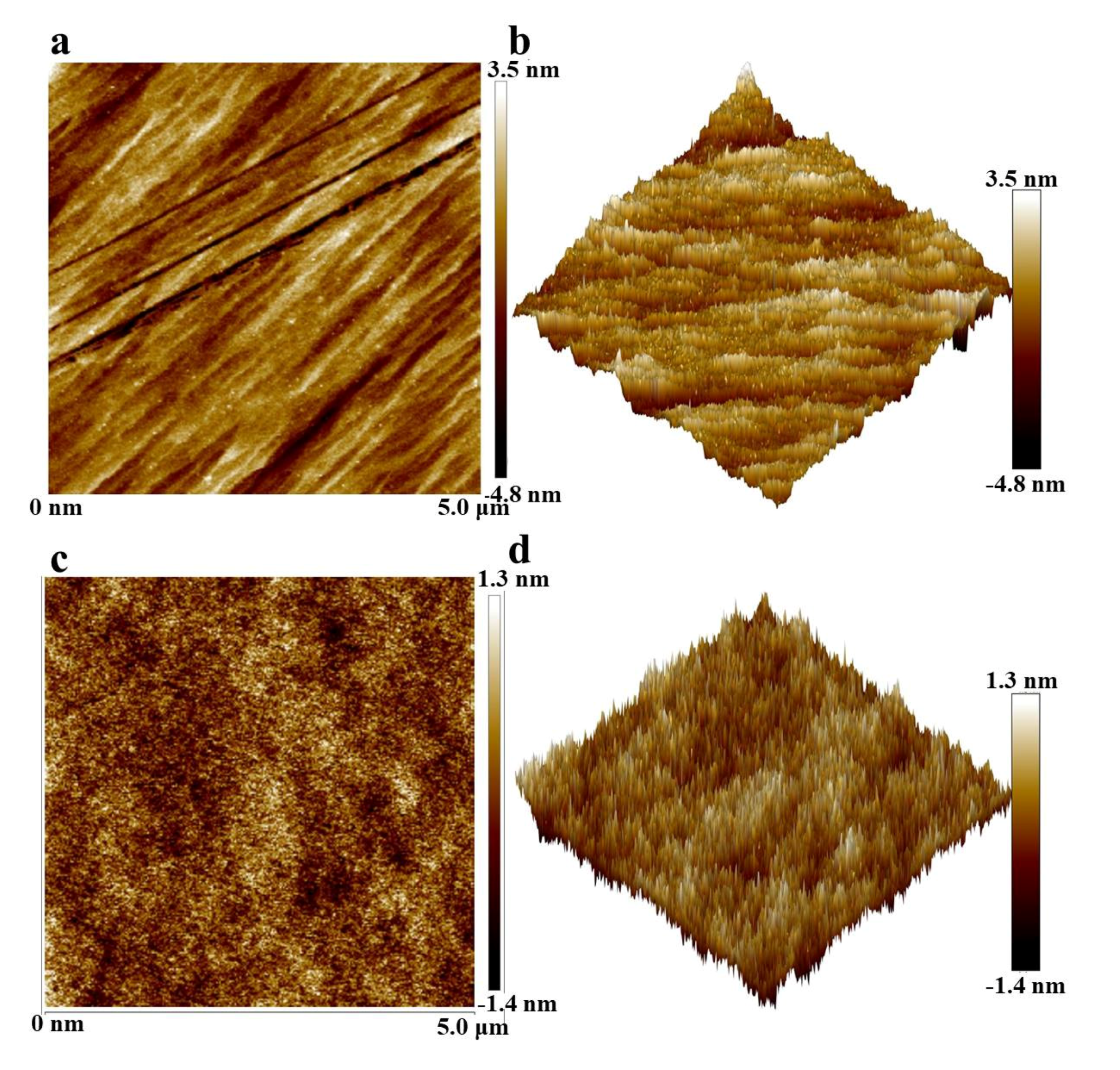

3.3. Water-Wet Calcite Surface Modification

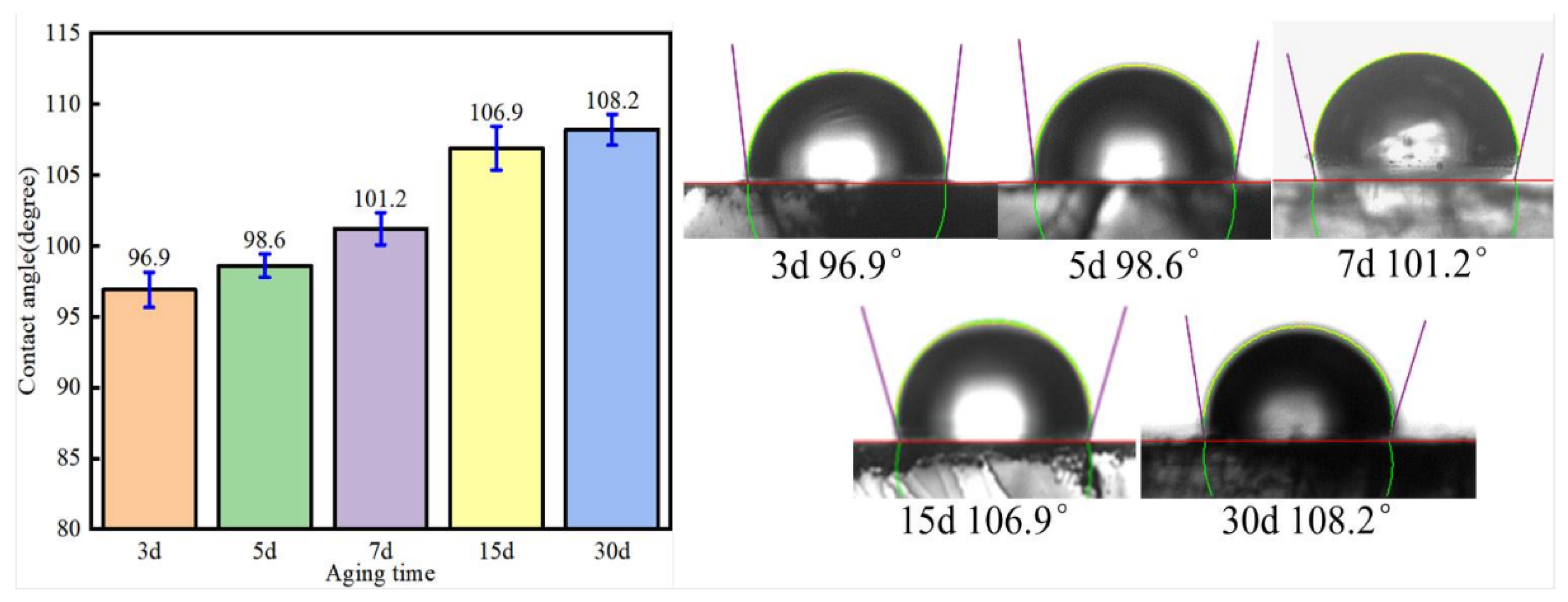

3.3.1. Aging Time on the Contact Angle

3.3.2. Morphology Analysis

3.3.3. Elemental Analysis

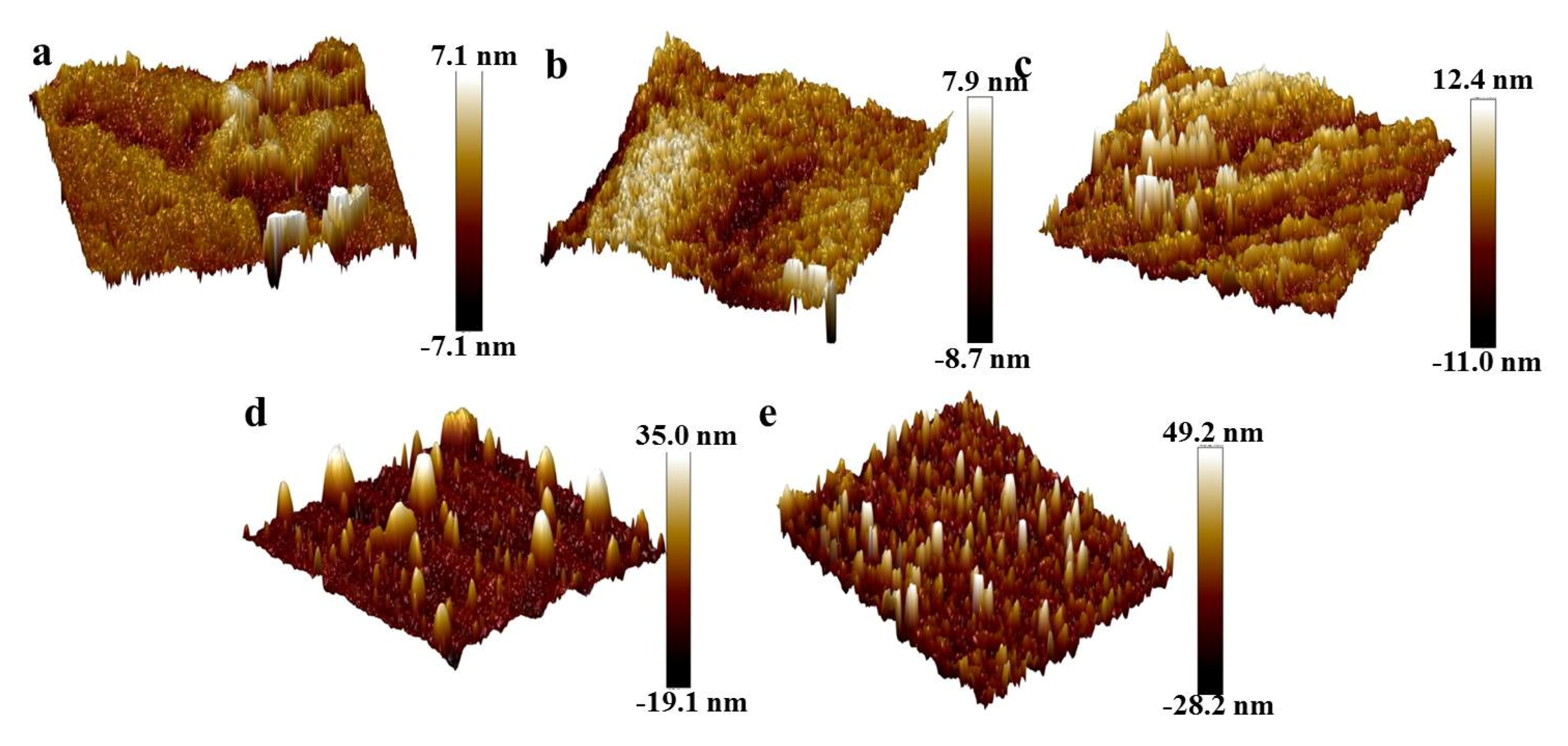

3.4. Nanofluids’ Effect on Oil-Wet Calcite Morphology and Structure

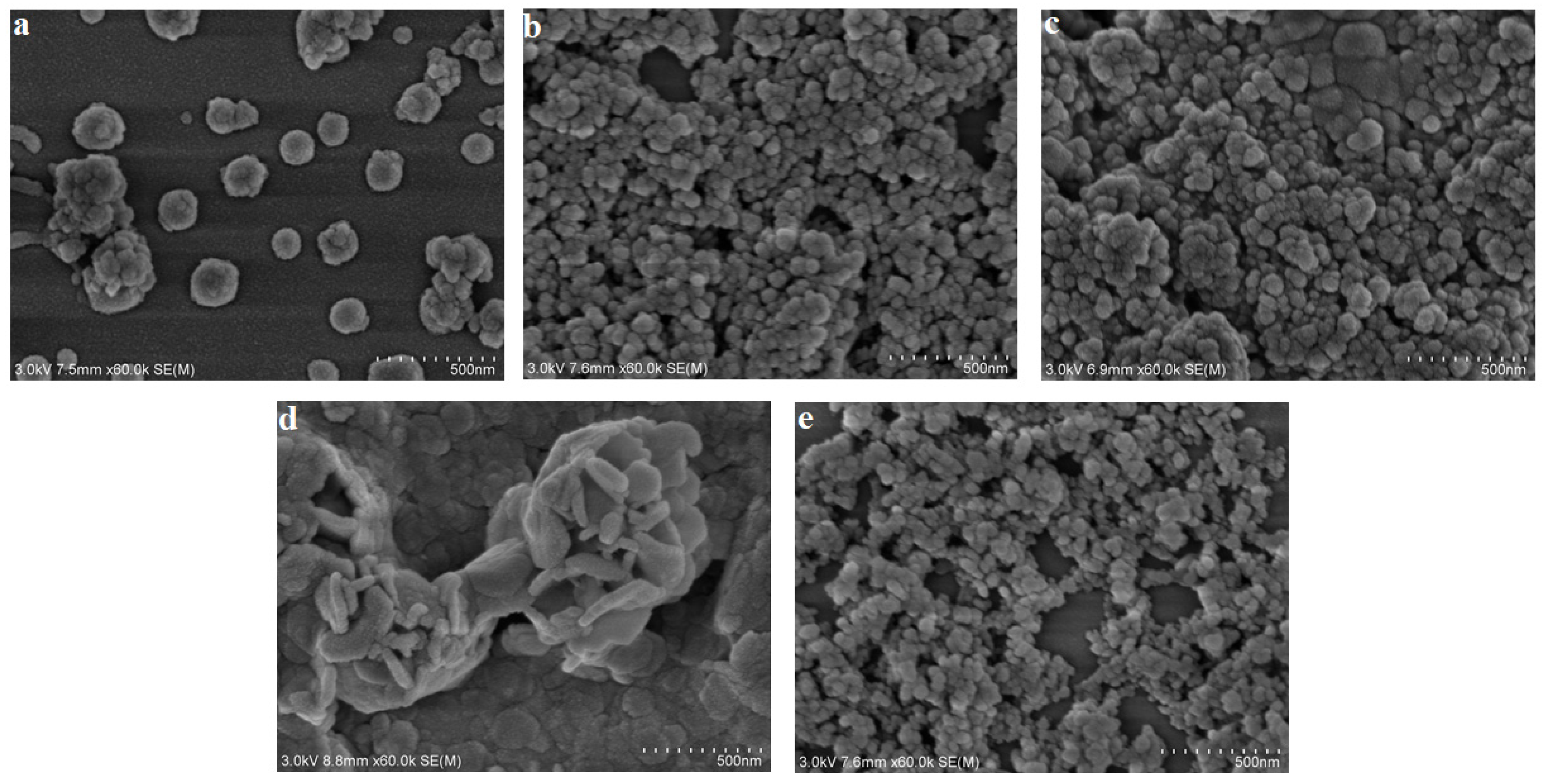

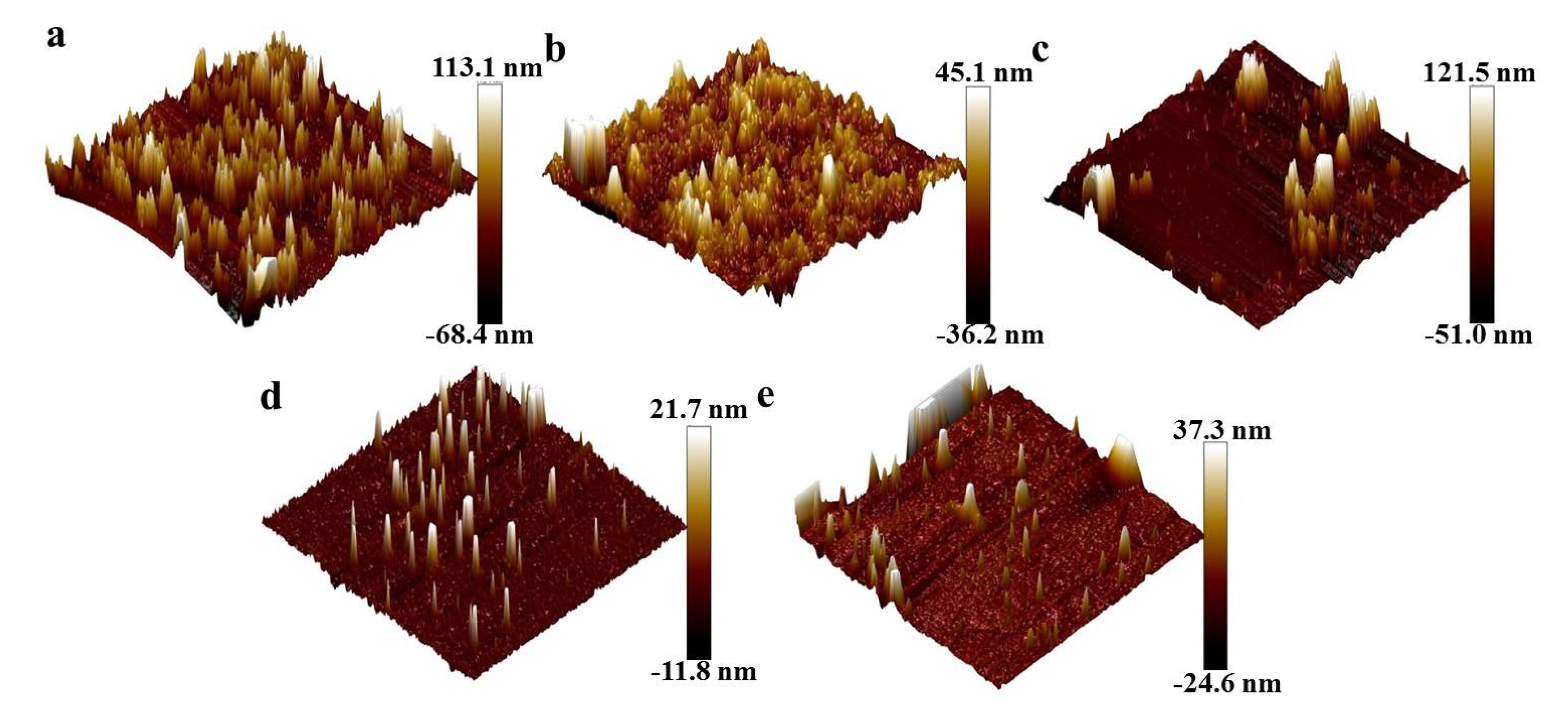

3.4.1. Morphology Analysis

3.4.2. Elemental Analysis

3.5. Surfactants’ Effect on Oil-Wet Calcite Morphology and Structure

3.5.1. Morphology Analysis

3.5.2. Elemental Analysis

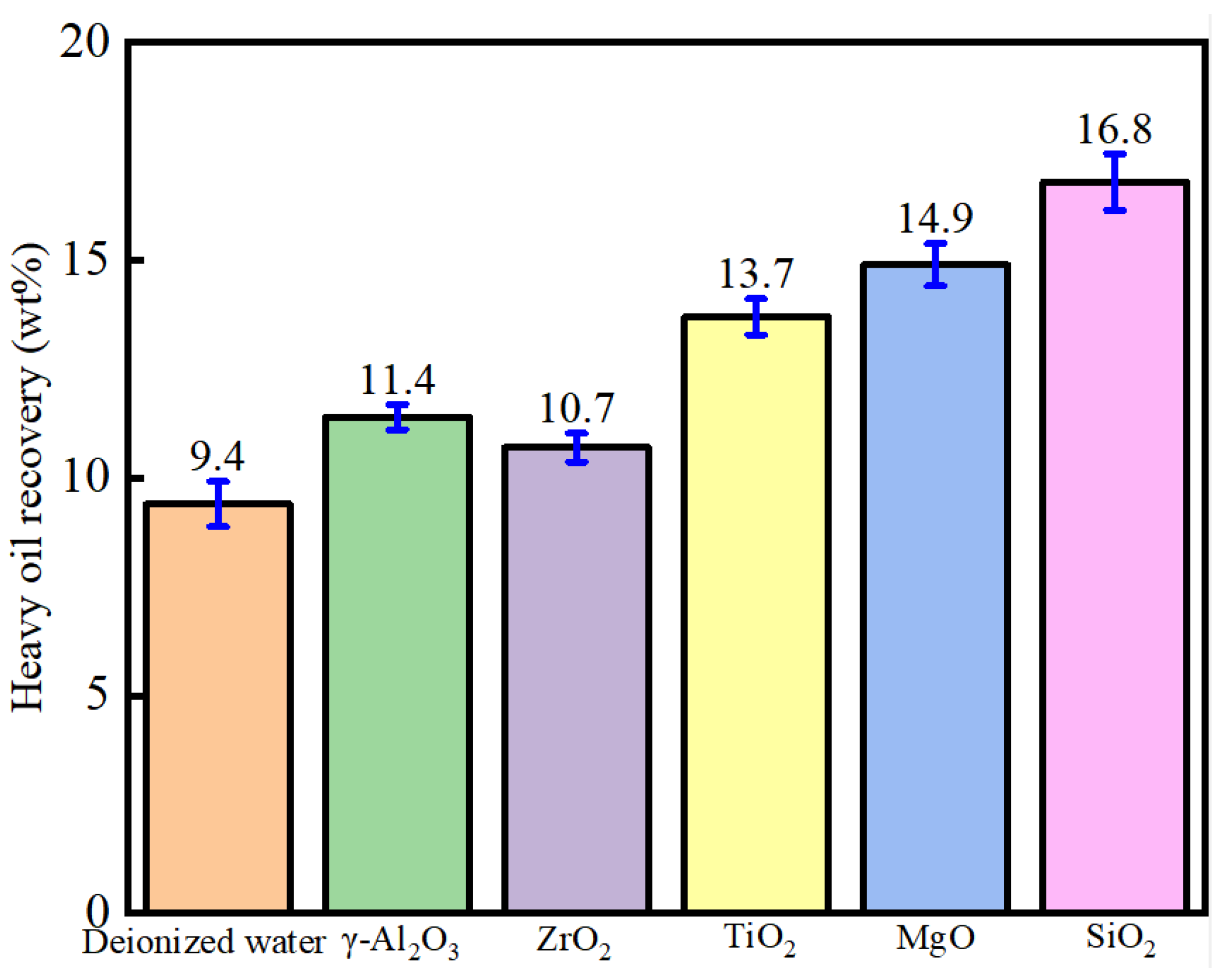

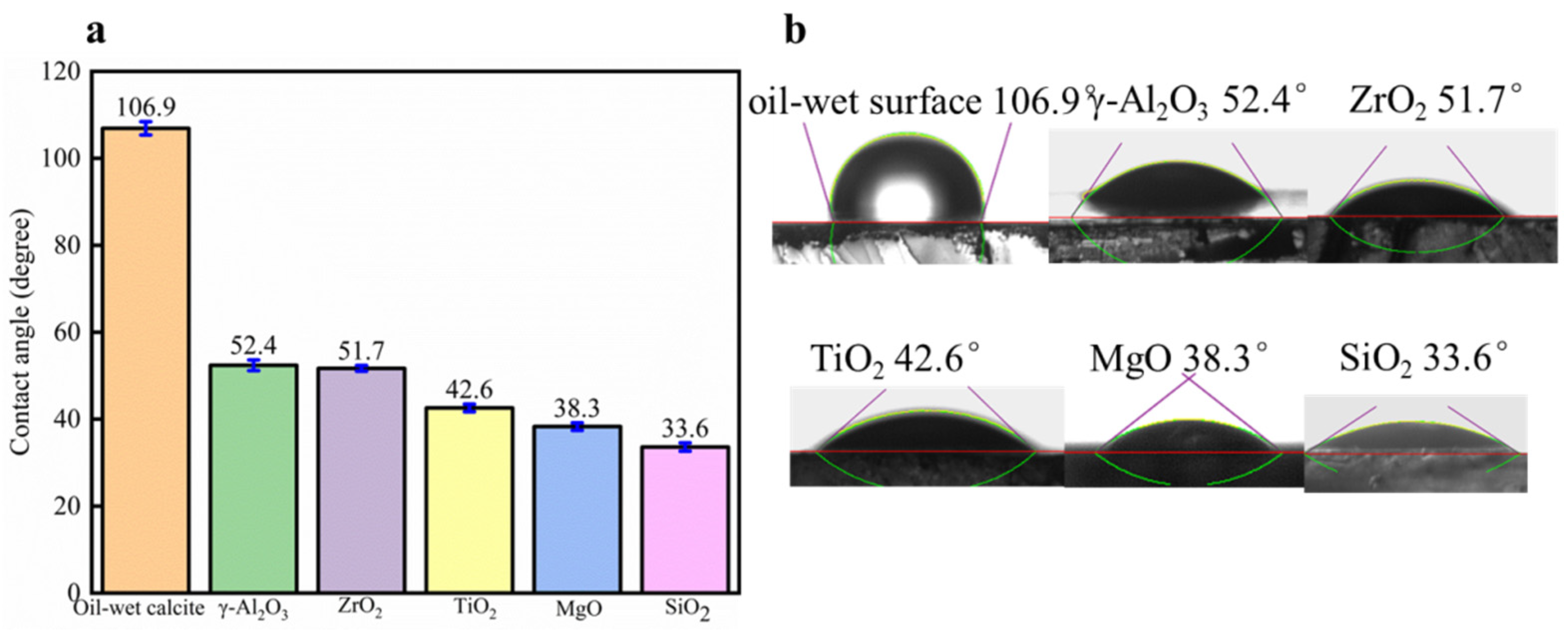

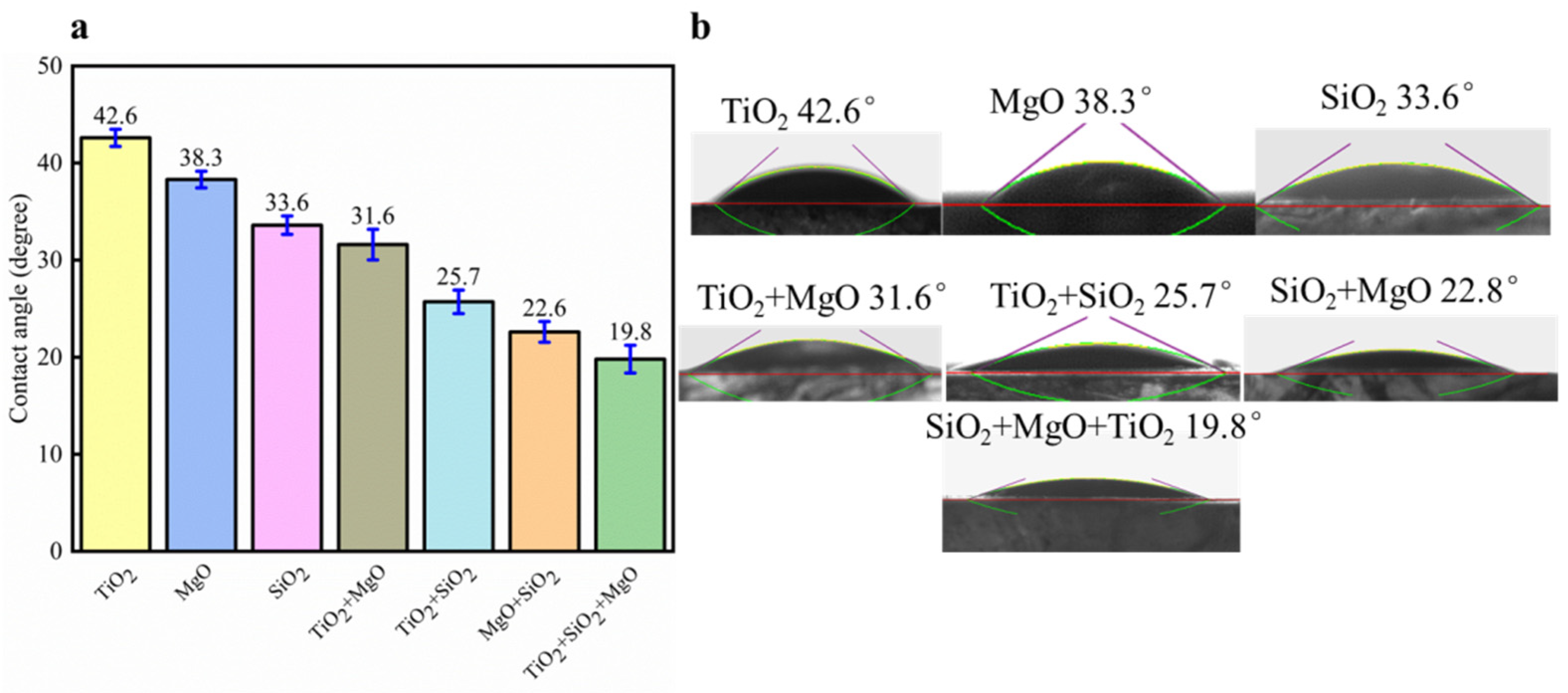

3.6. Nanofluids’ Effect on Oil-Wet Calcite Wettability

3.6.1. Nanofluid Species Effect

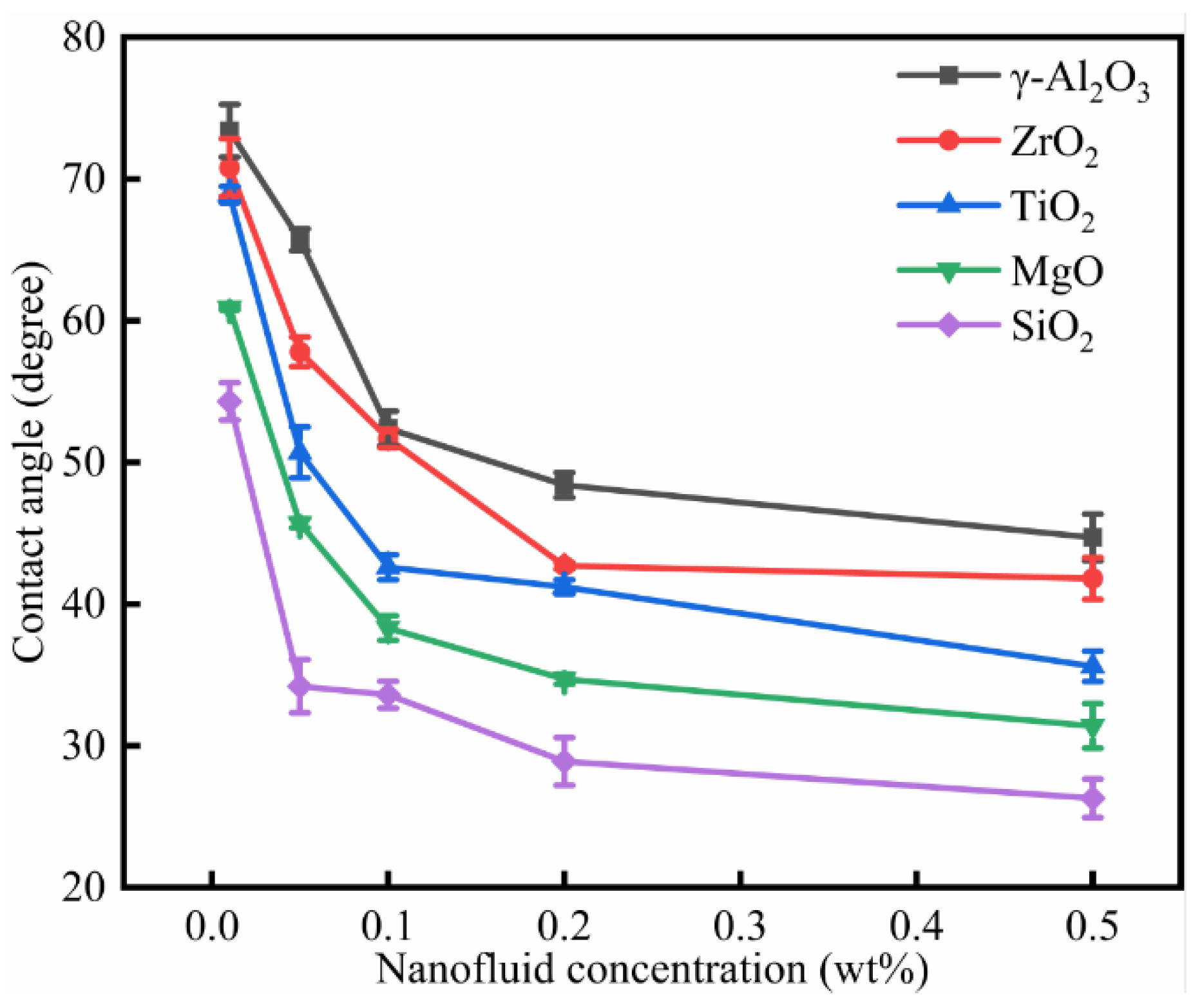

3.6.2. Nanofluid Concentration Effect

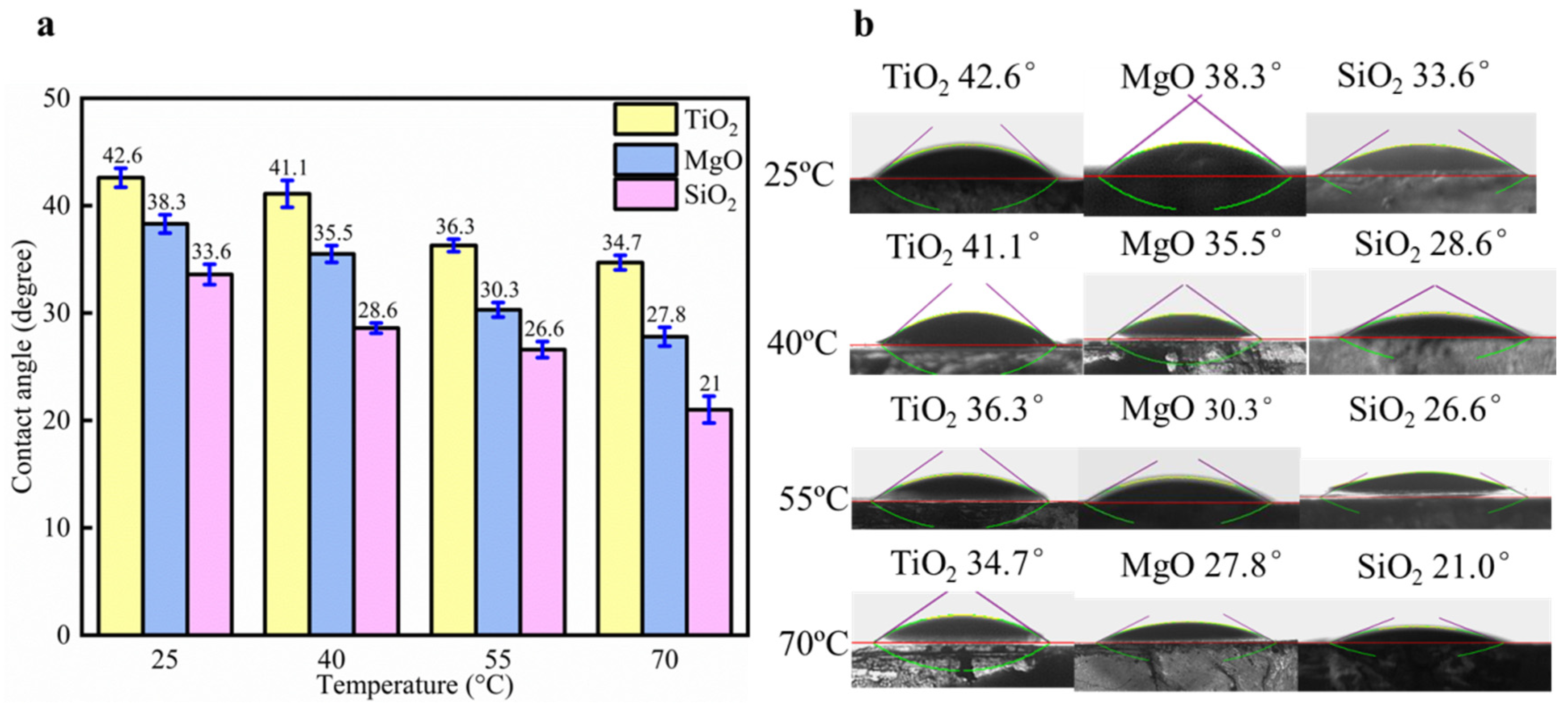

3.6.3. Temperature Effect

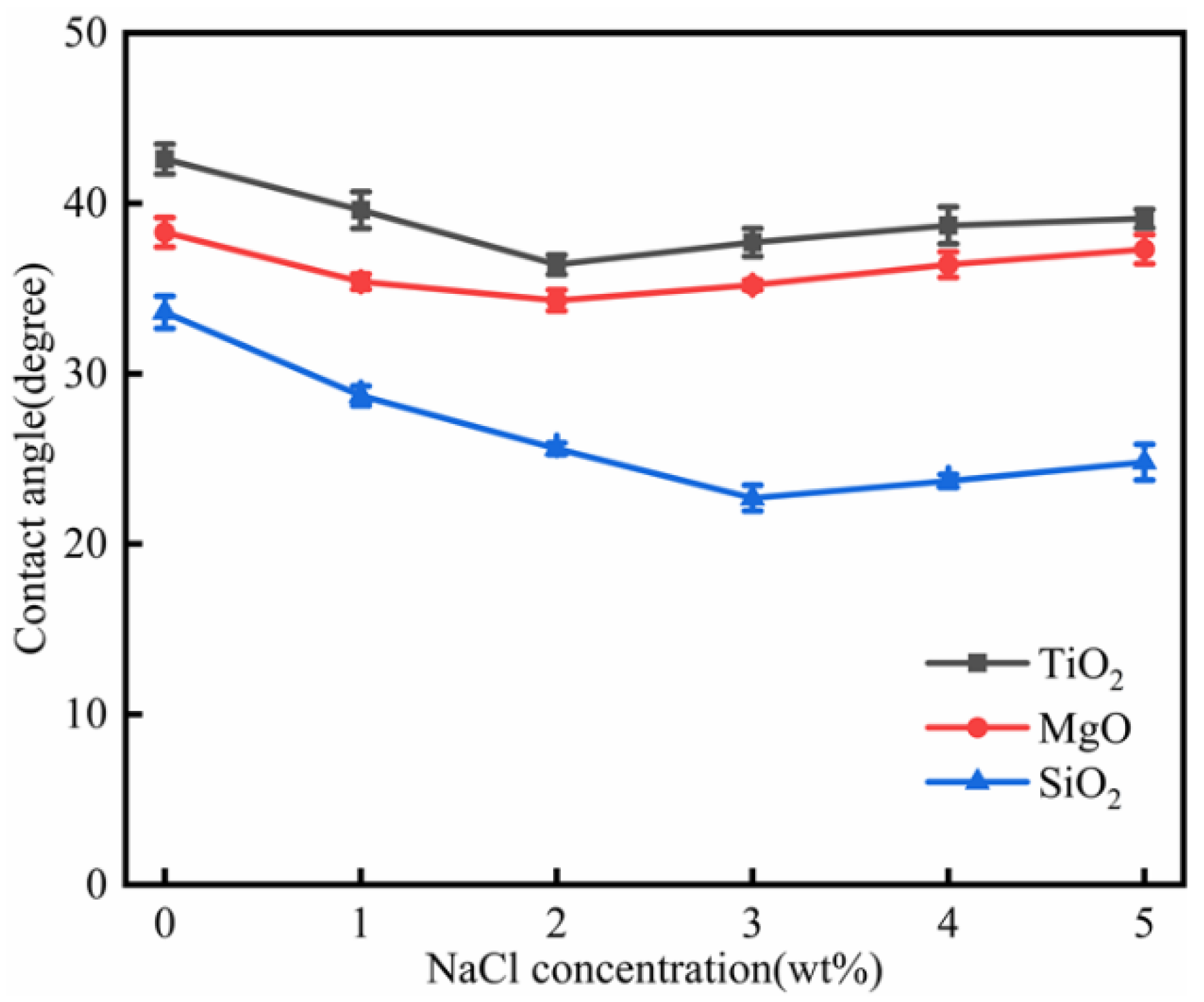

3.6.4. Salinity Effect

3.7. Surfactants’ Effect on Oil-Wet Calcite Wettability

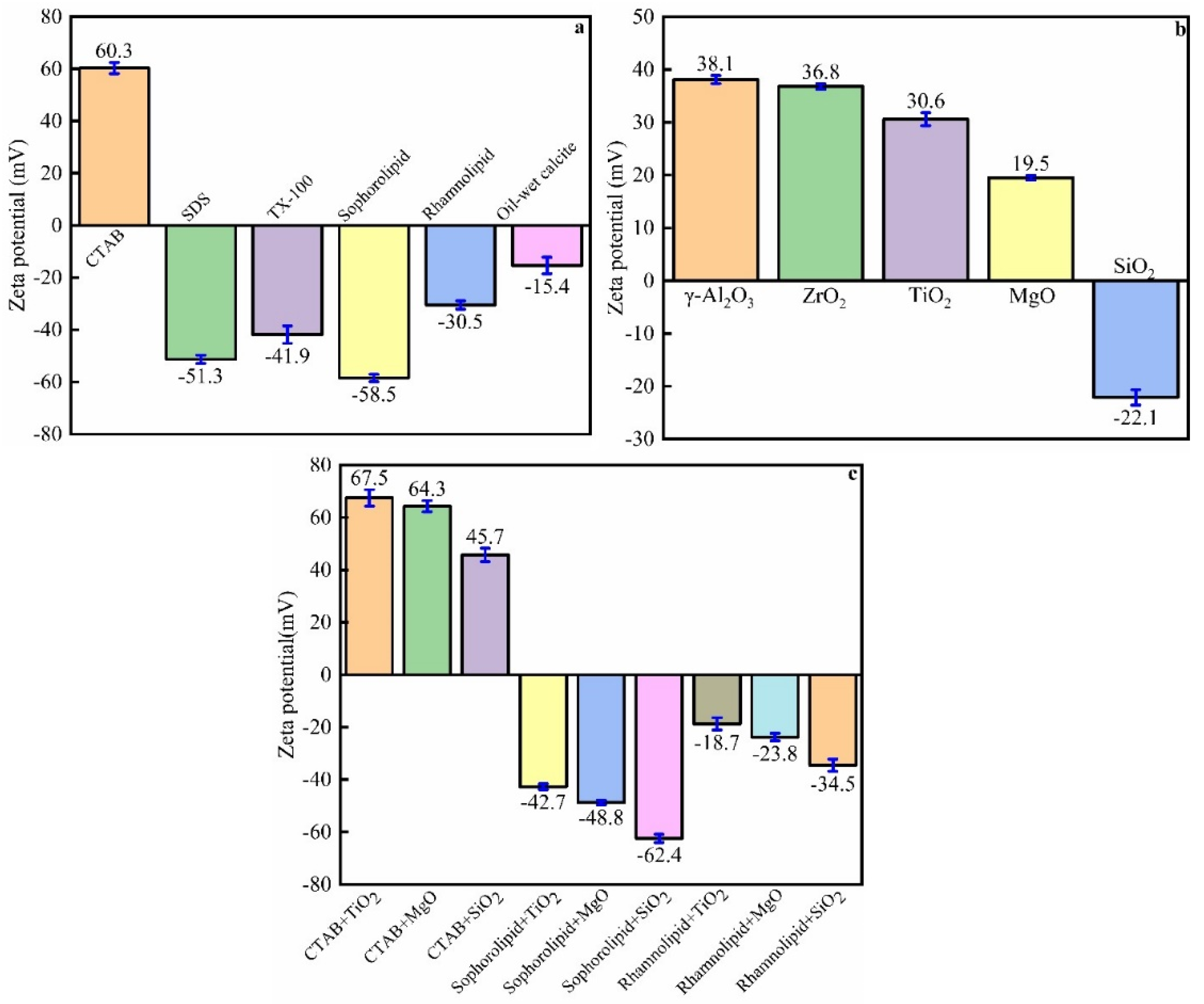

3.8. Zeta Potential Measurement

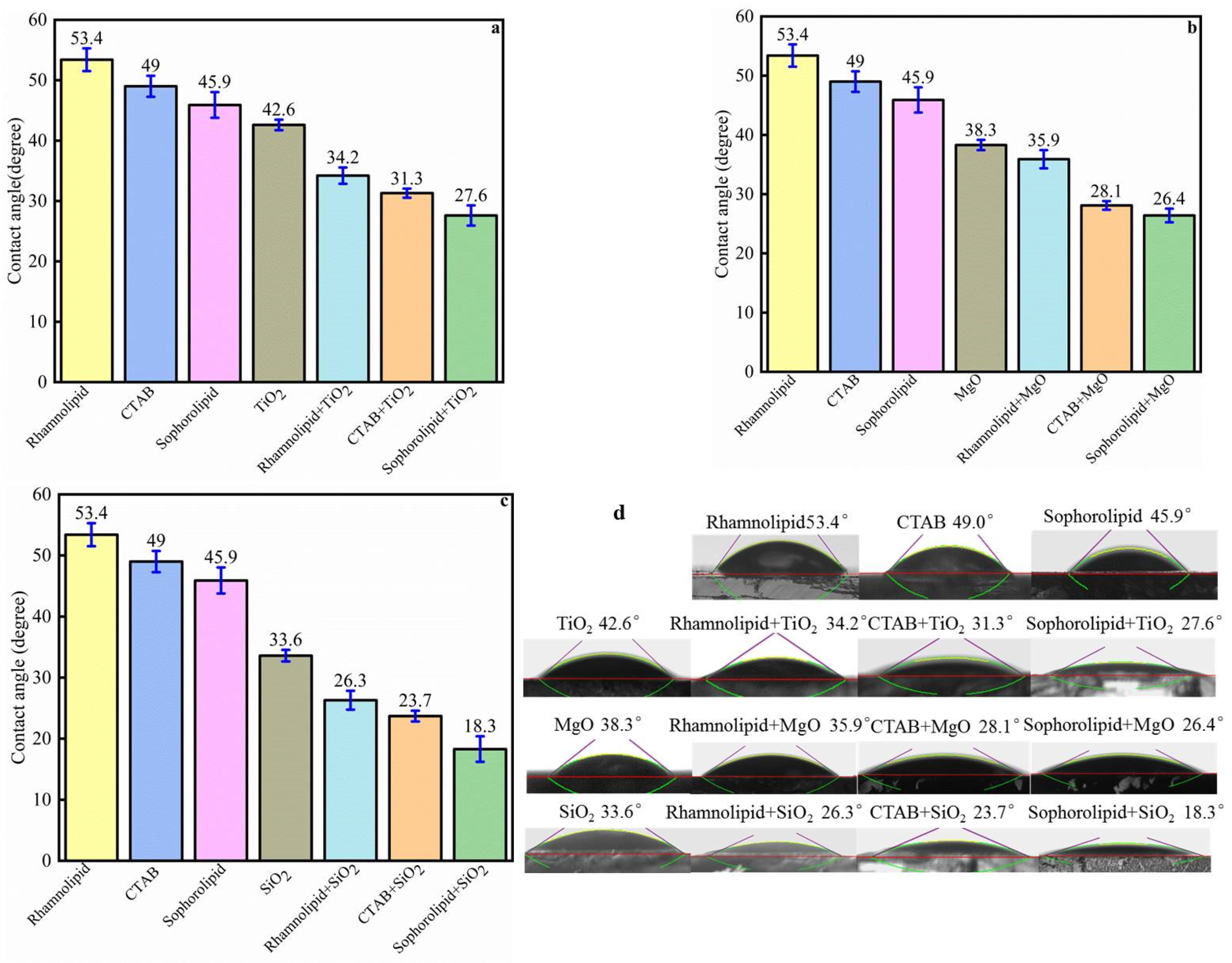

3.9. Synergistic Effect of Nanofluids and Surfactants on Oil-Wet Calcite Wettability

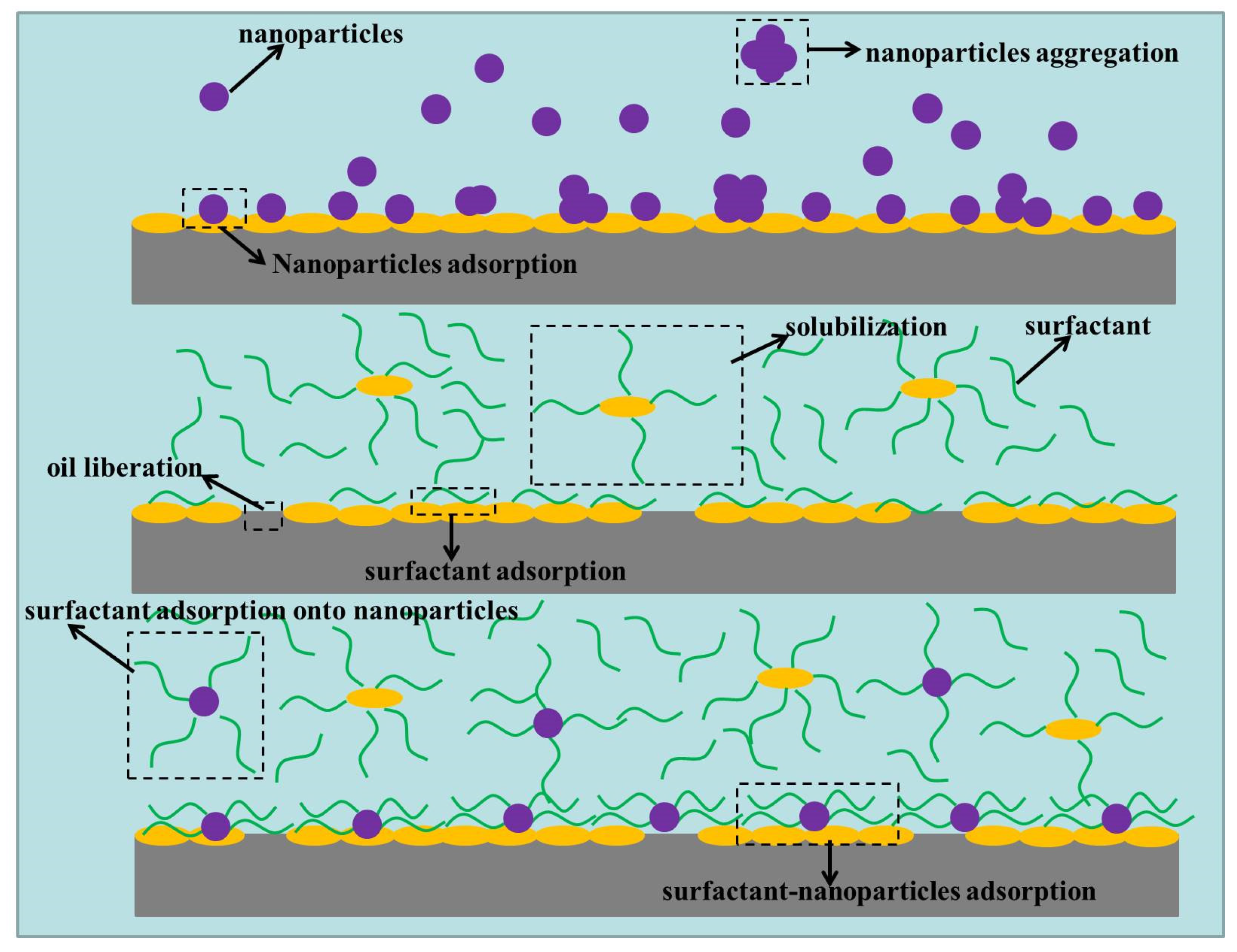

3.10. Synergistic Effect Mechanism

4. Conclusions

- Nanofluids alone or surfactants alone could effectively alter oil-wet calcite surface wettability and render the oil-wet calcite surface more hydrophilic. The reasons were as follows: Nanoparticles could adsorb onto the mineral surface, which made the oil-wet calcite surface more hydrophilic. Furthermore, surfactant molecules could assist heavy oil to be released from the calcite surface, which exposed the surface. The surfactants could then adsorb onto the oil-wet calcite surface, and the nanofluids and surfactants could synergistically alter the oil-wet calcite surface wettability.

- Surfactants alone could alter the oil-wet calcite surface wettability, and their effect in increasing the water contact angle occurred according to the following order: sophorolipid (45.9°) < CTAB (49°) < rhamnolipid (53.4°) < TX-100 (58.4°) < SDS (67.5°). Of the tested surfactants, sophorolipid showed the optimal effect on the oil-wet calcite surface.

- Nanofluids alone could also alter oil-wet calcite surface wettability, and their effect in increasing oil-wet calcite wettability occurred according to the following order: SiO2 > MgO > TiO2 > ZrO2 > γ-Al2O3. Nanofluid concentration, salinity, and temperature influence the oil-wet calcite wettability; the optimal nanofluid concentration was 0.2 wt%, and the optimal salinity was 3 wt% for SiO2 nanofluids.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, W.S.; Guo, X.W.; Liu, J. Bitumen Recovery from Indonesian Oil Sands Using ASP (Alkali, Surfactant and Polymer) Agent. China Pet. Process. Petrochem. Technol. 2018, 20, 110–115. [Google Scholar]

- Nie, F.; He, D.M.; Guan, J.; Bao, H.; Zhang, K.S.; Meng, T.; Zhang, Q.M. Influence of Temperature on the Product Distribution during the Fast Pyrolysis of Indonesian Oil Sands and the Relationships of the Products to the Oil Sand Organic Structure. Energy Fuels 2017, 31, 1318–1328. [Google Scholar] [CrossRef]

- Han, D.Y.; Luo, K.Y.; Shi, W.W.; Qiao, H.Y.; Cao, Z.B. Enhanced recovery of bitumen from Indonesian oil sands using organic and aqueous double phase extraction system. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 1679–1685. [Google Scholar] [CrossRef]

- Wang, Q.; Jia, C.X.; Ge, J.X.; Guo, W.X. H-1 NMR and C-13 NMR Studies of Oil from Pyrolysis of Indonesian Oil Sands. Energy Fuels 2016, 30, 2478–2491. [Google Scholar]

- Chen, H.S.; Li, X.; Zhang, Q.M.; Liu, Y.S. Effects of Hot Water-Based Extraction Process on the Removal of Petroleum Hydrocarbons from the Oil-Contaminated Soil. Energy Fuels 2020, 34, 3621–3627. [Google Scholar] [CrossRef]

- Khammar, M.; Xu, Y.M. Batch Solvent Extraction of Bitumen from Oil Sand. Part 1: Theoretical Basis. Energy Fuels 2017, 31, 4616–4625. [Google Scholar] [CrossRef]

- Khammar, M.; Xu, Y.M. Batch Solvent Extraction of Bitumen from Oil Sand. Part 2: Experimental Development and Modeling. Energy Fuels 2017, 31, 4626–4636. [Google Scholar] [CrossRef]

- Rudyk, S.; Spirov, P.; Al-Hajri, R.; Vakili-Nezhaad, G. Supercritical carbon dioxide extraction of oil sand enhanced by water and alcohols as Co-solvents. J. CO2 Util. 2017, 17, 90–98. [Google Scholar] [CrossRef]

- Soiket, M.I.H.; Oni, A.O.; Kumar, A. The development of a process simulation model for energy consumption and greenhouse gas emissions of a vapor solvent-based oil sands extraction and recovery process. Energy 2019, 173, 799–808. [Google Scholar] [CrossRef]

- Jha, N.K.; Ivanova, A.; Lebedev, M.; Barifcani, A.; Cheremisin, A.; Iglauer, S.; Sangwai, J.S.; Sarmadivaleh, M. Interaction of low salinity surfactant nanofluids with carbonate surfaces and molecular level dynamics at fluid-fluid interface at ScCO2 loading. J. Colloid Interface Sci. 2021, 586, 315–325. [Google Scholar] [CrossRef]

- Chen, Q.Y.; Jiang, X.; Zhen, J.C. Preparation and characterization of temperature sensitive iron oxide nanoparticle and its application on enhanced oil recovery. J. Pet. Sci. Eng. 2021, 198, 7. [Google Scholar] [CrossRef]

- Cheraghian, G.; Hendraningrat, L. A review on applications of nanotechnology in the enhanced oil recovery part A: Effects of nanoparticles on interfacial tension. Int. Nano Lett. 2016, 6, 129–138. [Google Scholar] [CrossRef] [Green Version]

- Cheraghian, G. Effects of titanium dioxide nanoparticles on the efficiency of surfactant flooding of heavy oil in a glass micromodel. Pet. Sci. Technol. 2016, 34, 260–267. [Google Scholar] [CrossRef]

- Smits, J.; Giri, R.P.; Shen, C.; Mendonca, D.; Murphy, B.; Huber, P.; Rezwan, K.; Maas, M. Synergistic and Competitive Adsorption of Hydrophilic Nanoparticles and Oil-Soluble Surfactants at the Oil-Water Interface. Langmuir ACS J. Surfaces Colloids 2021, 37, 5659–5672. [Google Scholar] [CrossRef] [PubMed]

- Lemahieu, G.; Ontiveros, J.F.; Souza, N.T.T.; Molinier, V.; Aubry, J.M. Fast and accurate selection of surfactants for enhanced oil recovery by dynamic Salinity-Phase-Inversion (SPI). Fuel 2021, 289, 119928. [Google Scholar] [CrossRef]

- Cheraghian, G. Improved Heavy Oil Recovery by Nanofluid Surfactant Flooding—An Experimental Study. In Proceedings of the 78th EAGE Conference and Exhibition, Online, 30 May–2 June 2016. [Google Scholar]

- Cheraghian, G.; Rostami, S.; Afrand, M. Nanotechnology in Enhanced Oil Recovery. Processes 2020, 8, 1073. [Google Scholar] [CrossRef]

- Hou, B.F.; Jia, R.X.; Fu, M.L.; Wang, Y.F.; Jiang, C.; Yang, B.; Huang, Y.Q. Wettability alteration of oil-wet carbonate surface induced by self- dispersing silica nanoparticles: Mechanism and monovalent metal ion’s effect. J. Mol. Liq. 2019, 294, 9. [Google Scholar] [CrossRef]

- Al-Anssari, S.; Arif, M.; Wang, S.B.; Barifcani, A.; Lebedev, M.; Iglauer, S. Wettability of nanofluid-modified oil-wet calcite at reservoir conditions. Fuel 2018, 211, 405–414. [Google Scholar] [CrossRef]

- Bayat, A.E.; Junin, R.; Samsuri, A.; Piroozian, A.; Hokmabadi, M. Impact of Metal Oxide Nanoparticles on Enhanced Oil Recovery from Limestone Media at Several Temperatures. Energy Fuels 2014, 28, 6255–6266. [Google Scholar] [CrossRef]

- Nowrouzi, I.; Manshad, A.K.; Mohammadi, A.H. Effects of concentration and size of TiO2 nano-particles on the performance of smart water in wettability alteration and oil production under spontaneous imbibition. J. Pet. Sci. Eng. 2019, 183, 14. [Google Scholar] [CrossRef]

- Ding, F.; Gao, M.L. Pore wettability for enhanced oil recovery, contaminant adsorption and oil/water separation: A review. Adv. Colloid Interface Sci. 2021, 289, 24. [Google Scholar] [CrossRef]

- Mahmoud, T.; Samak, N.A.; Abdelhamid, M.M.; Aboulrous, A.A.; Xing, J.M. Modification Wettability and Interfacial Tension of Heavy Crude Oil by Green Bio-surfactant Based on Bacillus licheniformis and Rhodococcus erythropolis Strains under Reservoir Conditions: Microbial Enhanced Oil Recovery. Energy Fuels 2021, 35, 1648–1663. [Google Scholar] [CrossRef]

- Wang, Y.; Guan, J.J.; Wang, J.; Feng, B.H.; Xu, X.F. Electrical Conductivity and Wettability of Nanofluids Prepared by Nanocomposite of MWCNTs and Dialkyl Pentasulfide. Curr. Nanosci. 2021, 17, 151–161. [Google Scholar] [CrossRef]

- Zhao, M.W.; Lv, W.J.; Li, Y.Y.; Dai, C.L.; Zhou, H.D.; Song, X.G.; Wu, Y.N. A Study on Preparation and Stabilizing Mechanism of Hydrophobic Silica Nanofluids. Materials 2018, 11, 1385. [Google Scholar] [CrossRef] [Green Version]

- He, Y.; Liao, K.; Bai, J.; Fu, L.; Ma, Q.; Zhang, X.; Ren, Z.; Wang, W. Study on a Nonionic Surfactant/Nanoparticle Composite Flooding System for Enhanced Oil Recovery. ACS Omega 2021, 6, 11068–11076. [Google Scholar] [CrossRef]

- Suleimanov, B.A.; Ismailov, F.S.; Veliyev, E.F. Nanofluid for enhanced oil recovery. J. Pet. Sci. Eng. 2011, 78, 431–437. [Google Scholar] [CrossRef]

- Liu, D.X.; Zhang, X.; Tian, F.C.; Liu, X.W.; Yuan, J.; Huang, B. Review on nanoparticle-surfactant nanofluids: Formula fabrication and applications in enhanced oil recovery. J. Dispers. Sci. Technol. 2020. [Google Scholar] [CrossRef]

- Li, K.W.; Wang, D.; Jiang, S.S. Review on enhanced oil recovery by nanofluids. Oil Gas Sci. Technol. 2018, 73, 26. [Google Scholar] [CrossRef] [Green Version]

- Al-Anssari, S.; Arif, M.; Wang, S.B.; Barifcani, A.; Lebedev, M.; Iglauer, S. Wettability of nano-treated calcite/CO2/brine systems: Implication for enhanced CO2 storage potential. Int. J. Greenh. Gas Control 2017, 66, 97–105. [Google Scholar] [CrossRef]

- Al-Anssari, S.; Barifcani, A.; Wang, S.B.; Maxim, L.; Iglauer, S. Wettability alteration of oil-wet carbonate by silica nanofluid. J. Colloid Interface Sci. 2016, 461, 435–442. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yapu, Z. Physical Mechanics of Surfaces and Interfaces; Science Press: Beijing, China, 2012. [Google Scholar]

- Klosowska-Chomiczewska, I.E.; Kotewicz-Siudowska, A.; Artichowicz, W.; Macierzanka, A.; Glowacz-Rozynska, A.; Szumala, P.; Medrzycka, K.; Hallmann, E.; Karpenko, E.; Jungnickel, C. Towards Rational Biosurfactant Design-Predicting Solubilization in Rhamnolipid Solutions. Molecules 2021, 26, 534. [Google Scholar] [CrossRef]

- Posada-Baquero, R.; Grifoll, M.; Ortega-Calvo, J.J. Rhamnolipid-enhanced solubilization and biodegradation of PAHs in soils after conventional bioremediation. Sci. Total Environ. 2019, 668, 790–796. [Google Scholar] [CrossRef]

- Song, D.D.; Liang, S.K.; Yan, L.L.; Shang, Y.J.; Wang, X.L. Solubilization of Polycyclic Aromatic Hydrocarbons by Single and Binary Mixed Rhamnolipid-Sophorolipid Biosurfactants. J. Environ. Qual. 2016, 45, 1405–1412. [Google Scholar] [CrossRef] [PubMed]

- Monfared, A.D.; Ghazanfari, M.H.; Jamialahmadi, M.; Helalizadeh, A. Adsorption of silica nanoparticles onto calcite: Equilibrium, kinetic, thermodynamic and DLVO analysis. Chem. Eng. J. 2015, 281, 334–344. [Google Scholar] [CrossRef]

- Al-Anssari, S.; Wang, S.B.; Barifcani, A.; Lebedev, M.; Iglauer, S. Effect of temperature and SiO2 nanoparticle size on wettability alteration of oil-wet calcite. Fuel 2017, 206, 34–42. [Google Scholar] [CrossRef] [Green Version]

- Gupta, R.; Mohanty, K.K. Temperature Effects on Surfactant-Aided Imbibition into Fractured Carbonates. SPE J. 2010, 15, 587–597. [Google Scholar] [CrossRef]

- Liu, Y.F.; Qiu, Z.S.; Zhao, C.; Nie, Z.; Zhong, H.Y.; Zhao, X.; Liu, S.J.; Xing, X.J. Characterization of bitumen and a novel multiple synergistic method for reducing bitumen viscosity with nanoparticles and surfactants. RSC Adv. 2020, 10, 10471–10481. [Google Scholar] [CrossRef]

- Hadia, N.J.; Ng, Y.H.; Stubbs, L.P.; Torsaeter, O. High Salinity and High Temperature Stable Colloidal Silica Nanoparticles with Wettability Alteration Ability for EOR Applications. Nanomaterials 2021, 11, 707. [Google Scholar] [CrossRef]

- Sun, X.F.; Zhang, Y.Y.; Chen, G.P.; Liu, T.L.; Ren, D.N.; Ma, J.Y.; Sheng, Y.K.; Karwani, S. Wettability of Hybrid Nanofluid-Treated Sandstone/Heavy Oil/Brine Systems: Implications for Enhanced Heavy Oil Recovery Potential. Energy Fuels 2018, 32, 11118–11135. [Google Scholar] [CrossRef]

- Monfared, A.D.; Ghazanfari, M.H.; Jamialahmadi, M.; Helalizadeh, A. Potential Application of Silica Nanoparticles for Wettability Alteration of Oil-Wet Calcite: A Mechanistic Study. Energy Fuels 2016, 30, 3947–3961. [Google Scholar] [CrossRef]

- Bahraminejad, H.; Manshad, A.K.; Riazi, M.; Ali, J.A.; Sajadi, S.M.; Keshavarz, A. CuO/TiO2/PAM as a Novel Introduced Hybrid Agent for Water-Oil Interfacial Tension and Wettability Optimization in Chemical Enhanced Oil Recovery. Energy Fuels 2019, 33, 10547–10560. [Google Scholar] [CrossRef]

- Abhishek, R.; Hamouda, A.A.; Abdulhameed, F.M. Adsorption kinetics and enhanced oil recovery by silica nanoparticles in sandstone. Pet. Sci. Technol. 2019, 37, 1363–1369. [Google Scholar] [CrossRef]

- Abbas, A.H.; Moslemizadeh, A.; Sulaiman, W.R.W.; Jaafar, M.Z.; Agi, A. An insight into a di-chain surfactant adsorption onto sandstone minerals under different salinity-temperature conditions: Chemical EOR applications. Chem. Eng. Res. Des. 2020, 153, 657–665. [Google Scholar] [CrossRef]

- Zhang, L.L.; Jian, G.Q.; Puerto, M.; Southwick, E.; Hirasaki, G.; Biswal, S.L. Static adsorption of a switchable diamine surfactant on natural and synthetic minerals for high-salinity carbonate reservoirs. Colloid Surf. A Physicochem. Eng. Asp. 2019, 583, 7. [Google Scholar] [CrossRef]

- Liu, Z.L.; Ghatkesar, M.K.; Sudholter, E.J.R.; Singh, B.; Kumar, N. Understanding the Cation-Dependent Surfactant Adsorption on Clay Minerals in Oil Recovery. Energy Fuels 2019, 33, 12319–12329. [Google Scholar] [CrossRef]

- Sari, G.L.; Trihadiningrum, Y.; Wulandari, D.A.; Pandebesie, E.S.; Warmadewanthi, I. Compost humic acid-like isolates from composting process as bio-based surfactant: Properties and feasibility to solubilize hydrocarbon from crude oil contaminated soil. J. Environ. Manag. 2018, 225, 356–363. [Google Scholar] [CrossRef]

- Pan, T.; Liu, C.Y.; Zeng, X.Y.; Xin, Q.; Xu, M.Y.; Deng, Y.W.; Dong, W. Biotoxicity and bioavailability of hydrophobic organic compounds solubilized in nonionic surfactant micelle phase and cloud point system. Environ. Sci. Pollut. Res. 2017, 24, 14795–14801. [Google Scholar] [CrossRef] [PubMed]

| Element | Weight Content (wt%) | |

|---|---|---|

| Water-wet calcite | CK | 6.46 |

| OK | 50.23 | |

| CaK | 43.31 | |

| Oil-wet calcite | CK | 30.22 |

| OK | 27.49 | |

| CaK | 42.29 |

| Treatment Method | Element | Weight Content (wt%) | Treatment Method | Element | Weight Content (wt%) |

|---|---|---|---|---|---|

| Oil-wet calcite | C | 30.22 | Al2O3 treat | C | 7.56 |

| O | 27.49 | O | 50.34 | ||

| Ca | 42.29 | Al | 8.85 | ||

| Ca | 33.25 | ||||

| ZrO2 treat | C | 5.00 | TiO2 treat | C | 10.62 |

| O | 47.05 | O | 47.87 | ||

| Zr | 6.01 | Ca | 39.61 | ||

| Ca | 41.93 | Ti | 1.90 | ||

| MgO treat | C | 7.48 | SiO2 treat | C | 4.85 |

| O | 51.91 | O | 49.82 | ||

| Mg | 1.55 | Si | 0.21 | ||

| Ca | 39.06 | Ca | 45.12 |

| Treatment Method | Element | Weight Content (wt%) | Treatment Method | Element | Weight Content (wt%) |

|---|---|---|---|---|---|

| Oil-wet calcite | C | 30.22 | TX-100 | C | 17.37 |

| O | 27.49 | O | 38.42 | ||

| Ca | 42.29 | Ca | 44.21 | ||

| CTAB | C | 7.08 | SDS treat | C | 24.74 |

| N | 1.66 | O | 32.09 | ||

| O | 49.84 | Na | 0.72 | ||

| Br | 0.06 | S | 1.78 | ||

| Ca | 41.36 | Ca | 40.67 | ||

| Sophorolipid | C | 33.62 | Rhamnolipid | C | 17.68 |

| O | 35.97 | O | 39.20 | ||

| Ca | 30.41 | Ca | 43.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, J.; Sun, L. Synergistic Effect of Nanofluids and Surfactants on Heavy Oil Recovery and Oil-Wet Calcite Wettability. Nanomaterials 2021, 11, 1849. https://doi.org/10.3390/nano11071849

Hou J, Sun L. Synergistic Effect of Nanofluids and Surfactants on Heavy Oil Recovery and Oil-Wet Calcite Wettability. Nanomaterials. 2021; 11(7):1849. https://doi.org/10.3390/nano11071849

Chicago/Turabian StyleHou, Jinjian, and Lingyu Sun. 2021. "Synergistic Effect of Nanofluids and Surfactants on Heavy Oil Recovery and Oil-Wet Calcite Wettability" Nanomaterials 11, no. 7: 1849. https://doi.org/10.3390/nano11071849

APA StyleHou, J., & Sun, L. (2021). Synergistic Effect of Nanofluids and Surfactants on Heavy Oil Recovery and Oil-Wet Calcite Wettability. Nanomaterials, 11(7), 1849. https://doi.org/10.3390/nano11071849