Growth, Properties and Applications of Bi0.5Na0.5TiO3 Ferroelectric Nanomaterials

Abstract

:1. Introduction

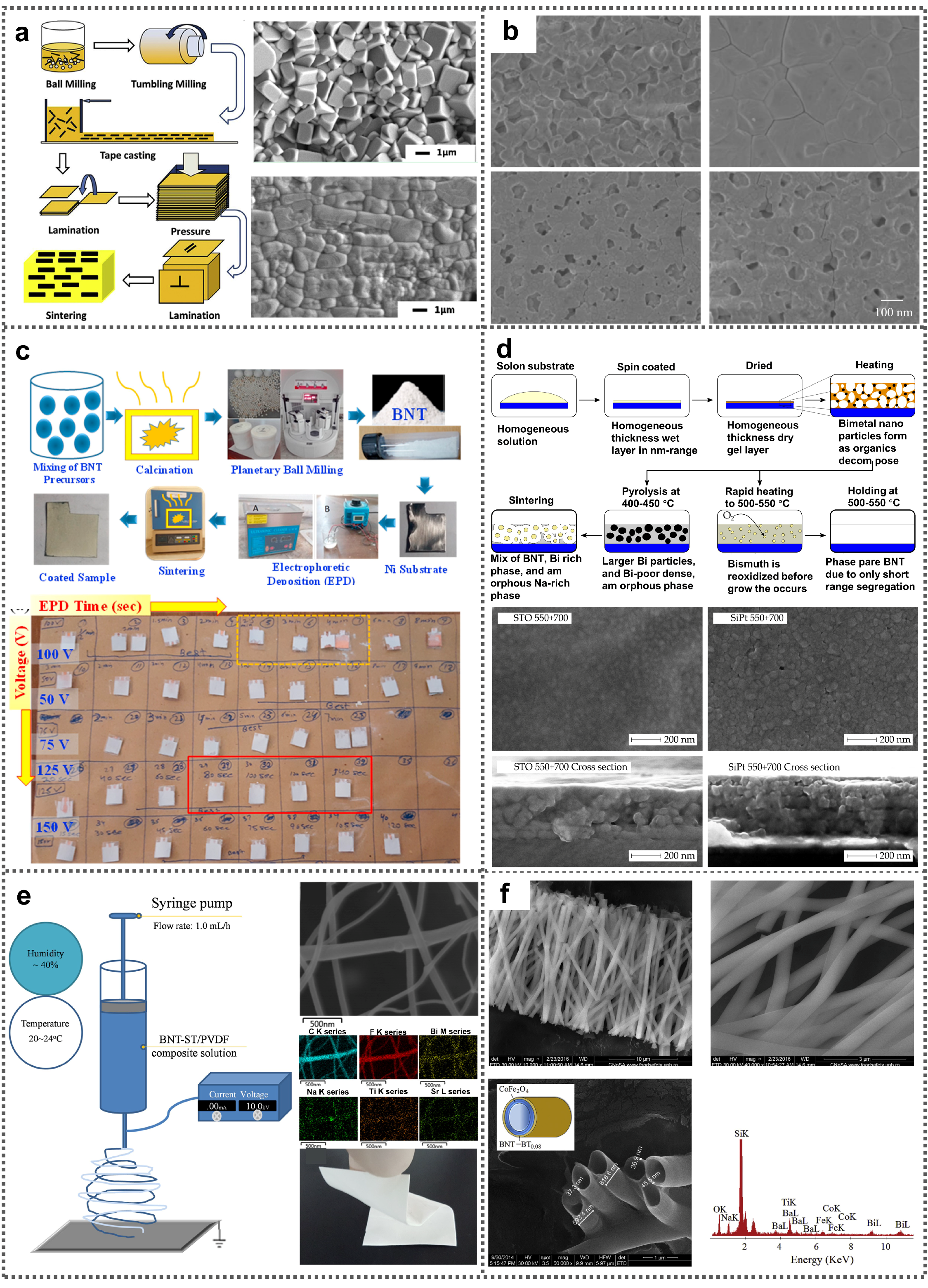

2. Growth

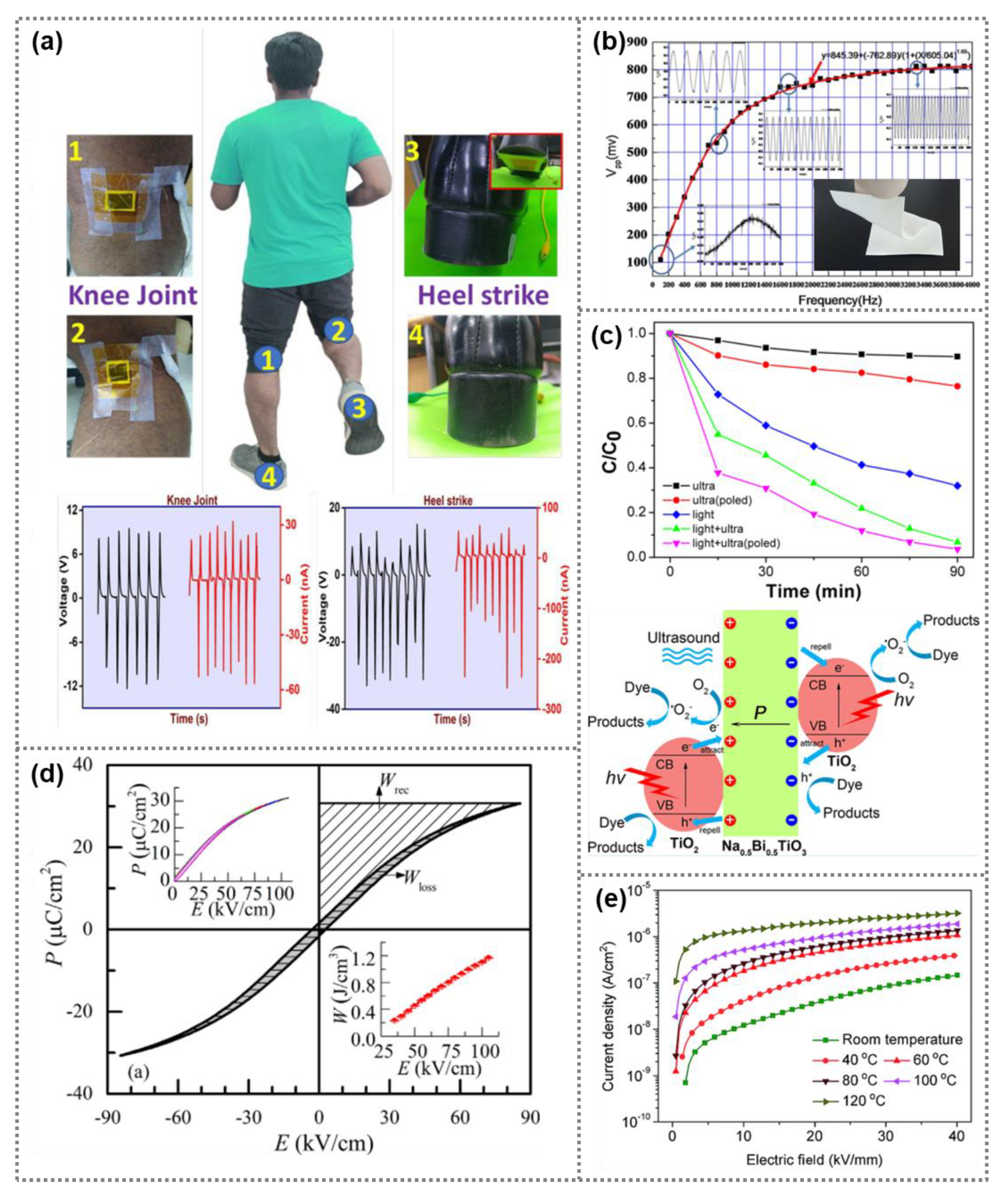

3. Properties

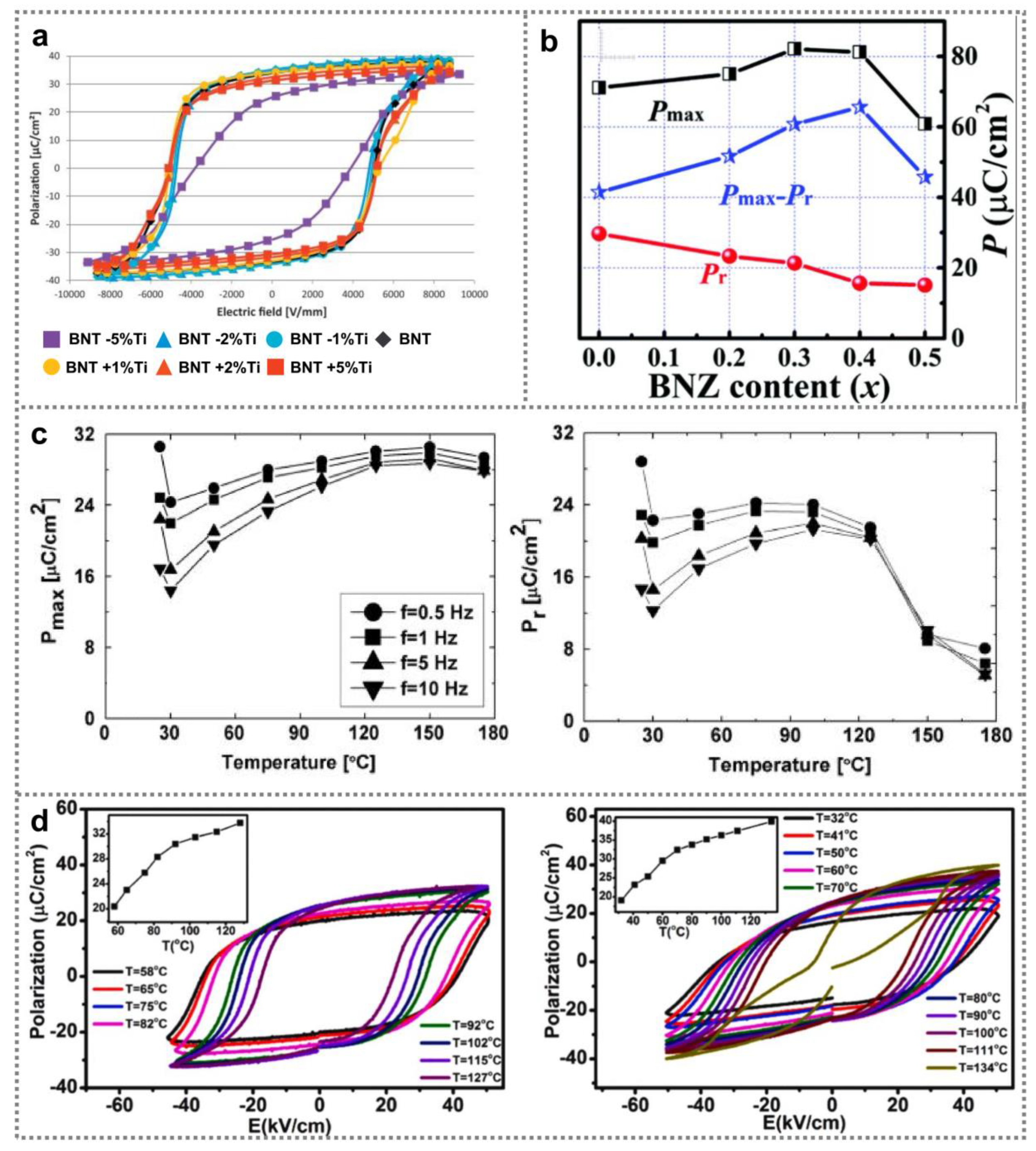

3.1. Ferroelectricity

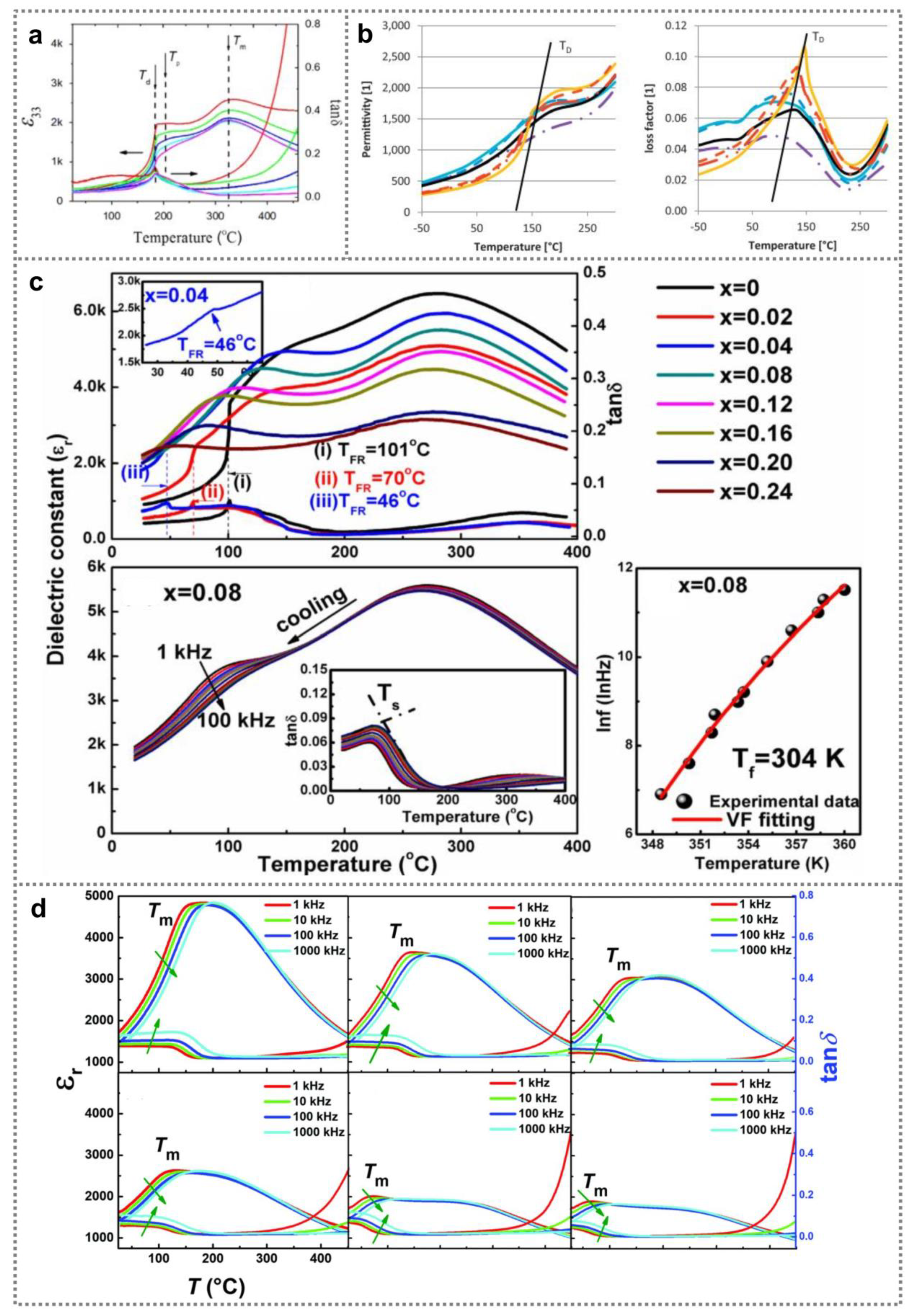

3.2. Dielectric Property

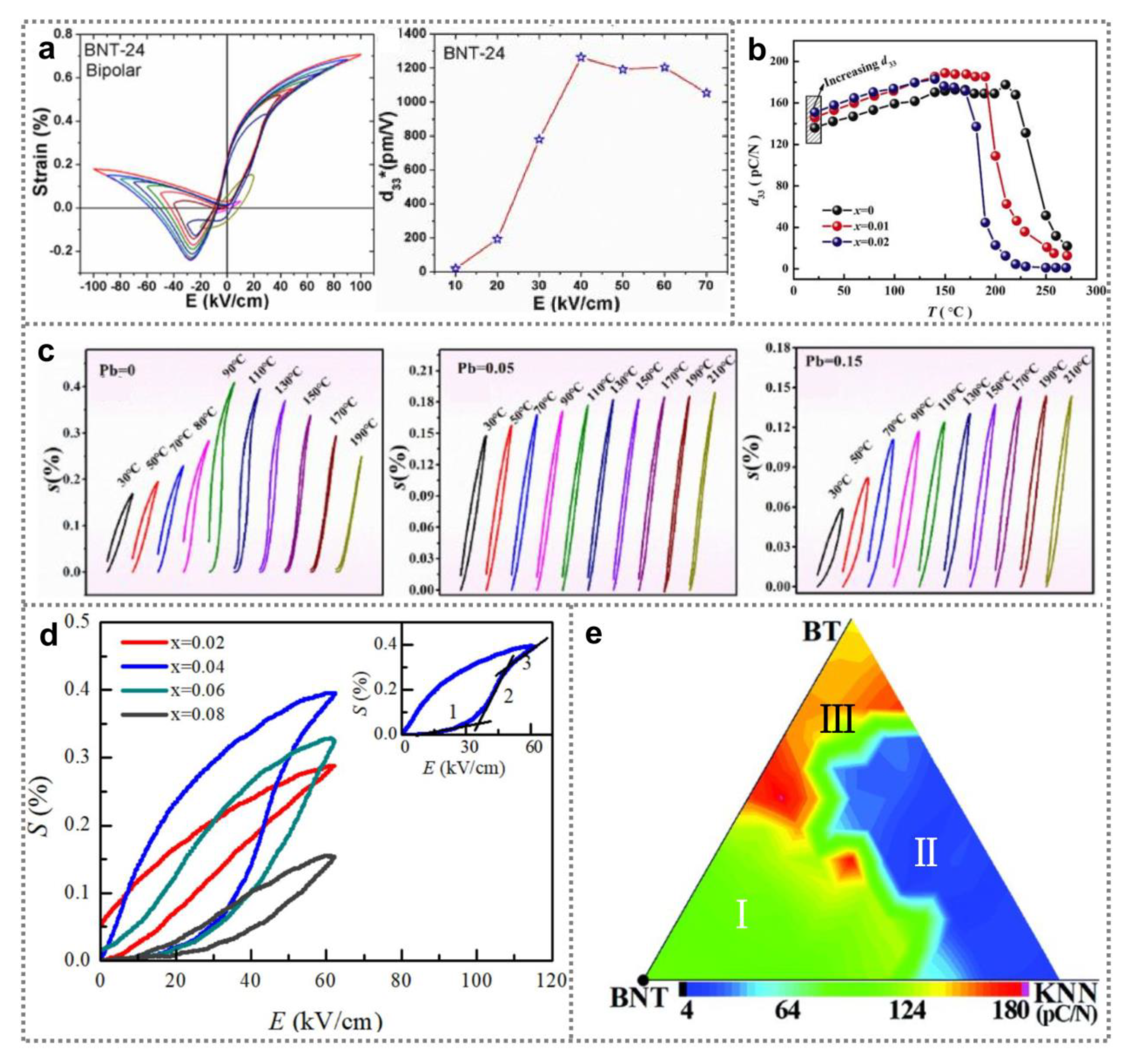

3.3. Piezoelectricity

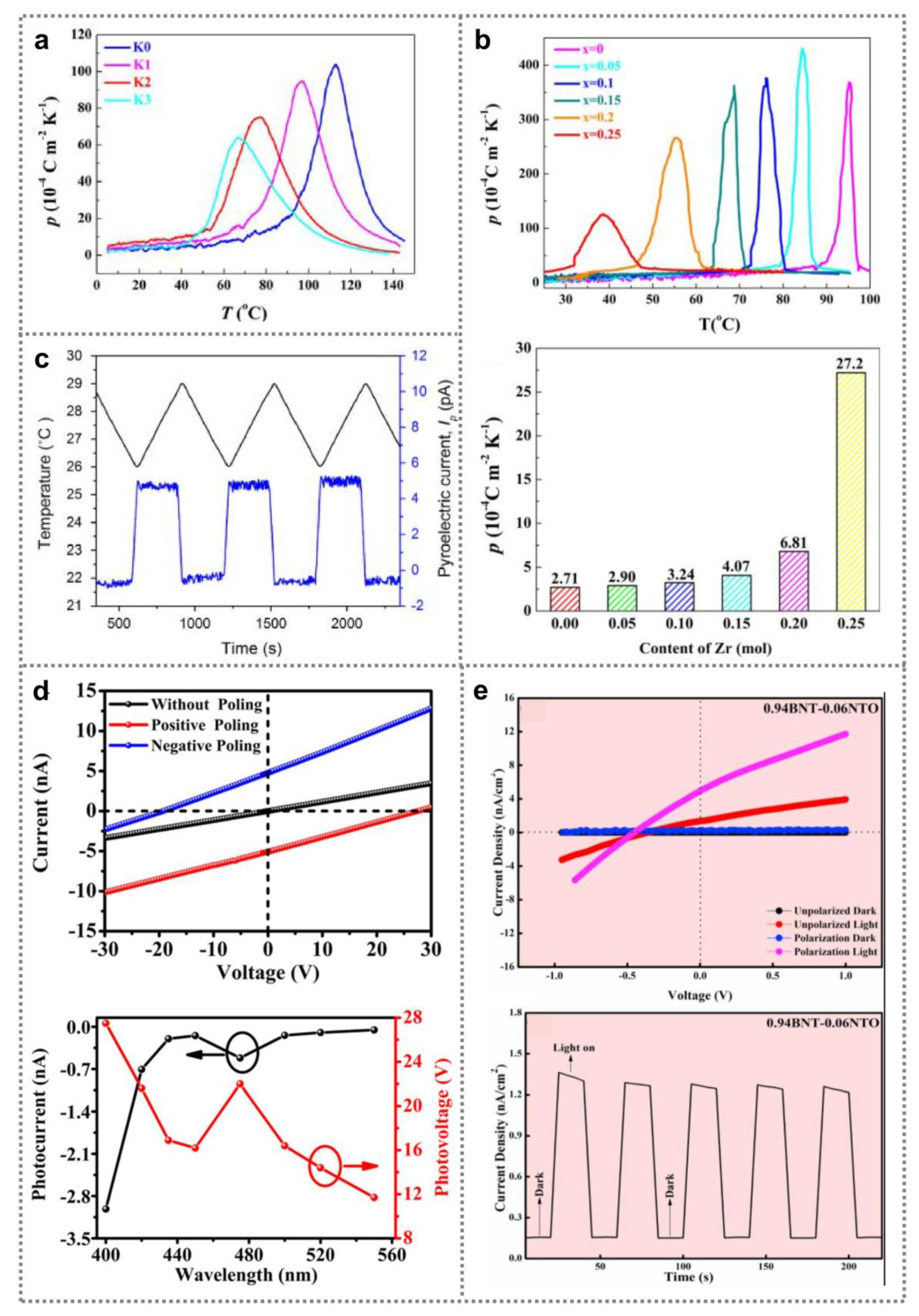

3.4. Pyroelectric and Photovoltaic Properties

4. Applications

5. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, R.; Ma, N.; Song, K.; Yang, Y. Boosting photocurrent via heating BiFeO3 materials for enhanced self-powered UV photodetectors. Adv. Funct. Mater. 2020, 30, 1906232. [Google Scholar] [CrossRef]

- Ma, N.; Yang, Y. Enhanced self-powered UV photoresponse of ferroelectric BaTiO3 materials by pyroelectric effect. Nano Energy 2017, 40, 352–359. [Google Scholar] [CrossRef]

- Khanchaitit, P.; Han, K.; Gadinski, M.R.; Li, Q.; Wang, Q. Ferroelectric polymer networks with high energy density and improved discharged efficiency for dielectric energy storage. Nat. Commun. 2013, 4, 2845. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ji, Y.; Liu, Y.; Yang, Y. Multieffect coupled nanogenerators. Research 2020. [Google Scholar] [CrossRef]

- Ji, Y.; Zhang, K.; Wang, Z.L.; Yang, Y. Piezo-pyro-photoelectric effects induced coupling enhancement of charge quantity in BaTiO3 materials for simultaneously scavenging light and vibration energies. Energy Environ. Sci. 2019, 12, 1231–1240. [Google Scholar] [CrossRef]

- Plourde, J.K.; Linn, D.F.; Obryan, H.M.; Thomson, J. Ba2Ti9O20 as a microwave dielectric resonator. J. Am. Ceram. Soc. 1975, 58, 418–420. [Google Scholar] [CrossRef]

- Zhang, S.; Yu, F. Piezoelectric materials for high temperature sensors. J. Am. Ceram. Soc. 2011, 94, 3153–3170. [Google Scholar] [CrossRef]

- Zhao, K.; Ouyang, B.; Bowen, C.R.; Wang, Z.L.; Yang, Y. One-structure-based multi-effects coupled nanogenerators for flexible and self-powered multi-functional coupled sensor systems. Nano Energy 2020, 71, 104632. [Google Scholar] [CrossRef]

- Ji, Y.; Wang, Y.; Yang, Y. Photovoltaic-pyroelectric-piezoelectric coupled effect induced electricity for self-powered coupled sensing. Adv. Electron. Mater. 2019, 5, 1900195. [Google Scholar] [CrossRef]

- Choi, K.J.; Biegalski, M.; Li, Y.L.; Sharan, A.; Schubert, J.; Uecker, R.; Reiche, P.; Chen, Y.B.; Pan, X.Q.; Gopalan, V.; et al. Enhancement of ferroelectricity in strained BaTiO3 thin films. Science 2004, 306, 1005–1009. [Google Scholar] [CrossRef] [Green Version]

- Zheng, H.; Wang, J.; Lofland, S.E.; Ma, Z.; Mohaddes-Ardabili, L.; Zhao, T.; Salamanca-Riba, L.; Shinde, S.R.; Ogale, S.B.; Bai, F.; et al. Multiferroic BaTiO3-CoFe2O4 nanostructures. Science 2004, 303, 661–663. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, K.; Li, J.-F. Domain engineering of lead-free li-modified (K,Na)NbO3 polycrystals with highly enhanced piezoelectricity. Adv. Funct. Mater. 2010, 20, 1924–1929. [Google Scholar] [CrossRef]

- Jo, W.; Daniels, J.E.; Jones, J.L.; Tan, X.; Thomas, P.A.; Damjanovic, D.; Roedel, J. Evolving morphotropic phase boundary in lead-free (Bi1/2Na1/2)TiO3- BaTiO3 piezoceramics. J. Appl. Phys. 2011, 109, 014110. [Google Scholar] [CrossRef] [Green Version]

- Takenaka, T.; Sakata, K.; Toda, K. Piezoelectric properties of (Bi1/2Na1/2)TiO3-based ceramics. Ferroelectrics 1990, 106, 375–380. [Google Scholar] [CrossRef]

- Qi, J.; Ma, N.; Ma, X.; Adelung, R.; Yang, Y. Enhanced photocurrent in BiFeO3 materials by coupling temperature and thermo-phototronic effects for self-powered ultraviolet photodetector system. ACS Appl. Mater. Interfaces 2018, 10, 13712–13719. [Google Scholar] [CrossRef]

- Smolenskii, G.A.; Isupov, V.A.; Agranovskaya, A.I.; Krainik, N.N. New ferroelectrics of complex composition IV. Sov. Phys. Solid State 1961, 2, 2651–2654. [Google Scholar]

- Pradhani, N.; Mahapatra, P.K.; Choudhary, R.N.P. Structural, impedance, and leakage current characteristics of stannum modified Bi0.5Na0.5TiO3 ceramic. J. Inorg. Organomet. P 2021, 31, 591–598. [Google Scholar] [CrossRef]

- Yan, F.; Huang, K.; Jiang, T.; Zhou, X.; Shi, Y.; Ge, G.; Shen, B.; Zhai, J. Significantly enhanced energy storage density and efficiency of BNT-based perovskite ceramics via A-site defect engineering. Energy Storage Mater. 2020, 30, 392–400. [Google Scholar] [CrossRef]

- Qiao, X.; Sheng, A.; Wu, D.; Zhang, F.; Chen, B.; Liang, P.; Wang, J.; Chao, X.; Yang, Z. A novel multifunctional ceramic with photoluminescence and outstanding energy storage properties. Chem. Eng. J. 2021, 408, 127368. [Google Scholar] [CrossRef]

- Zhong, M.; Yuan, C.; Liu, X.; Zhu, B.; Meng, L.; Zhou, C.; Liu, F.; Xu, J.; Wang, J.; Rao, G. High photocurrent densities in Bi0.5Na0.5TiO3 ferroelectric semiconductors. Mater. Lett. 2021, 287, 129299. [Google Scholar] [CrossRef]

- Jo, W.; Schaab, S.; Sapper, E.; Schmitt, L.A.; Kleebe, H.-J.; Bell, A.J.; Roedel, J. On the phase identity and its thermal evolution of lead free (Bi1/2Na1/2)TiO3-6 mol% BaTiO3. J. Appl. Phys. 2011, 110, 074106. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.-T.; Kounga, A.B.; Aulbach, E.; Ehrenberg, H.; Roedel, J. Giant strain in lead-free piezoceramics Bi0.5Na0.5TiO3- BaTiO3-K0.5Na0.5NbO3 system. Appl. Phys. Lett. 2007, 91, 112906. [Google Scholar] [CrossRef]

- Ma, W.G.; Zhu, Y.W.; Marwat, M.A.; Fan, P.Y.; Xie, B.; Salamon, D.; Ye, Z.G.; Zhang, H.B. Enhanced energy-storage performance with excellent stability under low electric fields in BNT-ST relaxor ferroelectric ceramics. J. Mater. Chem. C 2019, 7, 281–288. [Google Scholar] [CrossRef]

- Liu, Y.T.; Ren, W.; Zhao, J.Y.; Wang, L.Y.; Shi, P.; Ye, Z.G. Effect of sintering temperature on structural and electrical properties of lead-free BNT-BT piezoelectric thick films. Ceram. Int. 2015, 41, S259–S264. [Google Scholar] [CrossRef]

- Ma, X.; Xue, L.H.; Wan, L.; Yin, S.M.; Thou, Q.L.; Yan, Y.W. Synthesis, sintering, and characterization of BNT perovskite powders prepared by the solution combustion method. Ceram. Int. 2013, 39, 8147–8152. [Google Scholar] [CrossRef]

- Pan, Z.; Hu, D.; Zhang, Y.; Liu, J.; Shen, B.; Zhai, J. Achieving high discharge energy density and efficiency with NBT-based ceramics for application in capacitors. J. Mater. Chem. C 2019, 7, 4072–4078. [Google Scholar] [CrossRef]

- Mahmood, N.B.; Al-Shakarchi, E.K. Dielectric properties of BNT-xBT prepared by hydrothermal process. J. Adv. Dielectr. 2017, 07, 1750019. [Google Scholar] [CrossRef] [Green Version]

- Bai, W.F.; Li, L.Y.; Li, W.; Shen, B.; Zhai, J.W.; Chen, H. Effect of SrTiO3 template on electric properties of textured BNT-BKT ceramics prepared by templated grain growth process. J. Alloys Compd. 2014, 603, 149–157. [Google Scholar] [CrossRef]

- Yu, T.; Kwok, K.W.; Chan, H.L.W. Preparation and properties of sol-gel-derived Na0.5Bi0.5TiO3 lead-free ferroelectric thin film. Thin Solid Films 2007, 515, 3563–3566. [Google Scholar] [CrossRef]

- Wu, S.H.; Chen, P.; Zhai, J.W.; Shen, B.; Li, P.; Li, F. Enhanced piezoelectricity and energy storage performances of Fe-doped BNT-BKT-ST thin films. Ceram. Int. 2018, 44, 21289–21294. [Google Scholar] [CrossRef]

- Zhao, J.; Niu, G.; Ren, W.; Wang, L.; Zhang, N.; Shi, P.; Liu, M.; Zhao, Y. Structural and electrical properties of sodium bismuth titanate based 0-3 composite lead-free ferroelectric thick films. J. Alloys Compd. 2020, 829, 154506. [Google Scholar] [CrossRef]

- Zhou, Z.; Luo, J.; Sun, W.; Li, J.F. Temperature and composition dependent phase transitions of lead-free piezoelectric (Bi0.5Na0.5)TiO3- BaTiO3 thin films. Phys. Chem. Chem. Phys. 2017, 19, 19992–19997. [Google Scholar] [CrossRef] [PubMed]

- Dittmer, R.; Jo, W.; Roedel, J.; Kalinin, S.; Balke, N. Nanoscale insight into lead-free BNT-BT-xKNN. Adv. Funct. Mater. 2012, 22, 4208–4215. [Google Scholar] [CrossRef]

- Uchida, H.; Yoshikawa, H.; Okada, I.; Matsuda, H.; Iijima, T.; Watanabe, T.; Kojima, T.; Funakubo, H. Approach for enhanced polarization of polycrystalline bismuth titanate films by Nd3+/V5+ cosubstitution. Appl. Phys. Lett. 2002, 81, 2229–2231. [Google Scholar] [CrossRef]

- Dargham, A.S.; Ponchel, F.; Zaatar, Y.; Assaad, J.; Remiens, D.; Zaouk, D. Synthesis and characterization of BNT thin films prepared by sol-gel method. Mater. Today Proc. 2016, 3, 810–815. [Google Scholar] [CrossRef]

- Rafiq, M.A.; Maqbool, A.; Khan, I.H.; Manzoor, M.U.; Shuaib, A.; Hakeem, A.S. A facile and cost-effective approach for the fabrication Bi0.5Na0.5TiO3 thick films on flexible substrate for energy storage capacitor applications. Ceram. Int. 2020, 46, 25113–25121. [Google Scholar] [CrossRef]

- Christensen, M.; Einarsrud, M.-A.; Grande, T. Fabrication of lead-free Na0.5Bi0.5TiO3 thin films by aqueous chemical solution deposition. Materials 2017, 10, 213. [Google Scholar] [CrossRef]

- Remondiere, F.; Malič, B.; Kosec, M.; Mercurio, J.-P. Study of the crystallization pathway of Na0.5Bi0.5TiO3 thin films obtained by chemical solution deposition. J. Sol. Gel. Sci. Techn. 2008, 46, 117–125. [Google Scholar] [CrossRef]

- Li, J.J.; Huang, R.X.; Peng, C.F.; Dai, Y.J.; Xiong, S.J.; Cai, C.H.; Lin, H.T. Low temperature synthesis of plate-like Na0.5Bi0.5TiO3 via molten salt method. Ceram. Int. 2020, 46, 19752–19757. [Google Scholar] [CrossRef]

- Xu, X.; Lin, X.; Yang, F.; Huang, S.; Cheng, X. Piezo-photocatalytic activity of Na0.5Bi0.5TiO3@TiO2 composite catalyst with heterojunction for degradation of organic dye molecule. J. Phys. Chem. C 2020, 124, 24126–24134. [Google Scholar] [CrossRef]

- Li, J.; Wang, G.; Wang, H.; Tang, C.; Wang, Y.; Liang, C.; Cai, W.; Zhang, L. In situ self-assembly synthesis and photocatalytic performance of hierarchical Na0.5Bi0.5TiO3 micro/nanostructures. J. Mater. Chem. 2009, 19, 2253–2258. [Google Scholar] [CrossRef]

- Hussain, A.; Rahman, J.U.; Ahmed, F.; Kim, J.-S.; Kim, M.-H.; Song, T.-K.; Kim, W.-J. Plate-like Na0.5Bi0.5TiO3 particles synthesized by topochemical microcrystal conversion method. J. Eur. Ceram. Soc. 2015, 35, 919–925. [Google Scholar] [CrossRef]

- Li, J.N.; Chen, G.L.; Lin, X.J.; Huang, S.F.; Cheng, X. Enhanced energy density in poly(vinylidene fluoride) nanocomposites with dopamine-modified bnt nanoparticles. J. Mater. Sci. 2020, 55, 2503–2515. [Google Scholar] [CrossRef]

- Luo, H.; Roscow, J.; Zhou, X.; Chen, S.; Han, X.; Zhou, K.; Zhang, D.; Bowen, C.R. Ultra-high discharged energy density capacitor using high aspect ratio Na0.5Bi0.5TiO3 nanofibers. J. Mater. Chem. A 2017, 5, 7091–7102. [Google Scholar] [CrossRef] [Green Version]

- Pan, Z.; An, M.J.; Chen, J.; Fan, L.L.; Liu, L.J.; Fang, L.; Xing, X.R. Preparation and electrical properties of the new lead-free (1 − x) Bi0.5Na0.5TiO3-xBa(Ni1/3Nb2/3)O3 piezoelectric ceramics. J. Ceram. Soc. Jpn. 2015, 123, 1038–1042. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Chen, J.; Fan, L.L.; Liu, L.J.; Fang, L.; Xing, X.R. Preparation and electric properties of Bi0.5Na0.5TiO3-Bi(Mg0.5Ti0.5)O3 lead-free piezoceramics. J. Am. Ceram. Soc. 2013, 96, 1171–1175. [Google Scholar] [CrossRef]

- Ji, S.H.; Cho, J.H.; Jeong, Y.H.; Paik, J.H.; Jon, J.D.; Yun, J.S. Flexible lead-free piezoelectric nanofiber composites based on BNT-ST and PVDF for frequency sensor applications. Sens. Actuators A Phys. 2016, 247, 316–322. [Google Scholar] [CrossRef]

- Cernea, M.; Vasile, B.S.; Surdu, V.A.; Trusca, R.; Sima, M.; Craciun, F.; Galassi, C. Piezoelectric ferromagnetic BNT-BT0.08/CoFe2O4 coaxial core-shell composite nanotubes for nanoelectronic devices. J. Alloys Compd. 2018, 752, 381–388. [Google Scholar] [CrossRef]

- Damjanovic, D. Ferroelectric, dielectric and piezoelectric properties of ferroelectric thin films and ceramics. Rep. Prog. Phys. 1998, 61, 1267–1324. [Google Scholar] [CrossRef] [Green Version]

- Naderer, M.; Kainz, T.; Schutz, D.; Reichmann, K. The influence of Ti-nonstoichiometry in Bi0.5Na0.5TiO3. J. Eur. Ceram. Soc. 2014, 34, 663–667. [Google Scholar] [CrossRef]

- Shi, J.; Liu, X.; Tian, W. Structure evolution and ferroelectric properties in stoichiometric Bi0.5+xNa0.5−xTi1−0.5xO3. J. Mater. Sci. 2019, 54, 5249–5255. [Google Scholar] [CrossRef]

- Sun, N.; Li, Y.; Zhang, Q.; Hao, X. Giant energy-storage density and high efficiency achieved in Bi0.5Na0.5TiO3–Bi(Ni0.5Zr0.5)O3 thick films with polar nanoregions. J. Mater. Chem. C 2018, 6, 10693–10703. [Google Scholar] [CrossRef]

- Xiong, S.; Huang, R.; Peng, C.; Dai, Y.; Li, J.; Bai, W.; Lin, H.-T. Structural transition, large strain induced by B-site equivalent doping with Hf4+ ions in BNT-based ceramics. Ceram. Int. 2021, 47, 6842–6847. [Google Scholar] [CrossRef]

- Wang, X.; Gao, H.; Hao, X.; Lou, X. Enhanced piezoelectric, electrocaloric and energy storage properties at high temperature in lead-free Bi0.5(Na1-xKx)0.5TiO3 ceramics. Ceram. Int. 2019, 45, 4274–4282. [Google Scholar] [CrossRef] [Green Version]

- Viola, G.; Ning, H.; Wei, X.; Deluca, M.; Adomkevicius, A.; Khaliq, J.; John Reece, M.; Yan, H. Dielectric relaxation, lattice dynamics and polarization mechanisms in Bi0.5Na0.5TiO3-based lead-free ceramics. J. Appl. Phys. 2013, 114, 014107. [Google Scholar] [CrossRef]

- Zheng, X.-C.; Zheng, G.-P.; Lin, Z.; Jiang, Z.-Y. Electro-caloric behaviors of lead-free Bi0.5Na0.5TiO3-BaTiO3 ceramics. J. Electroceram. 2011, 28, 20–26. [Google Scholar] [CrossRef]

- Li, F.; Chen, G.; Liu, X.; Zhai, J.; Shen, B.; Zeng, H.; Li, S.; Li, P.; Yang, K.; Yan, H. Phase–composition and temperature dependence of electrocaloric effect in lead-free Bi0.5Na0.5TiO3-BaTiO3-(Sr0.7Bi0.2□0.1)TiO3 ceramics. J. Eur. Ceram. Soc. 2017, 37, 4732–4740. [Google Scholar] [CrossRef]

- Jiang, X.; Luo, L.; Wang, B.; Li, W.; Chen, H. Electrocaloric effect based on the depolarization transition in (1 − x) Bi0.5Na0.5TiO3-xKNbO3 lead-free ceramics. Ceram. Int. 2014, 40, 2627–2634. [Google Scholar] [CrossRef]

- Halim, N.A.; Velayutham, T.S.; Abd Majid, W.H. Pyroelectric, ferroelectric, piezoelectric and dielectric properties of Na0.5Bi0.5TiO3 ceramic prepared by sol-gel method. Ceram. Int. 2016, 42, 15664–15670. [Google Scholar] [CrossRef]

- Hiruma, Y.; Nagata, H.; Takenaka, T. Phase transition temperatures and piezoelectric properties of (Bi1/2Na1/2)TiO3-(Bi1/2K1/2)TiO3- BaTiO3 lead-free piezoelectric ceramics. Jpn. J. Appl. Phys. 2006, 45, 7409–7412. [Google Scholar] [CrossRef]

- Hiruma, Y.; Nagata, H.; Takenaka, T. Thermal depoling process and piezoelectric properties of bismuth sodium titanate ceramics. J. Appl. Phys. 2009, 105, 084112. [Google Scholar] [CrossRef]

- Schuetz, D.; Deluca, M.; Krauss, W.; Feteira, A.; Jackson, T.; Reichmann, K. Lone-pair-induced covalency as the cause of temperature- and field-induced instabilities in bismuth sodium titanate. Adv. Funct. Mater. 2012, 22, 2285–2294. [Google Scholar] [CrossRef] [Green Version]

- Qi, H.; Zuo, R. Linear-like lead-free relaxor antiferroelectric Bi0.5Na0.5TiO3-NaNbO3 with giant energy-storage density/efficiency and super stability against temperature and frequency. J. Mater. Chem. A 2019, 7, 3971–3978. [Google Scholar] [CrossRef]

- Kontsos, A.; Landis, C.M. Computational modeling of domain wall interactions with dislocations in ferroelectric crystals. Int. J. Solids Struct. 2009, 46, 1491–1498. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Zhang, H.; Huang, C.-H.; Tseng, C.-W.; Meng, N.; Koval, V.; Chou, Y.-C.; Zhang, Z.; Yan, H. Ultrahigh field-induced strain in lead-free ceramics. Nano Energy 2020, 76, 105037. [Google Scholar] [CrossRef]

- Zhang, X.; Jiang, G.; Liu, D.; Yang, B.; Cao, W. Enhanced electric field induced strain in (1 − x)((Bi0.5Na0.5)TiO3-Ba(Ti, Zr)O3)-xSrTiO3 ceramics. Ceram. Int. 2018, 44, 12869–12876. [Google Scholar] [CrossRef]

- Liu, X.; Tan, X. Giant strains in non-textured (Bi1/2Na1/2)TiO3 -based lead-free ceramics. Adv. Mater. 2016, 28, 574–578. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xiao, D.Q.; Wu, J.G.; Wu, L.; Zhu, J.G.; Yu, P.; Lin, D.M.; Liao, Y.W.; Sun, Y. Investigation on the composition design and properties study of perovskite lead-free piezoelectric ceramics. J. Mater. Sci. 2009, 44, 5408–5419. [Google Scholar] [CrossRef]

- Hiruma, Y.; Nagata, H.; Takenaka, T. Phase diagrams and electrical properties of (Bi1/2Na1/2)TiO3 -based solid solutions. J. Appl. Phys. 2008, 104, 124106. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, P.; Patterson, E.; Zang, J.; Jiang, S.; Roedel, J. Preparation and enhanced electrical properties of grain-oriented (Bi1/2Na1/2)TiO3 -based lead-free incipient piezoceramics. J. Eur. Ceram. Soc. 2015, 35, 2501–2512. [Google Scholar] [CrossRef]

- Takenaka, T.; Nagata, H.; Hiruma, Y.; Yoshii, Y.; Matumoto, K. Lead-free piezoelectric ceramics based on perovskite structures. J. Electroceram. 2007, 19, 259–265. [Google Scholar] [CrossRef]

- Wei, Q.; Zhu, M.; Zheng, M.; Hou, Y. High piezoelectric properties above 150 °C in (Bi0.5Na0.5)TiO3-based lead-free piezoelectric ceramics. Mater. Chem. Phys. 2020, 249, 122966. [Google Scholar] [CrossRef]

- Han, J.; Yin, J.; Wu, J. (Bi0.5Na0.5)TiO3 ferroelectric ceramics: Achieving high depolarization temperature and improved piezoelectric properties. J. Eur. Ceram. Soc. 2020, 40, 5392–5401. [Google Scholar] [CrossRef]

- Dong, G.; Fan, H.; Jia, Y.; Liu, H.; Wang, W.; Li, Q. Strain properties of (1 − x)Bi0.5Na0.4K0.1TiO3-xBi(Mg2/3Ta1/3)O3 electroceramics. Ceram. Int. 2020, 46, 21211–21215. [Google Scholar] [CrossRef]

- Song, G.H.; Liu, Z.B.; Zhang, F.Q.; Liu, F.; Gu, Y.; Liu, Z.F.; Li, Y.X. High-throughput synthesis and electrical properties of BNT-BT-KNN lead-free piezoelectric ceramics. J. Mater. Chem. C 2020, 8, 3655–3662. [Google Scholar] [CrossRef]

- Guo, Y.; Fan, H.; Long, C.; Shi, J.; Yang, L.; Lei, S. Electromechanical and electrical properties of Bi0.5Na0.5Ti1-xMnxO3-δ ceramics with high remnant polarization. J. Alloys Compd. 2014, 610, 189–195. [Google Scholar] [CrossRef]

- Ambacher, O.; Majewski, J.; Miskys, C.; Link, A.; Hermann, M.; Eickhoff, M.; Stutzmann, M.; Bernardini, F.; Fiorentini, V.; Tilak, V.; et al. Pyroelectric properties of al(in)gan/gan hetero- and quantum well structures. J. Phys. Condens. Mat. 2002, 14, 3399–3434. [Google Scholar] [CrossRef]

- Glass, A.M. Investigation of electrical properties of Sr1-xBaxNb2O6 with special reference to pyroelectric detection. J. Appl. Phys. 1969, 40, 4699–4713. [Google Scholar] [CrossRef]

- Whatmore, R.W. Pyroelectric devices and materials. Rep. Prog. Phys. 1986, 49, 1335–1386. [Google Scholar] [CrossRef]

- Jin, F.; Auner, G.W.; Naik, R.; Schubring, N.W.; Mantese, J.V.; Catalan, A.B.; Micheli, A.L. Giant effective pyroelectric coefficients from graded ferroelectric devices. Appl. Phys. Lett. 1998, 73, 2838–2840. [Google Scholar] [CrossRef]

- Plepis, A.M.D.; Goissis, G.; DasGupta, D.K. Dielectric and pyroelectric characterization of anionic and native collagen. Polym. Eng. Sci. 1996, 36, 2932–2938. [Google Scholar] [CrossRef]

- Qian, X.-S.; Ye, H.-J.; Zhang, Y.-T.; Gu, H.; Li, X.; Randall, C.A.; Zhang, Q.M. Giant electrocaloric response over a broad temperature range in modified BaTiO3 ceramics. Adv. Funct. Mater. 2014, 24, 1300–1305. [Google Scholar] [CrossRef]

- Shen, M.; Qin, Y.F.; Zhang, Y.J.; Marwat, M.A.; Zhang, C.; Wang, W.Q.; Li, M.Y.; Zhang, H.B.; Zhang, G.Z.; Jiang, S.L. Enhanced pyroelectric properties of lead-free BNT-BA-KNN ceramics for thermal energy harvesting. J. Am. Ceram. Soc. 2019, 102, 3990–3999. [Google Scholar] [CrossRef]

- Shen, M.; Li, W.R.; Li, M.Y.; Liu, H.; Xu, J.M.; Qiu, S.Y.; Zhang, G.Z.; Lu, Z.X.; Li, H.L.; Jiang, S.L. High room-temperature pyroelectric property in lead-free BNT-BZT ferroelectric ceramics for thermal energy harvesting. J. Eur. Ceram. Soc. 2019, 39, 1810–1818. [Google Scholar] [CrossRef]

- Mahdi, R.I.; Al-Bahnam, N.J.; Abbo, A.I.; Hmood, J.K.; Majid, W.H.A. Optimization of sintering temperature for the enhancement of pyroelectric properties of lead-free 0.88(Na0.5Bi0.5)TiO3-0.084(K0.5Bi0.5)TiO3-0.036 BaTiO3 piezoelectric ceramics. J. Alloys Compd. 2016, 688, 77–87. [Google Scholar] [CrossRef]

- Bune, A.V.; Zhu, C.X.; Ducharme, S.; Blinov, L.M.; Fridkin, V.M.; Palto, S.P.; Petukhova, N.G.; Yudin, S.G. Piezoelectric and pyroelectric properties of ferroelectric langmuir-blodgett polymer films. J. Appl. Phys. 1999, 85, 7869–7873. [Google Scholar] [CrossRef] [Green Version]

- Ploss, B.; Ploss, B.; Shin, F.G.; Chan, H.L.W.; Choy, C.L. Pyroelectric or piezoelectric compensated ferroelectric composites. Appl. Phys. Lett. 2000, 76, 2776–2778. [Google Scholar] [CrossRef] [Green Version]

- Lovinger, A.J. Ferroelectric polymers. Science 1983, 220, 1115–1121. [Google Scholar] [CrossRef] [PubMed]

- Naber, R.C.G.; Tanase, C.; Blom, P.W.M.; Gelinck, G.H.; Marsman, A.W.; Touwslager, F.J.; Setayesh, S.; De Leeuw, D.M. High-performance solution-processed polymer ferroelectric field-effect transistors. Nat. Mater. 2005, 4, 243–248. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.M.; Bharti, V.; Zhao, X. Giant electrostriction and relaxor ferroelectric behavior in electron-irradiated poly(vinylidene fluoride-trifluoroethylene) copolymer. Science 1998, 280, 2101–2104. [Google Scholar] [CrossRef] [PubMed]

- Dias, C.J.; DasGupta, D.K. Inorganic ceramic/polymer ferroelectric composite electrets. IEEE Trans. Dielectr. Electr. Insul. 1996, 3, 706–734. [Google Scholar] [CrossRef]

- Furukawa, T.; Ishida, K.; Fukada, E. Piezoelectric properties in the composite systems of polymers and PZT ceramics. J. Appl. Phys. 1979, 50, 4904–4912. [Google Scholar] [CrossRef]

- Mandi, R.I.; Gan, W.C.; Halim, N.A.; Velayutham, T.S.; Abd Majid, W.H. Ferroelectric and pyroelectric properties of novel lead-free polyvinylidenefluoride-trifluoroethylene-Bi0.5Na0.5TiO3 nanocomposite thin films for sensing applications. Ceram. Int. 2015, 41, 13836–13843. [Google Scholar]

- Grinberg, I.; West, D.V.; Torres, M.; Gou, G.; Stein, D.M.; Wu, L.; Chen, G.; Gallo, E.M.; Akbashev, A.R.; Davies, P.K.; et al. Perovskite oxides for visible-light-absorbing ferroelectric and photovoltaic materials. Nature 2013, 503, 509–512. [Google Scholar] [CrossRef] [PubMed]

- Choi, T.; Lee, S.; Choi, Y.J.; Kiryukhin, V.; Cheong, S.W. Switchable ferroelectric diode and photovoltaic effect in BiFeO3. Science 2009, 324, 63–66. [Google Scholar] [CrossRef]

- Xiao, Z.; Yuan, Y.; Shao, Y.; Wang, Q.; Dong, Q.; Bi, C.; Sharma, P.; Gruverman, A.; Huang, J. Giant switchable photovoltaic effect in organometal trihalide perovskite devices. Nat. Mater. 2015, 14, 193–198. [Google Scholar] [CrossRef]

- Ji, Y.; Zhang, K.; Yang, Y. A One-structure-based multieffects coupled nanogenerator for simultaneously scavenging thermal, solar, and mechanical energies. Adv. Sci. 2018, 5, 1700622. [Google Scholar] [CrossRef]

- Ma, N.; Yang, Y. Boosted photocurrent in ferroelectric BaTiO3 materials via two dimensional planar-structured contact configurations. Nano Energy 2018, 50, 417–424. [Google Scholar] [CrossRef]

- Zhao, K.; Ouyang, B.; Yang, Y. Enhancing photocurrent of radially polarized ferroelectric BaTiO3 materials by ferro-pyro-phototronic effect. Iscience 2018, 3, 208–216. [Google Scholar] [CrossRef] [Green Version]

- Bhatnagar, A.; Chaudhuri, A.R.; Kim, Y.H.; Hesse, D.; Alexe, M. Role of domain walls in the abnormal photovoltaic effect in BiFeO3. Nat. Commun. 2013, 4, 2835. [Google Scholar] [CrossRef] [Green Version]

- Kim, C.-Y.; Sekino, T.; Niihara, K. Optical, mechanical, and dielectric properties of (Bi1/2Na1/2)TiO3 thin film synthesized by sol-gel method. J. Sol-Gel Sci. Technol. 2010, 55, 306–310. [Google Scholar] [CrossRef]

- Gong, Y.; Chen, C.; Zhang, F.; He, X.; Zeng, H.; Yang, Q.; Li, Y.; Yi, Z. Ferroelectric photovoltaic and flexo-photovoltaic effects in (1 − x) (Bi0.5Na0.5)TiO3-x BiFeO3 systems under visible light. J. Am. Ceram. Soc. 2020, 103, 4363–4372. [Google Scholar] [CrossRef]

- Chen, Z.; Yuan, C.; Liu, X.; Meng, L.; Cheng, S.; Xu, J.; Zhou, C.; Wang, J.; Rao, G. Optical and electrical properties of ferroelectric Bi0.5Na0.5TiO3-NiTiO3 semiconductor ceramics. Mat. Sci. Semicon. Proc. 2020, 115, 105089. [Google Scholar] [CrossRef]

- Alonso-Sanjose, D.; Jimenez, R.; Bretos, I.; Calzada, M.L. Lead-free ferroelectric (Na1/2Bi1/2)TiO3-BaTiO3 thin films in the morphotropic phase boundary composition: Solution processing and properties. J. Am. Ceram. Soc. 2009, 92, 2218–2225. [Google Scholar] [CrossRef]

- Maria Joseph Raj, N.P.; Ks, A.; Khandelwal, G.; Alluri, N.R.; Kim, S.-J. A lead-free ferroelectric Bi0.5Na0.5TiO3 based flexible, lightweight nanogenerator for motion monitoring applications. Sustain. Energy Fuels 2020, 4, 5636–5644. [Google Scholar] [CrossRef]

- Chauhan, A.; Singh Kushwaha, H.; Kumar, R.V.; Vaish, R. Bi0.5Na0.5TiO3-BiOCl composite photocatalyst for efficient visible light degradation of dissolved organic impurities. J. Environ. Chem. Eng. 2019, 7, 102842. [Google Scholar] [CrossRef]

- Shi, J.; Liu, X.; Tian, W. High energy-storage properties of Bi0.5Na0.5TiO3- BaTiO3-SrTi0.875Nb0.1O3 lead-free relaxor ferroelectrics. J. Mater. Sci. Technol. 2018, 34, 2371–2374. [Google Scholar] [CrossRef]

| Material | Nanostructures | Wavelength | Synthesis Techniques | Reference |

|---|---|---|---|---|

| BNT | Spheric flower | 300 nm–2 μm | In situ self-assembly synthesis | [41] |

| BNT | Nanoplate | 10–20 μm | Topochemical microcrystal conversion method | [42] |

| PVDF-BNT | Nanofiber | 60–70 nm | Hydrothermal synthesis | [44] |

| BNT-BT0.08/CoFe2O4 | Core-shell nanotube | 40–45 nm | Template and sol-gel process | [48] |

| BNT-ST | Nanofiber | 100–300 nm | Electrospinning method | [47] |

| BNT | Thick film | 20 mm | Electrophoretic deposition | [36] |

| BNT-BT | Thin films | 60–90 nm | Sol-gel method | [32] |

| Material | Pr(μC/cm2) | Pmax(μC/cm2) | Ec (kV/cm) | Wrec (J /cm3) | Reference |

|---|---|---|---|---|---|

| BNT-BT-xSBT | 2–32 | 24–43 | 22–46 | [57] | |

| BNT-xKN | 5–41 | 25–47 | 8–52 | [58] | |

| BNT | ~47 | ~56 | ~55 | [59] | |

| BNT-ST-xAN | 1.6–22 | 32–49.5 | 6–23 | 1.5–2.5 | [23] |

| BNT-xBNZ | 18–34 | 60–82 | 24.2–50.1 | [42] | |

| BNKT | 23–30 | 30.2–40.1 | 20–52 | 0.42–0.83 | [54] |

| BNT-BKT-ST-xFe | 14.8 | 71.5 | 11–20.34 | [30] | |

| BNT-BT | 26.3 | ~36 | 27.1 | [24] | |

| BNT-xBNN | 0–32 | 21–38 | 7.8–32 | [45] | |

| BNT-xBT | 3–10 | 12.5–38 | [32] | ||

| BNT-BST-xKNN | 26–40 | 1.5–2.65 | [26] | ||

| PVDF-BNT | 12.7 | [44] |

| Material | Q33 | S(%) | εr | Piezoelectric Coefficient | Reference | |

|---|---|---|---|---|---|---|

| d33 (pC/N) | d33* (pm/V) | |||||

| BNKT-xBMT | 0.15–0.4 | ~5300 | 632 | [74] | ||

| BNKT-xPb | 0.04–0.15 | ~11,000 | 140 | [73] | ||

| BNKT-xZr | 0.09–0.14 | ~8000 | ~75‘ | [73] | ||

| BNT-BT | 112 | [24] | ||||

| BNTx-BT-yKNN | 0.025–0.035 | 0.1–0.44 | ~6500 | 181 | 528 | [75] |

| BNT-BT-KN | 0.1–0.2 | 135 | [72] | |||

| BNLT-xSr | 0.1–0.75 | 3500 | ~1300 | [65] | ||

| BNT | 885 | 120 | [59] | |||

| BNT-xKN | 380–1977 | [58] | ||||

| BNKT | 0.12–0.35 | 250–550 | 100–160 | 640–720 | [54] | |

| BNT-xBNZ | 0.15–0.3 | 1200–1500 | 214–428 | [42] | ||

| BNT-xTi | 380–502 | 86–98 | [50] | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Ji, Y.; Yang, Y. Growth, Properties and Applications of Bi0.5Na0.5TiO3 Ferroelectric Nanomaterials. Nanomaterials 2021, 11, 1724. https://doi.org/10.3390/nano11071724

Liu Y, Ji Y, Yang Y. Growth, Properties and Applications of Bi0.5Na0.5TiO3 Ferroelectric Nanomaterials. Nanomaterials. 2021; 11(7):1724. https://doi.org/10.3390/nano11071724

Chicago/Turabian StyleLiu, Yuan, Yun Ji, and Ya Yang. 2021. "Growth, Properties and Applications of Bi0.5Na0.5TiO3 Ferroelectric Nanomaterials" Nanomaterials 11, no. 7: 1724. https://doi.org/10.3390/nano11071724

APA StyleLiu, Y., Ji, Y., & Yang, Y. (2021). Growth, Properties and Applications of Bi0.5Na0.5TiO3 Ferroelectric Nanomaterials. Nanomaterials, 11(7), 1724. https://doi.org/10.3390/nano11071724