Colloidal Lithography for Photovoltaics: An Attractive Route for Light Management

Abstract

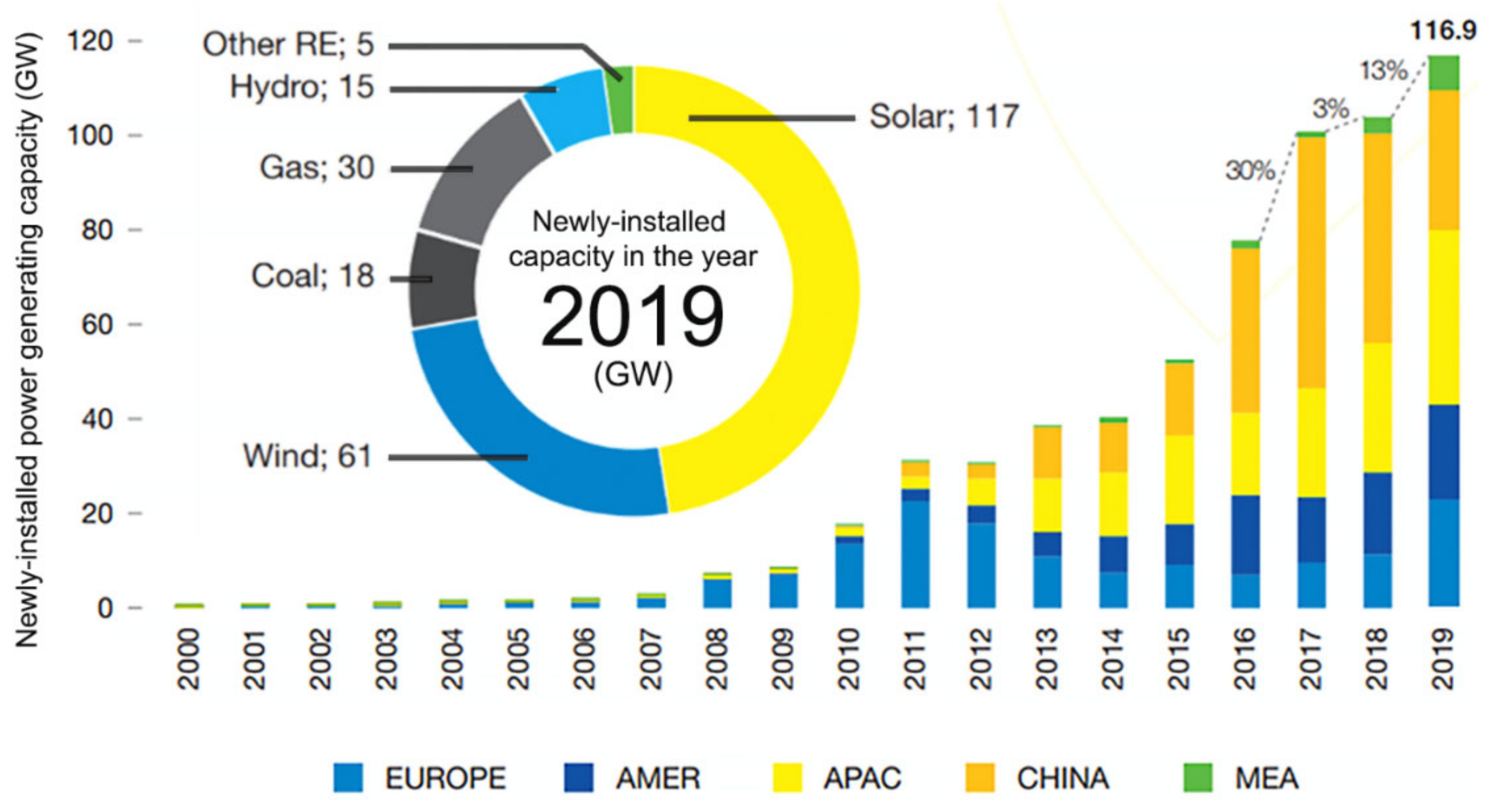

1. Introduction

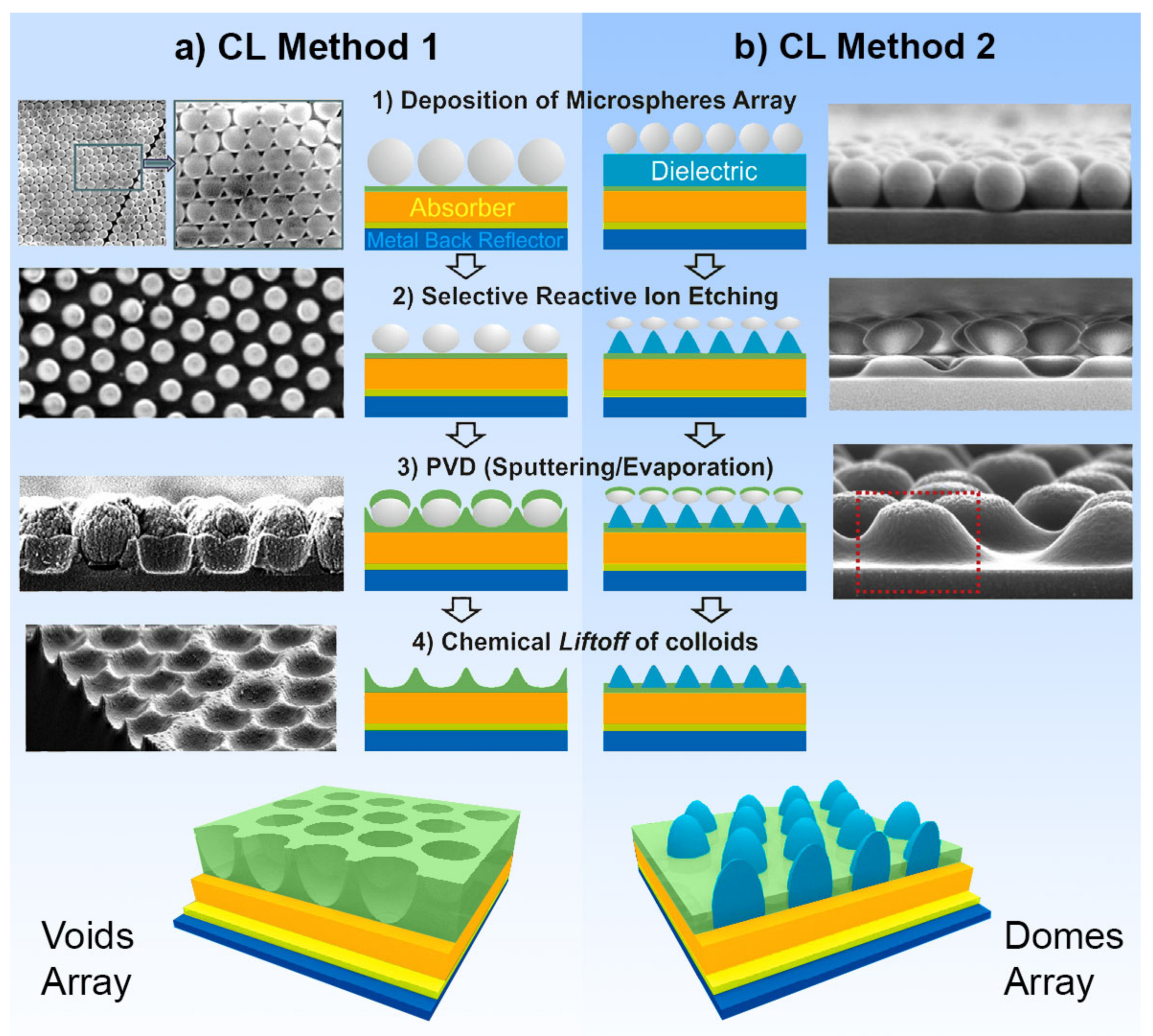

2. Colloidal Lithography (CL) Methodologies

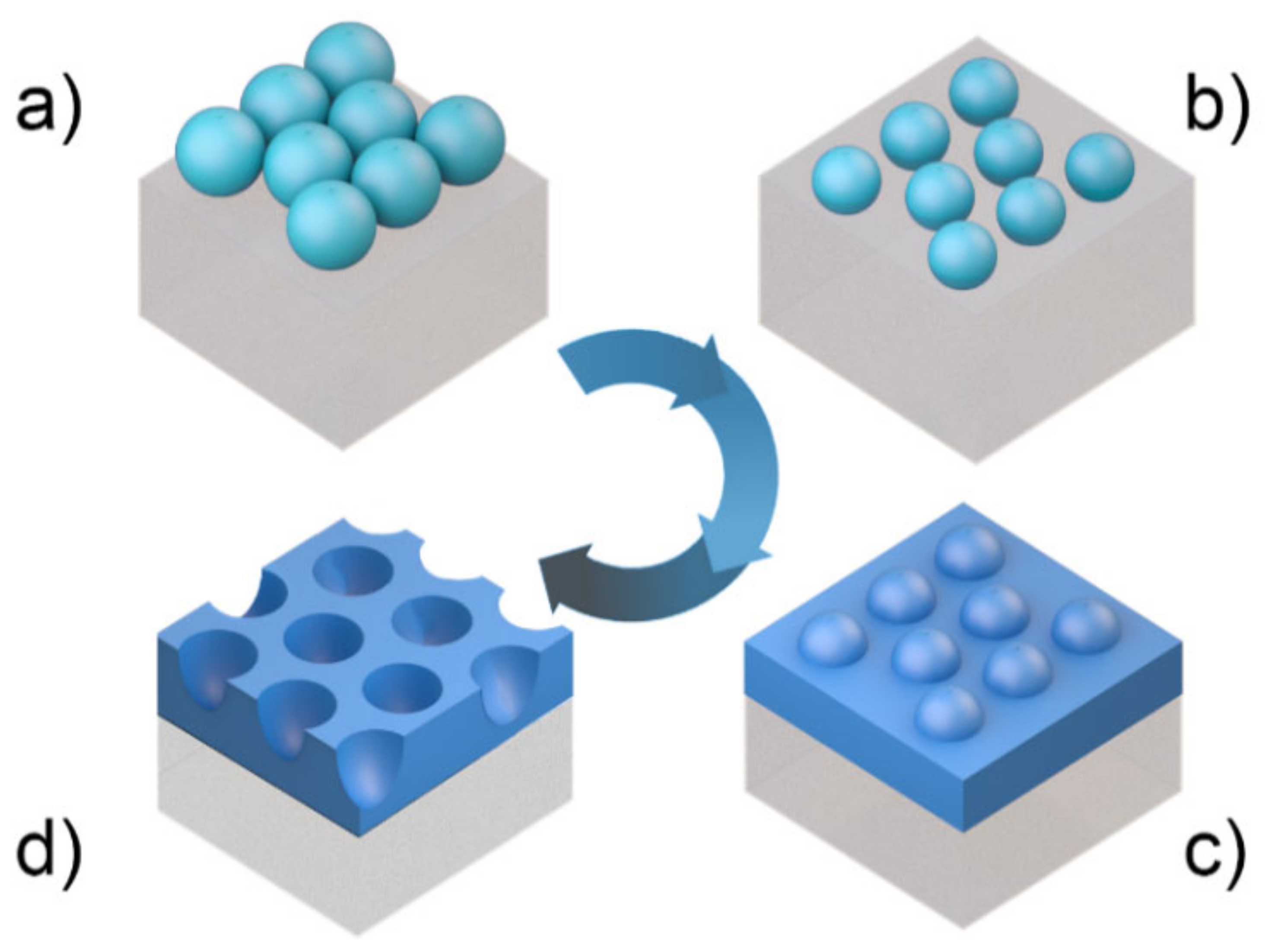

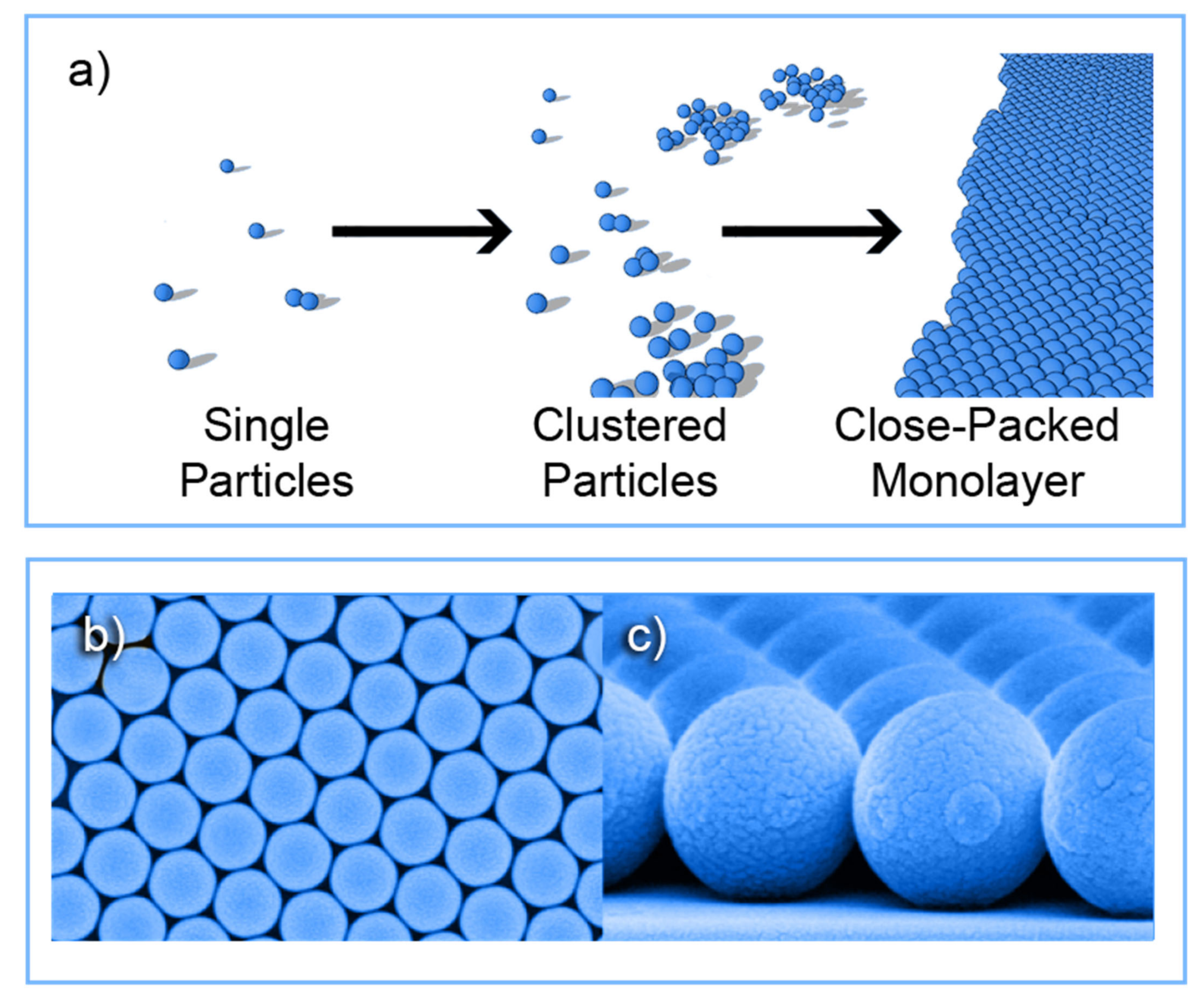

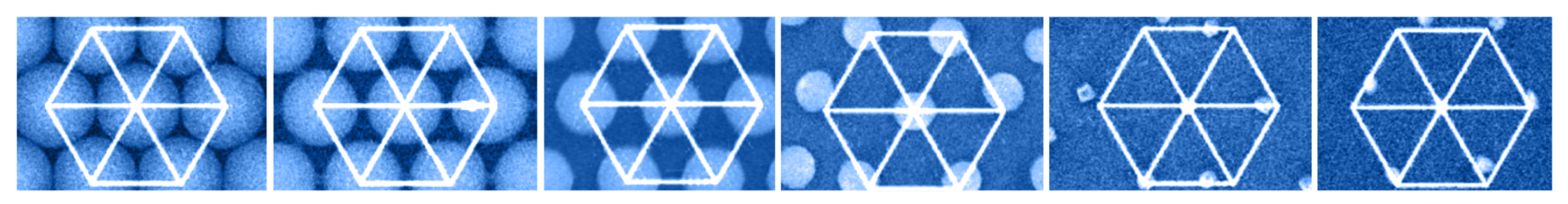

2.1. Colloidal Self-Assembly

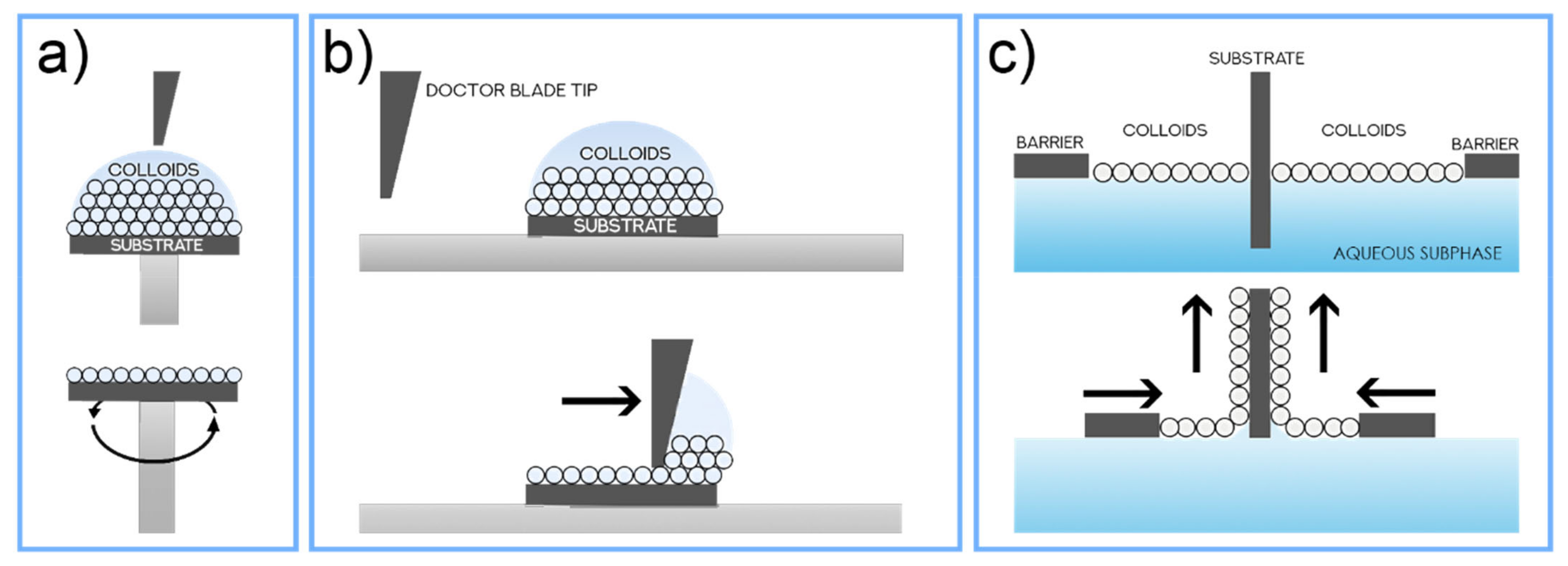

2.2. Deposition of Colloidal Arrays

2.3. Colloidal Masking for Surface Patterning

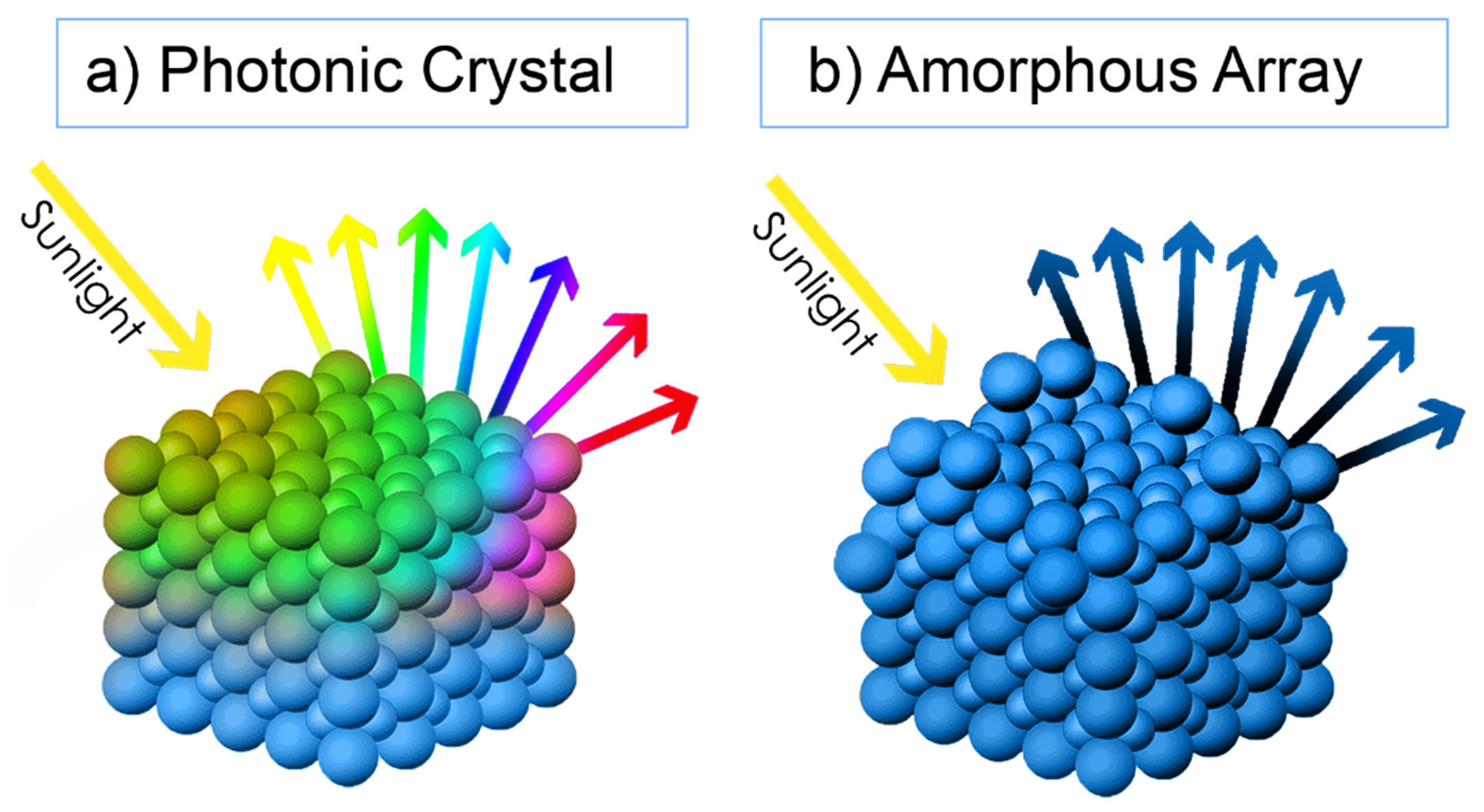

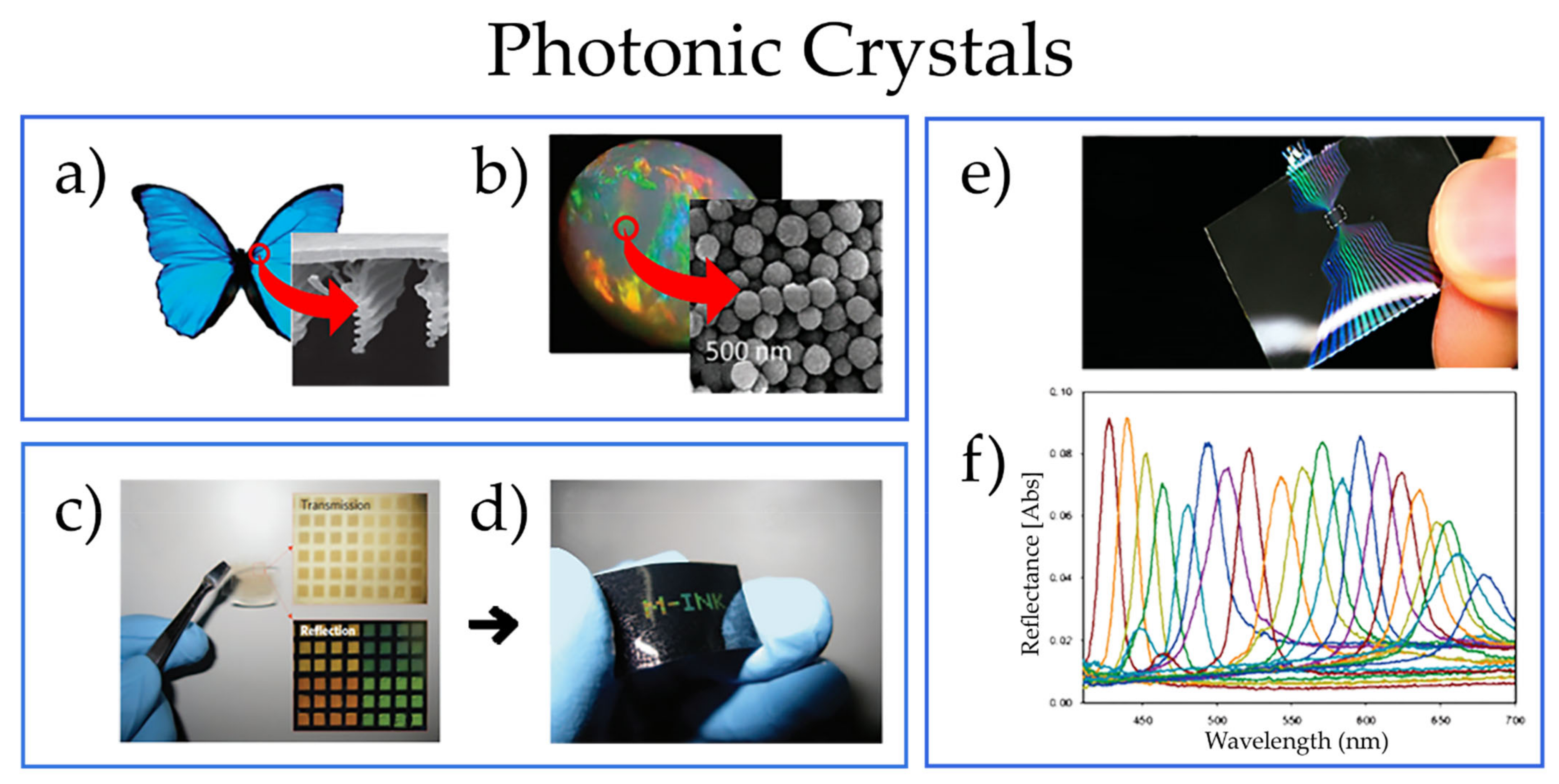

3. Photonic Crystals

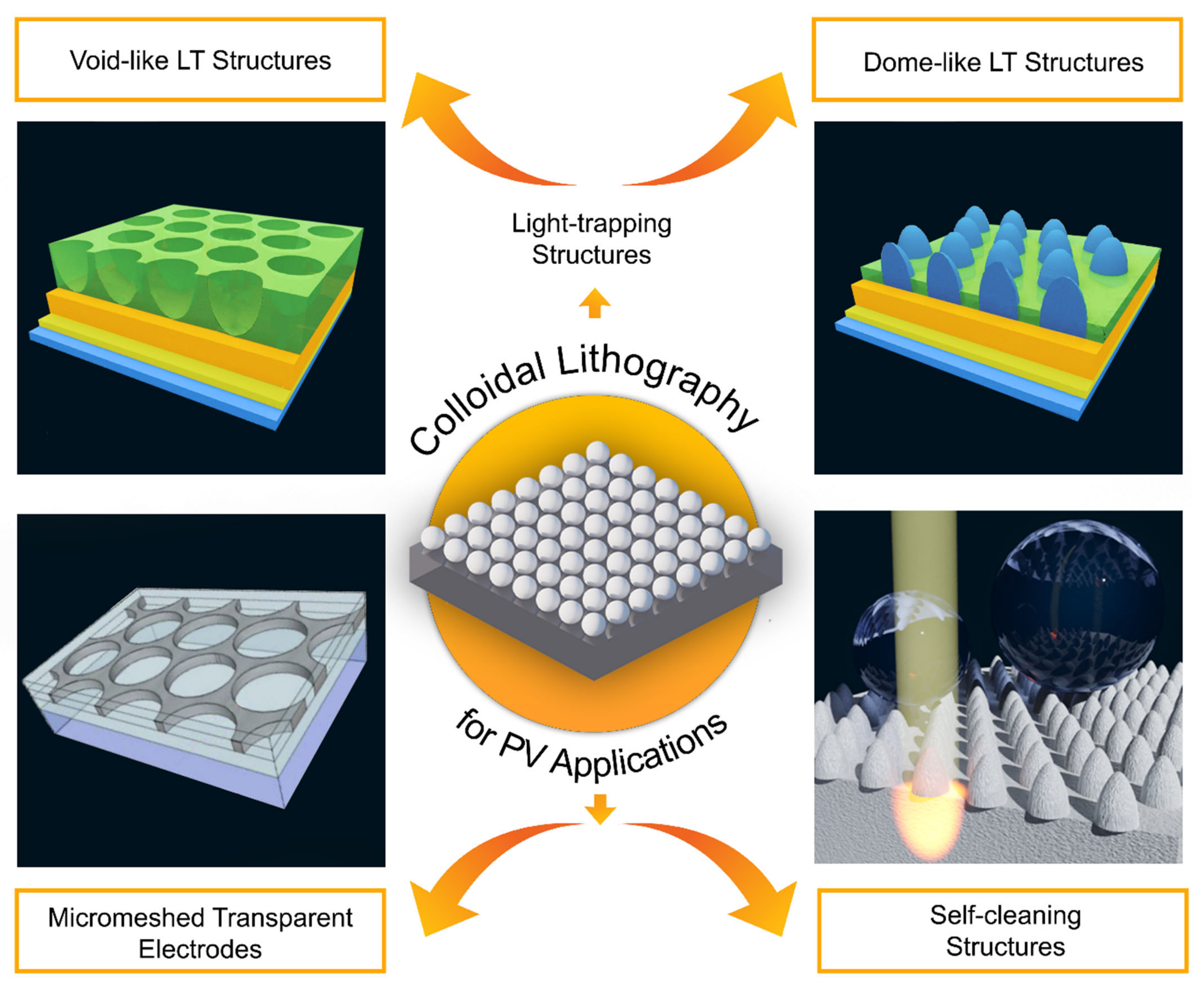

4. Photovoltaics Enhanced with Micro-Structuring

4.1. Light-Trapping in Photovoltaics

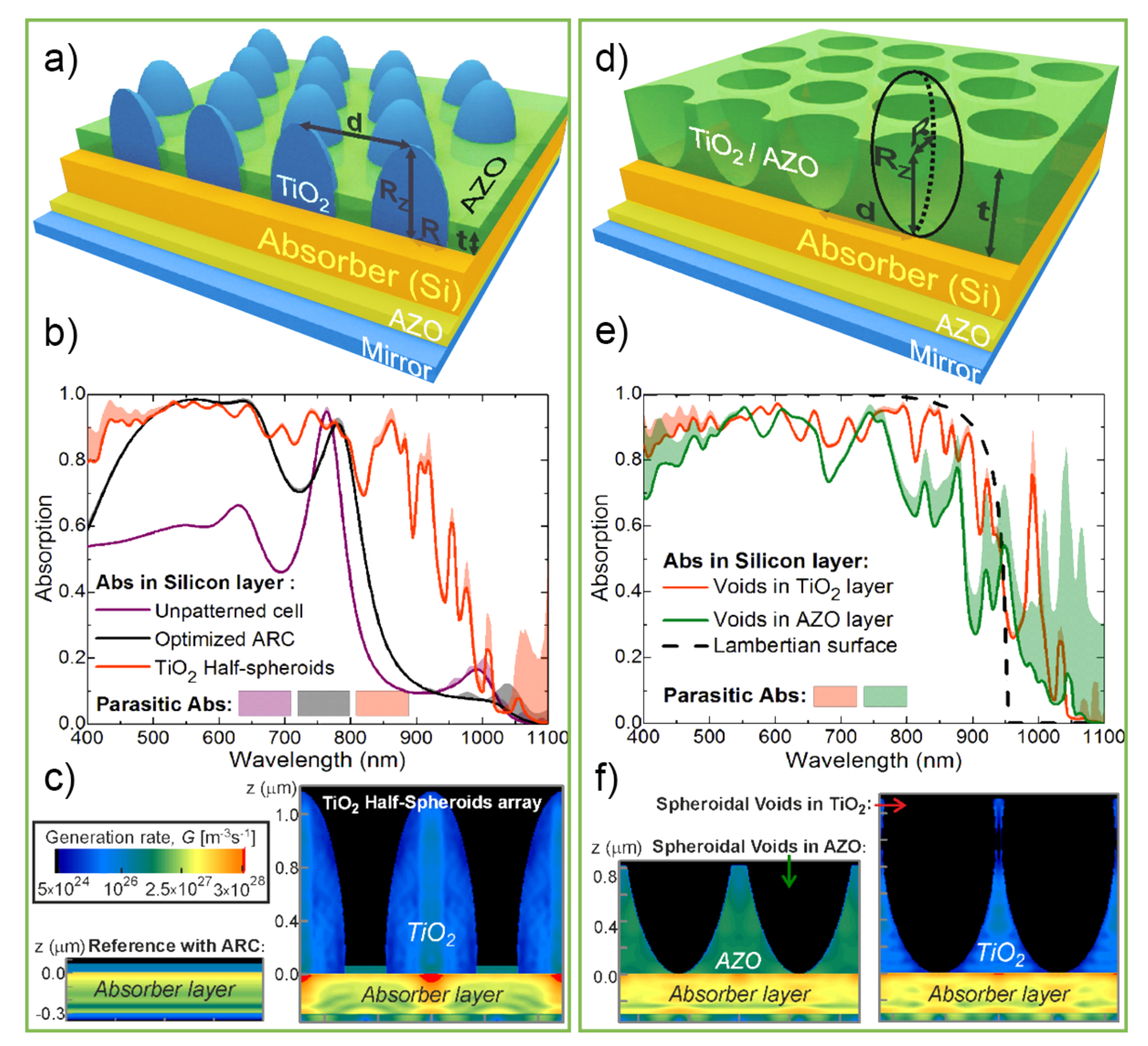

4.1.1. Computational Design and Optimization of Photonic Solutions

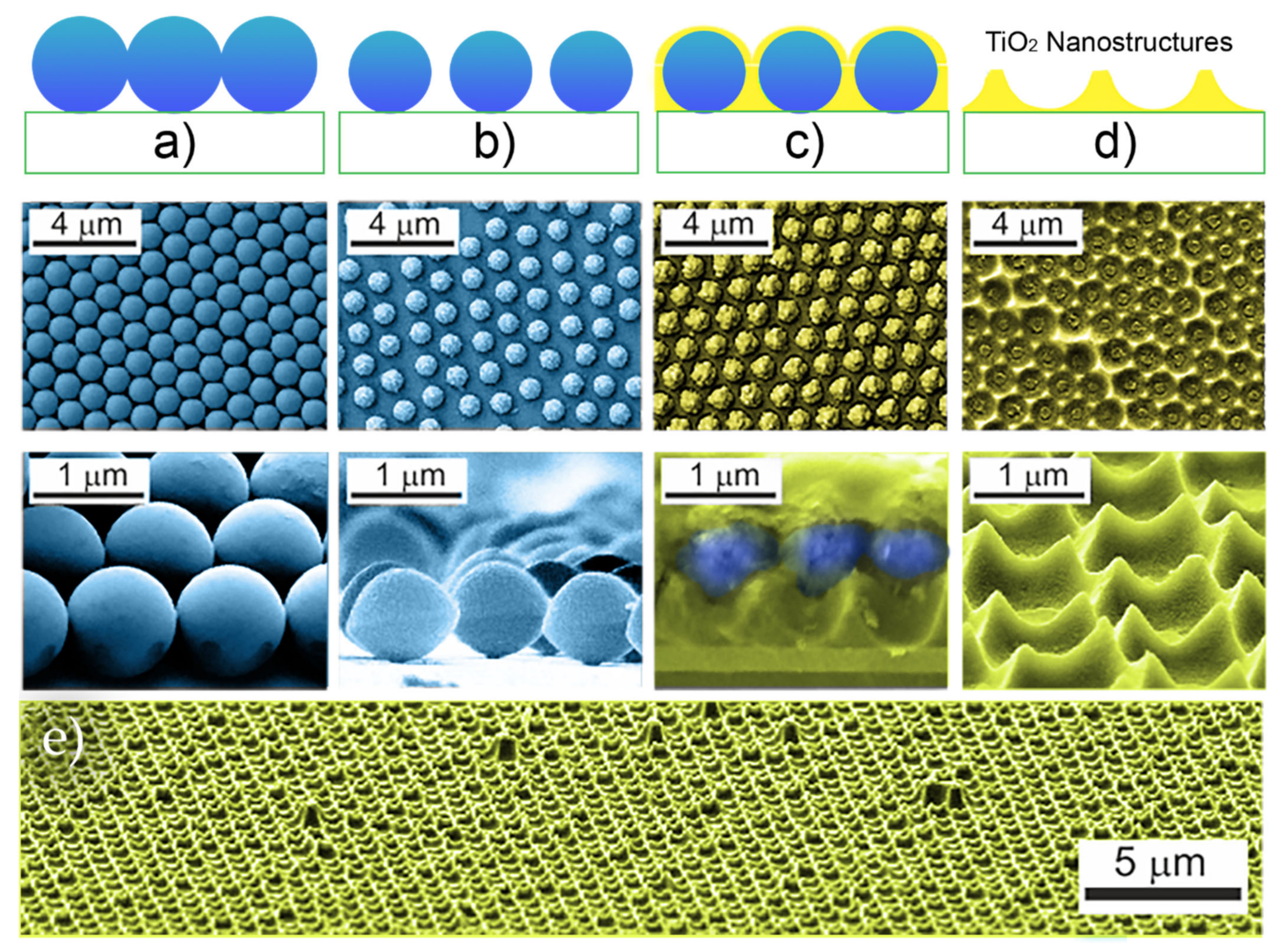

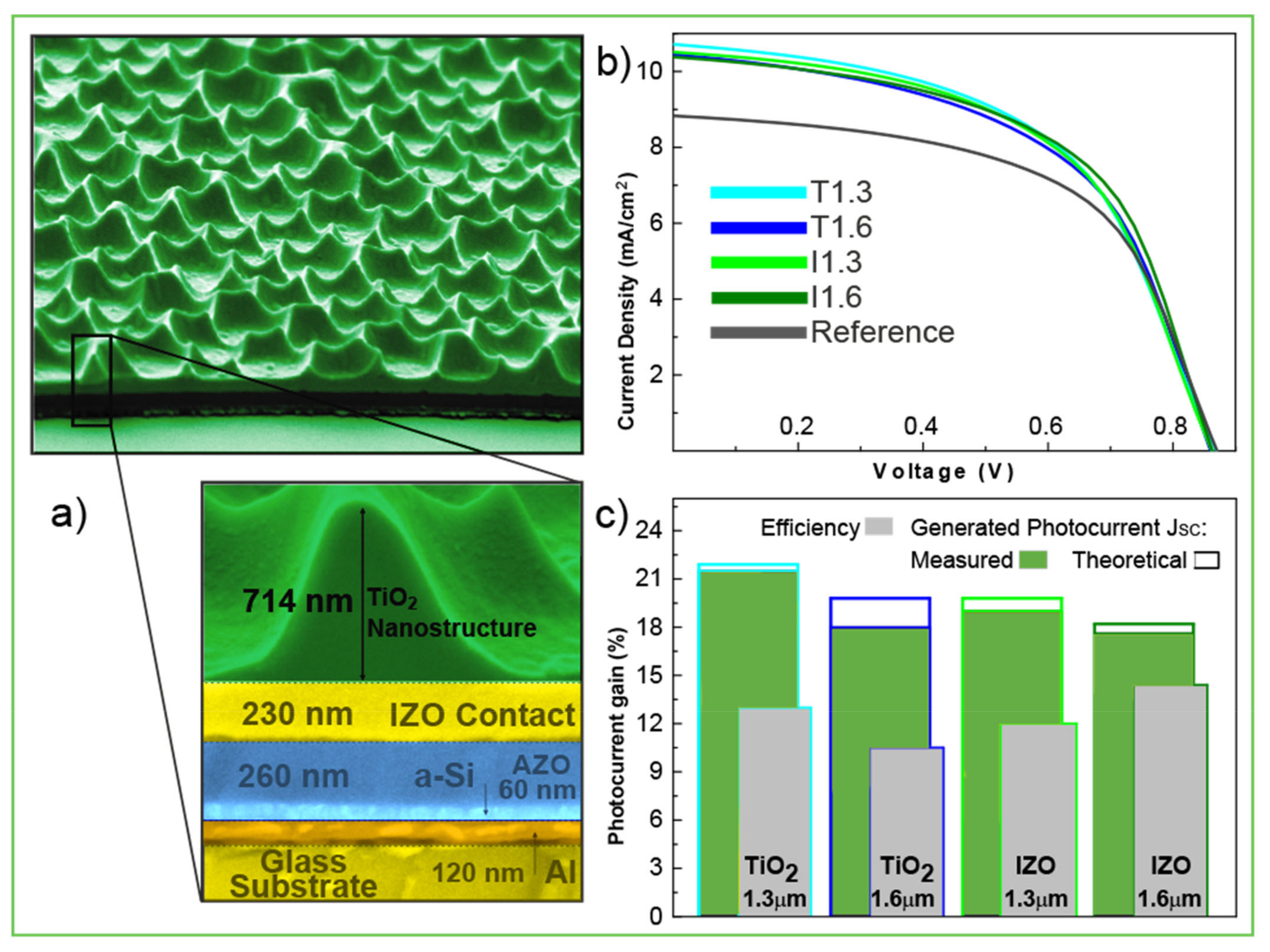

4.1.2. Thin-Film Solar Cells Improved with Front-Located Photonic Structures

4.1.3. Photonic-Enhanced Perovskite Solar Cells and CL Compatibility

4.2. Micro-Meshed Transparent Electrodes

4.3. Self-Cleaning with Photonic Structuring

4.4. Overview of Achievements

5. Other Applications of Colloidal Lithography: Biological Cell Studies

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Green, M.A. Commercial progress and challenges for photovoltaics. Nat. Energy 2016, 1, 15015. [Google Scholar] [CrossRef]

- Tawalbeh, M.; Al-Othman, A.; Kafiah, F.; Abdelsalam, E.; Almomani, F.; Alkasrawi, M. Environmental impacts of solar photovoltaic systems: A critical review of recent progress and future outlook. Sci. Total Environ. 2021, 759, 143528. [Google Scholar] [CrossRef]

- Kannan, N.; Vakeesan, D. Solar energy for future world: A review. Renew. Sustain. Energy Rev. 2016, 62, 1092–1105. [Google Scholar] [CrossRef]

- Breyer, C.; Bogdanov, D.; Aghahosseini, A.; Gulagi, A.; Child, M.; Oyewo, A.S.; Farfan, J.; Sadovskaia, K.; Vainikka, P. Solar photovoltaics demand for the global energy transition in the power sector. Prog. Photovolt. Res. Appl. 2018, 26, 505–523. [Google Scholar] [CrossRef]

- Schmela, M. Global Market Outlook for Solar Power 2020–2024; Solar Power: Brussels, Belgium, 2020. [Google Scholar]

- International Renewable Energy Agency. Renewable Power Generation Costs in 2019; IRENA (2020), Renewable Power Generation Costs in 2019; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2020. [Google Scholar]

- Liu, J.; Yao, M.; Shen, L. Third generation photovoltaic cells based on photonic crystals. J. Mater. Chem. C 2019, 7, 3121–3145. [Google Scholar] [CrossRef]

- Hagfeldt, A.; Boschloo, G.; Sun, L.; Kloo, L.; Pettersson, H. Dye-Sensitized Solar Cells. Chem. Rev. 2010, 110, 6595–6663. [Google Scholar] [CrossRef]

- Yan, N.; Zhao, C.; You, S.; Zhang, Y.; Li, W. Recent progress of thin-film photovoltaics for indoor application. Chin. Chem. Lett. 2020, 31, 643–653. [Google Scholar] [CrossRef]

- Li, M.; Igbari, F.; Wang, Z.; Liao, L. Indoor Thin-Film Photovoltaics: Progress and Challenges. Adv. Energy Mater. 2020, 10. [Google Scholar] [CrossRef]

- Lee, T.D.; Ebong, A.U. A review of thin film solar cell technologies and challenges. Renew. Sustain. Energy Rev. 2017, 70, 1286–1297. [Google Scholar] [CrossRef]

- Edoff, M. Thin Film Solar Cells: Research in an Industrial Perspective. Ambio 2012, 41, 112–118. [Google Scholar] [CrossRef]

- Lizin, S.; van Passel, S.; de Schepper, E.; Vranken, L. The future of organic photovoltaic solar cells as a direct power source for consumer electronics. Sol. Energy Mater. Sol. Cells 2012, 103, 1–10. [Google Scholar] [CrossRef]

- Hoffmann, W. PV solar electricity industry: Market growth and perspective. Sol. Energy Mater. Sol. Cells 2006, 90, 3285–3311. [Google Scholar] [CrossRef]

- Schuss, C.; Rahkonen, T. Photovoltaic (PV) energy as recharge source for portable devices such as mobile phones. In Proceedings of the 2012 12th Conference of Open Innovations Association (FRUCT), Oulu, Finland, 5–9 November 2012; pp. 1–9. [Google Scholar] [CrossRef]

- Vicente, A.T.; Araújo, A.; Mendes, M.J.; Nunes, D.; Oliveira, M.J.; Sanchez-Sobrado, O.; Ferreira, M.P.; Águas, H.; Fortunato, E.; Martins, R. Multifunctional cellulose-paper for light harvesting and smart sensing applications. J. Mater. Chem. C 2018, 6, 3143–3181. [Google Scholar] [CrossRef]

- Vicente, A.; Águas, H.; Mateus, T.; Araújo, A.; Lyubchyk, A.; Siitonen, S.; Fortunato, E.; Martins, R. Solar cells for self-sustainable intelligent packaging. J. Mater. Chem. A 2015, 3, 13226–13236. [Google Scholar] [CrossRef]

- Águas, H.; Mateus, T.; Vicente, A.; Gaspar, D.; Mendes, M.J.; Schmidt, W.A.; Pereira, L.; Fortunato, E.; Martins, R. Thin Film Silicon Photovoltaic Cells on Paper for Flexible Indoor Applications. Adv. Funct. Mater. 2015, 25, 3592–3598. [Google Scholar] [CrossRef]

- Shockley, W.; Queisser, H.J. Detailed Balance Limit of Efficiency of p-n Junction Solar Cells. J. Appl. Phys. 1961, 32, 510–519. [Google Scholar] [CrossRef]

- Karg, M.; König, T.A.; Retsch, M.; Stelling, C.; Reichstein, P.M.; Honold, T.; Thelakkat, M.; Fery, A. Colloidal self-assembly concepts for light management in photovoltaics. Mater. Today 2015, 18, 185–205. [Google Scholar] [CrossRef]

- Balling, P.; Christiansen, J.; Christiansen, R.E.; Eriksen, E.; Lakhotiya, H.; Mirsafaei, M.; Møller, S.; Nazir, A.; Vester-Petersen, J.; Jeppesen, B.; et al. Improving the efficiency of solar cells by upconverting sunlight using field enhancement from optimized nano structures. Opt. Mater. 2018, 83, 279–289. [Google Scholar] [CrossRef]

- Parchine, M.; Kohoutek, T.; Bardosova, M.; Pemble, M.E. Large area colloidal photonic crystals for light trapping in flexible organic photovoltaic modules applied using a roll-to-roll Langmuir-Blodgett method. Sol. Energy Mater. Sol. Cells 2018, 185, 158–165. [Google Scholar] [CrossRef]

- Brongersma, M.L.; Cui, Y.; Fan, S. Light management for photovoltaics using high-index nanostructures. Nat. Mater. 2014, 13, 451–460. [Google Scholar] [CrossRef] [PubMed]

- Battaglia, C.; Hsu, C.-M.; Söderström, K.; Escarré, J.; Haug, F.-J.; Charrière, M.; Boccard, M.; Despeisse, M.; Alexander, D.T.L.; Cantoni, M.; et al. Light Trapping in Solar Cells: Can Periodic Beat Random? ACS Nano 2012, 6, 2790–2797. [Google Scholar] [CrossRef] [PubMed]

- Rim, S.-B.; Zhao, S.; Scully, S.R.; McGehee, M.D.; Peumans, P. An effective light trapping configuration for thin-film solar cells. Appl. Phys. Lett. 2007, 91, 243501. [Google Scholar] [CrossRef]

- Grandidier, J.; Weitekamp, R.A.; Deceglie, M.G.; Callahan, D.M.; Battaglia, C.; Bukowsky, C.R.; Ballif, C.; Grubbs, R.H.; Atwater, H.A. Solar cell efficiency enhancement via light trapping in printable resonant dielectric nanosphere arrays. Phys. Status Solidi Appl. Mater. Sci. 2012, 210, 255–260. [Google Scholar] [CrossRef]

- Haque, S.; Mendes, M.J.; Sanchez-Sobrado, O.; Águas, H.; Fortunato, E.; Martins, R. Photonic-structured TiO2 for high-efficiency, flexible and stable Perovskite solar cells. Nano Energy 2019, 59, 91–101. [Google Scholar] [CrossRef]

- Alexandre, M.; Chapa, M.; Haque, S.; Mendes, M.J.; Águas, H.; Fortunato, E.; Martins, R. Optimum Luminescent Down-Shifting Properties for High Efficiency and Stable Perovskite Solar Cells. ACS Appl. Energy Mater. 2019, 2, 2930–2938. [Google Scholar] [CrossRef]

- Sanchez-Sobrado, O.; Mendes, M.J.; Mateus, T.; Costa, J.; Nunes, D.; Águas, H.; Fortunato, E.; Martins, R. Photonic-structured TCO front contacts yielding optical and electrically enhanced thin-film solar cells. Sol. Energy 2020, 196, 92–98. [Google Scholar] [CrossRef]

- Haque, S.; Alexandre, M.; Mendes, M.J.; Águas, H.; Fortunato, E.; Martins, R. Design of wave-optical structured substrates for ultra-thin perovskite solar cells. Appl. Mater. Today 2020, 20, 100720. [Google Scholar] [CrossRef]

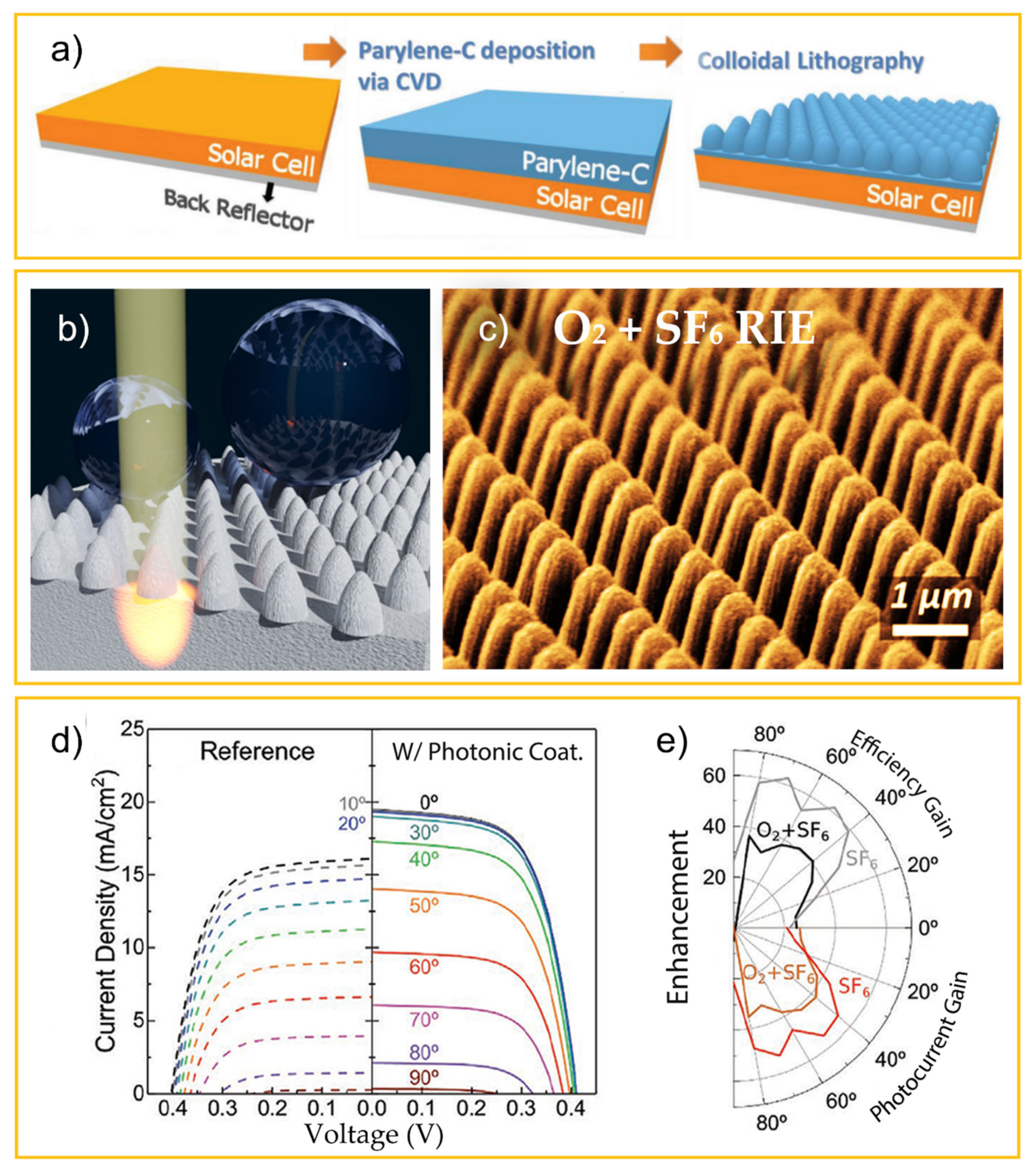

- Centeno, P.; Alexandre, M.; Chapa, M.; Pinto, J.V.; Deuermeier, J.; Mateus, T.; Fortunato, E.; Martins, R.; Águas, H.; Mendes, M.J. Self-Cleaned Photonic-Enhanced Solar Cells with Nanostructured Parylene-C. Adv. Mater. Interfaces 2020, 7. [Google Scholar] [CrossRef]

- Ye, X.; Qi, L. Two-dimensionally patterned nanostructures based on monolayer colloidal crystals: Controllable fabrication, assembly, and applications. Nano Today 2011, 6, 608–631. [Google Scholar] [CrossRef]

- Sanchez-Sobrado, O.; Mendes, M.J.; Haque, S.; Mateus, T.; Araujo, A.; Aguas, H.; Fortunato, E.; Martins, R. Colloidal-lithographed TiO2 photonic nanostructures for solar cell light trapping. J. Mater. Chem. C 2017, 5, 6852–6861. [Google Scholar] [CrossRef]

- Dimitrov, S.D.; Durrant, J.R. Materials design considerations for charge generation in organic solar cells. Chem. Mater. 2014, 26, 616–630. [Google Scholar] [CrossRef]

- Levenson, M.; Viswanathan, N.; Simpson, R. Improving resolution in photolithography with a phase-shifting mask. IEEE Trans. Electron Devices 1982, 29, 1828–1836. [Google Scholar] [CrossRef]

- Xia, Y.; Whitesides, G.M. Soft Lithography. Annu. Rev. Mater. Res. 1998, 28, 153–184. [Google Scholar] [CrossRef]

- Stepanova, M.; Dew, S. Nanofabrication: Techniques and Principles; Springer: Vienna, Austria, 2011; ISBN 9783709104248. [Google Scholar]

- Cui, Z. Nanofabrication: Principles, Capabilities and Limits, 2nd ed.; Springer: Gewerbestrasse, Switerzland, 2017; ISBN 9783319393612. [Google Scholar]

- Ai, B.; Möhwald, H.; Wang, D.; Zhang, G. Advanced Colloidal Lithography Beyond Surface Patterning. Adv. Mater. Interfaces 2016, 4. [Google Scholar] [CrossRef]

- Vieu, C.; Carcenac, F.; Pépin, A.; Chen, Y.; Mejias, M.; Lebib, A.; Manin-Ferlazzo, L.; Couraud, L.; Launois, H. Electron beam lithography: Resolution limits and applications. Appl. Surf. Sci. 2000, 164, 111–117. [Google Scholar] [CrossRef]

- Melngailis, J. Focused ion beam technology and applications. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 1987, 5, 469–495. [Google Scholar] [CrossRef]

- Liu, H.; Ding, Y.; Jiang, W.; Lian, Q.; Yin, L.; Shi, Y.; Lu, B. Novel imprint lithography process used in fabrication of micro/nanostructures in organic photovoltaic devices. J. Micro/Nanolithogr. MEMS MOEMS 2009, 8, 021170. [Google Scholar] [CrossRef]

- Glinsner, T.; Lindner, P.; Mühlberger, M.; Bergmair, I.; Schöftner, R.; Hingerl, K.; Schmidt, H.; Kley, E.-B. Fabrication process of 3D-photonic crystals via UV-nanoimprint lithography. In Proceedings of the 2007 NSTI Nanotechnology Conference and Trade Show, Santa Clara, CA, USA, 20–24 May 2007. [Google Scholar] [CrossRef]

- Pourdavoud, N.; Hu, T.; Chen, Y.; Marianovich, A.; Kowalsky, W.; Heiderhoff, R.; Scheer, H.; Riedl, T.; Wang, S.; Mayer, A. Photonic Nanostructures: Photonic Nanostructures Patterned by Thermal Nanoimprint Directly into Organo-Metal Halide Perovskites. Adv. Mater. 2017, 29. [Google Scholar] [CrossRef]

- Nazirizadeh, Y.; von Oertzen, F.; Plewa, K.; Barié, N.; Jakobs, P.-J.; Guttmann, M.; Leiste, H.; Gerken, M. Sensitivity optimization of injection-molded photonic crystal slabs for biosensing applications. Opt. Mater. Express 2013, 3, 556–565. [Google Scholar] [CrossRef]

- Miller, M.; Brooks, C.B.; Lentz, D.; Doyle, G.; Resnick, D.; LaBrake, D.L. Step and flash imprint process integration techniques for photonic crystal patterning: Template replication through wafer patterning irrespective of tone. In Proceedings of the Advanced Fabrication Technologies for Micro/Nano Optics and Photonics, San Jose, CA, USA, 21–23 January 2008. [Google Scholar] [CrossRef]

- Hong, L.; Yao, H.; Wu, Z.; Cui, Y.; Zhang, T.; Xu, Y.; Yu, R.; Liao, Q.; Gao, B.; Xian, K.; et al. Eco-Compatible Solvent-Processed Organic Photovoltaic Cells with Over 16% Efficiency. Adv. Mater. 2019, 31, e1903441. [Google Scholar] [CrossRef]

- Sanchez-Sobrado, O.; Mendes, M.J.; Haque, S.; Mateus, T.; Águas, H.; Fortunato, E.; Martins, R. Lightwave trapping in thin film solar cells with improved photonic-structured front contacts. J. Mater. Chem. C 2019, 7, 6456–6464. [Google Scholar] [CrossRef]

- Acikgoz, C.; Hempenius, M.A.; Huskens, J.; Vancso, G.J. Polymers in conventional and alternative lithography for the fabrication of nanostructures. Eur. Polym. J. 2011, 47, 2033–2052. [Google Scholar] [CrossRef]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Imprint Lithography with 25-Nanometer Resolution. Science 1996, 272, 85–87. [Google Scholar] [CrossRef]

- Grandidier, J.; Atwater, H.A.; Deceglie, M.G.; Callahan, D.M. Simulations of solar cell absorption enhancement using resonant modes of a nanosphere array. In Proceedings of the Physics, Simulation, and Photonic Engineering of Photovoltaic Devices, San Francisco, CA, USA, 23–26 January 2012. [Google Scholar]

- Mendes, M.J.; Sanchez-Sobrado, O.; Haque, S.; Mateus, T.; Águas, H.; Fortunato, E.; Martins, R. Wave-optical front structures on silicon and perovskite thin-film solar cells. In Solar Cells and Light Management; Enrichi, F., Righini, G.C., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 315–354. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, G. Colloidal Lithography. In Updates in Advanced Lithography; Hosaka, S., Ed.; InTechOpen: London, UK, 2013; ISBN 978-953-51-1175-7. [Google Scholar]

- Chen, J.; Dong, P.; Di, D.; Wang, C.; Wang, H.; Wang, J.; Wu, X. Controllable fabrication of 2D colloidal-crystal films with polystyrene nanospheres of various diameters by spin-coating. Appl. Surf. Sci. 2013, 270, 6–15. [Google Scholar] [CrossRef]

- You, J.; Wang, J.; Wang, L.; Wang, Z.; Wang, Z.; Li, J.; Lin, X. Dynamic particle packing in freezing colloidal suspensions. Colloids Surf. A Physicochem. Eng. Asp. 2017, 531, 93–98. [Google Scholar] [CrossRef]

- Birdi, K.S. Surface and Colloid Chemistry: Principles and Applications; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2010; ISBN 9781420095036. [Google Scholar]

- Vlad, A.; Huynen, I.; Melinte, S. Wavelength-scale lens microscopy via thermal reshaping of colloidal particles. Nanotechnology 2012, 23, 285708. [Google Scholar] [CrossRef] [PubMed]

- Chandramohan, A.; Sibirev, N.V.; Dubrovskii, V.G.; Petty, M.C.; Gallant, A.J.; Zeze, D.A. Model for large-area monolayer coverage of polystyrene nanospheres by spin coating. Sci. Rep. 2017, 7, 40888. [Google Scholar] [CrossRef] [PubMed]

- Technique, M.S.L.; Wei-dong, R.; Zhi-cheng, L.; Nan, J.I.; Chun-xu, W.; Bing, Z.; Jun-hu, Z. Facile Fabrication of Large Area Polystyrene Colloidal Crystal Monolayer via Surfactant-free Langmuir-Blodgett Technique. Chem. Res. Chin. Univ. 2007, 3, 712–714. [Google Scholar]

- Chen, Y.; Shi, D.; Chen, Y.; Chen, X.; Gao, J.; Zhao, N.; Wong, C.-P. A Facile, Low-Cost Plasma Etching Method for Achieving Size Controlled Non-Close-Packed Monolayer Arrays of Polystyrene Nano-Spheres. Nanomaterials 2019, 9, 605. [Google Scholar] [CrossRef] [PubMed]

- Peng, X.; Jin, J.; Ericsson, E.M.; Ichinose, I. General Method for Ultrathin Free-Standing Films of Nanofibrous Composite Materials. J. Am. Chem. Soc. 2007, 129, 8625–8633. [Google Scholar] [CrossRef]

- Torrisi, G.; Luis, J.S.; Sanchez-Sobrado, O.; Raciti, R.; Mendes, M.J.; Águas, H.; Fortunato, E.; Martins, R.; Terrasi, A. Colloidal-structured metallic micro-grids: High performance transparent electrodes in the red and infrared range. Sol. Energy Mater. Sol. Cells 2019, 197, 7–12. [Google Scholar] [CrossRef]

- Chen, J.; Liao, W.-S.; Chen, X.; Yang, T.; Wark, S.E.; Son, D.H.; Batteas, J.D.; Cremer, P.S. Evaporation-Induced Assembly of Quantum Dots into Nanorings. ACS Nano 2008, 3, 173–180. [Google Scholar] [CrossRef] [PubMed]

- Ober, C.; Lok, K.P.; Hair, M.L. Monodispersed, micron-sized polystyrene particles by dispersion polymerization. J. Polym. Sci. Part C Polym. Lett. 1985, 23, 103–108. [Google Scholar] [CrossRef]

- Kallepalli, L.D.; Constantinescu, C.; Delaporte, P.; Utéza, O.; Grojo, D. Ultra-high ordered, centimeter scale preparation of microsphere Langmuir films. J. Colloid Interface Sci. 2015, 446, 237–243. [Google Scholar] [CrossRef]

- Zou, D.; Aklonis, J.J.; Salovey, R. Model filled polymers. XI. Synthesis of monodisperse crosslinked polymethacrylonitrile beads. J. Polym. Sci. Part A Polym. Chem. 1992, 30, 2443–2449. [Google Scholar] [CrossRef]

- Shen, S.; Sudol, E.D.; El-Aasser, M.S. Dispersion polymerization of methyl methacrylate: Mechanism of particle formation. J. Polym. Sci. Part A Polym. Chem. 1994, 32, 1087–1100. [Google Scholar] [CrossRef]

- van Dommelen, R.; Fanzio, P.; Sasso, L. Surface self-assembly of colloidal crystals for micro- and nano-patterning. Adv. Colloid Interface Sci. 2018, 251, 97–114. [Google Scholar] [CrossRef]

- Li, W.; Song, X.; Zhao, X.; Zhang, X.; Chen, R.; Zhang, X.; Jiang, C.; He, J.; Xiao, X. Design of wafer-scale uniform Au nanotip array by ion irradiation for enhanced single conductive filament resistive switching. Nano Energy 2020, 67, 104213. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Y.; Zhang, X.; Yang, B. Colloidal Self-Assembly Meets Nanofabrication: From Two-Dimensional Colloidal Crystals to Nanostructure Arrays. Adv. Mater. 2010, 22, 4249–4269. [Google Scholar] [CrossRef]

- Fischer, U.C.; Zingsheim, H.P. Submicroscopic pattern replication with visible light. Proc. J. Vac. Sci. Technol. 1981, 19, 881–885. [Google Scholar] [CrossRef]

- Deckman, H.W.; Dunsmuir, J.H. Natural lithography. Appl. Phys. Lett. 1982, 41, 377–379. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, M.; Lai, Y.; Chi, L. Advanced colloidal lithography: From patterning to applications. Nano Today 2018, 22, 36–61. [Google Scholar] [CrossRef]

- Syafiq, A.; Pandey, A.K.; Adzman, N.N.; Rahim, N.A. Advances in approaches and methods for self-cleaning of solar photovoltaic panels. Sol. Energy 2018, 162, 597–619. [Google Scholar] [CrossRef]

- Velev, O.; Jede, T.A.; Lobo, R.F.; Lenhoff, A. Porous silica via colloidal crystallization. Nat. Cell Biol. 1997, 389, 447–448. [Google Scholar] [CrossRef]

- Maskaly, G.R.; Petruska, M.A.; Nanda, J.; Bezel, I.V.; Schaller, R.D.; Htoon, H.; Pietryga, J.M.; Klimov, V.I. Amplified Spontaneous Emission in Semiconductor-Nanocrystal/Synthetic-Opal Composites: Optical-Gain Enhancement via a Photonic Crystal Pseudogap. Adv. Mater. 2006, 18, 343–347. [Google Scholar] [CrossRef]

- Urban, J.J.; Talapin, D.V.; Shevchenko, E.V.; Murray, C.B. Self-Assembly of PbTe Quantum Dots into Nanocrystal Superlattices and Glassy Films. J. Am. Chem. Soc. 2006, 128, 3248–3255. [Google Scholar] [CrossRef]

- Edwards, E.W.; Wang, D.; Möhwald, H. Hierarchical Organization of Colloidal Particles: From Colloidal Crystallization to Supraparticle Chemistry. Macromol. Chem. Phys. 2007, 208, 439–445. [Google Scholar] [CrossRef]

- Zhang, C.; Cvetanovic, S.; Pearce, J.M. Fabricating ordered 2-D nano-structured arrays using nanosphere lithography. MethodsX 2017, 4, 229–242. [Google Scholar] [CrossRef]

- Fang, Y.; Phillips, B.M.; Askar, K.; Choi, B.; Jiang, P.; Jiang, B. Scalable bottom-up fabrication of colloidal photonic crystals and periodic plasmonic nanostructures. J. Mater. Chem. C 2013, 1, 6031–6047. [Google Scholar] [CrossRef]

- Park, B.; Na, S.Y.; Bae, I.-G. Uniform two-dimensional crystals of polystyrene nanospheres fabricated by a surfactant-assisted spin-coating method with polyoxyethylene tridecyl ether. Sci. Rep. 2019, 9, 1–9. [Google Scholar] [CrossRef]

- Birnie, D.P. Spin coating technique. In Sol-Gel Technologies for Glass Producers and Users; Aegerter, M.A., Menning, M., Eds.; Springer: New York, NY, USA, 2004; pp. 49–55. [Google Scholar]

- Hsieh, C.-H.; Lu, Y.-C.; Yang, H. Self-Assembled Mechanochromic Shape Memory Photonic Crystals by Doctor Blade Coating. ACS Appl. Mater. Interfaces 2020, 12, 36478–36484. [Google Scholar] [CrossRef] [PubMed]

- Prevo, B.G.; Velev, O. Controlled, Rapid Deposition of Structured Coatings from Micro- and Nanoparticle Suspensions. Langmuir 2004, 20, 2099–2107. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Jiang, P. Large-Scale Colloidal Self-Assembly by Doctor Blade Coating. Langmuir 2010, 26, 13173–13182. [Google Scholar] [CrossRef]

- Corkery, R.W. Langmuir−Blodgett (L−B) Multilayer Films. Langmuir 1997, 13, 3591–3594. [Google Scholar] [CrossRef]

- Bardosova, M.; Pemble, M.E.; Povey, I.M.; Tredgold, R.H. The langmuir-blodgett approach to making colloidal photonic crystals from silica spheres. Adv. Mater. 2010, 22, 3104–3124. [Google Scholar] [CrossRef] [PubMed]

- Hussain, S.A.; Dey, B.; Bhattacharjee, D.; Mehta, N. Unique supramolecular assembly through Langmuir—Blodgett (LB) technique. Heliyon 2018, 4, e01038. [Google Scholar] [CrossRef]

- Açıkbaş, Y.; Evyapan, M.; Ceyhan, T.; Çapan, R.; Bekaroğlu, Ö. Characterisation of Langmuir–Blodgett films of new multinuclear copper and zinc phthalocyanines and their sensing properties to volatile organic vapours. Sens. Actuators B Chem. 2007, 123, 1017–1024. [Google Scholar] [CrossRef]

- Huang, S.; Tsutsui, G.; Sakaue, H.; Shingubara, S.; Takahagi, T. Experimental conditions for a highly ordered monolayer of gold nanoparticles fabricated by the Langmuir–Blodgett method. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 2001, 19, 2045. [Google Scholar] [CrossRef]

- Schwartz, D. Langmuir-Blodgett film structure. Surf. Sci. Rep. 1997, 27, 245–334. [Google Scholar] [CrossRef]

- Kausar, A. Survey on Langmuir–Blodgett Films of Polymer and Polymeric Composite. Polym. Technol. Eng. 2016, 56, 932–945. [Google Scholar] [CrossRef]

- Pechkova, E.; Nicolini, C. Langmuir-Blodgett Protein Multilayer Nanofilms by XFEL. NanoWorld J. 2018, 4. [Google Scholar] [CrossRef]

- Vogel, N.; Goerres, S.; Landfester, K.; Weiss, C. A Convenient Method to Produce Close- and Non-close-Packed Monolayers using Direct Assembly at the Air-Water Interface and Subsequent Plasma-Induced Size Reduction. Macromol. Chem. Phys. 2011, 212, 1719–1734. [Google Scholar] [CrossRef]

- Retsch, M.; Zhou, Z.; Rivera, S.; Kappl, M.; Zhao, X.S.; Jonas, U.; Li, Q. Fabrication of Large-Area, Transferable Colloidal Monolayers Utilizing Self-Assembly at the Air/Water Interface. Macromol. Chem. Phys. 2009, 210, 230–241. [Google Scholar] [CrossRef]

- Hur, J.; Won, Y.-Y. Fabrication of high-quality non-close-packed 2D colloid crystals by template-guided Langmuir–Blodgett particle deposition. Soft Matter 2008, 4, 1261–1269. [Google Scholar] [CrossRef] [PubMed]

- Parchine, M.; McGrath, J.; Bardosova, M.; Pemble, M.E. Large Area 2D and 3D Colloidal Photonic Crystals Fabricated by a Roll-to-Roll Langmuir–Blodgett Method. Langmuir 2016, 32, 5862–5869. [Google Scholar] [CrossRef]

- Reynaert, S.; Moldenaers, P.; Vermant, J. Control over Colloidal Aggregation in Monolayers of Latex Particles at the Oil-Water Interface. Langmuir 2006, 22, 4936–4945. [Google Scholar] [CrossRef]

- Zhavnerko, G.; Marletta, G. Developing Langmuir–Blodgett strategies towards practical devices. Mater. Sci. Eng. B 2010, 169, 43–48. [Google Scholar] [CrossRef]

- Chen, I.-T.; Schappell, E.; Zhang, X.; Chang, C.-H. Continuous roll-to-roll patterning of three-dimensional periodic nanostructures. Microsyst. Nanoeng. 2020, 6, 1–11. [Google Scholar] [CrossRef]

- Li, X.; Gilchrist, J. Large-Area Nanoparticle Films by Continuous Automated Langmuir–Blodgett Assembly and Deposition. Langmuir 2016, 32, 1220–1226. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, D.; Möhwald, H. Decoration of Microspheres with Gold Nanodots—Giving Colloidal Spheres Valences. Angew. Chem. 2005, 117, 7945–7948. [Google Scholar] [CrossRef]

- Zheng, J.; Dai, Z.; Mei, F.; Xiao, X.; Liao, L.; Wu, W.; Zhao, X.; Ying, J.; Ren, F.; Jiang, C. Micro–Nanosized Nontraditional Evaporated Structures Based on Closely Packed Monolayer Binary Colloidal Crystals and Their Fine Structure Enhanced Properties. J. Phys. Chem. C 2014, 118, 20521–20528. [Google Scholar] [CrossRef]

- Li, Z.-W.; Zhou, J.; Zhang, Z.-J.; Dang, H.-X. Self-assembly of carboxyl functionalized polystyrene nano-spheres into close-packed monolayers via chemical adsorption. Chin. J. Chem. 2010, 22, 1133–1137. [Google Scholar] [CrossRef]

- Dickreuter, S.; Gleixner, J.; Kolloch, A.; Boneberg, J.; Scheer, E.; Leiderer, P. Mapping of plasmonic resonances in nanotriangles. Beilstein J. Nanotechnol. 2013, 4, 588–602. [Google Scholar] [CrossRef] [PubMed]

- Haynes, C.L.; Duyne, R.P. Van Nanosphere Lithography: A Versatile Nanofabrication Tool for Studies of Size-Dependent Nanoparticle Optics. J. Polym. Sci. Part B Polym. Phys. 2001, 105, 5599–5611. [Google Scholar] [CrossRef]

- Lee, S.H.; Bantz, K.C.; Lindquist, N.C.; Oh, S.-H.; Haynes, C.L. Self-Assembled Plasmonic Nanohole Arrays. Langmuir 2009, 25, 13685–13693. [Google Scholar] [CrossRef] [PubMed]

- Ai, B.; Yu, Y.; Möhwald, H.; Wang, L.; Zhang, G. Resonant Optical Transmission through Topologically Continuous Films. ACS Nano 2014, 8, 1566–1575. [Google Scholar] [CrossRef]

- Naureen, S.; Sanatinia, R.; Shahid, N.; Anand, S. High Optical Quality InP-Based Nanopillars Fabricated by a Top-Down Approach. Nano Lett. 2011, 11, 4805–4811. [Google Scholar] [CrossRef]

- Li, Y.; Ye, X.; Ma, Y.; Qi, L. Interfacial Nanosphere Lithography toward Ag2S-Ag Heterostructured Nanobowl Arrays with Effective Resistance Switching and Enhanced Photoresponses. Small 2014, 11, 1183–1188. [Google Scholar] [CrossRef]

- Yao, Y.; Yao, J.; Narasimhan, V.K.; Ruan, Z.; Xie, C.; Fan, S.; Cui, Y. Broadband light management using low-Q whispering gallery modes in spherical nanoshells. Nat. Commun. 2012, 3, 664. [Google Scholar] [CrossRef]

- Liu, G.; Li, Y.; Duan, G.; Wang, J.; Changhao, L.; Cai, W. Tunable Surface Plasmon Resonance and Strong SERS Performances of Au Opening-Nanoshell Ordered Arrays. ACS Appl. Mater. Interfaces 2012, 4, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Li, Y.; Zhang, J.; Li, Y.; Zhao, Z.; Zhang, K.; Zhang, G.; Guo, J.; Yang, B. A Universal Approach to Fabricate Various Nanoring Arrays Based on a Colloidal-Crystal-Assisted-Lithography Strategy. Adv. Funct. Mater. 2008, 18, 4036–4042. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, D.; Möhwald, H. Patterning Microsphere Surfaces by Templating Colloidal Crystals. Nano Lett. 2005, 5, 143–146. [Google Scholar] [CrossRef] [PubMed]

- Rizzato, S.; Primiceri, E.; Monteduro, A.G.; Colombelli, A.; Leo, A.; Manera, M.G.; Rella, R.; Maruccio, G. Interaction-tailored organization of large-area colloidal assemblies. Beilstein J. Nanotechnol. 2018, 9, 1582–1593. [Google Scholar] [CrossRef] [PubMed]

- Kumar, K.; Kim, Y.-S.; Yang, E.-H. The influence of thermal annealing to remove polymeric residue on the electronic doping and morphological characteristics of graphene. Carbon 2013, 65, 35–45. [Google Scholar] [CrossRef]

- Vlad, A.; Frölich, A.; Zebrowski, T.; Dutu, C.A.; Busch, K.; Melinte, S.; Wegener, M.; Huynen, I. Direct Transcription of Two-Dimensional Colloidal Crystal Arrays into Three-Dimensional Photonic Crystals. Adv. Funct. Mater. 2012, 23, 1164–1171. [Google Scholar] [CrossRef]

- Marlow, F.; Muldarisnur, M.; Sharifi, P.; Brinkmann, R.; Mendive, C.B. Opals: Status and Prospects. Angew. Chem. Int. Ed. 2009, 48, 6212–6233. [Google Scholar] [CrossRef]

- Lee, S.Y.; Gradoń, L.; Janeczko, S.; Iskandar, F.; Okuyama, K. Formation of Highly Ordered Nanostructures by Drying Micrometer Colloidal Droplets. ACS Nano 2010, 4, 4717–4724. [Google Scholar] [CrossRef] [PubMed]

- Lourtioz, J.-M.; Benisty, H.; Berge, V.; Gerard, J.-M.; Maystre, D.; Tchelnokov, A. Photonic Crystals: Towards Nanoscale Photonic Devices; Springer: Berlin/Heidelberg, Germany, 2003; ISBN 9783540244318. [Google Scholar]

- Armstrong, E.; O’Dwyer, C. Artificial opal photonic crystals and inverse opal structures—Fundamentals and applications from optics to energy storage. J. Mater. Chem. C 2015, 3, 6109–6143. [Google Scholar] [CrossRef]

- Kim, H.; Ge, J.; Kim, J.; Choi, S.-E.; Lee, H.; Lee, H.; Park, W.; Yin, Y.; Kwon, S. Structural colour printing using a magnetically tunable and lithographically fixable photonic crystal. Nat. Photon. 2009, 3, 534–540. [Google Scholar] [CrossRef]

- Kim, S.-H.; Park, H.S.; Choi, J.H.; Shim, J.W.; Yang, S.-M. Integration of Colloidal Photonic Crystals toward Miniaturized Spectrometers. Adv. Mater. 2009, 22, 946–950. [Google Scholar] [CrossRef]

- Xu, H.; Wu, P.; Zhu, C.; Elbaz, A.; Gu, Z.Z. Photonic crystal for gas sensing. J. Mater. Chem. C 2013, 1, 6087–6098. [Google Scholar] [CrossRef]

- Noda, S. Photonic crystals. In Comprehensive Microsystems; Elsevier: Amsterdam, The Netherlands, 2007; pp. 101–112. ISBN 9780444521903. [Google Scholar] [CrossRef]

- Fudouzi, H.; Xia, Y. Colloidal Crystals with Tunable Colors and Their Use as Photonic Papers. Langmuir 2003, 19, 9653–9660. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Ho, J.; Ng, R.C.; Ng, R.J.H.; Hall-Chen, V.H.; Koay, E.H.H.; Dong, Z.; Liu, H.; Qiu, C.-W.; et al. Structural color three-dimensional printing by shrinking photonic crystals. Nat. Commun. 2019, 10, 1–8. [Google Scholar] [CrossRef]

- Arsenault, A.C.; Puzzo, D.P.; Manners, I.; Ozin, G.A. Photonic-crystal full-colour displays. Nat. Photon. 2007, 1, 468–472. [Google Scholar] [CrossRef]

- Ding, T.; Song, K.; Clays, K.; Tung, C.-H. Controlled Directionality of Ellipsoids in Monolayer and Multilayer Colloidal Crystals. Langmuir 2010, 26, 11544–11549. [Google Scholar] [CrossRef] [PubMed]

- Hosein, I.D.; Lee, S.; Liddell, C.M. Dimer-Based Three-Dimensional Photonic Crystals. Adv. Funct. Mater. 2010, 20, 3085–3091. [Google Scholar] [CrossRef]

- Hynninen, A.-P.; Thijssen, J.; Vermolen, E.C.M.; Dijkstra, M.; Van Blaaderen, A. Self-assembly route for photonic crystals with a bandgap in the visible region. Nat. Mater. 2007, 6, 202–205. [Google Scholar] [CrossRef] [PubMed]

- Rinne, S.A.; García-Santamaría, F.; Braun, P.V. Embedded cavities and waveguides in three-dimensional silicon photonic crystals. Nat. Photon. 2007, 2, 52–56. [Google Scholar] [CrossRef]

- Blaszczyk-Lezak, I.; Aparicio, F.J.; Borras, A.; Barranco, A.; Alvarez-Herrero, A.; Fernández-Rodríguez, M.; Gonzalez-Elipe, A. Optically Active Luminescent Perylene Thin Films Deposited by Plasma Polymerization. J. Phys. Chem. C 2009, 113, 431–438. [Google Scholar] [CrossRef]

- Qi, M.; Lidorikis, E.; Rakich, P.T.; Johnson, S.G.; Joannopoulos, J.D.; Ippen, E.P.; Smith, H.I. A three-dimensional optical photonic crystal with designed point defects. Nat. Cell Biol. 2004, 429, 538–542. [Google Scholar] [CrossRef]

- Shao, J.; Liu, G.; Zhou, L. Biomimetic Nanocoatings for Structural Coloration of Textiles; Elsevier: Amsterdam, The Netherlands, 2016; pp. 269–299. [Google Scholar]

- Jiang, C.; Markutsya, S.; Pikus, Y.; Tsukruk, V.V. Freely suspended nanocomposite membranes as highly sensitive sensors. Nat. Mater. 2004, 3, 721–728. [Google Scholar] [CrossRef]

- Feng, D.; Lv, Y.; Wu, Z.; Dou, Y.; Han, L.; Sun, Z.; Xia, Y.; Zheng, G.; Zhao, D. Free-Standing Mesoporous Carbon Thin Films with Highly Ordered Pore Architectures for Nanodevices. J. Am. Chem. Soc. 2011, 133, 15148–15156. [Google Scholar] [CrossRef] [PubMed]

- Jin, J.; Wakayama, Y.; Peng, X.; Ichinose, I. Surfactant-assisted fabrication of free-standing inorganic sheets covering an array of micrometre-sized holes. Nat. Mater. 2007, 6, 686–691. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.-T.; Chao, X.; Asher, S.A. Asymmetric Free-Standing 2-D Photonic Crystal Films and Their Janus Particles. J. Am. Chem. Soc. 2013, 135, 11397–11401. [Google Scholar] [CrossRef] [PubMed]

- Stein, A.; Li, F.; Denny, N.R. Morphological Control in Colloidal Crystal Templating of Inverse Opals, Hierarchical Structures, and Shaped Particles. Chem. Mater. 2008, 20, 649–666. [Google Scholar] [CrossRef]

- Kim, S.-H.; Lee, S.Y.; Yang, S.-M.; Yi, G.-R. Self-assembled colloidal structures for photonics. NPG Asia Mater. 2011, 3, 25–33. [Google Scholar] [CrossRef]

- Mendes, M.J.; Haque, S.; Sanchez-Sobrado, O.; Araújo, A.; Águas, H.; Fortunato, E.; Martins, R. Optimal-Enhanced Solar Cell Ultra-thinning with Broadband Nanophotonic Light Capture. iScience 2018, 3, 238–254. [Google Scholar] [CrossRef]

- Karmouch, R.; El Hor, H. Solar Cells Performance Reduction under the Effect of Dust in Jazan Region. J. Fundam. Renew. Energy Appl. 2017, 7. [Google Scholar] [CrossRef]

- He, G.; Zhou, C.; Li, Z. Review of Self-Cleaning Method for Solar Cell Array. Procedia Eng. 2011, 16, 640–645. [Google Scholar] [CrossRef]

- Saravanan, V.; Darvekar, S.K. Solar Photovoltaic Panels Cleaning Methods A Review. Int. J. Pure Appl. Math. 2018, 118, 1–17. [Google Scholar]

- Deceglie, M.G.; Ferry, V.E.; Alivisatos, A.P.; Atwater, H.A.; Alivisatos, P. Design of Nanostructured Solar Cells Using Coupled Optical and Electrical Modeling. Nano Lett. 2012, 12, 2894–2900. [Google Scholar] [CrossRef]

- Isabella, O.; Vismara, R.; Linssen, D.; Wang, K.; Fan, S.; Zeman, M. Advanced light trapping scheme in decoupled front and rear textured thin-film silicon solar cells. Sol. Energy 2018, 162, 344–356. [Google Scholar] [CrossRef]

- Righini, G.C.; Enrichi, F. Solar cells’ evolution and perspectives: A short review. In Solar Cells and Light Management; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–32. ISBN 978-0-08-102762-2. [Google Scholar]

- Mendes, M.J.; Araújo, A.; Vicente, A.; Águas, H.; Ferreira, I.; Fortunato, E.; Martins, R. Design of optimized wave-optical spheroidal nanostructures for photonic-enhanced solar cells. Nano Energy 2016, 26, 286–296. [Google Scholar] [CrossRef]

- Mendes, M.J.; Tobías, I.; Martí, A.; Luque, A. Light concentration in the near-field of dielectric spheroidal particles with mesoscopic sizes. Opt. Express 2011, 19, 16207–16222. [Google Scholar] [CrossRef]

- Li, K.; Haque, S.; Martins, A.; Fortunato, E.; Martins, R.; Mendes, M.J.; Schuster, C. Simple, yet mighty, principles to maximise photon absorption in thin media. Opt. 2020, 7. [Google Scholar] [CrossRef]

- Ariga, K.; Yamauchi, Y.; Mori, T.; Hill, J.P. 25th Anniversary Article: What Can Be Done with the Langmuir-Blodgett Method? Recent Developments and its Critical Role in Materials Science. Adv. Mater. 2013, 25, 6477–6512. [Google Scholar] [CrossRef] [PubMed]

- Kirchartz, T. Photon Management in Perovskite Solar Cells. J. Phys. Chem. Lett. 2019, 10, 5892–5896. [Google Scholar] [CrossRef]

- NREL. Best Research-Cell Efficiencies Chart; Rev. 04–06–2020; 2020. Available online: https://www.nrel.gov/pv/cell-efficiency.html (accessed on 4 June 2021).

- Dudem, B.; Heo, J.H.; Leem, J.W.; Yu, J.S.; Im, S.H. CH3NH3PbI3planar perovskite solar cells with antireflection and self-cleaning function layers. J. Mater. Chem. A 2016, 4, 7573–7579. [Google Scholar] [CrossRef]

- Thangavel, N.R.; Adhyaksa, G.W.P.; Dewi, H.A.; Tjahjana, L.; Bruno, A.; Birowosuto, M.D.; Wang, H.; Mathews, N.; Mhaisalkar, S. Disordered Polymer Antireflective Coating for Improved Perovskite Photovoltaics. ACS Photon. 2020, 7, 1971–1977. [Google Scholar] [CrossRef]

- Heifetz, A.; Kong, S.-C.; Sahakian, A.V.; Taflove, A.; Backman, V. Photonic Nanojets. J. Comput. Theor. Nanosci. 2009, 6, 1979–1992. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.-D.; Jin, T.-Y.; Li, Y.-Q.; Tang, J.-X. Recent progress of light manipulation strategies in organic and perovskite solar cells. Nanoscale 2019, 11, 18517–18536. [Google Scholar] [CrossRef]

- Erwin, W.R.; Zarick, H.F.; Talbert, E.M.; Bardhan, R. Light trapping in mesoporous solar cells with plasmonic nanostructures. Energy Environ. Sci. 2016, 9, 1577–1601. [Google Scholar] [CrossRef]

- Zhang, H.; Toudert, J. Optical management for efficiency enhancement in hybrid organic-inorganic lead halide perovskite solar cells. Sci. Technol. Adv. Mater. 2018, 19, 411–424. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, P.; Zhou, X.; Li, C.; Li, H.; Hu, X.; Li, F.; Liu, X.; Li, M.; Song, Y. Diffraction-Grated Perovskite Induced Highly Efficient Solar Cells through Nanophotonic Light Trapping. Adv. Energy Mater. 2018, 8. [Google Scholar] [CrossRef]

- Deng, K.; Liu, Z.; Wang, M.; Li, L. Nanoimprinted Grating-Embedded Perovskite Solar Cells with Improved Light Management. Adv. Funct. Mater. 2019, 29. [Google Scholar] [CrossRef]

- Ito, S.; Tanaka, S.; Manabe, K.; Nishino, H. Effects of Surface Blocking Layer of Sb2S3 on Nanocrystalline TiO2 for CH3NH3PbI3 Perovskite Solar Cells. J. Phys. Chem. C 2014, 118, 16995–17000. [Google Scholar] [CrossRef]

- Leijtens, T.; Eperon, G.E.; Pathak, S.; Abate, A.; Lee, M.M.; Snaith, H.J. Overcoming ultraviolet light instability of sensitized TiO2 with meso-superstructured organometal tri-halide perovskite solar cells. Nat. Commun. 2013, 4, 2885. [Google Scholar] [CrossRef]

- Quitsch, W.-A.; Dequilettes, D.W.; Pfingsten, O.; Schmitz, A.; Ognjanovic, S.; Jariwala, S.; Koch, S.; Winterer, M.; Ginger, D.S.; Bacher, G. The Role of Excitation Energy in Photobrightening and Photodegradation of Halide Perovskite Thin Films. J. Phys. Chem. Lett. 2018, 9, 2062–2069. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.-W.; Kim, S.; Bae, S.; Cho, K.; Chung, T.; Mundt, L.E.; Lee, S.; Park, S.; Park, H.; Schubert, M.C.; et al. UV Degradation and Recovery of Perovskite Solar Cells. Sci. Rep. 2016, 6, 38150. [Google Scholar] [CrossRef] [PubMed]

- Farooq, A.; Hossain, I.M.; Moghadamzadeh, S.; Schwenzer, J.A.; Abzieher, T.; Richards, B.S.; Klampaftis, E.; Paetzold, U.W. Spectral Dependence of Degradation under Ultraviolet Light in Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2018, 10, 21985–21990. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, Y.; Yang, M.; Fan, L.; Yang, L.; Sui, Y.; Yang, J.; Zhang, X. Toward ultra-thin and omnidirectional perovskite solar cells: Concurrent improvement in conversion efficiency by employing light-trapping and recrystallizing treatment. Nano Energy 2019, 60, 198–204. [Google Scholar] [CrossRef]

- Aydin, E.; Allen, T.G.; De Bastiani, M.; Xu, L.; Ávila, J.; Salvador, M.; Van Kerschaver, E.; De Wolf, S. Interplay between temperature and bandgap energies on the outdoor performance of perovskite/silicon tandem solar cells. Nat. Energy 2020, 5, 851–859. [Google Scholar] [CrossRef]

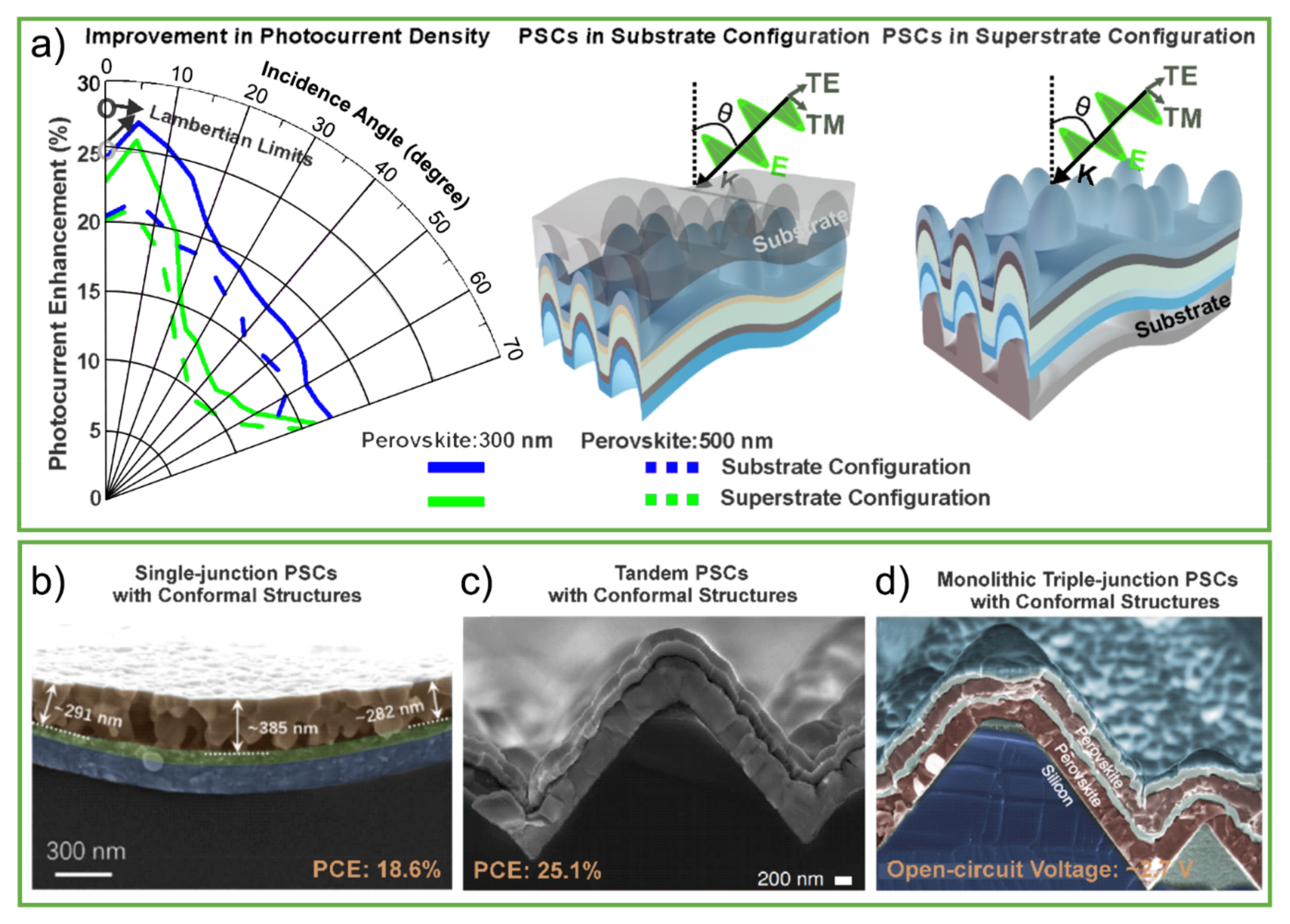

- Werner, J.; Sahli, F.; Fu, F.; Leon, J.J.D.; Walter, A.; Kamino, B.A.; Niesen, B.; Nicolay, S.; Jeangros, Q.; Ballif, C. Perovskite/Perovskite/Silicon Monolithic Triple-Junction Solar Cells with a Fully Textured Design. ACS Energy Lett. 2018, 3, 2052–2058. [Google Scholar] [CrossRef]

- SigmaAldrich. Indium Tin Oxide Coated Glass Slide, Square. Available online: https://www.sigmaaldrich.com/catalog/product/aldrich/703192?lang=pt®ion=PT (accessed on 23 June 2021).

- Gao, T.; Wang, B.; Ding, B.; Lee, J.-K.; Leu, P.W. Correction to Uniform and Ordered Copper Nanomeshes by Microsphere Lithography for Transparent Electrodes. Nano Lett. 2014, 14, 3694. [Google Scholar] [CrossRef]

- Lyubchyk, A.; Vicente, A.; Alves, P.U.; Catela, B.; Soule, B.; Mateus, T.; Mendes, M.J.; Águas, H.; Fortunato, E.; Martins, R. Influence of post-deposition annealing on electrical and optical properties of ZnO-based TCOs deposited at room temperature. Phys. Status Solidi Appl. Mater. Sci. 2016, 213, 2317–2328. [Google Scholar] [CrossRef]

- Tuna, O.; Selamet, Y.; Aygun, G.; Ozyuzer, L. High quality ITO thin films grown by dc and RF sputtering without oxygen. J. Phys. D Appl. Phys. 2010, 43. [Google Scholar] [CrossRef]

- Gao, T.; Wang, B.; Ding, B.; Lee, J.-K.; Leu, P.W. Uniform and Ordered Copper Nanomeshes by Microsphere Lithography for Transparent Electrodes. Nano Lett. 2014, 14, 2105–2110. [Google Scholar] [CrossRef]

- Kim, W.-K.; Lee, S.; Lee, D.H.; Park, I.H.; Bae, J.S.; Lee, T.W.; Kim, J.-Y.; Park, J.H.; Cho, Y.C.; Cho, C.R.; et al. Cu mesh for flexible transparent conductive electrodes. Sci. Rep. 2015. [Google Scholar] [CrossRef]

- Chapa, M.; Alexandre, M.F.; Mendes, M.J.; Águas, H.; Fortunato, E.; Martins, R. All-Thin-Film Perovskite/C-Si Four-Terminal Tandems: Interlayer and Intermediate Contacts Optimization. ACS Appl. Energy Mater. 2019. [Google Scholar] [CrossRef]

- Li, X.-M.; Reinhoudt, D.; Crego-Calama, M. What do we need for a superhydrophobic surface? A review on the recent progress in the preparation of superhydrophobic surfaces. Chem. Soc. Rev. 2007, 36, 1350–1368. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Chen, D.; Kang, Z. One-Step Electrodeposition Process to Fabricate Corrosion-Resistant Superhydrophobic Surface on Magnesium Alloy. ACS Appl. Mater. Interfaces 2015, 7, 1859–1867. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Wang, D.; Gu, Z.-Z.; Möhwald, H. Fabrication of Superhydrophobic Surfaces from Binary Colloidal Assembly. Langmuir 2005, 21, 9143–9148. [Google Scholar] [CrossRef]

- Jindasuwan, S.; Nimittrakoolchai, O.; Sujaridworakun, P.; Jinawath, S.; Supothina, S. Surface characteristics of water-repellent polyelectrolyte multilayer films containing various silica contents. Thin Solid Films 2009, 517, 5001–5005. [Google Scholar] [CrossRef]

- Hikita, M.; Tanaka, K.; Nakamura, T.; Kajiyama, T.; Takahara, A. Super-Liquid-Repellent Surfaces Prepared by Colloidal Silica Nanoparticles Covered with Fluoroalkyl Groups. Langmuir 2005, 21, 7299–7302. [Google Scholar] [CrossRef] [PubMed]

- Meng, E.; Li, P.-Y.; Tai, Y.-C. Plasma removal of Parylene C. J. Micromech. Microeng. 2008, 18. [Google Scholar] [CrossRef]

- Kim, H.; Lee, J.; Kim, B.; Byun, H.R.; Kim, S.H.; Oh, H.M.; Baik, S.; Jeong, M.S. Enhanced Stability of MAPbI3 Perovskite Solar Cells using Poly(p-chloro-xylylene) Encapsulation. Sci. Rep. 2019, 9, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Ortigoza-Diaz, J.; Scholten, K.; Meng, E. Characterization and Modification of Adhesion in Dry and Wet Environments in Thin-Film Parylene Systems. J. Microelectromech. Syst. 2018, 27, 874–885. [Google Scholar] [CrossRef]

- Gołda, M.; Brzychczy-Włoch, M.; Faryna, M.; Engvall, K.; Kotarba, A. Oxygen plasma functionalization of parylene C coating for implants surface: Nanotopography and active sites for drug anchoring. Mater. Sci. Eng. C 2013, 33, 4221–4227. [Google Scholar] [CrossRef]

- Ciurana, J. Designing, prototyping and manufacturing medical devices: An overview. Int. J. Comput. Integr. Manuf. 2014, 27, 901–918. [Google Scholar] [CrossRef]

- Andersson, A.-S.; Brink, J.; Lidberg, U.; Sutherland, D.S. Influence of systematically varied nanoscale topography on the morphology of epithelial cells. IEEE Trans. Nanobiosci. 2003, 2, 49–57. [Google Scholar] [CrossRef]

- Wood, M. Colloidal lithography and current fabrication techniques producing in-plane nanotopography for biological applications. J. R. Soc. Interface 2006, 4, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Dalby, M.J.; O Riehle, M.; Sutherland, D.S.; Agheli, H.; Curtis, A.S.G. Morphological and microarray analysis of human fibroblasts cultured on nanocolumns produced by colloidal lithography. Eur. Cells Mater. 2005, 9, 1–8. [Google Scholar] [CrossRef]

- Wood, M.A.; Wilkinson, C.D.W.; Curtis, A.S.G. The Effects of Colloidal Nanotopography on Initial Fibroblast Adhesion and Morphology. IEEE Trans. Nanobiosci. 2006, 5, 20–31. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Sutherland, D.S.; Broberg, M.; Nygren, H.; Kasemo, B. Influence of Nanoscale Surface Topography and Chemistry on the Functional Behaviour of an Adsorbed Model Macromolecule. Macromol. Biosci. 2001. [Google Scholar] [CrossRef]

- Denis, F.A.; Hanarp, P.; Sutherland, D.S.; Gold, J.; Mustin, C.; Rouxhet, A.P.G.; Dufrêne, Y.F. Protein Adsorption on Model Surfaces with Controlled Nanotopography and Chemistry. Langmuir 2002, 18, 819–828. [Google Scholar] [CrossRef]

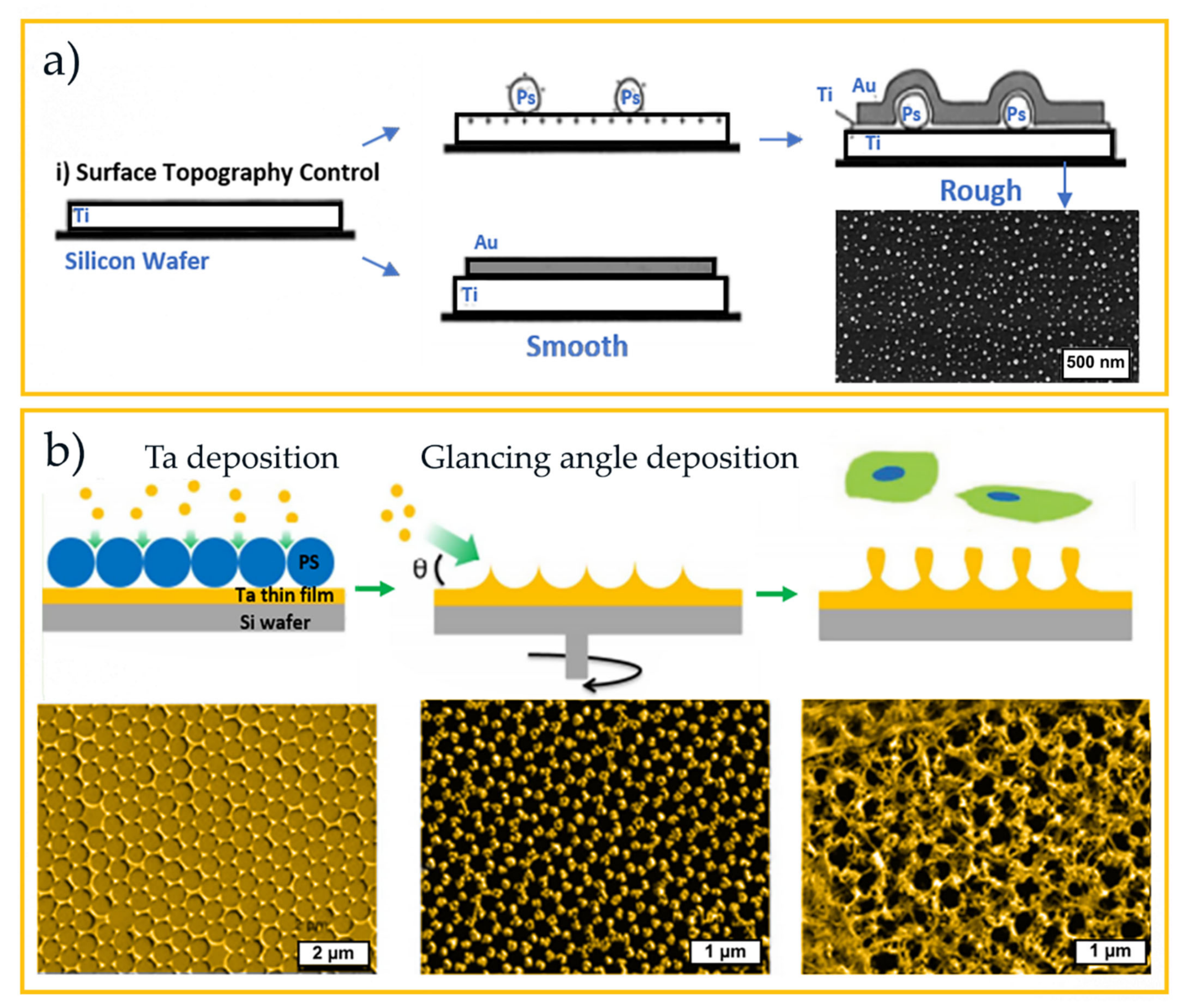

- Wang, P.-Y.; Bennetsen, D.T.; Foss, M.; Ameringer, T.; Thissen, H.; Kingshott, P. Modulation of Human Mesenchymal Stem Cell Behavior on Ordered Tantalum Nanotopographies Fabricated Using Colloidal Lithography and Glancing Angle Deposition. ACS Appl. Mater. Interfaces 2015, 7, 4979–4989. [Google Scholar] [CrossRef] [PubMed]

- Dalby, M.J.; Riehle, M.O.; Sutherland, D.S.; Agheli, H.; Curtis, A.S. Fibroblast response to a controlled nanoenvironment produced by colloidal lithography. J. Biomed. Mater. Res. 2004, 69, 314–322. [Google Scholar] [CrossRef] [PubMed]

| Authors | Year [Ref.] | Simulated Structure | Best Results |

|---|---|---|---|

| Mendes et al. | 2016 [149] | Front-located TiO2 domes on planar Si solar cells | Photocurrent gain of 50% for thin c-Si cells with 1.5 µm thick absorber |

| 2018 [142] | Front-located TiO2/TCO wavelength-sized dome/void arrays | Photocurrent gains of 37%, 27%, and 48% in 100 nm a-Si, 300 nm a-Si, and 1.5 µm c-Si, respectively | |

| Isabella et al. | 2018 [148] | Thin-film nc-Si:H solar cells with decoupled front and back textures | Photocurrent densities reaching 41.1 mA/cm2 with 2-μm thick nc-Si:H absorber. |

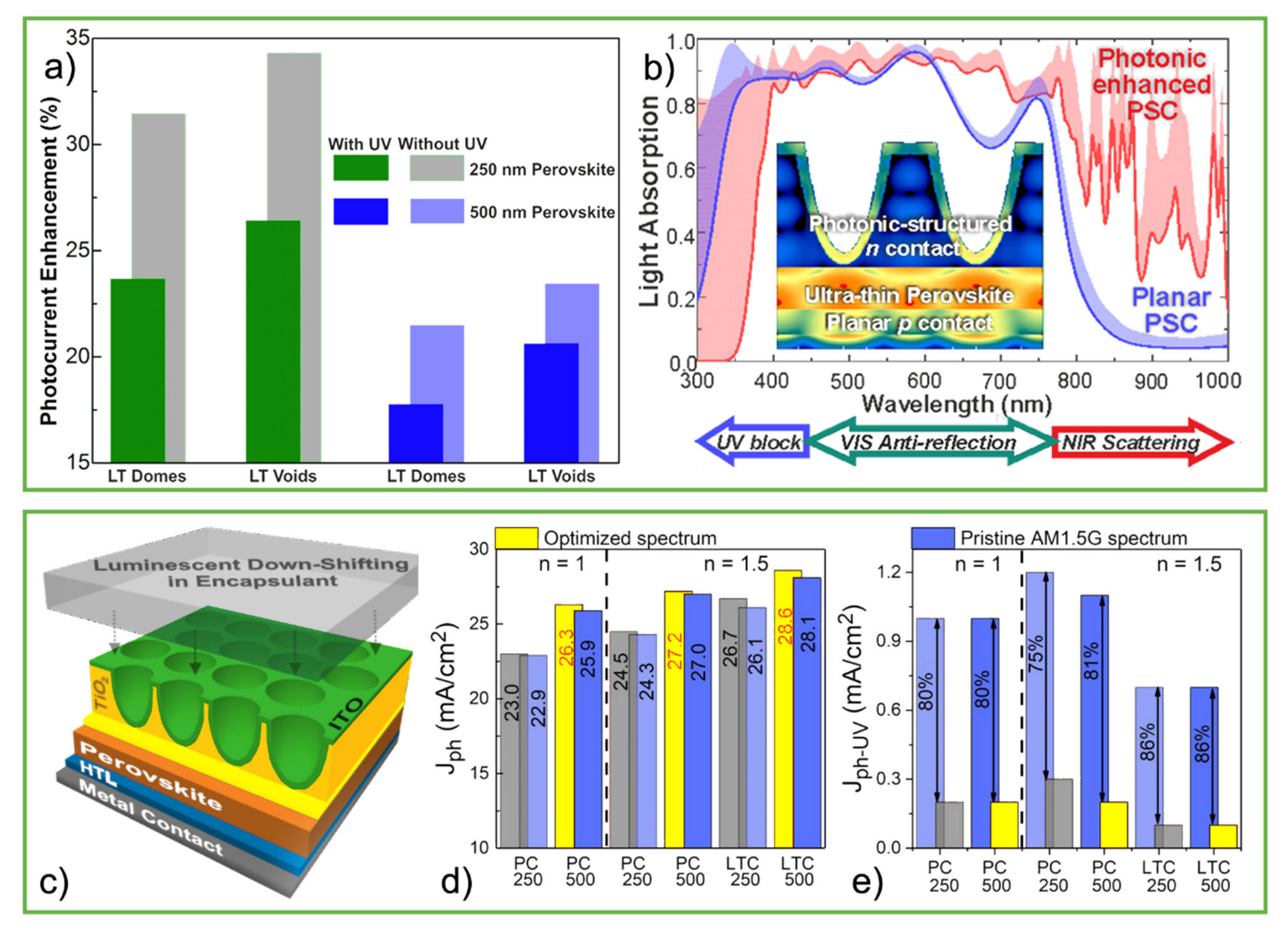

| Haque et al. | 2019 [27] | TiO2 LT structures integrated on the front contact of flat Perovskite solar cells (PSC) | Photocurrent gains up to 27% with planar ultrathin (250 nm) perovskite layers, together with UV blocking effect granting improved stability. |

| 2020 [30] | Microstructured PSCs on transparent and opaque photonic substrates | Photocurrent gains of 22.8% and 24.4%, respectively with transparent and opaque substrates, with 300 nm perovskite. | |

| Alexandre et al. | 2019 [28] | Combined luminescent down-shifting and front-located photonic structures on PSCs | Photocurrent gains similar to Haque et al., together with up to 86% reduction of UV penetration in the perovskite layer. |

| Authors | Year [Ref.] | Experimental Structure | Best Results |

|---|---|---|---|

| Grandidier et al. | 2013 [26] | Close-packed monolayer of silica microspheres on the front of a-Si:H solar cells | Spheres acting as resonant Mie scatterers provide photocurrent and efficiency gains up to 8.9% and 11.1%, respectively. |

| Sanchez-Sobrado et al. | 2017 [33] | Front-located TiO2 microstructures on a-Si:H thin-film absorbers | Absorption enhancement of 27.3% on spectral average in 300 nm a-Si:H absorbers |

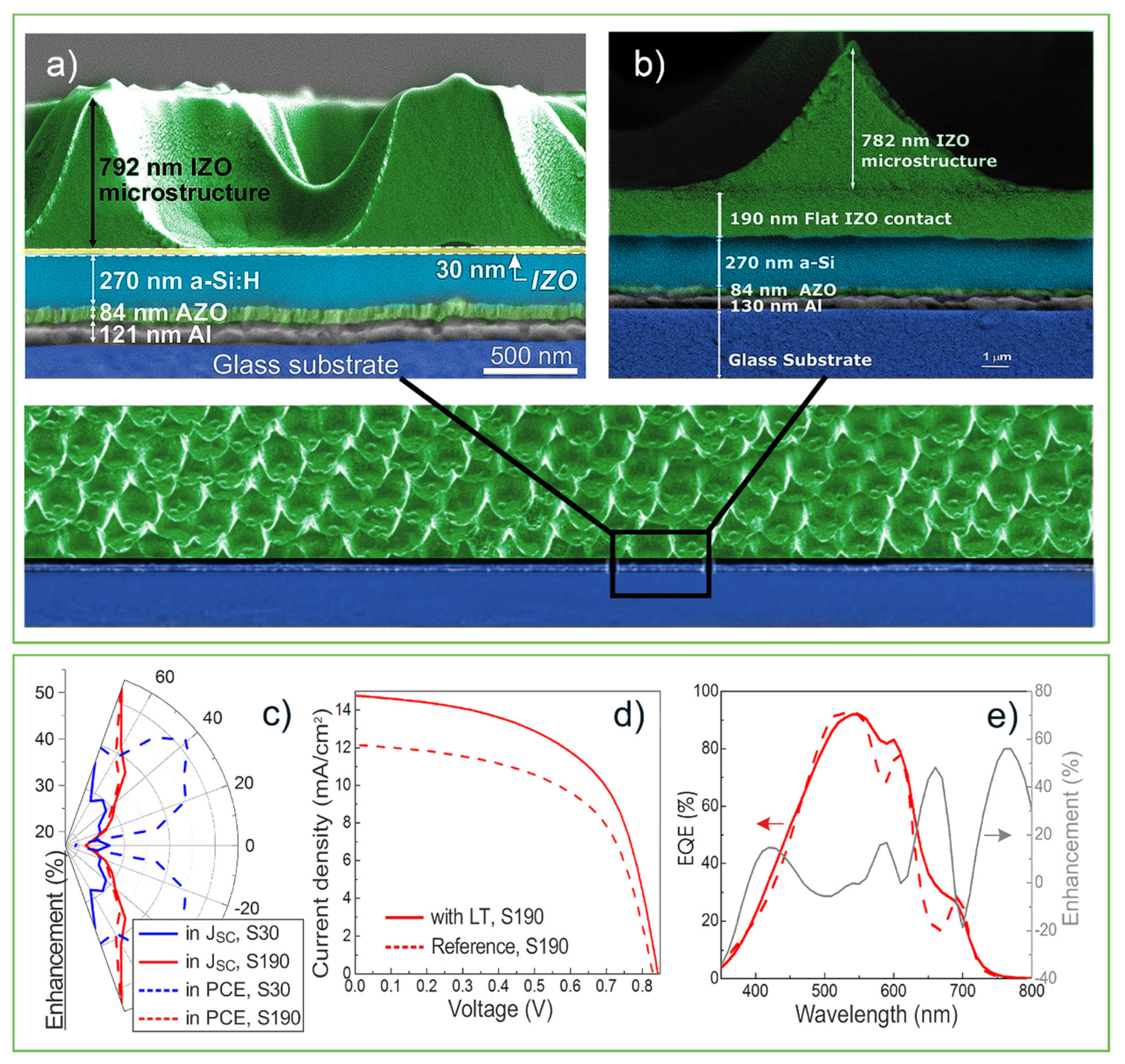

| 2019 [48] | TiO2 or IZO structures integrated into front contact of a-Si:H solar cells | Photocurrent gains up to 21.5% with TiO2 (better optically) and efficiency gain up to 14.4% with IZO (better electrically) LT structures. | |

| 2020 [29] | Front-located IZO structures on a-Si:H solar cells with optimized parameters | Photocurrent and efficiency gains up to 26.7% and 23.1%, respectively, while gains >50% are attained at an oblique incidence. | |

| Centeno et al. | 2020 [31] | Micro-patterned parylene-C film with micro-cone array coated on the front TCO of nc-Si:H solar cells. | Water repellant (self-cleaning) surface, granting photocurrent and efficiency gains up to 23.6%, and up to ~60% at oblique incidence. |

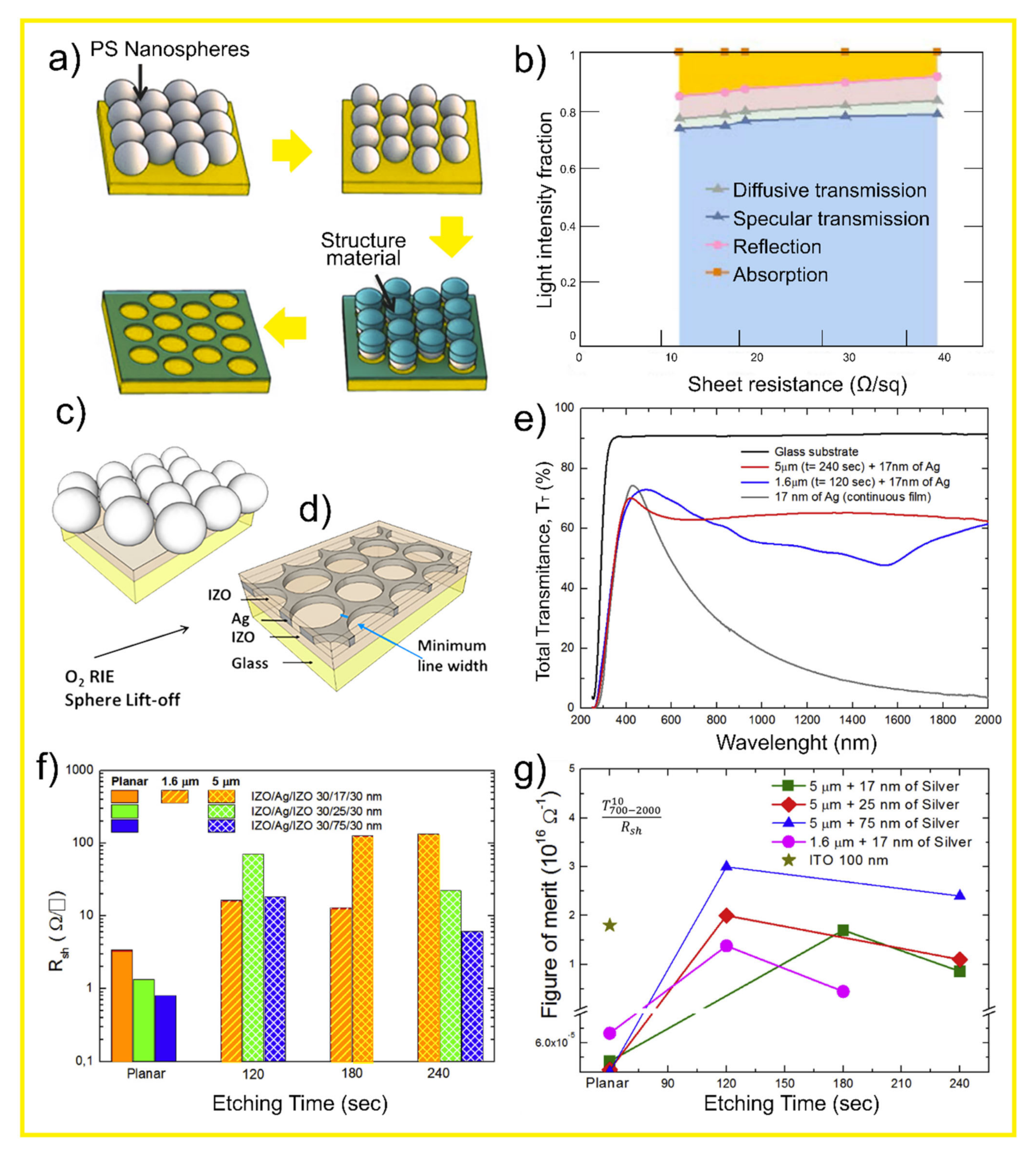

| Gao et al. | 2014 [172] | Cu micro-mesh electrode as a transparent conductive material | Diffuse transmission of 80% in the visible range; sheet resistance of 17 Ω/□ on quartz; high flexural robustness. |

| Torrisi et al. | 2019 [62] | Ag micro-grids sandwiched between ultrathin TCO layers | Sheet resistances below 10 Ω/□ and near-infrared transmittance over 50%. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, R.D.; Mouquinho, A.; Centeno, P.; Alexandre, M.; Haque, S.; Martins, R.; Fortunato, E.; Águas, H.; Mendes, M.J. Colloidal Lithography for Photovoltaics: An Attractive Route for Light Management. Nanomaterials 2021, 11, 1665. https://doi.org/10.3390/nano11071665

Oliveira RD, Mouquinho A, Centeno P, Alexandre M, Haque S, Martins R, Fortunato E, Águas H, Mendes MJ. Colloidal Lithography for Photovoltaics: An Attractive Route for Light Management. Nanomaterials. 2021; 11(7):1665. https://doi.org/10.3390/nano11071665

Chicago/Turabian StyleOliveira, Rui D., Ana Mouquinho, Pedro Centeno, Miguel Alexandre, Sirazul Haque, Rodrigo Martins, Elvira Fortunato, Hugo Águas, and Manuel J. Mendes. 2021. "Colloidal Lithography for Photovoltaics: An Attractive Route for Light Management" Nanomaterials 11, no. 7: 1665. https://doi.org/10.3390/nano11071665

APA StyleOliveira, R. D., Mouquinho, A., Centeno, P., Alexandre, M., Haque, S., Martins, R., Fortunato, E., Águas, H., & Mendes, M. J. (2021). Colloidal Lithography for Photovoltaics: An Attractive Route for Light Management. Nanomaterials, 11(7), 1665. https://doi.org/10.3390/nano11071665