Femtosecond Laser Assisted Crystallization of Gold Thin Films

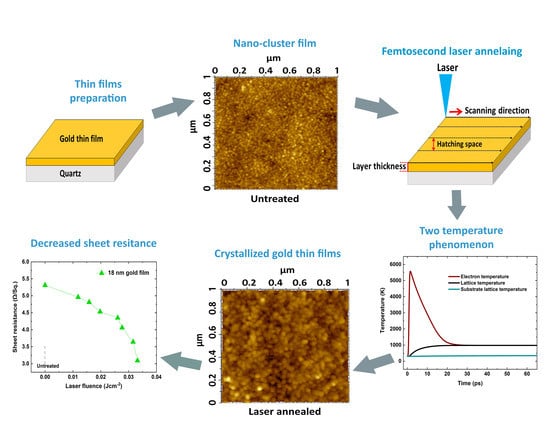

Abstract

1. Introduction

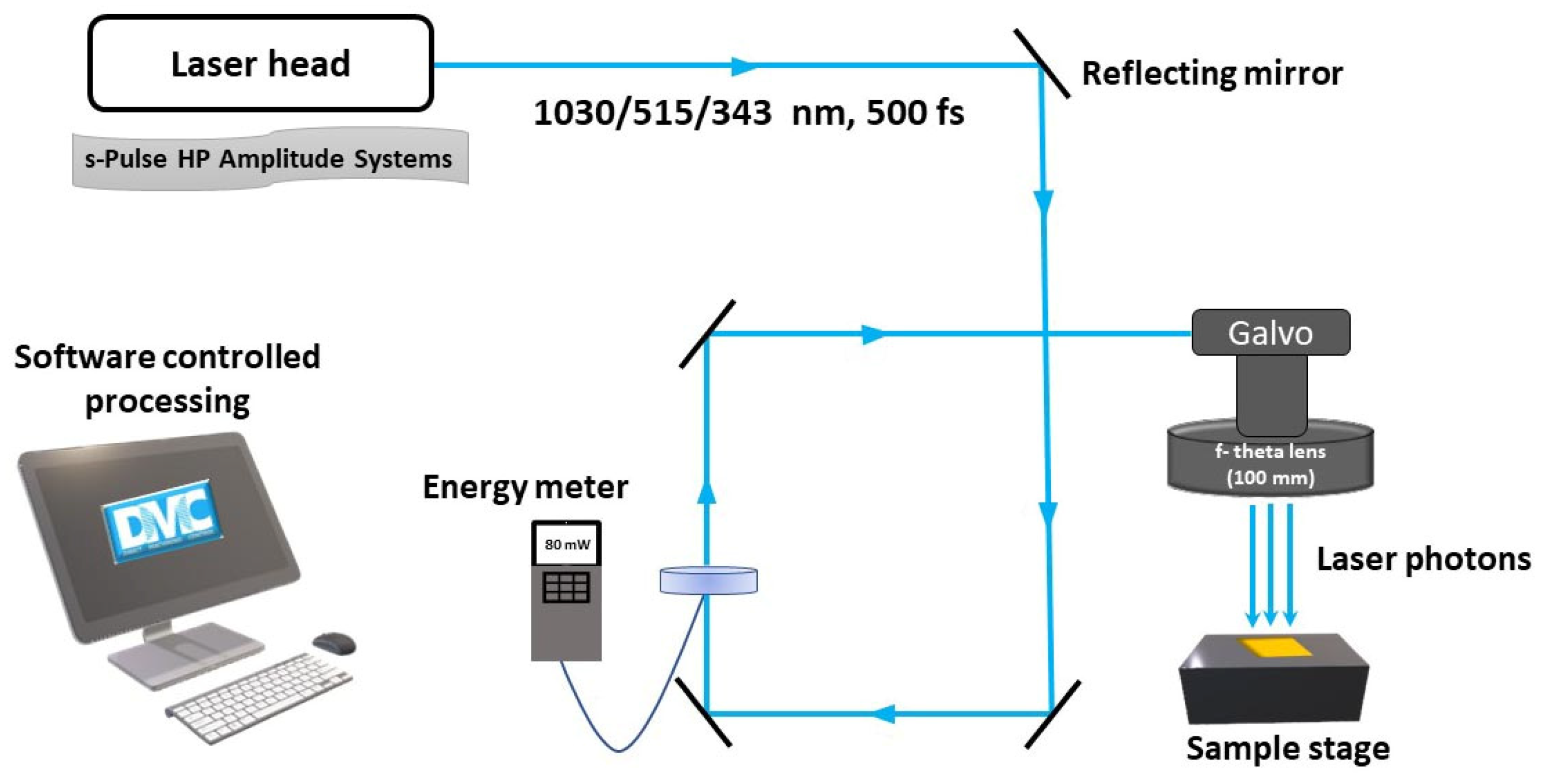

2. Materials and Methods

3. Results and Discussion

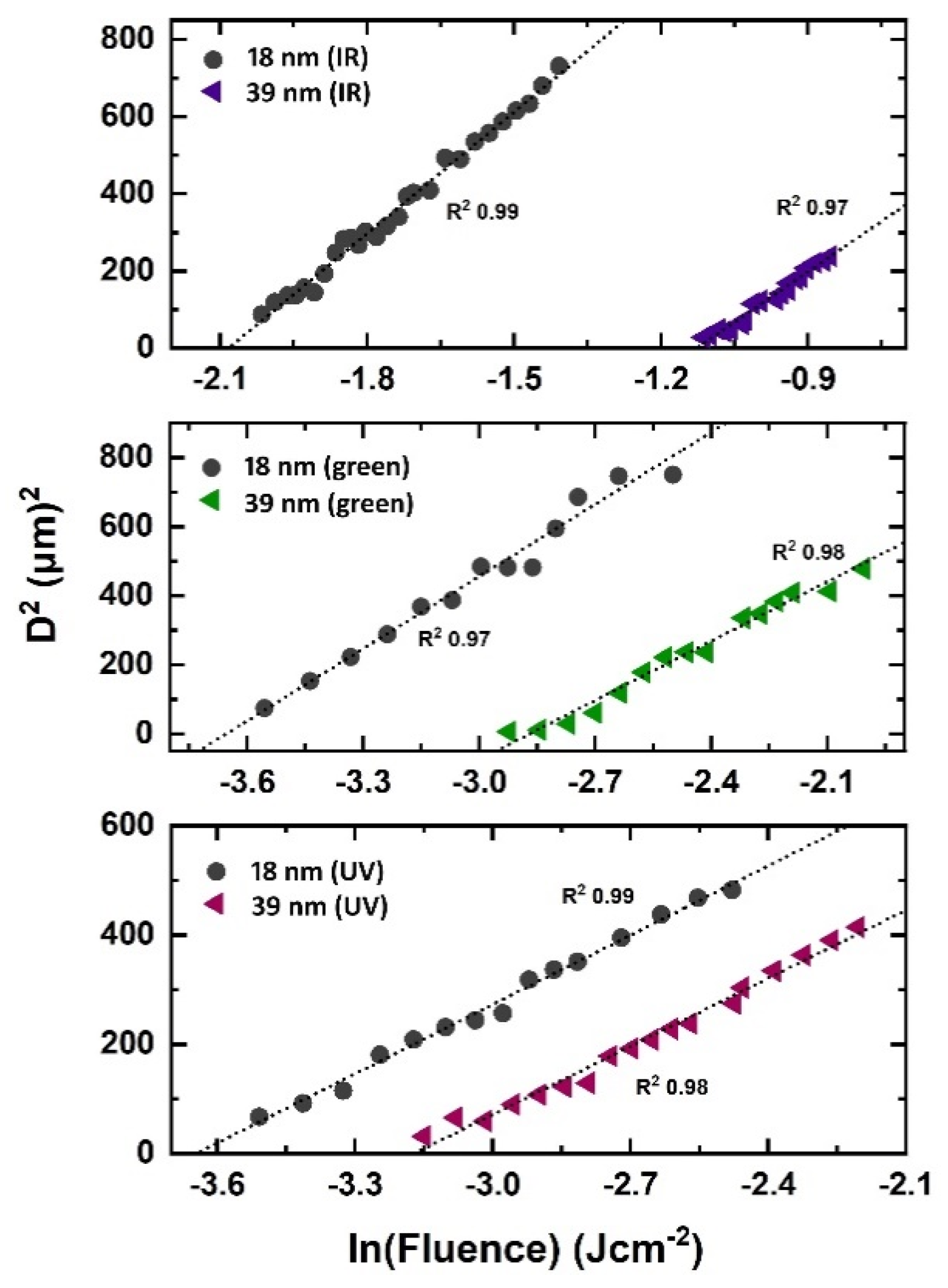

3.1. Damage Threshold Fluence () Measurements

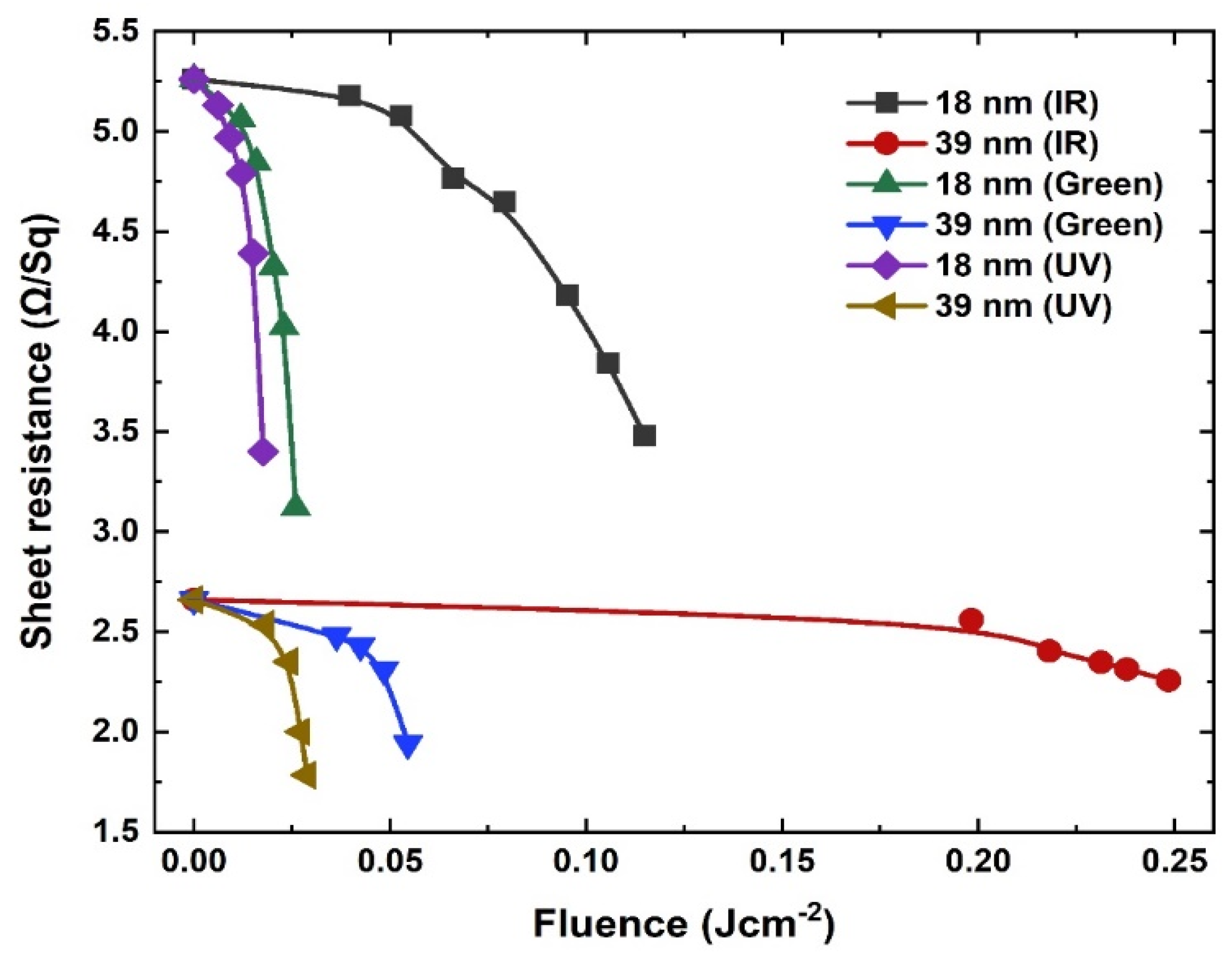

3.2. Conductivity Measurements

3.3. AFM Measurements

3.4. XRD Analysis

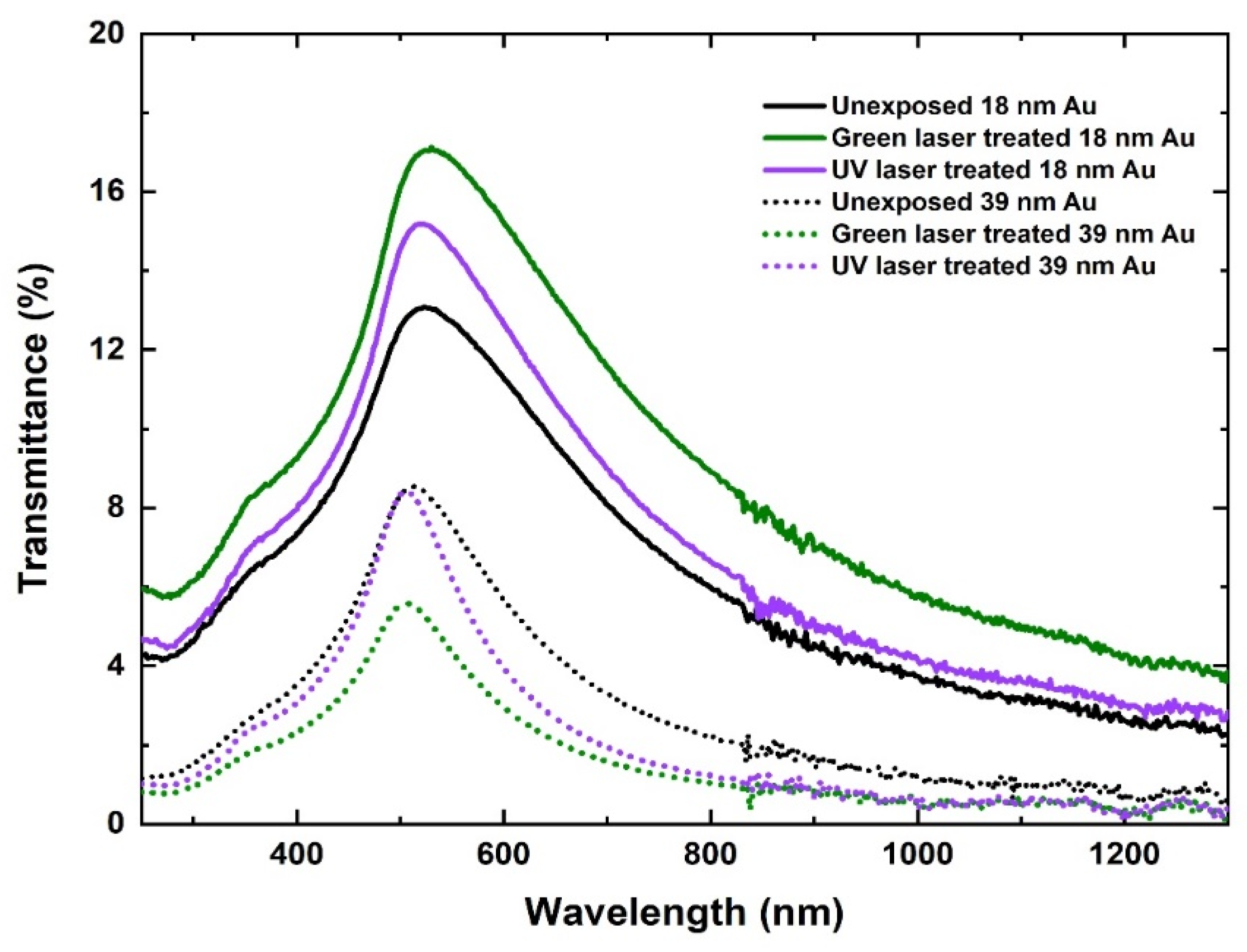

3.5. Optical Properties

4. Numerical Modelling

Two Temperature Gold-Quartz Interface Model

| Property | Gold | Quartz (SiO2) |

|---|---|---|

| Melting temperature Tmelt (K) | 1337.33 [17] | 1943 [29] |

| Mass density ρ (Kgm−3) | 19320 [40] | 2620 @ 293 K [29] |

| Fermi temperature TF (K) | 6.42 × 104 [41] | ----- |

| Lattice heat capacity Cl (Jm−3K−1) | 2.5 × 106 [42] | 1.93 × 106 [43] |

| Thermal heat conductivity kl (Wm−1K−1) | 317 @ 300 K [44] | 13.93 @ 300 K [43] |

| Absorption coefficient α (m−1) | 8.178 × 107 @ 1030 nm [24] | 0.725 @ 1030 nm [45] |

| Reflectance R | 0.97 @ 1030 nm [24] | 0.8821 @ 1030 nm [46] |

| Constants (Wm−1K−1) and for equation 10 | 353, 0.16 [37] | |

| Rls (m2K W−1) | 2.5 × 10−8 [47] |

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amendola, V.; Pilot, R.; Frasconi, M.; Maragò, O.M.; Iatì, M.A. Surface plasmon resonance in gold nanoparticles: A review. J. Phys. Condens. Matter. 2017, 29, 203002. [Google Scholar] [CrossRef] [PubMed]

- Elahi, N.; Kamali, M.; Baghersad, M.H. Recent biomedical applications of gold nanoparticles: A review. Talanta 2018, 184, 537–556. [Google Scholar] [CrossRef] [PubMed]

- Toudeshkchoui, M.G.; Rabiee, N.; Rabiee, M.; Bagherzadeh, M.; Tahriri, M.; Tayebi, L.; Hamblin, M.R. Microfluidic devices with gold thin film channels for chemical and biomedical applications: A review. Biomed. Microdevices 2019, 21, 93. [Google Scholar] [CrossRef]

- Daggumati, P.; Matharu, Z.; Seker, E. Effect of nanoporous gold thin film morphology on electrochemical DNA sensing. Anal. Chem. 2015, 87, 8149–8156. [Google Scholar] [CrossRef] [PubMed]

- Qi, H.; Niu, L.; Zhang, J.; Chen, J.; Wang, S.; Yang, J.; Guo, S.; Lawson, T.; Shi, B.; Song, C. Large-area gold nanohole arrays fabricated by one-step method for surface plasmon resonance biochemical sensing. Sci. China Life Sci. 2018, 61, 476–482. [Google Scholar] [CrossRef]

- Lansåker, P.C.; Petersson, P.; Niklasson, G.A.; Granqvist, C.-G. Thin sputter deposited gold films on In2O3: Sn, SnO2: In, TiO2 and glass: Optical, electrical and structural effects. Sol. Energy Mater. Sol. Cells 2013, 117, 462–470. [Google Scholar] [CrossRef]

- Chang, J.; Young, T.; Yang, Y.; Ueng, H.; Chang, T. Silicide formation of Au thin films on (1 0 0) Si during annealing. Mater. Chem. Phys. 2004, 83, 199–203. [Google Scholar] [CrossRef]

- Sun, X.; Li, H. Gold nanoisland arrays by repeated deposition and post-deposition annealing for surface-enhanced Raman spectroscopy. Nanotechnology 2013, 24, 355706. [Google Scholar] [CrossRef]

- Dishner, M.H.; Ivey, M.M.; Gorer, S.; Hemminger, J.C.; Feher, F.J. Preparation of gold thin films by epitaxial growth on mica and the effect of flame annealing. J. Vac. Sci. Technol. A Vac. Surf. Film. 1998, 16, 3295–3300. [Google Scholar] [CrossRef]

- Do, M.T.; Tong, Q.C.; Lidiak, A.; Luong, M.H.; Ledoux-Rak, I.; Lai, N.D. Nano-patterning of gold thin film by thermal annealing combined with laser interference techniques. Appl. Phys. A 2016, 122, 360. [Google Scholar] [CrossRef]

- Duley, W.W. Laser Processing and Analysis of Materials; Springer: New York, NY, USA, 2012. [Google Scholar]

- Arnob, M.M.P.; Zhao, F.; Zeng, J.; Santos, G.M.; Li, M.; Shih, W.-C. Laser rapid thermal annealing enables tunable plasmonics in nanoporous gold nanoparticles. Nanoscale 2014, 6, 12470–12475. [Google Scholar] [CrossRef] [PubMed]

- Wu, T.-H.; Kalim, S.; Callahan, C.; Teitell, M.A.; Chiou, P.-Y. Image patterned molecular delivery into live cells using gold particle coated substrates. Opt. Express 2010, 18, 938–946. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.; Krishna, M.G. A comparative study of laser-and electric-field-induced effects on the crystallinity, surface morphology and plasmon resonance of indium and gold thin films. Phys. Status Solidi A 2010, 207, 947–954. [Google Scholar] [CrossRef]

- Bäuerle, D. Laser Processing and Chemistry, 4th ed.; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Gamaly, E.G. Femtosecond Laser-Matter Interaction: Theory, Experiments and Applications, 1st ed.; Jenny Stanford Publishing: Singapore, 2011. [Google Scholar]

- Jiang, L.; Tsai, H.-L. Improved two-temperature model and its application in ultrashort laser heating of metal films. J. Heat Transfer. 2005. [Google Scholar] [CrossRef]

- Zhan, X.-P.; Hou, M.-Y.; Ma, F.-S.; Su, Y.; Chen, J.-Z.; Xu, H.-L. Room temperature crystallization of amorphous silicon film by ultrashort femtosecond laser pulses. Opt. Laser Technol. 2019, 112, 363–367. [Google Scholar] [CrossRef]

- Hoppius, J.S.; Bialuschewski, D.; Mathur, S.; Ostendorf, A.; Gurevich, E.L. Femtosecond laser crystallization of amorphous titanium oxide thin films. Appl. Phys. Lett. 2018, 113, 071904. [Google Scholar] [CrossRef]

- Chen, S.-C.; She, N.-Z.; Juang, J.-Y.; Chen, Y.-Z.; Kuo, H.-C.; Chueh, Y.-L.; Wu, K.-H. Femtosecond Laser Crystallization for Boosting the Conversion Efficiency of Flexible Ink-Printing Cu (In, Ga) Se2 Thin Film Solar Cells. In CLEO: Applications and Technology, San Jose, CA, USA, 14–19 May 2017; Optical Society of America: Washington, DC, USA, 2017; p. JTu5A-11. [Google Scholar]

- Zhang, G.; Gu, D.; Gan, F.; Jiang, X.; Chen, Q. Femtosecond laser-induced crystallization in amorphous Ge2Sb2Te5 films. Thin Solid Film 2005, 474, 169–172. [Google Scholar] [CrossRef]

- Katayama, S.; Tsutsumi, N.; Nakamura, T.; Horiike, M.; Hirao, K. Femtosecond laser induced crystallization and permanent relief grating structures in amorphous inorganic (In 2 O 3+ 1 wt% TiO 2) films. Appl. Phys. Lett. 2002, 81, 832–834. [Google Scholar] [CrossRef]

- Liu, J. Simple technique for measurements of pulsed Gaussian-beam spot sizes. Opt. Lett. 1982, 7, 196–198. [Google Scholar] [CrossRef]

- Johnson, P.B.; Christy, R.-W. Optical constants of the noble metals. Phys. Rev. B 1972, 6, 4370. [Google Scholar] [CrossRef]

- Krüger, J.; Dufft, D.; Koter, R.; Hertwig, A. Femtosecond laser-induced damage of gold films. Appl. Surf. Sci. 2007, 253, 7815–7819. [Google Scholar] [CrossRef]

- Wellershoff, S.-S.; Hohlfeld, J.; Güdde, J.; Matthias, E. The role of electron–phonon coupling in femtosecond laser damage of metals. Appl. Phys. A 1999, 69, S99–S107. [Google Scholar]

- Haustrup, N.; O’Connor, G. Impact of wavelength dependent thermo-elastic laser ablation mechanism on the generation of nanoparticles from thin gold films. Appl. Phys. Lett. 2012, 101, 263107. [Google Scholar] [CrossRef]

- Catherine, L.; Olivier, P. Gold Nanoparticles for Physics, Chemistry and Biology, 2nd ed.; World Scientific Publishing Company: Singapore, 2017. [Google Scholar]

- Haustrup, N. Wavelength Dependence of Femtosecond Laser Ablation of Thin Gold Films. Ph.D. Thesis, National University of Ireland, Galway, Ireland, 2014. [Google Scholar]

- Zhang, X.; Huang, C.; Wang, M.; Huang, P.; He, X.; Wei, Z. Transient localized surface plasmon induced by femtosecond interband excitation in gold nanoparticles. Sci. Rep. 2018, 8, 1–7. [Google Scholar] [CrossRef]

- Shim, E.S.; Kang, H.S.; Pang, S.S.; Kang, J.S.; Yun, I.; Lee, S.Y. Annealing effect on the structural and optical properties of ZnO thin film on InP. Mater. Sci. Eng. B 2003, 102, 366–369. [Google Scholar] [CrossRef]

- Klug, H.P.; Alexander, L.E. X-ray diffraction procedures: For polycrystalline and amorphous materials. In X-ray Diffraction Procedures: For Polycrystalline and Amorphous Materials, 2nd ed.; Wiley-VCH: Hoboken, NJ, USA, 1974; p. 992. ISBN 0-471-49369-4. [Google Scholar]

- Axelevitch, A.; Gorenstein, B.; Golan, G. Investigation of optical transmission in thin metal films. Phys. Procedia 2012, 32, 1–13. [Google Scholar] [CrossRef]

- Farid, N.; Sharif, A.; Vijayaraghavan, R.; Wang, M.; Chan, H.; Brunton, A.; McNally, P.; Choy, K.; O’Connor, G. Improvement of electrical properties of ITO thin films by melt-free ultra-short laser crystallization. J. Phys. D Appl. Phys. 2021, 54, 185103. [Google Scholar] [CrossRef]

- Yao, Q.; Guo, L.; Iyer, V.; Xu, X. Ultrafast Electron–Phonon Coupling at Metal-Dielectric Interface. Heat Transf. Eng. 2019, 40, 1211–1219. [Google Scholar] [CrossRef]

- Majumdar, A.; Reddy, P. Role of electron–phonon coupling in thermal conductance of metal–nonmetal interfaces. Appl. Phys. Lett. 2004, 84, 4768–4770. [Google Scholar] [CrossRef]

- Chen, J.; Latham, W.; Beraun, J. The role of electron–phonon coupling in ultrafast laser heating. J. Laser Appl. 2005, 17, 63–68. [Google Scholar] [CrossRef]

- Lin, Z.; Zhigilei, L.V.; Celli, V. Electron-phonon coupling and electron heat capacity of metals under conditions of strong electron-phonon nonequilibrium. Phys. Rev. B 2008, 77, 075133. [Google Scholar] [CrossRef]

- Letfullin, R.R.; George, T.F.; Duree, G.C.; Bollinger, B.M. Ultrashort laser pulse heating of nanoparticles: Comparison of theoretical approaches. Adv. Opt. Technol. 2008, 2008, 251718. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, J. Melting and resolidification of gold film irradiated by nano-to femtosecond lasers. Appl. Phys. A 2007, 88, 289–297. [Google Scholar] [CrossRef]

- Majchrzak, E.; Dziatkiewicz, J. Application of the two-temperature model for a numerical study of multiple laser pulses interactions with thin metal films. Sci. Res. Inst. Math. Comput. Sci. 2012, 11, 63–70. [Google Scholar] [CrossRef][Green Version]

- Kanamori, H.; Fujii, N.; Mizutani, H. Thermal diffusivity measurement of rock-forming minerals from 300° to 1100° K. J. Geophys. Res. 1968, 73, 595–605. [Google Scholar] [CrossRef]

- Ho, C.Y.; Powell, R.W.; Liley, P.E. Thermal Conductivity of the Elements. J. Phys. Chem. Ref. Data 1972, 1, 279–421. [Google Scholar] [CrossRef]

- Khashan, M.; Nassif, A. Dispersion of the optical constants of quartz and polymethyl methacrylate glasses in a wide spectral range: 0.2–3 μm. Opt. Commun. 2001, 188, 129–139. [Google Scholar] [CrossRef]

- Coblentz, W.W. Absorption, Reflection, and Dispersion Constants of Quartz; US Government Printing Office: Washington, DC, USA, 1915.

- Losego, M.D.; Grady, M.E.; Sottos, N.R.; Cahill, D.G.; Braun, P.V. Effects of chemical bonding on heat transport across interfaces. Nat. Mater. 2012, 11, 502–506. [Google Scholar] [CrossRef]

- Giret, Y.; Daraszewicz, S.L.; Duffy, D.M.; Shluger, A.L.; Tanimura, K. Nonthermal solid-to-solid phase transitions in tungsten. Phys. Rev. B 2014, 90, 094103. [Google Scholar] [CrossRef]

| Laser Wavelength | Absorption Length lopt [24] | Beam Diameter 2 ωo | SPA | Pulse Overlap | ||

|---|---|---|---|---|---|---|

| 18 nm | 39 nm | |||||

| nm | nm | µm | % | Jcm−2 | Jcm−2 | |

| IR (1030) | 12.50 | 43.9 | 24.39 | 96 | 0.124 ± 8.11 × 10−4 | 0.323 ± 8.11 × 10−4 |

| Green (515) | 20.27 | 35.7 | 19.86 | 95 | 0.025 ± 7.07 × 10−4 | 0.056 ± 8.37 × 10−4 |

| UV (343) | 14.59 | 29.0 | 16.12 | 93.8 | 0.026 ± 5.30 × 10−4 | 0.042 ± 3.80 × 10−4 |

| Gold Films | Untreated | Laser Treated | |||||

|---|---|---|---|---|---|---|---|

| Thickness | IR (1030 nm) | Green (515 nm) | UV (343 nm) | ||||

| (nm) | L (nm) | L (nm) | Crystallinity | L (nm) | Crystallinity | L (nm) | Crystallinity |

| 18 | 9.10 | 11.05 | 33% | 12.09 | 40% | 11.80 | 35% |

| 39 | 9.24 | 9.82 | 15% | 12.8 | 27% | 12.99 | 29% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharif, A.; Farid, N.; Vijayaraghavan, R.K.; McNally, P.J.; O’Connor, G.M. Femtosecond Laser Assisted Crystallization of Gold Thin Films. Nanomaterials 2021, 11, 1186. https://doi.org/10.3390/nano11051186

Sharif A, Farid N, Vijayaraghavan RK, McNally PJ, O’Connor GM. Femtosecond Laser Assisted Crystallization of Gold Thin Films. Nanomaterials. 2021; 11(5):1186. https://doi.org/10.3390/nano11051186

Chicago/Turabian StyleSharif, Ayesha, Nazar Farid, Rajani K. Vijayaraghavan, Patrick J. McNally, and Gerard M. O’Connor. 2021. "Femtosecond Laser Assisted Crystallization of Gold Thin Films" Nanomaterials 11, no. 5: 1186. https://doi.org/10.3390/nano11051186

APA StyleSharif, A., Farid, N., Vijayaraghavan, R. K., McNally, P. J., & O’Connor, G. M. (2021). Femtosecond Laser Assisted Crystallization of Gold Thin Films. Nanomaterials, 11(5), 1186. https://doi.org/10.3390/nano11051186