X-ray Photoemission Spectroscopy Study of Uniaxial Magnetic Anisotropy Induced in a Ni Layer Deposited on a LiNbO3 Substrate

Abstract

1. Introduction

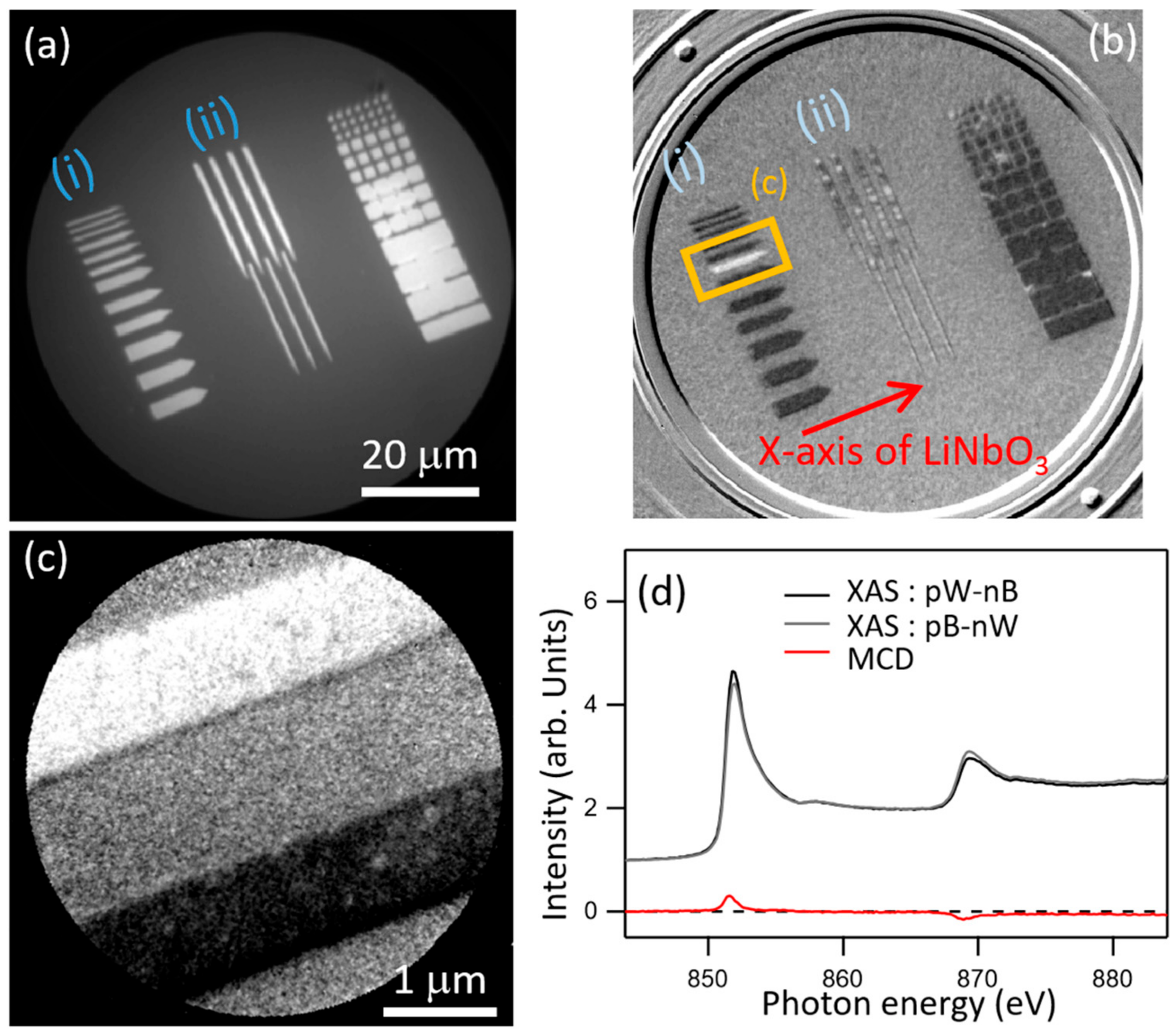

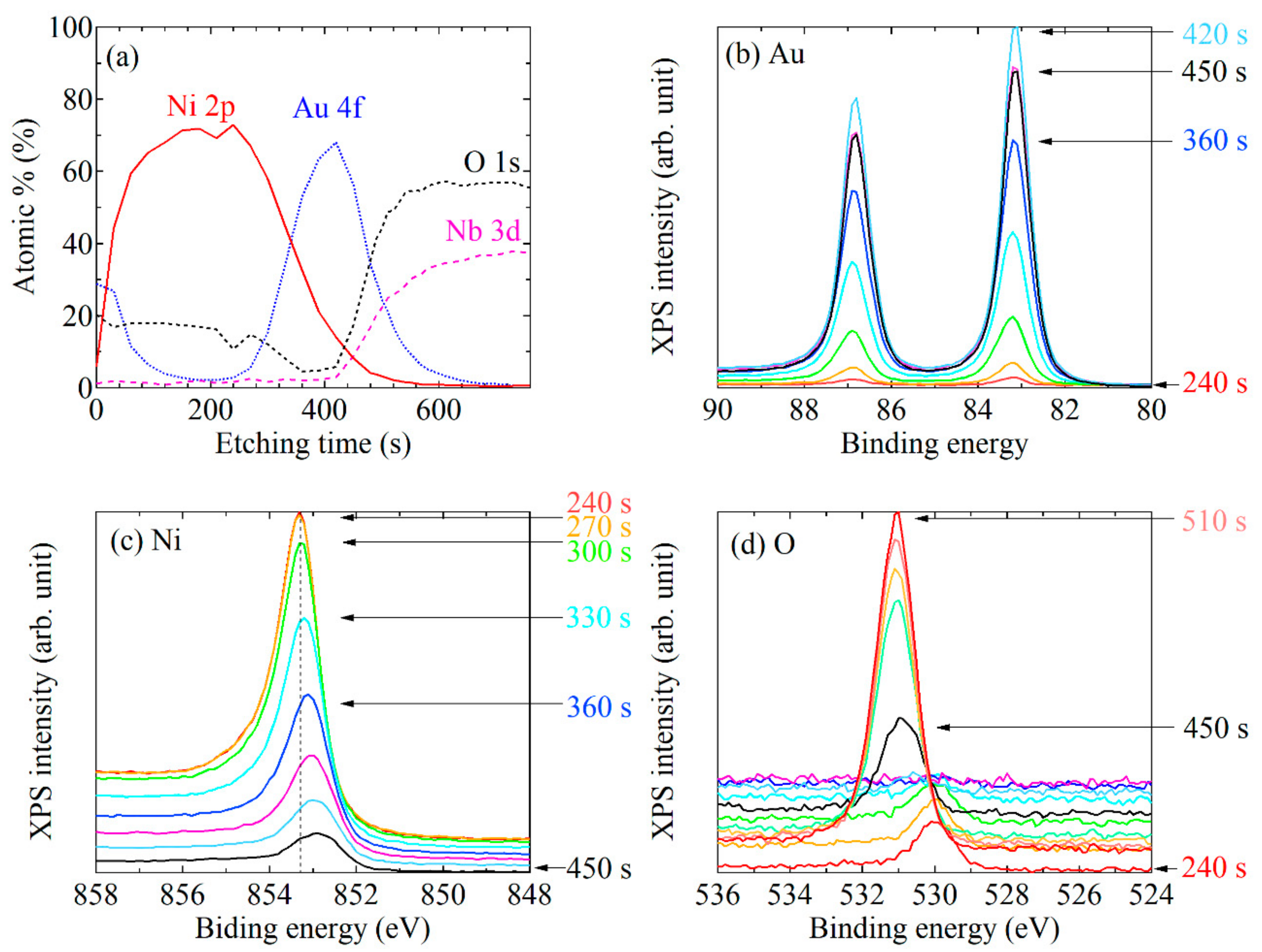

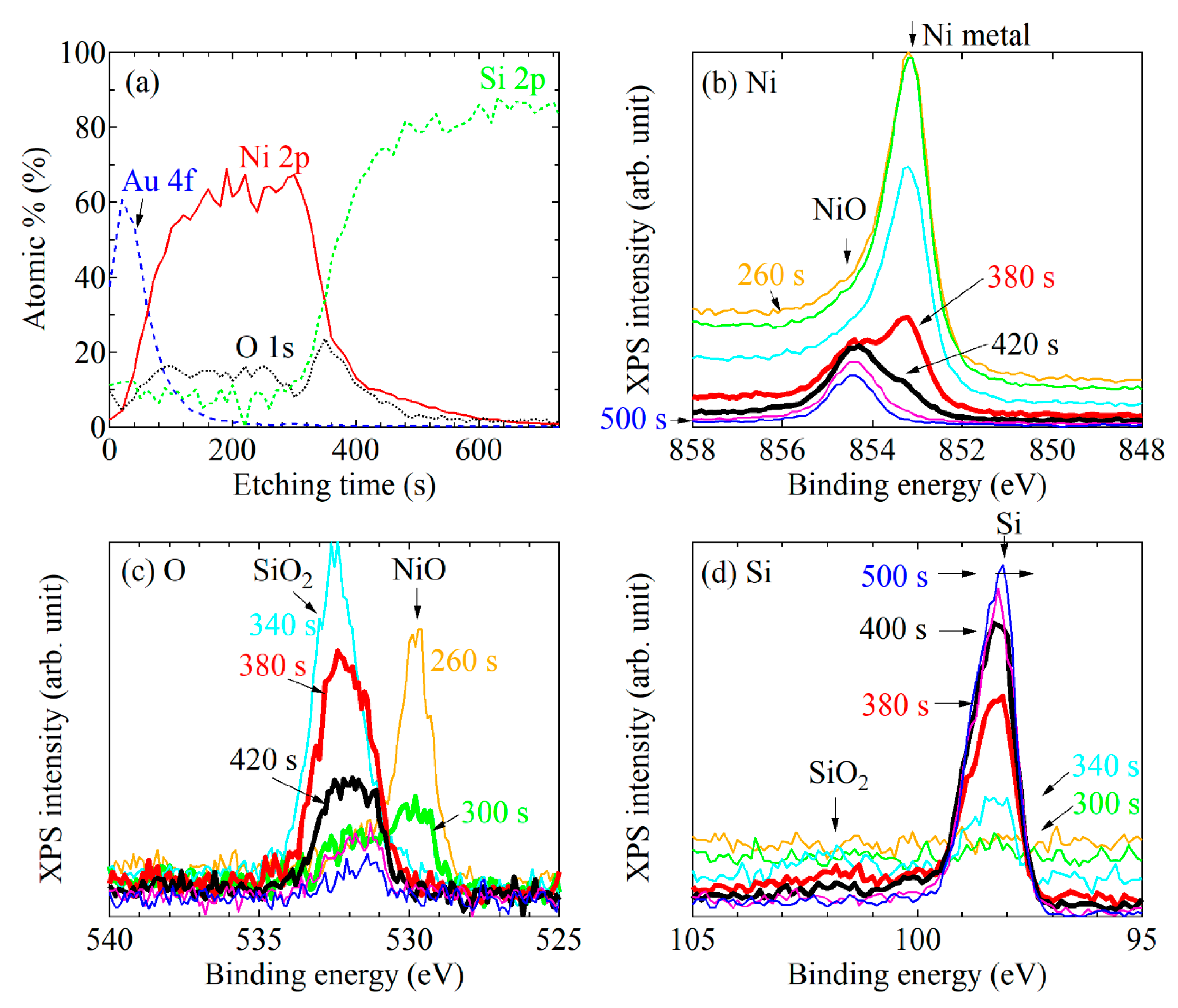

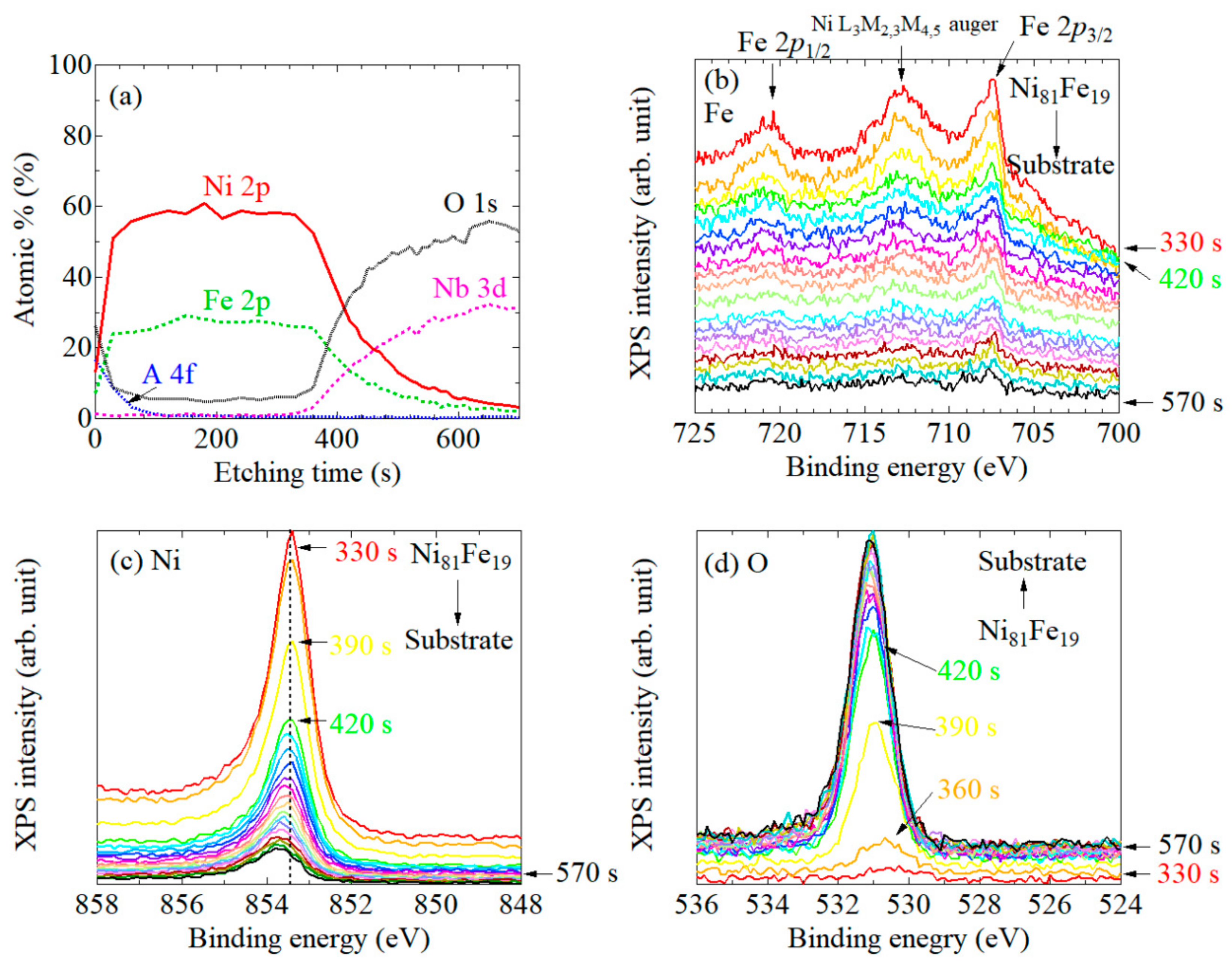

2. Sample Fabrication and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fiebig, M.; Lottermoser, T.; Meier, D.; Trassin, M. The evolution of multiferroics. Nat. Rev. Mater. 2016, 1, 16046. [Google Scholar] [CrossRef]

- Moormann, H.; Kohl, D.; Heiland, G. Work function and band bending on clean cleaved zinc oxide surfaces. Surf. Sci. 1979, 80, 261. [Google Scholar] [CrossRef]

- Amemiya, K.; Kitagawa, S.; Matsumura, D.; Abe, H.; Ohta, T.; Yokoyama, T. Direct observation of magnetic depth profiles of thin Fe films on Cu(100) and Ni/Cu(100) with the depth-resolved x-ray magnetic circular dichroism. Appl. Phys. Lett. 2004, 84, 936. [Google Scholar] [CrossRef]

- Amemiya, K.; Sakai, E.; Matsumura, D.; Abe, H.; Ohta, T.; Yokoyama, T. Spin-reorientation transition of Ni/Cu(100) and CO/Ni/Cu(100): Separation of the surface and bulk components of the x-ray magnetic circular dichroism spectrum. Phys. Rev. B 2005, 71, 214420. [Google Scholar] [CrossRef]

- Okabayashi, J.; Miura, Y.; Taniyama, T. Strain-induced reversible manipulation of orbital magnetic moments in Ni/Cu multilayers on ferroelectric BaTiO3. NPJ Quantum Mater. 2019, 4, 21. [Google Scholar] [CrossRef]

- Okabayashi, J.; Koo, J.W.; Sukegawa, H.; Mitani, S.; Takagi, Y.; Yokoyama, T. Perpendicular magnetic anisotropy at the interface between ultrathin Fe film and MgO studied by angular-dependent x-ray magnetic circular dichroism. Appl. Phys. Lett. 2014, 105, 122408. [Google Scholar] [CrossRef]

- Nogués, J.; Schuller, I.K. Exchange bias. J. Magn. Magn. Mater. 1999, 192, 203. [Google Scholar] [CrossRef]

- Stöhr, J.; Anders, S. X-ray spectro-microscopy of complex materials and surfaces. IBM J. Res. Develop. 2000, 44, 536. [Google Scholar] [CrossRef]

- Duba, L.; Stöhr, J.; Mancini, D.C.; Nilsson, A.; Wassdahl, N.; Nordgren, J.; Samant, M.G. Magnetic dichroism in L2,3 emission of Fe, Co, and Ni following energy-dependent excitation with circularly polarized x-rays. Phys. Rev. B 1994, 50, 16758. [Google Scholar]

- Kim, K.; Lee, K.-J.; Lee, H.; Stiles, M.D. Perpendicular magnetic anisotropy of two-dimensional Rashba ferromagnet. Phys. Rev. B 2016, 94, 184402. [Google Scholar] [CrossRef]

- Pradipto, A.M.; Yakushuji, K.; Ham, W.S.; Kim, S.; Shiota, Y.; Moriyama, T.; Kim, K.; Lee, H.; Nakamura, K.; Lee, K.; et al. Enhanced perpendicular magnetocrystalline anisotropy energy in an artificial magnetic material with bulk spin-momentum coupling. Phys. Rev. B 2019, 99, 108410(R). [Google Scholar] [CrossRef]

- Yin, Y.; Han, D.; Kim, J.; Lavrijsen, R.; Lee, K.; Lee, S.; Kim, K.; Lee, H.; Swagten, H.J.M.; Koopmans, B. Chiral magnetoresistance in Pt/Co/Pt zigzag wires. Appl. Phys. Lett. 2017, 110, 122401. [Google Scholar] [CrossRef]

- Grünberg, P.; Shreiber, R.; Pang, Y.; Brodsky, M.B.; Sowers, H. Layered Magnetic Structures: Evidence for Antiferromagnetic Coupling of Fe Layers across Cr Interlayers. Phys. Rev. Lett. 1986, 57, 2442. [Google Scholar] [CrossRef]

- Baibich, M.N.; Broto, J.M.; Fert, A.; van Dau, F.N.; Petroff, F.; Etienne, P.; Creuzet, G.; Friederich, A.; Chazelas, J. Giant Magnetoresistance of (001)Fe/(001)Cr Magnetic Superlattices. Phys. Rev. Lett. 1988, 61, 2472. [Google Scholar] [CrossRef]

- Parkin, S.S.; Bhadra, R.; Roche, K.P. Oscillatory magnetic exchange coupling through thin copper layers. Phys. Rev. Lett. 1991, 66, 2152. [Google Scholar] [CrossRef]

- Miyazaki, T.; Tezuka, N. Giant magnetic tunneling effect in Fe/Al2O3/Fe junction. J. Magn. Magn. Mater. 1994, 139, L231. [Google Scholar] [CrossRef]

- Yuasa, S.; Fukushima, A.; Nagahama, T.; Ando, K.; Suzuki, Y. High Tunnel Magnetoresistance at Room Temperature in Fully Epitaxial Fe/MgO/Fe Tunnel Junctions due to Coherent Spin-Polarized Tunneling. Jpn. J. Appl. Phys. 2004, 43, L588. [Google Scholar] [CrossRef]

- Parkin, S.S.P.; Kaiser, C.; Panchula, A.; Rice, P.M.; Hughes, B.; Samant, M.; Yang, S.-H. Giant tunnelling magnetoresistance at room temperature with MgO (100) tunnel barriers. Nat. Mater. 2004, 3, 862. [Google Scholar] [CrossRef]

- Hong, J.; Wu, R.Q.; Lindner, J.; Kosubek, E.; Baberschke, K. Manipulation of Spin Reorientation Transition by Oxygen Surfactant Growth: A Combined Theoretical and Experimental Approach. Phys. Rev. Lett. 2004, 92, 147202. [Google Scholar] [CrossRef]

- Hillebrecht, F.U.; Fuggle, J.C.; Bennett, P.A.; ZoInierek, Z.; Freiburg, C. Electronic structure of Ni and Pd alloys. II. X-ray photoelectron core-level spectra. Phys. Rev. B 1983, 27, 2179. [Google Scholar] [CrossRef]

- Dzyaloshinskii, L.E. Thermodynamic Theory of “Weak” Ferromagnetism in Antiferromagnetic Substances. Sov. Phys. JIETP 1957, 5, 1259. [Google Scholar]

- Moriya, T. Anisotropic Superexchange Interaction and Weak Ferromagnetism. Phy. Rev. 1960, 120, 91. [Google Scholar] [CrossRef]

- Bychkov, Y.A.; Mel’nikov, V.I.; Rashba, É. Effect of spin-orbit coupling on the energy spectrum of a 2D electron systems in a tilted magnetic field. Zh. Eksp. Theor. Fiz. 1990, 98, 717. [Google Scholar]

- Chikazumi, S. Physics of Ferromagnetism; Clarendon: Oxford, UK, 1997. [Google Scholar]

- Pateras, A.; Harder, R.; Manna, S.; Kiefer, B.; Sandberg, R.L.; Trugman, S.; Kim, J.W.; de la Venta, J.; Fullerton, E.E.; Shpyrko, O.G.; et al. Room temperature giant magnetostriction in single-crystal nickel nanowires. NPG Asia Mater. 2019, 11, 59. [Google Scholar] [CrossRef]

- Hillebrands, B.; Ounadiela, K.E. Spin Dynamics in Confined Magnetic Structures; Springer: Berlin/Heidelberg, Germany, 2002; Volume I–III. [Google Scholar]

- Schrefl, T.; Fidler, J.; Kirk, K.J.; Chapman, J.N. Domain structures and switching mechanisms in patterned magnetic elements. J. Magn. Magn. Mater. 1997, 175, 193. [Google Scholar] [CrossRef]

- Shigeto, K.; Shinjo, T.; Ono, T. Injection of a magnetic domain wall into a submicron magnetic wire. Appl. Phys. Lett. 1999, 75, 2815. [Google Scholar] [CrossRef]

- Cowburn, R.P.; Gray, S.J.; Ferré, J.; Bland, J.A.C.; Miltat, J. Magnetic switching and in-plane uniaxial anisotropy in ultrathin Ag/Fe/Ag(100) epitaxial films. J. Appl. Phys. 1995, 78, 7210. [Google Scholar] [CrossRef]

- Yamaguchi, A.; Ono, T.; Nasu, S.; Miyake, K.; Mibu, K.; Shinjo, T. Real-Space Observation of Current-Driven Domain Wall Motion in Submicron Magnetic Wires. Phys. Rev. Lett. 2004, 92, 077205. [Google Scholar] [CrossRef]

- Dean, J.; Bryan, M.T.; Cooper, J.D.; Virbule, A.; Cunningham, J.E.; Hayward, T.J. A sound idea: Manipulating domain walls in magnetic nanowires using surface acoustic waves. Appl. Phys. Lett. 2015, 107, 142405. [Google Scholar] [CrossRef]

- Ostler, T.A.; Cuadrado, R.; Chantrell, R.W.; Rushforth, A.W.; Cavill, S.A. Strain Induced Vortex Core Switching in Planar Magnetostrictive Nanostructures. Phys. Rev. Lett. 2015, 115, 067202. [Google Scholar] [CrossRef]

- Yamaguchi, A.; Ohkouchi, T.; Yasui, A.; Kinoshita, T.; Yamada, K. Control of Domain Structure in Artificial Ni Wires Fabricated on an LiNbO3 Substrate. IEEE Trans. Magn. 2017, 53, 8108504. [Google Scholar] [CrossRef]

- Yamaguchi, A.; Ohkouchi, T.; Yasui, A.; Kinoshita, T.; Yamada, K. Heterojunction-induced magnetic anisotropy and magnetization reversal of Ni wires on LiNbO3 substrate. J. Magn. Magn. Mater. 2018, 453, 107. [Google Scholar] [CrossRef]

- Yamaguchi, A.; Yamada, K.; Nakao, A.; Saiki, T.; Utsumi, Y.; Ogasawara, T. The Study on Magnetization Reversal of Stripe-Domain Structure in Ni Wires Fabricated on a LiNbO3 Substrate. IEEE Trans. Magn. 2019, 55, 2500404. [Google Scholar] [CrossRef]

- Nakamura, R.; Saegusa, S.; Suzuki, S.; Nakao, A.; Utsumi, Y.; Ohkochi, T.; Oura, M.; Takizawa, Y.; Saiki, T.; Lee, T.; et al. Magnetic Scattering in Ni Wires Fabricated on Ferroelectric LiNbO3 Substrate for Magnetic Sensor Application. Sens. Mater. 2019, 31, 3007. [Google Scholar] [CrossRef]

- Foerster, M.; Aballe, L.; Hernàndez, J.M.; Macià, F. Subnanosecond magnetization dynamics driven by strain waves. MRS Bull. 2019, 43, 854. [Google Scholar] [CrossRef]

- Foerster, M.; Macià, F.; Statuto, N.; Finizio, S.; Hernàndez-Mínguez, A.; Lendínez, S.; Santos, P.V.; Fontcuberta, J.; Hernàndez, J.M.; Kläi, M.; et al. Direct imaging of delayed magneto-dynamic modes induced by surface acoustic waves. Nat. Commun. 2019, 8, 407. [Google Scholar] [CrossRef]

- Guo, F.Z.; Muro, T.; Matsushita, T.; Wakita, T.; Ohashi, H.; Senba, Y.; Kinoshita, T.; Kobayashi, K.; Saitoh, Y.; Koshikawa, T.; et al. Characterization of spectroscopic photoemission and low energy electron microscope using multipolarized soft x rays at BL17SU/SPring-8. Rev. Sci. Instrum. 2007, 78, 066107. [Google Scholar] [CrossRef]

- Tanuma, S.; Powell, C.J.; Penn, D.R. Calculation of electron inelastic mean free paths (IMFPs) VII. Reliability of the TPP-2M IMFP predictive equation. Surf. Interf. Anal. 1993, 21, 165. [Google Scholar] [CrossRef]

- NIST X-ray Photoelectron Spectroscopy Database. Available online: https://srdata.nist.gov/xps/ (accessed on 14 April 2021).

- Vakulov, Z.; Zamburg, E.; Khajhulin, D.; Geldash, A.; Golosov, D.A.; Zavadski, S.M.; Miakonkikh, A.V.; Rudenko, K.V.; Dostanko, A.P.; He, Z.; et al. Oxygen Pressure Influence on Properties of Nanocrystalline LiNbO3 Films Grown by Laser Ablation. Nanomaterials 2020, 10, 1371. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yamaguchi, A.; Ohkochi, T.; Oura, M.; Yamada, K.; Saiki, T.; Suzuki, S.; Utsumi, Y.; Nakao, A. X-ray Photoemission Spectroscopy Study of Uniaxial Magnetic Anisotropy Induced in a Ni Layer Deposited on a LiNbO3 Substrate. Nanomaterials 2021, 11, 1024. https://doi.org/10.3390/nano11041024

Yamaguchi A, Ohkochi T, Oura M, Yamada K, Saiki T, Suzuki S, Utsumi Y, Nakao A. X-ray Photoemission Spectroscopy Study of Uniaxial Magnetic Anisotropy Induced in a Ni Layer Deposited on a LiNbO3 Substrate. Nanomaterials. 2021; 11(4):1024. https://doi.org/10.3390/nano11041024

Chicago/Turabian StyleYamaguchi, Akinobu, Takuo Ohkochi, Masaki Oura, Keisuke Yamada, Tsunemasa Saiki, Satoru Suzuki, Yuichi Utsumi, and Aiko Nakao. 2021. "X-ray Photoemission Spectroscopy Study of Uniaxial Magnetic Anisotropy Induced in a Ni Layer Deposited on a LiNbO3 Substrate" Nanomaterials 11, no. 4: 1024. https://doi.org/10.3390/nano11041024

APA StyleYamaguchi, A., Ohkochi, T., Oura, M., Yamada, K., Saiki, T., Suzuki, S., Utsumi, Y., & Nakao, A. (2021). X-ray Photoemission Spectroscopy Study of Uniaxial Magnetic Anisotropy Induced in a Ni Layer Deposited on a LiNbO3 Substrate. Nanomaterials, 11(4), 1024. https://doi.org/10.3390/nano11041024