Abstract

This study aimed to synthesize a new magnetic photocatalytic nanosystem composed of Ag-CuFe2O4@WO3 and to investigate its photodegradation efficiency for two drug pollutants of Gemfibrozil (GEM) and Tamoxifen (TAM) under Ultraviolet (UV) light irradiation. In this regard, the effect of pH, catalyst dosage, and drug concentration was thoroughly determined. The largest photodegradation level for GEM (81%) and TAM (83%) was achieved at pH 5, a photocatalyst dosage of 0.2 g/L, drug concentration of 5 mg/L, and contact time of 150 min. The drug photodegradation process followed the pseudo first-order kinetic model. In addition to the photodegradation effect, the nanocomposites were proved to be efficient in terms of antibacterial activity, proportional to the Ag doping level. The Ag-CuFe2O4@WO3 nanocomposite exhibited a stable, efficient performance without an obvious catalytic loss after five successive cycles. Taken together, the developed magnetic photocatalyst is able to simultaneously disinfect wastewater streams and to degrade pharmaceutical contaminants and thus shows a promising potential for purification of multi-contaminant water systems.

1. Introduction

The pharmacological active compounds (PhACs) are an important, emerging group of organic contaminants that are persistent and show toxicity. They produce active metabolites when released into aquatic environments [1,2]. These compounds enter into the environment from the pharmaceutical industries, hospitals, and municipal wastewater treatment plants and after consumption in agriculture and aquaculture [3]. Numerous studies have been conducted on the formation and fate of PhACs’ active metabolites and their toxic effects. According to such investigations, these compounds are partially destroyed during conventional wastewater/water treatment processes and are non-biodegradable [4]. Although these compounds are present in the aqueous environment in trace quantities such as ng/L and mg/L, their chronic toxicity is challenging due to the steady exposure of human kind to these compounds. In fact, they are considered as pollutants with side effects on the aquatic organisms and account for a negative impact on human health [5]. Among various drug pollutants, Gemfibrozil (5-(2,5-Dimethylphenoxy)-2,2-dimethylpentanoic acid (GEM)), a fibrous hypolipidemic agent that is effective in reducing the incidence of coronary heart disease, and Tamoxifen 2-[4-[(Z)-1,2-diphenylbut-1-enyl]phenoxy]-N,N-dimethyl ethanamine (TAM), a nonsteroidal anti-estrogen drug that is widely used in the treatment and prevention of breast cancer, are frequently found in the wastewater streams [6]. Since conventional wastewater treatment processes are unable to remove these pharmaceutical compounds [7] and due to the fact that they are hardly biodegraded, they enter into surface water and groundwater. Such a contamination is considered as an environmental challenge and needs to be addressed through appropriate approaches. In recent years, Advanced Oxidation Processes (AOPs) have been widely used as effective methods for the removal of organic pollutants [8,9,10,11]. Among the various AOPs, photocatalysis has proved to be notably efficient in degradation of pharmaceuticals [12]. While semiconductor materials have shown a high potential for photodecomposition of different organic pollutants, commercial visible light photocatalysts are unstable or lose their efficiency upon irradiation. To overcome such limitations, group II–VI semiconductors whose energy gaps span the visible light spectral range have been suggested as superior, compatible substitutes [13,14]. Extensive agglomeration, difficult separation, and recovery are the other shortcomings that have hindered the large utility of photocatalytic nanoparticles on a scalable, industrial scale [14,15,16]. One excellent strategy to address the abovementioned limitations is hybridization of such photocatalytic nanoparticles with other supplementary, supportive components as a nanocomposite system.

As one of the newly studied photocatalysts, tungsten trioxide (WO3) has shown promising potentials such as a low band gap (2.6 eV), non-toxicity, low cost, light sensitivity, chemical stability, and environmental friendliness. Moreover, thanks to offering a photocatalytic activity under visible light, WO3 nanoparticles have been appealing for further research [13,17]. Despite such merits, recovery and separation of the WO3 nanoparticles from the reaction medium are challenging [18], and they also suffer from a relatively low specific surface area (2.7 m2/g) [19]. To overcome these bottlenecks, magnetic nanocomposites have been coupled with WO3 as a core–shell structure. Accordingly, not only the catalytic performance of WO3 is improved, but it can also be readily separated from water [20].

MFe2O4 (M = Zn, Ag, Cu, Ni, or Co) magnetic nanoparticles are thermally stable and show an optimum photocatalytic activity [21]. These magnetic nanoparticles are p-type and can bind to n-type semiconductors and form p-n catalytic nanocomposites such as ZnFe2O4/TiO2, CuFe2O4/TiO2, and CuFe2O4/WO3 [22]. As a result of such a combination, the electron-hole recombination rate is reduced and the photocatalytic efficiency is improved. As an example, a composite photocatalyst composed of CuFe2O4 plus other semiconductors such as WO3 can be easily activated by visible light. In addition, such a magnetic photocatalyst can readily enable recovery of WO3 [5]. These kinds of photocatalysts are also biocompatible and show a high potential for a wide range of applications in photocatalysis, CO2 reduction, energy conversion, solar energy production, and supercapacitors [23].

With respect to the other bottleneck of WO3 which is its low specific surface area, different metal nanoparticle-based coatings have been implemented. The presence of metal nanoparticles such as Au, Ag, Pt, or Pd on the surface of WO3, acting as electron receptors, prevents the recombination of electron-hole pairs and thus increases the surface charge transfer efficiency in the as-developed composites [24,25]. In addition, metal nanoparticles improve the visible light absorption based on surface plasmon resonance [26]. Specifically, Ag nanoparticles bring along additional merits such as antibacterial effects, as well. The inorganic antibacterial materials, particularly antibacterial metals such as Zn, Ag, Hg, and Cu, have been noticed owing to their superior properties over traditionally applied organic reagents in terms of thermal resistance, chemical stability, safety, and long term efficacy. Among them, Ag has the strongest antibacterial activity and has been extensively used as a bactericide since a long time ago due to its wide antibacterial spectrum, stability, and durability.

In this study, for the first time, we addressed the shortcomings of WO3 photocatalyst by coupling it with the magnetic phase of CuFe2O4, to ease its recovery, and Ag nanoparticles, to endow it with the additional feature of bactericidal activity. It is worth noting that such additional components may extend the applicability of the photocatalyst to under light irritation. Eventually, the as-synthesized nanocomposite was challenged for photodecomposition of two aforementioned organic (drug) pollutant models.

2. Materials and Methods

2.1. Materials

Iron (III) chloride, tungsten hexachloride (WCl6), polyethylene glycol (PEG), hydrochloric acid, copper (II) acetate (Cu(CH3COO)2), potassium ferricyanide (K3Fe(CN)6), polyvinyl pyrrolidone (PVP), and ethanol were purchased from Merck (Darmstadt, Germany). Silver nitrate, Tamoxifen, and Gemfibrozil were obtained from Sigma Aldrich (St. Louis, MO, USA). All the materials were used without further purification. Deionized water was used to prepare the aqueous solutions in this study.

2.2. Synthesis of the WO3 Nanoparticles

A solvothermal method was applied for synthesis of the WO3 nanoparticles. To do so, 1.5 mmol of WCl6 and 0.3 g of PEG were added to 70 mL of ethanol and then sonicated. Subsequently, the as-prepared solution was placed in an autoclave and heated at 110 °C for 3 h. After cooling down to the ambient temperature, the synthesized nanoparticles were collected and washed several times with deionized water and finally dried in an oven at 60 °C for 8 h [27].

2.3. Synthesis of the CuFe2O4@WO3 Nanoparticles

The CuFe2O4@WO3 nanoparticles were prepared via a chemical deposition method. First, 0.06 g of Cu(CH3COO)2·H2O was dissolved in 10 mL of deionized water. In parallel, 0.196 g of K3Fe(CN)6 was dissolved in 30 mL of deionized water. The latter solution was added to the first one drop-wise and stirred for 10 min within an ice bath. Afterwards, the WO3 nanoparticles were added to the mixture solution and stirred for one hour within an ice bath. The as-prepared suspension was later refrigerated at 0–4 °C for 120 min. Eventually, the resulting nanoparticles were collected and washed with distilled water and ethanol and dried in an oven at 60 °C for 3 h [28].

2.4. Synthesis of the Ag-CuFe2O4@WO3 Nanoparticles

At this step, 60 mg of CuFe2O4@WO3 was added to 15 mL of AgNO3 and vigorously stirred for 30 min. Then, 15 mL of ethanol containing 0.1 g of PVP was added to the suspension and stirred for 4 h at 60 °C. Finally, the mixture was transferred into a quartz tube and ultraviolet (UV) irradiated by a 150 W Hg lamp (λ = 365 nm) at the ambient temperature for several hours. At the end of the reaction, the as-synthesized nanoparticles were collected by a magnet, washed with distilled water and ethanol, and dried for 6 h at 70 °C [29].

2.5. Characterization of the Nanoparticles

Morphology of the nanoparticles was characterized using FESEM; Scanning Electron Microscope (TE-SCAN MIRA3 FESEM, Kohoutovice, Czech Republic). The crystalline structure of the Ag-CuFe2O4@WO3 nanoparticles was analyzed by X-ray Diffraction (XRD) (Rigaku MiniFlex 600, Tokyo, Japan) using Cu-Kα radiation (λ = 0.15418). The elemental analysis of the nanocomposite nanoparticles was performed using Electron Dispersion X-ray Spectroscopy. The Fourier Transforms Infrared Spectroscopy (FTIR) spectra of the nanoparticles were recorded in the scanning range of 400–4000 cm−1 (Shimadzu, FT-IR1650 spectrophotometer, Kyoto, Japan). Thermogravimetric Analysis (TGA) was performed by a Perkin Elmer instrument (Waltham, MA, USA) at the temperature range of 50 to 800 °C under nitrogen atmosphere. The magnetic properties of the nanoparticles were measured using a Vibrating Sample Magnetometer (VSM) (Lake Shore 7403, Westerville, OH, USA). The UV–Vis (DRS) spectra of the nanoparticles were recorded by a UV–Vis spectrometer (Shimadzu, UV-2550, Kyoto, Japan). X-ray Photoelectron Spectroscopy (XPS) was measured by a FOUNDRYMASTER Smart X-ray photoelectron device (Hitachi Advanced Technology, Tokyo, Japan) using monochromated Al-Kα as the X-ray source. Photoluminescence (PL) spectra of the nanoparticles were measured by using an excitation wavelength of 300 nm in an Agilent instrument (model G9800A, Santa Clara, CA, USA). Magnetic Electron Resonance (ESR) analysis was also done by a Bruker ELEXSYS 500 spectrometer (Billerica, MA, USA) to investigate the active free radicals.

2.6. Photodegradation Tests

Photodegradation levels of TAM and GEM by the Ag-CuFe2O4@WO3 magnetic nanoparticles were quantified in a photochemical reactor containing drug contaminated aqueous solutions. As the irradiation source, four UV lamps of 6 W (UVA light, 320–400 nm, with λmax = 365 nm) were employed for the photocatalytic reactions. The photodegradation efficiency of the nanocomposite photocatalyst was determined at various pH levels (3, 5, 7, 9, and 11), catalyst dosages (0.05, 0.1, 0.2, 0.4, 0.6, and 0.8 g/L), and initial concentrations of TAM and GEM (5, 10, 20, 30, and 40 mg/L). Furthermore, the effect of H2O2 concentration (0.1, 0.2, 0.3, and 0.5 mg.L-1) and mineral salt ions (including Cl−, SO42−, NO3−, and CO32− at the concentration of 1.5 mmol) on the photocatalytic degradation of TAM and GEM was investigated. An aeration pump (with the feed rate of 1.5 L/min) and a magnetic stirrer (with the rotation speed of 70 rpm) were used to mix and to provide the required oxygen in the measurements. NaOH and HCl (0.1 M) were used to adjust the pH of the tested solutions. It is worth noting that before switching on the lamps, the drug containing solutions were stirred for 30 min in the dark to ensure an adsorption/desorption equilibrium between the photocatalyst and the drug molecules. Then, at a specific time interval, 5 mL of the solution was taken from the reactor, the nanoparticles were separated using a magnetic field and analyzed by a spectrophotometer (at the wavelength of 236 and 276 nm for TAM and GEM, respectively). The photodegradation efficiency of the photocatalyst nanoparticles was determined through the following Equation (1) [30]:

2.7. Antibacterial Efficiency Tests

The antibacterial activity of Ag-CuFe2O4@WO3 nanoparticles against the Escherichia coli bacteria was determined via the Luria-Bertani (LB) counting method (the plate counting method). To differentiate the antibacterial effect of CuFe2O4@WO3 from that of Ag, this experiment was solely performed under the visible light. Accordingly, the achieved antibacterial activity is only attributed to the Ag nanoparticles. The antibacterial tests were conducted in a 100 mL sterilized glass container containing E. coli suspension (7 mL phosphate buffer solution containing the bacteria) and 0.4 g/L of the photocatalyst nanoparticles. The pH of the medium was kept neutral and it was incubated at 37 °C under magnetic stirring for up to 24 h. Then, 0.5 mL of the solutions was cultured on an agar plate and incubated at 37 °C for 16 h. Eventually, the number of isolated colonies was counted to represent the density of the remaining bacteria. As a control, the antibacterial efficiency of the CuFe2O4@WO3 nanoparticles was also measured to enable a comparison with the nanoparticles containing Ag. The antibacterial efficiency (R) was quantified via the Equation (2) [31]:

where R is the bacterial reduction ratio, A is the number of bacterial colonies of the solution containing CuFe2O4@WO3, and B is the number of bacterial colonies of the solution containing Ag-CuFe2O4@WO3 after different isothermal incubation periods.

3. Results and Discussion

3.1. Morphology and Size of the Nanoparticles

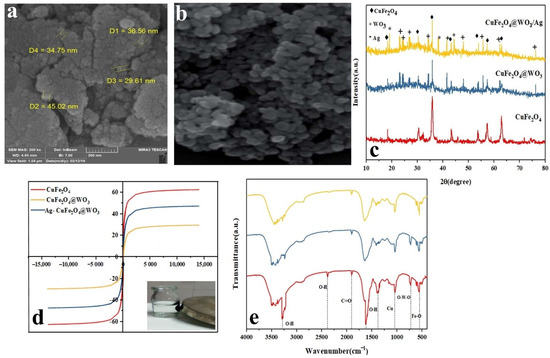

The FESEM images of the Ag-CuFe2O4@WO3 nanoparticles are shown in Figure 1a,b. As seen in the images, the nanoparticles are almost uniform in terms of size and shape (spherical). The average diameter of the nanoparticles lies within the range of 30–45 nm. As a fact, the nanoparticles are agglomerated, due to their high magnetic properties, engendering their mutual attraction [3].

Figure 1.

(a,b) FESEM images of the Ag-CuFe2O4@WO3 nanoparticles at different magnifications (the scale bar in (a) represents 200 nm); (c) XRD spectra for the Ag-CuFe2O4@WO3 nanoparticles; (d) magnetic behavior of the Ag-CuFe2O4@WO3 nanoparticles; (e) FTIR spectra of the Ag-CuFe2O4@WO3 nanoparticles representing their various bonds and functional groups.

3.2. Crystallinity of the Nanoparticles

The crystalline structure of the CuFe2O4, CuFe2O4@WO3, and Ag-CuFe2O4@WO3 nanoparticles was evaluated via XRD analysis. As shown in Figure 1c, the diffraction peaks appearing at 2θ of 18.35°, 18.30°, 35.5°, 43.2°, 53.58°, 57.14°, and 62.74° are attributed to CuFe2O4 and the crystallographic planes of (111), (220), (311), (400), (422), (511), and (440), respectively (according to JCPDS no. 77-0010) [28]. On the other hand, the characteristic peaks seen at 2θ of 23°, 24.15°, 26.7°, 34°, 52.41°, 48°, 55.7°, 62.25°, and 23.76° correspond with WO3’s crystallographic planes of (001), (200), (120), (220), (221), (240), (132), and (422), respectively (JCPDS card no. 32-1395) [32]. For the composite structures, the lower dispersion radiation intensity of CuFe2O4 was caused by the WO3 coating and due to absorption of X-ray. The XRD spectrum of Ag-CuFe2O4@WO3 nanoparticles shows several additional peaks appearing at 19.04°, 38.11°, and 44.32° related to Ag component’s crystallographic planes of (110), (111), and (220), respectively (JCPDS code.00-001-1281). By coating WO3 nanoparticles, in addition to creating new peaks, the intensity of peaks in CuFe2O4@WO3 is also reduced. In other words, the decrease in the scattering intensity of CuFe2O4 as a result of WO3 coating is due to the absorption of X-rays through WO3.

3.3. Elemental Analysis of the Nanoparticles

The EDS analysis verified the presence of elements such as O, Fe, W, Ag, and Cu in the Ag-CuFe2O4@WO3 nanoparticles. The weight percentage of the elements is 11.5 (Cu), 24.1 (Fe), 33 (W), 22.3 (O), and 8.6 (Ag) (note that the numbers have been rounded). Among the five elements (O, Fe, W, Cu, and Ag) demonstrated, the W content is higher than that of CuFe2O4 which could be due to the formation of a WO3 layer on the CuFe2O4 nanoparticles. Furthermore, the signal of Ag around 2.78 keV confirms the presence of Ag nanoparticles in the nanocomposite.

3.4. Magnetic Properties of the Nanoparticles

The magnetic properties of CuFe2O4, CuFe2O4@WO3, and Ag-CuFe2O4@WO3 nanoparticles were investigated using a vibrating sample magnetometer at the ambient temperature. As shown in Figure 1d, the magnetic saturation of the CuFe2O4 nanoparticles was as large as 62.57 emu/g, indicating that these nanoparticles are supermagnetic, and their magnetic hysteresis loop passes through the origin of the coordinates [17]. The magnetic saturation of the nanocomposite nanoparticles of CuFe2O4@WO3 and Ag-CuFe2O4@WO3 was recorded as 47.32 emu/g and 29.49 emu/g, respectively, implying that in the presence of the coating, this property declines. However, paramagnetic properties of the nanoparticles are preserved and this allows easy separation of them from the solution under an external magnetic field [22].

3.5. Surface Chemistry of the Nanoparticles

The FTIR spectra the CuFe2O4, CuFe2O4@WO3, and Ag-CuFe2O4@WO3 nanoparticles are shown in Figure 1e. The band centered at 415 cm−1 and 1044 cm−1 are assigned to the stretching vibration of Fe–O and Cu, respectively, associated with copper ferrite [33,34]. The dips appearing at 3400 cm−1 and 2378 cm−1 relate to the stretching vibrations of O-H [35] and the one emerging at 2853 cm−1 corresponds to C=O vibration [36]. With respect to the WO3 phase, the bond stretching of O-W-O appears in the range of 600–800 cm−1 [37]. Lastly, incorporation of Ag into the CuFe2O4@WO3 nanoparticles leads to emergence of a new dip at 1383 cm−1, representing the Ag-O bond [38]. After the silver coating, there was no change in the position of the CuFe2O4@WO3 peaks, and only one vibrational tensile peak was created in 2004 (cm−1), which indicates the Ag-O bond. The peaks have not changed, indicating that WO3 and Ag have not destroyed the structure of CuFe2O4. Moreover, no notable peak shift implies that the components are merely physically connected and no significant hydrogen bonding or chelation has not taken place. FTIR spectra could clearly indicate the respective functional groups of each component in the structure of nanocomposites. This could also point out to preservation of each phase after production cycle and assures that the system benefits from unique function of each component without any notable compromise that could be resulted from intermolecular bonding.

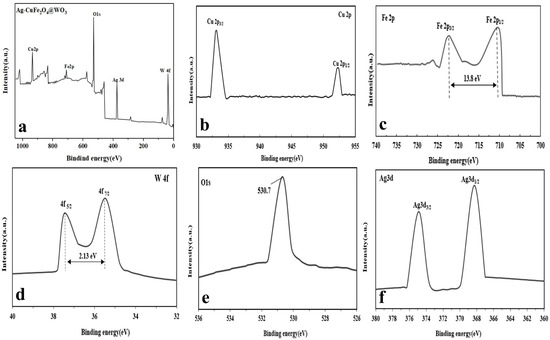

3.6. Surface Chemical Composition of the Nanoparticles

Based on the XPS analysis (general spectrum), surface composition of the Ag-CuFe2O4@WO3 nanoparticles consists of Fe, Cu, W, Ag, and O atoms (Figure 2a). More precisely monitoring, Figure 2b shows that the Cu binding energy is represented in the two peaks of 933 and 953 eV, which are attributed to Cu 2p3/2 and Cu 2p1/2, respectively. There are two distinct peaks in the Fe 2p spectrum, appearing at 710.7 and 724.5 eV, corresponding to the binding energies of Fe 2p1/2 and Fe 2p3/2, respectively [39] (Figure 2c). The mentioned binding energies arise from CuFe2O4. After coating CuFe2O4 with WO3, as shown in Figure 2d, two new signals appear at 35.47 and 37.6 eV corresponding to W4f7/2 and W4f5/2, respectively. The peaks are separated with a gap of 2.13 eV [40]. Figure 2e shows the O1s spectrum of the nanoparticles with a binding energy peak at 530.7 eV, attributed to oxygen at the W-O bond [41]. The Ag3d surface spectrum of the nanoparticles possesses two peaks with the binding energies of 368.3 eV and 374.10 eV, as shown in Figure 2f, that are attributed to Ag3d5/2 and Ag3d3/2, respectively. The 5.8 eV gap between the two peaks indicates the presence of Ag. Noteworthy, with no track of Ag+, it can be confidently said that Ag ions have been reduced to metallic silver in the nanocomposite particles [5].

Figure 2.

XPS analysis of the Ag-CuFe2O4@WO3 nanoparticles: (a) general XPS spectrum of the compound, and (b) Cu2p; (c) Fe2p; (d) W4f, (e) O1s; and (f) Ag3d spectrum of the compound.

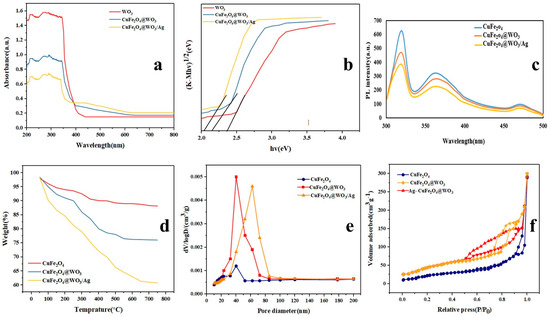

3.7. Band Gap Energy and Optical Activity of the Nanoparticles

The UV–Vis-diffuse reflectance spectra of the CuFe2O4, CuFe2O4@WO3, and Ag-CuFe2O4@WO3 nanoparticles are shown in Figure 3a. As seen here, the latter class of the nanoparticles containing Ag is able to absorb UV light and partly visible light and their light absorption intensity is higher than that for the CuFe2O4@WO3 nanoparticles. It is worth noting that the WO3 nanoparticles can only absorb UV radiation due to the wide band gap (2.42 eV) of WO3. In contrast, CuFe2O4 shows a narrow band gap and might cause a defect in the WO3 network and extend its optical activity to the visible light range. Thus, compared with WO3, the CuFe2O4@WO3 and Ag-CuFe2O4@WO3 photocatalysts can potentially offer a higher photodegradation efficiency under UV–Vis light irradiation. The band gap energy of the nanoparticles is equal to (1/2)(Ahv) where hv is the photon energy [42]. The band gap energy values of WO3, CuFe2O4@WO3, and Ag-CuFe2O4@WO3 nanoparticles are calculated as 2.42, 2.21, and 2.13 eV, respectively. Therefore, these kinds of nanoparticles exhibit a high photocatalytic activity under visible light irradiation. As shown in Figure 3b, the band gap energy in WO3 nanoparticles was 2.42 eV. When coated on CuFe2O4, the band gap energy in CuFe2O4@WO3 declines to 2.21 eV [43]. Furthermore, inclusion of Ag leads to further decrease of the band gap energy to 2.13 eV. The red shift of the optical response for the Ag-CuFe2O4@WO3 nanoparticles stems from interference of the semiconductor band gaps as well as the surface plasma resonance (SPR) effect of the spatially confined electrons in metallic Ag nanoparticles.

Figure 3.

(a) UV–Vis DR spectra and (b) band gap energy curves of the Ag-CuFe2O4@WO3 nanoparticles compared to those of the WO3 and CuFe2O4@WO3 nanoparticles; (c) photoluminescence (PL) analysis of the Ag-CuFe2O4@WO3 nanoparticles; (d) TGA curve for the Ag-CuFe2O4@WO3 nanoparticles in comparison with the controls; (e) the pore diameter distribution curves and (f) N2 adsorption/desorption isotherms of the CuFe2O4, CuFe2O4@WO3, and Ag-CuFe2O4@WO3 nanoparticles.

CuFe2O4 nanoparticles can absorb UV light and visible light due to their narrow band gap, thus increasing electron-hole recombination. After WO3 deposition, the adsorption capacity of CuFe2O4@WO3 in the visible light increases due to the synergistic effects of WO3 (transfer) and CuFe2O4 (adsorption). The Ag coating significantly increases the ability to absorb visible light, which is due to the plasmon resonance effect of the Ag surface. Therefore, with the coating of nanoparticles, the amount of band gap is reduced, thus it has the capability to absorb light and increase photocatalytic activity.

3.8. Electron Transfer Ability of the Nanoparticles

Photoluminescence (PL) spectroscopy was applied to determine the electron transfer ability of the photocatalytic nanoparticles and their capacity for separation of light-generated charge carriers. The PL spectra of the CuFe2O4, CuFe2O4@WO3, and Ag-CuFe2O4@WO3 nanoparticles are shown in Figure 3c. The main peak appearing at 320 nm represents the electron-hole recombination in the conduction and valence band of the photocatalyst. According to the PL spectra, the CuFe2O4 nanoparticles exhibit the highest PL emission intensity, implying their largest electron-hole recombination rate. However, upon coating of the CuFe2O4 core with WO3 and Ag, the peak intensity declines, indicating a decrease in the recombination rate of optical charge carriers. Such a lower electron-hole recombination rate can be interpreted as a higher photocatalytic activity and larger photodegradation efficiency of the photocatalyst nanoparticle.

3.9. Thermal Stability of the Nanoparticles

TGA curves of the CuFe2O4, CuFe2O4@WO3, and Ag-CuFe2O4@WO3 nanoparticles are shown in Figure 3d. Based on these curves, a weight loss of 17.2% takes place for the CuFe2O4 nanoparticles within the temperature range of 50–500 °C. Over 500 °C, no further weight loss occurs, indicating thermal stability of the CuFe2O4 nanoparticles at high temperatures. In the case of the CuFe2O4@WO3 nanoparticles, weight loss takes place in three steps. The initial weight loss occurs at 50–150 °C, due to evaporation of alcohol and absorbed water. The second weight loss is recorded between 250 °C and 500 °C, due to decomposition of some organic molecules [22]. The last weight loss happens in the temperature range of 500–800 °C. The Ag-CuFe2O4@WO3 nanoparticles show the largest weight loss due to water evaporation, phase transformation, decomposition of some residual organic molecules from solvent and/or removal of the hydroxyl groups present on the surface [44]. Thermal stability analysis of nanoparticles showed that with the addition of WO3 and Ag, thermal stability increases. This raised stability is due to the fact that the decomposition of organic matter in the reaction is reduced. Therefore, it adds to the stability of the nanoparticles and stabilizes the sample at 500 °C.

3.10. Surface Porosity of the Nanoparticles

Figure 3e,f show the surface pore diameter distribution and the N2 adsorption/desorption isotherms of the CuFe2O4, CuFe2O4@WO3, and Ag-CuFe2O4@WO3 nanoparticles, respectively. Regarding the CuFe2O4 nanoparticles, the average pore diameter was measured to be ~5 nm. The surface area and the total pore volume of these nanoparticles was 46.034 m2 g−1 and 0.457 cm3 g−1, respectively. The N2 adsorption/desorption isotherm of the CuFe2O4 is a type III isotherm according to IUPAC, implying insignificant surface porosity of the CuFe2O4 nanoparticles. When the CuFe2O4 core is coated with WO3 and further with Ag, the isotherms transform to the IUPAC IV isotherm with H2 hysteresis loops, witnessing the mesoporosity of the nanoparticles. The average pore diameter of the CuFe2O4@WO3 nanoparticles was equivalent to ~9 nm, and the surface area and total pore volume were determined to be 349.38 m2 g−1 and 0.449 cm3 g−1, respectively. Upon inclusion of Ag into the nanoparticles, the surface area raised up to 131.15 m2 g−1 and the average pore diameter and the total pore volume decreased to ~7 nm and 0.398 cm3 g−1, respectively.

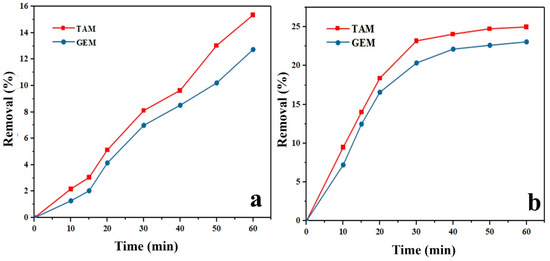

3.11. Effect of Adsorption and Photolysis

Photolysis trials were conducted in the absence of the photocatalyst, at pH 7, with 10 mg/L initial concentration of contaminants and under UV light irradiation for 60 min. The adsorption amount of Ag-CuFe2O4@WO3 nanocomposite at different times, qt (mg/g), was calculated using the following equation:

where C0 was the initial concentration and Ct concentration of the contaminant at time t (mg/L), V was the volume of the TAM and GEM solution, and m was the mass of Ag-CuFe2O4@WO3 (mg). Moreover, the adsorption capacity of Ag-CuFe2O4@WO3, qe (mg/g), was obtained according to the following equation:

where C0 and Ce were the initial concentration and pollutant equilibrium concentration (mg/L), respectively, V the volume of the TAM and GEM solutions (mL), and m the mass of Ag-CuFe2O4@WO3 (mg). As Figure 4a,b shows, the removal percentage of TAM and GEM contaminants under photolysis and adsorption was insignificant ( less than 30%).

Figure 4.

Photolysis (a) and adsorption (b) of Tamoxifen (TAM) and Gemfibrozil (GEM) by the Ag-CuFe2O4@WO3 nanoparticles. The photolysis conditions included: pH 7, 10 mg/L initial concentration of TAM and GEM, UV light irradiation for 60 min.

3.12. Photodegradation Efficiency

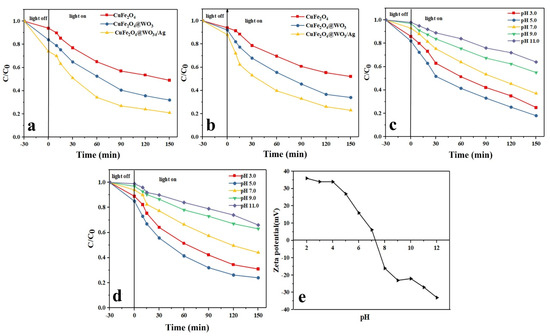

The drug photodegradation behavior of the CuFe2O4, CuFe2O4@WO3, and Ag-CuFe2O4@WO3 nanoparticles was evaluated at pH 7, catalyst dosage of 0.1 g/L, and drug concentration of 10 mg/L. The results are shown in Figure 5a,b for TAM and GEM, respectively. In the absence of the nanoparticles, only a minor percentage of TAM and GEM was degraded under light irradiation. In contrast, upon inclusion of the photocatalysts, photodegradation efficiency increased and the Ag-CuFe2O4@WO3 nanoparticles showed the highest efficiency, followed by the CuFe2O4@WO3 nanoparticles. With addition of WO3, the electron-hole recombination declines, thus resulting in a more optimum photocatalytic performance. This efficiency further rises by addition of Ag nanoparticles, due to the lower band gap energy of Ag than the transfer band of WO3, leading to better charge carrier separation and less electron-hole recombination.

Figure 5.

Photodegradation efficiency of the Ag-CuFe2O4@WO3 nanoparticles over a 150 min time period for TAM (a) and GEM; (b) effect of pH on the photocatalytic degradation of (c) TAM and (d) GEM; (e) Zeta potential measurement at different pHs for the Ag-CuFe2O4@WO3 nanoparticles.

3.12.1. Effect of pH

Given the crucial effect of pH on the surface charge of the adsorbents and the pollutant molecules, the influence of this parameter on removal of the drug models was monitored. In this regard, the photodegradation tests were conducted under different pH conditions between pH 3 and pH 11. As shown in Figure 5c,d, the highest photodegradation efficiency was achieved at pH 5, which is below the isoelectric point of the CuFe2O4 nanoparticles, i.e., 6.2 (Figure 5e). Under this pH level, the nanoparticles’ surface is protonated and positively charged and attracts the anionic molecules of the drugs. While over pH 6.2, an opposite situation is the case and the drug molecules are repelled from the negatively charged surface of the nanoparticles and therefore the degradation efficiency declines. pH can also affect the extent of production of the oxidative radicals [45]. Over pH 6.2, the photodegradation efficiency decreases due to a lower density of the hydroxyl radicals, thus a less oxidation potential [46]. Another reason for the lower photodegradation efficiency under alkaline conditions is the formation of insoluble compounds in the media, which hampers light penetration and thereby leads to a reduction in generation of the hydroxyl radicals [47,48].

3.12.2. Effect of Initial Drug Concentration

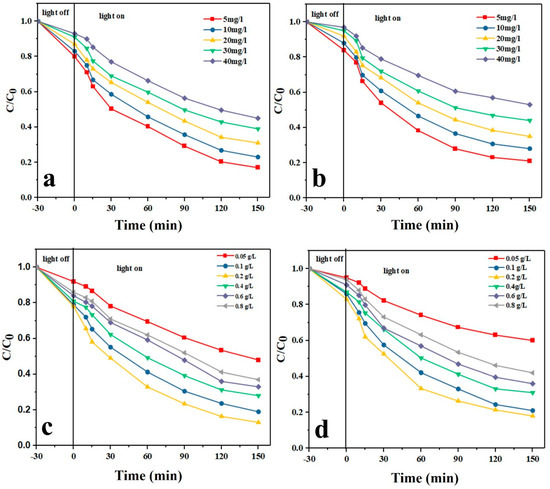

As shown in Figure 6a,b, with increasing the initial drug concentration, the photodegradation efficiency for both drug models decreases. Another observation is that with increasing the radiation time, the photodegradation rate increases. The highest photodegradation efficiency was achieved at 5 mg/L drug concentration and after 150 min. Over a large time, the number of holes and hydroxyl radicals rises and this leads to an increased photocatalytic degradation efficiency [6,49]. In contrast, at higher drug concentrations, given the fixed amount of the catalyst, less hydroxyl radicals are available to interact and thus a lower photodegradation efficiency is obtained. Moreover, at higher drug concentrations, larger amounts of intermediate compounds are produced that can consume the present free radicals, thereby reducing the photodegradation efficiency [50]. The photolysis tests also implied that in the absence of the photocatalyst nanoparticles, the drugs are negligibly photodegraded solely due to their hydrolysis [51].

Figure 6.

Effect of initial drug concentration on the photocatalytic degradation of (a) TAM and (b) GEM; effect of the photocatalyst dosage on the photocatalytic degradation of (c) TAM and (d) GEM.

3.12.3. Effect of the Photocatalyst Dosage

As shown in Figure 6c,d, with increasing the dosage of the Ag-CuFe2O4@WO3 photocatalyst up to 0.2 g/L, the photodegradation level of TAM and GEM rises, whereas the photodegradation rate declines. The results can be explained by the number of available active sites on the photocatalyst surface and the penetration of UV light into the drug aqueous solution. By increasing the photocatalyst dosage, the number of active sites and thereby the production level of hydroxyl radicals rises, which leads to a higher photodegradation efficiency [52]. On the other hand, when the photocatalyst dosage exceeds the optimal limit, i.e., 0.2 g/L, the solution gets turbid and the UV light penetration is hampered and the photodegradation efficiency declines [53].

3.12.4. Photodegradation Kinetics

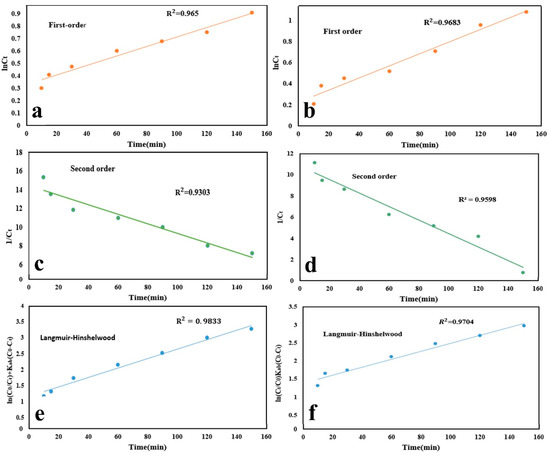

The kinetics of the photodegradation reactions was assessed to understand the underlying mechanisms (Figure 7a-f). For this purpose, optimum conditions for the photodegradation process of the drug models including pH 5, the initial drug concentration of 5–40 mg/L, and the photocatalyst dosage of 0.2 g/L were taken into account. Three possible kinetic models, including first-order kinetic model, second-order kinetic model, and Langmuir–Hinshelwood kinetic model were investigated [54].

Figure 7.

Kinetic plots of photodegradation process of (a,c,e) TAM and (b,d,f) GEM, obtained through several kinetic models of first-order, second-order, and Langmuir–Hinshelwood.

First-order kinetic model

Second-order kinetic model

Langmuir–Hinshelwood kinetics model

where C0 and Ct represent the concentrations of TAM and GEM at time = 0 and time = t, respectively. K1, K2, and K3 are the rate constants of first-order, second-order, and Langmuir–Hinshelwood, respectively. In addition, Kab was exhibited as the Langmuir constant.

As shown in Figure 7a–f, study of TAM and GEM photocatalytic degradation kinetics using Ag-CuFe2O4@WO3 photocatalyst with these three kinetic models showed that the highest correlation coefficient was related to the Langmuir–Hinshelwood kinetic model, with the highest R2 of 0.9833 and 0.9704 for TAM and GEM, respectively [55,56].

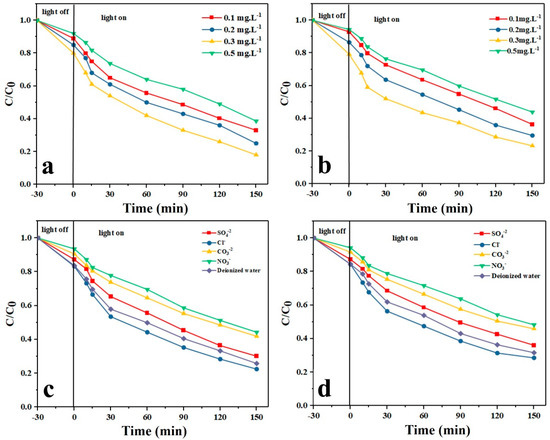

3.12.5. Effect of H2O2 Dosage

Figure 8a,b shows the effect of H2O2 dosage on the photodegradation of TAM and GEM drugs, respectively, by the Ag-CuFe2O4@WO3 nanoparticles. In these experiments, H2O2 in different dosages including 0.1, 0.2, 0.3, and 0.5 mg/L was added to the drug containing aqueous solutions and the photodegradation tests were performed under optimal conditions (photocatalyst dosage: 0.2 g/L, drug concentration: 5 mg/L, and pH 5). As shown in Figure 8 a,b, with increasing the dosage of H2O2, up to 0.5 mg/L, the photodegradation efficiency rises and thereafter it declines. The improved photodegradation efficiency could be attributed to the raised concentration of oxygen due to decomposition of H2O2 and also the contributing role of H2O2 in production of oxidative hydroxyl radicals. However, when H2O2 dosage exceeds a threshold, it starts to compete with the drug pollutants for reaction (consumption) with (of) the hydroxyl radicals, leading to generation of weaker radicals of •OOH, which have a negligible impact on photodegradation of the drug molecules [57]. The influence of H2O2 dosage on the degradation of pollutants can be explained in terms of the number of generated OH radicals and the capture of OH radicals. It is well known that H2O2 can trap photoinduced e- to stabilize the paired e- and h+. In fact, according to the available literatures, hydrogen peroxide in this study could act as (1) the electron acceptor; (2) the scavenger of positive holes; (c) the scavenger of hydroxyl radicals; or (3) the producer of hydroxyl radicals [58].

Figure 8.

Effect of H2O2 dosage on the photocatalytic degradation of (a) TAM and (b) GEM; effect of anions on the photocatalytic degradation of (c) TAM and (d) GEM.

3.12.6. Effect of Inorganic Anions

Inorganic anions are of the substances typically seen in real secondary wastewater effluents and notably impact on the catalytic reactions [58]. Figure 8c,d shows the effect of addition of different anions such as Cl−, SO42−, NO3−, and CO32− on the photocatalytic degradation of the drug models by the Ag-CuFe2O4@WO3 nanoparticles. The inhibiting effect of the mentioned anions on the photodegradation efficiency of the nanoparticles follows the order of Cl− > SO42− > CO32− > NO3−. These anions can compete with the drug molecules for the available active sites on the photocatalyst surface, thereby inactivating the photocatalyst [58]. Moreover, the reduction in photodegradation efficiency is attributed to the electrostatic repulsion and the limited active sites in the catalyst [59,60]. In fact, on the catalyst surface these anions act as receptors for •OH radicals, leading to increased electron and hole recombination. The reason for the significant reduction in the photocatalytic degradation efficiency in the presence of CO32− and NO3− ions is that these ions act as pH buffers and render the solution alkaline and thereby the surface of the photocatalyst hydroxylated. The as-charged surface repels the drug molecules electrostatically and thus lowers the adsorption capacity of the photocatalyst nanoparticles and their photodegradation efficiency. Furthermore, the free radicals generated at the photocatalyst surface are trapped by CO32− and NO3− anions and cannot participate in the degradation process [40].

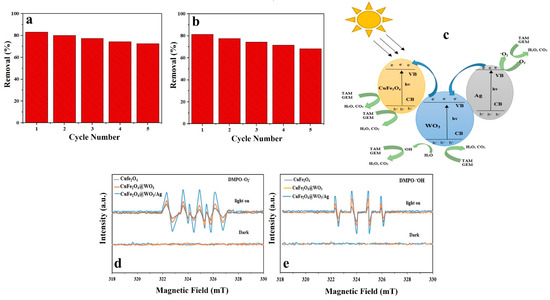

3.13. Stability and Reuse of the Photocatalyst

Reusability and stability of a photocatalyst are crucial with respect to its practical and economic application. In this study, reusability of the photocatalyst nanoparticles was challenged in five consecutive cycles. After each cycle, the nanoparticles were separated from the solution using an external magnetic field, washed with distilled water and ethanol, and finally dried in an oven and used for photodegradation of TAM and GEM in a new cycle. As shown in Figure 9a,b, the photocatalytic activity of the nanoparticles did not notably alter after five cycles, implying proper stability and reusability of the Ag-CuFe2O4@WO3 nanoparticles for photodegradation processes. After five cycles, TAM and GEM degradation reduced from 83.15 to 72.64% and from 81.47 to 68.25%, respectively. As indicated the photocatalytic activity loss was insignificant which signifies the photocatalytic stability of these nanoparticles during the photocatalytic reactions. Therefore, not only are the resources saved, but also is the cost of water and wastewater treatment reduced and the process holds great promise for an economic water purification approach.

Figure 9.

Reusability of the Ag-CuFe2O4@WO3 photocatalyst after five cycles of photodegradation of (a) TAM and (b) GEM; (c) photodegradation pathway of the drug models by the Ag-CuFe2O4@WO3 nanoparticles; ESR spectrum of (d) DMPO-◦O2 and (e) DMPO-◦OH compound for the CuFe2O4, CuFe2O4@WO3 and Ag-CuFe2O4@WO3 nanoparticles under UV irradiation.

3.14. Photodegradation Mechanism

The mechanism of photocatalytic degradation of the drugs by the Ag-CuFe2O4@WO3 nanoparticles is demonstrated in Figure 9c. When the nanoparticles are UV irradiated, electrons and holes are generated in the valence band (VB) and the conduction band (CB) of WO3, respectively. The photo-excited electrons from the valence band of WO3 can recombine with the holes present in the conduction band of CuFe2O4, and the charge transfer increases the separation of the electron-hole pairs produced in the CuFe2O4@WO3 compound. On the other hand, Fe+3 ions act as electron and hole traps, thereby forming Fe2+ and Fe4+ ions, which are less stable and tend to switch back to Fe3+. As a result of this process, active radicals of •OH and •O2 are produced [13,39]. Ag nanoparticles are able to accumulate a large density of electrons. In this regard, the photo-excited electrons can be transferred from the CB of WO3 to the Ag nanoparticles due to the existing difference between the CB of WO3 and the Fermi level of the silver nanoparticles [61]. In other words, due to the capability of Ag nanoparticles to accumulate electrons, the transfer of photoexcited electrons from the WO3 surface to Ag leads the overall Fermi surface of the composite nanoparticles to shift to a negative potential. Moreover, since the energy level at WO3 is higher than the new equilibrium Fermi surface, the electrons generated in the CB of WO3 are transferred to the Ag nanoparticles.

On the whole, Ag nanoparticles act as electron acceptors and thus lower the chance of electron and hole recombination. The photogenerated electrons can be trapped by oxygen and the holes can be trapped by OH. As a result, the highly oxidizing hydroxyl (•OH) and superoxide anion radicals (O◦2−) form that can effectively decompose TAM and GEM drug molecules [28]. The main mechanism of the photodegradation process of the drug models can be described by the following reactions:

3.15. Electron Paramagnetic Resonance (EPR)

The production of reactive oxidative species (ROSs) by the CuFe2O4, CuFe2O4@WO3, and Ag-CuFe2O4@WO3 nanoparticles was evaluated through the EPR spin-trap method by DMPO. As shown in Figure 9d, e, no evident signal was recorded in the dark, implying that the removal of TAM and GEM took place solely through adsorption onto the nanoparticles. However, upon UV light irradiation, signals with the intensity of 1:1:1:1 in the DMPO-O2 combination appeared that indicated the production of O2 radicals. The intensity of this signal was the highest for the Ag-CuFe2O4@WO3 nanoparticles, due to generation of free electrons able to form O2 radicals. The EPR signals in the DMPO− •OH compound with the intensity ratio of 1:2:2:1 are shown in the Figure 9e. The signals represent generation of oxidative hydroxyl radicals (•OH) degrading the TAM and GEM drugs. Therefore, the results of EPR analysis show that ◦O2− and •OH are the active species playing role in the photodegradation of TAM and GEM drugs.

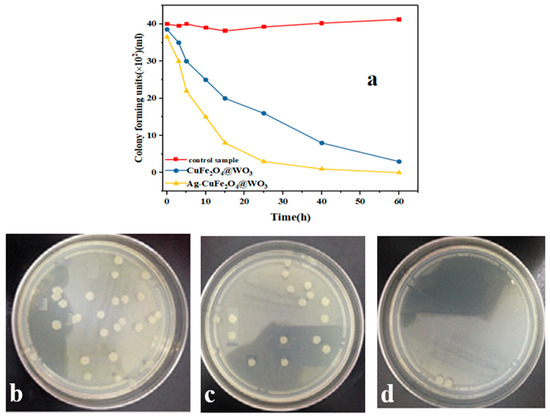

3.16. Antibacterial Properties

The antibacterial properties of the Ag-CuFe2O4@WO3 nanoparticles are shown in Figure 10a. As seen in this figure, no major change in the concentration of E. coli is trackable in the nanoparticle free control sample after 1 h. Meanwhile, this concentration gradually declines for the CuFe2O4@WO3 and Ag-CuFe2O4@WO3 nanoparticle containing media being UV irradiated. Particularly, the highest bactericidal rate was recorded for the Ag doped nanoparticles after 12 h of incubation. Thanks to the presence of Ag, the Ag-CuFe2O4@WO3 nanoparticles show an improved antibacterial efficiency [62]. Ag releases silver ions with well-known bactericidal effect. On the other hand, Ag nanoparticles contribute to further generation of the oxidative radicals that could damage the bacteria membranes. The antibacterial activity of silver nanoparticles on the composite surface can be also associated to their plasmon resonance behavior [63,64]. Figure 10b–d shows that clearly the number of the E. coli colonies in adjacent to the CuFe2O4@WO3 and particularly the Ag-CuFe2O4@WO3 nanoparticles declines. At the surface of the CuFe2O4 and WO3 nanoparticles, the electrons injected from Ag are trapped by the O2 molecules, and thereby reactive species such as O2, OOH◦, HOH are produced that can efficiently kill bacteria [65].

Figure 10.

(a) Antibacterial properties of the Ag-CuFe2O4@WO3 nanoparticles against Escherichia coli over a 60 h incubation period under UV light irradiation. The camera images show the number of the E. coli bacteria colonies after 60 h incubation for the petri dishes without the nanoparticles (b) and for those containing (c) CuFe2O4@WO3 and (d) Ag-CuFe2O4@WO3 nanoparticles.

4. Conclusions

In this study, we successfully synthesized a nanocomposite nanoparticle photocatalyst system composed of Ag-CuFe2O4@WO3 that could easily be separated and recovered thanks to the presence of CuFe2O4 magnetic component. Moreover, the system was able to offer a bactericidal effect due to Ag phase. Most importantly, the system could show a superior photodegradation efficiency for the drug pollutants, stemming from a low electron-hole recombination rate realized by the heterostructure of the photocatalyst. The photocatalytic nanoparticles can be reused up to five times with negligible loss of photodegradation efficiency, thus holding promise for a low-cost water decontamination process. Given the high potential of the developed photocatalyst in removal of drug pollutants and bacteria from water, a promising outlook for this system in purification of the multicontaminant water streams is imaginable.

Author Contributions

M.H.S.: supervision, formal analysis, validation, conceptualization, funding acquisition, writing—original draft; N.A.: investigation, formal analysis, writing—original draft, validation; S.H.: formal analysis, writing—original draft, writing—review & editing. All authors have read and agreed to the published version of the manuscript

Funding

This research was funded by the Research Council of University of Ardakan.

Data Availability Statement

All data created during this research is openly available from the University of Ardakan Research Data Archive.

Acknowledgments

M.H.S. gratefully acknowledge the Research Council of Ardakan University. Furthermore, they appreciate the assistance of laboratories in the Faculty of Natural Resources and Environment, University of Birjand, during the course of the experiments and analysis.

Conflicts of Interest

There are no conflict to declare.

References

- Yazdani, A.; Sayadi, M.H. Sonochemical degradation of azithromycin in aqueous solution. Environ. Heal. Eng. Manag. 2018, 5, 85–92. [Google Scholar] [CrossRef]

- Yazdi, M.; Sayadi, M.H.; Farsad, F. Removal of penicillin in aqueous solution using chlorella vulgaris and spirulina platensis from hospital wastewater. Desalin. Water Treat. 2018, 123, 315–320. [Google Scholar] [CrossRef]

- Ahmadpour, N.; Sayadi, M.H.; Sobhani, S.; Hajiani, M. Photocatalytic degradation of model pharmaceutical pollutant by novel magnetic TiO2@ZnFe2O4/Pd nanocomposite with enhanced photocatalytic activity and stability under solar light irradiation. J. Environ. Manage. 2020, 271, 110964. [Google Scholar] [CrossRef] [PubMed]

- Koltsakidou, A.; Antonopoulou, M.; Εvgenidou, Ε.; Konstantinou, I.; Lambropoulou, D. A comparative study on the photo-catalytic degradation of Cytarabine anticancer drug under Fe3+/H2O2, Fe3+/S2O82−, and [Fe(C2O4)3]3−/H2O2 processes. Kinetics, identification, and in silico toxicity assessment of generated transforma. Environ. Sci. Pollut. Res. 2019, 26, 7772–7784. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, Z.; Chen, L.; Zhang, L.; Li, X.; Xu, H.; Wang, H.; Zhu, G. Preparation of magnetic Fe3O4/TiO2/Ag composite microspheres with enhanced photocatalytic activity. Solid State Sci. 2016, 52, 42–48. [Google Scholar] [CrossRef]

- Molinari, R.; Caruso, A.; Argurio, P.; Poerio, T. Degradation of the drugs Gemfibrozil and Tamoxifen in pressurized and de-pressurized membrane photoreactors using suspended polycrystalline TiO2 as catalyst. J. Memb. Sci. 2008, 319, 54–63. [Google Scholar] [CrossRef]

- Knoop, O.; Woermann, M.; Lutze, H.V.; Sures, B.; Schmidt, T.C. Ecotoxicological effects prior to and after the ozonation of tamoxifen. J. Hazard. Mater. 2018, 358, 286–293. [Google Scholar] [CrossRef]

- Ganzenko, O.; Oturan, N.; Sirés, I.; Huguenot, D.; van Hullebusch, E.D.; Esposito, G.; Oturan, M.A. Fast and complete removal of the 5-fluorouracil drug from water by electro-Fenton oxidation. Environ. Chem. Lett. 2018, 16, 281–286. [Google Scholar] [CrossRef]

- Homaeigohar, S. The nanosized dye adsorbents for water treatment. Nanomaterials 2020, 10, 295. [Google Scholar] [CrossRef]

- Ghadimi, M.; Zangenehtabar, S.; Homaeigohar, S. An Overview of the Water Remediation Potential of Nanocomposite and Their Ecotoxicological Impacts. Water 2020, 12, 1150. [Google Scholar] [CrossRef]

- Homaeigohar, S.; Mahdavi, H.; Elbahri, M. Extraordinarily water permeable sol–gel formed nanocomposite nanofibrous membranes. Colloid. Interface Sci. 2012, 366, 51–56. [Google Scholar] [CrossRef] [PubMed]

- Mondal, S.K.; Saha, A.K.; Sinha, A. Removal of ciprofloxacin using modified advanced oxidation processes: Kinetics, pathways and process optimization. J. Clean. Prod. 2018, 171, 1203–1214. [Google Scholar] [CrossRef]

- Bahmani, M.; Dashtian, K.; Mowla, D.; Esmaeilzadeh, F.; Ghaedi, M. UiO-66(Ti)-Fe3O4-WO3 photocatalyst for efficient ammonia degradation from wastewater into continuous flow-loop thin film slurry flat-plate photoreactor. J. Hazard. Mater. 2020, 393, 122360. [Google Scholar] [CrossRef] [PubMed]

- Santhosh, C.; Velmurugan, V.; Jacob, G.; Jeong, S.K.; Grace, A.N.; Bhatnagar, A. Role of nanomaterials in water treatment applications: A review. Chem. Eng. J. 2016, 306, 1116–1137. [Google Scholar] [CrossRef]

- Bhattacharyya, A.; Kawi, S.; Ray, M. Photocatalytic degradation of orange II by TiO2 catalysts supported on adsorbents. Catal. Today 2004, 98, 431–439. [Google Scholar] [CrossRef]

- Gao, B.; Yap, P.S.; Lim, T.M.; Lim, T.-T. Adsorption-photocatalytic degradation of Acid Red 88 by supported TiO2: Effect of activated carbon support and aqueous anions. Chem. Eng. J. 2011, 171, 1098–1107. [Google Scholar] [CrossRef]

- Chen, H.; Xiong, X.; Hao, L.; Zhang, X.; Xu, Y. Improved visible light photocatalytic activity of WO3 through CuWO4 for phenol degradation. Appl. Surf. Sci. 2016, 389, 491–495. [Google Scholar] [CrossRef]

- Peng, H.; Ouyang, J.; Peng, Y. A simple approach for the synthesis of bi-functional Fe3O4@WO3−x core–shell nanoparticles with magnetic-microwave to heat responsive properties. Inorg. Chem. Commun. 2017, 84, 138–143. [Google Scholar] [CrossRef]

- Visa, M.; Bogatu, C.; Duta, A. Tungsten oxide—fly ash oxide composites in adsorption and photocatalysis. J. Hazard. Mater. 2015, 289, 244–256. [Google Scholar] [CrossRef]

- Bai, S.; Zhang, K.; Sun, J.; Luo, R.; Li, D.; Chen, A. Surface decoration of WO3 architectures with Fe2O3 nanoparticles for visible-light-driven photocatalysis. CrystEngComm 2014, 16, 3289–3295. [Google Scholar] [CrossRef]

- Kim, J.H.; Jang, Y.J.; Kim, J.H.; Jang, J.W.; Choi, S.H.; Lee, J.S. Defective ZnFe2O4 nanorods with oxygen vacancy for photoelectrochemical water splitting. Nanoscale 2015, 7, 19144–19151. [Google Scholar] [CrossRef] [PubMed]

- Ahmadpour, N.; Sayadi, M.H.; Sobhani, S.; Hajiani, M. A potential natural solar light active photocatalyst using magnetic ZnFe2O4@TiO2/Cu nanocomposite as a high performance and recyclable platform for degradation of naproxen from aqueous solution. J. Clean. Prod. 2020, 268, 122023. [Google Scholar] [CrossRef]

- Priyadharsan, A.; Vasanthakumar, V.; Shanavas, S.; Karthikeyan, S.; Anbarasan, P.M. Crumpled sheet like graphene based WO 3-Fe2O3 nanocomposites for enhanced charge transfer and solar photocatalysts for environmental remediation. Appl. Surf. Sci. 2019, 470, 114–128. [Google Scholar] [CrossRef]

- Atacan, K.; Güy, N.; Çakar, S. Preparation and antibacterial activity of solvothermal synthesized ZnFe2O4/Ag-TiO2 nanocomposite. Sak. Univ. J. Sci. 2018, 22, 1. [Google Scholar] [CrossRef]

- Maicu, M.; Hidalgo, M.C.; Colón, G.; Navío, J.A. Comparative study of the photodeposition of Pt, Au and Pd on pre-sulphated TiO2 for the photocatalytic decomposition of phenol. Photochem. Photobiol. A Chem. 2011, 217, 275–283. [Google Scholar] [CrossRef]

- He, X.; Cai, Y.; Zhang, H.; Liang, C. Photocatalytic degradation of organic pollutants with Ag decorated free-standing TiO2 nanotube arrays and interface electrochemical response. J. Mater. Chem. 2011, 21, 475–480. [Google Scholar] [CrossRef]

- Lima, M.S.; Cruz-Filho, J.F.; Noleto, L.F.G.; Silva, L.J.; Costa, T.M.S.; Luz, G.E. Synthesis, characterization and catalytic activity of Fe3O4@WO3/SBA-15 on photodegradation of the acid dichlorophenoxyacetic (2,4-D) under UV irradiation. J. Environ. Chem. Eng. 2020, 8, 104145. [Google Scholar] [CrossRef]

- Liu, Y.; He, H.; Li, J.; Li, W.; Yang, Y.; Li, Y.; Chen, Q. Preparation and enhanced photoelectrochemical performance of a p-n heterojunction CuFe2O4/WO3 nanocomposite film. RSC Adv. 2015, 5, 99378–99384. [Google Scholar] [CrossRef]

- Tseng, W.J.; Chuang, Y.C.; Chen, Y.A. Mesoporous Fe3O4@Ag@TiO2 nanocomposite particles for magnetically recyclable photocatalysis and bactericide. Adv. Powder Technol. 2018, 29, 664–671. [Google Scholar] [CrossRef]

- Ahmadpour, N.; Sayadi, M.H.; Verma, A.; Mansouri, B. Ultrasonic degradation of ibuprofen from the aqueous solution in the presence of titanium dioxide nanoparticles/hydrogen peroxide. Desalin. Water Treat. 2019, 145, 291–299. [Google Scholar] [CrossRef]

- Lin, W.C.; Chen, C.N.; Tseng, T.T.; Wei, M.H.; Hsieh, J.H.; Tseng, W.J. Micellar layer-by-layer synthesis of TiO2/Ag hybrid particles for bactericidal and photocatalytic activities. J. Eur. Ceram. Soc. 2010, 30, 2849–2857. [Google Scholar] [CrossRef]

- Yin, L.; Chen, D.; Feng, M.; Ge, L.; Yang, D.; Song, Z.; Fan, B.; Zhang, R.; Shao, G. Hierarchical Fe2O3@WO3 nanostructures with ultrahigh specific surface areas: Microwave-assisted synthesis and enhanced H2S-sensing performance. RSC Adv. 2015, 5, 328–337. [Google Scholar] [CrossRef]

- Fan, H.; Chen, D.; Ai, X.; Han, S.; Wei, M.; Yang, L.; Liu, H.; Yang, J. Mesoporous TiO2 coated ZnFe2O4 nanocomposite loading on activated fly ash cenosphere for visible light photocatalysis. RSC Adv. 2018, 8, 1398–1406. [Google Scholar] [CrossRef]

- Batoo, K.M.; Ansari, M.S. Low temperature-fired Ni-Cu-Zn ferrite nanoparticles through auto-combustion method for multilayer chip inductor applications. Nanoscale Res. Lett. 2012, 7, 112. [Google Scholar] [CrossRef] [PubMed]

- Senthil, R.A.; Priya, A.; Theerthagiri, J.; Selvi, A.; Nithyadharseni, P.; Madhavan, J. Facile synthesis of α-Fe2O3/WO3 composite with an enhanced photocatalytic and photo-electrochemical performance. Ionics Kiel. 2018, 24, 3673–3684. [Google Scholar] [CrossRef]

- Chandrika, M.; Ravindra, A.V.; Rajesh, C.; Ramarao, S.D.; Ju, S. Studies on structural and optical properties of nano ZnFe2O4 and ZnFe2O4-TiO2 composite synthesized by co-precipitation route. Mater. Chem. Phys. 2019, 230, 107–113. [Google Scholar] [CrossRef]

- Aslam, I.; Cao, C.; Tanveer, M.; Farooq, M.H.; Khan, W.S.; Tahir, M.; Idrees, F.; Khalid, S. A novel Z-scheme WO3/CdWO4 photocatalyst with enhanced visible-light photocatalytic activity for the degradation of organic pollutants. RSC Adv. 2015, 5, 6019–6026. [Google Scholar] [CrossRef]

- Preetha, D.; Arun, R.; Kumari, P.; Aarti, C. Synthesis and characterization of silver nanoparticles using cannonball leaves and their cytotoxic activity against Mcf-7 cell line. J. Nanotechnol. 2013, 2013, 1–5. [Google Scholar]

- Jia, X.; Dai, R.; Lian, D.; Han, S.; Wu, X.; Song, H. Facile synthesis and enhanced magnetic, photocatalytic properties of one-dimensional Ag@Fe3O4-TiO. Appl. Surf. Sci. 2017, 392, 268–276. [Google Scholar] [CrossRef]

- Cong, S.; Tian, Y.; Li, Q.; Zhao, Z.; Geng, F. Single-crystalline tungsten oxide quantum dots for fast pseudocapacitor and electrochromic applications. Adv. Mater. 2014, 26, 4260–4267. [Google Scholar] [CrossRef]

- Wang, M.; Sun, L.; Cai, J.; Huang, P.; Su, Y.; Lin, C. A facile hydrothermal deposition of ZnFe2O4 nanoparticles on TiO2 nanotube arrays for enhanced visible light photocatalytic activity. J. Mater. Chem. A 2013, 1, 12082–12087. [Google Scholar] [CrossRef]

- Delekar, S.D.; Yadav, H.M.; Achary, S.N.; Meena, S.S.; Pawar, S.H. Structural refinement and photocatalytic activity of Fe-doped anatase TiO2 nanoparticles. Appl. Surf. Sci. 2012, 263, 536–545. [Google Scholar] [CrossRef]

- Theerthagiri, J.; Senthil, R.A.; Malathi, A.; Selvi, A.; Madhavan, J.; Ashokkumar, M. Synthesis and characterization of a CuS-WO3 composite photocatalyst for enhanced visible light photocatalytic activity. RSC Adv. 2015, 5, 52718–52725. [Google Scholar] [CrossRef]

- Ba-abbad, M.M.; Kadhum, A.A.H.; Mohamad, A.B.; Takriff, M.S. 7064871.Pdf. Int. J. Electrochem. Sci. 2012, 7, 4871–4888. [Google Scholar]

- Norzaee, S.; Bazrafshan, E.; Djahed, B.; Kord Mostafapour, F.; Khaksefidi, R. UV Activation of Persulfate for Removal of Penicillin G Antibiotics in Aqueous Solution. Sci. World J. 2017, 2017. [Google Scholar] [CrossRef]

- Kamranifar, M.; Allahresani, A.; Naghizadeh, A. Synthesis and characterizations of a novel CoFe2O4@CuS magnetic nanocomposite and investigation of its efficiency for photocatalytic degradation of penicillin G antibiotic in simulated wastewater. J. Hazard. Mater. 2019, 366, 545–555. [Google Scholar] [CrossRef]

- Dehghani, M.; Nasseri, S.; Ahmadi, M.; Samaei, M.R.; Anushiravani, A. Removal of penicillin G from aqueous phase by Fe+3-TiO2/UV-A process. J. Environ. Heal. Sci. Eng. 2014, 12, 1–7. [Google Scholar] [CrossRef]

- Ahmadpour, N.; Sayadi, M.H.; Homaeigohar, S. A hierarchical Ca/TiO2/NH2-MIL-125 nanocomposite photocatalyst for solar visible light induced photodegradation of organic dye pollutants in water. RSC Adv. 2020, 10, 29808–29820. [Google Scholar] [CrossRef]

- Ye, S.; Yan, M.; Tan, X.; Liang, J.; Zeng, G.; Wu, H.; Song, B.; Zhou, C.; Yang, Y.; Wang, H. Facile assembled biochar-based nanocomposite with improved graphitization for efficient photocatalytic activity driven by visible light. Appl. Catal. B Environ. 2019, 250, 78–88. [Google Scholar] [CrossRef]

- Nasseh, N.; Al-Musawi, T.J.; Miri, M.R.; Rodriguez-Couto, S.; Hossein Panahi, A. A comprehensive study on the application of FeNi3@SiO2@ZnO magnetic nanocomposites as a novel photo-catalyst for degradation of tamoxifen in the presence of simulated sunlight. Environ. Pollut. 2020, 261, 114127. [Google Scholar] [CrossRef]

- Sayadi, M.H.; Sobhani, S.; Shekari, H. Photocatalytic degradation of azithromycin using GO@Fe3O4/ZnO/SnO2 nanocomposites. J. Clean. Prod. 2019, 232, 127–136. [Google Scholar] [CrossRef]

- Popa, A.; Stefan, M.; Toloman, D.; Pana, O.; Mesaros, A.; Leostean, C.; Macavei, S.; Marincas, O.; Suciu, R.; Barbu-Tudoran, L. Fe3O4-TiO2: Gd nanoparticles with enhanced photocatalytic activity and magnetic recyclability. Powder Technol. 2018, 325, 441–451. [Google Scholar] [CrossRef]

- Meng, X.; Zhuang, Y.; Tang, H.; Lu, C. Hierarchical structured ZnFe2O4@SiO2@TiO2 composite for enhanced visible-light photocatalytic activity. J. Alloys Compd. 2018, 761, 15–23. [Google Scholar] [CrossRef]

- Hsiao, P.H.; Li, T.C.; Chen, C.Y. ZnO/Cu2O/Si Nanowire Arrays as Ternary Heterostructure-Based Photocatalysts with Enhanced Photodegradation Performances. Nanoscale Res. lett. 2019, 14, 244. [Google Scholar] [CrossRef] [PubMed]

- Tang, C.H.; Chen, K.Y.; Chen, C.Y. Solution-processed ZnO/Si based heterostructures with enhanced photocatalytic performance. New J. Chem. 2018, 42, 13797–13802. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, D.; Liu, S.; Xu, S.; Yuan, Y.; Xiong, L. Kinetics and mechanisms of p-nitrophenol biodegradation by Pseudomonas aeruginosa HS-D. J. Environ. Sci. 2009, 21, 1194–1199. [Google Scholar] [CrossRef]

- Homaeigohar, S.; Botcha, N.K.; Zarie, E.; Elbahri, M. Ups and downs of water photodecolorization by nanocomposite polymer nanofibers. Nanomaterials 2019, 9, 250. [Google Scholar] [CrossRef]

- Rajamanickam, D.; Shanthi, M. Photocatalytic degradation of an organic pollutant by zinc oxide—solar process. Arab. J. Chem. 2016, 9, S1858–S1868. [Google Scholar] [CrossRef]

- Xu, L.; Yang, L.; Johansson, E.M.J.; Wang, Y.; Jin, P. Photocatalytic activity and mechanism of bisphenol a removal over TiO2−x/rGO nanocomposite driven by visible light. Chem. Eng. J. 2018, 350, 1043–1055. [Google Scholar] [CrossRef]

- Wang, J.; Tang, L.; Zeng, G.; Deng, Y.; Liu, Y.; Wang, L.; Zhou, Y.; Guo, Z.; Wang, J.; Zhang, C. Atomic scale g-C3N4/Bi2WO6 2D/2D heterojunction with enhanced photocatalytic degradation of ibuprofen under visible light irradiation. Appl. Catal. B Environ. 2017, 209, 285–294. [Google Scholar] [CrossRef]

- Xi, G.; Yue, B.; Cao, J.; Ye, J. Fe3O4/WO3 hierarchical core–shell structure: High-performance and recyclable visible-light photocatalysis. Chem. A Eur. 2011, 17, 5145–5154. [Google Scholar] [CrossRef] [PubMed]

- Su, R.; Tiruvalam, R.; He, Q.; Dimitratos, N.; Kesavan, L.; Hammond, C.; Lopez-Sanchez, J.A.; Bechstein, R.; Kiely, C.J.; Hutchings, G.J.; et al. Promotion of phenol photodecomposition over TiO2 Using Au, Pd, and Au-Pd nanoparticles. ACS Nano. 2012, 6, 6284–6292. [Google Scholar] [CrossRef] [PubMed]

- Rupa, A.V.; Manikandan, D.; Divakar, D.; Sivakumar, T. Effect of deposition of Ag on TiO2 nanoparticles on the photodegradation of Reactive Yellow. J. Hazard. Mater. 2007, 147, 906–913. [Google Scholar] [CrossRef] [PubMed]

- Mlalila, N.G.; Swai, H.S.; Hilonga, A.; Kadam, D.M. Antimicrobial dependence of silver nanoparticles on surface plasmon resonance bands against Escherichia coli. Nanotechnol. Sci. Appl. 2017, 10, 1–9. [Google Scholar] [CrossRef]

- Pant, H.R.; Pant, B.; Sharma, R.K.; Amarjargal, A.; Kim, H.J.; Park, C.H.; Tijing, L.D.; Kim, C.S. Antibacterial and photocatalytic properties of Ag/TiO2/ZnO nano-flowers prepared by facile one-pot hydrothermal process. Ceram. Int. 2013, 39, 1503–1510. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).