Structural and Surfacial Modification of Carbon Nanofoam as an Interlayer for Electrochemically Stable Lithium-Sulfur Cells

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Chemical Characterization

2.2. Electrochemical and Cell Performance Characterization

3. Results and Discussion

3.1. Material Characterization of the Carbon Nanofoams

3.2. Chemical Analysis of Carbon Nanofoam

3.3. Electrochemical Analysis of Carbon Nanofoam

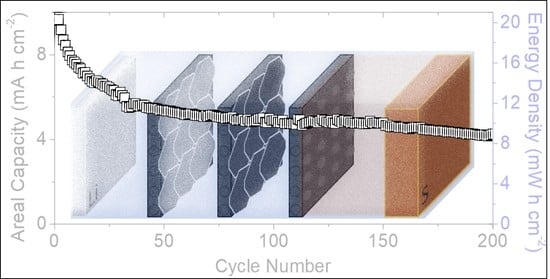

3.4. Lithium-Sulfur Cell Performance of Carbon Nanofoam

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tarascon, J.M.; Armand, N. Issues and challenges facing rechargeable lithium batteries. Nature 2001, 41, 359–367. [Google Scholar] [CrossRef] [PubMed]

- Bruce, P.G.; Scrosati, B.; Tarascon, J.M. Nanomaterials for rechargeable lithium batteries. Angew. Chem. Int. Ed. 2008, 47, 2930–2946. [Google Scholar] [CrossRef] [PubMed]

- Goodenough, J.B.; Kim, Y. Challenges for rechargeable Li batteries. Chem. Mater. 2010, 22, 587–603. [Google Scholar] [CrossRef]

- Chung, S.-H.; Manthiram, A. Current status and future prospects of metal–sulfur batteries. Adv. Mater. 2019, 31, 1901397. [Google Scholar] [CrossRef]

- He, J.; Manthiram, A. A review on the status and challenges of electrocatalysts in lithium-sulfur batteries. Energy Storage Mater. 2019, 20, 55–70. [Google Scholar] [CrossRef]

- Zhao, M.; Li, B.-Q.; Zhang, X.-Q.; Huang, J.-Q.; Zhang, Q. A perspective toward practical lithium–sulfur batteries. ACS Cent. Sci. 2020, 6, 1095–1104. [Google Scholar] [CrossRef]

- Yuan, H.; Peng, H.-J.; Huang, J.-Q.; Zhang, Q. Sulfur redox reactions at working interfaces in lithium–sulfur batteries: A perspective. Adv. Mater. Interfaces 2019, 6, 1802046. [Google Scholar] [CrossRef]

- Moorthy, B.; Kwon, S.; Kim, J.-H.; Ragupathy, P.; Lee, H.M.; Kim, D.K. Tin sulfide modified separator as an efficient polysulfide trapper for stable cycling performance in Li–S batteries. Nanoscale Horiz. 2019, 4, 214–222. [Google Scholar] [CrossRef]

- Thangavel, R.; Kannan, A.G.; Ponraj, R.; Kaliyappan, K.; Yoon, W.-S.; Kim, D.-W.; Lee, Y.-S. Cinnamon-derived hierarchically porous carbon as an effective lithium polysulfide reservoir in lithium–sulfur batteries. Nanomaterials 2020, 10, 1220. [Google Scholar] [CrossRef]

- Huang, S.; Wang, Z.; Lim, Y.V.; Wang, Y.; Li, Y.; Zhang, D.; Yang, H.Y. Recent advances in heterostructure engineering for lithium–sulfur batteries. Adv. Energy Mater. 2021, 11, 2003689. [Google Scholar] [CrossRef]

- Fang, Y.; Yao, Y.; Yang, H.; Fan, Y.; Nomura, N.; Zhou, W.; Ni, D.; Li, X.; Jiang, W.; Qiu, P.; et al. Incorporating cobalt nanoparticles in nitrogen-doped mesoporous carbon spheres through composite micelle assembly for high-performance lithium–sulfur batteries. ACS Appl. Mater. Interfaces 2021, 13, 38604–38612. [Google Scholar] [CrossRef]

- Wild, M.; O’Neill, L.; Zhang, T.; Purkayastha, R.; Minton, G.; Marinescu, M.; Offer, G.J. Lithium sulfur batteries, a mechanistic review. Energy Environ. Sci. 2015, 8, 3477–3494. [Google Scholar] [CrossRef]

- Fang, R.; Zhao, S.; Sun, Z.; Wang, D.-W.; Cheng, H.-M.; Li, F. More reliable lithium-sulfur batteries: Status, solutions and prospects. Adv. Mater. 2017, 29, 1606823. [Google Scholar] [CrossRef]

- Peng, H.-J.; Huang, J.-Q.; Cheng, X.-B.; Zhang, Q. Review on High-loading and high-energy lithium–sulfur batteries. Adv. Energy Mater. 2017, 7, 1700260. [Google Scholar] [CrossRef]

- Hagen, M.; Hanselmann, D.; Ahlbrecht, K.; Maça, R.; Gerber, D.; Tübke, J. Lithium–sulfur cells: The gap between the state-of-the-art and the requirements for high energy battery cells. Adv. Energy Mater. 2015, 5, 1401986. [Google Scholar] [CrossRef]

- Ely, T.O.; Kamzabek, D.; Chakraborty, D.; Doherty, M.F. Lithium–sulfur batteries: State of the art and future directions. ACS Appl. Energy Mater. 2018, 1, 1783. [Google Scholar]

- Aurbach, D. Introduction to the focus issue on lithium-sulfur batteries: Materials, mechanisms, modeling, and applications. J. Electrochem. Soc. 2018, 165, Y1. [Google Scholar] [CrossRef]

- Bonnick, P.; Nagai, E.; Muldoon, J. Lithium-sulfur batteries. J. Electrochem. Soc. 2018, 165, A6005–A6007. [Google Scholar] [CrossRef]

- Cleaver, T.; Kovacil, P.; Marinescu, M.; Zhang, T.; Offer, G. Commercializing lithium sulfur batteries: Are we doing the right research? J. Electrochem. Soc. 2018, 165, A6029–A6033. [Google Scholar] [CrossRef]

- Fan, L.; Li, M.; Li, X.; Xia, W.; Chen, Z.; Lu, J. Interlayer material selection for lithium-sulfur batteries. Joule 2019, 3, 361–386. [Google Scholar] [CrossRef] [Green Version]

- Chen, L.; Yu, H.; Li, W.; Dirican, M.; Liu, Y.; Zhang, X. Interlayer design based on carbon materials for lithium-sulfur batteries: A review. J. Mater. Chem. A 2020, 8, 10709–10735. [Google Scholar] [CrossRef]

- Yen, Y.-J.; Chung, S.-H. Lean-electrolyte lithium–sulfur electrochemical cells with high-loading carbon nanotube/nanofiber–polysulfide cathodes. Chem. Commun. 2020, 57, 2009–2012. [Google Scholar] [CrossRef]

- Lin, H.; Yang, L.; Jiang, X.; Li, G.; Zhang, T.; Yao, Q.; Zheng, G.W.; Lee, J.Y. Electrocatalysis of polysulfide conversion by sulfur-deficient MoS2 nanoflakes for lithium–sulfur batteries. Energy Environ. Sci. 2017, 10, 1476–1486. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Cui, C.; Liu, Y.; Liu, W.; Wei, J. Application of MoS2 in the cathode of lithium sulfur batteries. RSC Adv. 2020, 10, 7384–7395. [Google Scholar] [CrossRef] [Green Version]

- Tian, C.; Wu, J.; Ma, Z.; Li, B.; Zhang, X.; Zu, X.; Xiang, X.; Li, S. A melt-diffusion strategy for tunable sulfur loading on CC@MoS2 for lithium–sulfur batteries. Energy Rep. 2020, 6, 172–180. [Google Scholar] [CrossRef]

- Li, N.; Zheng, M.; Lu, H.; Hu, Z.; Shen, C.; Chang, X.; Ji, G.; Cao, J.; Shi, Y. High-rate lithium–sulfur batteries promoted by reduced graphene oxide coating. Chem. Commun. 2012, 48, 4106–4108. [Google Scholar] [CrossRef] [PubMed]

- Yu, M.; Li, R.; Wu, M.; Shi, G. Graphene materials for lithium-sulfur batteries. Energy Storage Mater. 2015, 1, 51–73. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, Z.; Song, N.; He, J.; Li, Z. Graphene and its derivatives in lithium-sulfur batteries. Mater. Today Energy 2018, 9, 319–335. [Google Scholar] [CrossRef]

- Sing, K.S.W.; Everett, D.H.; Haul, R.A.W.; Moscou, L.; Pierotti, R.A.; Rouquerol, J.; Siemieniewska, T. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Fang, R.; Chen, K.; Yin, L.; Sun, Z.; Li, F.; Cheng, H.-M. The regulating role of carbon nanotubes and graphene in lithium-ion and lithium-sulfur batteries. Adv. Mater. 2019, 31, 1800863. [Google Scholar] [CrossRef]

- Zhang, Q.; Cheng, X.-B.; Huang, J.-Q.; Peng, H.-J.; Wei, F. Review of carbon materials for advanced lithium–sulfur batteries. Carbon 2015, 81, 850. [Google Scholar] [CrossRef]

- Ho, Y.-C.; Chung, S.-H. A design of the cathode substrate for high-loading polysulfide cathodes in lean-electrolyte lithium-sulfur cells. Chem. Eng. J. 2021, 422, 130363. [Google Scholar] [CrossRef]

- Cheng, C.-S.; Chung, S.-H. Nickel-plated sulfur nanocomposites for electrochemically stable high-loading sulfur cathodes in a lean-electrolyte lithium-sulfur cell. Chem. Eng. J. 2022, 429, 132257. [Google Scholar] [CrossRef]

- McClosekey, B.D. Attainable gravimetric and volumetric energy density of Li−S and Li ion battery cells with solid separator-protected Li metal anodes. J. Phys. Chem. Lett. 2015, 6, 4581–4588. [Google Scholar] [CrossRef] [PubMed]

- Zhao, T.; Ye, Y.; Peng, X.; Divitini, G.; Kim, H.-K.; Lao, C.-Y.; Coxon, P.R.; Xi, K.; Liu, Y.; Ducati, C.; et al. Advanced lithium–sulfur batteries enabled by a bio-inspired polysulfide adsorptive brush. Adv. Funct. Mater. 2016, 26, 8418–8426. [Google Scholar] [CrossRef] [Green Version]

- Fang, R.; Zhao, S.; Pei, S.; Cheng, Y.; Hou, P.; Liu, M.; Cheng, H.M.; Liu, C.; Li, F. An integrated electrode/separator with nitrogen and nickel functionalized carbon hybrids for advanced lithium/polysulfide batteries. Carbon 2016, 109, 719–726. [Google Scholar] [CrossRef]

- Zhang, Y.-Z.; Zhang, Z.; Liu, S.; Li, G.-R.; Gao, X.-P. Free-standing porous carbon nanofiber/carbon nanotube film as sulfur immobilizer with high areal capacity for lithium-sulfur battery. ACS Appl. Mater. Interfaces 2018, 10, 8749–8757. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, D.; Muhammad, Z.; Wan, F.; Xie, W.; Wang, Y.; Song, L.; Niu, Z.; Chen, J. Single nickel atoms on nitrogen-doped graphene enabling enhanced kinetics of lithium–sulfur batteries. Adv. Mater. 2019, 31, 1903955. [Google Scholar] [CrossRef]

- Yu, Z.; Wang, B.; Liao, X.; Zhao, K.; Yang, Z.; Xia, F.; Sun, C.; Wang, Z.; Fan, C.; Zhang, J.; et al. Boosting polysulfide redox kinetics by graphene-supported Ni nanoparticles with carbon coating. Adv. Energy Mater. 2020, 10, 2000907. [Google Scholar] [CrossRef]

- Marangon, V.; Di Lecce, D.; Orsatti, F.; Brett, D.J.; Shearing, P.R.; Hassoun, J. Investigating high-performance sulfur–metal nanocomposites for lithium batteries. Sustain. Energy Fuels 2020, 4, 2907–2923. [Google Scholar] [CrossRef]

- Ji, J.; Sha, Y.; Li, Z.; Gao, X.; Zhang, T.; Zhou, S.; Qiu, T.; Zhou, S.; Zhang, L.; Ling, M. Selective adsorption and electrocatalysis of polysulfides through hexatomic nickel clusters embedded in N-doped graphene toward high-performance Li-S batteries. Research 2020, 2020, 5714349. [Google Scholar] [CrossRef]

- Wei, Y.; Wang, Y.; Zhang, X.; Wang, B.; Wang, Q.; Wu, N.; Zhang, Y.; Wu, H. Superhierarchical conductive framework implanted with nickel/graphitic carbon nanocages as sulfur/lithium metal dual-role hosts for Li–S batteries. ACS Appl. Mater. Interfaces 2020, 12, 35058–35070. [Google Scholar] [CrossRef] [PubMed]

- Yu, C.-H.; Chung, S.-H. Nanoporosity of carbon–sulfur nanocomposites toward the lithium–sulfur battery electrochemistry. Nanomaterials 2021, 11, 1518. [Google Scholar] [CrossRef] [PubMed]

- Chiu, L.-L.; Chung, S.-H. A poly (ethylene oxide)/lithium bis (trifluoromethanesulfonyl) imide-coated polypropylene membrane for a high-loading lithium–sulfur battery. Polymers 2021, 13, 535. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Zhao, Z.; Zhou, H.; Cheng, M.; Yan, R.; Tao, X.; Li, S.; Liu, X.; Cheng, C.; Ran, F. Cobalt-based double catalytic sites on mesoporous carbon as reversible polysulfide catalysts for fast-kinetic Li–S batteries. ACS Appl. Mater. Interfaces 2021, 13, 51174–51185. [Google Scholar] [CrossRef]

| Element (%) | Carbon Nanofoam | Mos2-Coated Carbon Nanofoam | Graphene-Coated Carbon Nanofoam |

|---|---|---|---|

| carbon | 95.7 | 72.2 | 97.5 |

| sulfur | 0.0 | 6.5 | 0.0 |

| molybdenum | 0.0 | 19.6 | 0.0 |

| oxygen | 4.2 | 1.6 | 2.5 |

| fluorine | 0.1 | 0.1 | 0.0 |

| Carbon-Nanofoam Interlayer | MoS2-Coated Carbon-Nanofoam Interlayer | Graphene-Coated Carbon-Nanofoam Interlayer | Reference | |

|---|---|---|---|---|

| C/20 analysis | ||||

| peak capacity [mAh g−1] | 1381 | 1462 | 1484 | 558 |

| reversible capacity [mAh g−1] | 680 | 552 | 572 | 357 |

| cycle life | 200 | 100 | 100 | 100 |

| retention rate | 49% | 38% | 39% | 64% |

| C/10 analysis | ||||

| peak capacity [mAh g−1] | 1125 | 1109 | 1115 | 432 |

| reversible capacity [mAh g−1] | 500 | 413 | 428 | 222 |

| cycle life | 200 | 200 | 200 | 100 |

| retention rate | 44% | 37% | 38% | 51% |

| a | b | c | d | e | f | g | h |

|---|---|---|---|---|---|---|---|

| 8 | 10 | 1057 | 8.4 | 42 | 200 | C/10 | This work |

| 3 | 20 | 1085 | 3.3 | 95 | 50 | C/5 | [35] |

| 3 | 20 | 867 | 2.6 | 90 | 200 | 1C | [35] |

| 8.5 | 30 | 1150 | 9.8 | 79 | 100 | C/2 | [36] |

| 8.5 | 30 | 952 | 8.1 | 75 | 200 | C/5 | [36] |

| 12 | 20 | 1126 | 13.5 | 71 | 50 | C/5 | [37] |

| 4 | 31 | 800 | 3.2 | 85 | 100 | 1C | [38] |

| 6 | 31 | 600 | 3.6 | 75 | 100 | 1C | [38] |

| 6 | 31 | 1059 | 6.3 | 78 | 100 | 1C | [38] |

| 8 | 6.25 | 663 | 5.3 | 85 | 100 | C/5 | [39] |

| 6.8 | 12 | 1000 | 6.8 | 88 | 10 | C/20 | [40] |

| 6.3 | 13 | 1100 | 6.9 | 87 | 10 | C/20 | [40] |

| 5 | 20 | 1104 | 5.5 | 72 | 80 | C/10 | [41] |

| 6.8 | 20 | 1387 | 9.4 | 69 | 30 | C/10 | [41] |

| 4 | 20 | 1000 | 4 | 70 | 70 | C/5 | [42] |

| 4 | 10 | 1084 | 4.3 | 75 | 100 | C/10 | [43] |

| 4 | 20 | 981 | 3.9 | 60 | 50 | C/10 | [44] |

| 6 | 20 | 637 | 3.8 | 69 | 50 | C/10 | [44] |

| 3.2 | 8 | 1150 | 3.7 | 45 | 120 | C/10 | [45] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Quay, Y.-J.; Chung, S.-H. Structural and Surfacial Modification of Carbon Nanofoam as an Interlayer for Electrochemically Stable Lithium-Sulfur Cells. Nanomaterials 2021, 11, 3342. https://doi.org/10.3390/nano11123342

Quay Y-J, Chung S-H. Structural and Surfacial Modification of Carbon Nanofoam as an Interlayer for Electrochemically Stable Lithium-Sulfur Cells. Nanomaterials. 2021; 11(12):3342. https://doi.org/10.3390/nano11123342

Chicago/Turabian StyleQuay, Yee-Jun, and Sheng-Heng Chung. 2021. "Structural and Surfacial Modification of Carbon Nanofoam as an Interlayer for Electrochemically Stable Lithium-Sulfur Cells" Nanomaterials 11, no. 12: 3342. https://doi.org/10.3390/nano11123342

APA StyleQuay, Y.-J., & Chung, S.-H. (2021). Structural and Surfacial Modification of Carbon Nanofoam as an Interlayer for Electrochemically Stable Lithium-Sulfur Cells. Nanomaterials, 11(12), 3342. https://doi.org/10.3390/nano11123342