Calculating the Effect of AlGaN Dielectric Layers in a Polarization Tunnel Junction on the Performance of AlGaN-Based Deep-Ultraviolet Light-Emitting Diodes

Abstract

:1. Introduction

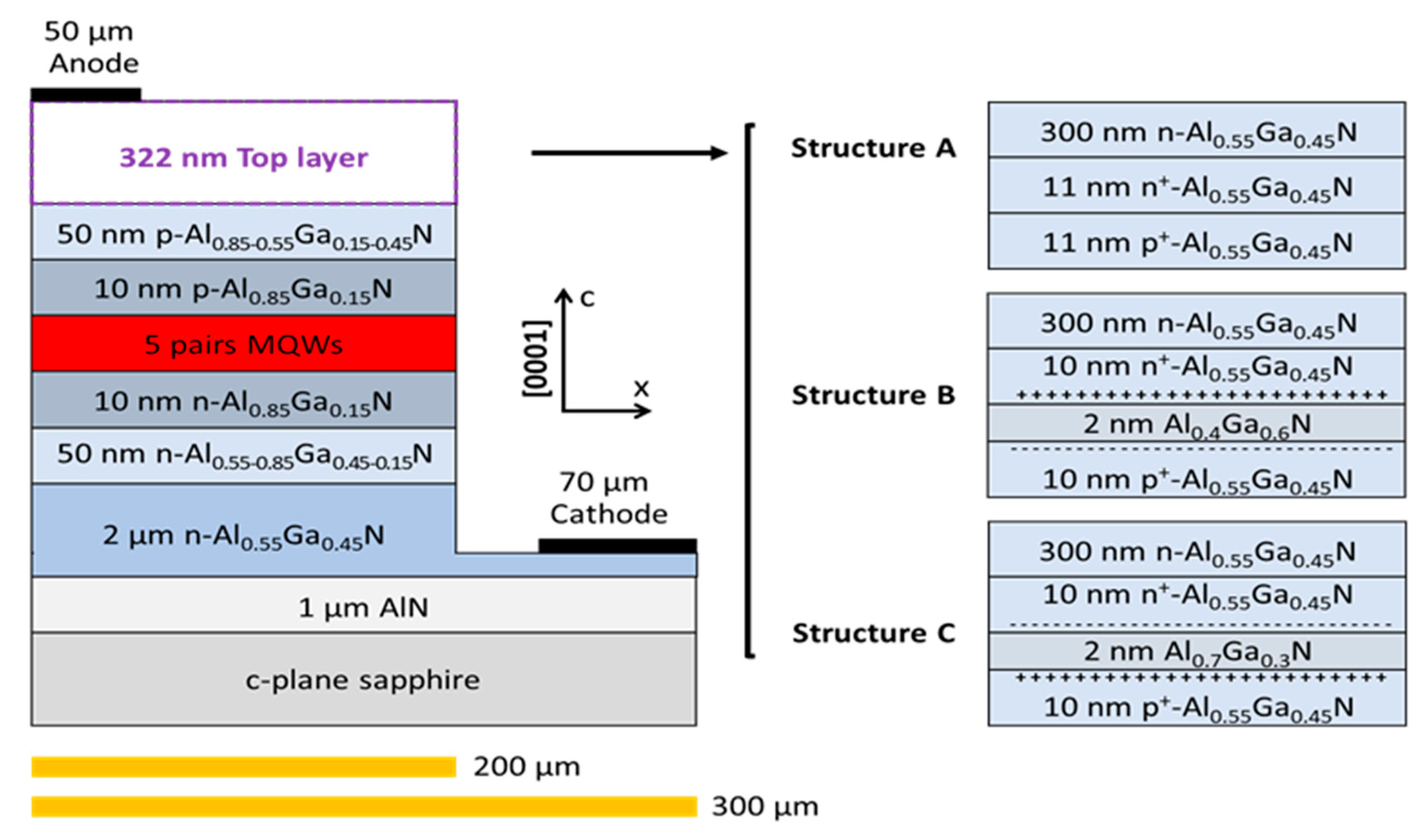

2. Research Methods and Physical Models

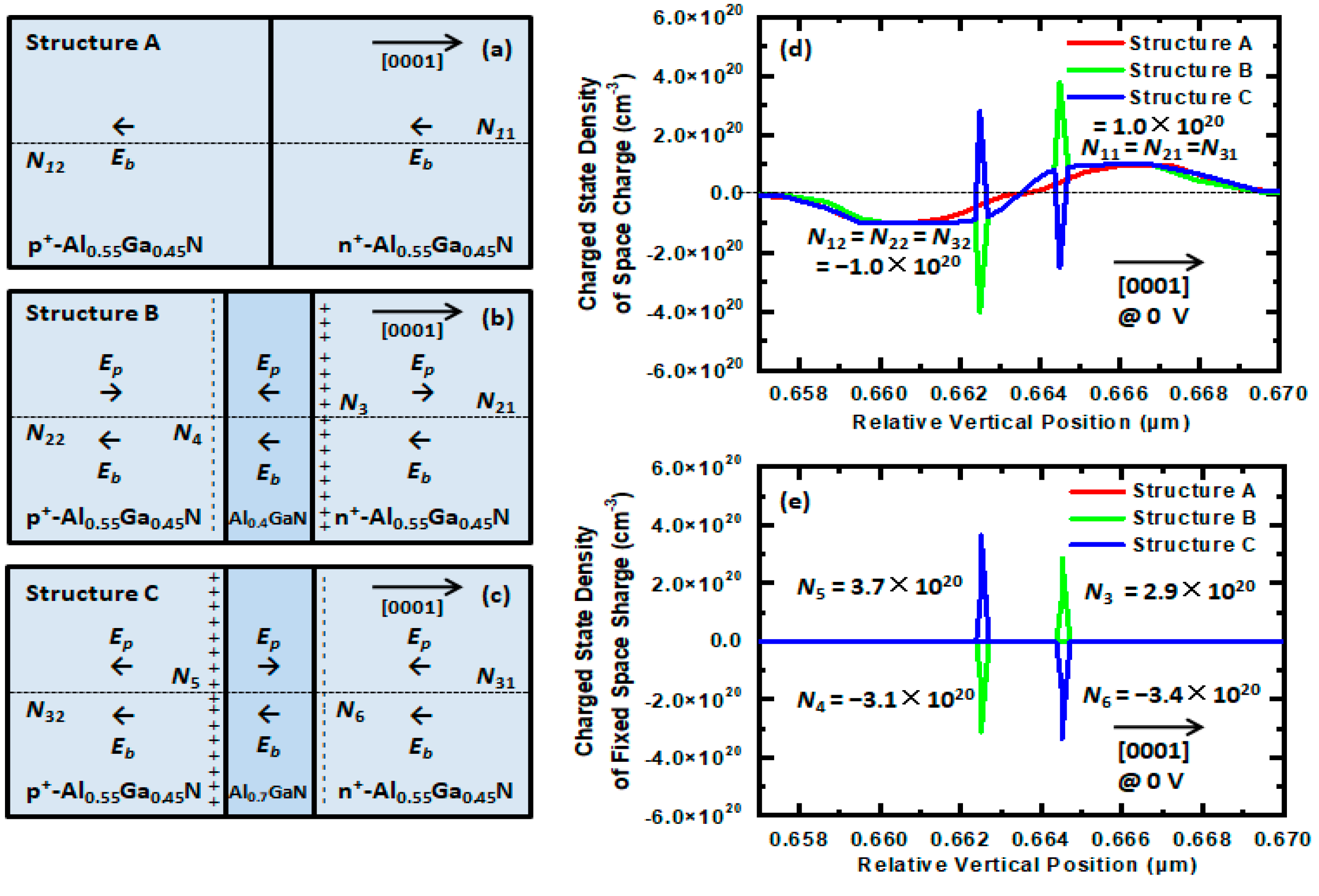

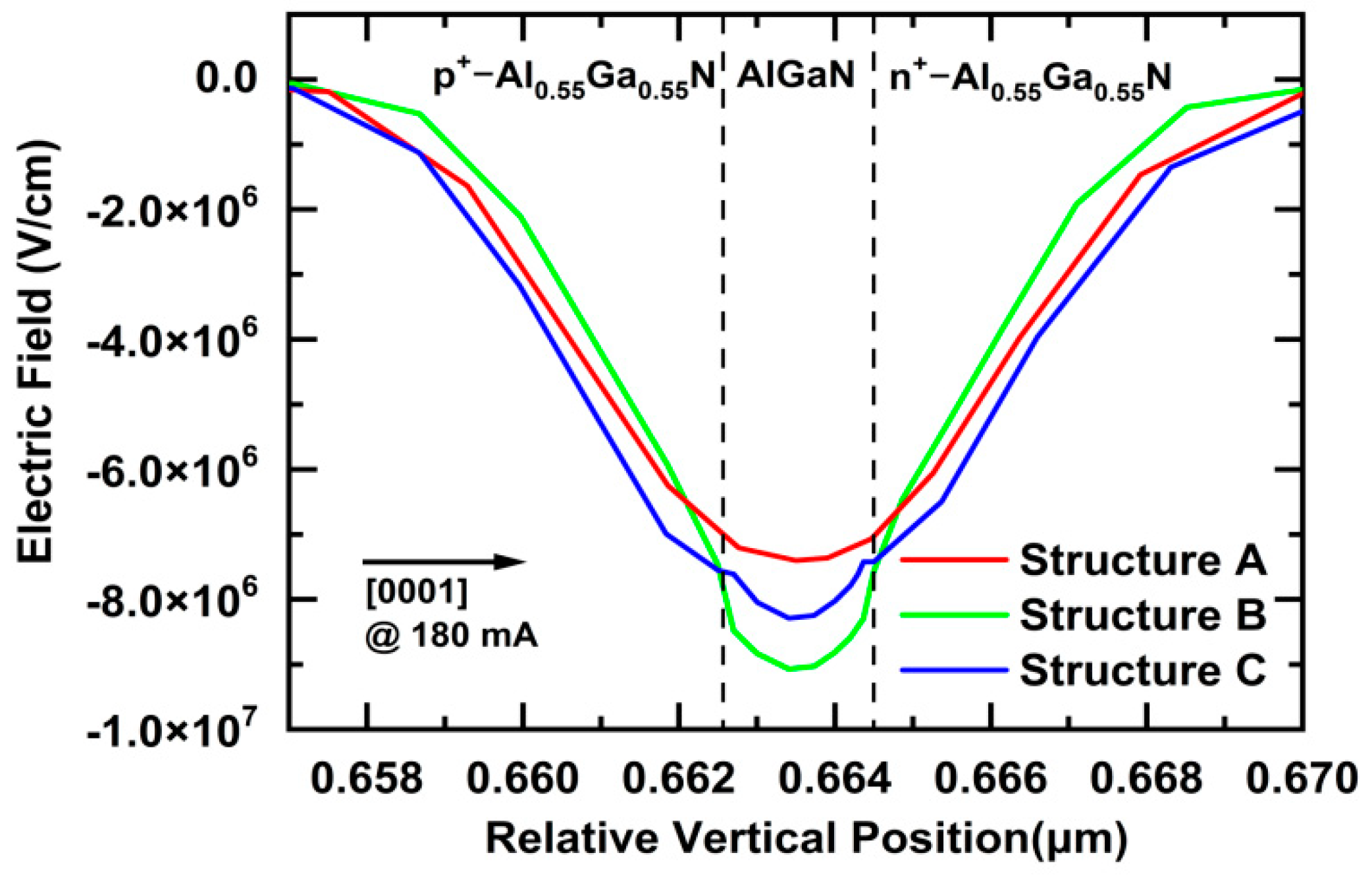

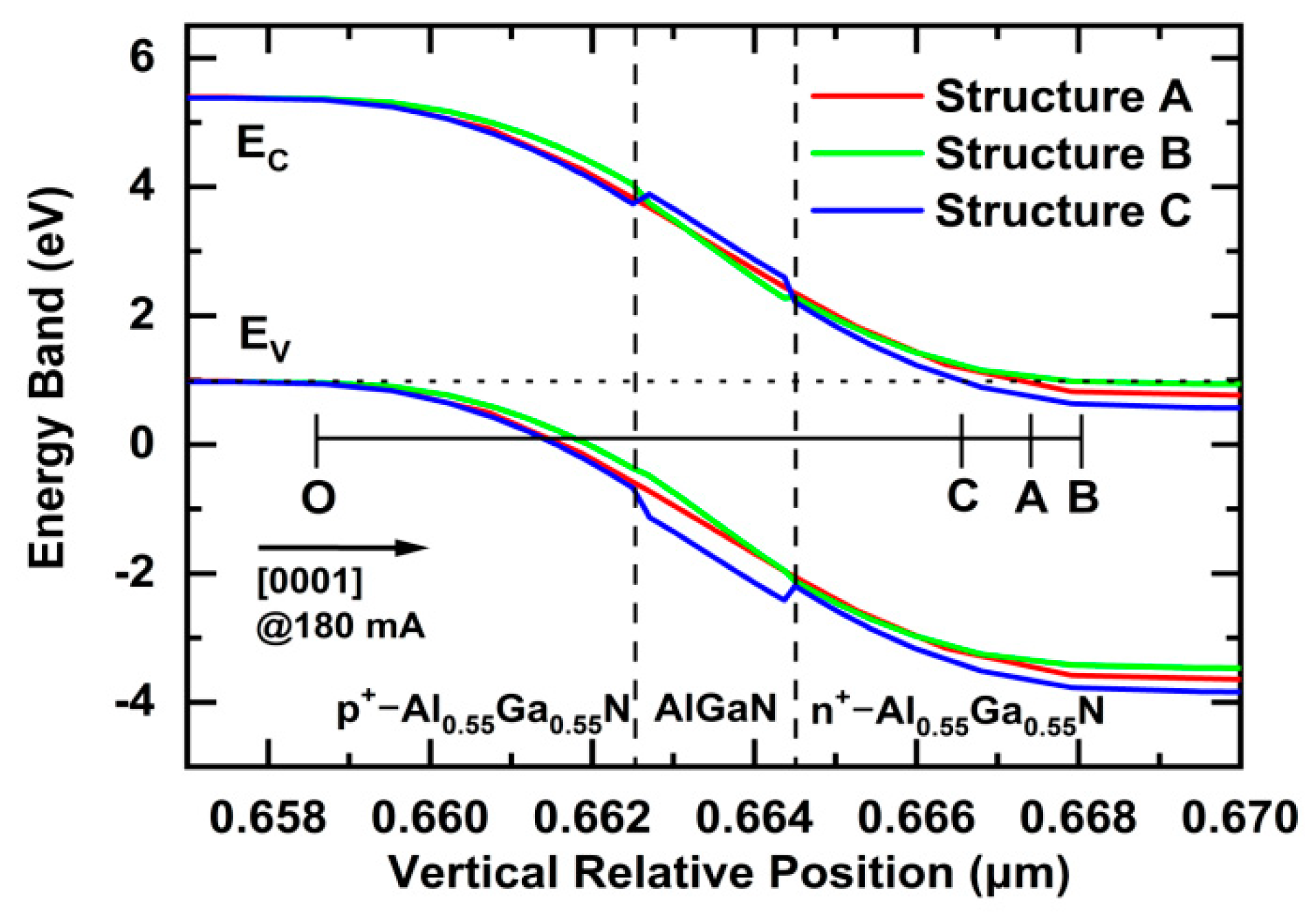

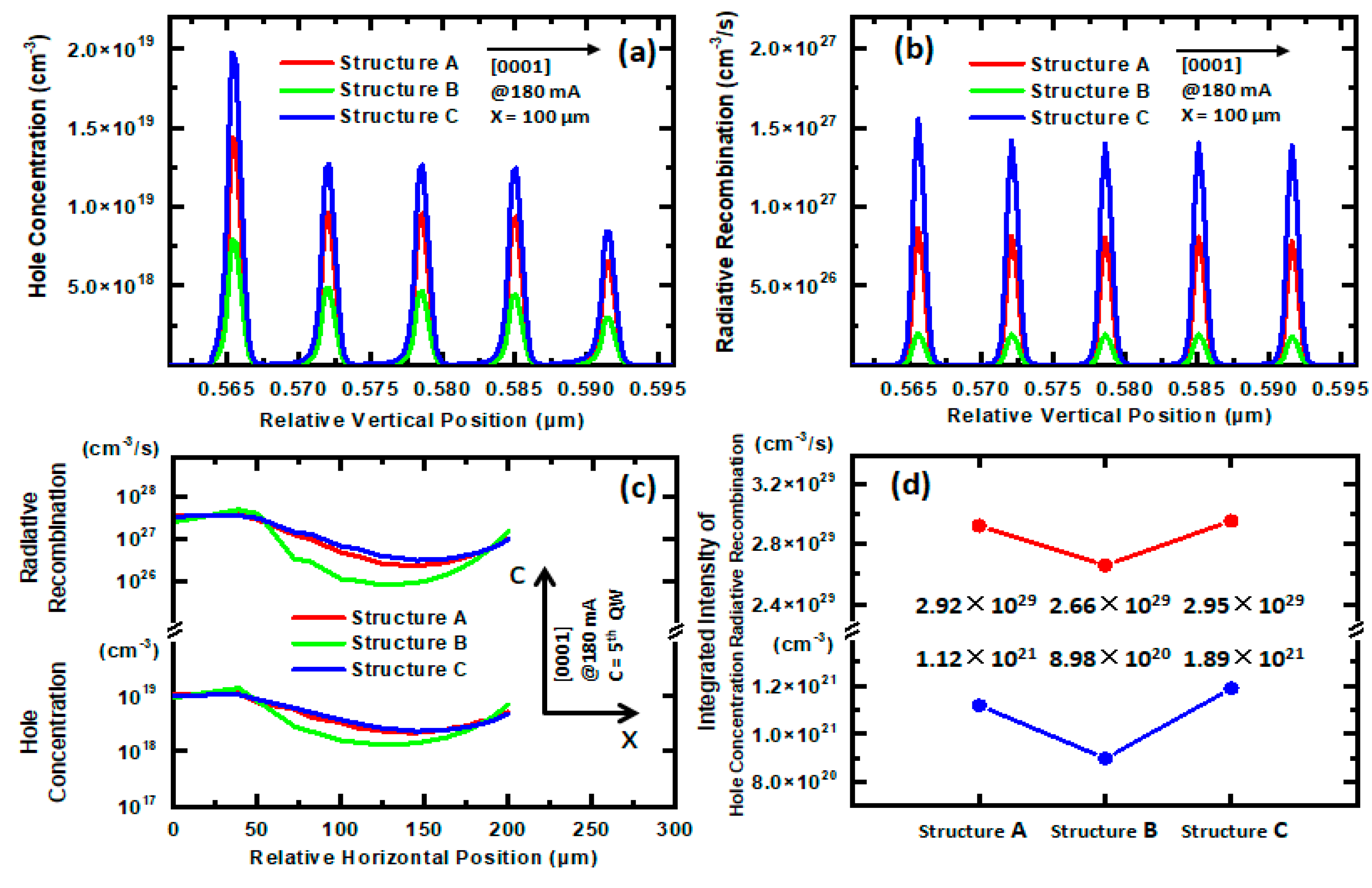

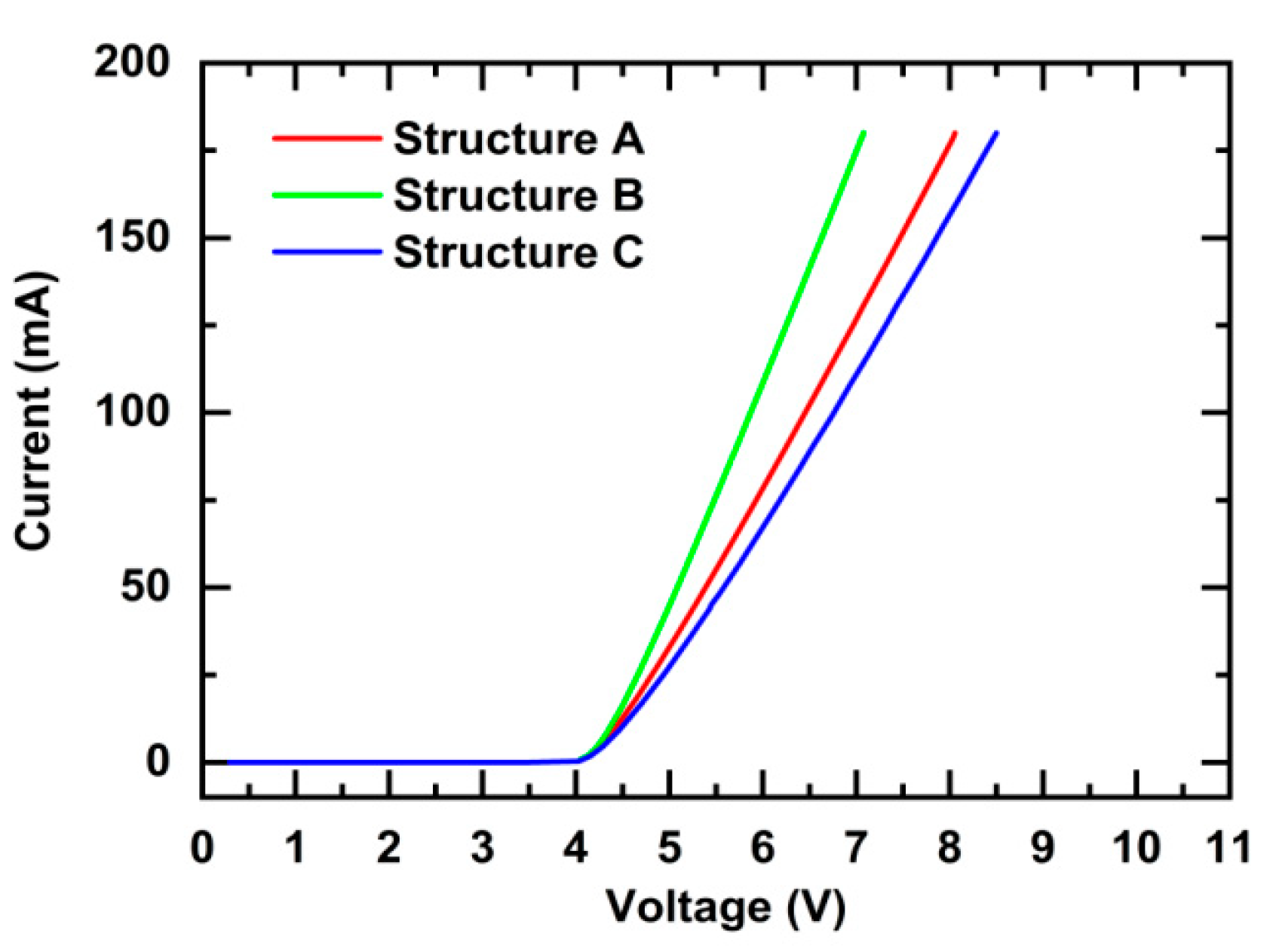

3. Results and Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, D.B.; Jiang, K.; Sun, X.J.; Guo, C.L. AlGaN photonics: Recent advances in materials and ultraviolet devices. Adv. Opt. Photonics 2018, 10, 43–110. [Google Scholar] [CrossRef]

- Taniyasu, Y.; Kasu, M.; Makimoto, T. An aluminum nitride light emitting diode with a wavelength of 210 nanometres. Nature 2006, 441, 325–328. [Google Scholar] [CrossRef]

- Takano, T.; Mino, T.; Sakai, J.; Noguchi, N.; Tsubaki, K.; Hirayama, H. Deep ultraviolet light-emitting diodes with external quantum efficiency higher than 20% at 275 nm achieved by improving light-extraction efficiency. Appl. Phys. Express 2017, 10, 031002. [Google Scholar] [CrossRef]

- Kojima, K.; Nagasawa, Y.; Hirano, A.; Ippommatsu, M.; Honda, Y.; Amano, H.; Akasaki, I.; Chichibu, S.F. Carrier localization structure combined with current micropaths in AlGaN quantum wells grown on an AlN template with macrosteps. Appl. Phys. Lett. 2019, 114, 011102. [Google Scholar] [CrossRef]

- Yang, W.; Li, D.; Liu, N.Y.; Chen, Z.; Wang, L.; Liu, L.; Li, L.; Wan, C.H.; Chen, W.H.; Hu, X.D.; et al. Improvement of hole injection and electron overflow by a tapered AlGaN electron blocking layer in InGaN-based blue laser diodes. Appl. Phys. Lett. 2012, 100, 031105. [Google Scholar] [CrossRef]

- Santi, C.D.; Meneghini, M.; Monti, D.; Glaab, J.; Guttmann, M.; Rass, J.; Einfeldt, S.; Mehnke, F.; Enslin, J.; Wernicke, T.; et al. Recombination mechanisms and thermal droop in AlGaN-based UV-B LEDs. Photonics Res. 2017, 5, A44–A51. [Google Scholar] [CrossRef]

- Yun, J.; Hirayama, H. Investigation of the light-extraction efficiency in 280nm AlGaN-based light-emitting diodes having a highly transparent p-AlGaN layer. J. Appl. Phys. 2017, 121, 013105. [Google Scholar] [CrossRef]

- Hou, M.J.; Qin, Z.X.; He, C.G.; Cai, J.A.; Wang, X.Q.; Shen, B. Effect of injection current on the optical polarization of AlGaN-based ultraviolet light emitting diodes. Opt. Express 2014, 22, 19589–19594. [Google Scholar] [CrossRef]

- Guo, Y.N.; Zhang, Y.; Yan, J.C.; Xie, H.Z.; Liu, L.; Chen, X.; Hou, M.J.; Qin, Z.X.; Wang, J.X.; Li, J.M. Light extraction enhancement of AlGaN-based ultraviolet light-emitting diodes by substrate sidewall roughening. Appl. Phys. Lett. 2017, 111, 011102. [Google Scholar] [CrossRef]

- Jiang, K.; Sun, X.J.; Shi, Z.M.; Zang, H.; Ben, J.W.; Deng, H.X.; Li, D.B. Quantum engineering of nonequilibrium efficient p-doping in ultra-wide band-gap nitrides. Light-Sci. Appl. 2021, 10, 69. [Google Scholar] [CrossRef] [PubMed]

- Nam, K.B.; Nakarmi, M.L.; Li, J.; Lin, J.Y.; Jiang, H.X. Mg acceptor level in AlN probed by deep ultraviolet photoluminescence. Appl. Phys. Lett. 2003, 83, 878–880. [Google Scholar] [CrossRef]

- Edwards, J.; Kawabe, K.; Stevens, G.; Tredgold, R.H. Space charge conduction and electrical behaviour of aluminium nitride single crystals. Solid State Commun. 1965, 3, 99–100. [Google Scholar] [CrossRef]

- Chin, V.W.L.; Tansley, T.L.; Osotchan, T. Electron mobilities in gallium, indium, and aluminum nitrides. J. Appl. Phys. 1994, 75, 7365–7372. [Google Scholar] [CrossRef]

- Chu, C.S.; Tian, K.K.; Che, J.M.; Shao, H.; Kou, J.Q.; Zhang, Y.H.; Zhang, Z.H.; Kuo, H.C. On the Impact of Electron Leakage on the Efficiency Droop for AlGaN Based Deep Ultraviolet Light Emitting Diodes. IEEE Photonics J. 2020, 12, 1600207. [Google Scholar] [CrossRef]

- Lang, J.; Xu, F.J.; Ge, W.K.; Liu, B.Y.; Zhang, N.; Sun, Y.H.; Wang, J.M.; Wang, M.X.; Xie, N.; Fang, X.Z.; et al. Greatly enhanced performance of AlGaN based deep ultraviolet light emitting diodes by introducing a polarization modulated electron blocking layer. Opt. Express 2019, 27, A1458–A1466. [Google Scholar] [CrossRef]

- Lang, J.; Xu, J.; Ge, W.K.; Liu, B.Y.; Zhang, N.; Sun, Y.H.; Wang, M.X.; Xie, N.; Fang, X.Z.; Kang, X.N.; et al. High performance of AlGaN deep-ultraviolet light emitting diodes due to improved vertical carrier transport by delta-accelerating quantum barriers. Appl. Phys. Lett. 2019, 114, 172105. [Google Scholar] [CrossRef]

- Lu, L.; Zhang, Y.; Xu, F.J.; Ding, G.G.; Liu, Y.H. Performance improvement of AlGaN-based deep-ultraviolet light-emitting diodes via Al-composition graded quantum wells. Superlattices Microstruct. 2018, 118, 55–60. [Google Scholar] [CrossRef]

- Xing, C.; Yu, H.B.; Ren, Z.J.; Zhang, H.C.; Dai, J.N.; Chen, C.Q.; Sun, H.D. Performance Improvement of AlGaN-Based Deep Ultraviolet Light-Emitting Diodes with Step-Like Quantum Barriers. IEEE J. Quantum Electron. 2020, 56, 3300106. [Google Scholar] [CrossRef]

- Mondal, R.K.; Chatterjee, V.; Pal, S. Effect of Step-graded Superlattice Electron Blocking Layer on performance of AlGaN based deep-UV light emitting diodes. Physica E Low Dimens. Syst. Nanostruct. 2019, 108, 233–237. [Google Scholar] [CrossRef]

- Ye, D.Q.; Zhang, D.Y.; Wu, C.Y.; Wang, D.X.; Xu, C.K.; Zhang, J.; Huang, M.C. Using a compositionally step graded hole reservoir layer with hole accelerating ability for reducing efficiency droop in GaN-based LEDs. AIP Adv. 2017, 7, 055016. [Google Scholar] [CrossRef] [Green Version]

- Yu, C.T.; Lai, W.C.; Yen, C.H.; Chang, S.J. Effects of InGaN layer thickness of AlGaN/InGaN superlattice electron blocking layer on the overall efficiency and efficiency droops of GaN-based light emitting diodes. Opt. Express 2014, 22, A663–A670. [Google Scholar] [CrossRef] [PubMed]

- Lin, B.C.; Chen, K.J.; Wang, C.H.; Chiu, C.H.; Lan, Y.P.; Lin, C.C.; Lee, P.T.; Shih, M.H.; Kuo, Y.K.; Kuo, H.C. Hole injection and electron overflow improvement in InGaN/GaN light-emitting diodes by a tapered AlGaN electron blocking layer. Opt. Express 2014, 22, 463–469. [Google Scholar] [CrossRef] [PubMed]

- Kwon, M.R.; Park, T.H.; Lee, T.H.; Lee, B.R.; Kim, T.G. Improving the performance of AlGaN-based deep-ultraviolet light-emitting diodes using electron blocking layer with a heart-shaped graded Al composition. Superlattices Microstruct. 2018, 116, 215–220. [Google Scholar] [CrossRef]

- Lin, R.M.; Lu, Y.C.; Chou, Y.L.; Chen, G.H.; Lin, Y.H.; Wu, M.C. Enhanced characteristics of blue InGaN/GaN light-emitting diodes by using selective activation to modulate the lateral current spreading length. Appl. Phys. Lett. 2008, 92, 261105. [Google Scholar] [CrossRef] [Green Version]

- Malyutenko, V.K.; Bolgov, S.S.; Tykhonov, A.N. Research on Electrical Efficiency Degradation Influenced by Current Crowding in Vertical Blue InGaN-on-SiC Light-Emitting Diodes. IEEE Photonics Technol. Lett. 2012, 24, 1124–1126. [Google Scholar] [CrossRef]

- Li, C.K.; Wu, Y.R. Study on the Current Spreading Effect and Light Extraction Enhancement of Vertical GaN/InGaN LEDs. IEEE Trans. Electron Devices 2012, 59, 400–407. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Tan, S.T.; Liu, W.; Ju, Z.G.; Zheng, K.; Kyaw, Z.B.; Ji, Y.; Hasanov, N.; Sun, X.W.; Demir, H.V. Improved InGaN/GaN light-emitting diodes with a p-GaN/n-GaN/p-GaN/n-GaN/p-GaN current spreading layer. Opt. Express 2013, 21, 4958–4969. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Horng, R.H.; Chen, K.Y.; Tien, C.H.; Liao, J.C. Effects of Mesa Size on Current Spreading and Light Extraction of GaN-Based LED. J. Disp. Technol. 2015, 11, 1010–1013. [Google Scholar] [CrossRef]

- Takehara, K.; Takeda, K.; Nagata, K.; Sakurai, H.; Ito, S.; Iwaya, M.; Takeuchi, T.; Kamiyama, S.; Akasaki, I.; Amano, H. Transparent electrode for UV light-emitting-diodes. Phys. Status Solidi C 2011, 8, 2375–2377. [Google Scholar] [CrossRef]

- Takeuchi, T.; Hasnain, G.; Corzine, S.; Hueschen, M.; Schneider, R.P., Jr.; Kocot, C.; Blomqvist, M.; Chang, Y.L.; Lefforge, D.; Krames, M.R.; et al. GaN-Based Light Emitting Diodes with Tunnel Junctions. Jpn. J. Appl. Phys. 2001, 40, L861–L863. [Google Scholar] [CrossRef]

- Jeon, S.R.; Song, Y.H.; Jang, H.J.; Yanga, G.M. Lateral current spreading in GaN-based light-emitting diodes utilizing tunnel contact junctions. Appl. Phys. Lett. 2001, 78, 3265–3267. [Google Scholar] [CrossRef]

- Jeon, S.R.; Song, Y.H.; Jang, H.J.; Kim, K.S.; Yang, G.M.; Hwang, S.W.; Son, S.J. Buried Tunnel Contact Junctions in GaN-Based Light-Emitting Diodes. Phys. Status Solidi A 2001, 188, 167–170. [Google Scholar] [CrossRef]

- Jeon, S.R.; Cho, M.S.; Yu, M.A.; Yang, G.M. GaN-Based Light-Emitting Diodes Using Tunnel Junctions. IEEE J. Sel. Top. Quantum Electron. 2002, 8, 739–743. [Google Scholar] [CrossRef]

- Lee, C.M.; Chuo, C.C.; Chen, I.L.; Chang, J.C.; Chyi, J.I. High-brightness inverted InGaN-GaN multiple-quantum-well light-emitting diodes without a transparent conductive layer. IEEE Electron Device Lett. 2003, 24, 156–158. [Google Scholar]

- Zhang, Z.H.; Tan, S.T.; Kyaw, Z.; Ji, Y.; Liu, W.; Ju, Z.G.; Hasanov, N.; Sun, X.W.; Demir, H.V. InGaN/GaN light-emitting diode with a polarization tunnel junction. Appl. Phys. Lett. 2013, 102, 193508. [Google Scholar] [CrossRef] [Green Version]

- Li, L.P.; Zhang, Y.H.; Tian, K.K.; Chu, C.S.; Fang, M.Q.; Meng, R.L.; Shi, Q.; Zhang, Z.H.; Bi, W.G. Numerical Investigations on the n+-GaN/AlGaN/p+-GaN Tunnel Junction for III-Nitride UV Light-Emitting Diodes. Phys. Status Solidi A 2017, 214, 1700624. [Google Scholar] [CrossRef]

- Li, L.P.; Shi, Q.; Tian, K.K.; Chu, C.S.; Fang, M.Q.; Meng, R.L.; Zhang, Y.H.; Zhang, Z.H.; Bi, W.G. A dielectric-constant-controlled tunnel junction for III-nitride light-emitting diodes. Phys. Status Solidi A 2017, 214, 1600937. [Google Scholar] [CrossRef]

- Zhang, Y.W.; Krishnamoorthy, S.; Johnson, J.M.; Akyol, F.; Allerman, A.; Moseley, M.W.; Armstrong, A.; Hwang, J.; Rajan, S. Interband tunneling for hole injection in III-nitride ultraviolet emitters. Appl. Phys. Lett. 2015, 106, 141103. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.W.; Krishnamoorthy, S.; Akyol, F.; Allerman, A.A.; Moseley, M.W.; Armstrong, A.M.; Rajan, S. Design and demonstration of ultra-wide bandgap AlGaN tunnel junctions. Appl. Phys. Lett. 2016, 109, 121102. [Google Scholar] [CrossRef]

- Zhang, Y.W.; Jamal-Eddine, Z.; Akyol, F.; Bajaj, S.; Johnson, J.M.; Calderon, G.; Allerman, A.A.; Moseley, M.W.; Armstrong, A.M.; Hwang, J.; et al. Tunnel-injected sub 290 nm ultra-violet light emitting diodes with 2.8% external quantum efficiency. Appl. Phys. Lett. 2018, 112, 071107. [Google Scholar] [CrossRef]

- Pandey, A.; Gim, J.; Hovden, R.; Mi, Z. Electron overflow of AlGaN deep ultraviolet light emitting diodes. Appl. Phys. Lett. 2021, 118, 241109. [Google Scholar] [CrossRef]

- Ozden, I.; Makarona, E.; Nurmikko, A.V.; Takeuchi, T.; Krames, M. A dual-wavelength indium gallium nitride quantum well light emitting diode. Appl. Phys. Lett. 2001, 79, 2532–2534. [Google Scholar] [CrossRef]

- Grundmann, M.J.; Mishra, U.K. Multi-color light emitting diode using polarization-induced tunnel junctions. Phys. Status Solidi C 2007, 4, 2830–2833. [Google Scholar] [CrossRef]

- Malinverni, M.; Martin, D.; Grandjean, N. InGaN based micro light emitting diodes featuring a buried GaN tunnel junction. Appl. Phys. Lett. 2015, 107, 051107. [Google Scholar] [CrossRef]

- Okawara, S.; Aoki, Y.; Kuwabara, M.; Takagi, Y.; Maeda, J.; Yoshida, H. Nitride-based stacked laser diodes with a tunnel junction. Appl. Phys. Express 2018, 11, 012701. [Google Scholar] [CrossRef]

- Fiorentini, V.; Bernardini, F.; Ambacher, O. Evidence for nonlinear macroscopic polarization in III–V nitride alloy heterostructures. Appl. Phys. Lett. 2002, 80, 1204. [Google Scholar] [CrossRef]

- Meneghini, M.; Trivellin, N.; Meneghesso, G.; Zanoni, E.; Zehnder, U.; Hahn, B. A combined electro-optical method for the determination of the recombination parameters in InGaN-based light-emitting diodes. J. Appl. Phys. 2009, 106, 114508. [Google Scholar] [CrossRef]

- Laubsch, A.; Sabathil, M.; Bergbauer, W.; Strassburg, M.; Lugauer, H.; Peter, M.; Lutgen, S.; Linder, N.; Streubel, K.; Hader, J.; et al. On the origin of IQE-‘droop’ in InGaN LEDs. Phys. Status Solidi C 2009, 6, S913–S916. [Google Scholar] [CrossRef]

- Piprek, J.; Li, S. Electron leakage effects on GaN-based light-emitting diodes. Opt. Quantum Electron. 2011, 42, 89–95. [Google Scholar] [CrossRef]

- Zhang, L.; Ding, K.; Liu, N.X.; Wei, T.B.; Ji, X.L.; Ma, P.; Yan, J.C.; Wang, J.X.; Zeng, Y.P.; Li, J.M. Theoretical study of polarization-doped GaN-based light-emitting diodes. Appl. Phys. Lett. 2011, 98, 101110. [Google Scholar] [CrossRef]

- Piprek, J. Efficiency droop in nitride-based light-emitting diodes. Phys. Status Solidi A 2010, 207, 2217–2225. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Liu, W.; Tan, S.T.; Ji, Y.; Wang, L.C.; Zhu, B.B.; Zhang, Y.P.; Lu, S.P.; Zhang, X.L.; Hasanov, N.; et al. A hole accelerator for InGaN/GaN light-emitting diodes. Appl, Phys. Lett. 2014, 105, 153503. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.H.; Zhang, Y.H.; Bi, W.G.; Geng, C.; Xu, S.; Demir, H.V.; Sun, X.W. A charge inverter for III-nitride light-emitting diodes. Appl. Phys. Lett. 2016, 108, 133502. [Google Scholar] [CrossRef] [Green Version]

- Suzuki, M.; Uenoyama, T.; Yanase, A. First-principles calculations of effective-mass parameters of AlN and GaN. Phys. Rev. B 1995, 52, 8132–8139. [Google Scholar] [CrossRef]

- Vurgaftman, I.; Meyer, J.R. Band parameters for nitrogen-containing semiconductors. J. Appl. Phys. 2003, 94, 3675–3696. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Zhang, Z.; Guo, L.; Chen, Y.; Li, Y.; Qi, Z.; Ben, J.; Sun, X.; Li, D. Calculating the Effect of AlGaN Dielectric Layers in a Polarization Tunnel Junction on the Performance of AlGaN-Based Deep-Ultraviolet Light-Emitting Diodes. Nanomaterials 2021, 11, 3328. https://doi.org/10.3390/nano11123328

Wang Y, Zhang Z, Guo L, Chen Y, Li Y, Qi Z, Ben J, Sun X, Li D. Calculating the Effect of AlGaN Dielectric Layers in a Polarization Tunnel Junction on the Performance of AlGaN-Based Deep-Ultraviolet Light-Emitting Diodes. Nanomaterials. 2021; 11(12):3328. https://doi.org/10.3390/nano11123328

Chicago/Turabian StyleWang, Yong, Zihui Zhang, Long Guo, Yuxuan Chen, Yahui Li, Zhanbin Qi, Jianwei Ben, Xiaojuan Sun, and Dabing Li. 2021. "Calculating the Effect of AlGaN Dielectric Layers in a Polarization Tunnel Junction on the Performance of AlGaN-Based Deep-Ultraviolet Light-Emitting Diodes" Nanomaterials 11, no. 12: 3328. https://doi.org/10.3390/nano11123328

APA StyleWang, Y., Zhang, Z., Guo, L., Chen, Y., Li, Y., Qi, Z., Ben, J., Sun, X., & Li, D. (2021). Calculating the Effect of AlGaN Dielectric Layers in a Polarization Tunnel Junction on the Performance of AlGaN-Based Deep-Ultraviolet Light-Emitting Diodes. Nanomaterials, 11(12), 3328. https://doi.org/10.3390/nano11123328