Numerical Study on Broadband Antireflection of Moth-Eye Nanostructured Polymer Film with Flexible Polyethylene Terephthalate Substrate

Abstract

:1. Introduction

2. Materials and Method

3. Result and Discussion

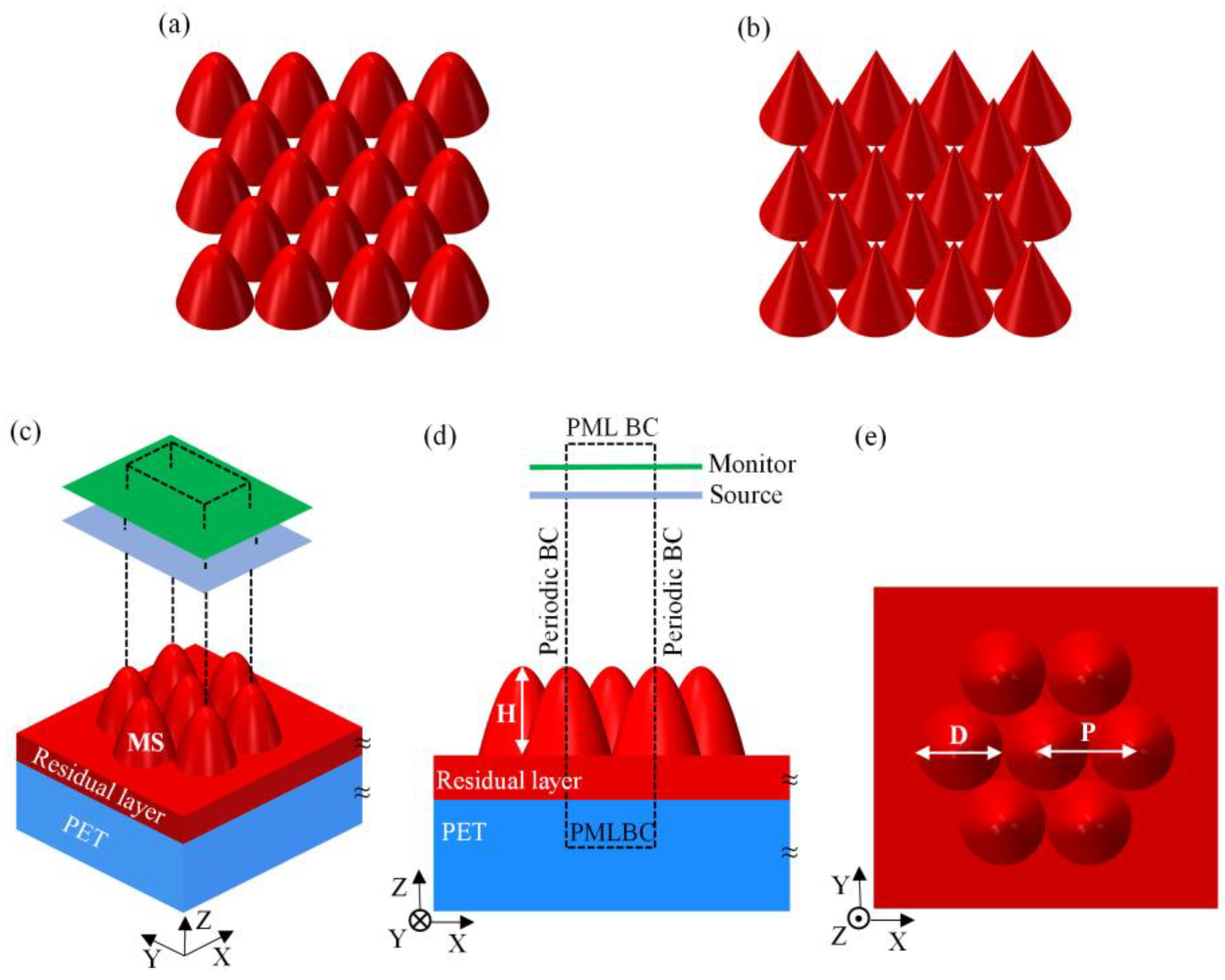

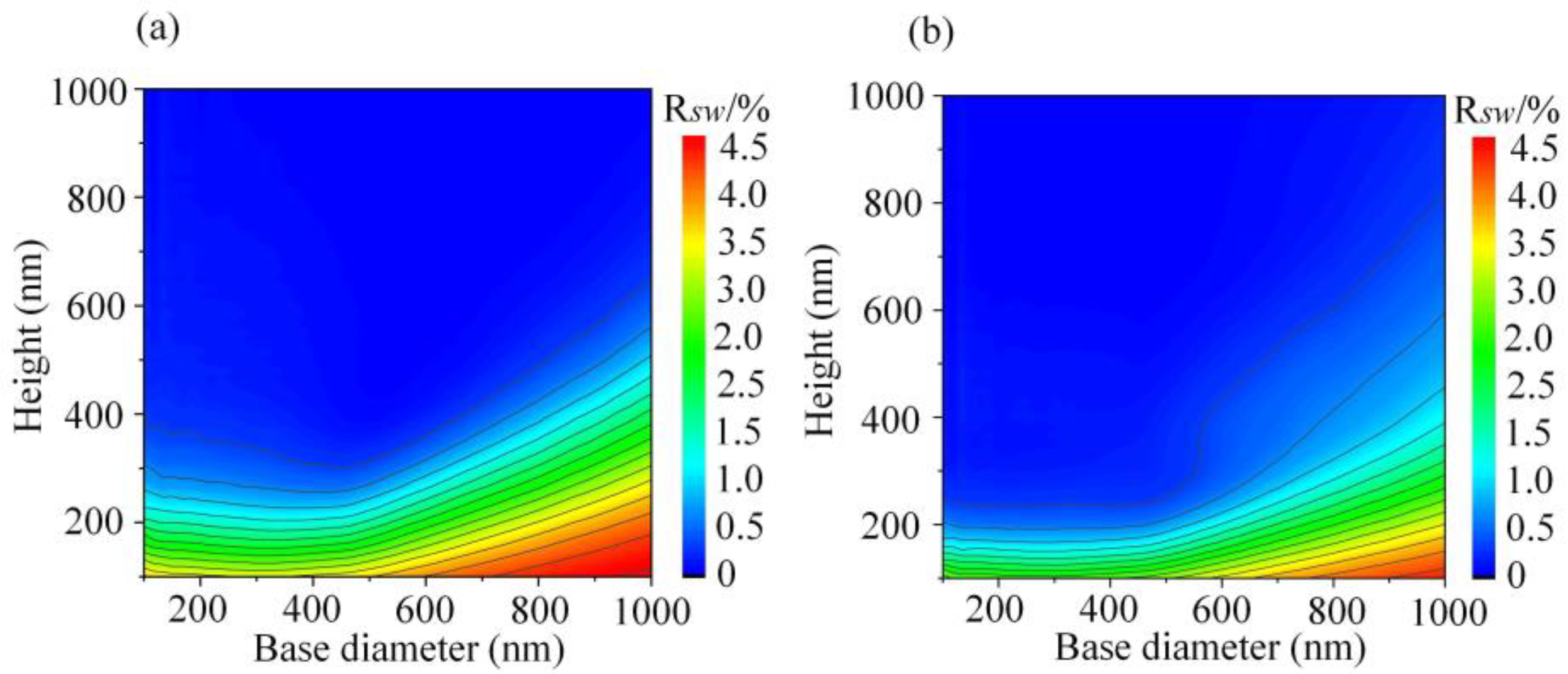

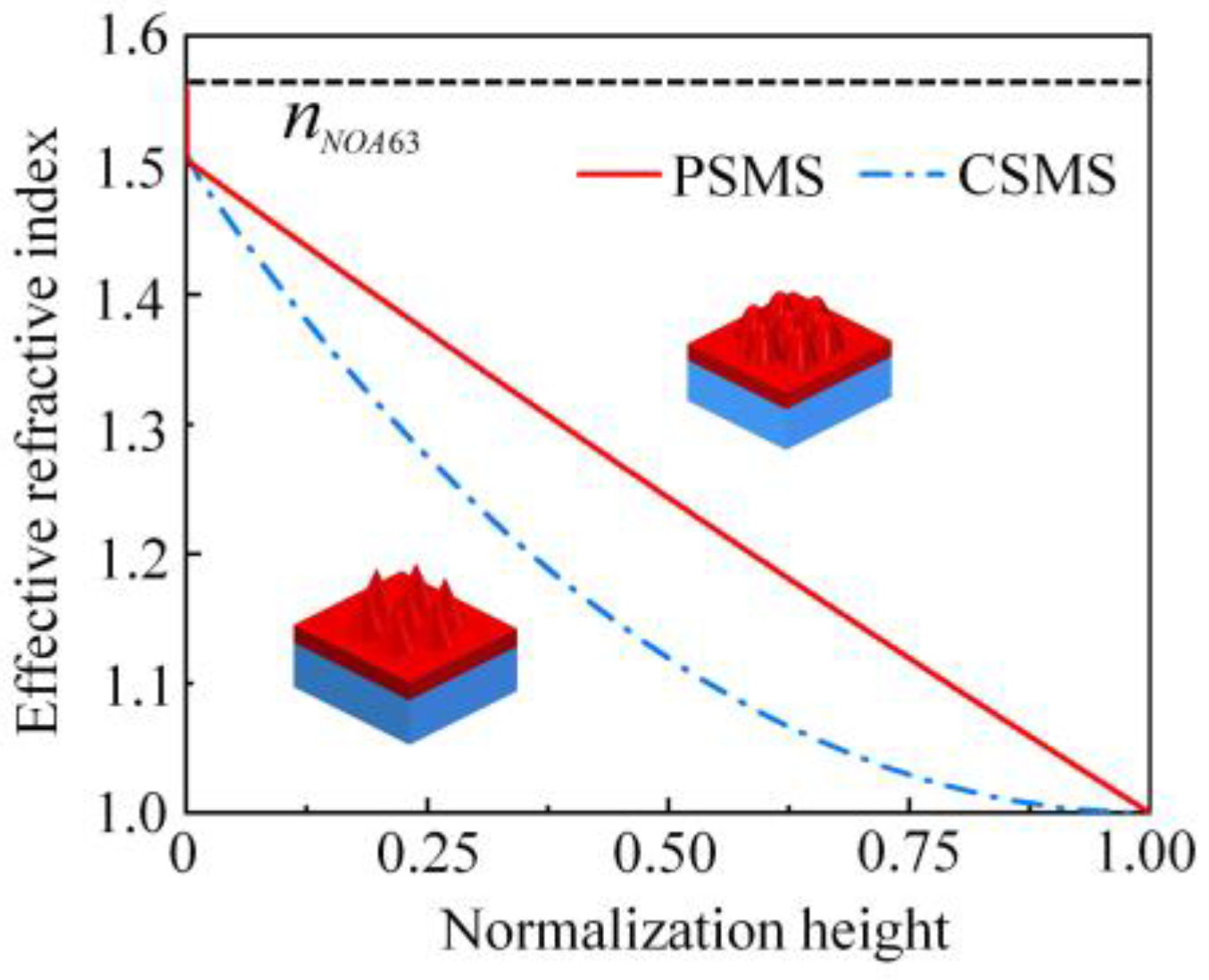

3.1. Shape Optimization of the Moth-Eye Structure Array

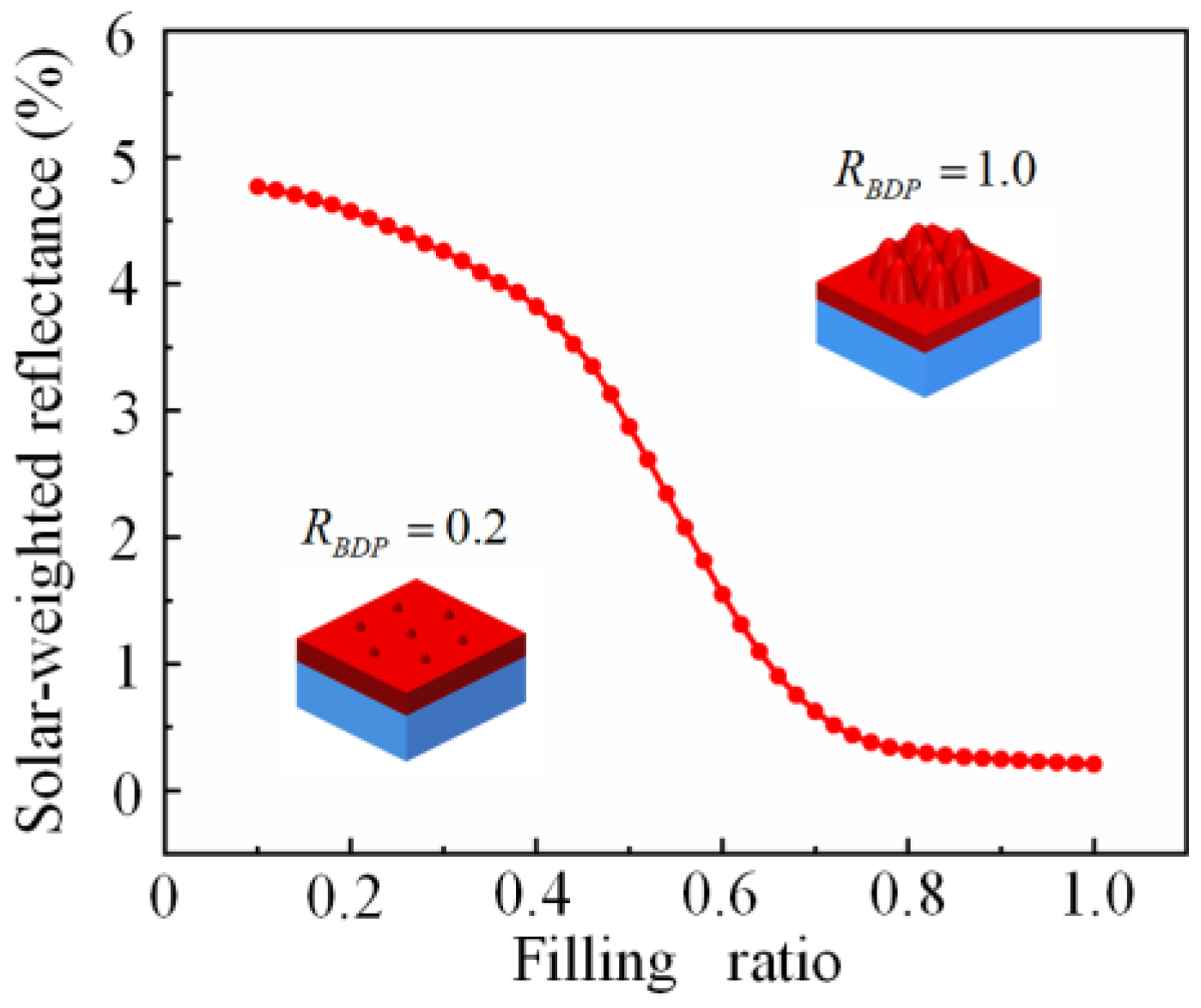

3.2. Parameter Optimization of NOA63 PSMS/PET

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fang, C.; Zhang, Z.J.; Zhuang, Y.; Liu, S.; He, X.; Zhang, Y. Biomimetic diodon-skin nanothorn polymer antireflection film for solar cell applications. Sol. Energy Mater. Sol. Cells 2020, 206, 110305. [Google Scholar] [CrossRef]

- Xu, Z.P.; Qiao, H.L.; Huangfu, H.C.; Li, X.W.; Guo, J.W.; Wang, H.Y. Optical absorption of several nanostructures arrays for silicon solar cells. Opt. Commun. 2015, 356, 526–529. [Google Scholar] [CrossRef]

- Tan, G.; Lee, J.H.; Lan, Y.H.; Wei, M.K.; Peng, L.H.; Cheng, I.C.; Wu, S.T. Broadband antireflection film with moth-eye-like structure for flexible display applications. Optica 2017, 4, 678–683. [Google Scholar] [CrossRef]

- Liu, W.; Wang, Y.; Guo, X.; Song, J.; Wang, X.; Yi, Y. Light Trapping in Single Elliptical Silicon Nanowires. Nanomaterials 2020, 10, 1740. [Google Scholar] [CrossRef] [PubMed]

- Ko, Y.H.; Yu, J.S. Highly transparent sapphire micro-grating structures with large diffuse light scattering. Opt. Express 2011, 19, 15574–15583. [Google Scholar] [CrossRef] [PubMed]

- Walheim, S.; Schaffer, E.; Mlynek, J.; Steiner, U. Nanophase-separated polymer films as high-performance antireflection coatings. Science 1999, 283, 520–522. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Haldar, A.; Reddy, M.S.; Vijaya, R. Enhancement of light collection through flexible polymeric films patterned using self-assembled photonic crystals. J. Phys. D Appl. Phys. 2015, 48, 265103. [Google Scholar] [CrossRef]

- Haldar, A.; Reddy, M.S.; Vijaya, R. Inexpensive graded-index antireflective surfaces for silicon-based optoelectronic devices. J. Opt. Soc. Am. B 2016, 33, 2331–2338. [Google Scholar] [CrossRef]

- Kuo, W.K.; Hsu, J.J.; Nien, C.K.; Yu, H.H. Moth-Eye-Inspired Biophotonic Surfaces with Antireflective and Hydrophobic Characteristics. ACS Appl. Mater. Interfaces 2016, 8, 32021–32030. [Google Scholar] [CrossRef]

- Dudem, B.; Jung, J.W.; Yu, J.S. Improved light harvesting efficiency of semitransparent organic solar cells enabled by broadband/omnidirectional subwavelength antireflective architectures. J. Mater. Chem. A 2018, 6, 14769–14779. [Google Scholar] [CrossRef]

- Yoon, J.; Jo, S.; Chun, I.S.; Jung, I.; Kim, H.S.; Meitl, M.; Menard, E.; Li, X.L.; Coleman, J.J.; Paik, U.; et al. GaAs photovoltaics and optoelectronics using releasable multilayer epitaxial assemblies. Nature 2010, 465, 329–333. [Google Scholar] [CrossRef] [PubMed]

- White, M.S.; Kaltenbrunner, M.; Glowacki, E.D.; Gutnichenko, K.; Kettlgruber, G.; Graz, I.; Aazou, S.; Ulbricht, C.; Egbe, D.A.M.; Miron, M.C.; et al. Ultrathin, highly flexible and stretchable PLEDs. Nat. Photonics 2013, 7, 811–816. [Google Scholar] [CrossRef]

- Stutzmann, N.; Friend, R.H.; Sirringhaus, H. Self-aligned, Vertical-Channel, Polymer Field-Effect Transistors. Science 2003, 299, 1881–1884. [Google Scholar] [CrossRef] [PubMed]

- Fan, F.R.; Tian, Z.Q.; Wang, Z.L. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Leem, J.W.; Choi, M.; Yu, J.S. Multifunctional Microstructured Polymer Films for Boosting Solar Power Generation of Silicon-Based Photovoltaic Modules. ACS Appl. Mater. Interfaces 2015, 7, 2349–2358. [Google Scholar] [CrossRef]

- Lee, S.H.; Han, K.S.; Shin, J.H.; Hwang, S.Y.; Lee, H. Fabrication of highly transparent self-cleaning protection films for photovoltaic systems. Prog. Photovolt Res. Appl. 2012, 21, 1056–1062. [Google Scholar] [CrossRef]

- Chuang, C.H.; Lu, D.M.; Wang, P.H.; Lee, W.Y.; Shaikh, M.O. Antireflective polymer films via roll to roll UV nanoimprint lithography using an AAO mold. Microsyst. Technol. 2018, 24, 389–395. [Google Scholar] [CrossRef]

- Yang, L.M.; Pan, C.Y.; Lu, F.P.; Chang, C.W.; Feng, S.W.; Tu, L.W. Anti-reflection sub-wavelength structures design for InGaN-based solar cells performed by the finite-difference-time-domain (FDTD) simulation method. Opt. Laser Technol. 2015, 67, 72–77. [Google Scholar] [CrossRef]

- Song, Y.M.; Choi, H.J.; Yu, J.S.; Lee, Y.T. Design of highly transparent glasses with broadband antireflective subwavelength structures. Opt. Express 2010, 18, 13063–13071. [Google Scholar] [CrossRef] [PubMed]

- Han, Z.W.; Jiao, Z.B.; Niu, S.C.; Ren, L.Q. Ascendant bioinspired antireflective materials: Opportunities and challenges coexist. Prog. Mater. Sci. 2019, 103, 1–68. [Google Scholar] [CrossRef]

- Sun, J.Y.; Wang, X.B.; Wu, J.H.; Shen, J.J.; Cooper, M.A.; Zheng, X.T.; Liu, Y.; Yang, Z.G.; Wu, D. Biomimetic Moth-eye Nanofabrication: Enhanced Antireflection with Superior Self-cleaning Characteristic. Sci. Rep. 2018, 8, 5348. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Leem, J.W.; Guan, X.Y.; Choi, M.; Yu, J.S. Broadband and omnidirectional highly-transparent coverglasses coated with biomimetic moth-eye nanopatterned polymer films for solar photovoltaic system applications. Sol. Energy Mater. Sol. Cells 2015, 134, 45–53. [Google Scholar] [CrossRef]

- Stavenga, D.G.; Foletti, S.; Palasantzas, G.; Arikawa, K. Light on the moth-eye corneal nipple array of butterflies. Proc. R. Soc. B 2006, 273, 661–667. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Refractive Index. INFO—Refractive Index Database. Available online: https://refractiveindex.info/ (accessed on 18 June 2021).

- Myers, J.D.; Cao, W.; Cassidy, V.; Eom, S.H.; Zhou, R.; Yang, L.; You, W.; Xue, J. A universal optical approach to enhancing efficiency of organic-based photovoltaic devices. Energy Environ. Sci. 2012, 5, 6900–6904. [Google Scholar] [CrossRef]

- Kim, M.C.; Jang, S.; Choi, J.; Kang, S.M.; Choi, M. Moth-eye Structured Polydimethylsiloxane Films for High-Efficiency Perovskite Solar Cells. Nano-Micro Lett. 2019, 11, 1–10. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Leem, J.W.; Kim, S.; Lee, S.H.; Rogers, J.A.; Kim, E.; Yu, J.S. Efficiency Enhancement of Organic Solar Cells Using Hydrophobic Antireflective Inverted Moth-Eye Nanopatterned PDMS Films. Adv. Energy Mater. 2014, 4, 1301315. [Google Scholar] [CrossRef]

- Qarony, W.; Hossain, M.I.; Dewan, R.; Fischer, S.; Meyer-Rochow, V.B.; Salleo, A.; Knipp, D.; Tsang, Y.H. Approaching Perfect Light Incoupling in Perovskite and Silicon Thin Film Solar Cells by Moth Eye Surface Textures. Adv. Theory Simul. 2018, 1, 1800030. [Google Scholar] [CrossRef]

- Heo, S.Y.; Koh, J.K.; Kang, G.; Ahn, S.H.; Chi, W.S.; Kim, K.; Kim, J.H. Bifunctional Moth-Eye Nanopatterned Dye-Sensitized Solar Cells: Light-Harvesting and Self-Cleaning Effects. Adv. Energy Mater. 2013, 4, 1300632. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lan, J.; Yang, Y.; Hu, S. Numerical Study on Broadband Antireflection of Moth-Eye Nanostructured Polymer Film with Flexible Polyethylene Terephthalate Substrate. Nanomaterials 2021, 11, 3313. https://doi.org/10.3390/nano11123313

Lan J, Yang Y, Hu S. Numerical Study on Broadband Antireflection of Moth-Eye Nanostructured Polymer Film with Flexible Polyethylene Terephthalate Substrate. Nanomaterials. 2021; 11(12):3313. https://doi.org/10.3390/nano11123313

Chicago/Turabian StyleLan, Jun, Yong Yang, and Song Hu. 2021. "Numerical Study on Broadband Antireflection of Moth-Eye Nanostructured Polymer Film with Flexible Polyethylene Terephthalate Substrate" Nanomaterials 11, no. 12: 3313. https://doi.org/10.3390/nano11123313

APA StyleLan, J., Yang, Y., & Hu, S. (2021). Numerical Study on Broadband Antireflection of Moth-Eye Nanostructured Polymer Film with Flexible Polyethylene Terephthalate Substrate. Nanomaterials, 11(12), 3313. https://doi.org/10.3390/nano11123313