Long-Time Behavior of Surface Properties of Microstructures Fabricated by Multiphoton Lithography

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. Methods

2.2.1. Multiphoton Lithography

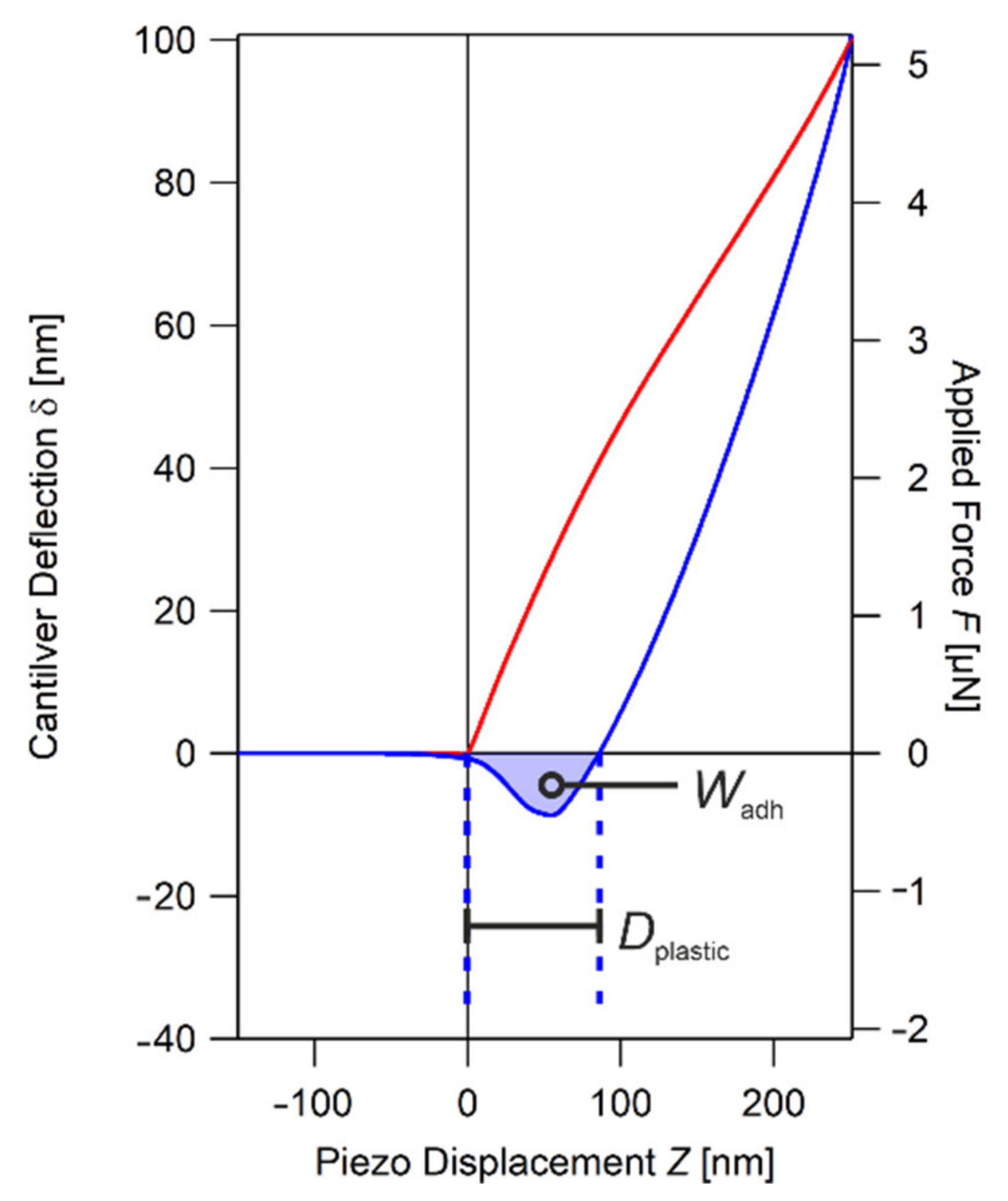

2.2.2. Force Distance Curves Atomic Force Microscopy

2.2.3. X-ray Photoelectron Spectroscopy

2.2.4. Scanning Electron Microscopy

3. Results and Discussion

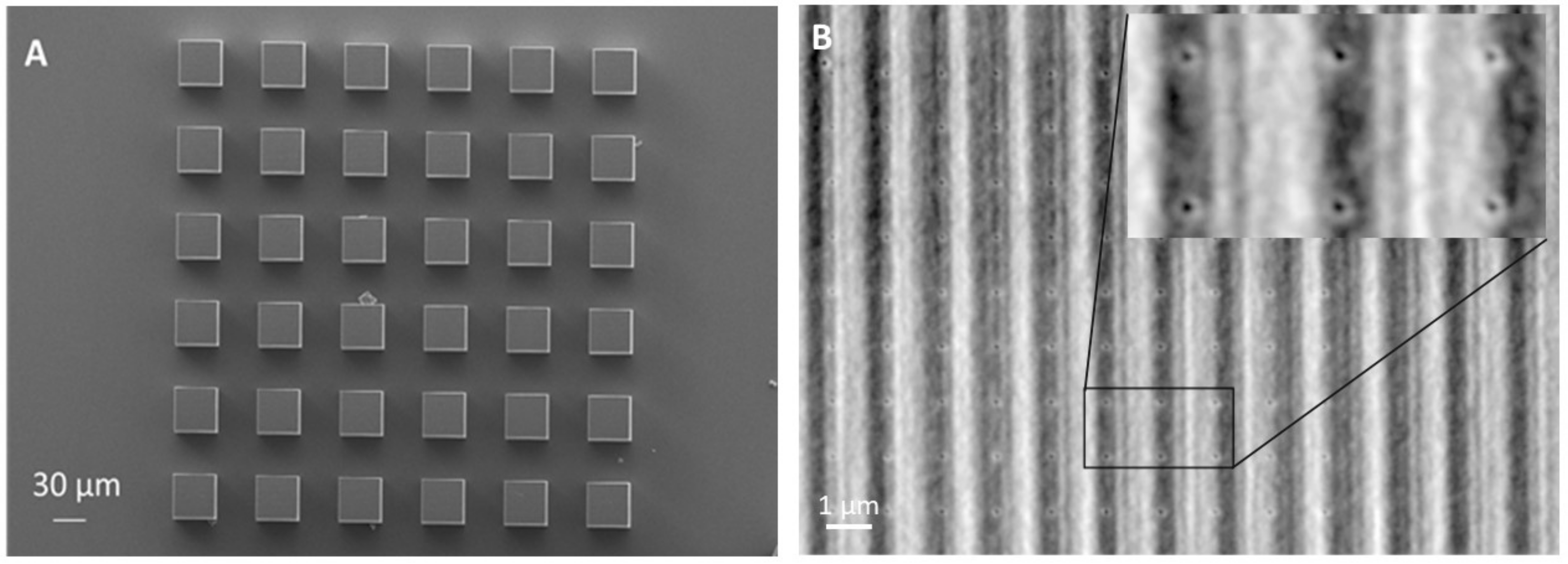

3.1. Topography of MPL Structures

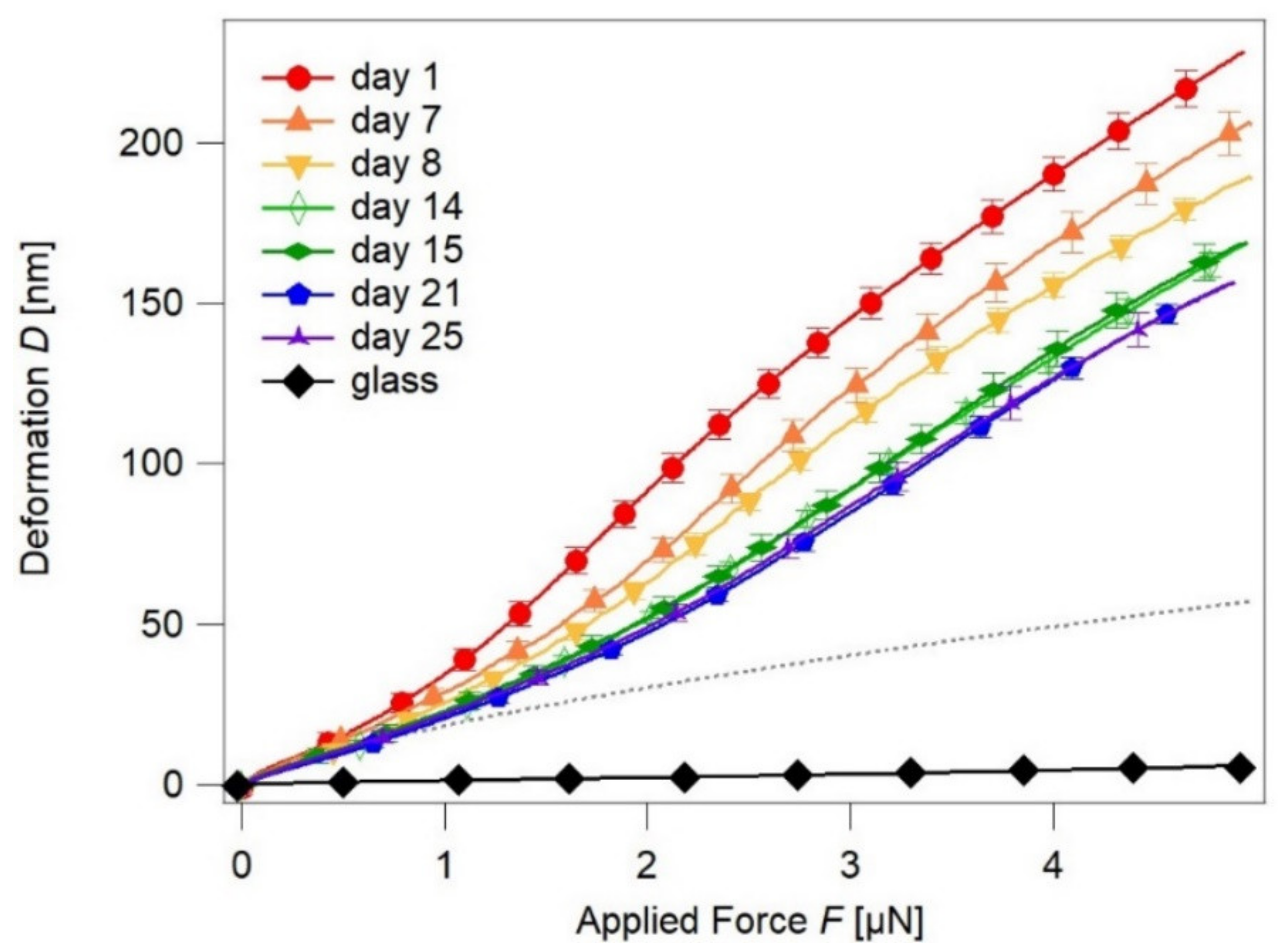

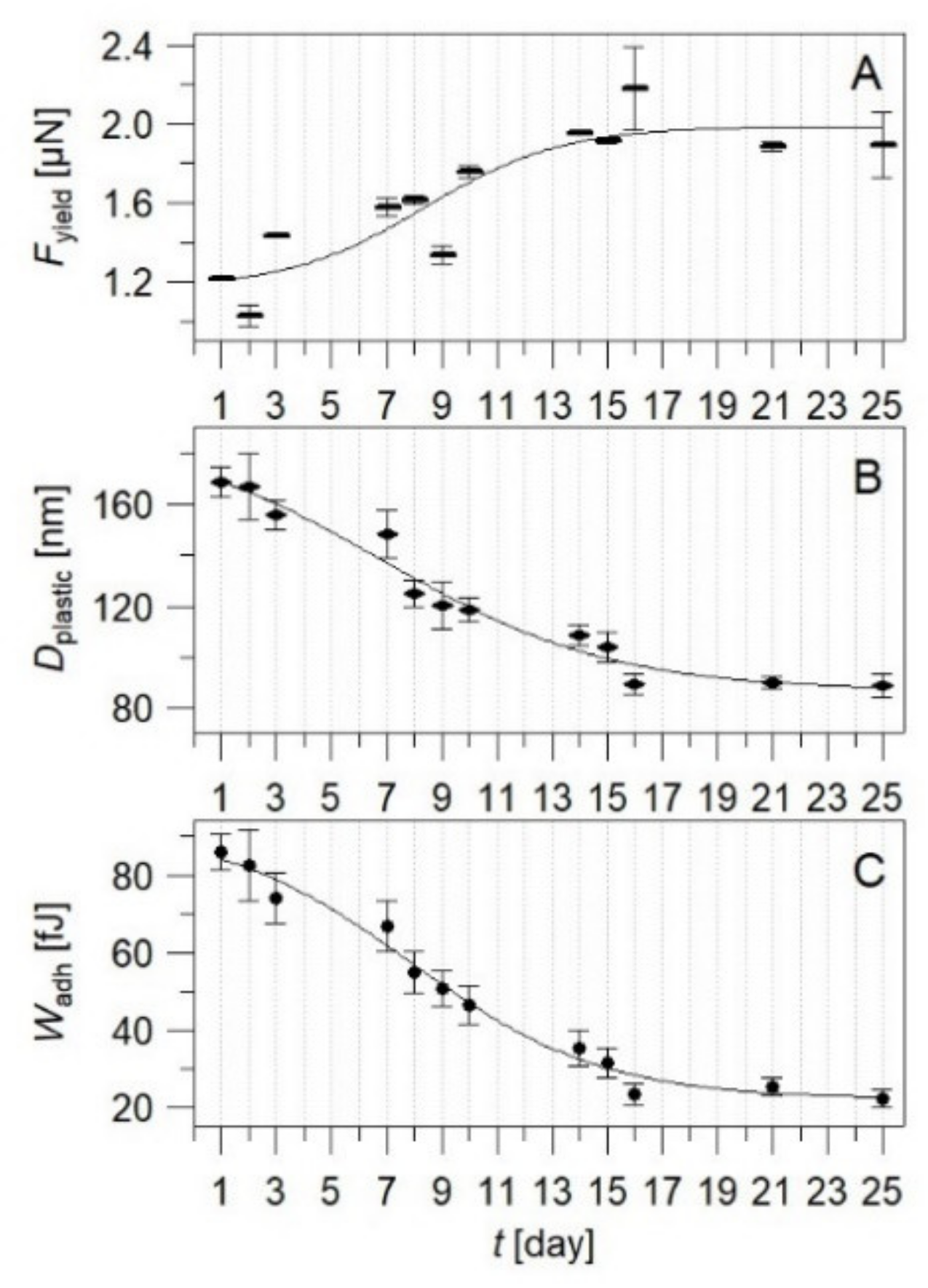

3.2. Mechanical Properties of the Surface

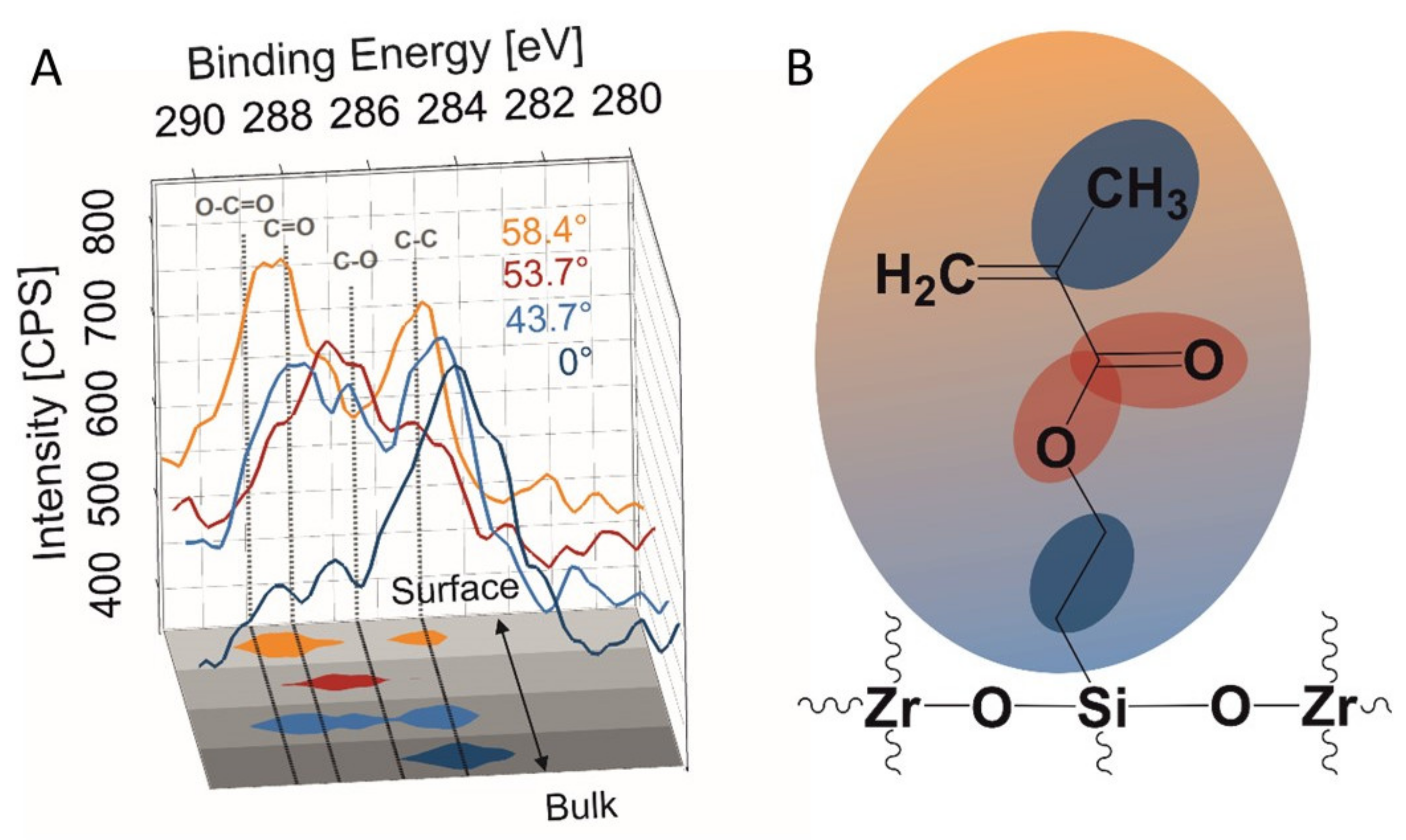

3.3. Chemical Composition of SZ2080 Surface

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Beedasy, V.; Smith, P.J. Printed Electronics as Prepared by Inkjet Printing. Materials 2020, 13, 704. [Google Scholar] [CrossRef] [Green Version]

- Guo, Y.; Patanwala, H.S.; Bognet, B.; Ma, A.W.K. Inkjet and inkjet-based 3D printing: Connecting fluid properties and printing performance. Rapid Prototyp. J. 2017, 23, 562–576. [Google Scholar] [CrossRef]

- Bagheri, A.; Jin, J.Y. Photopolymerization in 3D Printing. ACS Appl. Polym. Mater. 2019, 1, 593–611. [Google Scholar] [CrossRef] [Green Version]

- Calvert, P. Inkjet printing for materials and devices. Chem. Mater. 2001, 13, 3299–3305. [Google Scholar] [CrossRef]

- Minemawari, H.; Yamada, T.; Matsui, H.; Tsutsumi, J.; Haas, S.; Chiba, R.; Kumai, R.; Hasegawa, T. Inkjet printing of single-crystal films. Nature 2011, 475, 364–367. [Google Scholar] [CrossRef]

- Cummins, G.; Desmulliez, M.P.Y. Inkjet printing of conductive materials: A review. Circuit World 2012, 38, 193–213. [Google Scholar] [CrossRef]

- Tiller, B.; Reid, A.; Zhu, B.T.; Guerreiro, J.; Domingo-Roca, R.; Jackson, J.C.; Windmill, J.F.C. Piezoelectric microphone via a digital light processing 3D printing process. Mater. Des. 2019, 165, 107593. [Google Scholar] [CrossRef]

- Lee, J.W.; Nahm, S.; Hwang, K.T.; Kim, J.H.; Kim, U.S.; Han, K.S. Synthesis and Characterization of Silica Composite for Digital Light Processing. Korean J. Mater. Res. 2019, 29, 23–29. [Google Scholar] [CrossRef]

- Fang, F.H.; Aabith, S.; Homer-Vanniasinkam, S.; Tiwari, M.K. High-resolution 3D printing for healthcare underpinned by small-scale fluidics. In 3D Printing in Medicine; Woodhead Publishing: Cambridge, UK, 2017; pp. 167–206. [Google Scholar] [CrossRef]

- Malinauskas, M.; Zukauskas, A.; Hasegawa, S.; Hayasaki, Y.; Mizeikis, V.; Buividas, R.; Juodkazis, S. Ultrafast laser processing of materials: From science to industry. Light. Sci. Appl. 2016, 5, e16133. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Juodkazis, S.; Mizeikis, V.; Seet, K.K.; Miwa, M.; Misawa, H. Two-photon lithography of nanorods in SU-8 photoresist. Nanotechnology 2005, 16, 846–849. [Google Scholar] [CrossRef]

- Park, S.H.; Yang, D.Y.; Lee, K.S. Two-photon stereolithography for realizing ultraprecise three-dimensional nano/microdevices. Laser Photonics Rev. 2009, 3, 1–11. [Google Scholar] [CrossRef]

- Li, L.J.; Fourkas, J.T. Multiphoton polymerization. Mater. Today 2007, 10, 30–37. [Google Scholar] [CrossRef]

- Maruo, S.; Nakamura, O.; Kawata, S. Three-dimensional microfabrication with two-photon-absorbed photopolymerization. Opt. Lett. 1997, 22, 132–134. [Google Scholar] [CrossRef] [Green Version]

- Wollhofen, R.; Katzmann, J.; Hrelescu, C.; Jacak, J.; Klar, T.A. 120 nm resolution and 55 nm structure size in STED-lithography. Opt. Express 2013, 21, 10831–10840. [Google Scholar] [CrossRef]

- Stankevicius, E.; Malinauskas, M.; Gedvilas, M.; Voisiat, B.; Raciukaitis, G. Fabrication of Periodic Micro-Structures by Multi-Photon Polymerization Using the Femtosecond Laser and Four-Beam Interference. Mater. Sci. 2011, 17, 244–248. [Google Scholar] [CrossRef] [Green Version]

- Klein, S.; Barsella, A.; Leblond, H.; Bulou, H.; Fort, A.; Andraud, C.; Lemercier, G.; Mulatier, J.C.; Dorkenoo, K. One-step waveguide and optical circuit writing in photopolymerizable materials processed by two-photon absorption. Appl. Phys. Lett. 2005, 86, 211118. [Google Scholar] [CrossRef]

- LaFratta, C.N.; Fourkas, J.T.; Baldacchini, T.; Farrer, R.A. Multiphoton fabrication. Angew. Chem. Int. Ed. 2007, 46, 6238–6258. [Google Scholar] [CrossRef]

- Pang, L.; Nakagawa, W.; Fainman, Y. Fabrication of two-dimensional photonic crystals with controlled defects by use of multiple exposures and direct write. Appl. Opt. 2003, 42, 5450–5456. [Google Scholar] [CrossRef] [PubMed]

- Guo, R.; Xiao, S.Z.; Zhai, X.M.; Li, J.W.; Xia, A.D.; Huang, W.H. Micro lens fabrication by means of femtosecond two photon photopolymerization. Opt. Express 2006, 14, 810–816. [Google Scholar] [CrossRef] [PubMed]

- Jasinski, F.; Zetterlund, P.B.; Braun, A.M.; Cherntob, A. Photopolymerization in dispersed systems. Prog. Polym. Sci. 2018, 84, 47–88. [Google Scholar] [CrossRef] [Green Version]

- Husar, B.; Ligon, S.C.; Wutzel, H.; Hoffmann, H.; Liska, R. The formulator’s guide to anti-oxygen inhibition additives. Prog. Org. Coat. 2014, 77, 1789–1798. [Google Scholar] [CrossRef]

- Gorsche, C.; Griesser, M.; Gescheidt, G.; Moszner, N.; Liska, R. beta-Allyl Sulfones as Addition-Fragmentation Chain Transfer Reagents: A Tool for Adjusting Thermal and Mechanical Properties of Dimethacrylate Networks. Macromolecules 2014, 47, 7327–7336. [Google Scholar] [CrossRef]

- Gorsche, C.; Koch, T.; Moszner, N.; Liska, R. Exploring the benefits of beta-allyl sulfones for more homogeneous dimethacrylate photopolymer networks. Polym. Chem. 2015, 6, 2038–2047. [Google Scholar] [CrossRef]

- Al Mousawi, A.; Dumur, F.; Garra, P.; Toufaily, J.; Hamieh, T.; Goubard, F.; Bui, T.T.; Graff, B.; Gigmes, D.; Fouassier, J.P.; et al. Azahelicenes as Visible Light Photoinitiators for Cationic and Radical Polymerization: Preparation of Photoluminescent Polymers and Use in High Performance LED Projector 3D Printing Resins. J. Polym. Sci. Pol. Chem. 2017, 55, 1189–1199. [Google Scholar] [CrossRef]

- Greer, A.I.M.; Vasiev, I.; Della-Rosa, B.; Gadegaard, N. Fluorinated ethylene-propylene: A complementary alternative to PDMS for nanoimprint stamps. Nanotechnology 2016, 27, 155301. [Google Scholar] [CrossRef] [Green Version]

- Yu, T.Y.; Ober, C.K.; Kuebler, S.M.; Zhou, W.H.; Marder, S.R.; Perry, J.W. Chemically amplified positive resists for two-photon three-dimensional microfabrication. Adv. Mater. 2003, 15, 517–521. [Google Scholar] [CrossRef]

- Ovsianikov, A.; Muhleder, S.; Torgersen, J.; Li, Z.Q.; Qin, X.H.; Van Vlierberghe, S.; Dubruel, P.; Holnthoner, W.; Redl, H.; Liska, R.; et al. Laser Photofabrication of Cell-Containing Hydrogel Constructs. Langmuir 2014, 30, 3787–3794. [Google Scholar] [CrossRef] [PubMed]

- Koroleva, A.; Gill, A.A.; Ortega, I.; Haycock, J.W.; Schlie, S.; Gittard, S.D.; Chichkov, B.N.; Claeyssens, F. Two-photon polymerization-generated and micromolding-replicated 3D scaffolds for peripheral neural tissue engineering applications. Biofabrication 2012, 4, 025005. [Google Scholar] [CrossRef]

- Psycharakis, S.; Tosca, A.; Melissinaki, V.; Giakoumaki, A.; Ranella, A. Tailor-made three-dimensional hybrid scaffolds for cell cultures. Biomed. Mater. 2011, 6, 045008. [Google Scholar] [CrossRef]

- Malinauskas, M.; Zukauskas, A.; Bickauskaite, G.; Gadonas, R.; Juodkazis, S. Mechanisms of three-dimensional structuring of photo-polymers by tightly focussed femtosecond laser pulses. Opt. Express 2010, 18, 10209–10221. [Google Scholar] [CrossRef]

- Ovsianikov, A.; Viertl, J.; Chichkov, B.; Oubaha, M.; MacCraith, B.; Sakellari, I.; Giakoumaki, A.; Gray, D.; Vamvakaki, M.; Farsari, M.; et al. Ultra-Low Shrinkage Hybrid Photosensitive Material for Two-Photon Polymerization Microfabrication. ACS Nano 2008, 2, 2257–2262. [Google Scholar] [CrossRef]

- Maciulaitis, J.; Deveikyte, M.; Rekstyte, S.; Bratchikov, M.; Darinskas, A.; Simbelyte, A.; Daunoras, G.; Laurinaviciene, A.; Laurinavicius, A.; Gudas, R.; et al. Preclinical study of SZ2080 material 3D microstructured scaffolds for cartilage tissue engineering made by femtosecond direct laser writing lithography. Biofabrication 2015, 7, 015015. [Google Scholar] [CrossRef] [PubMed]

- Khorasani, M.G.Z.; Silbernagl, D.; Szymoniak, P.; Hodoroaba, V.D.; Sturm, H. The effect of boehmite nanoparticles (gamma-AlOOH) on nanomechanical and thermomechanical properties correlated to crosslinking density of epoxy. Polymer 2019, 164, 174–182. [Google Scholar] [CrossRef]

- Wurzler, N.; Sobol, O.; Altmann, K.; Radnik, J.; Ozcan, O. Preconditioning of AISI 304 stainless steel surfaces in the presence of flavins-Part I: Effect on surface chemistry and corrosion behavior. Mater. Corros. 2021, 72, 974–982. [Google Scholar] [CrossRef]

- Jedrzejczak-Silicka, M.; Trukawka, M.; Dudziak, M.; Piotrowska, K.; Mijowska, E. Hexagonal Boron Nitride Functionalized with Au Nanoparticles-Properties and Potential Biological Applications. Nanomaterials 2018, 8, 605. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Smales, G.J.; Pauw, B.R. The MOUSE project: A meticulous approach for obtaining traceable, wide-range X-ray scattering information. J. Instrum. 2021, 16, P06034. [Google Scholar] [CrossRef]

- Szymoniak, P.; Qu, X.T.; Abbasi, M.; Pauw, B.R.; Henning, S.; Li, Z.; Wang, D.Y.; Schick, C.; Saalwachter, K.; Schonhals, A. Spatial inhomogeneity, interfaces and complex vitrification kinetics in a network forming nanocomposite. Soft Matter 2021, 17, 2775–2790. [Google Scholar] [CrossRef] [PubMed]

- Cuenot, S.; Fretigny, C.; Demoustier-Champagne, S.; Nysten, B. Surface tension effect on the mechanical properties of nanomaterials measured by atomic force microscopy. Phys. Rev. B 2004, 69, 165410. [Google Scholar] [CrossRef] [Green Version]

- Bayindir, Z.; Sun, Y.; Naughton, M.J.; LaFratta, C.N.; Baldacchini, T.; Fourkas, J.T.; Stewart, J.; Saleh, B.E.A.; Teich, M.C. Polymer microcantilevers fabricated via multiphoton absorption polymerization. Appl. Phys. Lett. 2005, 86, 064105. [Google Scholar] [CrossRef] [Green Version]

- Belqat, M.; Wu, X.Y.; Gomez, L.P.C.; Malval, J.P.; Dominici, S.; Leuschel, B.; Spangenberg, A.; Mougin, K. Tuning nanomechanical properties of microstructures made by 3D direct laser writing. Addit. Manuf. 2021, 47, 102232. [Google Scholar] [CrossRef]

- Buchroithner, B.; Hartmann, D.; Mayr, S.; Oh, Y.J.; Sivun, D.; Karner, A.; Buchegger, B.; Griesser, T.; Hinterdorfer, P.; Klar, T.A.; et al. 3D multiphoton lithography using biocompatible polymers with specific mechanical properties. Nanoscale Adv. 2020, 2, 2422–2428. [Google Scholar] [CrossRef]

- Cappella, B.; Silbernagl, D. Nanomechanical properties of mechanical double-layers: A novel semiempirical analysis. Langmuir 2007, 23, 10779–10787. [Google Scholar] [CrossRef]

- Cappella, B.; Silbernagl, D. Nanomechanical properties of polymer thin films measured by force-distance curves. Thin Solid Films 2008, 516, 1952–1960. [Google Scholar] [CrossRef]

- Butt, H.J.; Cappella, B.; Kappl, M. Force measurements with the atomic force microscope: Technique, interpretation and applications. Surf. Sci. Rep. 2005, 59, 1–152. [Google Scholar] [CrossRef] [Green Version]

- Silbernagl, D.; Khorasani, M.G.Z.; Murillo, N.C.; Elert, A.M.; Sturm, H. Bulk chemical composition contrast from attractive forces in AFM force spectroscopy. Beilstein J. Nanotechnol. 2021, 12, 58–71. [Google Scholar] [CrossRef] [PubMed]

- Garcia, R. Nanomechanical mapping of soft materials with the atomic force microscope: Methods, theory and applications. Chem. Soc. Rev. 2020, 49, 5850–5884. [Google Scholar] [CrossRef]

- Pertoldi, L.; Zega, V.; Comi, C.; Osellame, R. Dynamic mechanical characterization of two-photon-polymerized SZ2080 photoresist. J. Appl. Phys. 2020, 128, 175102. [Google Scholar] [CrossRef]

- Oswald, S.; Bruckner, W. XPS depth profile analysis of non-stoichiometric NiO films. Surf. Interface Anal. 2004, 36, 17–22. [Google Scholar] [CrossRef]

| Post-Fabrication Period [Days] | Young’s Modulus E [GPa] |

|---|---|

| 1 | 0.775 ± 0.002 |

| 7 | 0.94 ± 0.04 |

| 8 | 1.05 ± 0.02 |

| 14 | 1.21 ± 0.006 |

| 15 | 1.24 ± 0.01 |

| 25 | 1.3 ± 0.1 |

| µ 50% | µ + σ 84.1% | µ + 2σ 97.7% | µ + 3σ 99.8% | |

|---|---|---|---|---|

| Fyield | 8.4 | 12.2 | 14 | 19.8 |

| Dplastic | 6.9 | 12.9 | 18.9 | 24.9 |

| Wadh | 7.9 | 13 | 18.1 | 23.2 |

| Functionality | C-C | C-O | C=O | O-C=O |

|---|---|---|---|---|

| Binding energy [eV] | 285.0 | 286.5 | 288.0 | 289.0 |

| Day 1 [%] | 83.6 | 1.6 | 6.7 | 8.1 |

| Day 25 [%] | 77.4 | 12.9 | 1.8 | 7.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dudziak, M.; Topolniak, I.; Silbernagl, D.; Altmann, K.; Sturm, H. Long-Time Behavior of Surface Properties of Microstructures Fabricated by Multiphoton Lithography. Nanomaterials 2021, 11, 3285. https://doi.org/10.3390/nano11123285

Dudziak M, Topolniak I, Silbernagl D, Altmann K, Sturm H. Long-Time Behavior of Surface Properties of Microstructures Fabricated by Multiphoton Lithography. Nanomaterials. 2021; 11(12):3285. https://doi.org/10.3390/nano11123285

Chicago/Turabian StyleDudziak, Mateusz, Ievgeniia Topolniak, Dorothee Silbernagl, Korinna Altmann, and Heinz Sturm. 2021. "Long-Time Behavior of Surface Properties of Microstructures Fabricated by Multiphoton Lithography" Nanomaterials 11, no. 12: 3285. https://doi.org/10.3390/nano11123285

APA StyleDudziak, M., Topolniak, I., Silbernagl, D., Altmann, K., & Sturm, H. (2021). Long-Time Behavior of Surface Properties of Microstructures Fabricated by Multiphoton Lithography. Nanomaterials, 11(12), 3285. https://doi.org/10.3390/nano11123285