Hydrophilic and Hydrophobic Nanostructured Copper Surfaces for Efficient Pool Boiling Heat Transfer with Water, Water/Butanol Mixtures and Novec 649

Abstract

:1. Introduction

1.1. Basics of Boiling Heat Transfer

1.2. Chemical Oxidation of Copper Surfaces and Their Structure

1.3. Surface Hydrophobization

1.4. Self-Rewetting Fluids

1.5. Boiling Heat Transfer with Dielectric Fluids

1.6. Motivation of This Work

2. Materials and Methods

2.1. Surface Functionalization and Evaluation

2.1.1. Type A Surfaces

2.1.2. Type B SurfacesFigure

2.1.3. Hydrophobization

2.1.4. Naming Convention

2.1.5. Evaluation of Surface Properties

2.2. Boiling Performance Evaluation

3. Results and Discussion

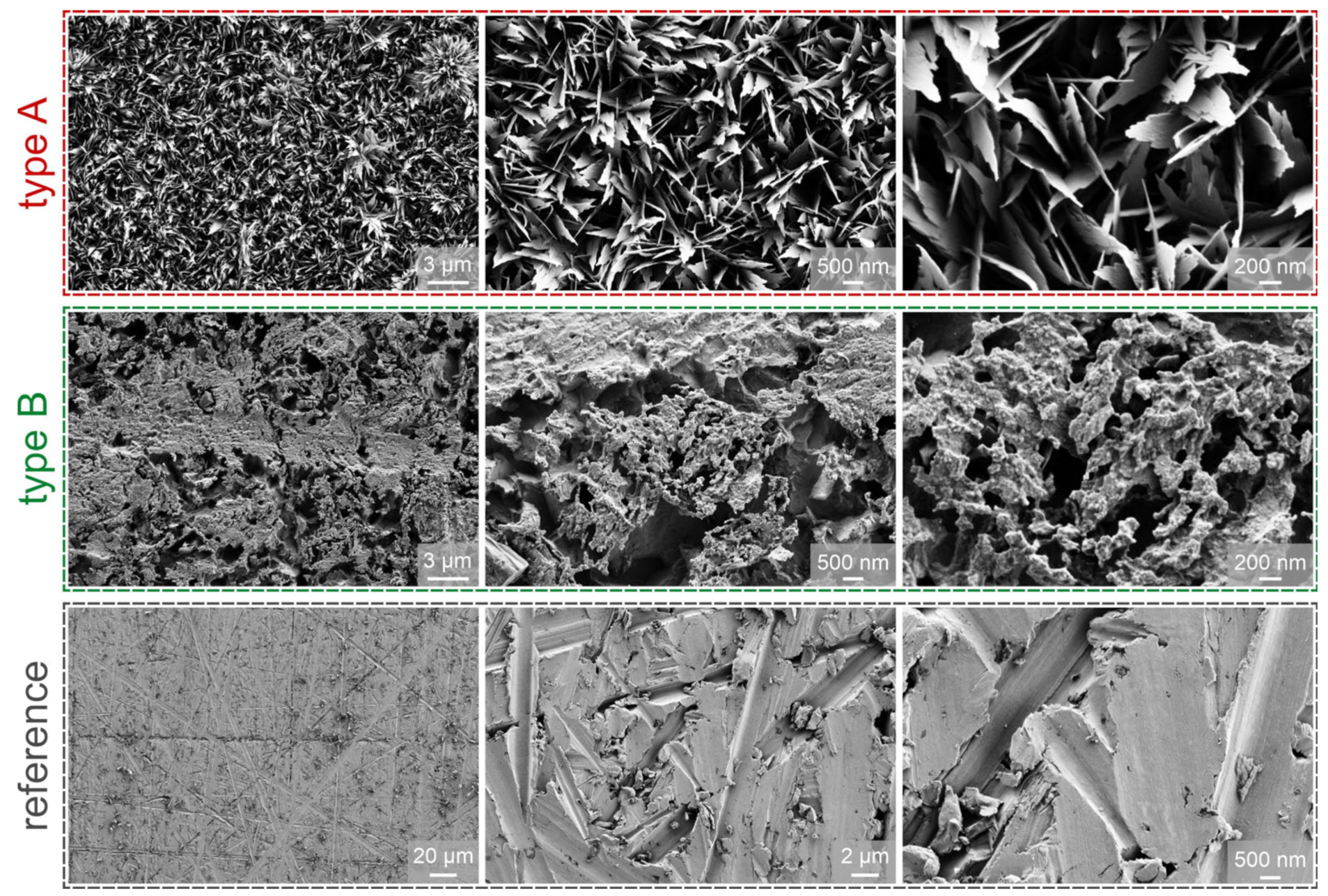

3.1. Functionalized Surfaces

3.1.1. Type A Surfaces

3.1.2. Type B Surfaces

3.1.3. Surface Wettability

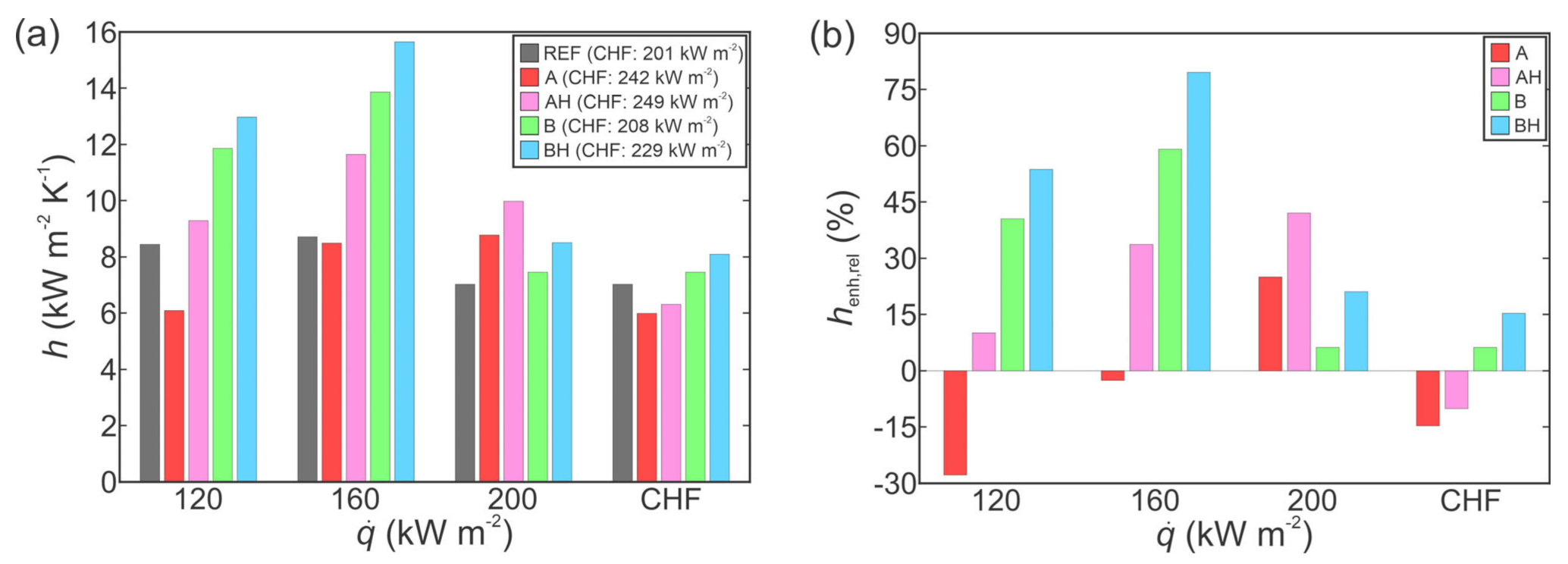

3.2. Boiling Heat Transfer with Water

3.2.1. Comparison of Boiling Curves and Heat Transfer Coefficients

3.2.2. Repeatability of Surface Functionalization and Surface Aging

3.3. Boiling Heat Transfer with Self-Rewetting Fluids

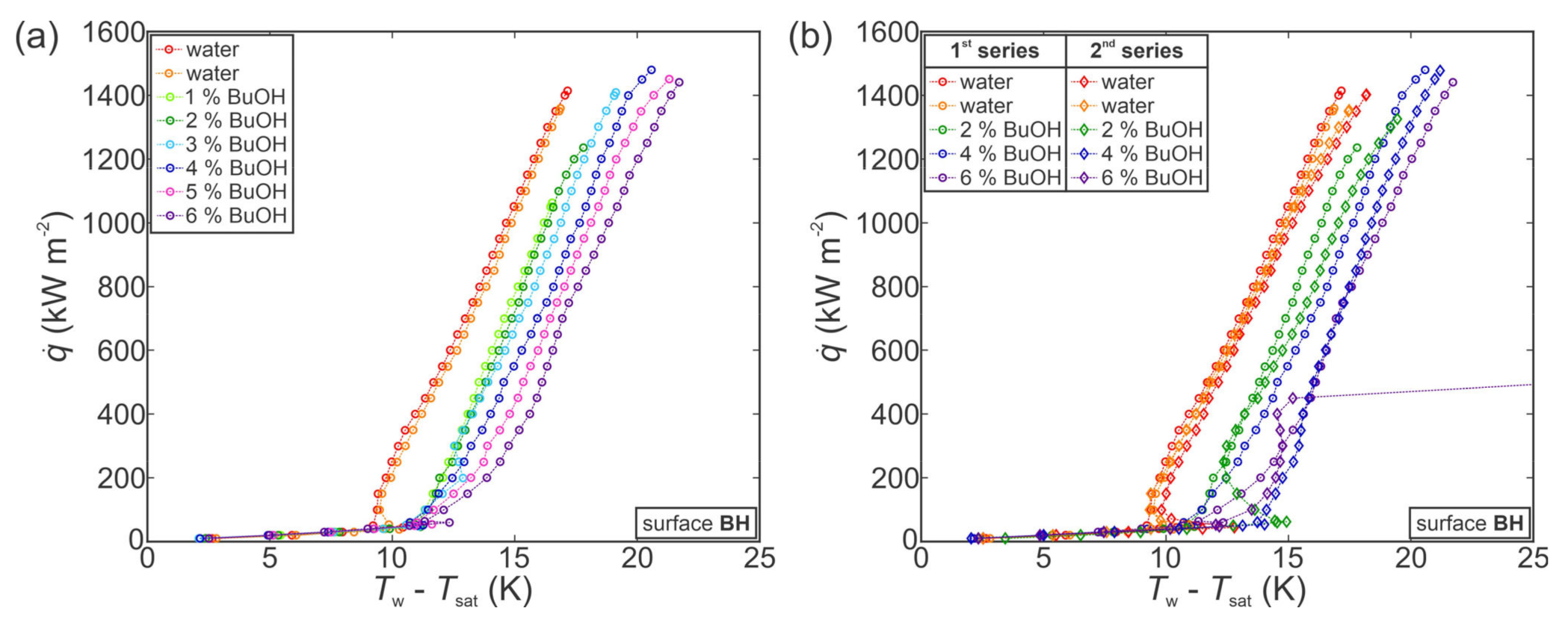

3.3.1. Effect of Butanol Concentration on Boiling Performance and Boiling Curve Shift

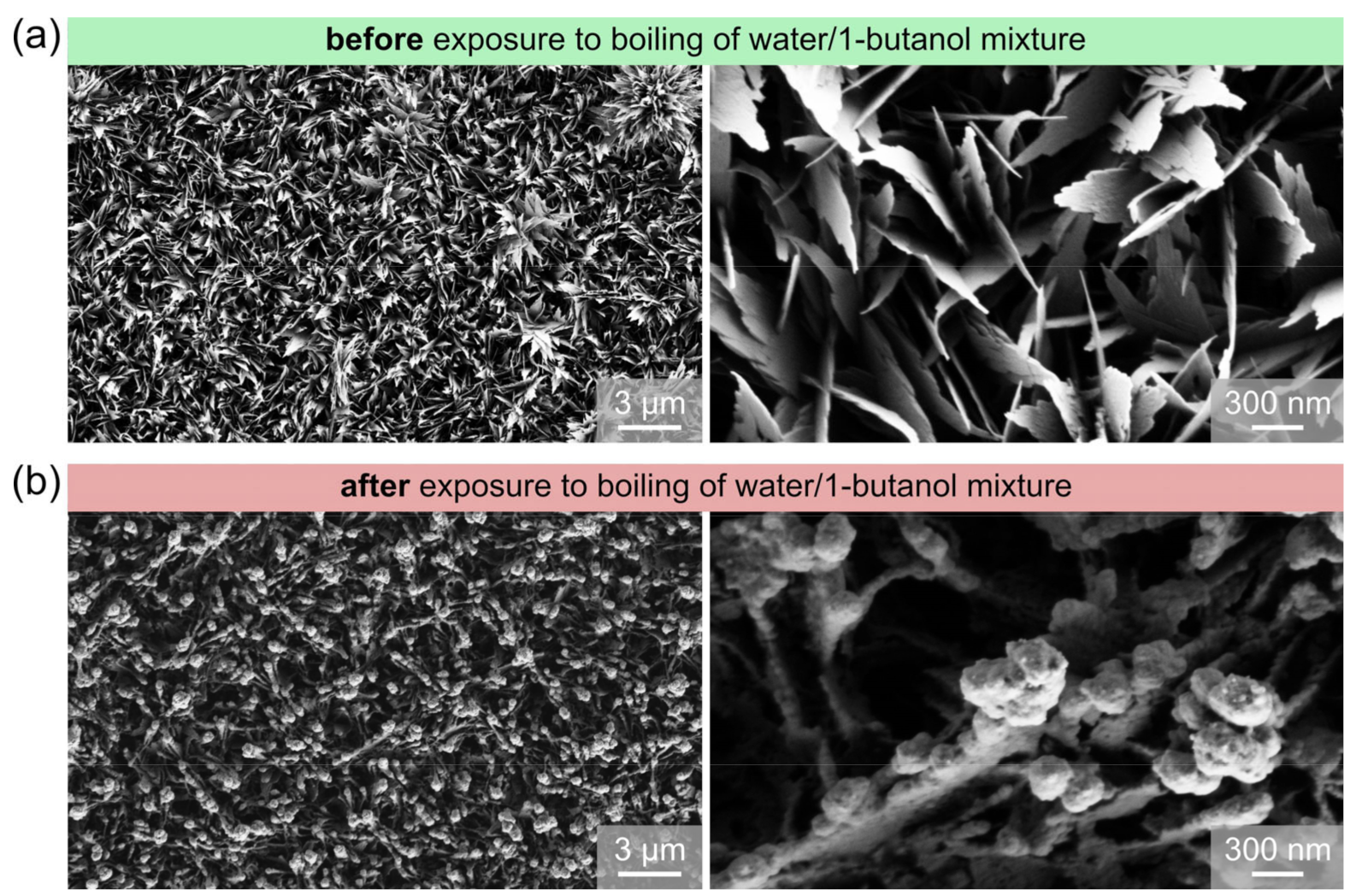

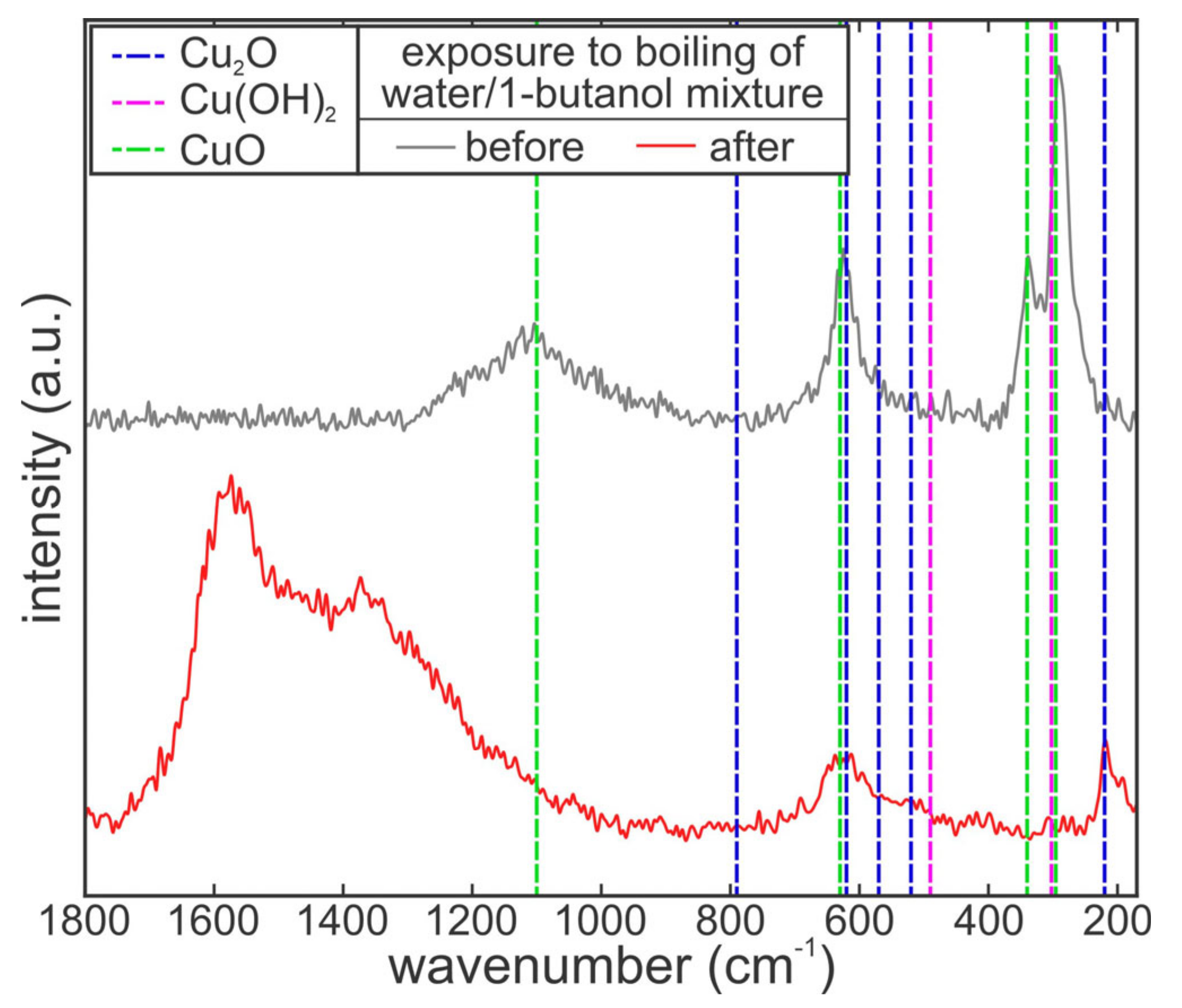

3.3.2. Surface Chemistry and Morphology Changes

3.4. Boiling Heat Transfer with Novec™ 649

4. Conclusions

- (1)

- Chemical oxidation combined with chemical vapor deposition (CVD) hydrophobization represents a facile way of functionalizing copper surfaces and inducing properties favorable for phase-change heat transfer enhancement.

- (2)

- Functionalized surfaces exhibited increased heat transfer coefficient (HTC) and critical heat flux (CHF) values in comparison with the untreated reference surface. HTCs of 83 kW m−2 K−1 and 13 kW m−2 K−1 were obtained using the hydrophobized surface BH with oxidation-induced microcavities with water and Novec™ 649, respectively. This represents and enhancement of 120% and 54% compared with the untreated surface operating at the same heat flux, respectively. The same functionalized surface increased the CHF value by 64% and 14% for water and Novec™ 649, respectively.

- (3)

- Surface fabrication repeatability was found to be favorable with only minor differences in performance between copies of the same surface. Surfaces were also shown to be stable in combination with boiling water but exhibited significant negative aging due to exposure to the boiling of Novec™ 649 in most cases.

- (4)

- Performance of self-rewetting fluids (SRFs) based on mixtures of water and 1-butanol at different concentrations boiling on functionalized copper surfaces was found to be unpredictable and problematic. Heat transfer performance was mostly degraded when SRFs were used instead of pure water. Furthermore, changes in surface morphology and in the chemical composition of the surface were detected.

- (5)

- The (hydrophobic) fluorinated silane coating at least temporarily protected the oxidized copper surfaces from chemical reactions with water/1-butanol mixtures or Novec™ 649.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lu, Y.-W.; Kandlikar, S.G. Nanoscale Surface Modification Techniques for Pool Boiling Enhancement—A Critical Review and Future Directions. Heat Transf. Eng. 2011, 32, 827–842. [Google Scholar] [CrossRef]

- Rioux, R.P.; Nolan, E.C.; Li, C.H. A systematic study of pool boiling heat transfer on structured porous surfaces: From nanoscale through microscale to macroscale. AIP Adv. 2014, 4, 117133. [Google Scholar] [CrossRef]

- Liang, G.; Mudawar, I. Review of pool boiling enhancement by surface modification. Int. J. Heat Mass Transf. 2019, 128, 892–933. [Google Scholar] [CrossRef]

- Liang, G.; Mudawar, I. Review of pool boiling enhancement with additives and nanofluids. Int. J. Heat Mass Transf. 2018, 124, 423–453. [Google Scholar] [CrossRef]

- Liang, G.; Mudawar, I. Review of nanoscale boiling enhancement techniques and proposed systematic testing strategy to ensure cooling reliability and repeatability. Appl. Therm. Eng. 2021, 184, 115982. [Google Scholar] [CrossRef]

- Mori, S.; Utaka, Y. Critical heat flux enhancement by surface modification in a saturated pool boiling: A review. Int. J. Heat Mass Transf. 2017, 108, 2534–2557. [Google Scholar] [CrossRef]

- Kim, D.E.; Yu, D.I.; Jerng, D.W.; Kim, M.H.; Ahn, H.S. Review of boiling heat transfer enhancement on micro/nanostructured surfaces. Exp. Therm. Fluid Sci. 2015, 66, 173–196. [Google Scholar] [CrossRef]

- Zhou, W.; Hu, X.; Mao, L.; He, Y. Markedly enhanced pool boiling heat transfer performance on maicropaorous copper surfaces fabricated utilizing a facile wire cutting process. Appl. Therm. Eng. 2020, 165, 114396. [Google Scholar] [CrossRef]

- Sankaran, A.; Zhang, W.; Yarin, A.L. Pool boiling in deep and shallow vessels and the effect of surface nano-texture and self-rewetting. Int. J. Heat Mass Transf. 2018, 127, 857–866. [Google Scholar] [CrossRef]

- Moghadasi, H.; Saffari, H. Experimental study of nucleate pool boiling heat transfer improvement utilizing micro/nanoparticles porous coating on copper surfaces. Int. J. Mech. Sci. 2021, 196, 106270. [Google Scholar] [CrossRef]

- Rishi, A.M.; Kandlikar, S.G.; Gupta, A. Salt templated and graphene nanoplatelets draped copper (GNP-draped-Cu) composites for dramatic improvements in pool boiling heat transfer. Sci. Rep. 2020, 10, 11941. [Google Scholar] [CrossRef] [PubMed]

- Shi, B.; Wang, Y.B.; Chen, K. Pool boiling heat transfer enhancement with copper nanowire arrays. Appl. Therm. Eng. 2015, 75, 115–121. [Google Scholar] [CrossRef]

- Chu, K.H.; Enright, R.; Wang, E.N. Structured surfaces for enhanced pool boiling heat transfer. Appl. Phys. Lett. 2012, 100, 241603. [Google Scholar] [CrossRef]

- Rahman, M.M.; Ölçeroğlu, E.; McCarthy, M. Role of wickability on the critical heat flux of structured superhydrophilic surfaces. Langmuir 2014, 30, 11225–11234. [Google Scholar] [CrossRef]

- Li, C.; Wang, Z.; Wang, P.I.; Peles, Y.; Koratkar, N.; Peterson, G.P. Nanostructured copper interfaces for enhanced boiling. Small 2008, 4, 1084–1088. [Google Scholar] [CrossRef]

- Zhang, F.; Jacobi, A.M. Aluminum surface wettability changes by pool boiling of nanofluids. Colloids Surf. A Physicochem. Eng. Asp. 2016, 506, 438–444. [Google Scholar] [CrossRef]

- Webb, R.L. The evolution of enhanced surface geometries for nucleate boiling. Heat Transf. Eng. 1981, 2, 46–69. [Google Scholar] [CrossRef]

- Nam, Y.; Ju, Y.S. A comparative study of the morphology and wetting characteristics of micro/nanostructured Cu surfaces for phase change heat transfer applications. J. Adhes. Sci. Technol. 2013, 27, 2163–2176. [Google Scholar] [CrossRef]

- Može, M. Effect of boiling-induced aging on pool boiling heat transfer performance of untreated and laser-textured copper surfaces. Appl. Therm. Eng. 2020, 181, 116025. [Google Scholar] [CrossRef]

- Nam, Y.; Sharratt, S.; Byon, C.; Kim, S.J.; Ju, Y.S. Fabrication and Characterization of the Capillary Performance of Superhydrophilic Cu Micropost Arrays. J. Microelectromech. Syst. 2010, 19, 581–588. [Google Scholar] [CrossRef]

- Chu, K.H.; Joung, Y.S.; Enright, R.; Buie, C.R.; Wang, E.N. Hierarchically structured surfaces for boiling critical heat flux enhancement. Appl. Phys. Lett. 2013, 102, 151602. [Google Scholar] [CrossRef] [Green Version]

- Enright, R.; Dou, N.; Miljkovic, N.; Nam, Y.; Wang, E.N. Condensation on Superhydrophobic Copper Oxide Nanostructures. In Proceedings of the ASME 2012 Third International Conference on Micro/Nanoscale Heat and Mass Transfer, Atlanta, GA, USA, 3–6 March 2012; American Society of Mechanical Engineers. pp. 419–425. [Google Scholar]

- Girard, A.R.; Kim, J.; You, S.M. Pool Boiling Heat Transfer of Water on Hydrophilic Surfaces With Different Wettability. In Heat Transfer and Thermal Engineering; ASME: Phoenix, AZ, USA, 2016; Volume 8, pp. 1–12. [Google Scholar]

- Kim, J.S.; Girard, A.; Jun, S.; Lee, J.; You, S.M. Effect of surface roughness on pool boiling heat transfer of water on hydrophobic surfaces. Int. J. Heat Mass Transf. 2018, 118, 802–811. [Google Scholar] [CrossRef]

- Liu, J.; Huang, X.; Li, Y.; Sulieman, K.M.; He, X.; Sun, F. Hierarchical nanostructures of cupric oxide on a copper substrate: Controllable morphology and wettability. J. Mater. Chem. 2006, 16, 4427–4434. [Google Scholar] [CrossRef]

- Wen, X.; Xie, Y.; Choi, C.L.; Wan, K.C.; Li, X.-Y.; Yang, S. Copper-Based Nanowire Materials: Templated Syntheses, Characterizations, and Applications. Langmuir 2005, 21, 4729–4737. [Google Scholar] [CrossRef]

- Chavan, S.; Park, D.; Singla, N.; Sokalski, P.; Boyina, K.; Miljkovic, N. Effect of Latent Heat Released by Freezing Droplets during Frost Wave Propagation. Langmuir 2018, 34, 6636–6644. [Google Scholar] [CrossRef]

- Bhavnani, S.; Narayanan, V.; Qu, W.; Jensen, M.; Kandlikar, S.; Kim, J.; Thome, J. Boiling augmentation with Micro/Nanostructured surfaces: Current status and research outlook. Nanoscale Microscale Thermophys. Eng. 2014, 18, 197–222. [Google Scholar] [CrossRef]

- Wu, F.; Ze, H.; Chen, S.; Gao, X. High-Efficiency Boiling Heat Transfer Interfaces Composed of Electroplated Copper Nanocone Cores and Low-Thermal-Conductivity Nickel Nanocone Coverings. ACS Appl. Mater. Interfaces 2020, 12, 39902–39909. [Google Scholar] [CrossRef] [PubMed]

- Ze, H.; Wu, F.; Chen, S.; Gao, X. Superhydrophilic Composite Structure of Copper Microcavities and Nanocones for Enhancing Boiling Heat Transfer. Adv. Mater. Interfaces 2020, 7, 2000482. [Google Scholar] [CrossRef]

- Dong, L.; Quan, X.; Cheng, P. An experimental investigation of enhanced pool boiling heat transfer from surfaces with micro/nano-structures. Int. J. Heat Mass Transf. 2014, 71, 189–196. [Google Scholar] [CrossRef]

- Zhou, W.; Luan, Y.; Dai, X.; Hu, X. Study on microbubble dynamic behaviors at vertical micro-nano hybrid surfaces based on open capillary microgrooves heat sink. Int. J. Therm. Sci. 2019, 135, 434–444. [Google Scholar] [CrossRef]

- Im, Y.; Dietz, C.; Lee, S.S.; Joshi, Y. Flower-like CuO nanostructures for enhanced boiling. Nanoscale Microscale Thermophys. Eng. 2012, 16, 145–153. [Google Scholar] [CrossRef]

- Chen, X.; Kong, L.; Dong, D.; Yang, G.; Yu, L.; Chen, J.; Zhang, P. Synthesis and characterization of superhydrophobic functionalized Cu(OH)2 nanotube arrays on copper foil. Appl. Surf. Sci. 2009, 255, 4015–4019. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, B.; Liu, Y.; Yang, Y.; Wei, J. Experimental study on pool boiling heat transfer enhancement with micro/nanostructured surfaces. Interfacial Phenom. Heat Transf. 2019, 7, 19–31. [Google Scholar] [CrossRef] [Green Version]

- Rahman, M.M.; McCarthy, M. Boiling Enhancement on Nanostructured Surfaces with Engineered Variations in Wettability and Thermal Conductivity. Heat Transf. Eng. 2017, 38, 1285–1295. [Google Scholar] [CrossRef]

- Gheitaghy, A.M.; Saffari, H.; Zhang, G.Q. Effect of Nanostructured Microporous Surfaces on Pool Boiling Augmentation. Heat Transf. Eng. 2019, 40, 762–771. [Google Scholar] [CrossRef]

- Malavasi, I.; Teodori, E.; Moita, A.S.; Moreira, A.L.N.; Marengo, M. Wettability Effect on Pool Boiling: A Review. In Encyclopedia of Two-Phase Heat Transfer and Flow III; World Scientific Pub. Co. Pte. Ltd.: Singapore, 2018; pp. 1–61. [Google Scholar]

- Phan, H.T.; Caney, N.; Marty, P.; Colasson, S.; Gavillet, J. Surface wettability control by nanocoating: The effects on pool boiling heat transfer and nucleation mechanism. Int. J. Heat Mass Transf. 2009, 52, 5459–5471. [Google Scholar] [CrossRef]

- Allred, T.P.; Weibel, J.A.; Garimella, S.V. The petal effect of parahydrophobic surfaces offers low receding contact angles that promote effective boiling. Int. J. Heat Mass Transf. 2019, 135, 403–412. [Google Scholar] [CrossRef]

- Može, M.; Senegačnik, M.; Gregorčič, P.; Hočevar, M.; Zupančič, M.; Golobič, I. Laser-Engineered Microcavity Surfaces with a Nanoscale Superhydrophobic Coating for Extreme Boiling Performance. ACS Appl. Mater. Interfaces 2020, 12, 24419–24431. [Google Scholar] [CrossRef]

- Allred, T.P.; Weibel, J.A.; Garimella, S.V. Enabling Highly Effective Boiling from Superhydrophobic Surfaces. Phys. Rev. Lett. 2018, 120, 174501. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Breedveld, V.; Hess, D.W. Creation of superhydrophobic stainless steel surfaces by acid treatments and hydrophobic film deposition. ACS Appl. Mater. Interfaces 2012, 4, 4549–4556. [Google Scholar] [CrossRef]

- Zakšek, P.; Zupančič, M.; Gregorčič, P.; Golobič, I. Investigation of Nucleate Pool Boiling of Saturated Pure Liquids and Ethanol-Water Mixtures on Smooth and Laser-Textured Surfaces. Nanoscale Microscale Thermophys. Eng. 2020, 24, 29–42. [Google Scholar] [CrossRef]

- Kandlikar, S.G. Boiling heat transfer with binary mixtures part I—A theoretical model for pool boiling. Am. Soc. Mech. Eng. Heat Transf. Div. HTD 1997, 342, 19–26. [Google Scholar] [CrossRef]

- Tzan, Y.L.; Yang, Y.M. Pool boiling of binary mixtures. Chem. Eng. Commun. 1988, 66, 71–82. [Google Scholar] [CrossRef]

- Fujita, Y.; Tsutsui, M. Heat transfer in nucleate pool boiling of binary mixtures. Int. J. Heat Mass Transf. 1994, 37, 291–302. [Google Scholar] [CrossRef]

- Thome, J.R. Prediction of binary mixture boiling heat transfer coefficients using only phase equilibrium data. Int. J. Heat Mass Transf. 1983, 26, 965–974. [Google Scholar] [CrossRef]

- Alavi Fazel, S.A.; Jamialahmadi, M. Semi-empirical modeling of pool boiling heat transfer in binary mixtures. Int. J. Heat Fluid Flow 2013, 44, 468–477. [Google Scholar] [CrossRef]

- Gupta, P.; Hayat, M.; Srivastava, R. A Review on Nucleate Pool Boiling Heat Transfer of Binary Mixtures. Asian J. Water Environ. Pollut. 2019, 16, 27–34. [Google Scholar] [CrossRef]

- Cai, C.; Liu, H.; Xi, X.; Jia, M.; Yin, H. Bubble growth model in uniformly superheated binary liquid mixture. Int. J. Heat Mass Transf. 2018, 127, 629–638. [Google Scholar] [CrossRef]

- Hu, Y.; Chen, S.; Huang, J.; Song, M. Marangoni effect on pool boiling heat transfer enhancement of self-rewetting fluid. Int. J. Heat Mass Transf. 2018, 127, 1263–1270. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, Z.; Du, X.; Yang, Y. Boiling characteristics of water and self-rewetting fluids in packed bed of spherical glass beads. Exp. Therm. Fluid Sci. 2015, 68, 537–544. [Google Scholar] [CrossRef]

- Sahu, R.P.; Sinha-Ray, S.; Sinha-Ray, S.; Yarin, A.L. Pool boiling of Novec 7300 and self-rewetting fluids on electrically-assisted supersonically solution-blown, copper-plated nanofibers. Int. J. Heat Mass Transf. 2016, 95, 83–93. [Google Scholar] [CrossRef]

- Abe, Y.; Savino, R. Self-Rewetting Fluids. In Boiling: Research and Advances; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Hu, Y.; Zhang, S.; Li, X.; Wang, S. Heat transfer enhancement of subcooled pool boiling with self-rewetting fluid. Int. J. Heat Mass Transf. 2015, 83, 64–68. [Google Scholar] [CrossRef]

- Ohta, H.; Sakai, T.; Yamaguchi, S.; Ito, Y.; Shinmoto, Y.; Abe, Y. Nucleate boiling of low-concentration alcohol aqueous solutions for the development of thermal management systems in space. Microgravity Sci. Technol. 2007, 19, 141–143. [Google Scholar] [CrossRef]

- Zupančič, M.; Zakšek, P.; Golobič, I. Experimental investigation of single-bubble growth during the saturated pool boiling of water and self-rewetting aqueous n-butanol mixtures. Case Stud. Therm. Eng. 2021, 28, 101513. [Google Scholar] [CrossRef]

- Hu, B.; Zhang, S.; Wang, D.; Chen, X.; Si, X.; Zhang, D. Experimental study of nucleate pool boiling heat transfer of self-rewetting solution by surface functionalization with TiO2 nanostructure. Can. J. Chem. Eng. 2019, 97, 1399–1406. [Google Scholar] [CrossRef]

- Zhou, L.; Li, W.; Ma, T.; Du, X. Experimental study on boiling heat transfer of a self-rewetting fluid on copper foams with pore-density gradient structures. Int. J. Heat Mass Transf. 2018, 124, 210–219. [Google Scholar] [CrossRef]

- Sajjad, U.; Sadeghianjahromi, A.; Ali, H.M.; Wang, C.C. Enhanced pool boiling of dielectric and highly wetting liquids—A review on enhancement mechanisms. Int. Commun. Heat Mass Transf. 2020, 119, 104950. [Google Scholar] [CrossRef]

- Leong, K.C.; Ho, J.Y.; Wong, K.K. A critical review of pool and flow boiling heat transfer of dielectric fluids on enhanced surfaces. Appl. Therm. Eng. 2017, 112, 999–1019. [Google Scholar] [CrossRef]

- Forrest, E.C.; Hu, L.-W.; Buongiorno, J.; McKrell, T. Pool Boiling Performance of Novec 649 Engineered Fluid. ECI Int. Conf. Boil. Heat Transf. Florianop. 2009, 1, 1–7. [Google Scholar]

- Forrest, E.C.; Hu, L.W.; Buongiorno, J.; McKrell, T.J. Pool boiling heat transfer performance of a dielectric fluid with low global warming potential. Heat Transf. Eng. 2013, 34, 1262–1277. [Google Scholar] [CrossRef]

- Kaniowski, R.; Pastuszko, R.; Nowakowski, L. Effect of geometrical parameters of open microchannel surfaces on pool boiling heat transfer. EPJ Web Conf. 2017, 143, 02049. [Google Scholar] [CrossRef] [Green Version]

- Kaniowski, R.; Pastuszko, R. Boiling of a refrigerant of low GWP on the surface with copper microchannels. E3S Web Conf. 2018, 70, 2–6. [Google Scholar] [CrossRef]

- Kaniowski, R.; Pastuszko, R. Pool boiling visualization of Novec-649 and FC-72 on copper microchannels. EPJ Web Conf. 2019, 213, 02037. [Google Scholar] [CrossRef]

- Pastuszko, R.; Kaniowski, R.; Dadas, N.; Bedla-Pawlusek, M. Pool boiling enhancement and a method of bubble diameter determination on surfaces with deep minichannels. Int. J. Heat Mass Transf. 2021, 179, 121713. [Google Scholar] [CrossRef]

- Ghaffari, O.; Grenier, F.; Morissette, J.-F.; Bolduc, M.; Jasmin, S.; Sylvestre, J. Pool Boiling Experiment of Dielectric Liquids and Numerical Study for Cooling a Microprocessor. In Proceedings of the 2019 18th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Las Vegas, NV, USA, 28–31 July 2019; pp. 540–545. [Google Scholar]

- Cao, Z.; Wu, Z.; Sundén, B. Pool Boiling of NOVEC-649 on Microparticle-Coated and Nanoparticle-Coated Surfaces. Heat Transf. Eng. 2020, 42, 1732–1747. [Google Scholar] [CrossRef]

- Cao, Z.; Wu, Z.; Sundén, B. Heat transfer prediction and critical heat flux mechanism for pool boiling of NOVEC-649 on microporous copper surfaces. Int. J. Heat Mass Transf. 2019, 141, 818–834. [Google Scholar] [CrossRef]

- Hsu, Y.T.; Li, J.X.; Lu, M.C. Enhanced immersion cooling using two-tier micro- and nano-structures. Appl. Therm. Eng. 2018, 131, 864–873. [Google Scholar] [CrossRef]

- Nam, Y.; Ju, Y.S. Comparative Study of Copper Oxidation Schemes and Their Effects on Surface Wettability. Am. Soc. Mech. Eng. 2016, 10, 1833–1838. [Google Scholar]

- Balamurugan, B.; Mehta, B.R.; Avasthi, D.K.; Singh, F.; Arora, A.K.; Rajalakshmi, M.; Raghavan, G.; Tyagi, A.K.; Shivaprasad, S.M. Modifying the nanocrystalline characteristics—Structure, size, and surface states of copper oxide thin films by high-energy heavy-ion irradiation. J. Appl. Phys. 2002, 92, 3304–3310. [Google Scholar] [CrossRef]

- Niaura, G. Surface-enhanced Raman spectroscopic observation of two kinds of adsorbed OH- ions at copper electrode. Electrochim. Acta 2000, 45, 3507–3519. [Google Scholar] [CrossRef]

- Gong, Y.S.; Lee, C.; Yang, C.K. Atomic force microscopy and Raman spectroscopy studies on the oxidation of Cu thin films. J. Appl. Phys. 1995, 77, 5422–5425. [Google Scholar] [CrossRef]

- Choudhary, S.; Sarma, J.V.N.; Pande, S.; Ababou-Girard, S.; Turban, P.; Lepine, B.; Gangopadhyay, S. Oxidation mechanism of thin Cu films: A gateway towards the formation of single oxide phase. AIP Adv. 2018, 8, 055114. [Google Scholar] [CrossRef]

- Chen, L.C.; Chen, C.C.; Liang, K.C.; Chang, S.H.; Tseng, Z.L.; Yeh, S.C.; Chen, C.T.; Wu, W.T.; Wu, C.G. Nano-structured CuO-Cu2O Complex Thin Film for Application in CH3NH3PbI3 Perovskite Solar Cells. Nanoscale Res. Lett. 2016, 11, 402. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hamilton, J.; Farmer, J.; Boney, C. Formation of Anodic Films on Copper and Silver in Sodium Hydroxide: An In Situ Raman Spectroscopic Investigation. Electrochem. Soc. Ext. Abstr. 1985, 85-1, 34–35. [Google Scholar]

- Akgul, F.A.; Akgul, G.; Yildirim, N.; Unalan, H.E.; Turan, R. Influence of thermal annealing on microstructural, morphological, optical properties and surface electronic structure of copper oxide thin films. Mater. Chem. Phys. 2014, 147, 987–995. [Google Scholar] [CrossRef]

- Bulakhe, R.N.; Nguyen, V.Q.; Tuma, D.; Lee, Y.R.; Zhang, H.; Zhang, S.; Shim, J.J. Chemically grown 3D copper hydroxide electrodes with different morphologies for high-performance asymmetric supercapacitors. J. Ind. Eng. Chem. 2018, 66, 288–297. [Google Scholar] [CrossRef]

- Peng, C.Y.; Hou, C.C.; Chen, Q.Q.; Wang, C.J.; Lv, X.J.; Zhong, J.; Fu, W.F.; Che, C.M.; Chen, Y. Cu(OH)2 supported on Fe(OH)3 as a synergistic and highly efficient system for the dehydrogenation of ammonia-borane. Sci. Bull. 2018, 63, 1583–1590. [Google Scholar] [CrossRef] [Green Version]

- Deng, Y.; Handoko, A.D.; Du, Y.; Xi, S.; Yeo, B.S. In Situ Raman Spectroscopy of Copper and Copper Oxide Surfaces during Electrochemical Oxygen Evolution Reaction: Identification of CuIII Oxides as Catalytically Active Species. ACS Catal. 2016, 6, 2473–2481. [Google Scholar] [CrossRef]

- Zimbovskiy, D.S.; Gavrilov, A.I.; Churagulov, B.R. Synthesis of copper oxides films via anodic oxidation of copper foil followed by thermal reduction. IOP Conf. Ser. Mater. Sci. Eng. 2018, 347, 012010. [Google Scholar] [CrossRef]

- Iriondo, A.; Guemez, M.B.; Requies, J.; Barrio, V.L.; Cambra, J.F.; Arias, P.L.; Fierro, J.L.G. Butyraldehyde production by butanol oxidation over Ru and Cu catalysts supported on ZrO2, TiO2 and CeO2. Stud. Surf. Sci. Catal. 2010, 175, 453–456. [Google Scholar] [CrossRef]

- Harju, H.; Lehtonen, J.; Lefferts, L. Steam reforming of n-butanol over Rh/ZrO2 catalyst: Role of 1-butene and butyraldehyde. Appl. Catal. B Environ. 2016, 182, 33–46. [Google Scholar] [CrossRef]

- Requies, J.; Güemez, M.B.; Iriondo, A.; Barrio, V.L.; Cambra, J.F.; Arias, P.L. Bio n-butanol partial oxidation to butyraldehyde in gas phase on supported Ru and Cu catalysts. Catal. Lett. 2012, 142, 417–426. [Google Scholar] [CrossRef]

- Shiau, C.; Liaw, S. Kinetic Model for Oxidative Dehydrogenation of n-Butanol over Copper-Barium Catalyst. J. Chem. Technol. Biotechnol. 1992, 53, 13–19. [Google Scholar] [CrossRef]

- Botta, R.; Chindaudon, P.; Eiamchai, P.; Horprathum, M.; Limwichean, S.; Chananonnawathorn, C.; Patthanasettakul, V.; Jomphoak, A.; Nuntawong, N. Detection and classification of volatile fatty acids using surface-enhanced Raman scattering and density functional theory calculations. J. Raman Spectrosc. 2019, 50, 1817–1828. [Google Scholar] [CrossRef]

- Chen, L.; Zhu, W.; Lin, K.; Hu, N.; Yu, Y.; Zhou, X.; Yuan, L.F.; Hu, S.M.; Luo, Y. Identification of Alcohol Conformers by Raman Spectra in the C-H Stretching Region. J. Phys. Chem. A 2015, 119, 3209–3217. [Google Scholar] [CrossRef] [PubMed]

- Wiley SpectraBase: N-Butyl Alcohol Raman Spectrum. Available online: https://spectrabase.com/spectrum/5daGGeHNBo (accessed on 29 October 2021).

- Wiley SpectraBase: Butanal Raman Spectrum. Available online: https://spectrabase.com/spectrum/5NzuD6F9OwS (accessed on 29 October 2021).

- Cheng, K.K.; Park, C. Surface tension of dilute alcohol-aqueous binary fluids: N-Butanol/water, n-Pentanol/water, and n-Hexanol/water solutions. Heat Mass Transf. Stoffuebertragung 2017, 53, 2255–2263. [Google Scholar] [CrossRef]

- Zhang, W.; Wen, X.; Yang, S. Controlled Reactions on a Copper Surface: Synthesis and Characterization of Nanostructured Copper Compound Films. Inorg. Chem. 2003, 42, 5005–5014. [Google Scholar] [CrossRef]

- Tang, K.; Wang, X.; Yan, W.; Yu, J.; Xu, R. Fabrication of superhydrophilic Cu2O and CuO membranes. J. Memb. Sci. 2006, 286, 279–284. [Google Scholar] [CrossRef]

- Wen, X.; Zhang, W.; Yang, S. Synthesis of Cu(OH)2 and CuO Nanoribbon Arrays on a Copper Surface. Langmuir 2003, 19, 5898–5903. [Google Scholar] [CrossRef]

- Hsu, Y.Y. On the Size Range of Active Nucleation Cavities on a Heating Surface. J. Heat Transfer 1962, 84, 207–213. [Google Scholar] [CrossRef]

- Jones, B.J.; Garimella, S.V. Effects of Surface Roughness on the Pool Boiling of Water. In Proceedings of the ASME/JSME 2007 Thermal Engineering Heat Transfer Summer Conference, Vancouver, BC, Canada, 8–12 July 2007; Volume 2, pp. 219–227. [Google Scholar]

- Jo, H.; Ahn, H.S.; Kang, S.; Kim, M.H. A study of nucleate boiling heat transfer on hydrophilic, hydrophobic and heterogeneous wetting surfaces. Int. J. Heat Mass Transf. 2011, 54, 5643–5652. [Google Scholar] [CrossRef]

- Betz, A.R.; Jenkins, J.; Kim, C.J.; Attinger, D. Boiling heat transfer on superhydrophilic, superhydrophobic, and superbiphilic surfaces. Int. J. Heat Mass Transf. 2013, 57, 733–741. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.Y.; Liu, Z.H.; Wang, G.S. A predictive model of nucleate pool boiling on heated hydrophilic surfaces. Int. J. Heat Mass Transf. 2013, 65, 789–797. [Google Scholar] [CrossRef]

- Witharana, S.; Phillips, B.; Strobel, S.; Kim, H.D.; McKrell, T.; Chang, J.B.; Buongiorno, J.; Berggren, K.K.; Chen, L.; Ding, Y. Bubble nucleation on nano- to micro-size cavities and posts: An experimental validation of classical theory. J. Appl. Phys. 2012, 112, 064904. [Google Scholar] [CrossRef] [Green Version]

- Kandlikar, S.; Mizo, V.; Cartwright, M. Bubble nucleation and growth characteristics in subcooled flow boiling of water. In Proceedings of the 32nd National Heat Transfer Conference, New York, NY, USA, 8–12 August 1997; pp. 11–18. [Google Scholar]

- Zupančič, M.; Može, M.; Gregorčič, P.; Golobič, I. Nanosecond laser texturing of uniformly and non-uniformly wettable micro structured metal surfaces for enhanced boiling heat transfer. Appl. Surf. Sci. 2017, 399, 480–490. [Google Scholar] [CrossRef] [Green Version]

- Može, M.; Vajc, V.; Zupančič, M.; Šulc, R.; Golobič, I. Pool boiling performance of water and self-rewetting fluids on hybrid functionalized aluminum surfaces. Processes 2021, 9, 1058. [Google Scholar] [CrossRef]

- Voglar, J.; Gregorčič, P.; Zupančič, M.; Golobič, I. Boiling performance on surfaces with capillary-length-spaced one- and two-dimensional laser-textured patterns. Int. J. Heat Mass Transf. 2018, 127, 1188–1196. [Google Scholar] [CrossRef] [Green Version]

- Može, M.; Zupančič, M.; Hočevar, M.; Golobič, I.; Gregorčič, P. Surface chemistry and morphology transition induced by critical heat flux incipience on laser-textured copper surfaces. Appl. Surf. Sci. 2019, 490, 220–230. [Google Scholar] [CrossRef]

- Jo, H.; Kim, S.; Kim, H.; Kim, J.; Kim, M.H. Nucleate boiling performance on nano/microstructures with different wetting surfaces. Nanoscale Res. Lett. 2012, 7, 242. [Google Scholar] [CrossRef] [Green Version]

- Golobic, I.; Petkovsek, J.; Kenning, D.B.R. Bubble growth and horizontal coalescence in saturated pool boiling on a titanium foil, investigated by high-speed IR thermography. Int. J. Heat Mass Transf. 2012, 55, 1385–1402. [Google Scholar] [CrossRef]

- Theofanous, T.G.; Dinh, T.N.; Tu, J.P.; Dinh, A.T. The boiling crisis phenomenon part II: Dryout dynamics and burnout. Exp. Therm. Fluid Sci. 2002, 26, 793–810. [Google Scholar] [CrossRef]

- Marmur, A. From Hygrophilic to Superhygrophobic: Theoretical Conditions for Making High-Contact-Angle Surfaces from Low-Contact-Angle Materials. Langmuir 2008, 24, 7573–7579. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.M.; Ridwan, S.; Fehlinger, D.; Mccarthy, M. Wicking Enhanced Critical Heat Flux for Highly Wetting Fluids on Structured Surfaces. Langmuir 2020, 36, 9643–9648. [Google Scholar] [CrossRef] [PubMed]

- Wemp, C.K.; Carey, V.P. Water Wicking and Droplet Spreading on Randomly Structured Thin Nanoporous Layers. Langmuir 2017, 33, 14513–14525. [Google Scholar] [CrossRef] [PubMed]

| Surface | Water Contact Angle | Novec™ 649 Contact Angle |

|---|---|---|

| REF | 91° ± 5° | 20.0° ± 0.8° |

| A | 14° ± 7° | 17.1° ± 1.2° |

| AH | 164° ± 2° | 21.3° ± 1.7° |

| B | 113° ± 7° | 17.2° ± 1.6° |

| BH | 152° ± 4° | 19.2° ± 1.1° |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Može, M.; Vajc, V.; Zupančič, M.; Golobič, I. Hydrophilic and Hydrophobic Nanostructured Copper Surfaces for Efficient Pool Boiling Heat Transfer with Water, Water/Butanol Mixtures and Novec 649. Nanomaterials 2021, 11, 3216. https://doi.org/10.3390/nano11123216

Može M, Vajc V, Zupančič M, Golobič I. Hydrophilic and Hydrophobic Nanostructured Copper Surfaces for Efficient Pool Boiling Heat Transfer with Water, Water/Butanol Mixtures and Novec 649. Nanomaterials. 2021; 11(12):3216. https://doi.org/10.3390/nano11123216

Chicago/Turabian StyleMože, Matic, Viktor Vajc, Matevž Zupančič, and Iztok Golobič. 2021. "Hydrophilic and Hydrophobic Nanostructured Copper Surfaces for Efficient Pool Boiling Heat Transfer with Water, Water/Butanol Mixtures and Novec 649" Nanomaterials 11, no. 12: 3216. https://doi.org/10.3390/nano11123216

APA StyleMože, M., Vajc, V., Zupančič, M., & Golobič, I. (2021). Hydrophilic and Hydrophobic Nanostructured Copper Surfaces for Efficient Pool Boiling Heat Transfer with Water, Water/Butanol Mixtures and Novec 649. Nanomaterials, 11(12), 3216. https://doi.org/10.3390/nano11123216