Laser Irradiation of a Bio-Waste Derived Carbon Unlocks Performance Enhancement in Secondary Lithium Batteries

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

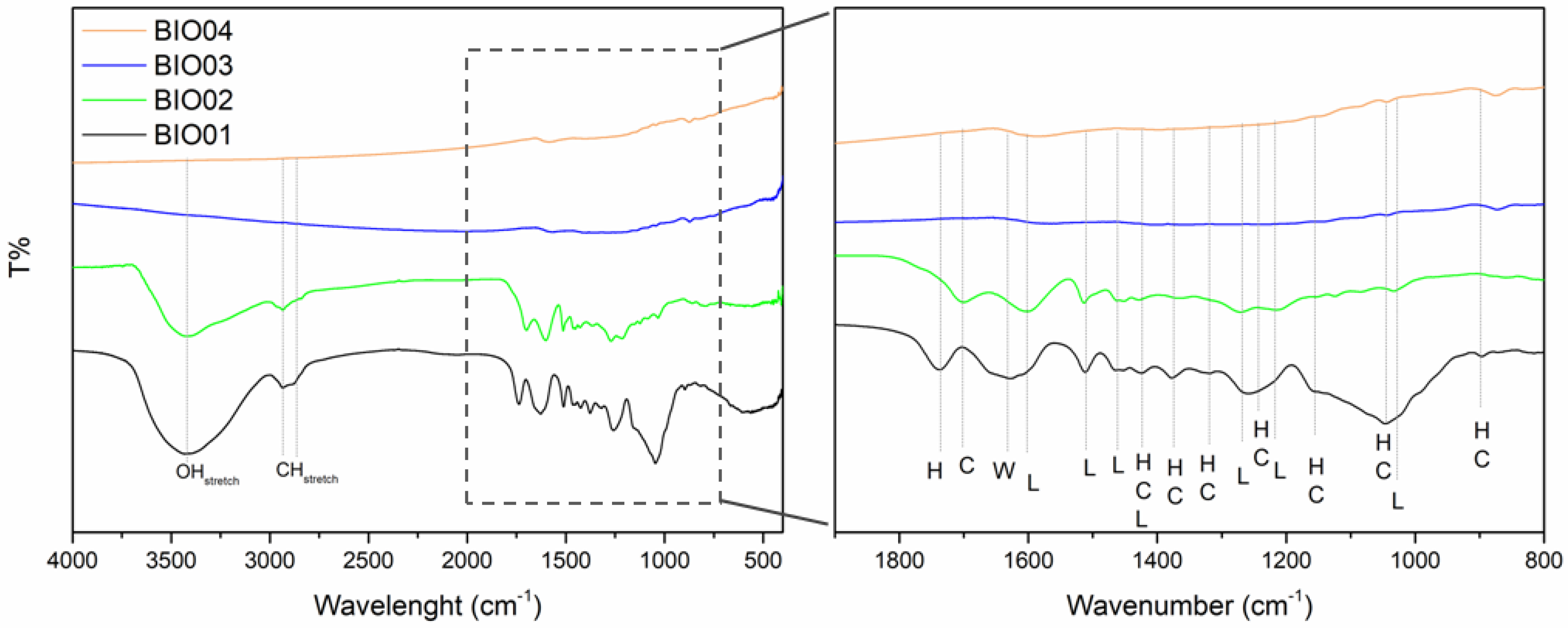

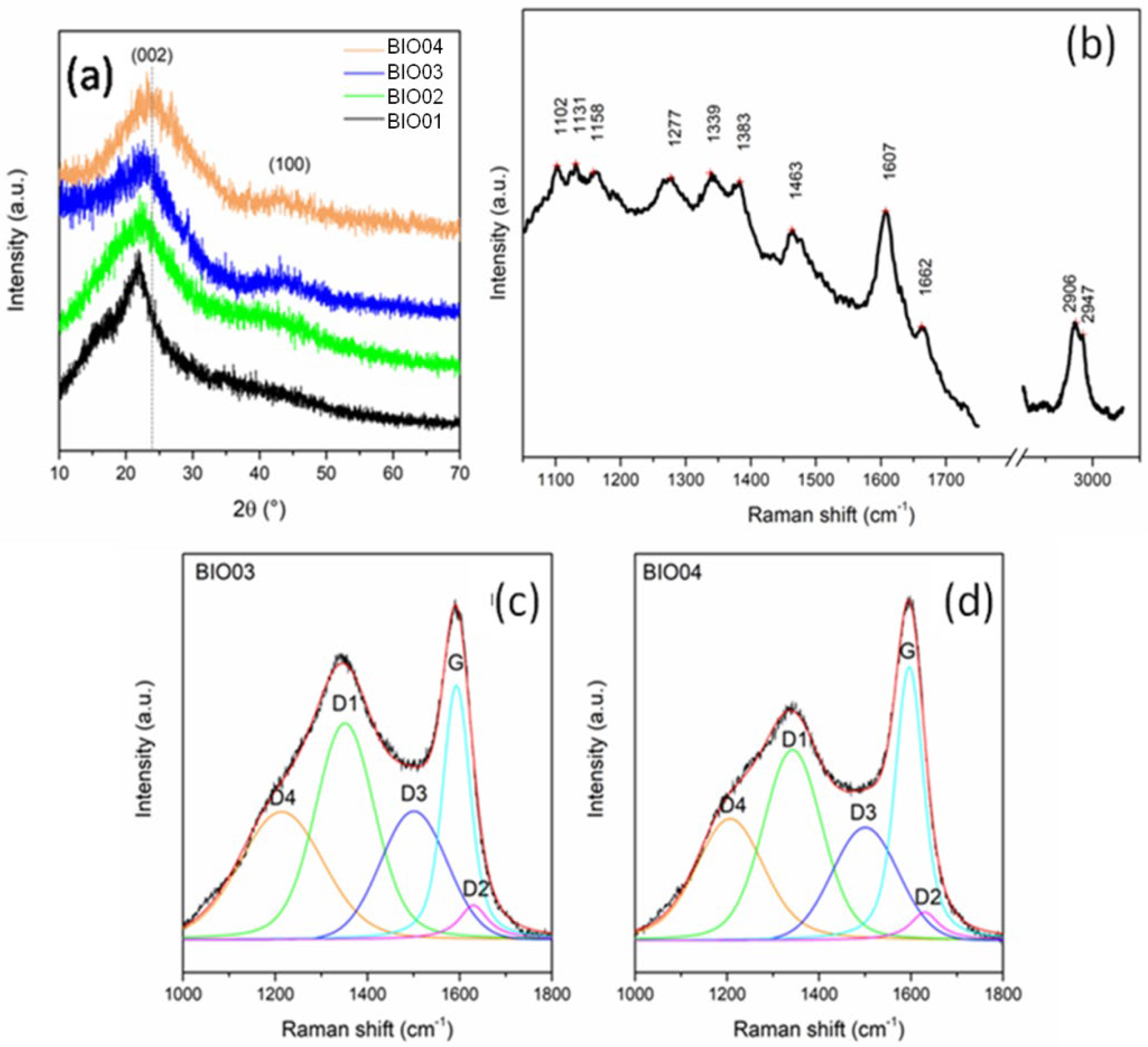

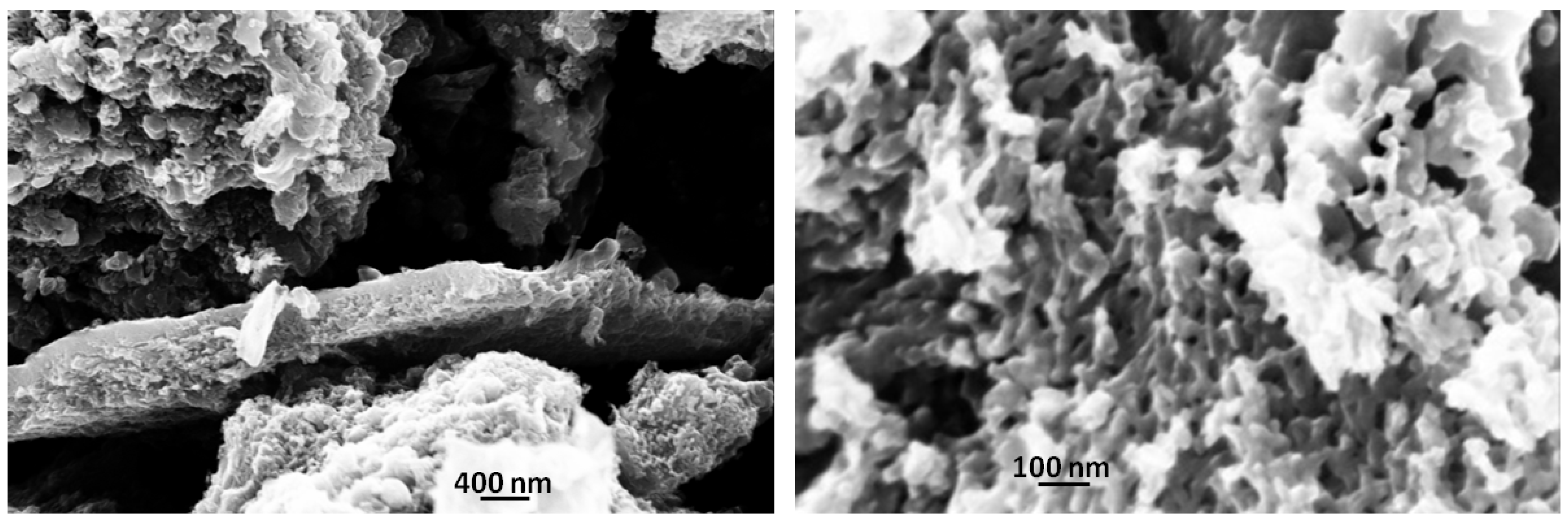

3.1. Physico-Chemical Characterization of the Carbon Preparation Process

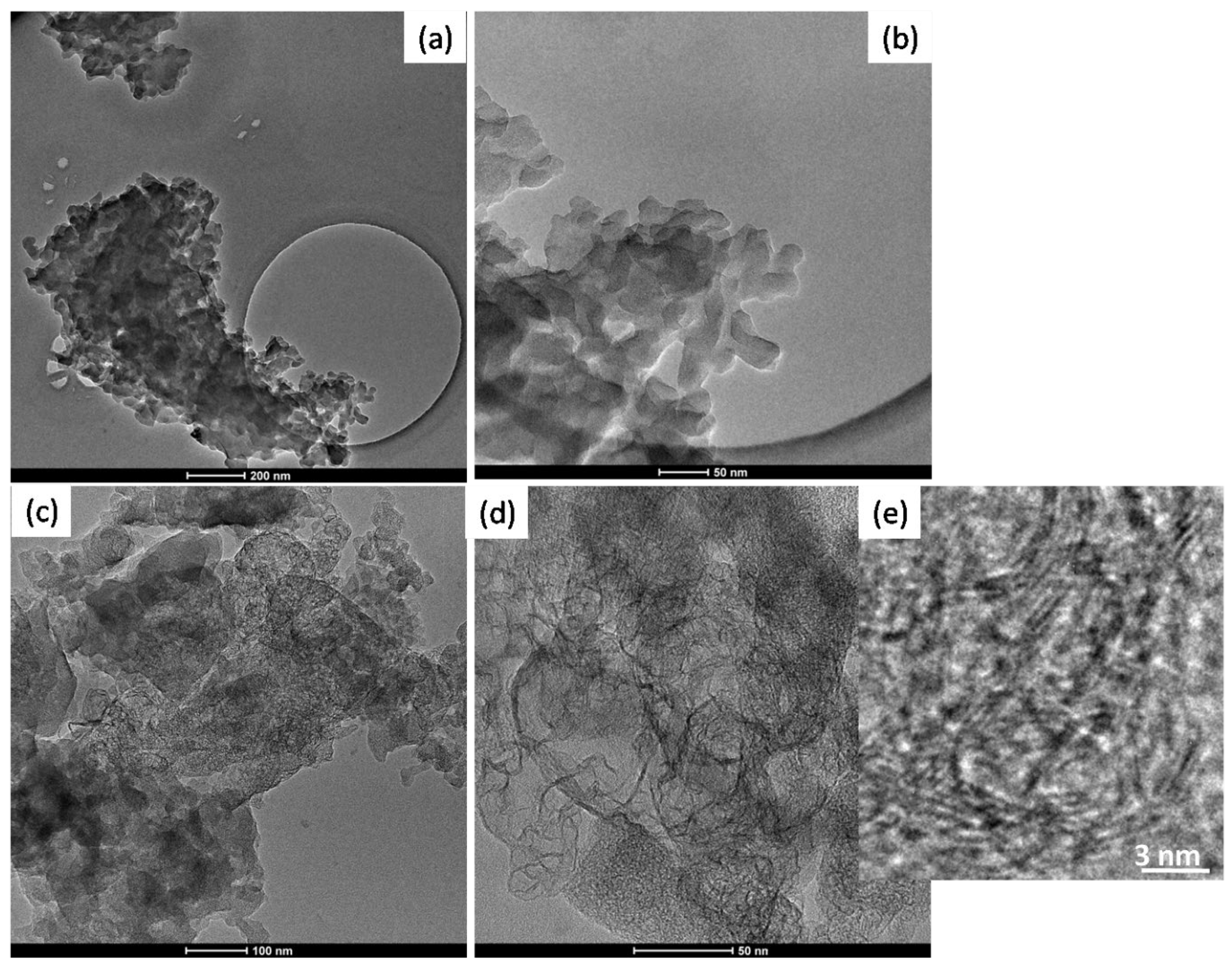

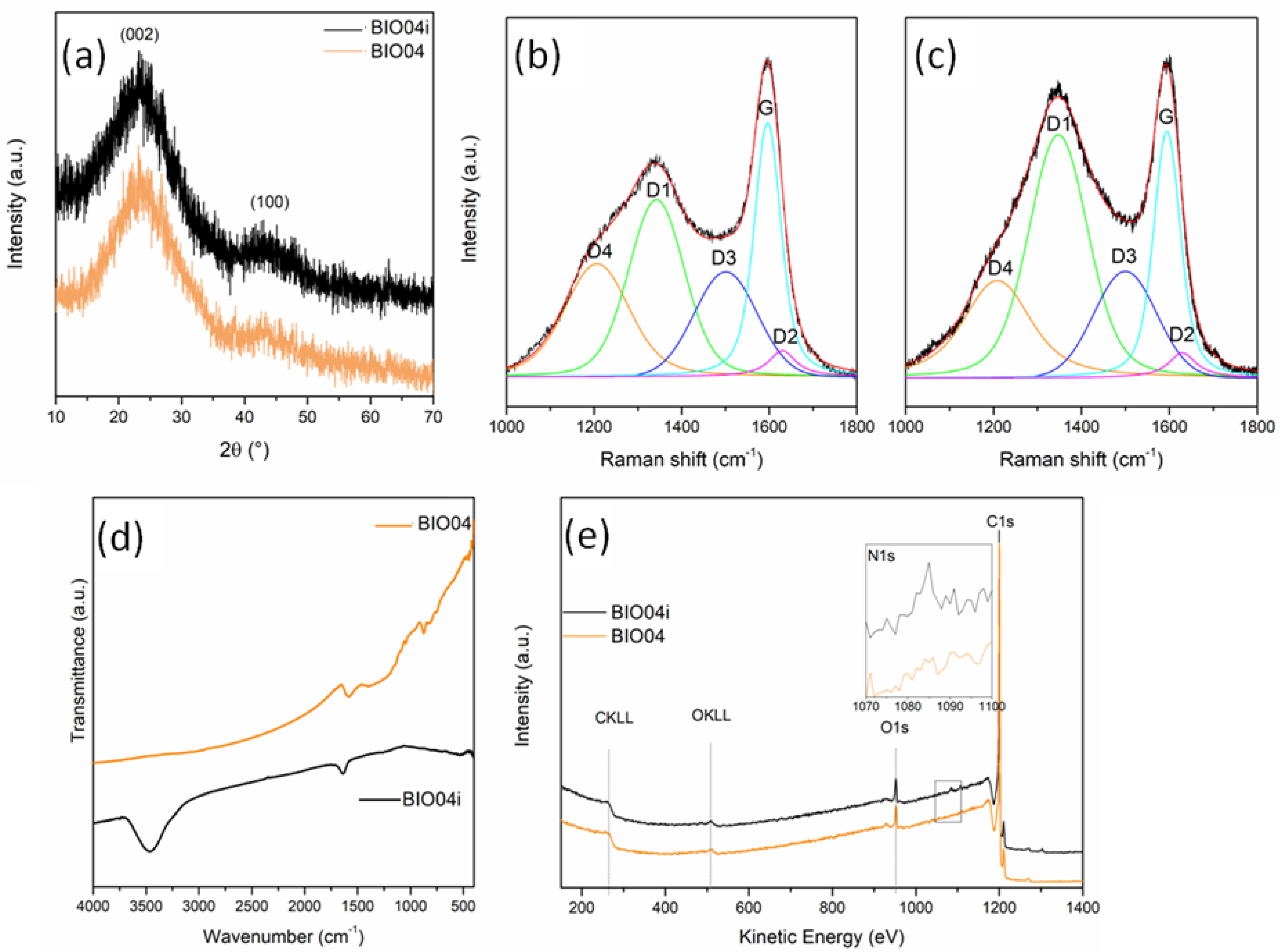

3.2. Impact of the Laser Irradiation on the BIO04i Physicochemical Properties

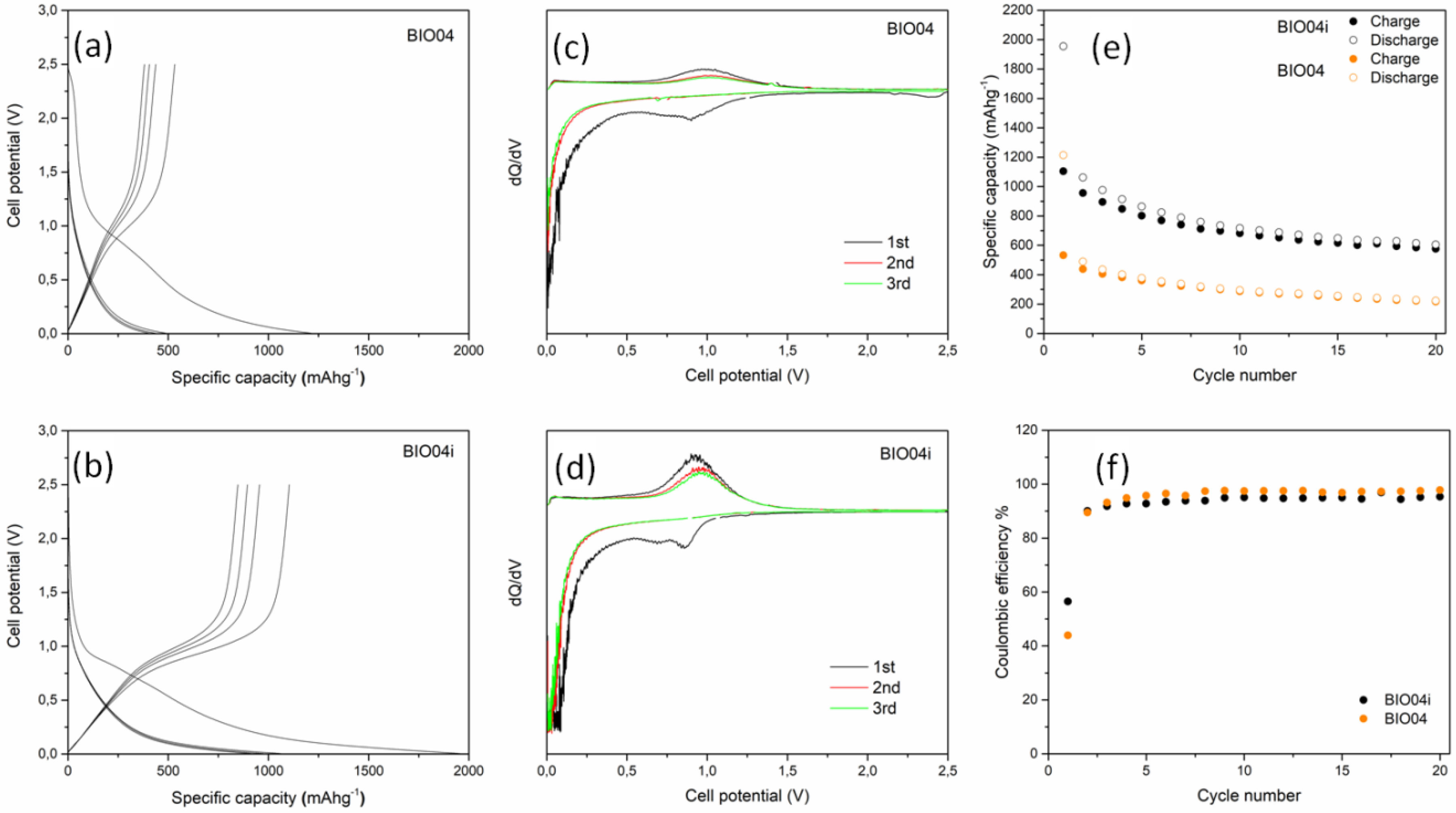

3.3. Impact of the Laser Irradiation on the Electrochemical Performance of the Hard Carbon in a Lithium Cell

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Vea, E.B.; Romeo, D.; Thomsen, M. Biowaste Valorisation in a Future Circular Bioeconomy. Proc. CIRP 2018, 69, 591–596. [Google Scholar] [CrossRef]

- Demichelis, F.; Piovano, F.; Fiore, S. Biowaste management in Italy: Challenges and perspectives. Sustainability 2019, 11, 4213. [Google Scholar] [CrossRef] [Green Version]

- Liedel, C. Sustainable Battery Materials from Biomass. ChemSusChem 2020, 13, 2110–2141. [Google Scholar] [CrossRef] [PubMed]

- Stephan, A.M.; Kumar, T.P.; Ramesh, R.; Thomas, S.; Jeong, S.K.; Nahm, K.S. Pyrolitic carbon from biomass precursors as anode materials for lithium batteries. Mater. Sci. Eng. A 2006, 430, 132–137. [Google Scholar] [CrossRef]

- Unur, E.; Brutti, S.; Panero, S.; Scrosati, B. Nanoporous carbons from hydrothermally treated biomass as anode materials for lithium ion batteries. Microporous Mesoporous Mater. 2013, 174, 25–33. [Google Scholar] [CrossRef]

- Niu, J.; Shao, R.; Liang, J.; Dou, M.; Li, Z.; Huang, Y.; Wang, F. Biomass-derived mesopore-dominant porous carbons with large specific surface area and high defect density as high performance electrode materials for Li-ion batteries and supercapacitors. Nano Energy 2017, 36, 322–330. [Google Scholar] [CrossRef]

- Mondal, A.K.; Kretschmer, K.; Zhao, Y.; Liu, H.; Fan, H.; Wang, G. Naturally nitrogen doped porous carbon derived from waste shrimp shells for high-performance lithium ion batteries and supercapacitors. Microporous Mesoporous Mater. 2017, 246, 72–80. [Google Scholar] [CrossRef]

- Mullaivananathan, V.; Sathish, R.; Kalaiselvi, N. Coir Pith Derived Bio-carbon: Demonstration of Potential Anode Behavior in Lithium-ion Batteries. Electrochim. Acta 2017, 225, 143–150. [Google Scholar] [CrossRef]

- Zhou, X.; Chen, F.; Bai, T.; Long, B.; Liao, Q.; Ren, Y.; Yang, J. Interconnected highly graphitic carbon nanosheets derived from wheat stalk as high performance anode materials for lithium ion batteries. Green Chem. 2016, 18, 2078–2088. [Google Scholar] [CrossRef]

- Yu, K.; Li, J.; Qi, H.; Liang, C. High-capacity activated carbon anode material for lithium-ion batteries prepared from rice husk by a facile method. Diam. Relat. Mater. 2018, 86, 139–145. [Google Scholar] [CrossRef]

- Li, Y.; Li, C.; Qi, H.; Yu, K.; Liang, C. Mesoporous activated carbon from corn stalk core for lithium ion batteries. Chem. Phys. 2018, 506, 10–16. [Google Scholar] [CrossRef]

- Dou, X.; Hasa, I.; Hekmatfar, M.; Diemant, T.; Behm, R.J.; Buchholz, D.; Passerini, S. Pectin, Hemicellulose, or Lignin? Impact of the Biowaste Source on the Performance of Hard Carbons for Sodium-Ion Batteries. ChemSusChem 2017, 10, 2668–2676. [Google Scholar] [CrossRef] [PubMed]

- Lotfabad, E.M.; Ding, J.; Cui, K.; Kohandehghan, A.; Kalisvaart, W.P.; Hazelton, M.; Mitlin, D. High-density sodium and lithium ion battery anodes from banana peels. ACS Nano 2014, 8, 7115–7129. [Google Scholar] [CrossRef] [PubMed]

- Fey, G.T.K.; Lee, D.C.; Lin, Y.Y.; Prem Kumar, T. High-capacity disordered carbons derived from peanut shells as lithium-intercalating anode materials. Synth. Met. 2003, 139, 71–80. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of The United Nations. FAOstat. Available online: faostat.fao.org (accessed on 8 November 2020).

- Wang, S.X.; Yang, L.; Stubbs, L.P.; Li, X.; He, C. Lignin-derived fused electrospun carbon fibrous mats as high performance anode materials for lithium ion batteries. ACS Appl. Mater. Interfaces 2013, 5, 12275–12282. [Google Scholar] [CrossRef]

- Zheng, F.; Liu, D.; Xia, G.; Yang, Y.; Liu, T.; Wu, M.; Chen, Q. Biomass waste inspired nitrogen-doped porous carbon materials as high-performance anode for lithium-ion batteries. J. Alloy. Compd. 2017, 693, 1197–1204. [Google Scholar] [CrossRef]

- Calcagno, G.; Agostini, M.; Xiong, S.; Matic, A.; Palmqvist, A.E.C.; Cavallo, C. Effect of nitrogen doping on the performance of mesoporous CMK-8 carbon anodes for Li-ion batteries. Energies 2020, 13, 4998. [Google Scholar] [CrossRef]

- Schneider, A.; Janek, J.; Brezesinski, T. Improving the capacity of lithium-sulfur batteries by tailoring the polysulfide adsorption efficiency of hierarchical oxygen/nitrogen-functionalized carbon host materials. Phys. Chem. Chem. Phys. 2017, 19, 8349–8355. [Google Scholar] [CrossRef]

- Amendola, V.; Amans, D.; Ishikawa, Y.; Koshizaki, N.; Scirè, S.; Compagnini, G.; Reichenberger, S.; Barcikowski, S. Room-Temperature Laser Synthesis in Liquid of Oxide, Metal-Oxide Core-Shells, and Doped Oxide Nanoparticles. Chem. A Eur. J. 2020, 26, 9206–9242. [Google Scholar] [CrossRef]

- Amans, D.; Cai, W.; Barcikowski, S. Status and demand of research to bring laser generation of nanoparticles in liquids to maturity. Appl. Surf. Sci. 2019, 488, 445–454. [Google Scholar] [CrossRef]

- Zhang, D.; Gökce, B.; Barcikowski, S. Laser Synthesis and Processing of Colloids: Fundamentals and Applications. Chem. Rev. 2017, 117, 3990–4103. [Google Scholar] [CrossRef] [PubMed]

- Pyatenko, A.; Wang, H.; Koshizaki, N.; Tsuji, T. Mechanism of pulse laser interaction with colloidal nanoparticles. Laser Photonics Rev. 2013, 7, 596–604. [Google Scholar] [CrossRef]

- Susanti, R.F.; Alvin, S.; Kim, J. Toward high-performance hard carbon as an anode for sodium-ion batteries: Demineralization of biomass as a critical step. J. Ind. Eng. Chem. 2020, 91, 317–329. [Google Scholar] [CrossRef]

- Yu, X.; Zhang, K.; Tian, N.; Qin, A.; Liao, L.; Du, R.; Wei, C. Biomass carbon derived from sisal fiber as anode material for lithium-ion batteries. Mater. Lett. 2015, 142, 193–196. [Google Scholar] [CrossRef]

- Demirbaş, A. Fuel characteristics of olive husk and walnut, hazelnut, sunflower, and almond shells. Energy Sources 2002, 24, 215–221. [Google Scholar] [CrossRef]

- Baldinelli, A.; Dou, X.; Buchholz, D.; Marinaro, M.; Passerini, S.; Barelli, L. Addressing the energy sustainability of biowaste-derived hard carbon materials for battery electrodes. Green Chem. 2018, 20, 1527–1537. [Google Scholar] [CrossRef]

- Horikawa, Y.; Hirano, S.; Mihashi, A.; Kobayashi, Y.; Zhai, S.; Sugiyama, J. Prediction of Lignin Contents from Infrared Spectroscopy: Chemical Digestion and Lignin/Biomass Ratios of Cryptomeria japonica. Appl. Biochem. Biotechnol. 2019, 188, 1066–1076. [Google Scholar] [CrossRef]

- Jeon, J.W.; Zhang, L.; Lutkenhaus, J.L.; Laskar, D.D.; Lemmon, J.P.; Choi, D.; Nandasiri, M.I.; Hashmi, A.; Xu, J.; Motkuri, R.K.; et al. Controlling porosity in lignin-derived nanoporous carbon for supercapacitor applications. ChemSusChem 2015, 8, 428–432. [Google Scholar] [CrossRef]

- Fawcett, T.G.; Crowder, C.E.; Kabekkodu, S.N.; Needham, F.; Kaduk, J.A.; Blanton, T.N.; Petkov, V.; Bucher, E.; Shpanchenko, R. Reference materials for the study of polymorphism and crystallinity in cellulosics. Powder Diffr. 2013, 28, 18–31. [Google Scholar] [CrossRef] [Green Version]

- Yan, L.; Pu, Y.; Bowden, M.; Ragauskas, A.J.; Yang, B. Physiochemical Characterization of Lignocellulosic Biomass Dissolution by Flowthrough Pretreatment. ACS Sustain. Chem. Eng. 2016, 4, 219–227. [Google Scholar] [CrossRef]

- Qiu, T.; Yang, J.G.; Bai, X.J.; Wang, Y.L. The preparation of synthetic graphite materials with hierarchical pores from lignite by one-step impregnation and their characterization as dye absorbents. RSC Adv. 2019, 9, 12737–12746. [Google Scholar] [CrossRef] [Green Version]

- Sadezky, A.; Muckenhuber, H.; Grothe, H.; Niessner, R.; Pöschl, U. Raman microspectroscopy of soot and related carbonaceous materials: Spectral analysis and structural information. Carbon 2005, 43, 1731–1742. [Google Scholar] [CrossRef]

- Marino, C.; Cabanero, J.; Povia, M.; Villevieille, C. Biowaste Lignin-Based Carbonaceous Materials as Anodes for Na-Ion Batteries. J. Electrochem. Soc. 2018, 165, A1400–A1408. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, T. Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev. B 2000, 61, 14095–14107. [Google Scholar] [CrossRef] [Green Version]

- Farahi, R.H.; Lereu, A.L.; Charrier, A.M.; Kalluri, U.C.; Davison, B.H.; Passian, A. Nanomechanics and raman spectroscopy of in situ native carbohydrate storage granules for enhancing starch quality and lignocellulosic biomass production. ACS Omega 2020, 5, 2594–2602. [Google Scholar] [CrossRef] [PubMed]

- Zeng, H.; Du, X.W.; Singh, S.C.; Kulinich, S.A.; Yang, S.; He, J.; Cai, W. Nanomaterials via laser ablation/irradiation in liquid: A review. Adv. Funct. Mater. 2012, 22, 1333–1353. [Google Scholar] [CrossRef]

- Zheng, F.; Yang, Y.; Chen, Q. High lithium anodic performance of highly nitrogen-doped porous carbon prepared from a metal-organic framework. Nat. Commun. 2014, 5, 5261. [Google Scholar] [CrossRef] [Green Version]

- Mao, Y.; Duan, H.; Xu, B.; Zhang, L.; Hu, Y.; Zhao, C.; Wang, Z.; Chen, L.; Yang, Y. Lithium storage in nitrogen-rich mesoporous carbon materials. Energy Environ. Sci. 2012, 5, 7950–7955. [Google Scholar] [CrossRef]

- Jung, H.J.; Choi, M.Y. One-pot synthesis of graphitic and nitrogen-doped graphitic layers on nickel nanoparticles produced by pulsed laser ablation in liquid: Solvent as the carbon and nitrogen source. Appl. Surf. Sci. 2018, 57, 1050–1056. [Google Scholar] [CrossRef]

- Lifshitz, A.; Tamburu, C. Thermal decomposition of acetonitrile. Kinetic modeling. Int. J. Chem. Kinet. 1998, 30, 341–347. [Google Scholar] [CrossRef]

- Shan, X.; Zhong, Y.; Zhang, L.; Zhang, Y.; Xia, X.; Wang, X.; Tu, J. A Brief Review on Solid Electrolyte Interphase Composition Characterization Technology for Lithium Metal Batteries: Challenges and Perspectives. J. Phys. Chem. C 2021, 125, 19060–19080. [Google Scholar] [CrossRef]

- Wang, H.; Cui, Y. Nanodiamonds for energy. Carbon Energy 2019, 1, 13–18. [Google Scholar] [CrossRef] [Green Version]

- Shi, Y.; Liu, G.; Jin, R.; Xu, H.; Wang, Q.; Gao, S. Carbon materials from melamine sponges for supercapacitors and lithium battery electrode materials: A review. Carbon Energy 2019, 1, 253–275. [Google Scholar] [CrossRef] [Green Version]

- Dhan, J.R.; Zheng, T.; Xue, J.S. Mechanism for lithium insertion in carbonaceous materials. Science 1995, 270, 590–593. [Google Scholar] [CrossRef]

- Wang, S.; Matsui, H.; Tamanura, H.; Matsumura, Y.; Yamabe, T. Mechanism of lithium insertion into disordered carbon. Phys. Rev. B 1998, 58, 8163. [Google Scholar] [CrossRef]

- Wang, S.; Kakumoto, T.; Matsui, H.; Matsumura, Y. Mechanism of lithium insertion into disordered carbon. Synth. Met. 1999, 103, 2523–2524. [Google Scholar] [CrossRef]

- Bonino, F.; Brutti, S.; Reale, P.; Scrosati, B.; Gherghel, L.; Wu, J.; Mullen, K. A disordered carbon as a novel anode materials in lithium-ion cells. Adv. Mater. 2005, 17, 743–746. [Google Scholar] [CrossRef]

- Togonon, J.J.H.; Chiang, P.-C.; Lin, H.-J.; Tsai, W.-C.; Yen, H.-J. Pure carbon-based electrodes for metal-ion batteries. CarbonTrends 2021, 3, 100035. [Google Scholar] [CrossRef]

| Code | Starting Materials | Preparation | Pyrolysis |

|---|---|---|---|

| BIO01 | hazelnut shells | Pulverization by ball milling | None |

| BIO02 | BIO01 2 g, Citric acid 25 mg, H2O 5 g | Mixing in ultrasonic bath in Teflon liner, hydrothermal treatment in autoclave at 220° for 12 h, drying at 80° for 6 h. | None |

| BIO03 | BIO01 | None | Annealing under Ar/H2 5% flow (120 mL/min) (3 h at 20°, heating 5°/min, 2 h at 900°, natural cooling) |

| BIO04 | BIO02 | None |

| Band Peak(cm−1) | Species | Assignment [5,28] |

|---|---|---|

| 896 | H/C | Anometric vibration at β-glycosidic linkage |

| 1028 | L | C-O stretching |

| 1045 | H/C | C-OH stretching |

| 1156 | H/C | C-O-C antisymmetric stretching |

| 1219 | L | C-O stretching (esters or ethers) |

| 1240 | H/C | C-O stretching (carboxylic acid) |

| 1265 | L | C-O stretching |

| 1316 | H/C | O-H in-plane bending |

| 1375 | H/C | C-H bending |

| 1423 | L | C-H bending (C-H3) |

| 1462 | L | C-H bending (C-H2) |

| 1510 | L | Aromatic skeletal vibration |

| 1600 | L | Aromatic skeletal vibration |

| 1636 | Adsorbed Water | O-H bending |

| 1702 | C | C=O stretching |

| 1735 | H/L | C=O stretching |

| Bands Position (cm−1) | Species | Assignment [36] |

|---|---|---|

| 1102 | C/H | Stretching C-C, C-O |

| 1131 | C/H | Stretching C-C, C-O |

| 1158 | L | Stretching C-C, C-O and HCC bending |

| 1277 | L/C | aryl-O, aryl-OH |

| 1339 | C | HCC and HCO bending |

| 1383 | L/C | HCC and HCO bending |

| 1463 | L | HCH and HCO bending |

| 1607 | L | Stretching aromatic ring |

| 1662 | C/H | C=C of coniferyl alcohol and coniferaldehyde |

| 2906 | L/C/H | CH stretching |

| 2947 | L/C/H | CH stretching |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Curcio, M.; Brutti, S.; Caripoti, L.; De Bonis, A.; Teghil, R. Laser Irradiation of a Bio-Waste Derived Carbon Unlocks Performance Enhancement in Secondary Lithium Batteries. Nanomaterials 2021, 11, 3183. https://doi.org/10.3390/nano11123183

Curcio M, Brutti S, Caripoti L, De Bonis A, Teghil R. Laser Irradiation of a Bio-Waste Derived Carbon Unlocks Performance Enhancement in Secondary Lithium Batteries. Nanomaterials. 2021; 11(12):3183. https://doi.org/10.3390/nano11123183

Chicago/Turabian StyleCurcio, Mariangela, Sergio Brutti, Lorenzo Caripoti, Angela De Bonis, and Roberto Teghil. 2021. "Laser Irradiation of a Bio-Waste Derived Carbon Unlocks Performance Enhancement in Secondary Lithium Batteries" Nanomaterials 11, no. 12: 3183. https://doi.org/10.3390/nano11123183

APA StyleCurcio, M., Brutti, S., Caripoti, L., De Bonis, A., & Teghil, R. (2021). Laser Irradiation of a Bio-Waste Derived Carbon Unlocks Performance Enhancement in Secondary Lithium Batteries. Nanomaterials, 11(12), 3183. https://doi.org/10.3390/nano11123183