Effect of Particle Sizes on the Efficiency of Fluorinated Nanodiamond Neutron Reflectors

Abstract

:1. Introduction

2. Samples

3. Results

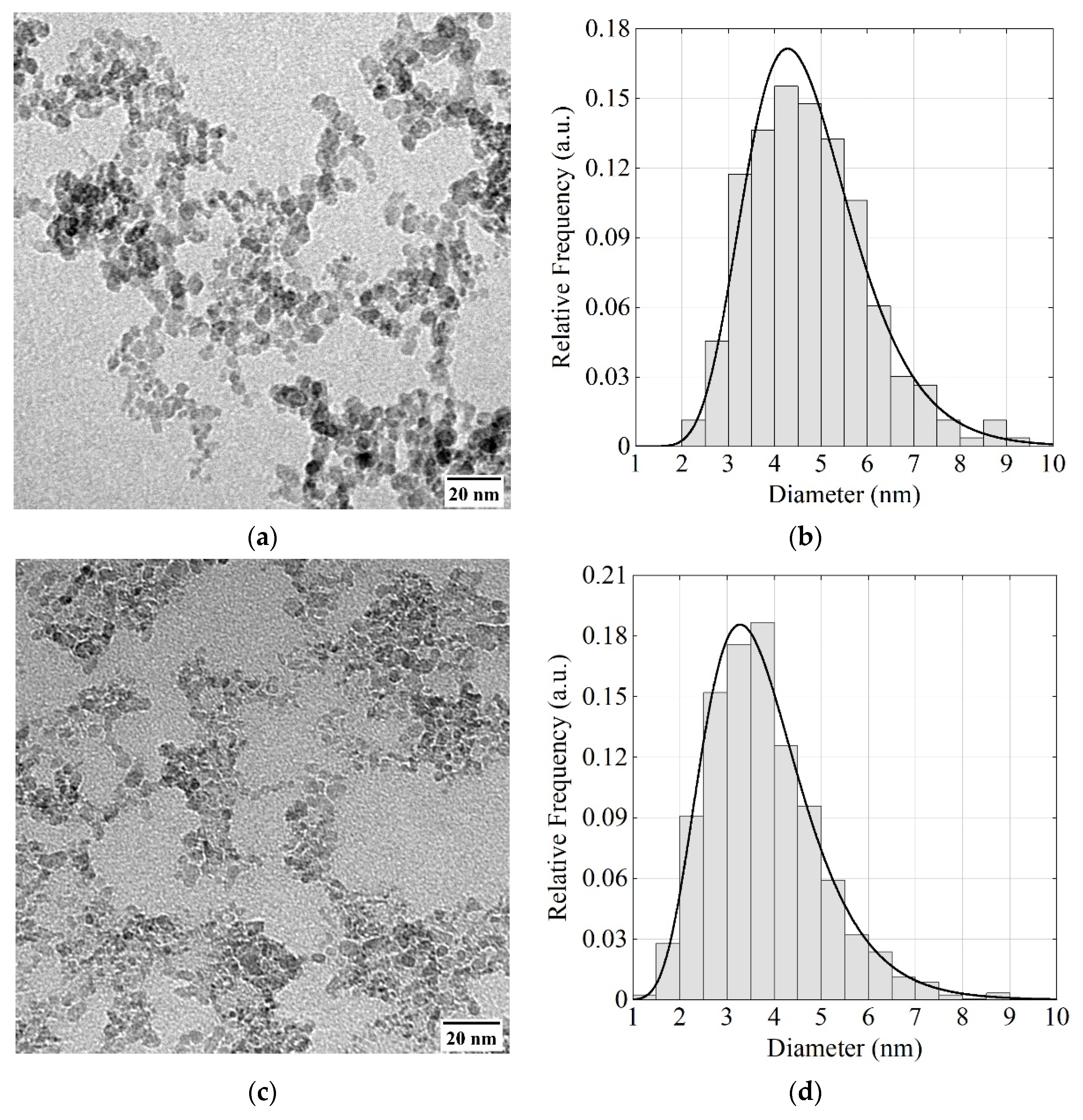

3.1. Transmission Electron Microscopy

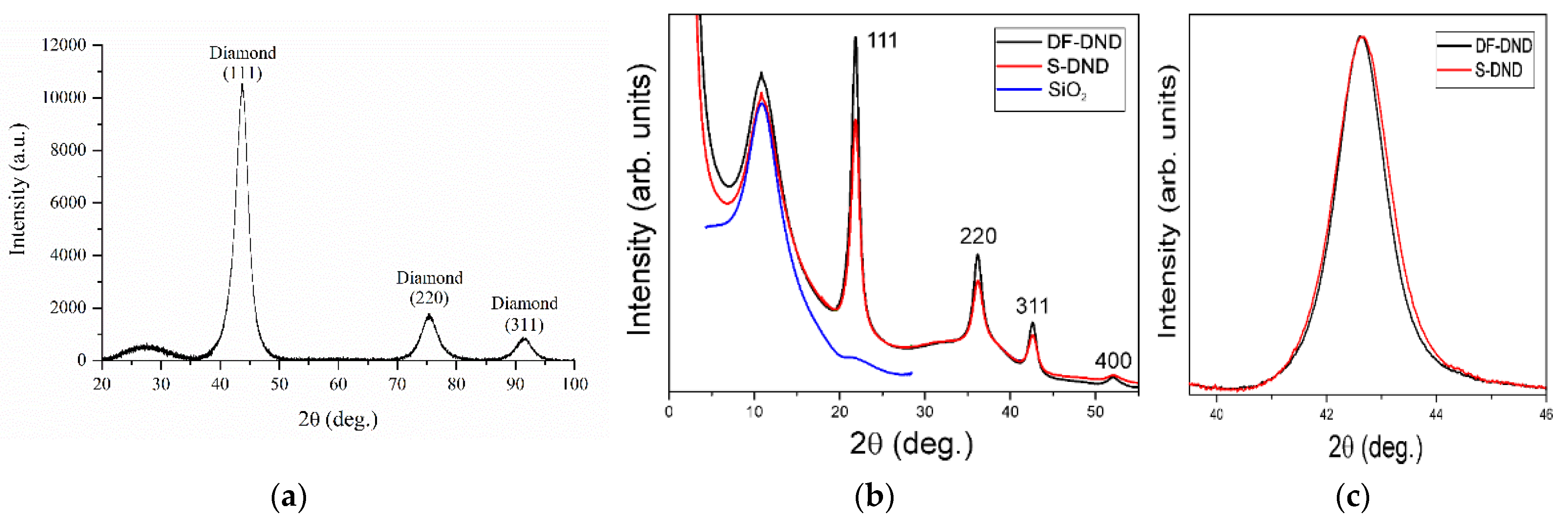

3.2. X-ray Diffraction

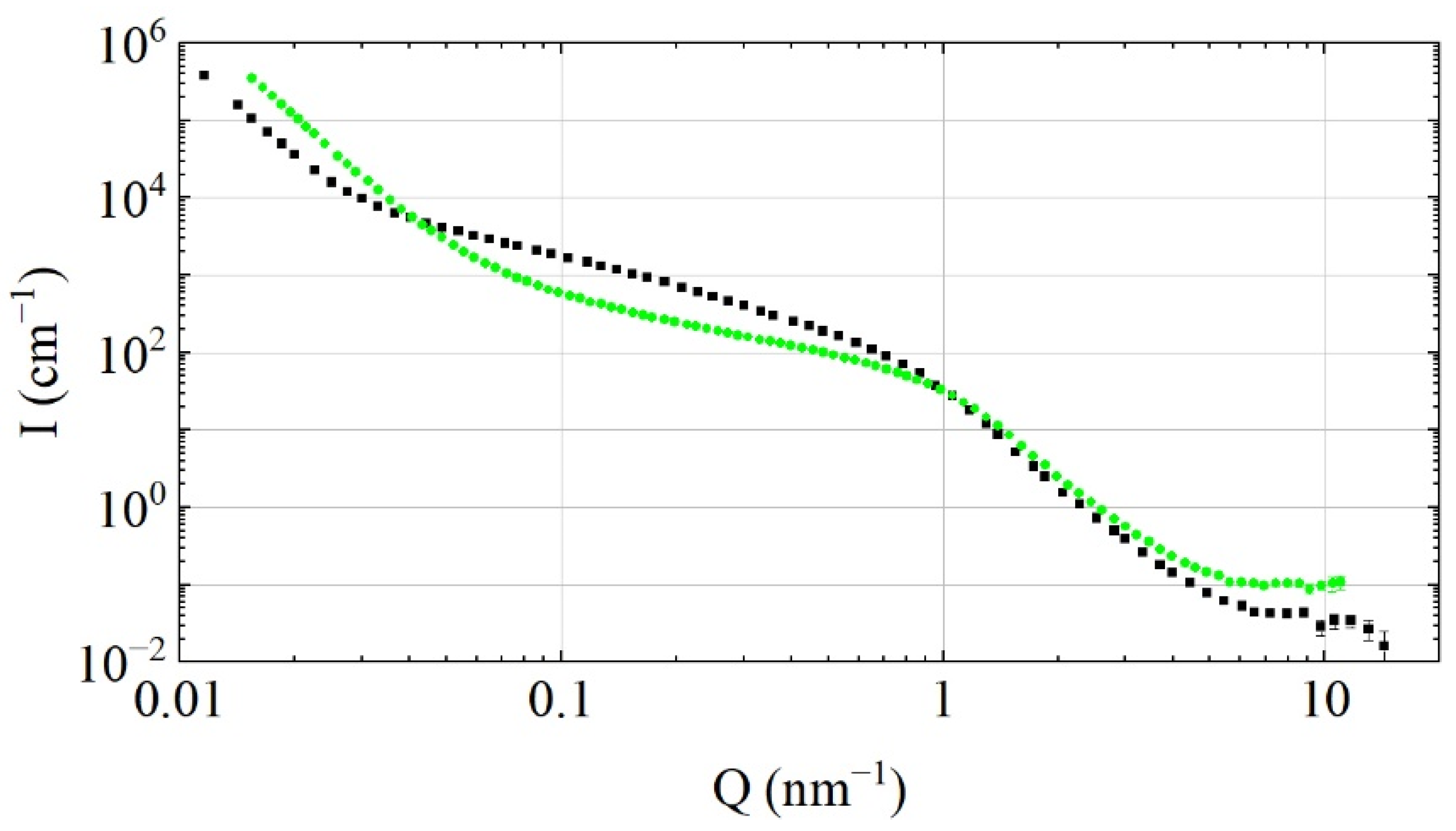

3.3. Small-Angle Neutron Scattering

4. Discussion

4.1. Approximation of the Size Distribution of DNDs Using MDDNS

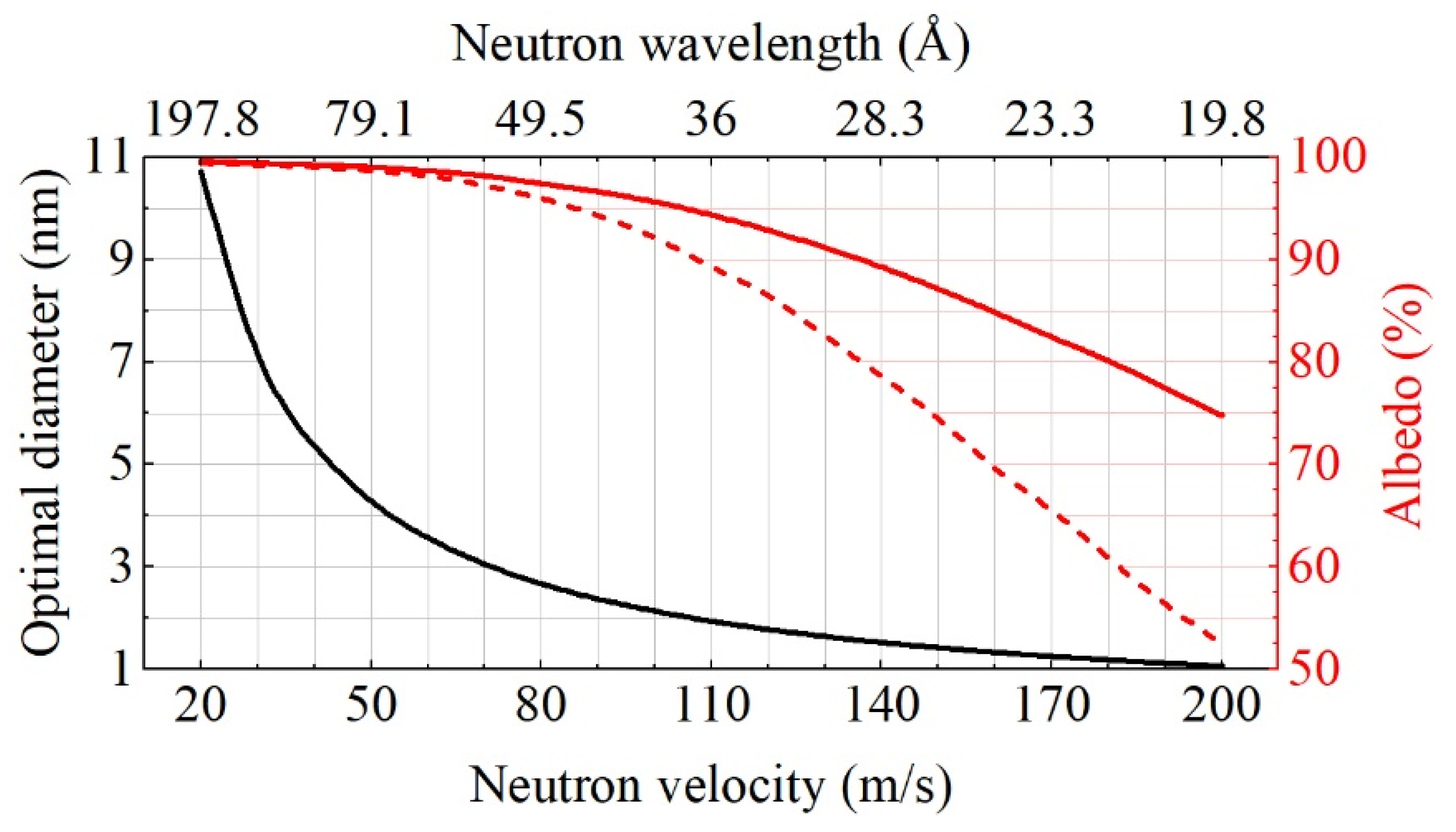

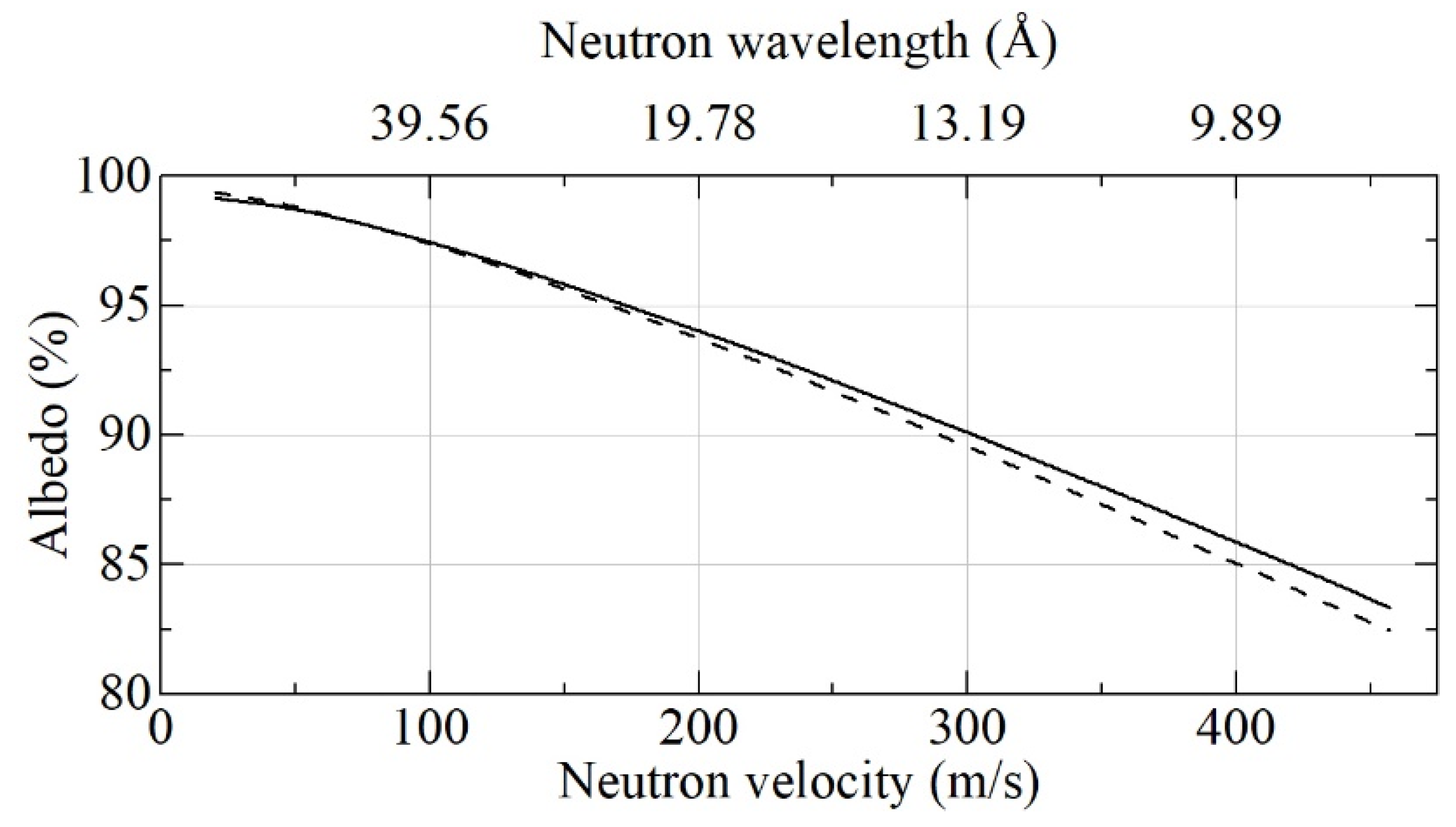

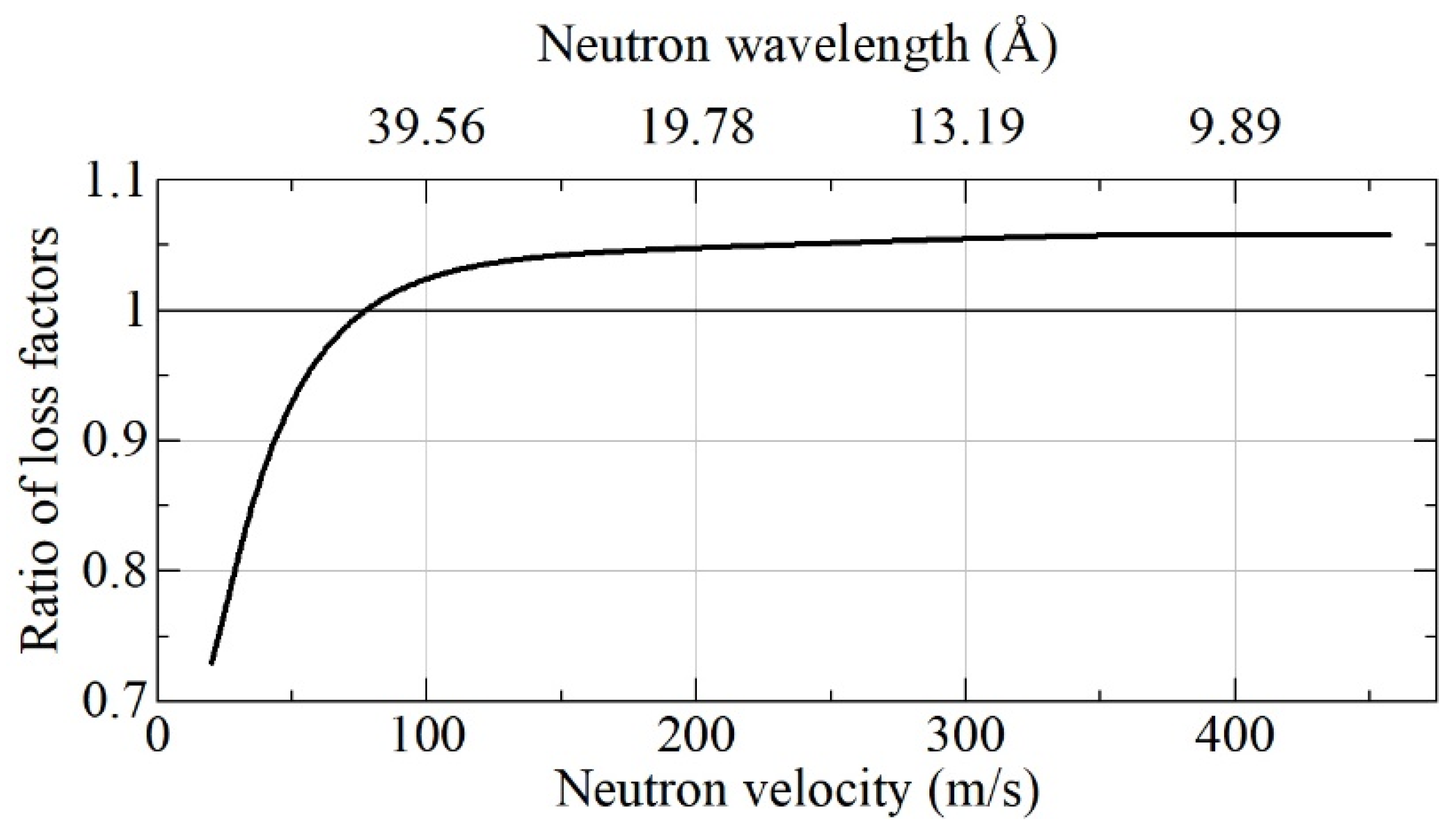

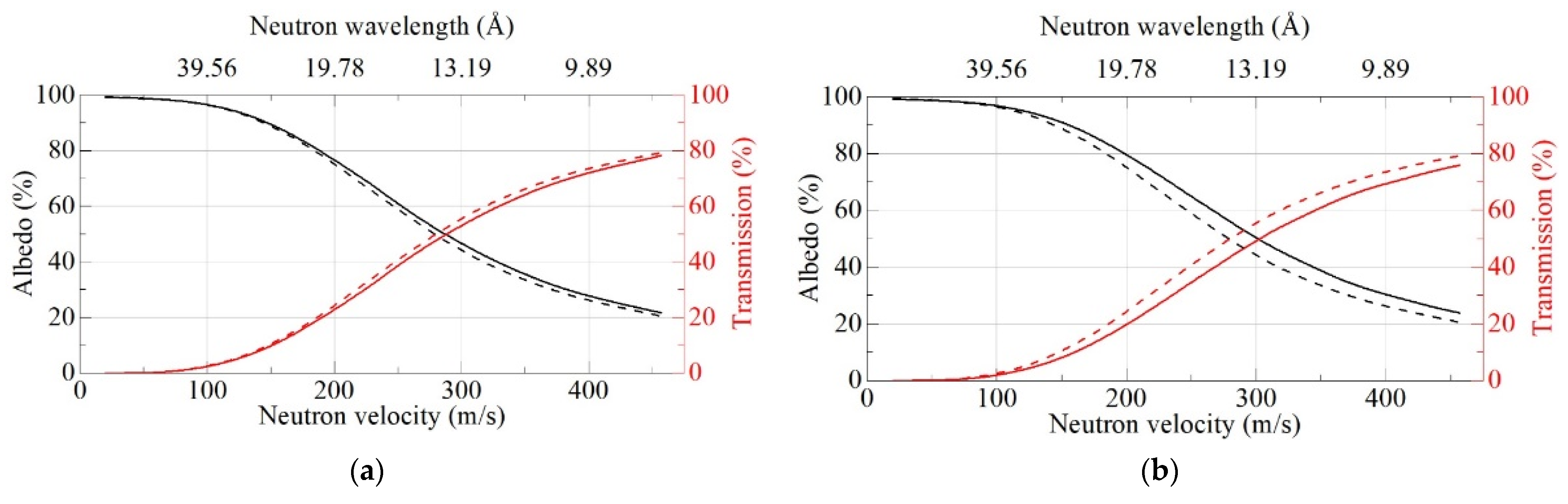

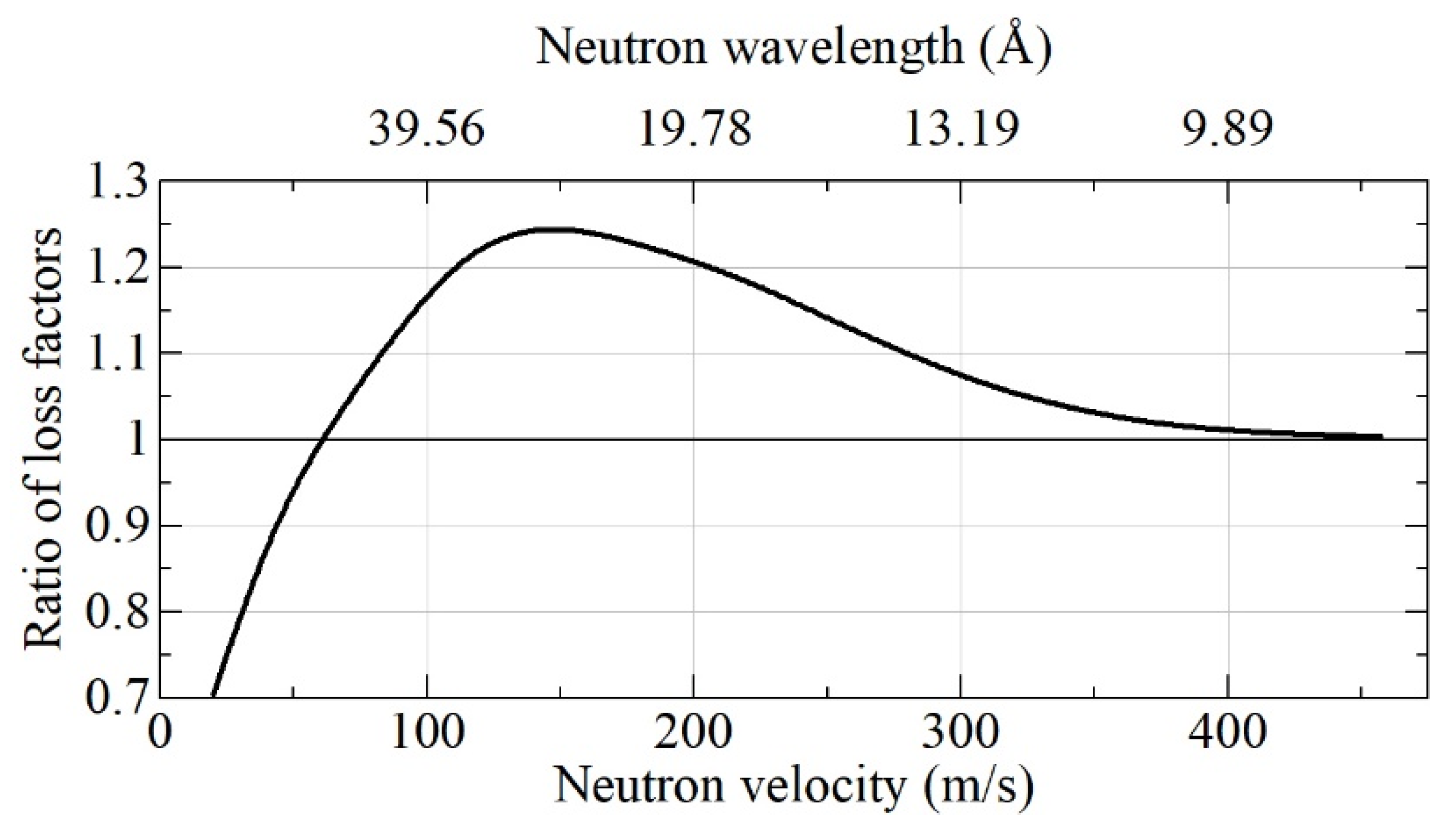

4.2. Albedo Calculations

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lushchikov, V.I.; Pokotilovskii, Y.N.; Strelkov, A.V.; Shapiro, F.L. Observation of ultracold neutrons. JETP Lett. 1969, 9, 23. [Google Scholar]

- Steyerl, A. Measurements of total cross sections for very slow neutrons with velocities from 100 m/s to 5 m/s. Phys. Lett. B 1969, 29, 33–35. [Google Scholar] [CrossRef]

- Ignatovich, V.K. The Physics of Ultracold Neutrons; Clarendon Press: Oxford, UK, 1990. [Google Scholar]

- Golub, R.; Richardson, D.; Lamoreaux, S.K. Ultracold Neutrons; CRC Press: Oxfordshire, UK, 1991. [Google Scholar]

- Steyerl, A. Ultracold Neutrons; World Scientific: Singapore, 2020. [Google Scholar]

- Ageron, P. Cold neutron sources. Nucl. Instr. Meth. A 1989, 284, 197. [Google Scholar] [CrossRef]

- Nesvizhevsky, V.V. Interaction of neutrons with nanoparticles. Phys. At. Nucl. 2002, 65, 400–408. [Google Scholar] [CrossRef]

- Artem’ev, V.A. Estimation of neutron reflection from nanodispersed materials. At. Energy 2006, 101, 901–904. [Google Scholar] [CrossRef]

- Nesvizhevsky, V.V.; Lychagin, E.V.; Muzychka, A.Y.; Strelkov, A.V.; Pignol, G.; Protasov, K.V. The reflection of very cold neutrons from diamond powder nanoparticles. Nucl. Instr. Meth. A 2008, 595, 631–636. [Google Scholar] [CrossRef] [Green Version]

- Lychagin, E.V.; Muzychka, A.Y.; Nesvizhevsky, V.V.; Pignol, G.; Protasov, K.V.; Strelkov, A.V. Storage of very cold neutrons in a trap with nano-structured walls. Phys. Lett. B 2009, 679, 186–190. [Google Scholar] [CrossRef]

- Nesvizhevsky, V.; Cubitt, R.; Lychagin, E.; Muzychka, A.; Nekhaev, G.; Pignol, G.; Protasov, K.; Strelkov, A. Application of diamond nanoparticles in low-energy neutron physics. Materials 2010, 3, 1768. [Google Scholar] [CrossRef]

- Cubitt, R.; Lychagin, E.V.; Muzychka, A.Y.; Nekhaev, G.V.; Nesvizhevsky, V.V.; Pignol, G.; Protasov, K.V.; Strelkov, A.V. Quasi-specular reflection of cold neutrons from nano-dispersed media at above critical angles. Nucl. Instr. Meth. A 2010, 622, 182–185. [Google Scholar] [CrossRef] [Green Version]

- Krylov, A.R.; Lychagin, E.V.; Muzychka, A.Y.; Nesvizhevsky, V.V.; Nekhaev, G.V.; Strelkov, A.V.; Ivanov, A.S. Study of bound hydrogen in powders of diamond nanoparticles. Crystal. Rep. 2011, 56, 1186–1191. [Google Scholar] [CrossRef]

- Nesvizhevsky, V.V.; Koster, U.; Dubois, M.; Batisse, N.; Frezet, L.; Bosak, A.; Gines, L.; Williams, O. Fluorinated nanodiamonds as unique neutron reflector. Carbon 2018, 130, 799–805. [Google Scholar] [CrossRef]

- Nesvizhevsky, V.V.; Dubois, M.; Gutfreund, P.; Lychagin, E.V.; Nezvanov, A.Y.; Zhernenkov, K.N. Effect of nanodiamond fluorination on the efficiency of quasi-specular reflection of cold neutrons. Phys. Rev. A 2018, 97, 023629. [Google Scholar] [CrossRef]

- Herraiz, M.; Batisse, N.; Dubois, M.; Nesvizhevsky, V.V.; Cavallari, C.; Brunelli, M.; Pischedda, V.; Radescu, S. A multitechnique study of fluorinated nanodiamonds for low-energy neutron physics applications. J. Phys. Chem. C 2020, 124, 14229–14236. [Google Scholar] [CrossRef]

- Bosak, A.; Dideikin, A.; Dubois, M.; Ivankov, O.; Lychagin, E.; Muzychka, A.; Nekhaev, G.; Nesvizhevsky, V.; Nezvanov, A.; Schweins, R.; et al. Fluorination of diamond nanoparticles in slow neutron reflectors does not destroy their crystalline cores and clustering while decreasing neutron losses. Materials 2020, 13, 3337. [Google Scholar] [CrossRef] [PubMed]

- Nesvizhevsky, V.V. Reflectors for VCN and applications of VCN. Rev. Mex. Fis. 2011, 57, 1–5. [Google Scholar]

- Ignatovich, V.K.; Nesvizhevsky, V.V. Reflection of slow neutrons from nanorod powder. At. Energy 2014, 116, 132–143. [Google Scholar] [CrossRef]

- Batsanov, S.S.; Osavchuk, A.N.; Naumov, S.P.; Gavrilkin, S.M.; Batsanov, A.S. Novel synthesis and properties of hydrogen-free detonation nanodiamond. Mater. Chem. Phys. 2018, 216, 120–129. [Google Scholar] [CrossRef] [Green Version]

- Ersez, T.; Osborn, J.C.; Lu, W.; Mata, J.P. Small angle and inelastic scattering investigations of nanodiamonds. Phys. B 2018, 551, 278–282. [Google Scholar] [CrossRef]

- Teshigawara, M.; Tsuchikawa, Y.; Ichikawa, G.; Takata, S.; Mishima, K.; Harada, M.; Ooi, M.; Kawamura, Y.; Kai, T.; Ohira-Kawamura, S.; et al. Ohira Measurement of neutron scattering cross section of nano-diamond with particle diameter of approximately 5 nm in energy range of 0.2 meV to 100 meV. Nucl. Instr. Meth. A 2019, 929, 113–120. [Google Scholar] [CrossRef]

- Grammer, K.B.; Gallmeier, F.X. The small-angle neutron scattering extension in MCNPX and the SANS cross section for nanodiamonds. Nucl. Instr. Meth. A 2020, 953, 163226. [Google Scholar] [CrossRef]

- Granada, J.R.; Damain, J.I.; Helman, C.H. Studies of reflector materials for cold neutrons. Eur. Phys. J. Web Conf. 2020, 231, 04002. [Google Scholar] [CrossRef]

- Jamalipour, M.; Zanini, L.; Gorini, G. Directional reflection of cold neutrons using nanodiamond particles for compact neutron sources. Eur. Phys. J. Web Conf. 2020, 231, 04003. [Google Scholar] [CrossRef]

- Badziag, P.; Verwoerd, W.S.; Ellis, W.P.; Greiner, N.R. Nanometre-sized diamonds are more stable then graphite. Nature 1990, 343, 244–245. [Google Scholar] [CrossRef]

- Greiner, N.R.; Philips, D.S.; Johnson, J.C. Diamonds in detonation soot. Nature 1988, 333, 440–442. [Google Scholar] [CrossRef]

- Aleksenskii, A.E.; Baidakova, M.V.; Vul′, A.Y.; Sikitskii, V.I. The structure of diamond nanoclusters. Phys. Solid State 1999, 41, 668–671. [Google Scholar] [CrossRef]

- Palosz, B.; Grzanka, E.; Gierlotka, S.; Stel’makh, S.; Pielaszek, R.; Bismayer, U.; Neuefeind, J.; Weber, H.-P.; Proffen, T.; von Dreele, R.; et al. Analysis of short and long range order in nanocrystalline diamonds with application of powder diffractometer. Z. Krist. Cryst. Mater. 2002, 217, 497–509. [Google Scholar] [CrossRef]

- Kruger, A.; Kataoka, F.; Ozawa, M.; Fujino, T.; Suzuki, Y.; Aleksenskii, A.E.; Vul’, A.Y.; Osawa, E. Usually tight aggregation in detonation nanodiamond: Identification and disintegration. Carbon 2005, 43, 1722–1730. [Google Scholar] [CrossRef]

- Baidakova, M.; Vul’, A. New prospects and frontiers of nanodiamond clusters. J. Phys. D Appl. Phys. 2007, 40, 6300–6311. [Google Scholar] [CrossRef]

- Avdeev, M.V.; Aksenov, V.L.; Rosta, L. Pressure induced charges in fractal structure of detonation nanodiamond powder by small-angle neutron scattering. Diam. Relat. Mater. 2007, 16, 2050–2053. [Google Scholar] [CrossRef]

- Enyashin, A.N.; Ivanovskii, A.L. Atomic and electronic structures and stability of icosahedral nanodiamonds and onions. Phys. Sol. St. 2007, 49, 392–397. [Google Scholar] [CrossRef]

- Osawa, E. Monodisperse single nanodiamond particles. Pure Appl. Chem. 2008, 80, 1365–1379. [Google Scholar] [CrossRef]

- Williams, O.; Hees, J.; Dieker, C.; Jager, W.; Kiste, L.; Nebel, C.E. Size-dependent reactivity of diamond nanoparticles. ACS Nano 2010, 4, 4824–4830. [Google Scholar] [CrossRef]

- Aleksenskii, A.E.; Eydelman, E.D.; Vul’, A.Y. Deagglomeration of detonation nanodiamonds. Nanosci. Nanotechnol. Lett. 2011, 3, 68–74. [Google Scholar] [CrossRef]

- Chang, L.-Y.; Osawa, E.; Barnard, A.S. Confirmation of the electrostatic self-assembly of nanodiamonds. Nanoscale 2011, 3, 958–962. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mochalin, V.N.; Shednerova, O.; Ho, D.; Gogotsi, Y. The properties and applications of nanodiamonds. Nat. Nanotechnol. 2012, 7, 11–23. [Google Scholar] [CrossRef] [PubMed]

- Osawa, E.; Sasaki, S.; Yamanoi, R. Deagglomeration of Detonation Nanodiamond. In Ultrananocrystalline Diamond: Synthesis, Properties and Applications; Gruen, D., Shenderova, O., Eds.; Elsevier: Amsterdam, The Netherlands, 2012; Chapter 6; pp. 165–179. [Google Scholar]

- Avdeev, M.V.; Aksenov, V.L.; Tomchuk, O.V.; Bulavin, L.A.; Garamus, V.M.; Osawa, E. The spatial diamond-graphite transition in detonation nanodiamond as revealed by small-angle neutron scattering. J. Phys. Cond. Mater. 2013, 25, 445001. [Google Scholar] [CrossRef] [Green Version]

- Vul’, A.; Shenderova, O. Detonation Nanodiamonds: Science and Applications; Pan Stanford Publishing: Singapore, 2014. [Google Scholar]

- Williams, O. Nanodiamond; RSC Publishing: Cambridge, UK, 2014. [Google Scholar]

- Zousman, B.; Levinson, O. Pure nanodiamonds produced by laser-assisted technique. In Nanodiamond; Williams, O., Ed.; RSC Nanoscience & Nanotechnology: London, UK, 2014; Chapter 5; pp. 112–127. [Google Scholar]

- Krueger, A. Current issues and challenges in surface chemistry in nanodiamonds. In Nanodiamonds: Advanced Material Analysis; Arnault, J.-C., Ed.; Elsevier: Amsterdam, The Netherlands, 2017; Chapter 8; pp. 184–242. [Google Scholar]

- Dideikin, A.T.; Aleksenskii, A.E.; Baidakova, M.V.; Brunkov, P.N.; Brzhezinskaya, M.; Davydov, V.Y.; Levitskii, V.S.; Kidalov, S.V.; Kukushkina, Y.A.; Kirilenko, D.A.; et al. Rehybridization of carbon on facets of detonation diamond nanocrystals and forming hydrosols of individual particles. Carbon 2017, 122, 737–745. [Google Scholar] [CrossRef]

- Aleksenskii, A.; Bleuel, M.; Bosak, A.; Chumakova, A.; Dideikin, A.; Dubois, M.; Korobkina, E.; Lychagin, E.; Muzychka, A.; Nekhaev, G.; et al. Clustering of Diamond Nanoparticles, Fluorination and Efficiency of Slow Neutron Reflectors. Nanomaterials 2021, 11, 1945. [Google Scholar] [CrossRef] [PubMed]

- Girard, A.; Nguyen-Thanh, T.; Souliou, S.M.; Stekiel, M.; Morgenroth, W.; Paolasini, L.; Minelli, A.; Gambetti, D.; Winkler, B.; Bosak, A. A new diffractometer for diffuse scattering studies on the ID28 beamline at the ESRF. J. Synchrotron Rad. 2019, 26, 272–279. [Google Scholar] [CrossRef]

- Dyadkin, V.; Patisson, P.; Dmitriev, V.; Chernyshov, D. A new multipurpose diffractometer PILATUS@SNBL. J. Synchrotron Rad. 2016, 23, 825. [Google Scholar] [CrossRef] [PubMed]

- Prescher, C.; Prakapenka, V.B. DIOPTAS: A program for reduction of two-dimensional X-ray diffraction data and data exploration. High. Press. 2015, 35, 223–230. [Google Scholar] [CrossRef]

- Pielaszek, R. FW1/5/4/5M method for determination of the grain size distribution from powder diffraction line profile. J. Alloys Compounds 2004, 382, 128–132. [Google Scholar] [CrossRef]

- Linder, P.; Zemb, T. Neutrons, X-ray and Light: Scattering Methods Applied to Soft Condensed Matter, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Kuklin, A.I.; Rogachev, A.V.; Soloviev, D.V.; Ivankov, O.I.; Kovalev, Y.S.; Utrobin, P.K.; Gordeliy, V.I. Neutronographic investigations of supramolecular structures on upgraded small-angle spectrometer YuMO. J. Phys. Conf. Ser. 2017, 848, 012010. [Google Scholar] [CrossRef]

- Linder, P.; Schweins, R. The D11 small-angle scattering instrument: A new benchmark for SANS. Neutron News 2010, 21, 15–18. [Google Scholar] [CrossRef]

- Richard, D.; Ferrand, M.; Kearley, G.J. Analysis and visualization of neutron-scattering data. J. Neutron Res. 1996, 4, 33–39. [Google Scholar] [CrossRef]

- Glinka, C.J.; Barker, J.G.; Hammouda, B.; Krueger, S.; Moyer, J.J.; Orts, W.J. The 30m small angle neutron scattering instruments at the National Institute of Standard and Technology. J. Appl. Cryst. 1998, 31, 430. [Google Scholar] [CrossRef]

- Kline, S.R. Reduction and analysis of SANS and USANS data using Igor Pro. J. Appl. Cryst. 2006, 39, 895–900. [Google Scholar] [CrossRef]

- Spanier, J.; Gelbard, E. Monte Carlo Principles and Neutron Transport. Problems; Addison Wesley Publication Company: New York, NY, USA, 1969. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aleksenskii, A.; Bleuel, M.; Bosak, A.; Chumakova, A.; Dideikin, A.; Dubois, M.; Korobkina, E.; Lychagin, E.; Muzychka, A.; Nekhaev, G.; et al. Effect of Particle Sizes on the Efficiency of Fluorinated Nanodiamond Neutron Reflectors. Nanomaterials 2021, 11, 3067. https://doi.org/10.3390/nano11113067

Aleksenskii A, Bleuel M, Bosak A, Chumakova A, Dideikin A, Dubois M, Korobkina E, Lychagin E, Muzychka A, Nekhaev G, et al. Effect of Particle Sizes on the Efficiency of Fluorinated Nanodiamond Neutron Reflectors. Nanomaterials. 2021; 11(11):3067. https://doi.org/10.3390/nano11113067

Chicago/Turabian StyleAleksenskii, Aleksander, Marcus Bleuel, Alexei Bosak, Alexandra Chumakova, Artur Dideikin, Marc Dubois, Ekaterina Korobkina, Egor Lychagin, Alexei Muzychka, Grigory Nekhaev, and et al. 2021. "Effect of Particle Sizes on the Efficiency of Fluorinated Nanodiamond Neutron Reflectors" Nanomaterials 11, no. 11: 3067. https://doi.org/10.3390/nano11113067

APA StyleAleksenskii, A., Bleuel, M., Bosak, A., Chumakova, A., Dideikin, A., Dubois, M., Korobkina, E., Lychagin, E., Muzychka, A., Nekhaev, G., Nesvizhevsky, V., Nezvanov, A., Schweins, R., Shvidchenko, A., Strelkov, A., Turlybekuly, K., Vul’, A., & Zhernenkov, K. (2021). Effect of Particle Sizes on the Efficiency of Fluorinated Nanodiamond Neutron Reflectors. Nanomaterials, 11(11), 3067. https://doi.org/10.3390/nano11113067