Effect of Nanostructuring on the Thermoelectric Properties of β-FeSi2

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

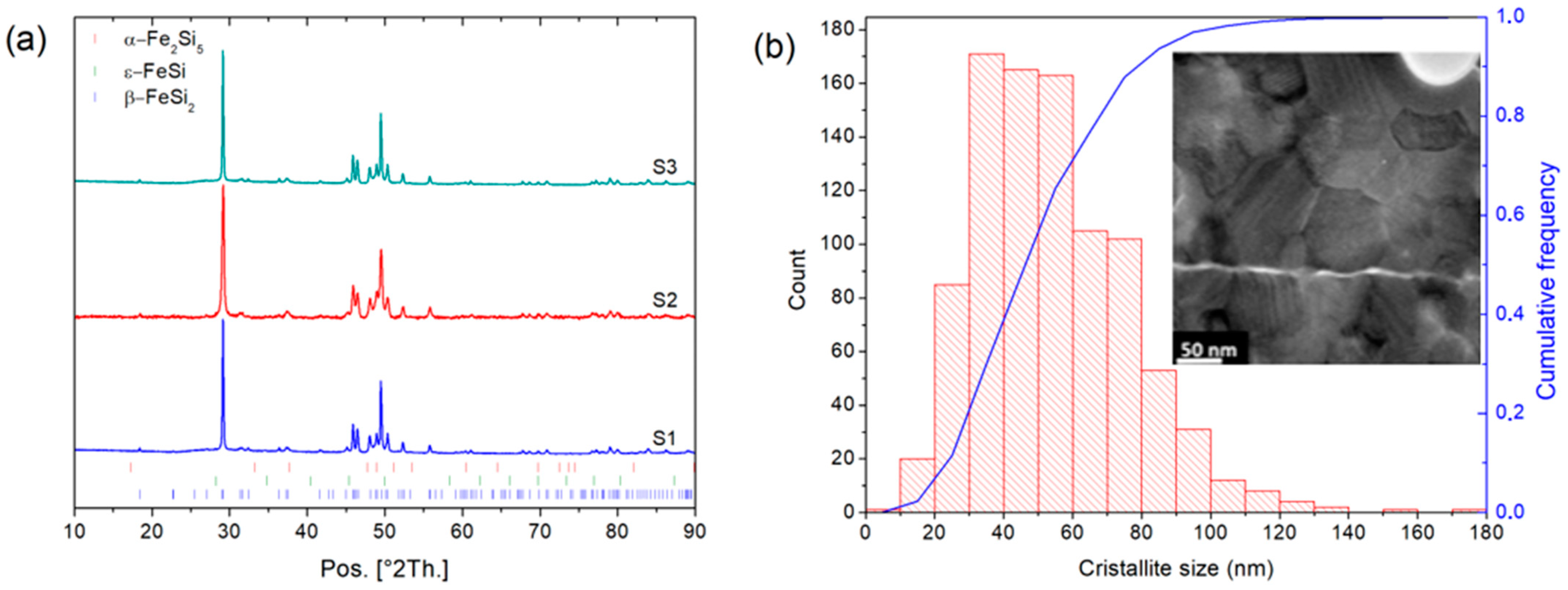

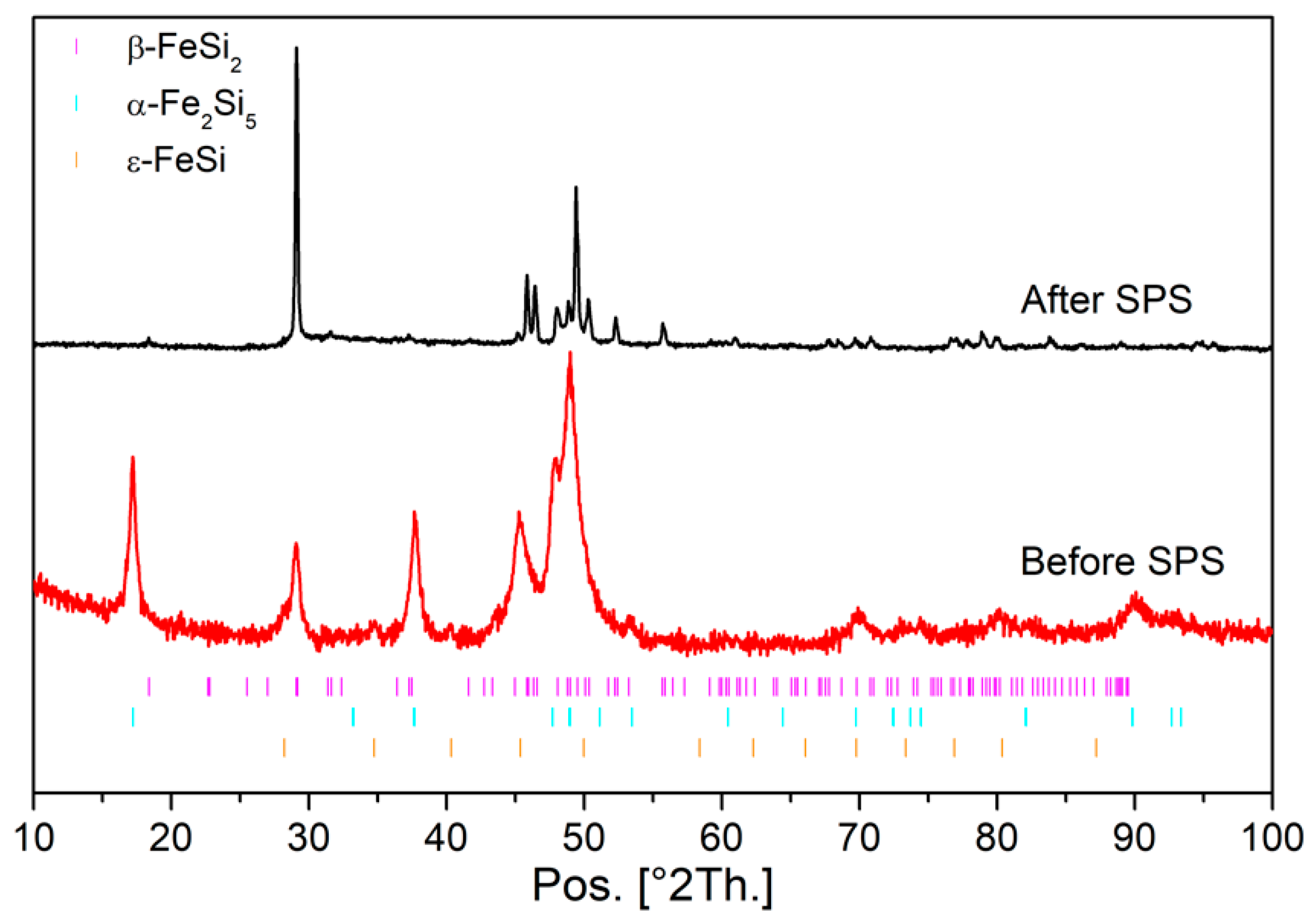

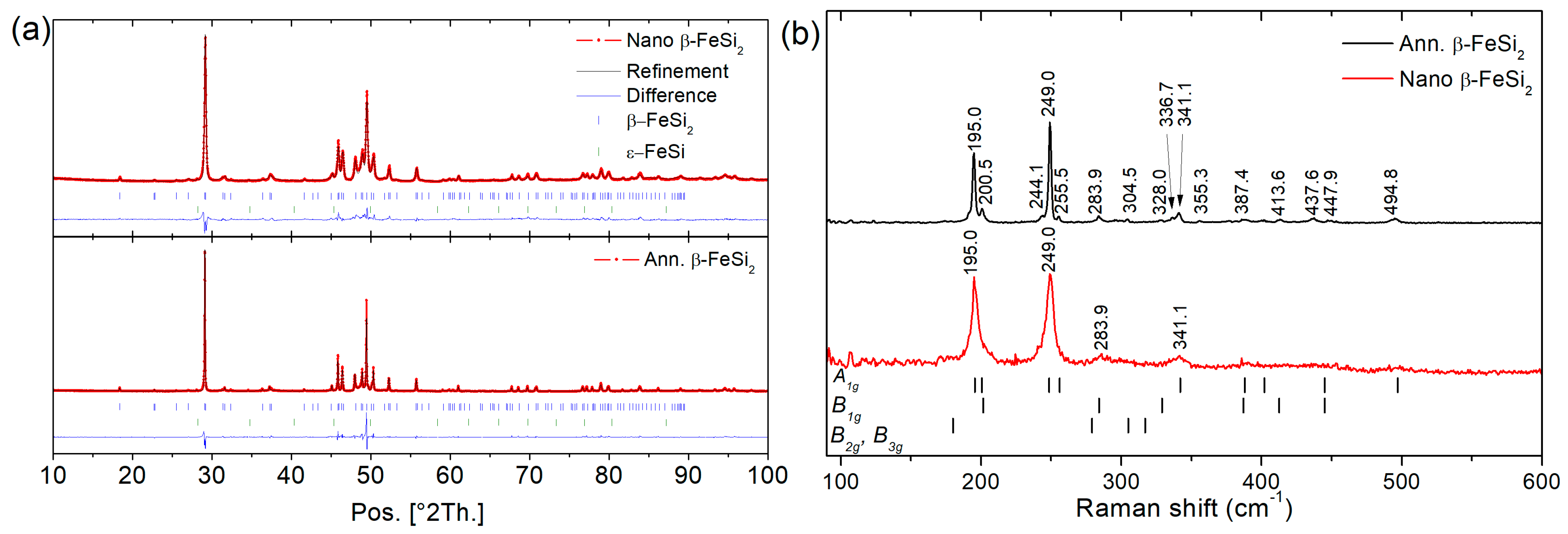

3.1. Structural Analysis

3.2. Lattice Dynamic of Bulk and Nanostructured β-FeSi2

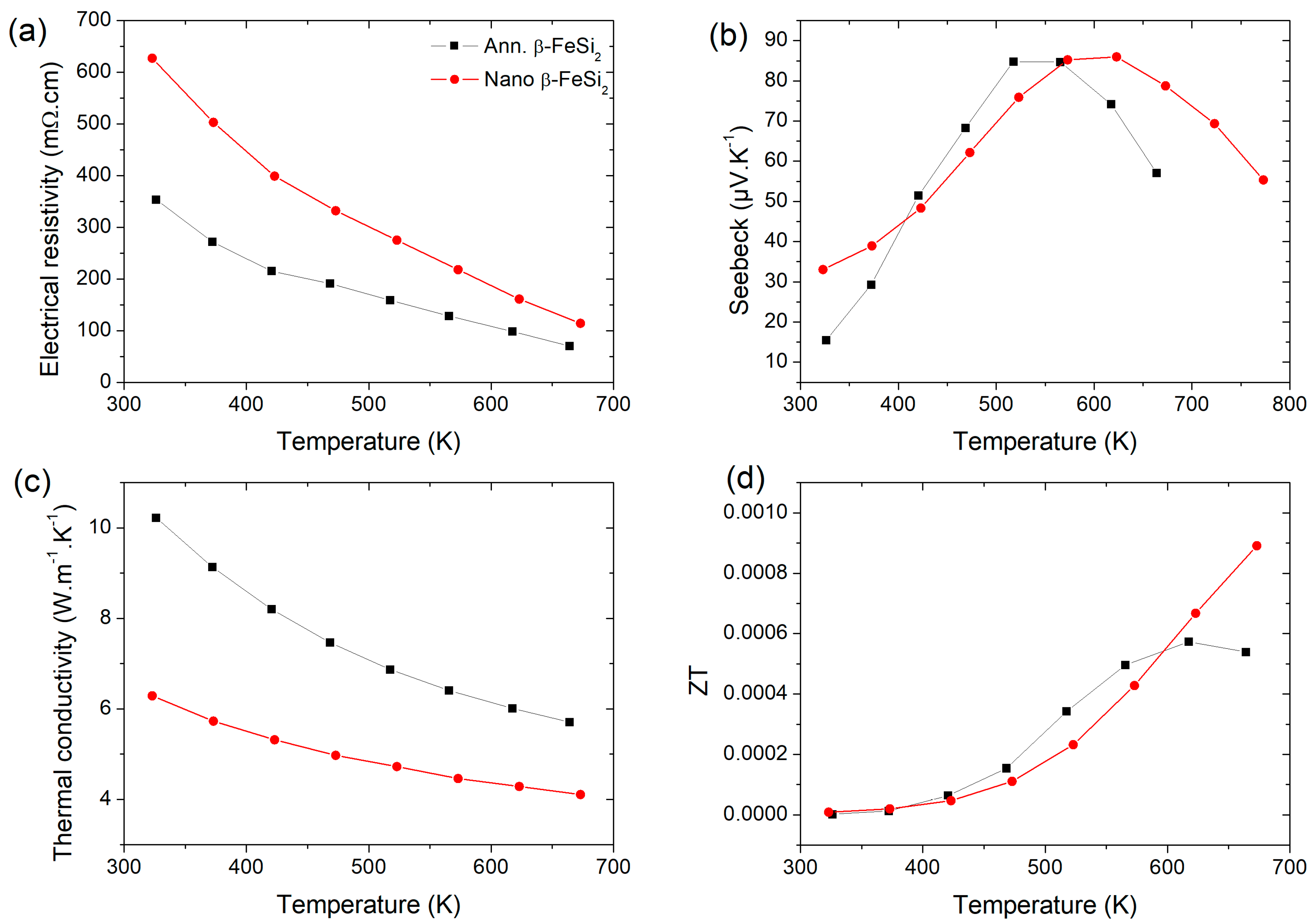

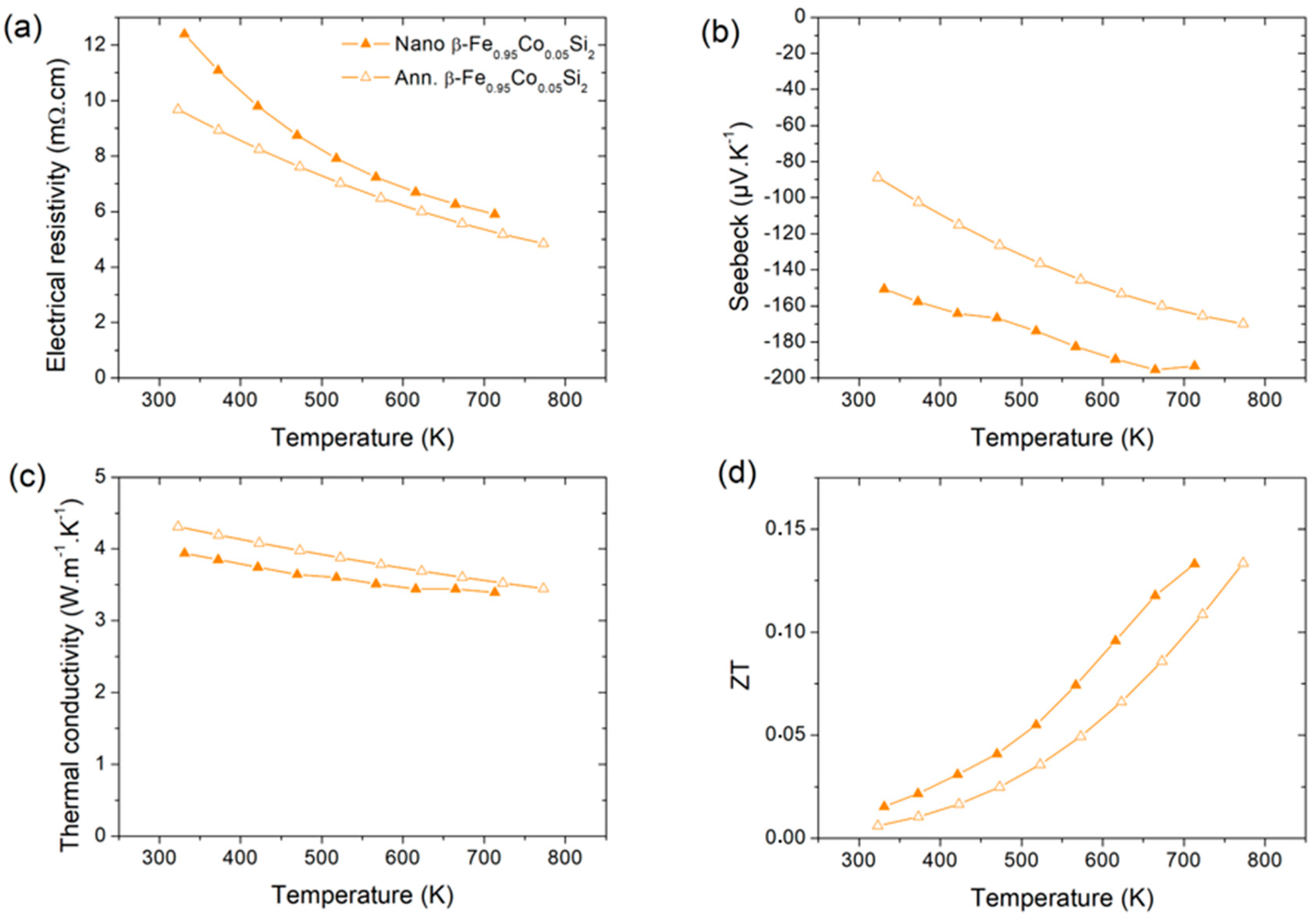

3.3. Thermoelectric Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Goldsmid, H.J. Thermoelectric Refrigeration; Springer: Boston, MA, USA, 1964. [Google Scholar]

- Vining, C.B. An inconvenient truth about thermoeletrics. Nat. Mater. 2009, 8, 83–85. [Google Scholar] [CrossRef] [PubMed]

- Amatya, R.; Ram, R.J. Trend for thermoelectric materials and their earth abundance. J. Electron. Mater. 2012, 41, 1011–1019. [Google Scholar] [CrossRef]

- Muchtar, A.R.; Srinivasan, B.; le Tonquesse, S.; Singh, S.; Soelami, N.; Yuliarto, B.; Berthebaud, D.; Mori, T. Physical insights on the lattice softening driven mid-temperature range thermoelectrics of Ti/Zr-inserted SnTe—An outlook beyond the horizons of conventional phonon scattering and excavation of Heikes’ equation for estimating carrier properties. Adv. Energy Mater. 2021, 11, 2101122. [Google Scholar] [CrossRef]

- Srinivasan, B.; le Tonquesse, S.; Gellé, A.; Bourgès, C.; Monier, L.; Ohkubo, I.; Halet, J.F.; Berthebaud, D.; Mori, T. Screening of transition (Y, Zr, Hf, V, Nb, Mo, and Ru) and rare-earth (La and Pr) elements as potential effective dopants for thermoelectric GeTe—An experimental and theoretical appraisal. J. Mater. Chem. A 2020, 8, 19805–19821. [Google Scholar] [CrossRef]

- Fedorov, M.I.; Isachenko, G.N. Silicides: Materials for thermoelectric energy conversion. Jpn. J. Appl. Phys. 2015, 54, 07JA05. [Google Scholar] [CrossRef] [Green Version]

- Hesse, J. Leistungsthermoelemente aus Eisendisilicid fur die Stromerzeugung (Power thermocouples made of iron disilicide for power generation). Z. Fur Angew. Phys. 1969, 28, 133. [Google Scholar]

- Dusausoy, Y.; Protas, J.; Wandji, R.; Roques, B. Structure cristalline du disiliciure de fer, FeSi2β (cristalline structure of iron disilicide, FeSi2β). Acta Crystallogr. Sect. B Struct. Crystallogr. Cryst. Chem. 1971, 27, 1209–1218. [Google Scholar] [CrossRef]

- Christensen, N.E. Electronic structure of β-FeSi2. Phys. Rev. B 1990, 42, 7148–7153. [Google Scholar] [CrossRef] [PubMed]

- Udono, H.; Kikuma, I.; Okuno, T.; Masumoto, Y.; Tajima, H. Indirect optical absorption of single crystalline β-FeSi2. Appl. Phys. Lett. 2004, 85, 1937–1939. [Google Scholar] [CrossRef] [Green Version]

- le Tonquesse, S.; Verastegui, Z.; Huynh, H.; Dorcet, V.; Guo, Q.; Demange, V.; Prestipino, C.; Berthebaud, D.; Mori, T.; Pasturel, M. Magnesioreduction synthesis of Co-Doped β-FeSi2: Mechanism, microstructure, and improved thermoelectric properties. ACS Appl. Energy Mater. 2019, 2, 8525–8534. [Google Scholar] [CrossRef]

- Ito, M.; Nagai, H.; Oda, E.; Katsuyama, S.; Majima, K. Effects of P doping on the thermoelectric properties of β-FeSi2. J. Appl. Phys. 2002, 91, 2138–2142. [Google Scholar] [CrossRef]

- Rowe, D.M. Thermoelectrics Handbook: Macro to Nano; CRC: Boca Raton, FL, USA; Taylor & Francis: Abingdon, UK, 2006. [Google Scholar]

- Liu, Z.; Sato, N.; Gao, W.; Yubuta, K.; Kawamoto, N.; Mitome, M.; Kurashima, K.; Owada, Y.; Nagase, K.; Lee, C.H.; et al. Demonstration of ultrahigh thermoelectric efficiency of ∼7.3% in Mg3Sb2/MgAgSb module for low-temperature energy harvesting. Joule 2021, 5, 1196–1208. [Google Scholar] [CrossRef]

- Du, X.; Qiu, P.; Chai, J.; Mao, T.; Hu, P.; Yang, J.; Sun, Y.-Y.; Shi, X.; Chen, L. Doubled thermoelectric figure of merite in p-type β-FeSi2-via synergistically optimizing electrical and thermal transports. ACS Appl. Mater. Interfaces 2020, 12, 12901–12909. [Google Scholar] [CrossRef]

- Heremans, J.P.; Dresselhaus, M.S.; Bell, L.E.; Morelli, D.T. When thermoelectrics reached the nanoscale. Nat. Nanotech. 2013, 8, 471–473. [Google Scholar] [CrossRef] [PubMed]

- Poudel, B.; Hao, Q.; Ma, Y.; Lan, Y.; Minnich, A.; Yu, B.; Yan, X.; Wang, D.; Muto, A.; Vashaee, D.; et al. High-thermoelectric performance of nanostructured bismuth antimonide telluride bulk alloys. Science 2008, 320, 634–638. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Joshi, G.; Lee, H.; Lan, Y.; Wang, X.; Zhu, G.; Wang, D.; Gould, R.W.; Cuff, D.C.; Tang, M.Y.; Dresselhaus, M.S.; et al. Enhanced thermoelectric figure of merit in nanostructured p-type silicon germanium bulk alloys. Nano Lett. 2008, 8, 4670–4674. [Google Scholar] [CrossRef] [PubMed]

- Bux, S.K.; Blair, R.G.; Gogna, P.K.; Lee, H.; Chen, G.; Dresselhaus, M.S.; Kaner, R.B.; Fleurial, J.-P. Nanostructured bulk silicon as an effective thermoelectric material. Adv. Funct. Mater. 2009, 19, 2445–2452. [Google Scholar] [CrossRef]

- Longhin, M.; Viennois, R.; Ravot, D.; Robin, J.-J.; Villeroy, B.; Vaney, J.-B.; Candolfi, C.; Lenoir, B.; Papet, P. Nanostructured CoSi obtained by spark plasma sintering. J. Electron. Mater. 2015, 44, 1963–1966. [Google Scholar] [CrossRef]

- Khalil, M. Investigation and Optimization of Semiconducting Chromium Disilicide Based Materials for Thermoelectric Applications. Ph.D. Thesis, University of Montpellier, Montpellier, France, 2015. [Google Scholar]

- Khalil, M.; Moll, A.; Godfroy, M.; Letrouit-Lebranchu, A.; Villeroy, B.; Alleno, E.; Viennois, R.; Beaudhuin, M. Thermoelectric properties and stability of nanostructured chromium disilicide CrSi2. J. Appl. Phys. 2019, 126, 135103. [Google Scholar] [CrossRef]

- Rodriguez-Carvajal, J. FULLPROF: A program for Rietveld refinement and pattern matching analysis. In Proceedings of the Satellite Meeting on Powder Diffraction of the XV Congress of the IUCr, Toulouse, France, 19–28 July 1990; p. 127. [Google Scholar]

- Treacy, M.M.J.; Newsam, J.M.; Deem, M.W. A general recursion method for calculating diffracted intensities from crystals containing planar faults. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1991, 433, 499–520. [Google Scholar]

- Casas-Cabanas, M.; Reynaud, M.; Rikarte, J.; Horbach, P.; Rodríguez-Carvajal, J. FAULTS: A program for refinement of structures with extended defects. J. Appl. Crystallogr. 2016, 49, 2259–2269. [Google Scholar] [CrossRef]

- Tani, J.-I.; Takahashi, M.; Kido, H. Lattice dynamics of β-FeSi2 from first-principles calculations. Physica B 2010, 405, 2200–2204. [Google Scholar] [CrossRef]

- Arushanov, E.K.; Carles, R.; Kloc, C.; Butcher, E.; Leotin, J.; Smirnov, D.V. Optical studies of monocrystalline β-FeSi2. Compd. Semicond. 1997, 1996, 1013–1016. [Google Scholar]

- Birdwell, A.G.; Glosser, R.; Leong, D.N.; Homewood, K.P. Raman investigation of ion beam synthesized β-FeSi2. J. Appl. Phys. 2000, 89, 965–972. [Google Scholar] [CrossRef]

- Moll, A.; Viennois, R.; Boehm, M.; Koza, M.M.; Sidis, Y.; Rouquette, J.; Laborde, S.; Debray, J.; Menaert, B.; Castellan, J.-P.; et al. Anharmonicity and effect of the nanostructuring on the lattice dynamics of CrSi2. J. Phys. Chem. C 2021, 125, 14786–14796. [Google Scholar] [CrossRef]

- Ito, M.; Nagai, H.; Tahata, T.; Katsuyama, S.; Majima, K. Effects of Zr substitution on phase transformation and thermoelectric properties of β-FeSi2. J. Appl. Phys. 2002, 92, 3217–3222. [Google Scholar] [CrossRef]

- Kim, H.-S.; Lee, K.H.; Yoo, J.; Shin, W.H.; Roh, J.W.; Hwang, J.-Y.; Kim, S.W.; Kim, S. Suppression of bipolar conduction via bandgap engineering for enhanced thermoelectric performance of p-type Bi0.4Sb1.6Te3 alloys. J. Alloys Compd. 2018, 741, 869–874. [Google Scholar] [CrossRef]

- Kim, H.-S.; Lee, K.H.; Kim, S. Understanding bipolar thermal conductivity in terms of concentration ratio of minority to majority carriers. J. Mater. Res. Technol. 2021, 14, 639–646. [Google Scholar] [CrossRef]

- Tani, J.-I.; Kido, H. Hall effect and thermoelectric properties of FeSix. Jpn. J. Appl. Phys. 2000, 39, 1054–1057. [Google Scholar] [CrossRef]

- Tani, J.-I.; Kido, H. First-principle study of native point defects in β-FeSi2. J. Alloys Compd. 2003, 352, 153–157. [Google Scholar] [CrossRef]

- Chai, J.; Ming, C.; Du, X.; Qiu, P.; Sun, Y.-Y.; Chen, L. Thermodynamics, kinetics and electronics properties of point defects in β-FeSi2. Phys. Chem. Chem. Phys. 2019, 21, 10497–10504. [Google Scholar] [CrossRef]

- Kim, S.W.; Cho, M.K.; Mishima, Y.; Choi, D.C. High temperature thermoelectric properties of p- and n- type β-FeSi2 with some dopants. Intermetallics 2003, 11, 399–405. [Google Scholar] [CrossRef]

- He, Z.; Platzek, D.; Stiewe, C.; Chen, H.; Karpinski, G.; Müller, E. Thermoelectric properties of hot-pressed Al- and Co-doped iron disilicide materials. J. Alloys Compd. 2007, 438, 303–309. [Google Scholar] [CrossRef]

- Tani, J.-I.; Kido, H. Thermoelectric properties of β-Fe1-xCoxSi2 semiconductors. Jpn. J. Appl. Phys. 2001, 40, 3236–3239. [Google Scholar] [CrossRef]

- Zeng, H.; Wu, Y.; Zhang, J.; Kuang, C.; Yue, M.; Zhou, S. Grain size-dependent electrical resistivity of bulk nanocrystalline Gd metals. Prog. Nat. Sci. Mater. Int. 2013, 23, 18–22. [Google Scholar] [CrossRef] [Green Version]

- Dura, O.J.; Andujar, R.; Falmbigl, M.; Rogl, P.; de la Torre, M.A.L.; Bauer, E. The effect of nanostructure on the thermoelectric figure-of-merit of La0.875Sr0.125CoO3. J. Alloys Compd. 2017, 711, 381–386. [Google Scholar] [CrossRef]

- Zheng, Y.; Slade, T.J.; Hu, L.; Tan, X.Y.; Luo, Y.; Luo, Z.-Z.; Xu, J.; Yan, Q.; Kanatzidis, M.G. Defect engineering in thermoelectric materials: What have we learned? Chem. Soc. Rev. 2021, 50, 9022–9054. [Google Scholar] [CrossRef] [PubMed]

- Rowe, D.M. CRC Handbook of Thermoelectrics; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Drasar, C.; Mueller, E.; Mrotzek, A.; Karpinski, G. Optimization of properties of Fe1-xCoxSi2+z for energy conversion and sensors. In Proceedings of the International Conference on Thermoelectrics (ICT’2002), Long Beach, CA, USA, 25–29 August 2002; pp. 81–84. [Google Scholar]

- Chen, X.; Shi, L.; Zhou, J.; Goodenough, J.B. Effects of ball milling on microstructures and thermoelectric properties of higher manganese silicides. J. Alloys Compd. 2015, 641, 30–36. [Google Scholar] [CrossRef] [Green Version]

| Sample | Composition | P (MPa) | T (K) | Relative Density (%) | Crystallite Size (nm) |

|---|---|---|---|---|---|

| S1 | β-FeSi2 | 300 | 973 | 93.2 | ~185 |

| S2 | β-FeSi2 | 500 | 873 | 93.1 | ~50 |

| S3 | β-FeSi2 | 500 | 973 | 95.2 | ~320 |

| S4 | β-Fe0.95Co0.05Si2 | 500 | 873 | 93.7 | ~110 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbassi, L.; Mesguich, D.; Berthebaud, D.; Le Tonquesse, S.; Srinivasan, B.; Mori, T.; Coulomb, L.; Chevallier, G.; Estournès, C.; Flahaut, E.; et al. Effect of Nanostructuring on the Thermoelectric Properties of β-FeSi2. Nanomaterials 2021, 11, 2852. https://doi.org/10.3390/nano11112852

Abbassi L, Mesguich D, Berthebaud D, Le Tonquesse S, Srinivasan B, Mori T, Coulomb L, Chevallier G, Estournès C, Flahaut E, et al. Effect of Nanostructuring on the Thermoelectric Properties of β-FeSi2. Nanomaterials. 2021; 11(11):2852. https://doi.org/10.3390/nano11112852

Chicago/Turabian StyleAbbassi, Linda, David Mesguich, David Berthebaud, Sylvain Le Tonquesse, Bhuvanesh Srinivasan, Takao Mori, Loïc Coulomb, Geoffroy Chevallier, Claude Estournès, Emmanuel Flahaut, and et al. 2021. "Effect of Nanostructuring on the Thermoelectric Properties of β-FeSi2" Nanomaterials 11, no. 11: 2852. https://doi.org/10.3390/nano11112852

APA StyleAbbassi, L., Mesguich, D., Berthebaud, D., Le Tonquesse, S., Srinivasan, B., Mori, T., Coulomb, L., Chevallier, G., Estournès, C., Flahaut, E., Viennois, R., & Beaudhuin, M. (2021). Effect of Nanostructuring on the Thermoelectric Properties of β-FeSi2. Nanomaterials, 11(11), 2852. https://doi.org/10.3390/nano11112852