Nanostructure of PMMA/MAM Blends Prepared by Out-of-Equilibrium (Extrusion) and Near-Equilibrium (Casting) Self-Assembly and Their Nanocellular or Microcellular Structure Obtained from CO2 Foaming

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Bulk and Film Solid Samples

2.3. Preparation of Bulk and Film Foamed Samples

2.4. Characterization Techniques

3. Results and Discussion

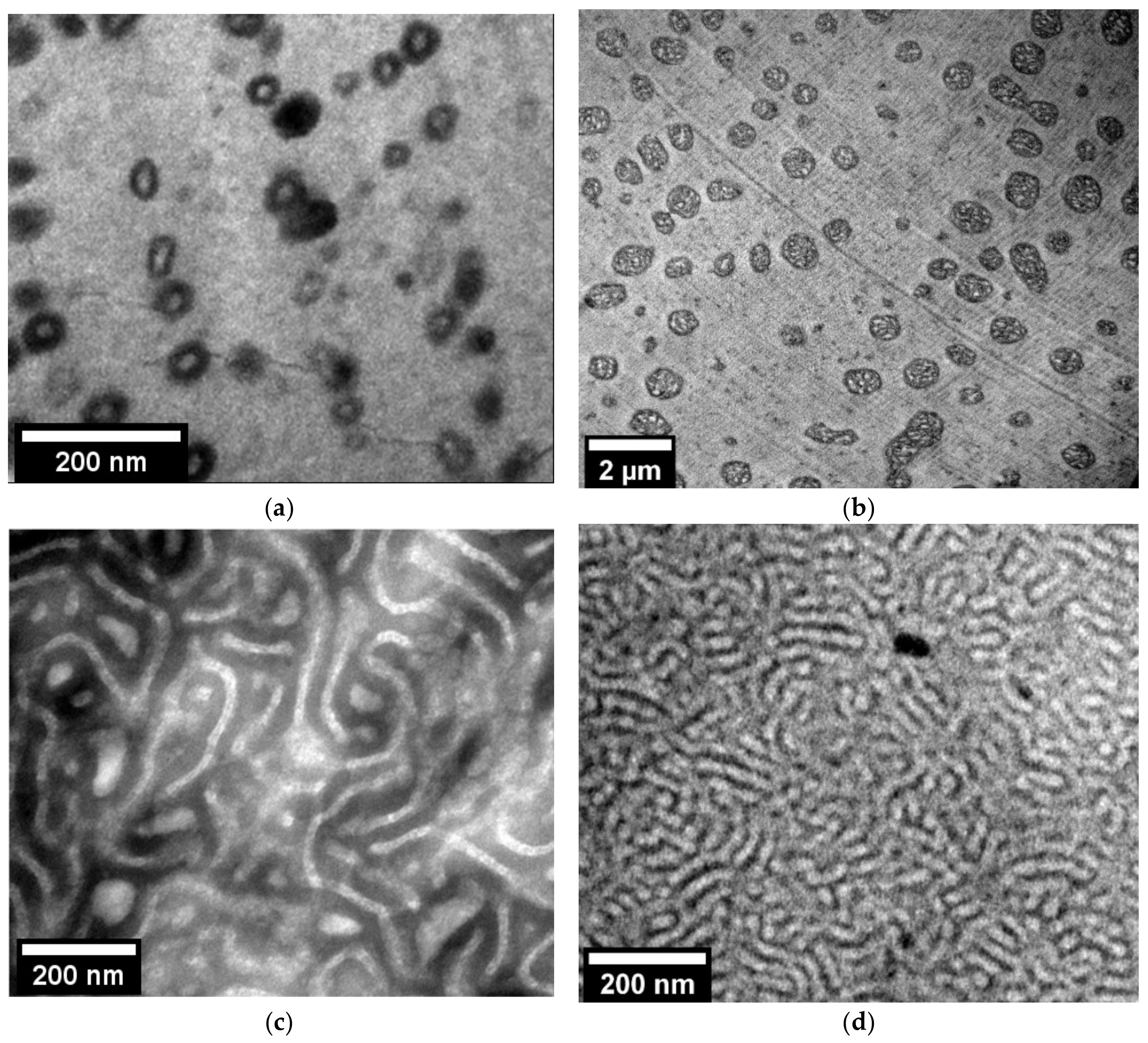

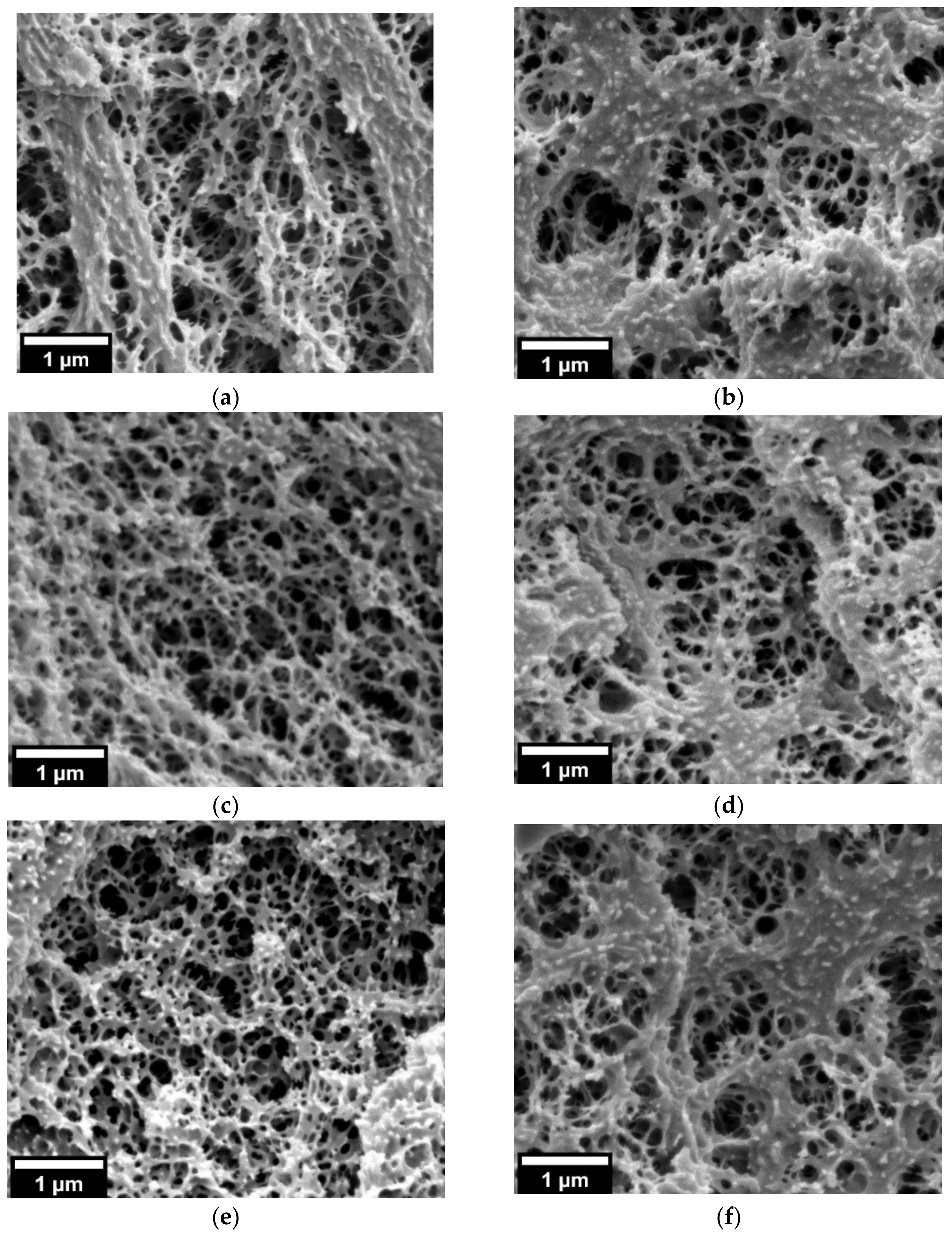

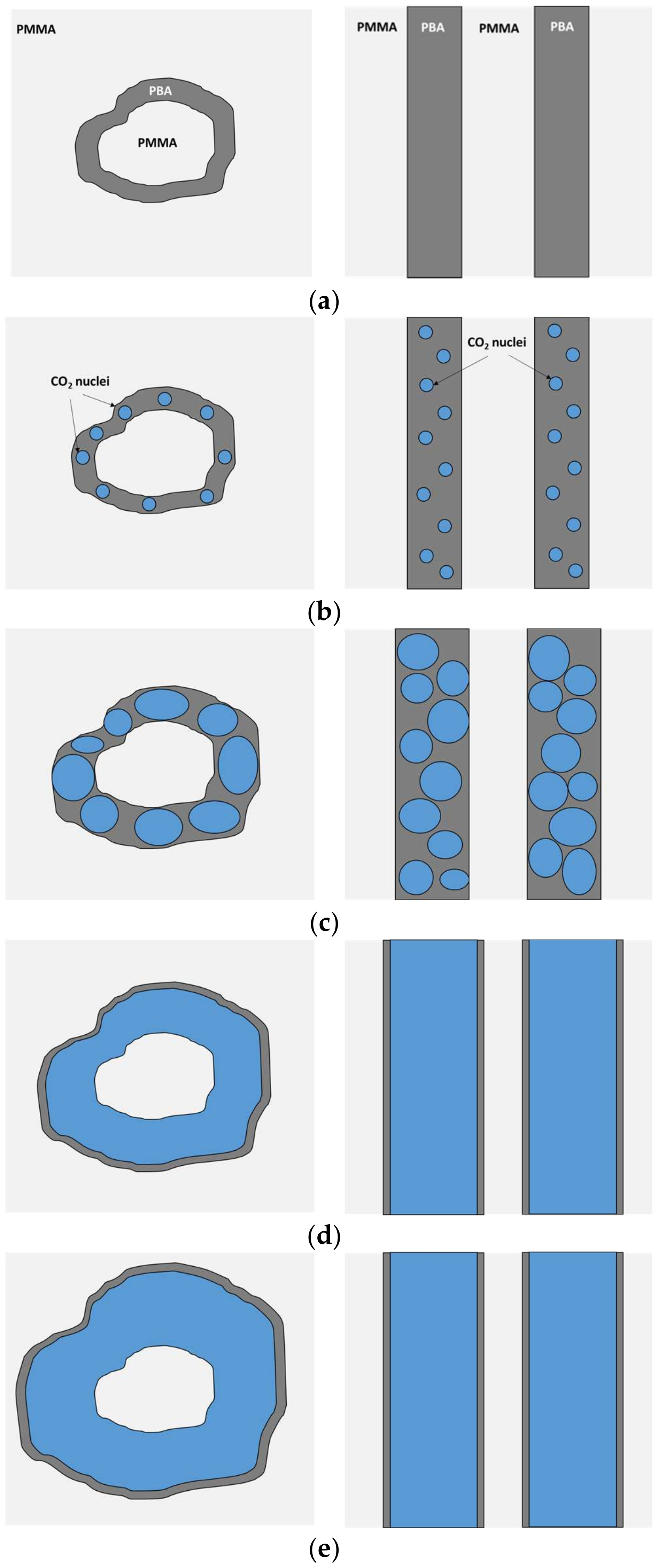

3.1. Out of Equilibrium and Near Equilibrium Nanostructuration of PMMA/MAM Blends

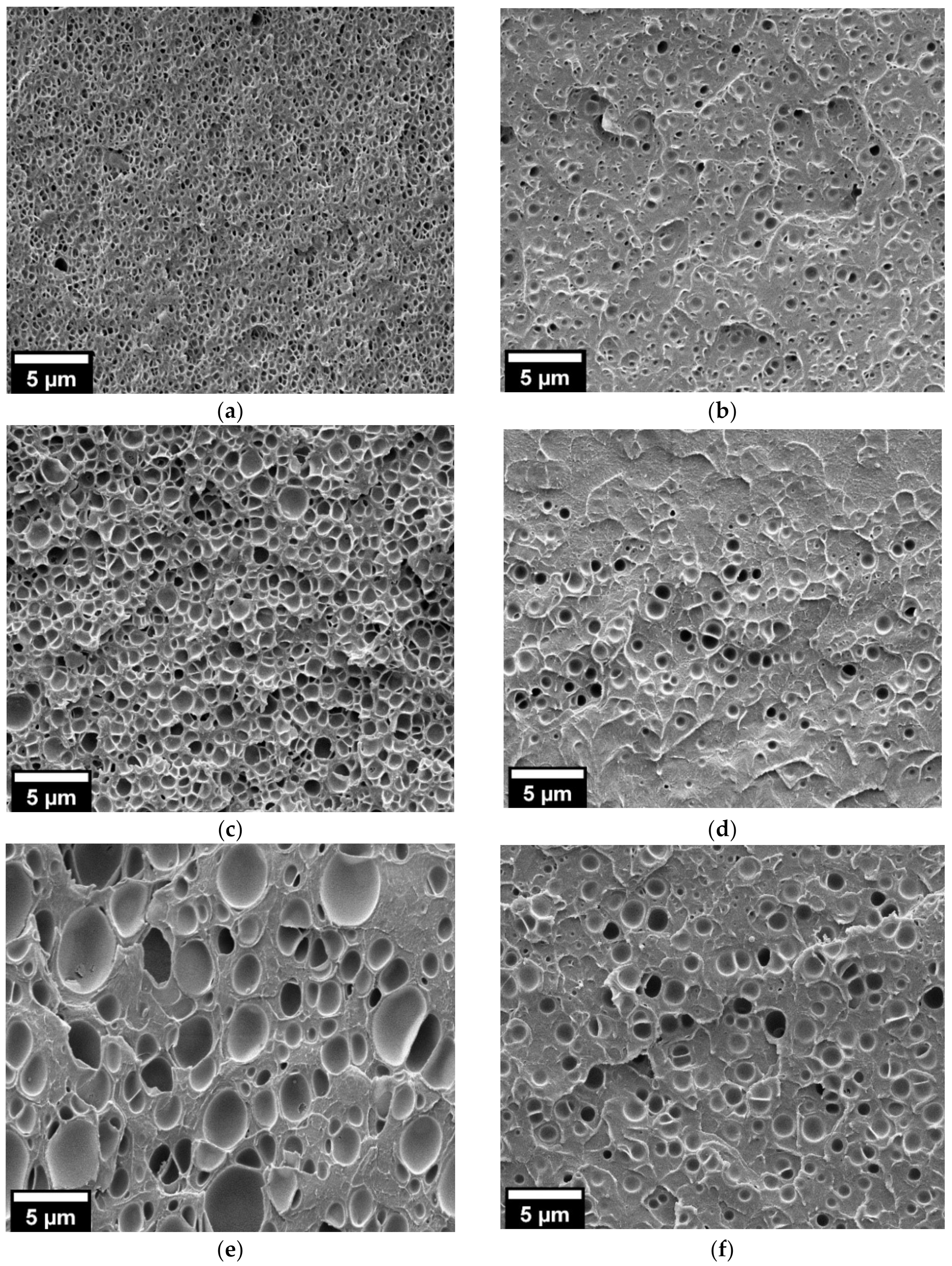

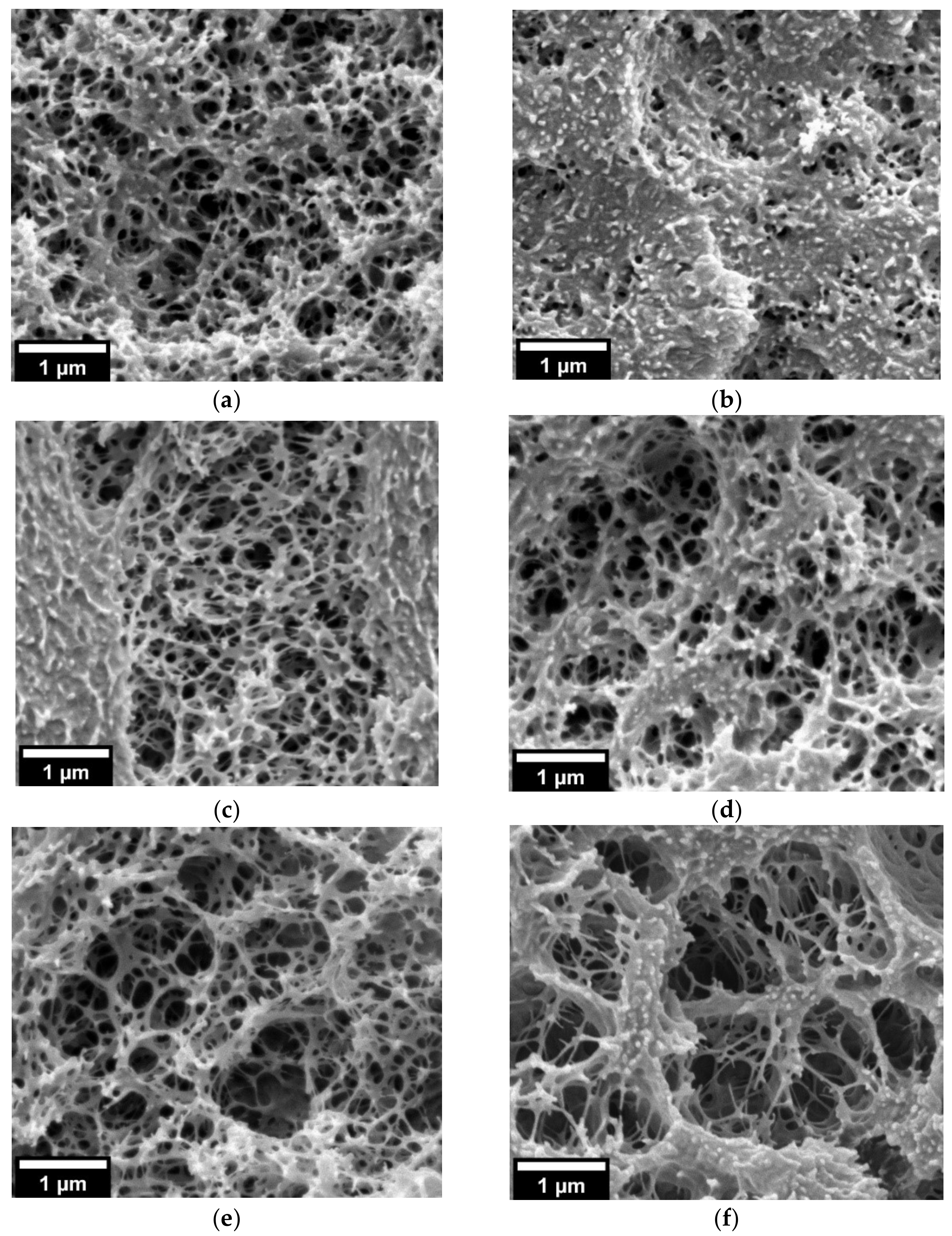

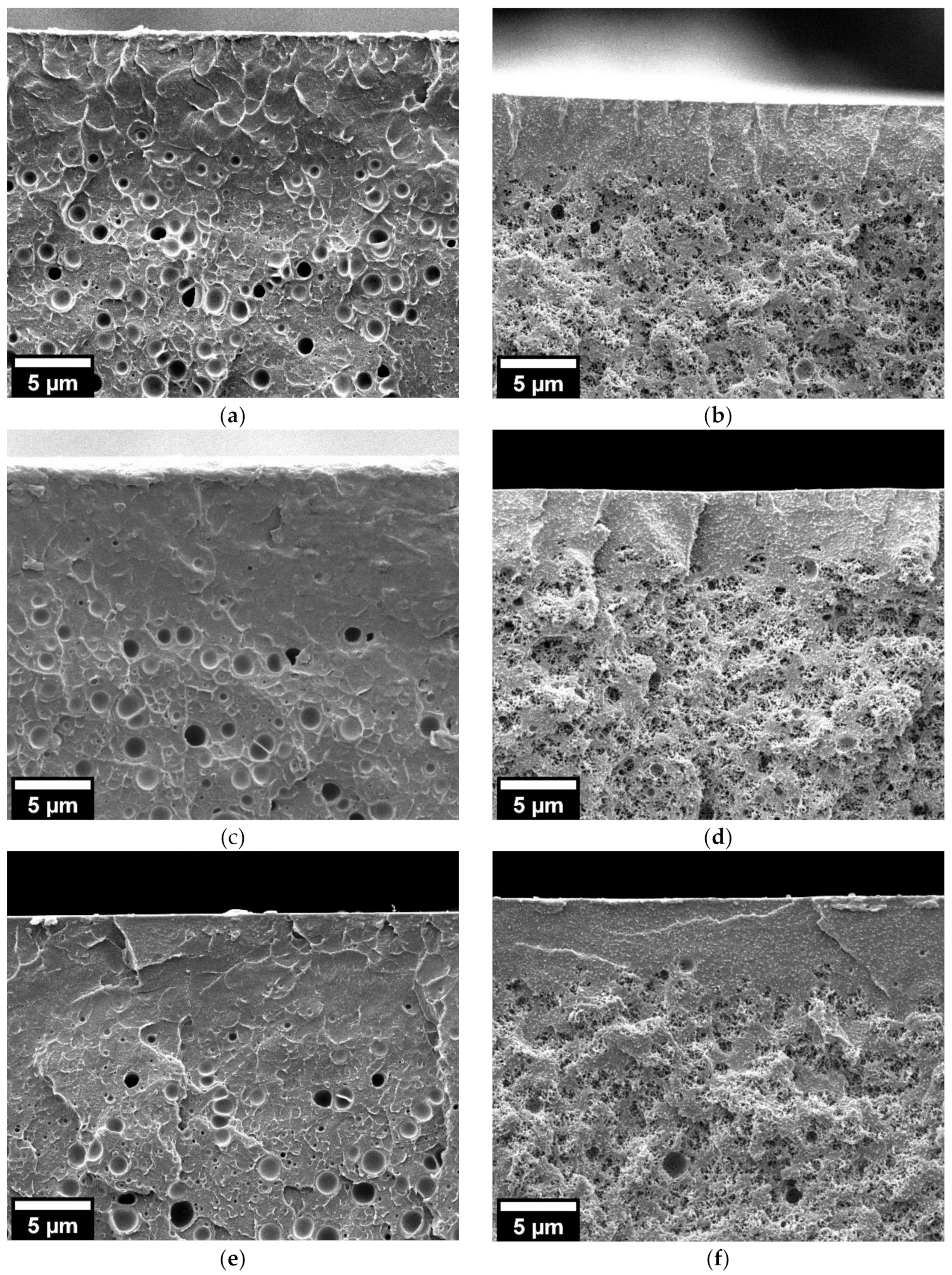

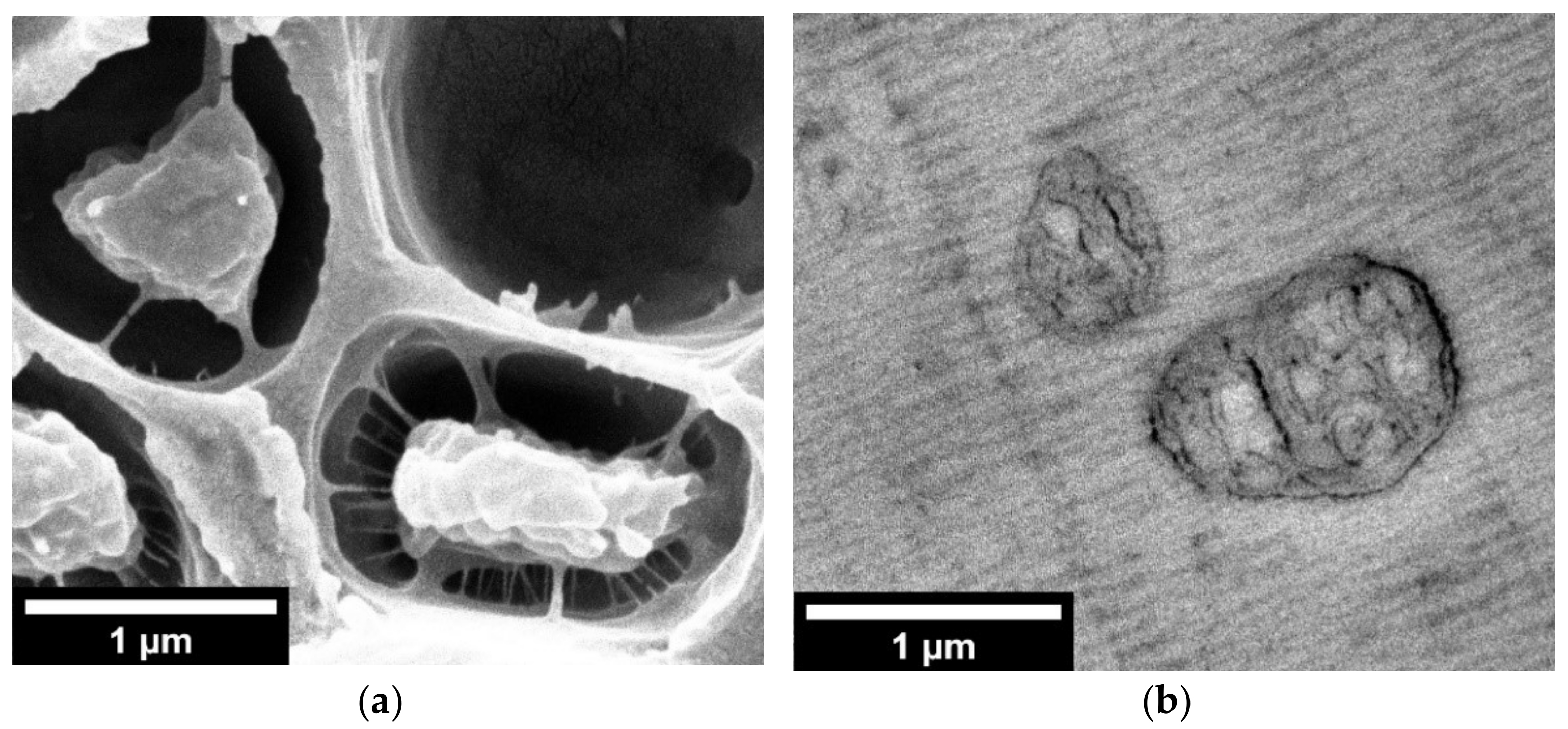

3.2. Nanocellular Foams Obtained from Out-of-Equilibrium and Near-Equilibrium Nanostructuration of PMMA/MAM Blends

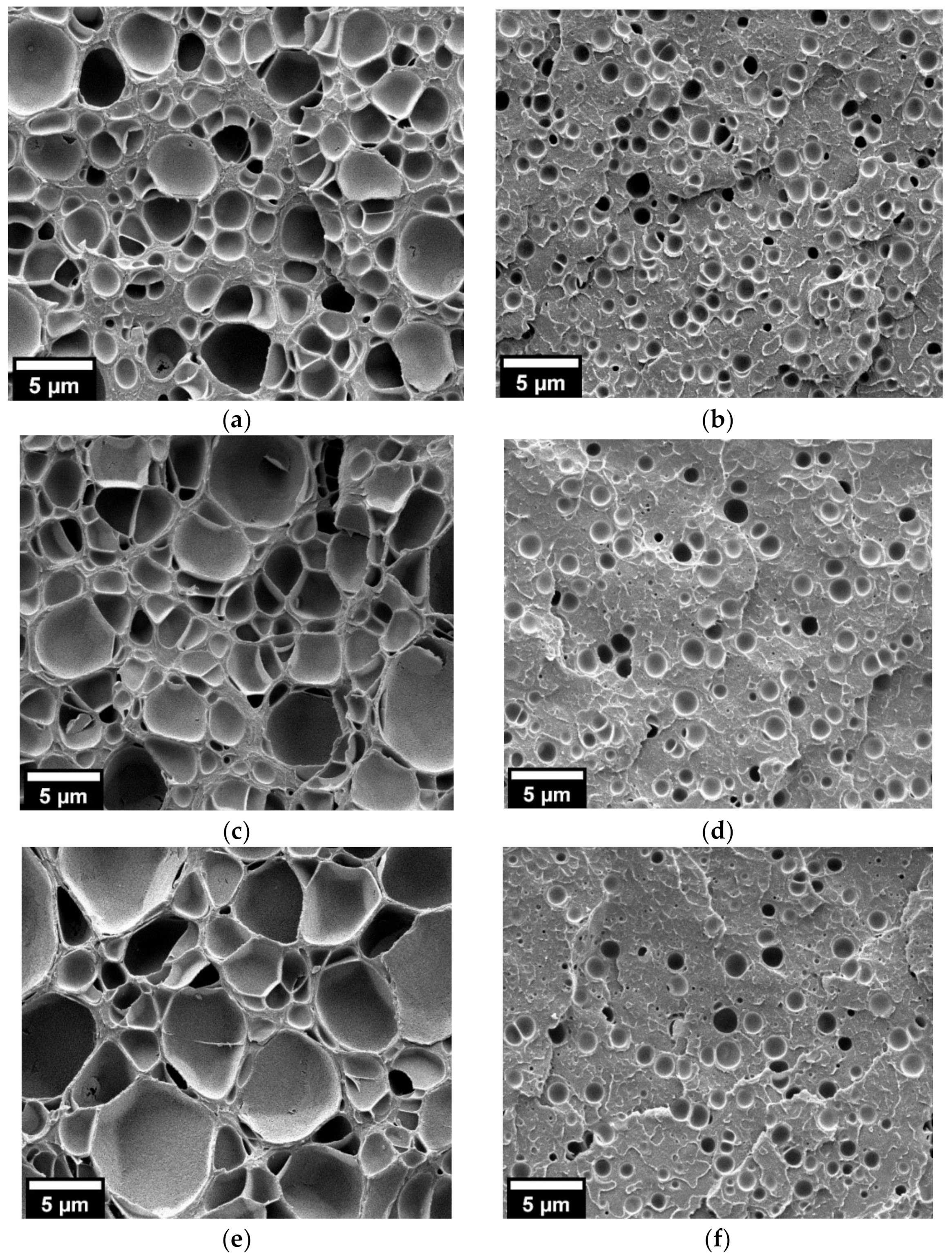

3.3. Influence of the Co-Continuous Out-of-Equilibrium and Near-Equilibrium Nanostructuration of 25/75 PMMA/MAM Blends on the Solid Outer Layers

| Sample | Geometry | Saturation Pressure (MPa) | Saturation Temperature (°C) | Relative Density Average/SD | Cell Size (nm) Average/SD | Solid Skin Thickness (µm) Average/SD | |||

|---|---|---|---|---|---|---|---|---|---|

| PMMA | Bulk | 20 | 40 | 0.78 | 0.03 | 1230 | 960 | 267.4 | 23.4 |

| PMMA | Bulk | 20 | 50 | 0.80 | 0.02 | 1310 | 703 | 250.5 | 36.2 |

| PMMA | Bulk | 20 | 60 | 0.81 | 0.03 | 1945 | 872 | 241.1 | 16.0 |

| PMMA | Bulk | 30 | 40 | 0.66 | 0.04 | 325 | 128 | 177.4 | 19.4 |

| PMMA | Bulk | 30 | 50 | 0.67 | 0.03 | 650 | 372 | 136.9 | 12.6 |

| PMMA | Bulk | 30 | 60 | 0.62 | 0.05 | 1745 | 740 | 88.3 | 9.2 |

| PMMA | Film | 20 | 40 | - | - | - | - | - | - |

| PMMA | Film | 20 | 50 | - | - | 833 | 262 | 14.9 | 1.6 |

| PMMA | Film | 20 | 60 | - | - | 1419 | 432 | 10.4 | 2.3 |

| PMMA | Film | 30 | 40 | - | - | 652 | 511 | 4.9 | 1.1 |

| PMMA | Film | 30 | 50 | - | - | 972 | 467 | 8.2 | 1.5 |

| PMMA | Film | 30 | 60 | - | - | 1296 | 560 | 8.1 | 1.8 |

| 25/75 PMMA/MAM | Bulk | 20 | 40 | 0.71 | 0.04 | 100 | 31 | 29.2 | 4.4 |

| 25/75 PMMA/MAM | Bulk | 20 | 50 | 0.68 | 0.05 | 110 | 39 | 10.7 | 1.0 |

| 25/75 PMMA/MAM | Bulk | 20 | 60 | 0.65 | 0.04 | 120 | 65 | 8.4 | 1.7 |

| 25/75 PMMA/MAM | Bulk | 30 | 40 | 0.66 | 0.03 | 135 | 60 | 9.4 | 1.3 |

| 25/75 PMMA/MAM | Bulk | 30 | 50 | 0.69 | 0.04 | 116 | 48 | 4.3 | 1.4 |

| 25/75 PMMA/MAM | Bulk | 30 | 60 | 0.59 | 0.03 | 140 | 78 | 7.2 | 1.7 |

| 25/75 PMMA/MAM | Film | 20 | 40 | - | - | 96 | 27 | 11.3 | 1.9 |

| 25/75 PMMA/MAM | Film | 20 | 50 | - | - | 124 | 45 | 7.4 | 1.0 |

| 25/75 PMMA/MAM | Film | 20 | 60 | - | - | 210 | 110 | 6.9 | 1.3 |

| 25/75 PMMA/MAM | Film | 30 | 40 | - | - | 95 | 47 | 6.5 | 0.4 |

| 25/75 PMMA/MAM | Film | 30 | 50 | - | - | 162 | 74 | 4.8 | 0.9 |

| 25/75 PMMA/MAM | Film | 30 | 60 | - | - | 258 | 164 | 3.3 | 0.7 |

| Sample | Geometry | Post-Foaming Temperature (°C) | Post-Foaming Time (min) | Relative Density Average/SD | Cell Size (nm) Average/SD | Solid Skin Thickness (µm) Average/SD | |||

|---|---|---|---|---|---|---|---|---|---|

| PMMA | Bulk | - | - | 0.67 | 0.03 | 650 | 372 | 136.9 | 12.6 |

| PMMA | Bulk | 40 | 1 | 0.51 | 0.05 | 1675 | 1138 | 61.9 | 6.5 |

| PMMA | Bulk | 60 | 1 | 0.38 | 0.04 | 1685 | 1385 | 24.0 | 2.0 |

| PMMA | Bulk | 80 | 1 | 0.26 | 0.05 | 1800 | 1487 | 9.1 | 1.7 |

| PMMA | Film | - | - | - | 972 | 467 | 8.2 | 1.5 | |

| PMMA | Film | 40 | 1 | - | 1250 | 436 | 7.9 | 0.7 | |

| PMMA | Film | 60 | 1 | - | 1446 | 404 | 10.6 | 1.5 | |

| PMMA | Film | 80 | 1 | - | 1191 | 360 | 9.7 | 1.7 | |

| 25/75 PMMA/MAM | Bulk | - | - | 0.69 | 0.04 | 116 | 48 | 4.3 | 1.4 |

| 25/75 PMMA/MAM | Bulk | 40 | 1 | 0.67 | 0.03 | 123 | 51 | 7.0 | 1.5 |

| 25/75 PMMA/MAM | Bulk | 60 | 1 | 0.67 | 0.03 | 103 | 49 | 8.9 | 1.1 |

| 25/75 PMMA/MAM | Bulk | 80 | 1 | 0.68 | 0.04 | 105 | 49 | 9.8 | 2.0 |

| 25/75 PMMA/MAM | Film | - | - | - | 162 | 74 | 4.8 | 0.9 | |

| 25/75 PMMA/MAM | Film | 40 | 1 | - | 141 | 63 | 5.6 | 0.4 | |

| 25/75 PMMA/MAM | Film | 60 | 1 | - | 136 | 62 | 3.7 | 0.6 | |

| 25/75 PMMA/MAM | Film | 80 | 1 | - | 118 | 61 | 4.8 | 0.8 | |

3.4. Cell Nucleation in the Near-Equilibrium Nanostructuration of PMMA/MAM Blends

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Union. Directive 2012/27/EU of the European Parliament and of the Council of 25 October 2012 on Energy Efficiency; Oficial Journal of the European Union (OJEU): Luxembourg, 2012; pp. 1–56. [Google Scholar]

- United Nations. Economic and Social Council Work Plan of the Group of Experts on Energy Efficiency for 2020–2021; United Nations: New York, NY, USA, 2019. [Google Scholar]

- Eurostat. Energy, Transport and Environment Statistics, 2019th ed.; Oficial Journal of the European Union (OJEU): Luxembourg, 2019; ISBN 9789276109716. [Google Scholar]

- Sadik, T.; Pillon, C.; Carrot, C.; Reglero Ruiz, J.A.; Vincent, M.; Billon, N. Polypropylene structural foams: Measurements of the core, skin, and overall mechanical properties with evaluation of predictive models. J. Cell. Plast. 2016, 53, 25–44. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Technology Roadmap Energy Efficient Building Envelopes; International Energy Agency: Paris, France, 2013. [Google Scholar]

- O’Grady, M.; Lechowska, A.A.; Harte, A.M. Application of infrared thermography technique to the thermal assessment of multiple thermal bridges and windows. Energy Build. 2018, 168, 347–362. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.C.; Xia, X.L.; Li, D.H.; Sun, C. Theoretical modeling and inverse analysis of thermal conductivity of skeletons in SiO2 nano-insulation materials. Nanomaterials 2019, 9, 934. [Google Scholar] [CrossRef] [Green Version]

- Notario, B.; Pinto, J.; Rodriguez-Perez, M.A. Nanoporous polymeric materials: A new class of materials with enhanced properties. Prog. Mater. Sci. 2016, 78–79, 93–139. [Google Scholar]

- Forest, C.; Chaumont, P.; Cassagnau, P.; Swoboda, B.; Sonntag, P. Polymer nano-foams for insulating applications prepared from CO2 foaming. Prog. Polym. Sci. 2015, 41, 122–145. [Google Scholar] [CrossRef]

- Cuadra-Rodriguez, D.; Barroso-Solares, S.; Pinto, J. Advanced Nanocellular Foams: Perspectives on the Current Knowledge and Challenges. Nanomaterials 2021, 11, 621. [Google Scholar] [CrossRef] [PubMed]

- Notario, B.; Pinto, J.; Rodriguez-Perez, M.A. Towards a new generation of polymeric foams: PMMA nanocellular foams with enhanced physical properties. Polymer (Guildford) 2015, 63, 116–126. [Google Scholar] [CrossRef]

- Martín-de León, J.; Van Loock, F.; Bernardo, V.; Fleck, N.A.; Rodríguez-Pérez, M.Á. The influence of cell size on the mechanical properties of nanocellular PMMA. Polymer (Guildford) 2019, 181, 121805. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, J.; Mark, L.H.; Wang, G.; Yu, K.; Wang, C.; Park, C.B.; Zhao, G. Ultra-tough and super thermal-insulation nanocellular PMMA/TPU. Chem. Eng. J. 2017, 325, 632–646. [Google Scholar] [CrossRef]

- Notario, B.; Pinto, J.; Solorzano, E.; de Saja, J.A.; Dumon, M.; Rodriguez-Perez, M.A. Experimental validation of the Knudsen effect in nanocellular polymeric foams. Polymer (Guildford) 2015, 56, 57–67. [Google Scholar] [CrossRef]

- Martín-de León, J.; Pura, J.L.; Bernardo, V.; Rodríguez-Pérez, M.Á. Transparent nanocellular PMMA: Characterization and modeling of the optical properties. Polymer (Guildford) 2019, 170, 16–23. [Google Scholar] [CrossRef]

- Costeux, S. CO2-Blown Nanocellular Foams. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Di Maio, E.; Kiran, E. Foaming of polymers with supercritical fluids and perspectives on the current knowledge gaps and challenges. J. Supercrit. Fluids 2018, 134, 157–166. [Google Scholar] [CrossRef]

- Park, B.K.; Hwang, D.J.; Kwon, D.E.; Yoon, T.J.; Lee, Y.W. Fabrication and characterization of multiscale PLA structures using integrated rapid prototyping and gas foaming technologies. Nanomaterials 2018, 8, 575. [Google Scholar] [CrossRef] [Green Version]

- Costeux, S.; Zhu, L. Low density thermoplastic nanofoams nucleated by nanoparticles. Polymer (Guildford) 2013, 54, 2785–2795. [Google Scholar] [CrossRef]

- Xu, X.; Cristancho, D.E.; Costeux, S.; Wang, Z.-G. Bubble nucleation in polymer–CO2 mixtures. Soft Matter 2013, 9, 9675–9683. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Spitael, P.; Macosko, C.W.; McClurg, R.B. Block Copolymer Micelles for Nucleation of Microcellular Thermoplastic Foams. Macromolecules 2004, 37, 6874–6882. [Google Scholar] [CrossRef]

- De León, J.M.; Bernardo, V.; Laguna-Gutiérrez, E.; Rodríguez-Pérez, M.Á. Influence of the viscosity of poly(methyl methacrylate) on the cellular structure of nanocellular materials. Polym. Int. 2020, 69, 72–83. [Google Scholar] [CrossRef]

- Liu, S.; Eijkelenkamp, R.; Duvigneau, J.; Vancso, G.J. Silica-Assisted Nucleation of Polymer Foam Cells with Nanoscopic Dimensions: Impact of Particle Size, Line Tension, and Surface Functionality. ACS Appl. Mater. Interfaces 2017, 9, 37929–37940. [Google Scholar] [CrossRef] [PubMed]

- Bernardo, V.; Martín-de León, J.; Rodríguez-Pérez, M.Á. Production of PMMA-based nanocellular polymers using low demanding saturation conditions. Mater. Lett. 2019, 255, 126551. [Google Scholar] [CrossRef]

- Forest, C.; Chaumont, P.; Cassagnau, P.; Swoboda, B.; Sonntag, P. CO2 nano-foaming of nanostructured PMMA. Polymer (Guildford) 2015, 58, 76–87. [Google Scholar] [CrossRef]

- Li, L.; Yokoyama, H.; Nemoto, T.; Sugiyama, K. Facile Fabrication of Nanocellular Block Copolymer Thin Films Using Supercritical Carbon Dioxide. Adv. Mater. 2004, 16, 1226–1229. [Google Scholar] [CrossRef]

- Shinkai, T.; Ito, M.; Sugiyama, K.; Ito, K.; Yokoyama, H. Ordered and foam structures of semifluorinated block copolymers in supercritical carbon dioxide. Soft Matter 2012, 8, 5811–5817. [Google Scholar] [CrossRef]

- Pinto, J.; Dumon, M.; Pedros, M.; Reglero, J.; Rodriguez-Perez, M.A. Nanocellular CO2 foaming of PMMA assisted by block copolymer nanostructuration. Chem. Eng. J. 2014, 243, 428–435. [Google Scholar] [CrossRef]

- Pinto, J.; Dumon, M.; Rodriguez-Perez, M.A.; Garcia, R.; Dietz, C. Block Copolymers Self-Assembly Allows Obtaining Tunable Micro or Nanoporous Membranes or Depth Filters Based on PMMA; Fabrication Method and Nanostructures. J. Phys. Chem. C 2014, 118, 4656–4663. [Google Scholar] [CrossRef] [Green Version]

- Costeux, S.; Foether, D. Continuous extrusion of nanocellular foam. In Proceedings of the ANTEC 2015 Conference, Orlando, FL, USA, 23–25 March 2015; pp. 2740–2745. [Google Scholar]

- Bernardo, V.; Martin-de Leon, J.; Laguna-Gutierrez, E.; Catelani, T.; Pinto, J.; Athanassiou, A.; Rodriguez-Perez, M.A. Understanding the role of MAM molecular weight in the production of PMMA/MAM nanocellular polymers. Polymer (Guildford) 2018, 153, 262–270. [Google Scholar] [CrossRef]

- Oss-Ronen, L.; Schmidt, J.; Abetz, V.; Radulescu, A.; Cohen, Y.; Talmon, Y. Characterization of Block Copolymer Self-Assembly: From Solution to Nanoporous Membranes. Macromolecules 2012, 45, 9631–9642. [Google Scholar] [CrossRef]

- Mann, S. Self-assembly and transformation of hybrid nano-objects and nanostructures under equilibrium and non-equilibrium conditions. Nat. Mater. 2009, 8, 781–792. [Google Scholar] [CrossRef] [PubMed]

- Tran, T.A.; Leonardi, F.; Bourrigaud, S.; Gerard, P.; Derail, C. All acrylic block copolymers based on poly (methyl methacrylate) and poly (butyl acrylate). A link between the physico-chemical properties and the mechanical behaviour on impact tests. Polym. Test. 2008, 27, 945–950. [Google Scholar] [CrossRef]

- Pinto, J.; Morselli, D.; Bernardo, V.; Notario, B.; Fragouli, D.; Rodriguez-Perez, M.A.; Athanassiou, A. Nanoporous PMMA foams with templated pore size obtained by localized in situ synthesis of nanoparticles and CO2 foaming. Polymer (Guildford) 2017, 124, 176–185. [Google Scholar] [CrossRef] [Green Version]

- Siripurapu, S.; DeSimone, J.M.; Khan, S.A.; Spontak, R.J. Controlled Foaming of Polymer Films through Restricted Surface Diffusion and the Addition of Nanosilica Particles or CO2-philic Surfactants. Macromolecules 2005, 38, 2271–2280. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, J.; Ge, C.; Zhao, G.; Park, C.B. Nanocellular poly(ether-block-amide)/MWCNT nanocomposite films fabricated by stretching-assisted microcellular foaming for high-performance EMI shielding applications. J. Mater. Chem. C 2021, 1245–1258. [Google Scholar] [CrossRef]

- Kumar, V.; Weller, J.E. A Model for the Unfoamed Skin of Microcellular Foams. Polym. Eng. Sci. 1994, 34, 169–173. [Google Scholar] [CrossRef]

- Pinto, J.; Pardo, S.; Solórzano, E.; Rodríguez-Pérez, M.A.; Dumon, M.; de Saja, J.A. Solid Skin Characterization of PMMA/MAM Foams Fabricated by Gas Dissolution Foaming over a Range of Pressures. Defect Diffus. Forum 2012, 326–328, 434–439. [Google Scholar] [CrossRef]

- Abràmoff, M.D.; Magalhães, P.J.; Ram, S.J. Image Processing with ImageJ Second Edition. Biophotonics Int. 2004, 11, 36–42. [Google Scholar]

- Pinto, J.; Solorzano, E.; Rodriguez-Perez, M.A.; de Saja, J.A. Characterization of the cellular structure based on user-interactive image analysis procedures. J. Cell. Plast. 2013, 49, 555–575. [Google Scholar] [CrossRef]

- Bernardo, V.; Martin-de Leon, J.; Pinto, J.; Catelani, T.; Athanassiou, A.; Rodriguez-Perez, M.A. Low-density PMMA/MAM nanocellular polymers using low MAM contents: Production and characterization. Polymer (Guildford) 2019, 163, 115–124. [Google Scholar] [CrossRef]

- Pinto, J. Fabrication and Characterization of Nanocellular Polymeric Materials from Nanostructured Polymers. Ph.D. Thesis, University of Valladolid, Valladolid, Spain, 2014. [Google Scholar]

- Liu, S.; Yin, S.; Duvigneau, J.; Vancso, G.J. Bubble Seeding Nanocavities: Multiple Polymer Foam Cell Nucleation by Polydimethylsiloxane-Grafted Designer Silica Nanoparticles. ACS Nano 2020, 14, 1623–1634. [Google Scholar] [CrossRef] [Green Version]

- Pinto, J.; Reglero-Ruiz, J.A.; Dumon, M.; Rodriguez-Perez, M.A. Temperature influence and CO2 transport in foaming processes of poly(methyl methacrylate)–block copolymer nanocellular and microcellular foams. J. Supercrit. Fluids 2014, 94, 198–205. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barroso-Solares, S.; Bernardo, V.; Cuadra-Rodriguez, D.; Pinto, J. Nanostructure of PMMA/MAM Blends Prepared by Out-of-Equilibrium (Extrusion) and Near-Equilibrium (Casting) Self-Assembly and Their Nanocellular or Microcellular Structure Obtained from CO2 Foaming. Nanomaterials 2021, 11, 2834. https://doi.org/10.3390/nano11112834

Barroso-Solares S, Bernardo V, Cuadra-Rodriguez D, Pinto J. Nanostructure of PMMA/MAM Blends Prepared by Out-of-Equilibrium (Extrusion) and Near-Equilibrium (Casting) Self-Assembly and Their Nanocellular or Microcellular Structure Obtained from CO2 Foaming. Nanomaterials. 2021; 11(11):2834. https://doi.org/10.3390/nano11112834

Chicago/Turabian StyleBarroso-Solares, Suset, Victoria Bernardo, Daniel Cuadra-Rodriguez, and Javier Pinto. 2021. "Nanostructure of PMMA/MAM Blends Prepared by Out-of-Equilibrium (Extrusion) and Near-Equilibrium (Casting) Self-Assembly and Their Nanocellular or Microcellular Structure Obtained from CO2 Foaming" Nanomaterials 11, no. 11: 2834. https://doi.org/10.3390/nano11112834

APA StyleBarroso-Solares, S., Bernardo, V., Cuadra-Rodriguez, D., & Pinto, J. (2021). Nanostructure of PMMA/MAM Blends Prepared by Out-of-Equilibrium (Extrusion) and Near-Equilibrium (Casting) Self-Assembly and Their Nanocellular or Microcellular Structure Obtained from CO2 Foaming. Nanomaterials, 11(11), 2834. https://doi.org/10.3390/nano11112834