Osmium Nanoparticles-Polypropylene Hollow Fiber Membranes Applied in Redox Processes

Abstract

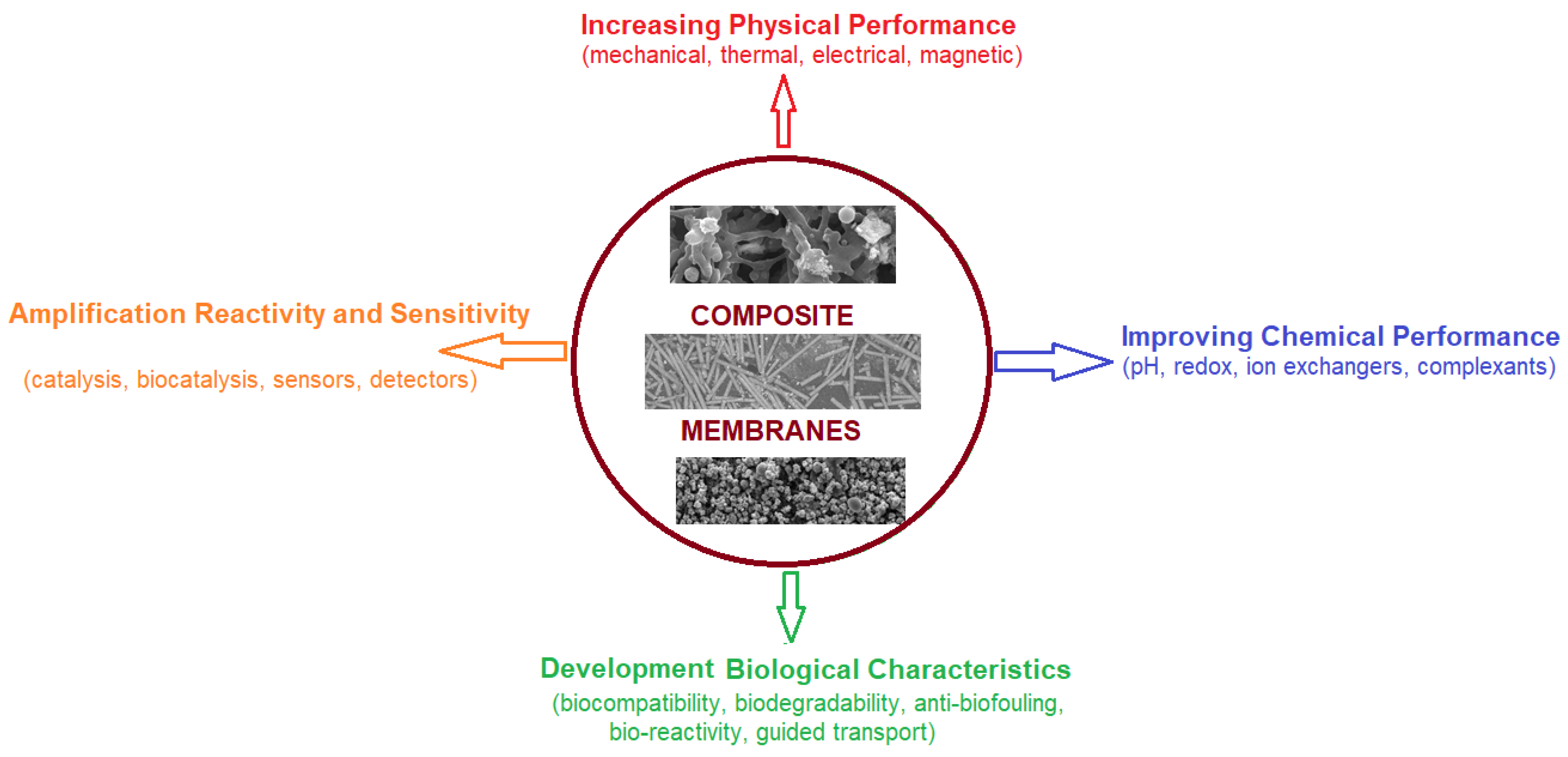

:1. Introduction

- Do not contaminate the working environment,

- Operate at relatively low temperatures,

- Provide a large contact area between reactants,

- Help to recover the reaction mass by ultrafiltration, and

- Allow successive oxidation and reduction operations in the same module.

2. Experiments

2.1. Materials

2.2. Procedures

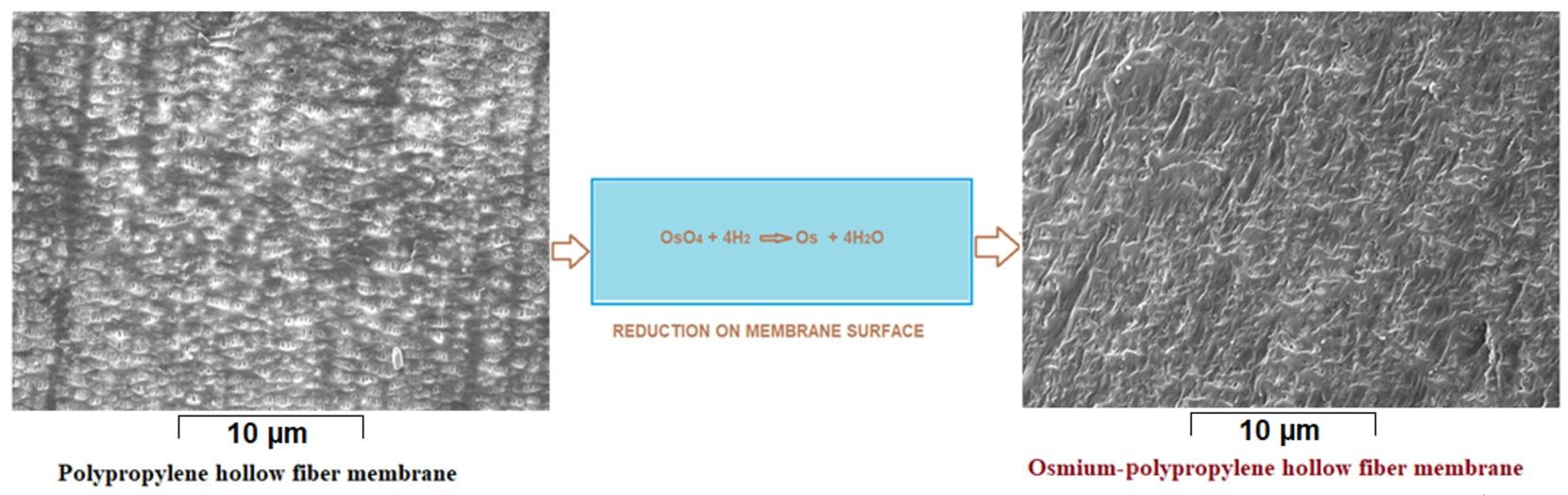

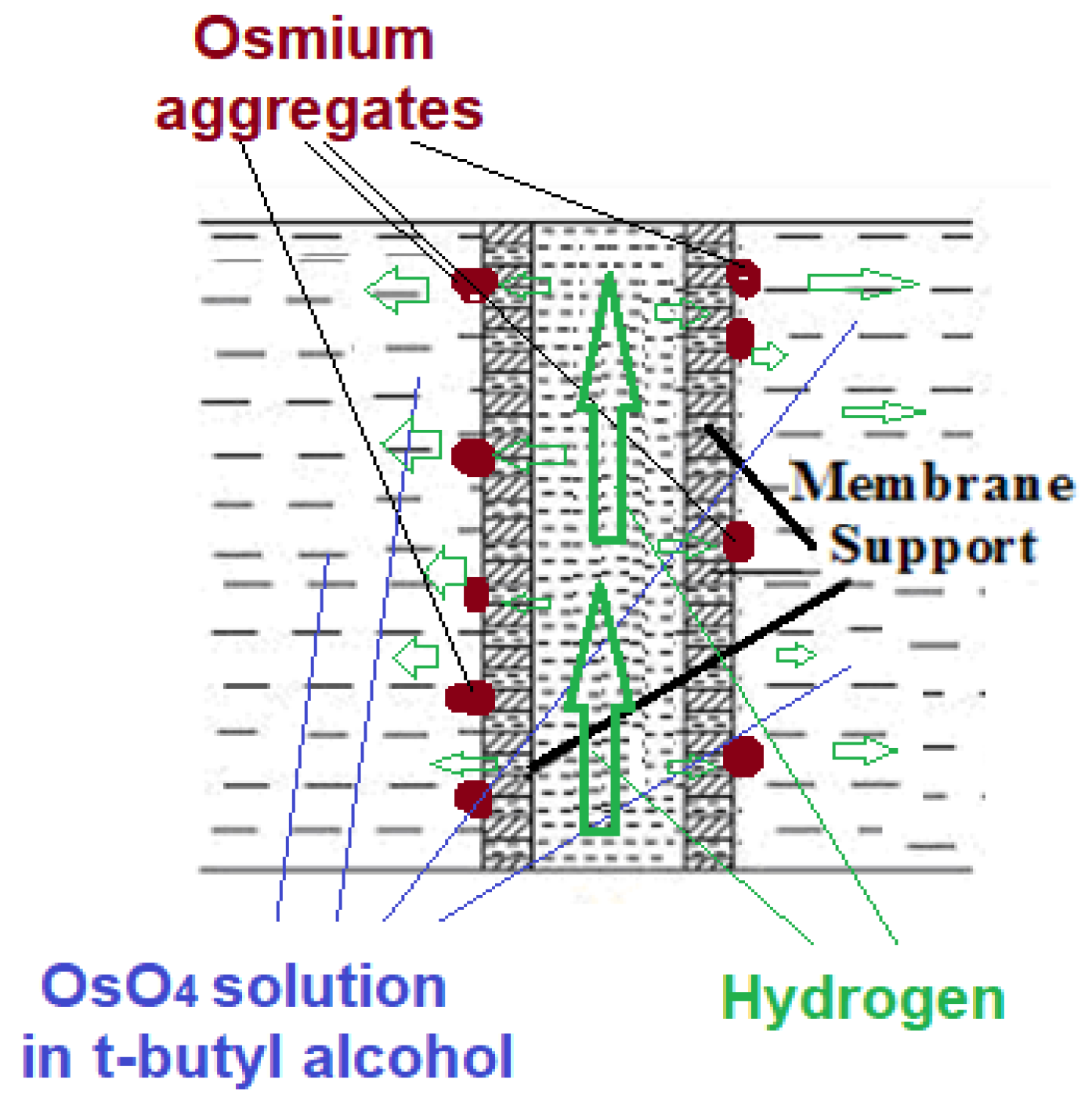

2.2.1. Preparation of Osmium Nanoparticles on Polypropylene Hollow Fiber Membranes

- Formation of the osmium tetroxide solution by dissolving 1 g of solid substance in 1000 mL of tert-butyl alcohol,

- Immersion of the fiber bundle in the alcoholic solution of osmium tetroxide,

- Reduction of osmium tetroxide with molecular hydrogen,

- Ethanol washing of osmium nanoparticles-polypropylene hollow fibers composite membranes, and

- Drying in a vacuum oven (60 °C).

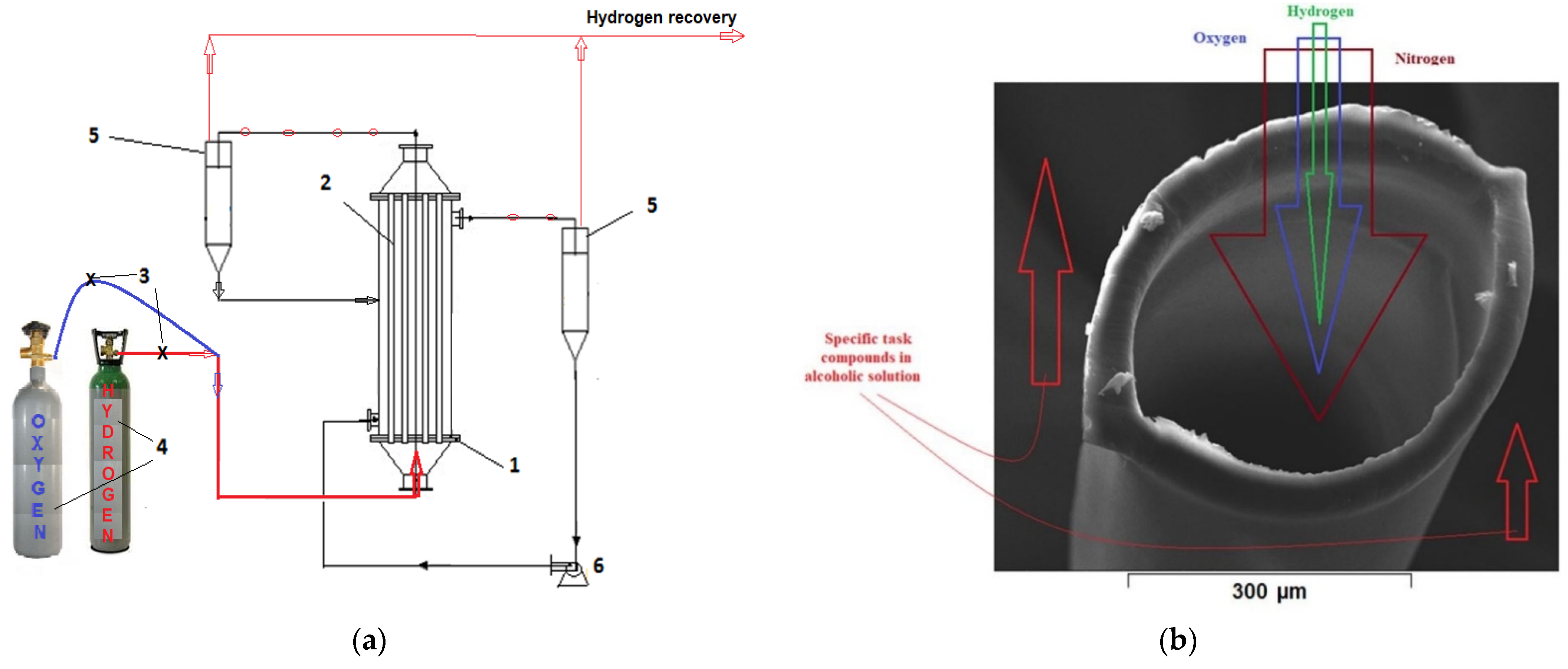

2.2.2. Carrying out the Process of Oxidation or Reduction

2.3. Equipment

3. Results and Discussions

- The preparation of composite membranes based on osmium-polypropylene hollow fiber (Os-PP), by in situ reduction of the osmium tetroxide from tert-butyl alcohol solution with molecular hydrogen,

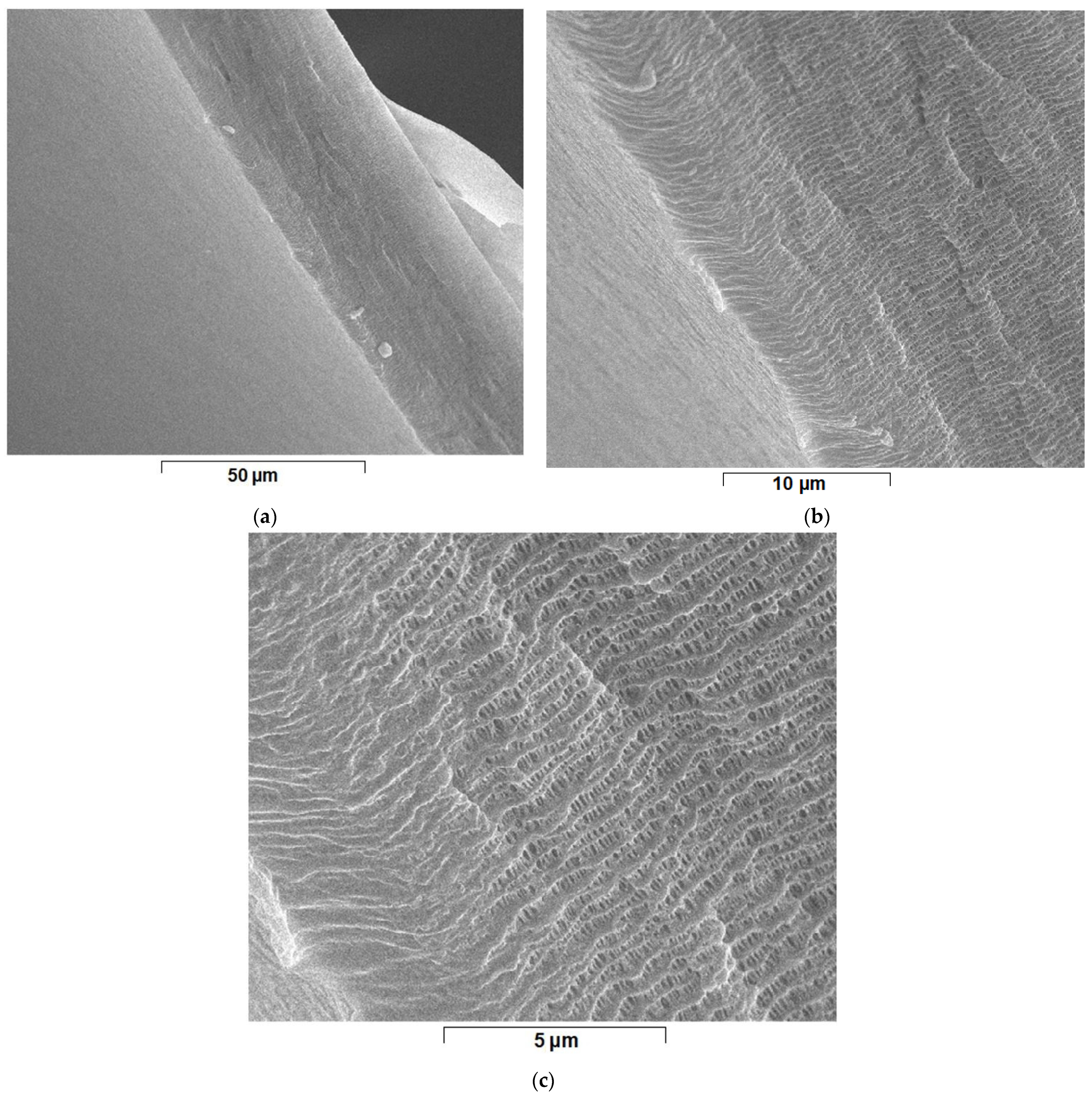

- Morpho-structural characterization of the obtained osmium-polypropylene hollow fiber composite membranes,

- The reduction of p-nitrophenol with molecular hydrogen in a module using osmium-polypropylene hollow fiber composite membranes, and

- Oxidation of 10-undecylenic acid with osmium-polypropylene hollow fiber composite membranes using molecular oxygen.

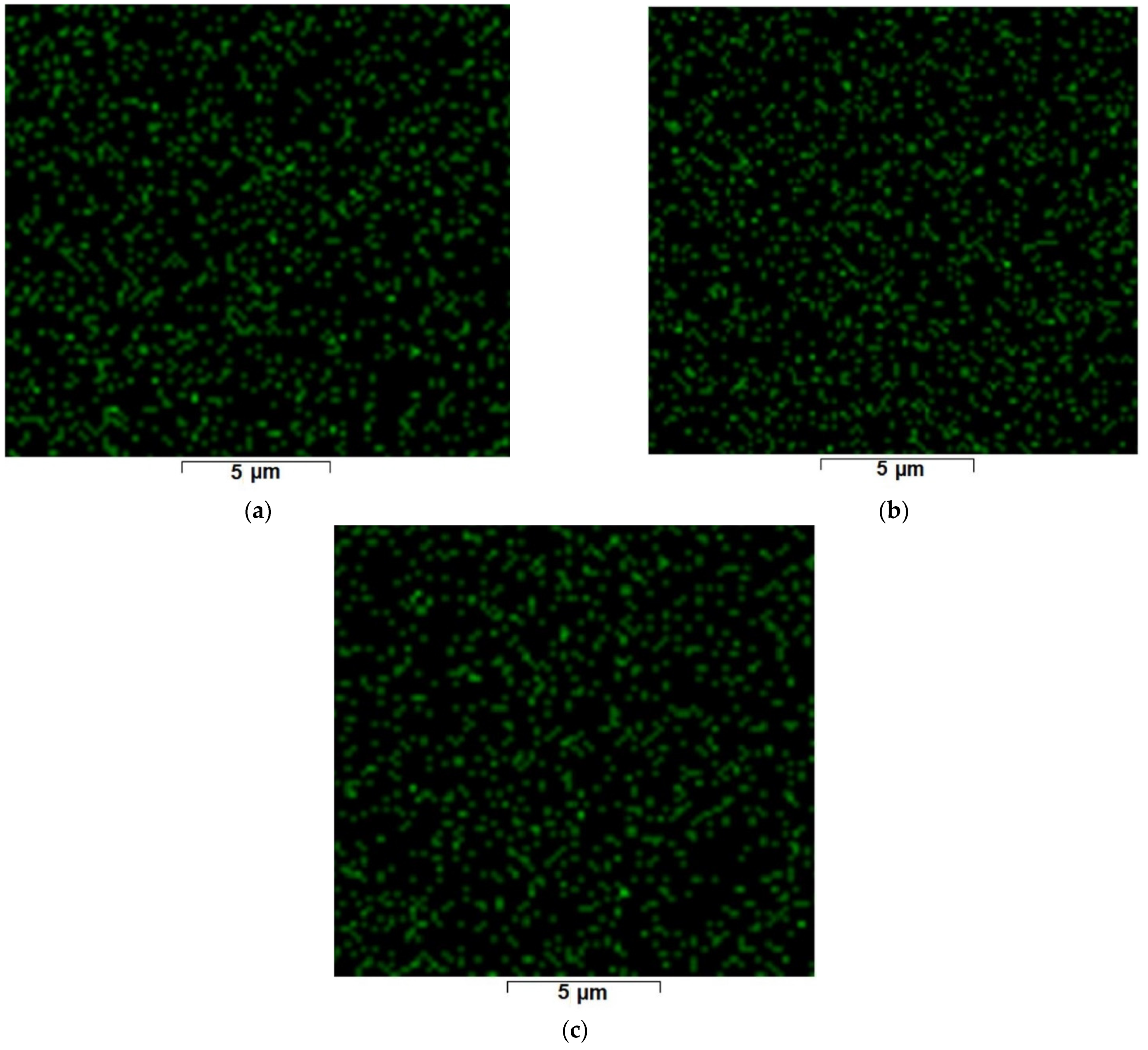

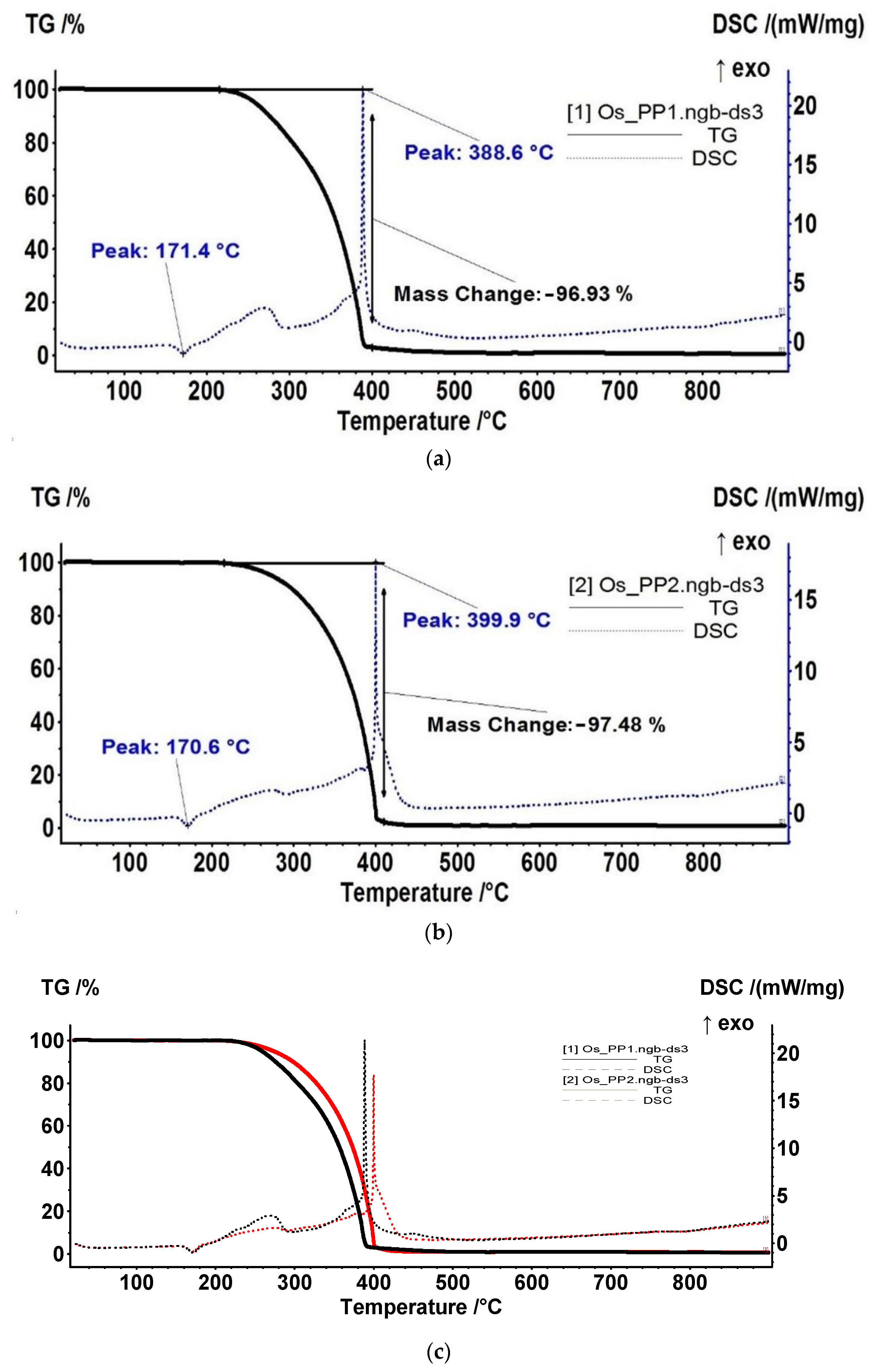

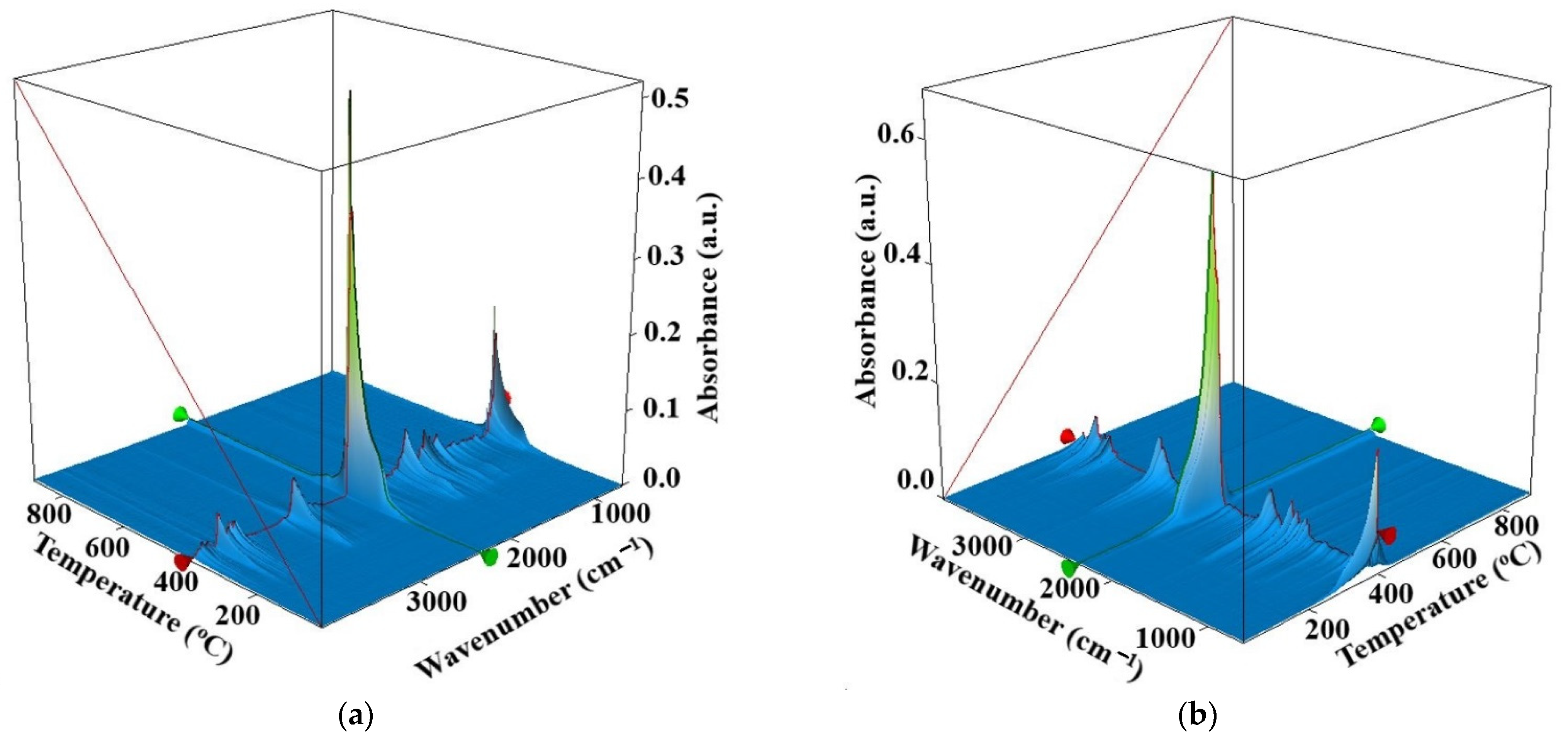

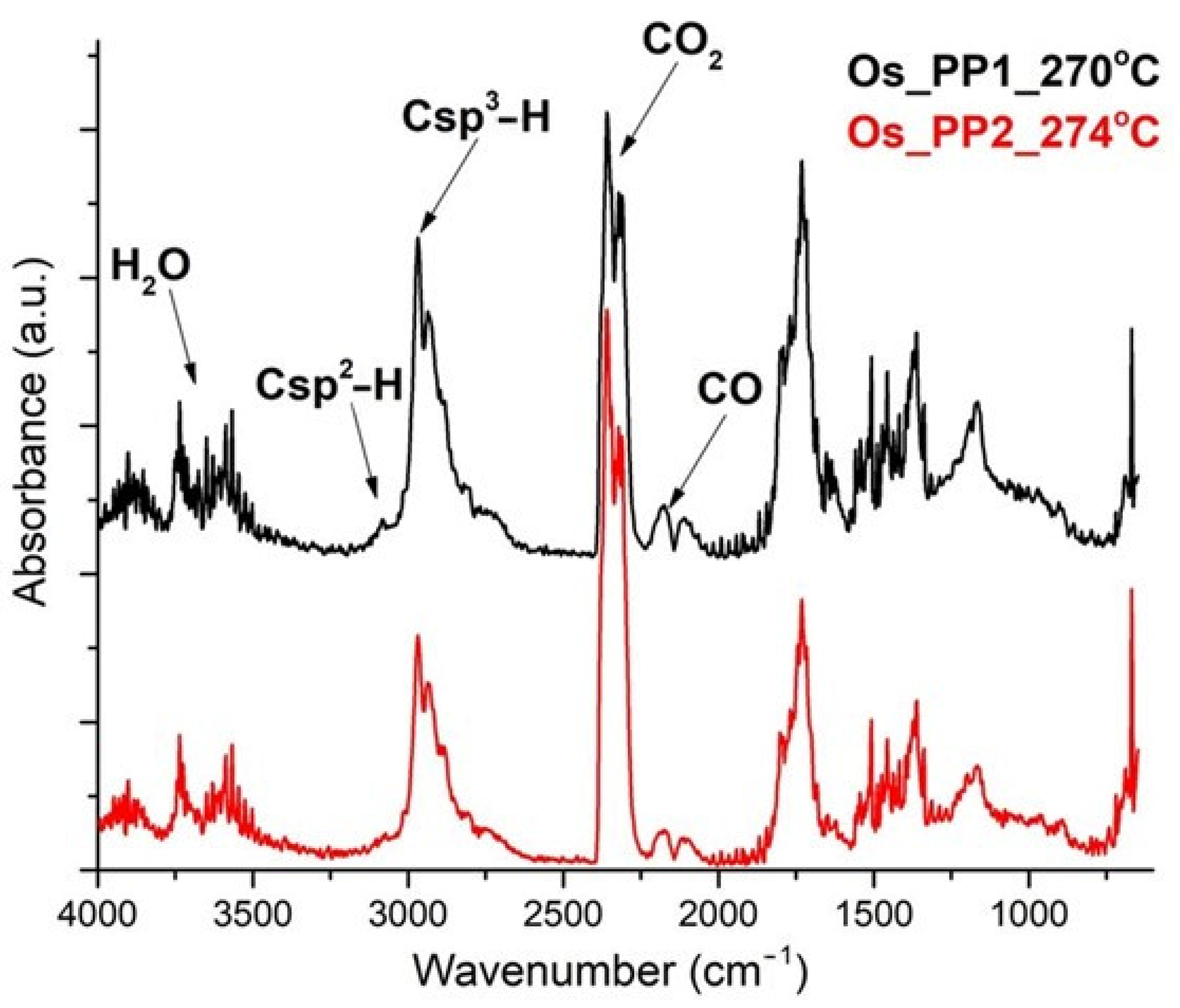

3.1. The Preparation and Characterization of the Composite Membrane Osmium-Polypropylene Hollow Fiber (Os-PP) by In Situ Reduction of Osmium Tetroxide

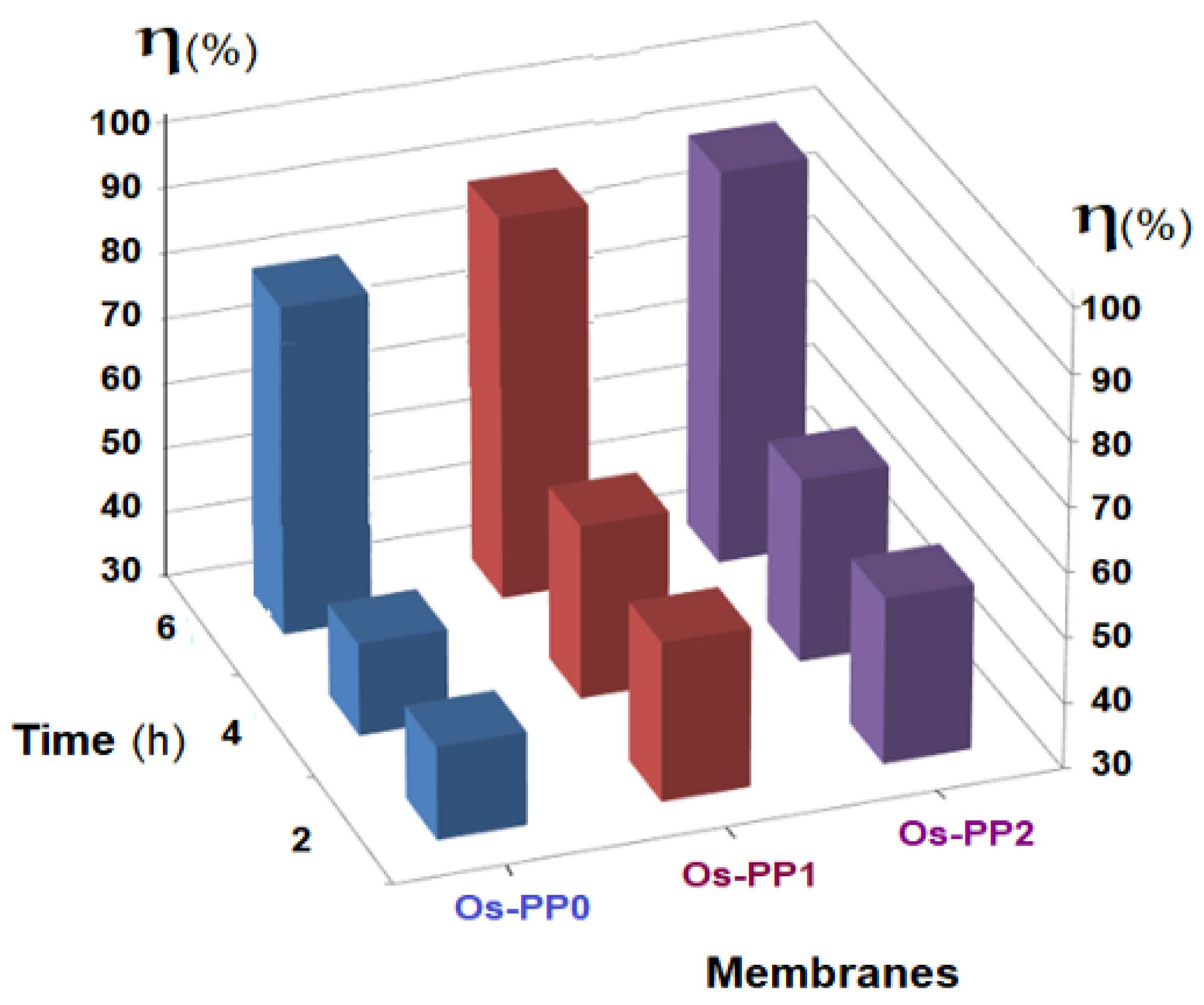

3.2. Reduction of P-Nitrophenol with Molecular Hydrogen with Osmium Nanoparticles-Polypropylene Hollow Fibers Composite Membranes

- Composite membrane of osmium nanoparticles-polypropylene hollow fibers: Os-PP2 (7.63% atomic bone on the surface),

- Operating time: six hours,

- Concentration of p-nitrophenol in t-butanol: 1 g/L,

- Primary alcohol: t-butanol.

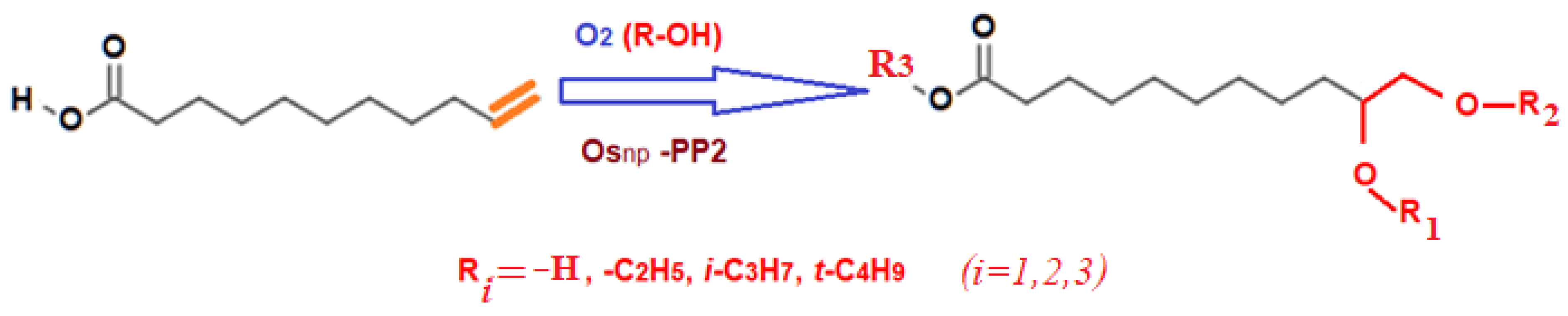

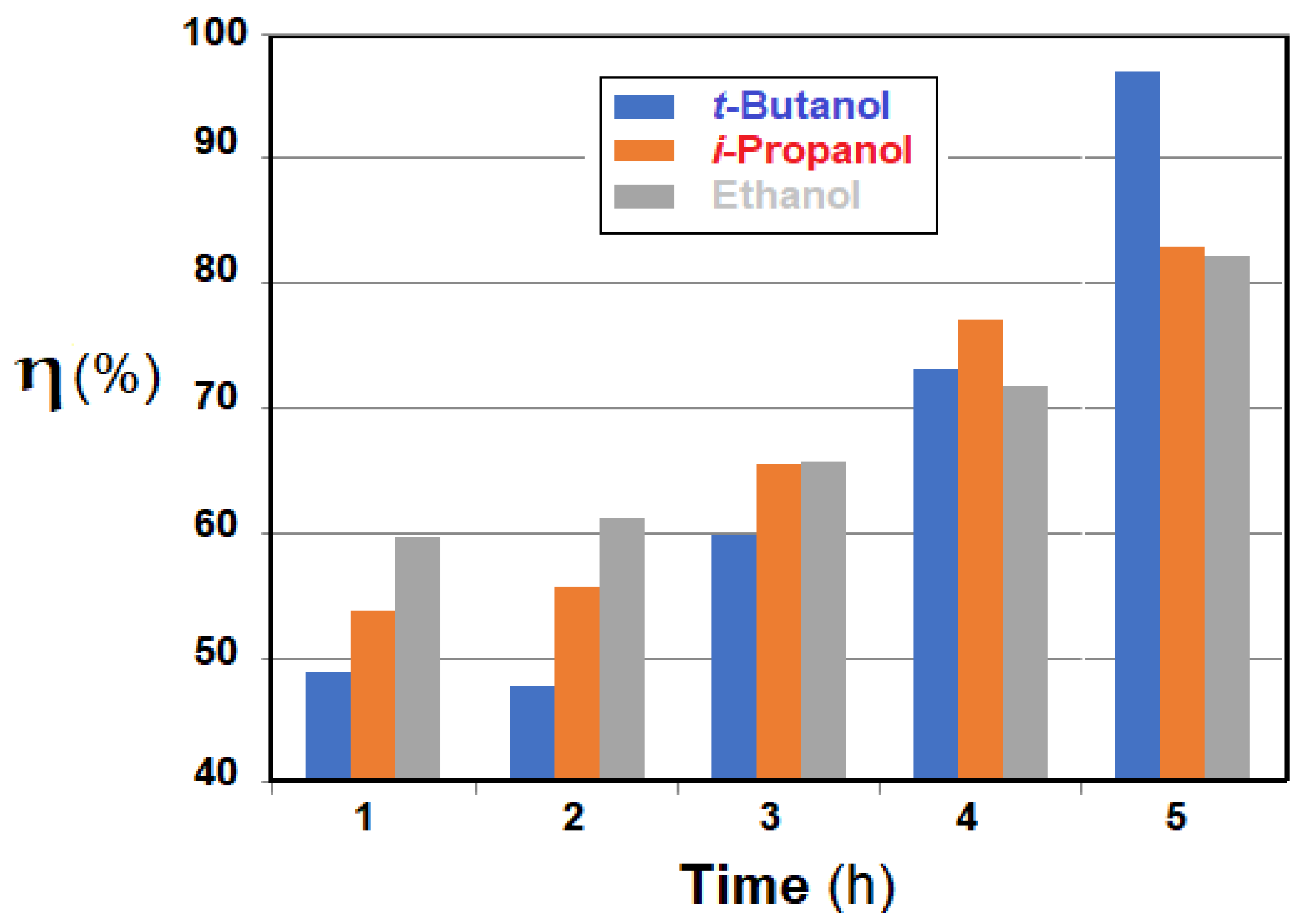

3.3. Oxidation of 10-Undecylenic Acid on Osmium Nanoparticles-Polypropylene Hollow Fiber Composite Membranes Using Molecular Oxygen

- Through the intervention of osmium nanoparticles, oxygen is physically-chemically linked to the double-bond;

- The alcohol (mostly in the environment) produces the alcoholysis of the osmic acid ester producing a variety of reaction products (the reaction was modified in manuscript according to these data); and

- The products are released into the environment.

4. Conclusions

- Composite membrane of osmium nanoparticles-polypropylene hollow fibers: Os-PP2 (7.63% atomic Os on the surface),

- Operating time: six hours,

- The concentration p-nitrophenol in t-butanol: 1 g/L,

- Primary alcohol: t-butanol.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liao, Z.; Zhu, J.; Li, X.; Van der Bruggen, B. Regulating composition and structure of nanofillers in thin film nanocomposite (TFN) membranes for enhanced separation performance: A critical review. Sep. Purif. Technol. 2021, 266, 118567. [Google Scholar] [CrossRef]

- Zhu, J.; Hou, J.; Uliana, A.; Zhang, Y.; Tian, M.; Van der Bruggen, B. The rapid emergence of two-dimensional nanomaterials for high-performance separation membranes. J. Mater. Chem. A 2018, 6, 3773–3792. [Google Scholar] [CrossRef]

- Abdelsamad, A.M.A.; Khalil, A.S.G.; Ulbricht, M. Influence of controlled functionalization of mesoporous silica nanoparticles as tailored fillers for thin-film nanocomposite membranes on desalination performance. J. Membr. Sci. 2018, 563, 149–161. [Google Scholar] [CrossRef]

- Ang, M.B.M.Y.; Pereira, J.M.; Trilles, C.A.; Aquino, R.R.; Huang, S.-H.; Lee, K.-R.; Lai, J.-Y. Performance and antifouling behavior of thin-film nanocomposite nanofiltration membranes with embedded silica spheres. Sep. Purif. Technol. 2019, 210, 521–529. [Google Scholar] [CrossRef]

- Lai, G.S.; Lau, W.J.; Goh, P.S.; Ismail, A.F.; Tan, Y.H.; Chong, C.Y.; Krause-Rehberg, R.; Awad, S. Tailor-made thin film nanocomposite membrane incorporated with graphene oxide using novel interfacial polymerization technique for enhanced water separation. Chem. Eng. J. 2018, 344, 524–534. [Google Scholar] [CrossRef]

- Firouzjaei, M.D.; Shamsabadi, A.A.; Aktij, S.A.; Seyedfour, S.F.; Sharifian Gh, M.; Rahimpour, A.; Esfahani, M.R.; Ulbricht, M.; Soroush, M. Exploiting synergetic effects of graphene oxide and a silver-based metal-organic M.R.; framework to enhance antifouling and anti-biofouling properties of thin-film nanocomposite membranes. ACS Appl. Mater. Interfaces 2018, 10, 42967–42978. [Google Scholar] [CrossRef]

- Zhang, A.; Zhang, Y.; Pan, G.; Xu, J.; Yan, H.; Liu, Y. In situ formation of copper nanoparticles in carboxylated chitosan layer: Preparation and characterization of surface modified TFC membrane with protein fouling resistance and long-lasting antibacterial properties. Sep. Purif. Technol. 2017, 176, 164–172. [Google Scholar] [CrossRef]

- Upadhyaya, L.; Semsarilar, M.; Quemener, D.; Fernández-Pacheco, R.; Martinez, G.; Coelhoso, I.M.; Nunes, S.P.; Crespo, J.G.; Mallada, R.; Portugal, C.A.M. Block Copolymer-Based Magnetic Mixed Matrix Membranes—Effect of Magnetic Field on Protein Permeation and Membrane Fouling. Membranes 2021, 11, 105. [Google Scholar] [CrossRef]

- Kuroda, K.; Ishida, T.; Haruta, M. Reduction of 4-nitrophenol to 4-aminophenolover Au nanoparticles deposited on PMMA. J. Mol. Catal. A Chem. 2009, 298, 7–11. [Google Scholar] [CrossRef]

- Koga, H.; Kitaoka, T. One-step synthesis of gold nanocatalysts on a micro-structured paper matrix for the reduction of 4-nitrophenol. Chem. Eng. J. 2011, 168, 420–425. [Google Scholar] [CrossRef]

- Dong, Z.; Le, X.; Dong, C.; Zhang, W.; Li, X.; Ma, J. Ni@Pd core-shell nanoparticles modified fibrous silica nanospheres as highly efficient and recoverable catalyst for reduction of 4-nitrophenol and hydrodechlorination of 4-chlorophenol. Appl. Catal. B Environ. 2015, 162, 372–380. [Google Scholar] [CrossRef]

- Woo, S.T.; Yun, T.; Kwak, S.-Y. Fouling-resistant microfiltration membrane modified with magnetite nanoparticles by reversible conjunction. Sep. Pur. Technol. 2018, 202, 299–306. [Google Scholar] [CrossRef]

- Ghaemi, N.; Madaeni, S.S.; Daraei, P.; Rajabi, H.; Zinadini, S.; Alizadeh, A.; Heydari, R.; Beygzadeh, M.; Ghouzivand, S. Polyethersulfone membrane enhanced with iron oxide nanoparticles for copper removal from water: Application of new functionalized Fe3O4 nanoparticles. Chem. Eng. J. 2015, 263, 101–112. [Google Scholar] [CrossRef]

- Agbaje, T.A.; Al-Gharabli, S.; Mavukkandy, M.O.; Kujawa, J.; Arafat, H.A. PVDF/magnetite blend membranes for enhanced flux and salt rejection in membrane distillation. Desalination 2018, 436, 69–80. [Google Scholar] [CrossRef]

- Harish, S.; Mathiyarasu, J.; Phani, K.L.N.; Yegnaraman, V. Synthesis of conducting polymer supported Pd nanoparticles in aqueous medium and catalytic activity towards 4-nitrophenol reduction. Catal. Lett. 2009, 128, 197. [Google Scholar] [CrossRef]

- Khalil, A.M.; Georgiadou, V.; Guerrouache, M.; Mahouche-Chergui, S.; Dendrinou-Samara, C.; Chehimi, M.M.; Carbonnier, B. Gold- decorated polymeric monoliths: In-situ vs. ex-situ immobilization strategies and flow through catalytic applications towards nitrophenols reduction. Polymer 2015, 77, 218–226. [Google Scholar] [CrossRef]

- Macanás, J.; Ouyang, L.; Bruening, M.L.; Muñoz, M.; Remigy, J.-C.; Lahitte, J.-F. Development of polymeric hollow fiber membranes containing catalytic metal nanoparticles. Catal. Today 2010, 156, 181–186. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Yin, J.; Han, S.; Jiao, T.; Bai, Z.; Zhou, J.; Zhang, L.; Peng, Q. Preparation of Palladium Nanoparticles Decorated Polyethyleneimine/Polycaprolactone Composite Fibers Constructed by Electrospinning with Highly Efficient and Recyclable Catalytic Performances. Catalysts 2019, 9, 559. [Google Scholar] [CrossRef] [Green Version]

- Rajakumaran, R.; Kumar, M.; Chetty, R. Morphological effect of ZnO nanostructures on desalination performance and antibacterial activity of thin-film nanocomposite (TFN) membrane. Desalination 2020, 495, 114673. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Zhu, J.; Zhang, Y.; Liu, J.; van der Bruggen, B. Construction of TiO2@graphene oxide incorporated antifouling nanofiltration membrane with elevated filtration performance. J. Membr. Sci. 2017, 533, 279–288. [Google Scholar] [CrossRef]

- Liu, C.; Faria, A.F.; Ma, J.; Elimelech, M. Mitigation of biofilm development on thin film composite membranes functionalized with zwitterionic polymers and silver nanoparticles. Environ. Sci. Technol. 2017, 51, 182–191. [Google Scholar] [CrossRef]

- Mehrabi, Z.; Taheri-Kafrani, A.; Asadnia, M.; Razmjou, A. Bienzymatic modification of polymeric membranes to mitigate biofouling. Sep. Purif. Technol. 2020, 237, 116464. [Google Scholar] [CrossRef]

- Hradil, J.; Krystl, V.; Hrabanek, P.; Bernauer, B.; Kocirık, M. Heterogeneous membranes based on polymeric adsorbents for separation of small molecules. React. Funct. Polym. 2004, 61, 303–313. [Google Scholar] [CrossRef]

- Yin, J.; Zhan, F.; Jiao, T.; Deng, H.; Zou, G.; Bai, Z.; Zhang, Q.; Peng, Q. Highly efficient catalytic performances of nitro compounds via hierarchical PdNPs-loaded MXene/polymer nanocomposites synthesized through electrospinning strategy for wastewater treatment. Chin. Chem. Lett. 2020, 31, 992–995. [Google Scholar] [CrossRef]

- Wang, H.; Dong, Z.; Na, C. Hierarchical carbon nanotube membrane-supported gold nanoparticles for rapid catalytic reduction of p-nitrophenol. ACS Sustain. Chem. Eng. 2013, 1, 746–752. [Google Scholar] [CrossRef]

- Wu, W.; Liu, G.; Liang, S.; Chen, Y.; Shen, L.; Zheng, H.; Yuan, R.; Hou, Y.; Wu, L. Efficient visible-light-induced photocatalytic reduction of 4-nitroaniline to p-phenylenediamine over nanocrystalline PbBi2Nb2O9. J. Catal. 2012, 290, 13–17. [Google Scholar] [CrossRef]

- Le, X.; Dong, Z.; Li, X.; Zhang, W.; Le, M.; Ma, J. Fibrous nano-silica supported palladium nanoparticles: An efficient catalyst for the reduction of 4-nitrophenol and hydrodechlorination of 4-chlorophenol under mild conditions. Catal. Commun. 2015, 59, 21–25. [Google Scholar] [CrossRef]

- Fang, Y.; Wang, E. Simple and direct synthesis of oxygenous carbon supported palladium nanoparticles with high catalytic activity. Nanoscale 2013, 5, 1843–1848. [Google Scholar] [CrossRef] [PubMed]

- Bazhenov, S.D.; Bildyukevich, A.V.; Volkov, A.V. Gas-liquid hollow fiber membrane contactors for different applications. Fibers 2018, 6, 76. [Google Scholar] [CrossRef] [Green Version]

- Sirkar, K.K.; Shanbhag, P.V.; Kovvali, A.S. Membrane in a Reactor: A Functional Perspective. Ind. Eng. Chem. Res. 1999, 38, 10, 3715–3737. [Google Scholar] [CrossRef]

- de Pedro, Z.M.; Diaz, E.; Mohedano, A.F.; Casas, J.A.; Rodriguez, J. Compared activity and stability of Pd/Al2O3 and Pd/AC catalysts in 4-chlorophenol hydrodechlorination in different pH media. J. Appl. Catal. B Environ. 2011, 103, 128–135. [Google Scholar] [CrossRef]

- Borja-Arco, E.; Castellanos, R.H.; Uribe-Godínez, J.; Altamirano-Gutiérrez, A.; Jiménez-Sandoval, O. Osmium-ruthenium carbonyl clusters as methanol tolerant electrocatalysts for oxygen reduction. J. Power Sources 2009, 188, 387–396. [Google Scholar] [CrossRef]

- Bolitho, E.M.; Coverdale, J.P.C.; Bridgewater, H.E.; Clarkson, G.J.; Quinn, P.D.; Sanchez-Cano, C.; Sadler, P.J. Tracking Reactions of Asymmetric Organo-Osmium Transfer Hydrogenation Catalysts in Cancer Cells. Angew. Chem. Int. Ed. 2021, 60, 6462–6472. [Google Scholar] [CrossRef]

- Adams, C.W.M.; Abdulla, Y.H.; Bayliss, O.B. Osmium tetroxide as a histochemical and histological reagent. Histochemie 1967, 9, 68–77. [Google Scholar] [CrossRef]

- Heller, A. Electron-conducting redox hydrogels: Design, characteristics and synthesis. Curr. Opin. Chem. Biol. 2006, 10, 664–672. [Google Scholar] [CrossRef]

- Uribe-Godínez, J.; Castellanos, E.; Borja-Arco, R.H.; Altamirano-Gutiérrez, A.; Jiménez-Sandoval, O. Novel osmium-based electrocatalysts for oxygen reduction and hydrogen oxidation in acid conditions. J. Power Sources 2008, 177, 286–295. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, G.; Shi, L.; Ye, J. Single-Atom Catalysts: Emerging Multifunctional Materials in Heterogeneous Catalysis. Adv. Mat. 2018, 8, 1701343. [Google Scholar] [CrossRef]

- Sharpless, K.B.; Amberg, W.; Bennani, Y.L.; Crispino, G.A.; Hartung, J.; Jeong, K.S.; Kwong, H.L.; Morikawa, K.; Wang, Z.M. The osmium-catalyzed asymmetric dihydroxylation: A new ligand class and a process improvement. J. Org. Chem. 1992, 57, 10, 2768–2771. [Google Scholar] [CrossRef]

- Kolb, H.C.; Van Nieuwenhze, M.S.; Sharpless, K.B. Catalytic Asymmetric Dihydroxylation. Chem. Rev. 1994, 94, 8, 2483–2547. [Google Scholar] [CrossRef]

- Ma, L.; Abney, C.; Lin, W. Enantioselective catalysis with homochiral metal–organic frameworks. Chem. Soc. Rev. 2009, 38, 1248–1256. [Google Scholar] [CrossRef]

- Yoon, T.P.; Jacobsen, E.N. Privileged Chiral Catalysts. Science 2003, 299, 1691–1693. [Google Scholar] [CrossRef]

- Keith, L.; Telliard, W. Priority Pollutants. Environ. Sci. Technol. 1979, 13, 416–423. [Google Scholar] [CrossRef]

- Nasrollahzadeh, M.; Jaleh, B.; Fakhri, P.; Zahraei, A.; Ghadery, E. Synthesis and catalytic activity of carbon supported copper nanoparticles for the synthesis of aryl nitriles and 1,2,3-triazoles. RSC Adv. 2015, 5, 2785–2793. [Google Scholar] [CrossRef]

- Kristanti, R.A.; Toyama, T.; Hadibarata, T.; Tanaka, Y.; Mori, K. Sustainable removal of nitrophenols by rhizoremediation using four strains of bacteria and giant duckweed (Spirodela polyrhiza). Water. Air. Soil Pollut. 2014, 225, 1928–1937. [Google Scholar] [CrossRef]

- Xiong, Z.; Zhang, H.; Zhang, W.; Lai, B.; Yao, G. Removal of Nitrophenols and their Derivatives by Chemical Redox: A Review. Chem. Eng. J. 2019, 359, 13–31. [Google Scholar] [CrossRef]

- Jaleh, B.; Karami, S.; Sajjadi, M.; Feizi, B.; Azizian, S.; Nasrollahzadeh, M.; Varma, R.S. Laser-assisted preparation of Pd nanoparticles on carbon cloth for the degradation of environmental pollutants in aqueous medium. Chemosphere 2020, 246, 125755. [Google Scholar] [CrossRef]

- Vassilev, D.; Petkova, N.; Tumbarski, Y.; Koleva, M.; Denev, P. Application of the principles of “green chemistry” for the synthesis of 10-undecylenic aliphatic esters with antimicrobial activity. J. Renew. Mater. 2020, 8, 675–686. [Google Scholar] [CrossRef]

- Yasa, S.; Cheguru, S.; Krishnasamy, S.; Korlipara, P.; Rajak, A.; Penumarthy, V. Synthesis of 10-undecenoic acid based C22-dimer acid esters and their evaluation as potential lubricant basestocks. Ind. Crops Prod. 2017, 103, 141–151. [Google Scholar] [CrossRef]

- Raku, T.; Kitagawa, M.; Shimakawa, H.; Tokiwa, Y. Enzymatic synthesis of hydrophilic undecylenic acid sugar esters and their biodegradability. Biotechnol. Lett. 2003, 25, 161–166. [Google Scholar] [CrossRef]

- Cavalcante, I.M.; Rocha, N.R.D.C.; de Brito, D.H.A.; Schuller, A.P.D.; Camara Neto, J.F.; de Morais, S.M.; de Luna, F.M.T.; Schanz, M.T.G.F.; Maier, M.E.; Ricardo, N.M.P.S. Synthesis and characterization of novel polyol esters of undecylenic acid as ecofriendly lubricants. J. Am. Oil Chem Soc. 2019, 96, 75–82. [Google Scholar] [CrossRef] [Green Version]

- Huerta-Ángeles, G.; Brandejsová, M.; Kopecká, K.; Ondreáš, F.; Medek, T.; Židek, O.; Kulhánek, J.; Vagnerová, H.; Velebný, V. Synthesis and Physicochemical Characterization of Undecylenic Acid Grafted to Hyaluronan for Encapsulation of Antioxidants and Chemical Crosslinking. Polymers 2020, 12, 35. [Google Scholar] [CrossRef] [Green Version]

- Ghimpusan, M.; Nechifor, G.; Din, I.S.; Nechifor, A.C.; Passeri, P. Application of Hollow Fibre Membrane Bioreactor Instead of Granular Activated Carbon Filtration for Treatment of Wastewater from Car Dismantler Activity. Mat. Plast. 2016, 53, 578–584. [Google Scholar]

- Din, I.S.; Cimbru, A.M.; Rikabi, A.A.K.K.; Tanczos, S.K.; Ticu (Cotorcea), S.; Nechifor, G. Iono-molecular Separation with Composite Membranes VI. Nitro-phenol separation through sulfonated polyether ether ketone on capillary polypropylene membranes. Rev. Chim. Buchar. 2018, 69, 1603–1607. [Google Scholar] [CrossRef]

- Ghimpusan, M.; Nechifor, G.; Nechifor, A.C.; Dima, S.O.; Passeri, P. Case studies on the physical-chemical parameters’ variation during three different purification approaches destined to treat wastewaters from food industry. J. Environ. Manag. 2017, 203, 811–816. [Google Scholar] [CrossRef] [PubMed]

- Dimulescu, I.A.; Nechifor, A.C.; Bărdacă, C.; Oprea, O.; Paşcu, D.; Totu, E.E.; Albu, P.C.; Nechifor, G.; Bungău, S.G. Accessible Silver-Iron Oxide Nanoparticles as a Nanomaterial for Supported Liquid Membranes. Nanomaterials 2021, 11, 1204. [Google Scholar] [CrossRef]

- Nechifor, A.C.; Cotorcea, S.; Bungău, C.; Albu, P.C.; Pașcu, D.; Oprea, O.; Grosu, A.R.; Pîrțac, A.; Nechifor, G. Removing of the Sulfur Compounds by Impregnated Polypropylene Fibers with Silver Nanoparticles-Cellulose Derivatives for Air Odor Correction. Membranes 2021, 11, 256. [Google Scholar] [CrossRef] [PubMed]

- Grosu, A.R.; Nafliu, I.M.; Din, I.S.; Cimbru, A.M.; Nechifor, G. Neutralization with simultaneous separation of aluminum and copper ions from condensed water through capillary polypropylene and cellulose. UPB Sci. Bull. Ser. B Chem. Mater. Sci. 2020, 82, 25–34. [Google Scholar]

- Nechifor, A.C.; Goran, A.; Grosu, V.-A.; Bungău, C.; Albu, P.C.; Grosu, A.R.; Oprea, O.; Păncescu, F.M.; Nechifor, G. Improving the Performance of Composite Hollow Fiber Membranes with Magnetic Field Generated Convection Application on pH Correction. Membranes 2021, 11, 445. [Google Scholar] [CrossRef]

- Nechifor, A.C.; Pîrțac, A.; Albu, P.C.; Grosu, A.R.; Dumitru, F.; Dimulescu, I.A.; Oprea, O.; Pașcu, D.; Nechifor, G.; Bungău, S.G. Recuperative Amino Acids Separation through Cellulose Derivative Membranes with Microporous Polypropylene Fiber Matrix. Membranes 2021, 11, 429. [Google Scholar] [CrossRef]

- Diaconu, I.; Nechifor, G.; Nechifor, A.C.; Ruse, E.; Totu, E.E. Membranary techniques used at the separation of some phenolic compounds from aqueous media, UPB Scientific Bulletin. Ser. B Chem. Mater. Sci. 2009, 71, 39–46. [Google Scholar]

- Szczepański, P.; Diaconu, I. Transport of p-nitrophenol through an agitated bulk liquid membrane. Sep. Sci. Technol. 2012, 47, 1725–1732. [Google Scholar] [CrossRef]

- Koter, S.; Szczepański, P.; Mateescu, M.; Nechifor, G.; Badalau, L.; Koter, I. Modeling of the cadmium transport through a bulk liquid membrane. Sep. Purif. Technol. 2013, 107, 135–143. [Google Scholar] [CrossRef]

- Diaconu, I.; Gîrdea, R.; Cristea, C.; Nechifor, G.; Ruse, E.; Totu, E.E. Removal and recovery of some phenolic pollutants using liquid membranes. Rom. Biotechnol. Lett. 2010, 15, 5702–5708. [Google Scholar]

- Nechifor, A.C.; Goran, A.; Grosu, V.-A.; Pîrțac, A.; Albu, P.C.; Oprea, O.; Grosu, A.R.; Pașcu, D.; Păncescu, F.M.; Nechifor, G.; et al. Reactional Processes on Osmium-Polymeric Membranes for 5-Nitrobenzimidazole Reduction. Membranes 2021, 11, 633. [Google Scholar] [CrossRef] [PubMed]

- Bărdacă Urducea, C.; Nechifor, A.C.; Dimulescu, I.A.; Oprea, O.; Nechifor, G.; Totu, E.E.; Isildak, I.; Albu, P.C.; Bungău, S.G. Control of Nanostructured Polysulfone Membrane Preparation by Phase Inversion Method. Nanomaterials 2020, 10, 2349. [Google Scholar] [CrossRef] [PubMed]

- George, A.; Selvan, D.; Mandal, S. Catalytic Reduction of Toxic Nitroarenes in Aqueous Medium Using Worm-Like Rhodium Nanoparticles. Chem. Sel. 2017, 2, 9718–9721. [Google Scholar] [CrossRef]

- Huang, T.; Fu, Y.; Peng, Q.; Yu, C.; Zhu, J.; Yu, A.; Wang, X. Catalytic hydrogenation of p-nitrophenol using a metal-free catalyst of porous crimped graphitic carbon nitride. Appl. Surf. Sci. 2019, 480, 888–895. [Google Scholar] [CrossRef]

- Lu, H.; Yin, H.; Liu, Y.; Jiang, T.; Yu, L. Influence of support on catalytic activity of Ni catalysts in p-nitrophenol hydrogenation to p-aminophenol. Catal. Commun. 2008, 10, 313–316. [Google Scholar] [CrossRef]

- Herskowitz, M.; Wisniak, J.; Skladman, L. Hydrogen solubility in organic liquids. J. Chem. Eng. Data 1983, 28, 164–166. [Google Scholar] [CrossRef]

- Mionić Ebersold, M.; Petrović, M.; Fong, W.-K.; Bonvin, D.; Hofmann, H.; Milošević, I. Hexosomes with Undecylenic Acid Efficient against Candida Albicans. Nanomaterials 2018, 8, 91. [Google Scholar] [CrossRef] [Green Version]

- Liakos, I.L.; Holban, A.M.; Carzino, R.; Lauciello, S.; Grumezescu, A.M. Electrospun Fiber Pads of Cellulose Acetate and Essential Oils with Antimicrobial Activity. Nanomaterials 2017, 7, 84. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shi, D.; Zhao, Y.; Yan, H.; Fu, H.; Shen, Y.; Lu, G.; Mei, H.; Qiu, Y.; Li, D.; Liu, W. Antifungal effects of undecylenic acid on the biofilm formation of Candida albicans. Int. J. Clin. Pharmacol. Ther. 2016, 54, 343–353. [Google Scholar] [CrossRef] [PubMed]

- Petrović, M.; Bonvin, D.; Hofmann, H.; Mionić Ebersold, M. Fungicidal PMMA-Undecylenic Acid Composites. Int. J. Mol. Sci. 2018, 19, 184. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zanje, S.B.; Kokare, A.N.; Suryavanshi, V.J.; Waghmode, D.P.; Joshi, S.S.; Anuse, M.A. Development of a reliable analytical method for the precise extractive spectrophotometric determination of osmium(VIII) with 2-nitrobenzaldehydethiocarbohydrazone: Analysis of alloys and real sample. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2016, 169, 223–229. [Google Scholar] [CrossRef] [PubMed]

- Tabatabaee, M.; Bagheri, H.; Shahvazian, M. Application of thionine dye for highly sensitive and selective catalytic kinetic determination of osmium. Prog. Color Colorants Coat. 2010, 3, 33–40. [Google Scholar]

- Tang, B.; Zhang, H.; Wang, Y. Flow injection kinetic spectrofluorimetric determination of trace amounts of osmium. Spectrochim. Acta Part A 2005, 61, 2239–2244. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, T.; Miyada, M.; Ohta, K.; Kaneco, S.; Mizuno, T. Determination of osmium in waste water by graphite furnace atomic absorption spectrometry. Mikrochim. Acta 1998, 129, 259–263. [Google Scholar] [CrossRef]

- Gregoire, D.C. Sample introduction techniques for the determination of osmium isotope ratios by inductively coupled plasma mass spectrometry. Anal. Chem. 1990, 62, 141–146. [Google Scholar] [CrossRef]

| Composite Membranes | (Os-PP0) | (Os-PP1) | (Os-PP2) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Surface Composition | Weight (%) | Atomic (%) | Error (%) | Weight (%) | Atomic (%) | Error (%) | Weight (%) | Atomic (%) | Error (%) |

| C K | 49.36 | 90.32 | 9.44 | 43.22 | 88.09 | 9.81 | 39.90 | 85.94 | 9.98 |

| O K | 2.89 | 4.05 | 29.4 | 3.29 | 5.03 | 31.05 | 3.98 | 6.43 | 33.41 |

| Os L | 47.75 | 5.63 | 11.12 | 53.49 | 6.88 | 13.32 | 56.12 | 7.63 | 14.03 |

| Sample | T10 | T20 | T30 | T40 | T50 | Melting Onset | Exo Burning |

|---|---|---|---|---|---|---|---|

| (°C) | (°C) | (°C) | (°C) | (°C) | (°C) | (°C) | |

| Os-PP1 | 276.1 | 303.8 | 327.2 | 344.2 | 356.8 | 159.7 | 388.6 |

| Os-PP2 | 298.3 | 327.6 | 347.7 | 362.3 | 373.5 | 160.4 | 399.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nechifor, G.; Păncescu, F.M.; Grosu, A.R.; Albu, P.C.; Oprea, O.; Tanczos, S.-K.; Bungău, C.; Grosu, V.-A.; Pîrțac, A.; Nechifor, A.C. Osmium Nanoparticles-Polypropylene Hollow Fiber Membranes Applied in Redox Processes. Nanomaterials 2021, 11, 2526. https://doi.org/10.3390/nano11102526

Nechifor G, Păncescu FM, Grosu AR, Albu PC, Oprea O, Tanczos S-K, Bungău C, Grosu V-A, Pîrțac A, Nechifor AC. Osmium Nanoparticles-Polypropylene Hollow Fiber Membranes Applied in Redox Processes. Nanomaterials. 2021; 11(10):2526. https://doi.org/10.3390/nano11102526

Chicago/Turabian StyleNechifor, Gheorghe, Florentina Mihaela Păncescu, Alexandra Raluca Grosu, Paul Constantin Albu, Ovidiu Oprea, Szidonia-Katalin Tanczos, Constantin Bungău, Vlad-Alexandru Grosu, Andreia Pîrțac, and Aurelia Cristina Nechifor. 2021. "Osmium Nanoparticles-Polypropylene Hollow Fiber Membranes Applied in Redox Processes" Nanomaterials 11, no. 10: 2526. https://doi.org/10.3390/nano11102526

APA StyleNechifor, G., Păncescu, F. M., Grosu, A. R., Albu, P. C., Oprea, O., Tanczos, S.-K., Bungău, C., Grosu, V.-A., Pîrțac, A., & Nechifor, A. C. (2021). Osmium Nanoparticles-Polypropylene Hollow Fiber Membranes Applied in Redox Processes. Nanomaterials, 11(10), 2526. https://doi.org/10.3390/nano11102526