A Review on the Wear, Corrosion and High-Temperature Resistant Properties of Wire Arc-Sprayed Fe-Based Coatings

Abstract

:1. Introduction

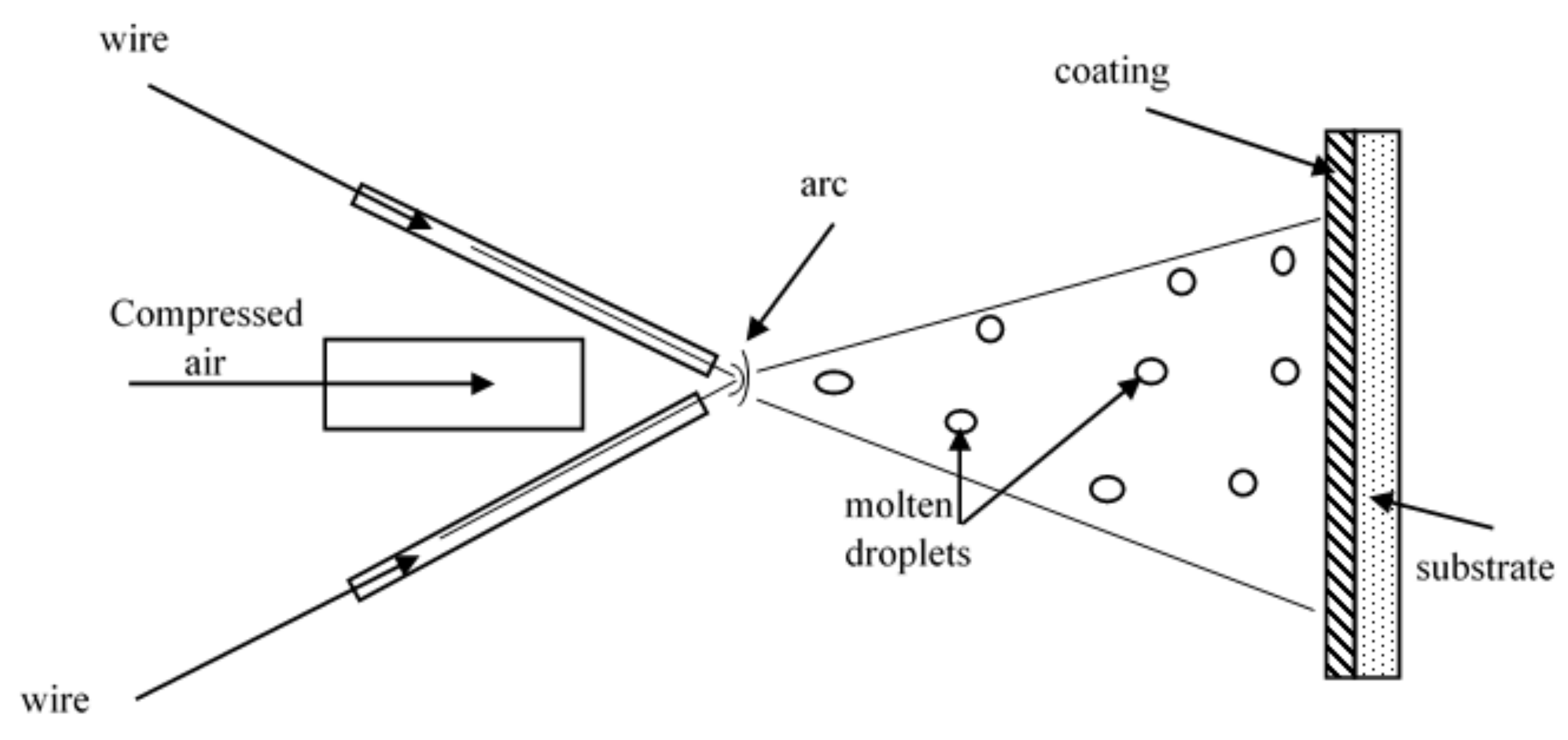

2. Working Principle of the Arc-Spraying Process

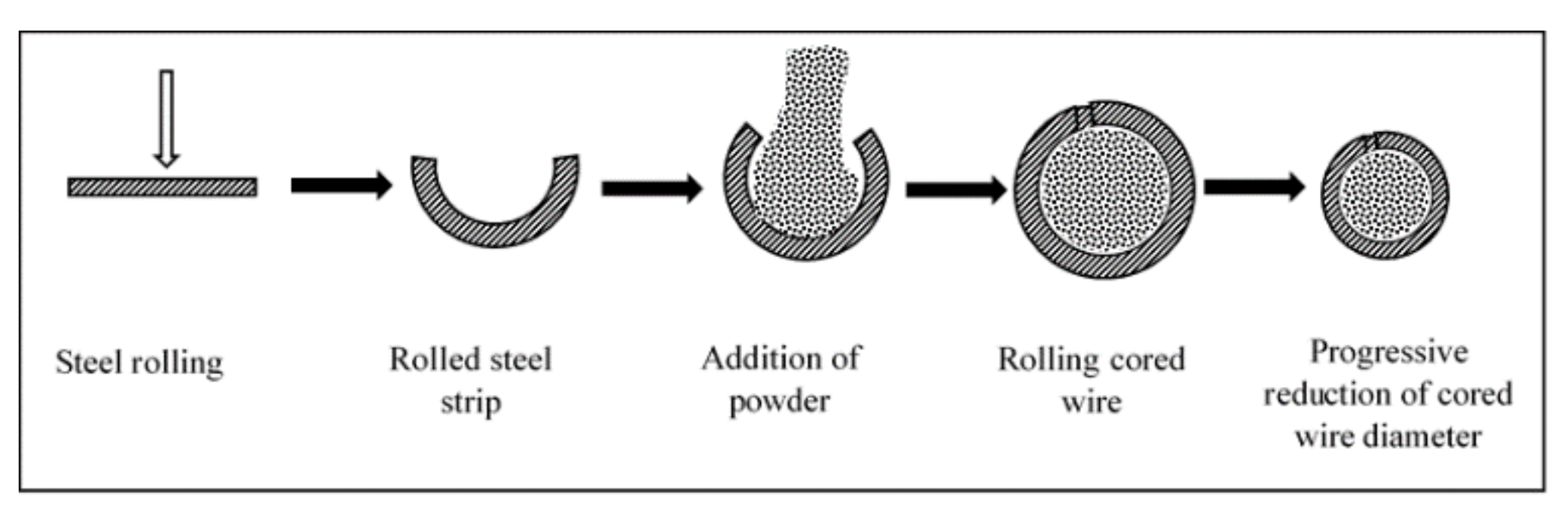

2.1. Coating Material Preparation

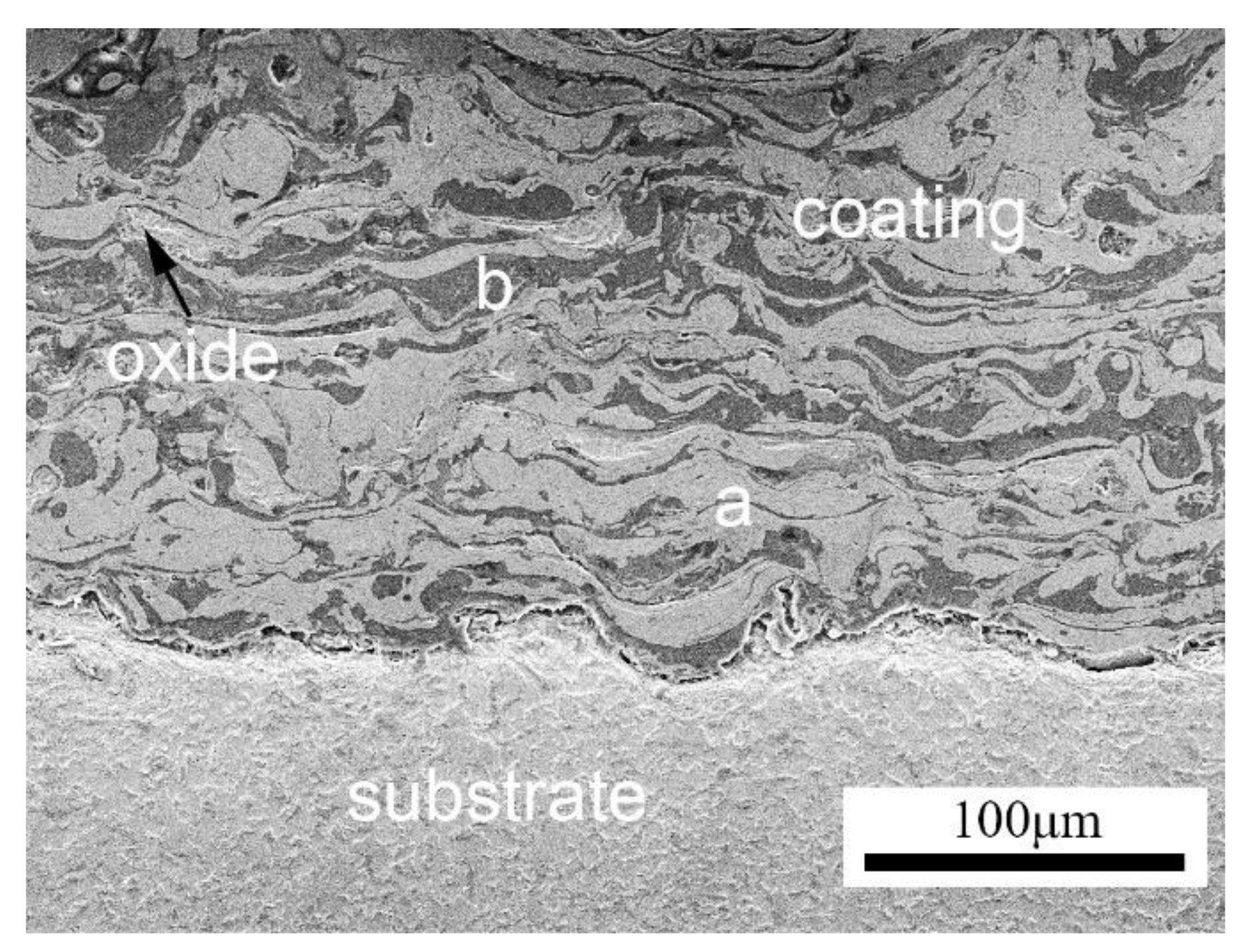

2.2. Arc-Sprayed Coating Microstructure

3. Properties of Arc-Sprayed Fe-Based Coatings

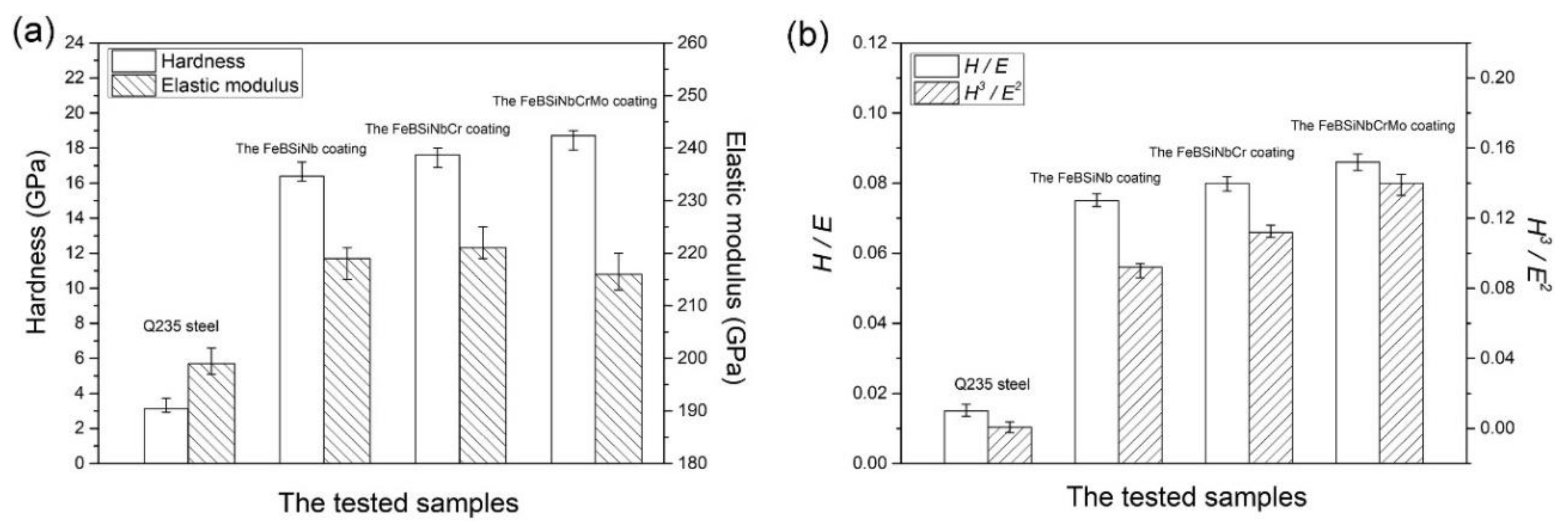

3.1. Wear Properties at Room Temperature

| Coating | Porosity | Hardness (H) | Elastic Modulus (GPa) | H/E | Specific Wear Rate | Wear Mechanism |

|---|---|---|---|---|---|---|

| FeCrBSiNbW | 2.8% | 14.7 GPa (~1499) HV | 198 | 0.074 | - | Dispersion strengthening of the amorphous/nanocrystalline grains prevent the material removal [25] |

| Fe-NiB Fe-NiB-Cr3C2 | 2.7% 2.1% | 950 HV0.1 1090 HV0.1 | - | - | - | Wear mechanism of the coatings was by flaking off and some slight plastic furrows [30] |

| Fe-CrB-Cr3C2 | 2.33% | 860–1260 HV0.1 | - | - | - | High hardness prevented micro-cutting. Mass loss by flaking mechanism [31] |

| FeBSiNb | 1.2% | 16.42 GPa (~1674) HV | 219 | 0.075 | Brittle failure and fracture [62] | |

| FeBSiCrNbMnY | 1.7% | 15.7 GPa (900–1050) HV0.1 | 217 | 0.07 | - | Brittle failure and fracture [58,59] |

| 3Cr13 | 6.9 GPa (~704) HV | 199 | 0.035 | - | Big pits and parallel grooves characterize cutting and delamination [63] | |

| FePSiBNb | <3% | 12.3 GPa (~1254) HV | 204 | 0.06 | (0.57 − 1.86) × 10−5 mm3/Nm (at different loads and sliding speeds) | Oxidative wear coupled with delamination [63] |

| Fe-FeB-WC/12Co Fe-FeB-WC/12Ni | 2.1% 3.2% | 920 HV0.1 872 HV0.1 | - | - | - | Selective removal of the binder caused by plastic deformation and fatigue [64] |

| FeCrCMoBWSiNb (140MXC) | 1.55% | 9.1 GPa (~928) HV | - | - | Delamination in combination with plastic deformation and oxidation [21] | |

| FeNiCrBCSi | 2.1% | 960 HV0.3 | - | - | - | Selective removal of the binder is probably caused by the plastic deformation and fatigue, Flaking off caused by microcracks [51] |

| 08Mn2Si 4Cr13 65Mn | 6.12% 3.33% 5.43% | 231.2 HV 288.9 HV 329.9 HV | - | - | - | Abrasive wear [50] |

| FeCrMnMoWBCSi | 4.85% | 883.8 HV0.1 | - | Fatigue wear and oxidation wear [65] | ||

| FeCrBSiMnMoW | 2.53% | 1150 HV0.3 | - | - | 3.3 × 10−5 mm3/Nm | Abrasive wear mechanism with brittle peeling pit and cracks [66] |

| FeNiCrAlBRE/Ni95Al | 3.74 % | 480–600 HV0.1 | - | - | - | Fracture of splats due to severe plastic deformation at the tip of splats. Cracks initiated at the edges of pores, between the boundaries of inclusions and splats or interfaces of splats [67] |

| FeNiCrAl/3Cr13 | - | 375–390 HV0.1 | - | - | 1.963 mm3/Nm | Abrasive wear mechanism [33] |

| WC/W2C-FeCMnSi | 5.4% 4.4% 2.7% 2.9% 3.3% | 567 ± 63 HV0.3 543 ± 86 HV0.3 561 ± 79 HV0.3 585 ± 117 HV0.3 630 ± 65 HV0.3 | 84.0 81.9 118.3 124.8 151.4 | 0.057 0.055 0.051 0.042 0.051 | - | [45] |

| FeBSiNbCrMo | 1.1% | 18.7 GPa (~1907) HV | - | - | - | Brittle delamination [68] |

| FeBSiNbCr | 1.5% | 1113 HV | - | - | - | Brittle breaking and fracture [69] |

3.2. Corrosion Properties at Room Temperature

3.3. High-Temperature Properties of Arc-Sprayed Fe-Based Coatings

3.3.1. High-Temperature Oxidation Behavior

3.3.2. High-Temperature Erosion (HTE) Behavior

3.3.3. High-Temperature Corrosion Behavior

3.3.4. High-Temperature Wear Behavior

4. Conclusions and Future Scope Recommendations

- The density, size, and structure of feedstock powders influence the phase composition of the deposited coatings in HVOF and APS thermal spraying methods. Cored wires in arc-spraying can explore the use of different-sized powders as filling materials to optimize the coating properties. Coating powders of arc-sprayed cored wires can apply nanoscale particles that result in densely packed nanostructured coatings [57]. Arc-sprayed FePSiNb coatings exhibited a nanoscale structure with a grain size range from 12 to 50 nm with good wear resistance properties [63]. More work will need to be done to determine the production and study of properties of arc-sprayed nanostructured coatings.

- The spraying parameters play an important role in determining the microstructural properties of the coatings. Optimizing methods such as response surface methodology (RSM) analyzes the interaction between spray parameters and their influence on the coating properties. The effects of process parameters on the amorphization of the arc-sprayed coatings could be studied to maximize the amorphous content of Fe-based amorphous coatings.

- The arc-sprayed Fe-based coatings have better hardness and wear resistance properties than conventional alloys due to the dense microstructure, the dispersion strengthening of the amorphous/nanocrystalline phases, and reinforcement ceramic particles. The elastic properties also determine the wear resistance of the Fe-based coatings.

- To increase the corrosion resistance, the coating defects (oxides, pores, and cracks) in the Fe-based coatings should be minimized by optimizing spray parameters to prevent the deterioration of coating properties in corrosive media.

- The high-temperature properties of the Fe-based coating are mainly affected by the microstructure and the elemental composition. The reinforcement ceramic particles added to the Fe-based alloys improve the tribological and high-temperature coating performance while the amorphous phase content is characterized by fewer dislocations, microcracks, and grain boundaries enhancing the properties of the Fe-based amorphous coatings. Future research should focus on understanding the combined corrosion-wear behavior of arc-sprayed Fe-based coatings at elevated temperatures.

- Adding appropriate alloying elements such as Al and Cr to Fe-based coatings improves high-temperature protection by forming oxide scales that prevent further oxidation of the underlying substrate. Future research should investigate the influence of different elements on high-temperature properties of Fe-based coatings.

Author Contributions

Funding

Conflicts of Interest

References

- Fukumoto, M. The current status of thermal spraying in Asia. J. Therm. Spray Technol. 2008, 17, 5–13. [Google Scholar] [CrossRef]

- Davis, J.R. Handbook of Thermal Spray technology; ASM International: Materials Park, OH, USA, 2004. [Google Scholar]

- Zhang, W.; Guo, Y.-M.; Chen, Y.-X. Applications and future development of thermal spraying technologies for remanufacturing engineering. China Surf. Eng. 2011, 24, 1–10. [Google Scholar]

- Szymański, K.; Hernas, A.; Moskal, G.; Myalska, H. Thermally sprayed coatings resistant to erosion and corrosion for power plant boilers-A review. Surf. Coat. Technol. 2015, 268, 153–164. [Google Scholar] [CrossRef]

- Steffens, H.-D.; Babiak, Z.; Wewel, M. Recent developments in arc spraying. IEEE Trans Plasma Sci. 1990, 18, 974–979. [Google Scholar] [CrossRef]

- Chi, X.; Song, C.; Bao, J.; Gao, Z.; Ren, X.; Ma, B. Research progress on fabrication of composite metal coatings by arc spraying. Therm. Spray Technol. 2019, 11, 72–76. [Google Scholar]

- Yadaw, R.C.; Singh, S.K.; Chattopadhyaya, S.; Kumar, S.; Singh, R. Tribological behavior of thin film coating-a review. Int. J. Eng. Technol. 2018, 7, 1656–1663. [Google Scholar] [CrossRef]

- Wielage, B.; Pokhmurska, H.; Student, M.; Gvozdeckii, V.; Stupnyckyj, T.; Pokhmurskii, V. Iron-based coatings arc-sprayed with cored wires for applications at elevated temperatures. Surf. Coat. Technol. 2013, 220, 27–35. [Google Scholar] [CrossRef]

- Degnan, C.; Shipway, P.J.W. A comparison of the reciprocating sliding wear behaviour of steel based metal matrix composites processed from self-propagating high-temperature synthesised Fe–TiC and Fe–TiB2 masteralloys. Wear 2002, 252, 832–841. [Google Scholar] [CrossRef]

- Xu, W.-P.; Xu, B.-S.; Zhang, W.; Wu, Y.-X. High temperature behaviors of high velocity arc sprayed Fe-Al/Cr3C2 composite coatings. Int. J. Miner. Metall. Mater. 2005, 12, 340–346. [Google Scholar]

- Li, R.; Zhou, Z.; He, D.; Wang, Y.; Wu, X.; Song, X. Microstructure and high temperature corrosion behavior of wire-arc sprayed FeCrSiB coating. J. Therm. Spray Technol. 2015, 24, 857–864. [Google Scholar] [CrossRef]

- Li, R.; He, D.Y.; Zhou, Z.; Wang, Z.J.; Song, X.Y. Wear and high temperature oxidation behaviour of wire arc sprayed iron based coatings. Surf. Eng. 2014, 30, 784–790. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Z.; Lin, J. High temperature oxidation behavior of arc-sprayed FeCrBAlMo coating. J. Adv. Oxid. Technol. 2016, 19, 105–112. [Google Scholar] [CrossRef]

- Luo, L.-M.; Liu, S.-G.; Jia, Y.; Juan, L.; Jian, L. Effect of Al content on high temperature erosion properties of arc-sprayed FeMnCrAl/Cr3C2 coatings. Trans. Nonferr. Met. Soc. China. 2010, 20, 201–206. [Google Scholar] [CrossRef]

- Koiprasert, H.; Ch, S.; Sheppard, P. FeAl and FeCrAl as alternative coatings for NiAl. Chiang Mai J. Sci. 2013, 40, 839–848. [Google Scholar]

- Zhang, S.; Du, S.; Zhang, Y. Research progress of Fe-based amorphous alloy coating prepared by thermal spraying. Hot Work Technol. 2010, 39, 89–91. [Google Scholar]

- Guo, W.; Wu, Y.; Zhang, J.; Hong, S.; Li, G.; Ying, G.; Guo, J.; Qin, Y. Fabrication and characterization of thermal-sprayed Fe-based amorphous/nanocrystalline composite coatings: An overview. J. Therm. Spray Technol. 2014, 23, 1157–1180. [Google Scholar] [CrossRef]

- Cheng, J.B.; Liang, X.B.; Xu, B.S. Devitrification of arc-sprayed FeBSiNb amorphous coatings: Effects on wear resistance and mechanical behavior. Surf. Coat. Technol. 2013, 235, 720–726. [Google Scholar] [CrossRef]

- Huang, L.; Yu, S.; Deng, Y.; Dai, M.; Xu, H. Research progress and application of arc spraying cored wires. Mater. Rev. 2011, 25, 63–65. [Google Scholar]

- Lotfi, B.; Shipway, P.; McCartney, D.; Edris, H. Abrasive wear behaviour of Ni (Cr)–TiB2 coatings deposited by HVOF spraying of SHS-derived cermet powders. Wear 2003, 254, 340–349. [Google Scholar] [CrossRef]

- Arizmendi-Morquecho, A.; Campa-Castilla, A.; Leyva-Porras, C.; Aguilar Martinez, J.A.; Vargas Gutiérrez, G.; Moreno Bello, K.J.; López López, L. Microstructural characterization and wear properties of Fe-based amorphous-crystalline coating deposited by twin wire arc spraying. Adv. Mater. Sci. Eng. 2014, 2014, 836739. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Sun, C.; Sun, J.; Zhao, W.; Dong, L.; Li, L.; Meng, F. Erosion behavior of arc sprayed FeTi/CrB MMC coating at elevated temperature. Surf. Coat. Technol. 2015, 262, 141–147. [Google Scholar] [CrossRef]

- Yao, H.; Zhou, Z.; Wang, Y.; He, D.; Bobzin, K.; Zhao, L.; Öte, M.; Königstein, T. Microstructure and properties of FeCrB alloy coatings prepared by wire-arc spraying. J. Therm. Spray Technol. 2017, 26, 483–491. [Google Scholar] [CrossRef]

- He, D. Study on arc-sprayed cored wires and wear properties of coatings. Ph.D Thesis, Beijing University of Technology, Beijing, China, 2004. [Google Scholar]

- Cheng, J.; Wang, Z.; Xu, B. Wear and corrosion behaviors of FeCrBSiNbW amorphous/nanocrystalline coating prepared by arc spraying process. J. Therm. Spray Technol. 2012, 21, 1025–1031. [Google Scholar] [CrossRef]

- Lin, J.; Wang, Z.; Lin, P.; Cheng, J.; Zhang, J.; Zhang, X. Microstructure and corrosion resistance of Fe-based coatings prepared by twin wires arc spraying process. J. Therm. Spray Technol. 2014, 23, 333–339. [Google Scholar] [CrossRef]

- Lin, J.; Wang, Z.; Lin, P.; Cheng, J.; Zhang, X.; Hong, S. Microstructure and cavitation erosion behavior of FeNiCrBSiNbW coating prepared by twin wires arc spraying process. Surf. Coat. Technol. 2014, 240, 432–436. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Z.; Lin, J.; Zhou, Z. A study on high temperature oxidation behavior of high-velocity arc sprayed Fe-based coatings. Surf. Coat. Technol. 2015, 283, 255–261. [Google Scholar] [CrossRef]

- Xu, B.; Zhu, Z.; Ma, S.; Zhang, W.; Liu, W. Sliding wear behavior of Fe–Al and Fe–Al/WC coatings prepared by high velocity arc spraying. Wear 2004, 257, 1089–1095. [Google Scholar] [CrossRef]

- Fu, B.-Y.; He, D.-Y.; Zhao, L.-D.; Li, X.-Y. Microstructure characterisation and wear properties of arc sprayed NiB containing amorphous coatings. Surf. Eng. 2009, 25, 326–332. [Google Scholar] [CrossRef]

- Fu, B.-Y.; He, D.-Y.; Zhao, L.-D.; Jiang, J.-M.; Li, X.-Y. Microstructure and properties of arc sprayed coatings containing Fe based amorphous phase and nanocrystallites. Surf. Eng. 2009, 25, 333–337. [Google Scholar] [CrossRef]

- Tian, H.; Wang, C.; Tang, Z.; Wei, S.; Xu, B.; Que, M. Effect of high velocity arc spraying parameters on properties of FeNiCrAl coating. J. Aeroun. Mater. 2016, 36, 40–47. [Google Scholar]

- Tian, H.; Wei, S.; Chen, Y.; Tong, H.; Liu, Y.; Xu, B.S. Adhesive strength and abrasive property of Fe based composite coating deposited by high velocity arc spraying. Mater Res Innov. 2014, 18, S2-363–S2-367. [Google Scholar] [CrossRef]

- Tian, H.; Wei, S.; Chen, Y.; Tong, H.; Lui, Y.; Xu, B. Properties of FeCrAl/Ni95Al coating by high velocity arc spraying. Heat Treat. Metals 2013, 38, 92–96. [Google Scholar]

- Daram, P.; Munroe, P.; Banjongprasert, C. Microstructural evolution and nanoindentation of NiCrMoAl alloy coating deposited by arc spraying. Surf. Coat. Technol. 2020, 391, 125565. [Google Scholar] [CrossRef]

- Kant, S.; Kumar, M.; Chawla, V.; Singh, S. Study of high temperature oxidation behavior of wire arc sprayed coatings. Mater. Today Proc. 2020, 21, 1741–1748. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, M.; Handa, A. Comparative study of high temperature oxidation behavior and mechanical properties of wire arc sprayed NiCr and NiAl coatings. Eng. Fail. Anal. 2019, 106, 104173. [Google Scholar] [CrossRef]

- Cheng, J.; Wu, Y.; Chen, L.; Hong, S.; Qiao, L.; Wei, Z. Hot corrosion behavior and mechanism of high-velocity arc-sprayed Ni-Cr alloy coatings. J. Therm. Spray Technol. 2019, 28, 1263–1274. [Google Scholar] [CrossRef]

- Talib, R.; Saad, S.; Toff, M.; Hashim, H. Thermal spray coating technology: A review. Solid State Sci Technol. 2003, 11, 109–117. [Google Scholar]

- Takalapally, S.; Kumar, S.; Pusuluri, S.H.; Palle, M. A critical review on surface coatings for engineering materials. Int. J. Mech. Eng. Technol. 2016, 7, 80–85. [Google Scholar]

- Liu, G.; Rożniatowski, K.; Kurzydłowski, K. Quantitative characteristics of FeCrAl films deposited by arc and high-velocity arc spraying. Mater. Charact. 2001, 46, 99–104. [Google Scholar] [CrossRef]

- Zhan, J.; Li, Z.; Lu, J.; Wu, Y.; Zhao, L.; Yu, N. Technics and performance analysis of Monel alloy coating prepared by high velocity arc spraying. Mater. Res. Innov. 2013, 17, 112–114. [Google Scholar] [CrossRef]

- Boronenkov, V.; Korobov, Y. Fundamentals of Arc Spraying; Springer International Publishing: Geneva, Switzerland, 2016; (Physical and Chemical Regularities). [Google Scholar]

- Liu, S.-G.; Wu, J.-M.; Zhang, S.-C.; Rong, S.-J.; Li, Z.-Z. High temperature erosion properties of arc-sprayed coatings using various cored wires containing Ti–Al intermetallics. Wear 2007, 262, 555–561. [Google Scholar] [CrossRef]

- Tillmann, W.; Hagen, L.; Kokalj, D. Spray characteristics and tribo-mechanical properties of high-velocity arc-sprayed WC-W2C iron-based coatings. J. Therm. Spray Technol. 2017, 26, 1685–1700. [Google Scholar] [CrossRef]

- Zeng, Z.-s.; Sakoda, N.; Tajiri, T. Corrosion behavior of wire-arc-sprayed stainless steel coating on mild steel. J. Therm. Spray Technol. 2006, 15, 431–437. [Google Scholar] [CrossRef]

- Jandin, G.; Liao, H.; Feng, Z.; Coddet, C. Correlations between operating conditions, microstructure and mechanical properties of twin wire arc sprayed steel coatings. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2003, 349, 298–305. [Google Scholar] [CrossRef] [Green Version]

- Horner, A.L.; Hall, A.C.; McCloskey, J.F. The effect of process parameters on twin wire arc spray pattern shape. Coatings 2015, 5, 115–123. [Google Scholar] [CrossRef] [Green Version]

- Johnston, A.L.; Hall, A.C.; McCloskey, J.F. Effect of process inputs on coating properties in the twin-wire arc zinc process. J. Therm. Spray Technol. 2013, 22, 856–863. [Google Scholar] [CrossRef]

- Li, Z.-R.; Li, D.-Y.; Zhang, N.-N.; Huang, H.; Wang, X. Wear mechanism of iron-based alloy coating by arc spraying. J. Iron Steel Res. Int. 2016, 23, 834–841. [Google Scholar] [CrossRef]

- Fu, B.-Y.; He, D.-Y.; Zhao, L.-D. Effect of heat treatment on the microstructure and mechanical properties of Fe-based amorphous coatings. J. Alloys Compd. 2009, 480, 422–427. [Google Scholar] [CrossRef]

- Newbery, A.; Grant, P. Oxidation during electric arc spray forming of steel. J. Mater. Process. Technol. 2006, 178, 259–269. [Google Scholar] [CrossRef]

- Ndiithi, N.J.; Kang, M.; Zhu, J.; Lin, J.; Nyambura, S.M.; Liu, Y.; Huang, F. Microstructural and corrosion behavior of high velocity arc sprayed FeCrAl/Al composite coating on Q235 steel substrate. Coatings 2019, 9, 542. [Google Scholar] [CrossRef] [Green Version]

- Brezinová, J.; Landová, M.; Guzanová, A.; Dulebová, Ľ.; Draganovská, D. Microstructure, wear behavior and corrosion resistance of WC-FeCrAl and WC-WB-Co coatings. Metals 2018, 8, 399. [Google Scholar] [CrossRef] [Green Version]

- Ding, P.; Liu, X.-J.; Liu, J.-J.; Li, J.-B.; Li, H.-Q.; Zhao, H.-Y.; Duan, J.-Y.; Jiao, Y.-Z. Study on the properties of FeCrNi/CBN composite coating with high velocity arc spraying. Arab J. Chem. 2018, 11, 935–941. [Google Scholar] [CrossRef]

- Newbery, A.; Grant, P.; Neiser, R. The velocity and temperature of steel droplets during electric arc spraying. Surf. Coat. Technol. 2005, 195, 91–101. [Google Scholar] [CrossRef]

- Basak, A.; Zein Eddine, W.; Celis, J.-P.; Matteazzi, P. Characterisation and tribological investigation on thermally processed nanostructured Fe-based and Cu-based cermet materials. J. Nanosci. Nanotechnol. 2010, 10, 1179–1184. [Google Scholar] [CrossRef]

- Cheng, J.-B.; Liang, X.-B.; Xu, B.-S.; Wu, Y.-X. Formation and properties of Fe-based amorphous/nanocrystalline alloy coating prepared by wire arc spraying process. J. Non-Cryst. Solids. 2009, 355, 1673–1678. [Google Scholar] [CrossRef]

- Cheng, J.; Liang, X.; Xu, B.; Wu, Y. Characterization of mechanical properties of FeCrBSiMnNbY metallic glass coatings. J. Mater. Sci. 2009, 44, 3356–3363. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. Design criteria for wear-resistant nanostructured and glassy-metal coatings. Surf. Coat. Technol. 2004, 177, 317–324. [Google Scholar] [CrossRef]

- YH, K.; Hiraga, K.; Inoue, A.; Masumoto, T. Crystallization and high mechanical strength of Al-based amorphous alloys. Mater. Trans. JIM. 1994, 35, 293–302. [Google Scholar]

- Cheng, J.; Liang, X.; Wang, Z.; Xu, B. Microstructure and mechanical properties of FeBSiNb metallic glass coatings by twin wire arc spraying. J. Therm. Spray Technol. 2013, 22, 471–477. [Google Scholar] [CrossRef]

- Cheng, J.; Liu, Q.; Sun, B.; Liang, X.; Zhang, B. Structural and tribological characteristics of nanoscale FePSiBNb coatings. J. Therm. Spray Technol. 2017, 26, 530–538. [Google Scholar] [CrossRef]

- He, D.-Y.; Fu, B.-Y.; Jiang, J.-M.; Li, X.-Y. Microstructure and wear performance of arc sprayed Fe-FeB-WC coatings. J. Therm. Spray. Technol. 2008, 17, 757–761. [Google Scholar] [CrossRef]

- Yan, Y.; Wei, X.; Jiang, H.; Ying, C.; Shen, J. Research on microstructure and friction and wear properties of Fe-based amorphous alloy coatings prepared by arc spraying. Hot Work Technol. 2018, 47, 117–121. [Google Scholar]

- Wu, D.; Fan, Z.S.; Yang, Y. Formation and properties of Fe-based amorphous/nanocrystalline alloy coating prepared by wire arc spraying process. In Materials Science Forum; Trans Tech Publications: Zürich, Switzerland, 2019; pp. 499–505. [Google Scholar]

- Tian, H.; Wei, S.; Chen, Y.; Tong, H.; Liu, Y.; Xu, B. Wear behavior of high velocity arc spraying FeNiCrAlBRE/Ni95Al composite coatings. Physics Procedia 2013, 50, 282–287. [Google Scholar] [CrossRef] [Green Version]

- Zhang, B.; Cheng, J.; Liang, X. Effects of Cr and Mo additions on formation and mechanical properties of Arc-sprayed FeBSiNb-based glassy coatings. J. Non-Cryst. Solids. 2018, 499, 245–251. [Google Scholar] [CrossRef]

- Cheng, J.; Liang, X.; Xu, B.; Wu, Y. Microstructure and wear behavior of FeBSiNbCr metallic glass coatings. J. Mater. Sci. Technol. 2009, 25, 687–690. [Google Scholar]

- Tian, H.; Wei, S.; Chen, Y.; Tong, H.; Liu, Y.; Xu, B. Microstructure and wear resistance of an arc-sprayed Fe-based coating after surface remelting treatment. Strength Mater. 2014, 46, 229–234. [Google Scholar] [CrossRef]

- Peng, Y.; Zhang, C.; Zhou, H.; Liu, L. On the bonding strength in thermally sprayed Fe-based amorphous coatings. Surf. Coat. Technol. 2013, 218, 17–22. [Google Scholar] [CrossRef]

- Niu, P.-F.; Tian, B.-L. Wear compensation model based on the theory of archard and definite integral method. Math. Probl. Eng. 2018, 2018. [Google Scholar] [CrossRef] [Green Version]

- Kumar, D.; Murtaza, Q.; Singh, R.C. Sliding wear behavior of aluminum alloy coating prepared by two-wire electric arc spray process. Int. J. Adv. Manuf. Technol. 2016, 85, 237–252. [Google Scholar] [CrossRef]

- Cheng, J.; Liang, X.; Wang, Z.; Xu, B. Dry sliding friction and wear properties of metallic glass coating and martensite stainless coating. Tribol. Int. 2013, 60, 140–146. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Chen, X.; Du, Y.; Chung, Y.-W. Commentary on using H/E and H3/E2 as proxies for fracture toughness of hard coatings. Thin Solid Film. 2019, 688, 137265. [Google Scholar] [CrossRef]

- Ahmed, N.; Bakare, M.; McCartney, D.; Voisey, K. The effects of microstructural features on the performance gap in corrosion resistance between bulk and HVOF sprayed Inconel 625. Surf. Coat. Technol. 2010, 204, 2294–2301. [Google Scholar] [CrossRef] [Green Version]

- Belkhaouda, M.; Bazzi, L.; Benlhachemi, A.; Salghi, R.; Hammouti, B.; Kertit, S. Effect of the heat treatment on the corrosion behaviour of amorphous Fe–Cr–P–C–Si alloy in 0.5 M H2SO4. Appl. Surf. Sci. 2006, 252, 7921–7925. [Google Scholar] [CrossRef]

- Lin, J.; Wang, Z.; Lin, P.; Cheng, J.; Zhang, X.; Hong, S. Effect of crystallisation on electrochemical properties of arc sprayed FeNiCrBSiNbW coatings. Surf Eng. 2014, 30, 683–687. [Google Scholar] [CrossRef]

- Cheng, J.; Liang, X.; Xu, B. Effects of crystallization on the corrosion resistance of arc-sprayed FeBSiNb coatings. J. Therm. Spray Technol. 2014, 23, 373–379. [Google Scholar] [CrossRef]

- Yoo, Y.H.; Lee, S.H.; Kim, J.G.; Kim, J.S.; Lee, C. Effect of heat treatment on the corrosion resistance of Ni-based and Cu-based amorphous alloy coatings. J. Alloy Compd. 2008, 461, 304–311. [Google Scholar] [CrossRef]

- Li, R.; Zhou, Z.; He, D.; Zhao, L.; Song, X. Microstructure and high-temperature oxidation behavior of wire-arc sprayed Fe-based coatings. Surf. Coat. Technol. 2014, 251, 186–190. [Google Scholar] [CrossRef]

- Zhuang, X.; Tan, Y.; You, X.; Li, P.; Zhao, L.; Cui, C.; Zhang, H.; Cui, H. High temperature oxidation behavior and mechanism of a new Ni-Co-based superalloy. Vacuum 2021, 189, 110219. [Google Scholar] [CrossRef]

- Li, Y.; Liang, T.; Ao, R.; Zhao, H.; Chen, X.; Zeng, J. Oxidation resistance of iron-based coatings by supersonic arc spraying at high temperature. Surf. Coat. Technol. 2018, 347, 99–112. [Google Scholar] [CrossRef]

- Luo, L.-M.; Luo, J.; Liu, S.-G.; Liu, Y.-l.; Li, J. Microstructure and high temperature oxidation resistance of FeMnCrAl/Cr3C2 coatings deposited by high velocity arc spraying. Trans. Mater. Heat Treat. 2010, 31, 139–142. (In Chinese) [Google Scholar]

- Pokhmurskii, V.; Student, M.; Gvozdeckii, V.; Stypnutskyy, T.; Student, O.; Wielage, B.; Pokhmurska, H. Arc-sprayed iron-based coatings for erosion-corrosion protection of boiler tubes at elevated temperatures. J. Therm. Spray Technol. 2013, 22, 808–819. [Google Scholar] [CrossRef]

- Berget, J.; Rogne, T.; Bardal, E. Erosion–corrosion properties of different WC–Co–Cr coatings deposited by the HVOF process—influence of metallic matrix composition and spray powder size distribution. Surf. Coat. Technol. 2007, 201, 7619–7625. [Google Scholar] [CrossRef]

- Guo, J.; Bin-shi, X.; Hai-dou, W.; Liang, Y.; Qing-fen, L.; Shi-cheng, W.; Xiufang, C. Erosion behavior of EEDS cermet coatings. Appl. Surf. Sci. 2008, 254, 5470–5474. [Google Scholar] [CrossRef]

- Cheng, J.; Liang, X.; Chen, Y.; Wang, Z.; Xu, B. High-temperature erosion resistance of FeBSiNb amorphous coatings deposited by arc spraying for boiler applications. J. Therm. Spray Technol. 2013, 22, 820–827. [Google Scholar] [CrossRef]

- Shewmon, P.; Sundararajan, G. The erosion of metals. Ann. Rev. of Mater. Sci. 1983, 13, 301–318. [Google Scholar] [CrossRef]

- Venugopal, K.; Agrawal, M. Evaluation of arc sprayed coatings for erosion protection of tubes in atmospheric fluidised bed combustion (AFBC) boilers. Wear 2008, 264, 139–145. [Google Scholar] [CrossRef]

- Liang, X.B.; Cheng, J.B.; Bai, J.Y.; Xu, B.S. Erosion properties of Fe based amorphous/nanocrystalline coatings prepared by wire arc spraying process. Surf. Eng. 2010, 26, 209–215. [Google Scholar] [CrossRef]

- Shukla, V.; Rana, N.; Jayaganthan, R.; Tewari, V. Degradation Studies of Wire arc Sprayed FeCrBSiMn alloy Coating in Molten Salt Environment. Procedia Eng. 2014, 75, 113–117. [Google Scholar] [CrossRef] [Green Version]

- Wenmin, G.; Yuping, W.; Gaiye, L.; Qian, W.; Zhihua, H.; Sheng, H. Hot corrosion behavior of a high velocity arc-sprayed Fe-Cr-BC coating. Rare Met. Mat. Eng. 2012, 41, 456–459. [Google Scholar]

- Seong, B.G.; Hwang, S.Y.; Kim, K.Y. High-temperature corrosion of recuperators used in steel mills. Surf. Coat. Technol. 2000, 126, 256–265. [Google Scholar] [CrossRef]

- Sidhu, B.S.; Prakash, S. Performance of NiCrAlY, Ni–Cr, Stellite-6 and Ni3Al coatings in Na2SO4–60% V2O5 environment at 900 C under cyclic conditions. Surf. Coat. Technol. 2006, 201, 1643–1654. [Google Scholar] [CrossRef]

- Guo, W.-M.; Wu, Y.-P.; Li, G.-Y.; Hong, S.; He, Z.-H. Hot corrosion of FeNiCr/Cr3C2 and NiCrTi arc spray coatings on mild steel. Trans. Mater. Heat Treat. 2011, 32, 128–134. [Google Scholar]

- Li, X.; Dong, T.; Li, G.; Zhou, X.; Zheng, X. Research status and development trend of high temperature wear resistance of thermal spraying coatings. Hot Work. Technol. 2018, 47, 32–36. [Google Scholar]

- Xu, B.-S.; Zhu, Z.-X.; Liu, Y.; Ma, S.-N.; Zhang, W. Fe-Al intermetallics coating produced by high velocity arc spraying. Chin. J. Nonferr. Met. 2004, 14, 154–158. [Google Scholar]

- Zhu, Z.-X.; Xu, B.-S.; Ma, S.-N.; Du, Z.-Y.; Liu, W.-M. Tribological properties of Fe-Al/WC composite coating prepared by high velocity arc spraying. Tribology-Beijing 2003, 23, 174–178. (In Chinese) [Google Scholar]

| Fe-Based Coatings | Coating Properties | References | ||

| Hardness | Porosity | Bond Strength | ||

| FeTi/CrB | 62.7 HRC (~805 HV) | 2.7% | 40.21 MPa | [22] |

| FeCrB | 811.4 HV0.1–920.1 HV0.1 | 3.31%–4.01% | - | [23] |

| FeNiBCrSi | 700–1025 HV0.1 | - | 57 MPa | [24] |

| FeCrBSiNbW | 14.7 GPa (~1499 HV) | 2.8% | - | [25] |

| FeNiCrBSiNbW | 850–1000 HV0.1 | 1.8% | 52.1 MPa | [26,27] |

| FeCrNiNbBSiMo | - | 3.46% | 42.3 MPa | [28] |

| FeAl | 6.47 GPa (~659.7 HV) | 1.83% | 24.5 MPa | [29] |

| FeNiB-Cr3C2 | 1090 HV0.1 | 2.1% | - | [30] |

| FeCrB-Cr3C2 | 860–1260 HV0.1 | 2.33% | - | [31] |

| FeCr | 480 HV0.1 | 5.02% | - | [11] |

| FeCrSiB | 650 HV0.1 | 4.08% | - | [11] |

| FeNiCrAl | 626 HV0.1 | 8.76% | 52.3 MPa | [32] |

| 3Cr13/FeNiCrAl | 375–390 HV0.1 | - | 45.7 MPa | [33] |

| Fe-Cr-B-C | 6.47 GPa (~659.7 HV) | - | ||

| Ni-Based Coatings | Coating Properties | |||

| Hardness | Porosity | Bond Strength | References | |

| FeCrAl/Ni95Al | 530 HV0.1 | - | 43 MPa | [34] |

| NiCrMoAl | 3.65 ± 0.56 GPa (~372.2 HV) | 2.4% | - | [35] |

| Ni-5Al | 290 HV | <2% | [36] | |

| Ni-5Al | 203.8 HV & 249 HV | 1.55%–1.58% | - | [37] |

| Ni-20Cr | 273.5 HV & 379.8 HV | 1.53%–1.54% | - | [37] |

| NiCrTi | 380 HV0.1 | 2.49% | - | [11] |

| Ni-30Cr | 244 ± 12 HV0.3 | 8.4% | - | [38] |

| Ni-45Cr | 242 ± 11 HV0.3 | 5.0% | ||

| Ni-50Cr | 209 ± 7 HV0.3 | 6.1% |

| Coatings | Substrate | Current Densities Icorr (µA/cm2) | Current Potential Ecorr (V) | Corrosion Behavior |

|---|---|---|---|---|

| 0Cr18Ni9 FeCrBSiNbW | AISI 1045 Steel | 32.6 4.3 | −0.68 −0.45 | Chemical and structural homogeneities of the amorphous coating with a dense structure and low porosity prevent electrolyte penetration. Absence of defects, grain boundaries, precipitates, and segregation. The ability of Cr to form a protective film [25]. |

| FeB FeBSi FeNiCrBSiNbW | AISI 1045 steel | 18.96 12.69 8.72 | −0.758 −0.738 −0.447 | Dissolution of Cr to produce a rich passive film, homogenous amorphous/nanocrystalline, compact structure with low porosity and low oxide content which improved corrosion resistance of the coating [26]. |

| FeBSiNb FeBSiNbCr FeBSiNbCrMo | Q235 Steel | 5.92 3.61 1.53 | −0.847 −0.802 −0.775 | Corrosion resistance is attributed to its glassy structure and chemical compositions. The lower porosity and the formation of chromium-rich oxide and Mo-rich passive film. Addition of Mo facilitates the passivation of Cr films [68]. |

| Coatings | High-Temperature Oxidation Data | ||

|---|---|---|---|

| Temperature (°C) | Oxidation Weight Change | Oxidation Products | |

| FeCrAl Fe17CrB(CSi) Fe21CrB(CSi) Fe25CrB(CSi) | 650 | - | Fe2O3, Cr2O3, Al2O3 Fe2O3, Cr2O3, CrBO3 [12] |

| Fe-15Cr, Fe-20Cr, Fe-25Cr Fe-30Cr Fe-35Cr, Fe-40Cr | 650 | - | Fe2O3, Fe-Cr-O spinel Cr2O3, Fe2O3, Fe-Cr-O Fe2O3, Cr2O3 [82] |

| FeCrNiNbBSiW FeCrNiNbBSiMo | 550 and 650 | - | FeO.(Fe, Cr)2O3, (Fe, Cr) 2O3, (Fe, Cr)2O3/Cr2O3 [28] |

| FeMnCr/Cr3C2 FeMnCrAl/Cr3C2 | 700 | 11.209 mg/cm2 4.369 mg/cm2 | Fe2O3, Cr2O3, Al2O3 [85] |

| FeCrBSiMo | 550 and 650 | - | Fe2O3/FeO.(Fe,Cr)2O3, (Fe,Cr) 2O3 [13] |

| FeCrBAlMo | 550 and 650 | - | Fe2O3, FeO.(Fe, Cr)2O3, (Fe,Cr) 2O3, AlFeO3 [13] |

| FeMnCrNiAl/Cr3C2 | 800 | - | Fe2O3, Cr2O3, Al2O3 [84] |

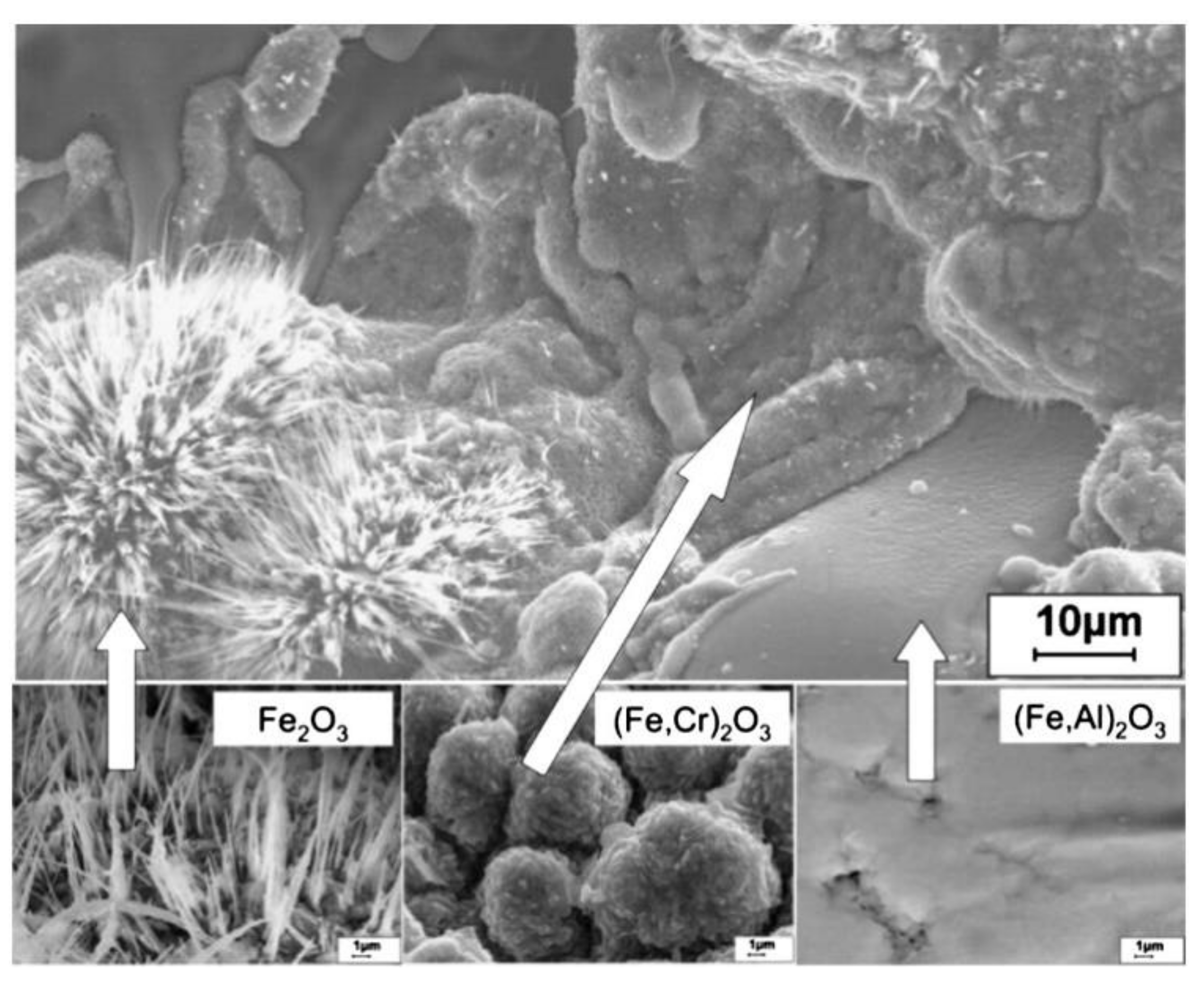

| FeCrBAl | 600–700 | 12–20 g/m2.h | (Fe, Cr)2O3, Fe2O3, (Fe, Al)2O3 [8] |

| Coatings | High-Temperature Erosion | ||

|---|---|---|---|

| Temperature °C | Impact Angle | Erosion Behavior | |

| Alpha 1800 | Room temperature (RT), 300, 400, 500, 600 | 30° and 90° | Erosion damage was by extrusion-forging mechanism. Shallow craters formed by particle impact and subsequent impact forged platelets into the surface [91] |

| FeBSiNb | 300, 450, 600 | 30° and 90° | Lower erosion rate at impact angle of 30° and erosion rate decreased with increasing temperature. Mass loss attributed to splat flaking. Main failure mechanism was brittle fracture [89] |

| FeAl/Cr3C2 | 550, 650, 800 | 90° | Erosion rates decreased with increasing temperature. Fe2O3, Al2O3, and Cr2O3 oxides formed protection coating from further oxidation [10] |

| FeCrBSiMnNbY FeBSiNbCr | 25, 300, 450, 650 | 30° and 90° | Erosion rates decreased with increasing temperature. FeBSiNbCr had better corrosion resistance than FeCrBSiMnNbY. Erosion mechanism is the brittle breaking and fracture mechanism [92] |

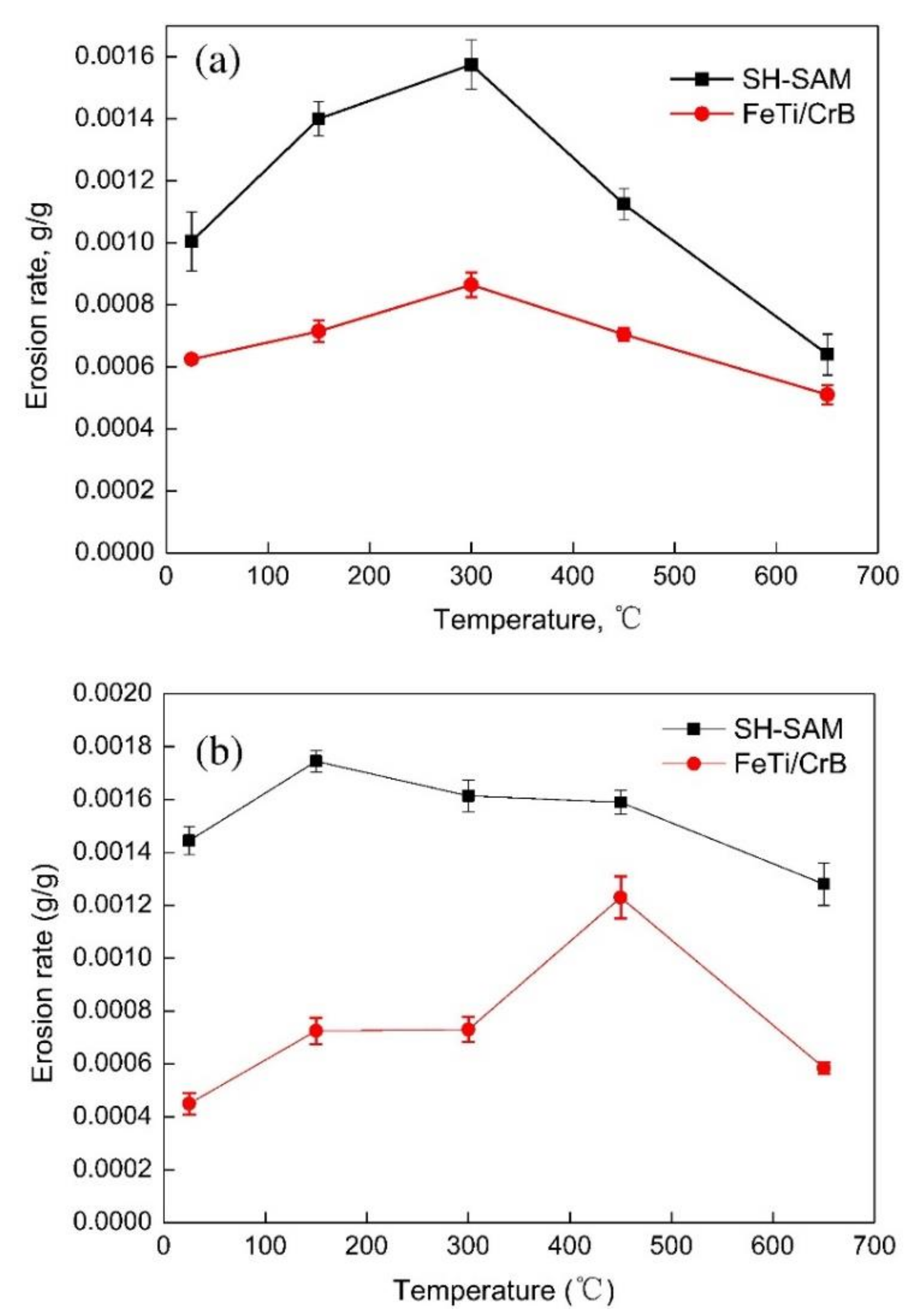

| FeTi/CrB | 20, 150, 300, 450, 650 | 30°, 60°, and 90° | Erosion rate increased with increasing impact angle. Abrasive cutting and plough wearing were the main erosion mechanisms [22] |

| FeMnCr/Cr3C2 FeMnCr8Al/Cr3C2 FeMnCr15Al/Cr3C2 | 900 | 30°, 45°, 60°, and 90° | Erosion mechanism was through brittle breaking, cutting, and fatigue spalling [14] |

| Coatings | Corrosive Environment | Temperature (°C) | Hot Corrosion Behavior |

|---|---|---|---|

| FeCrSiB | Na2SO4 − 25% K2SO4 | 650 | Formation of Cr2O3 and SiO2 mixed scale with low diffusion coefficients preventing further penetration of solution [11]. |

| FeCrBSiMn | Na2SO4 − 82% Fe2(SO4)3 | 900 | Fe and Cr enhanced the corrosion resistance of the coatings [93]. |

| Fe-Al/Cr3C2 | Na2SO4 + K2SO4 (7:3) | 450, 650, 800 | The formation of Cr2O3 oxides speeded the formation of Al2O3, which protected the coatings [10]. |

| FeCrBC | Na2SO4 + K2SO4 (7:3) | 700 | Compact and dense Cr2O3 acted as diffusion barriers for the solution [94]. |

| FeNiCr/Cr3C2 | Na2SO4 + K2SO4 (7:3) | 700 | Oxidation, sulfidation, and internal sulfidation were the main hot corrosion mechanisms [97] |

| Coatings | Temperature | High-Temperature Wear Behavior |

|---|---|---|

| FeAl | Up to 650 °C | Coefficient of friction decreased with temperature increase and protective film formed during the sliding process. Delamination was the main wear mechanism. High strength and hardness Fe3Al and FeAl intermetallics prevented crack propagation and fracture of splats [99]. |

| FeAl/Cr3C2 | Up to 600 °C | Main wear mechanism was peeling wear. The Cr2O3 facilitated the formation of Al2O3 to reduce the wear loss, High hardness and the good amalgamation between the Cr3C2 and FeAl intermetallics improved the coating ductility [10]. |

| FeAl/WC | Up to 650 °C | Main wear mechanism was delamination. Coefficient of friction decreased due to oxide films that acted as a solid lubricant during sliding wear [100]. |

| FeCrBAl | 600 °C | Increased Al content improved the wear resistance. Lower tensile stresses formed as the coating heterogeneity increased with an increase in Al content. Reduction of tensile stresses was due to the oxidation of microcracks and coating lamellae [8]. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ndumia, J.N.; Kang, M.; Gbenontin, B.V.; Lin, J.; Nyambura, S.M. A Review on the Wear, Corrosion and High-Temperature Resistant Properties of Wire Arc-Sprayed Fe-Based Coatings. Nanomaterials 2021, 11, 2527. https://doi.org/10.3390/nano11102527

Ndumia JN, Kang M, Gbenontin BV, Lin J, Nyambura SM. A Review on the Wear, Corrosion and High-Temperature Resistant Properties of Wire Arc-Sprayed Fe-Based Coatings. Nanomaterials. 2021; 11(10):2527. https://doi.org/10.3390/nano11102527

Chicago/Turabian StyleNdumia, Joseph Ndiithi, Min Kang, Bertrand Vigninou Gbenontin, Jinran Lin, and Samuel Mbugua Nyambura. 2021. "A Review on the Wear, Corrosion and High-Temperature Resistant Properties of Wire Arc-Sprayed Fe-Based Coatings" Nanomaterials 11, no. 10: 2527. https://doi.org/10.3390/nano11102527

APA StyleNdumia, J. N., Kang, M., Gbenontin, B. V., Lin, J., & Nyambura, S. M. (2021). A Review on the Wear, Corrosion and High-Temperature Resistant Properties of Wire Arc-Sprayed Fe-Based Coatings. Nanomaterials, 11(10), 2527. https://doi.org/10.3390/nano11102527