1. Introduction

Since the discovery of graphene by Geim and Novoselov in 2004 [

1], two-dimensional materials have gained renewed interest, because of their exceptional electronic properties, low dangling bond density, and high specific surface areas that are important for optoelectronics, sensing, catalysis, and energy storage applications. Recently, transition metal dichalcogenides (TMDs), such as MoS

2, WoS

2, and Bi

2Se

3, have become the research focus. The latter material is of particular interest as a topological insulator and thermoelectric material [

2,

3,

4,

5,

6]. Layered Bi

2Se

3 possesses an insulating bulk gap of 0.3–0.35 eV and metallic surface states with a single Dirac cone [

7,

8,

9,

10], enabling excellent transport properties with a high carrier mobility [

11]. In addition, the surface conduction can be significantly boosted and easily tailored in few-layer nanostructures consisting of large surface-to-volume ratios [

12,

13,

14,

15]. Being analogous to the optoelectronic applications of graphene, a thin layer of Bi

2Se

3 has been proved to be a promising material for broadband and high-performance optoelectronic devices, such as photodetectors, terahertz lasers, and transparent electrodes [

3,

16]. In particular, transparent conductive electrodes (TCE) play a vitally important role in modern optoelectronic devices, including displays, light-emitting diodes, touch screens, and photovoltaics. Doped metal oxides, such as indium tin oxides (ITO), are predominantly utilized for such applications, owing to their high electrical conductivity and good optical transparency in the visible light region. However, due to the limited reserves of indium, the optoelectronic applications of ITO are severely restricted. Therefore, next-generation transparent electrodes consisting of the emerging 2D materials are highly desirable.

In this work, mica was used as the substrate, owing to its 2D layered structural nature with relatively weak interlayer interaction, which favors the 2D/2D van der Waals epitaxial (vdWE) growth. Furthermore, mica presents an atomically flat, chemically saturated, mechanically flexible, electrically insulating, and optically transparent surface, which is considered an ideal substrate for flexible transparent conductive electrodes [

17,

18]. Then, molecular beam epitaxial (MBE) growth of high-quality Bi

2Se

3 thin films has been realized on mica substrates, exhibiting a high (001) texture with an XRD rocking curve full-width at half-maximum (FWHM) of 0.088° and a mobility of 726 cm

2/(Vs) at room temperature and up to 1469 cm

2/(Vs) at 12 K. An optoelectronic device consisting of the Bi

2Se

3/mica structure as the 2D flexible TCE and PTB7:PC

71BM as the light absorber was fabricated, producing a photocurrent of 2.75 mA/cm

2 and an open-circuit voltage of 697 mV, demonstrating the feasibility of Bi

2Se

3 for optoelectronic applications.

2. Materials and Methods

Bi2Se3 was synthesized by the MBE technique on the mica 2D substrate. In addition, 5N purity Bi2Se3 pieces (purchased from American Elements, Los Angeles, CA, USA) were used as the evaporation source, loaded in a K-cell and heated up to 470 °C for the film deposition. The substrate temperature was maintained at ~340 °C, and the film growth rate was evaluated to be around 4.5 nm/min by ex-situ measurement of the film thickness with the help of an Alpha Step 500 profiler. The Bi2Se3/mica 2D material-based transparent conductive electrode was then covered by a thin layer of V2O5 as the hole-transporting layer by thermal evaporation, followed by spin-coating the PTB7:PC71BM absorber. Consequently, a calcium/aluminum electrode was evaporated onto the layers, forming an optoelectronic device.

The microstructure and crystal phase of the prepared Bi2Se3 thin films were characterized by high-resolution XRD and recorded on a Rigaku Smartlab 9 kW X-ray diffractometer (Rigaku Corporation, Tokyo, Japan), equipped with a Cu-Kα1 radiation source (λ = 1.5406 Å) and a two-crystal Ge (220) two-bounce hybrid monochromator (Rigaku Corporation, Tokyo, Japan). The film surface morphology was examined by AFM, which was performed on a Bruker NanoScope 8 (Billerica, MA, USA) in tapping mode using a silicon cantilever with a tip radius of less than 10 nm and resonance frequency of 341 kHz. Scanning electron microscopy (SEM) was also employed to investigate the morphology and the microstructure of the films, using a JEOL 6490 (JEOL Ltd., Tokyo, Japan) microscope by applying an accelerating voltage of 20 kV. Transmission electron microscopy (TEM) was employed to characterize the film microstructure, which was recorded through a JEM-2100F (field emission) scanning transmission electron microscope (JEOL Ltd., Tokyo, Japan) equipped with an Oxford INCA x-sight EDS Si(Li) detector (Oxford Instruments, Abingdon, UK)at an acceleration voltage of 200 kV. The film electrical properties were determined by Hall measurements using the four-probe van der Pauw method, performed on a Bio-Rad 5500 Hall system (Hercules, CA, USA) at room temperature using a permanent magnet with a magnetic field of 0.32 T, and conducted in a cryostat equipped with a CTI-Cryogenics 22 Refrigerator (Helix Technology Corporation, Mansfield, MA, USA) from room temperature to ~12 K under an electromagnetic field of 0.32 T. The work function of the Bi2Se3 thin film was deduced from ultraviolet photoelectron spectroscopy (UPS) measurements, which were conducted in ultra-high vacuum at 5 × 10−8 mbar, by irradiating with 21.22 eV photons (He I line). The photoelectric response of the prepared device was recorded on an Agilent B1500A semiconductor device parameter analyzer (Santa Clara, CA, USA). The photocurrent was collected under a simulated Air Mass 1.5 Global (AM 1.5 G) illumination, which was provided by a Newport Oriel Sol3A Solar Simulator (Irvine, CA, USA) with a 100 mW/cm2 radiance intensity.

3. Results and Discussion

Being a 2D layered material, high-quality Bi

2Se

3 can be deposited on various substrates, especially on 2D substrates, in spite of the large lattice mismatch.

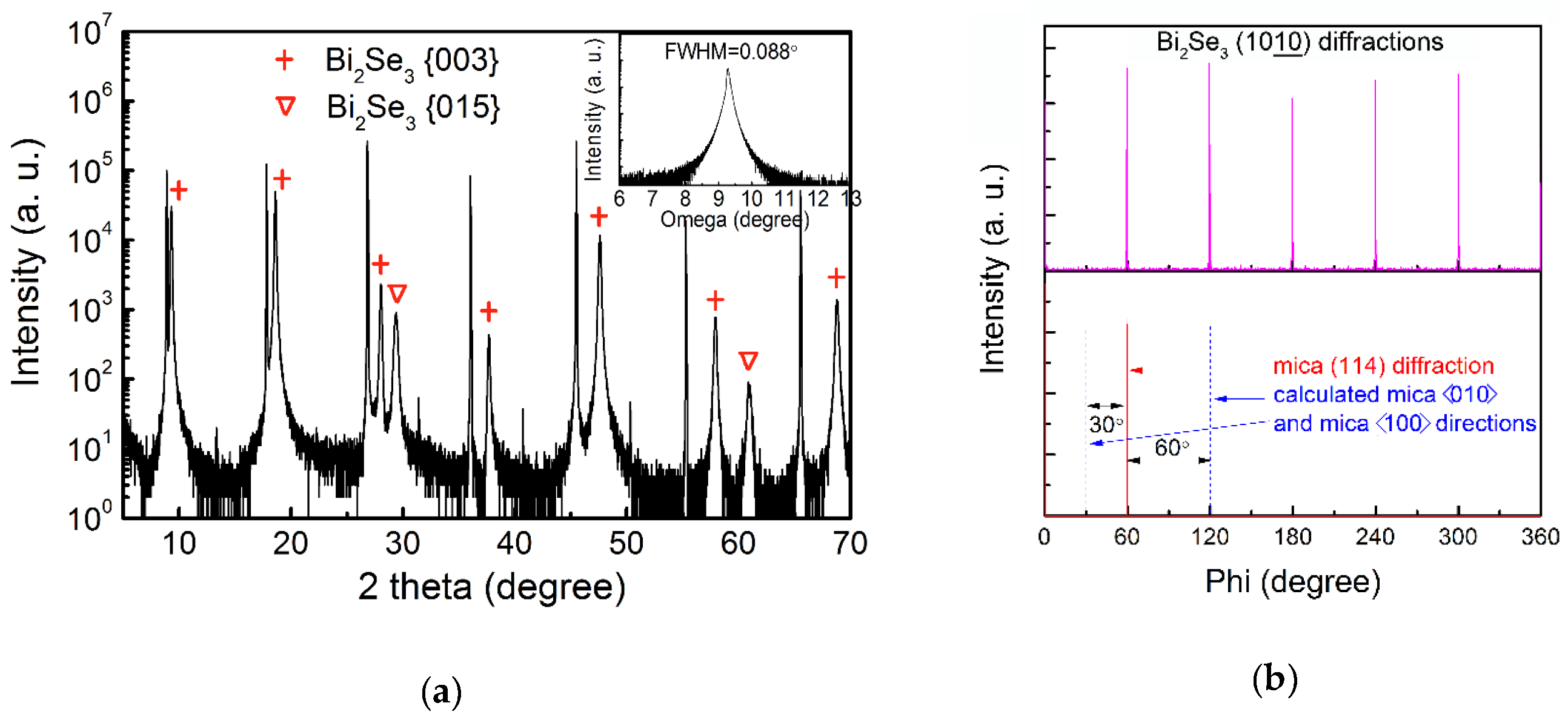

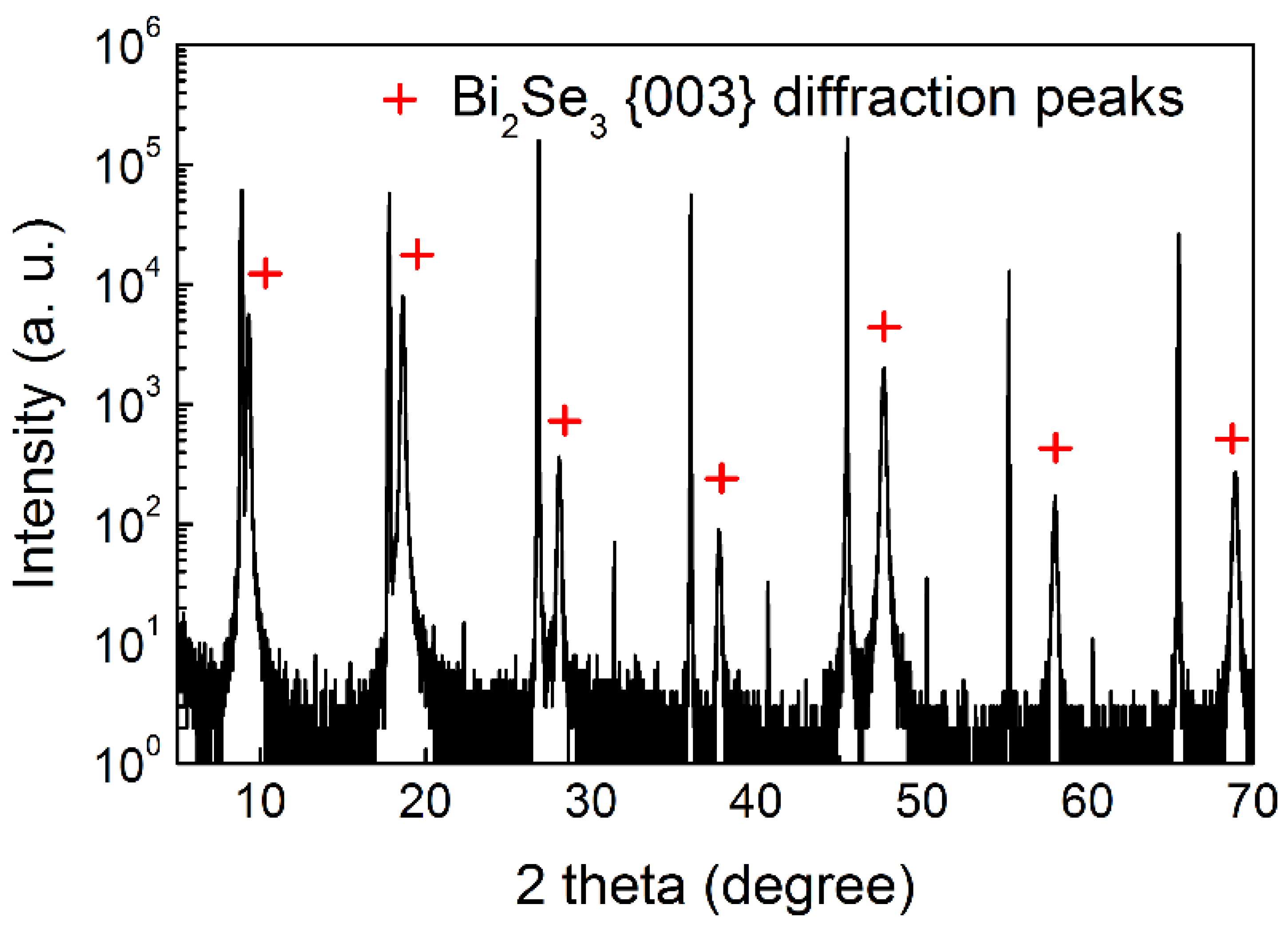

Figure 1 shows the XRD patterns of Bi

2Se

3 on the mica substrate. As indicated by the red crosses in

Figure 1a, the predominant diffractions originated from the Bi

2Se

3 {003} family planes, suggesting that the Bi

2Se

3 film stacks vertically on the mica substrate along a highly c-axis-oriented direction. The presence of the Bi

2Se

3 {015} diffractions, as labeled by the inverted triangles, indicated that a certain quantity of crystals with the Bi

2Se

3 (015) planes parallel to the mica (001) surface simultaneously emerged. The inset in

Figure 1a gives the XRD rocking curve, in which a full-width at half-maximum (FWHM) of 0.088° (~317 arc seconds) was attained, implying an excellent Bi

2Se

3 crystallinity and a perfect crystal alignment of vertical growth.

Figure 1b shows the in-plane phi scans conducted on the Bi

2Se

3 (10

10) plane and the mica (114) plane. Six sharp peaks separated by 60° showed up in the Bi

2Se

3 (10

10) diffraction pattern, consistent with reports [

19,

20,

21,

22,

23]. The observed six-fold symmetry, instead of three peaks expected for the trigonal system, was ascribed to the twin domains either stacking in the sequence -[ABCAB]- or -[CABCA]- [

20]. Azimuthal diffractions of mica (114) and (

) planes were superimposed on the same plot, from which the mica <100> and <010> directions on the mica (001) surface can be derived, as indicated by the blue dotted lines in

Figure 1b [

17]. The in-plane crystallographic relationship between Bi

2Se

3 and the mica substrate is then deduced as follows: Bi

2Se

3 (001) // mica (001) and Bi

2Se

3 <100> // mica <100>.

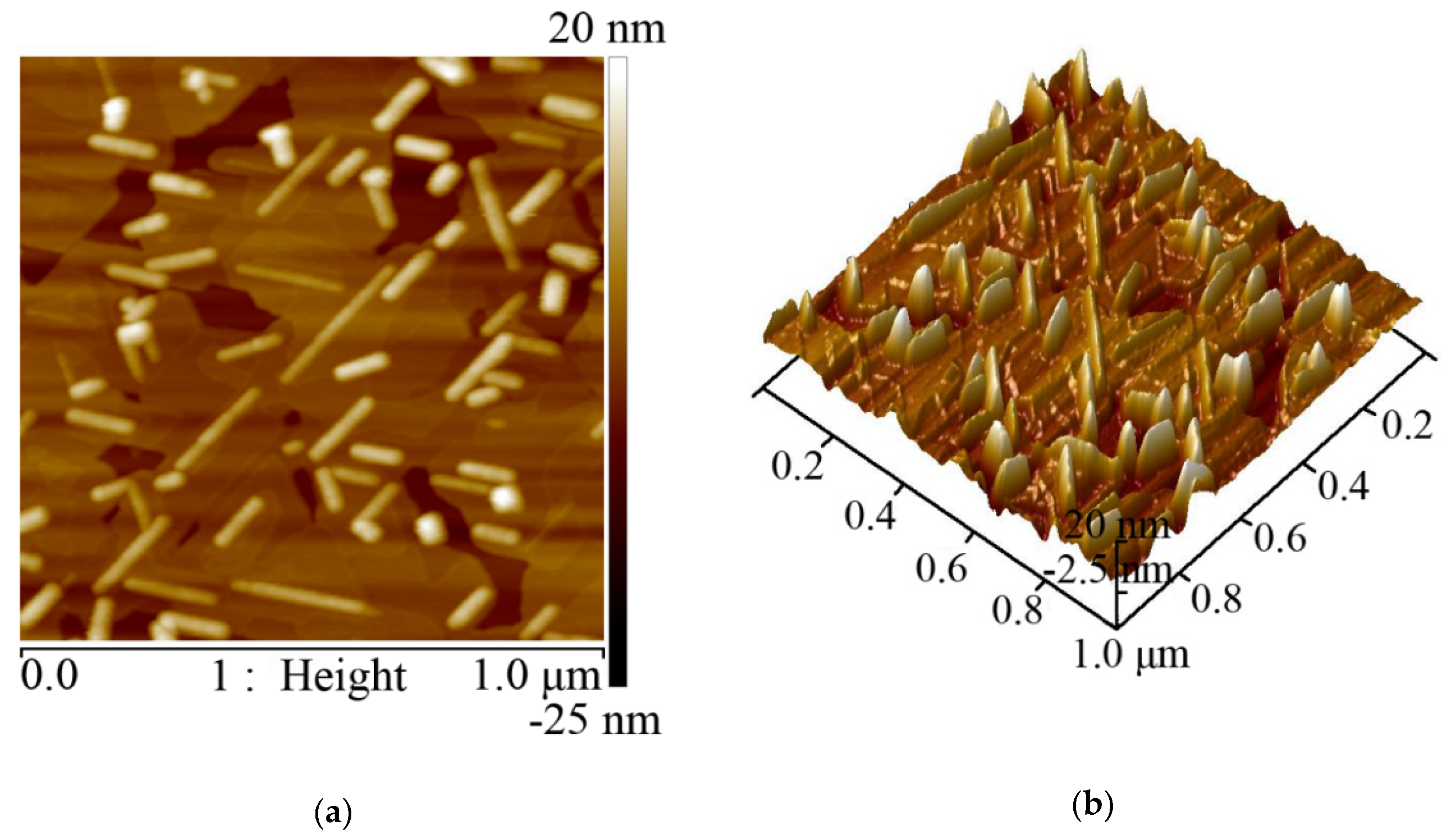

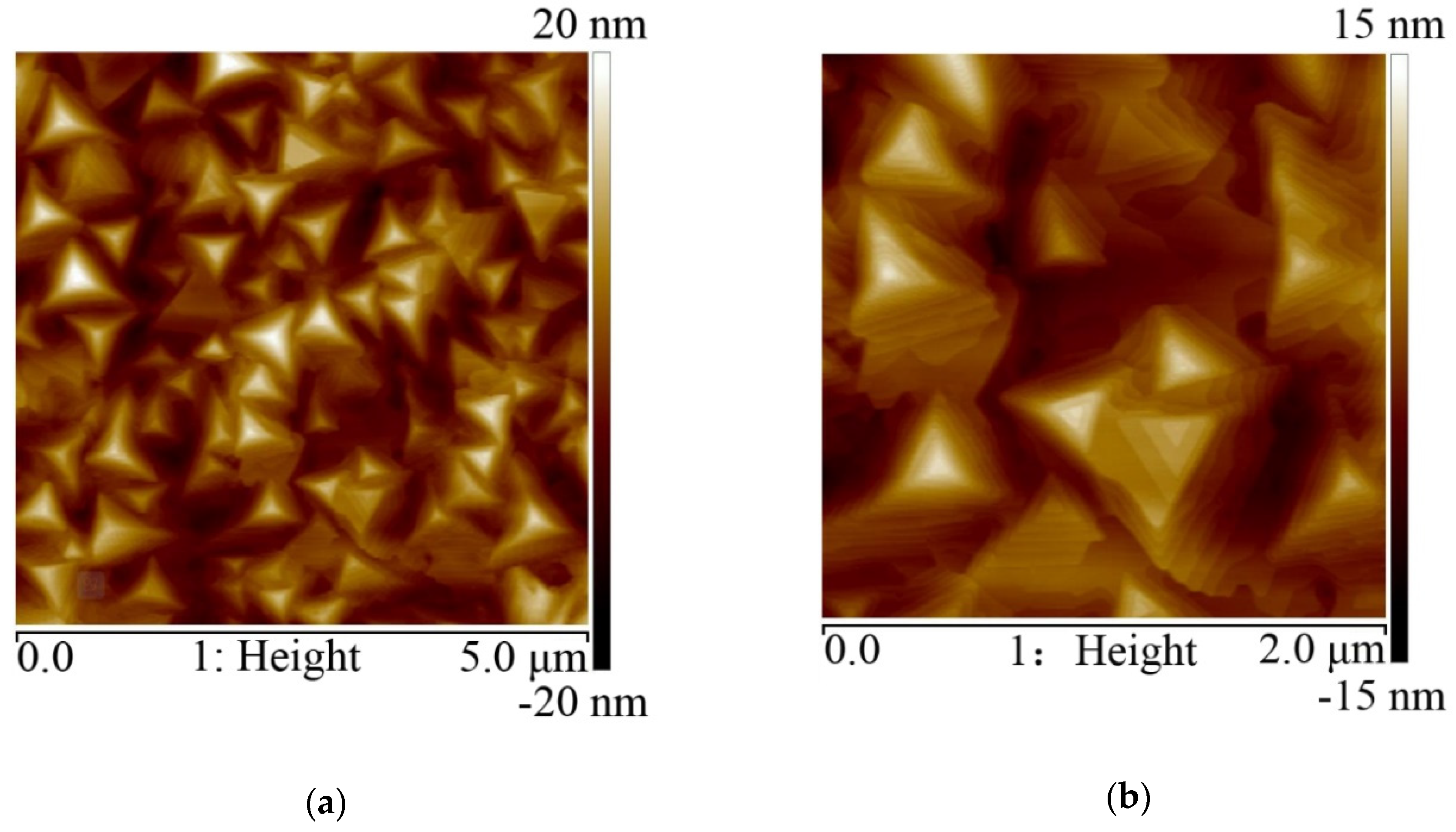

As shown in the AFM top view image in

Figure 2a, rhombohedral-shaped planes were observed, suggesting the highly c-oriented van der Waals (vdW) epitaxial growth. At the same time, fence-like vertical planes emerged, as shown clearly in the AFM perspective view in

Figure 2b. These fence-like planes are parallel to the edge of the rhombohedral planes and are oriented at 60° and 120° relative to each other.

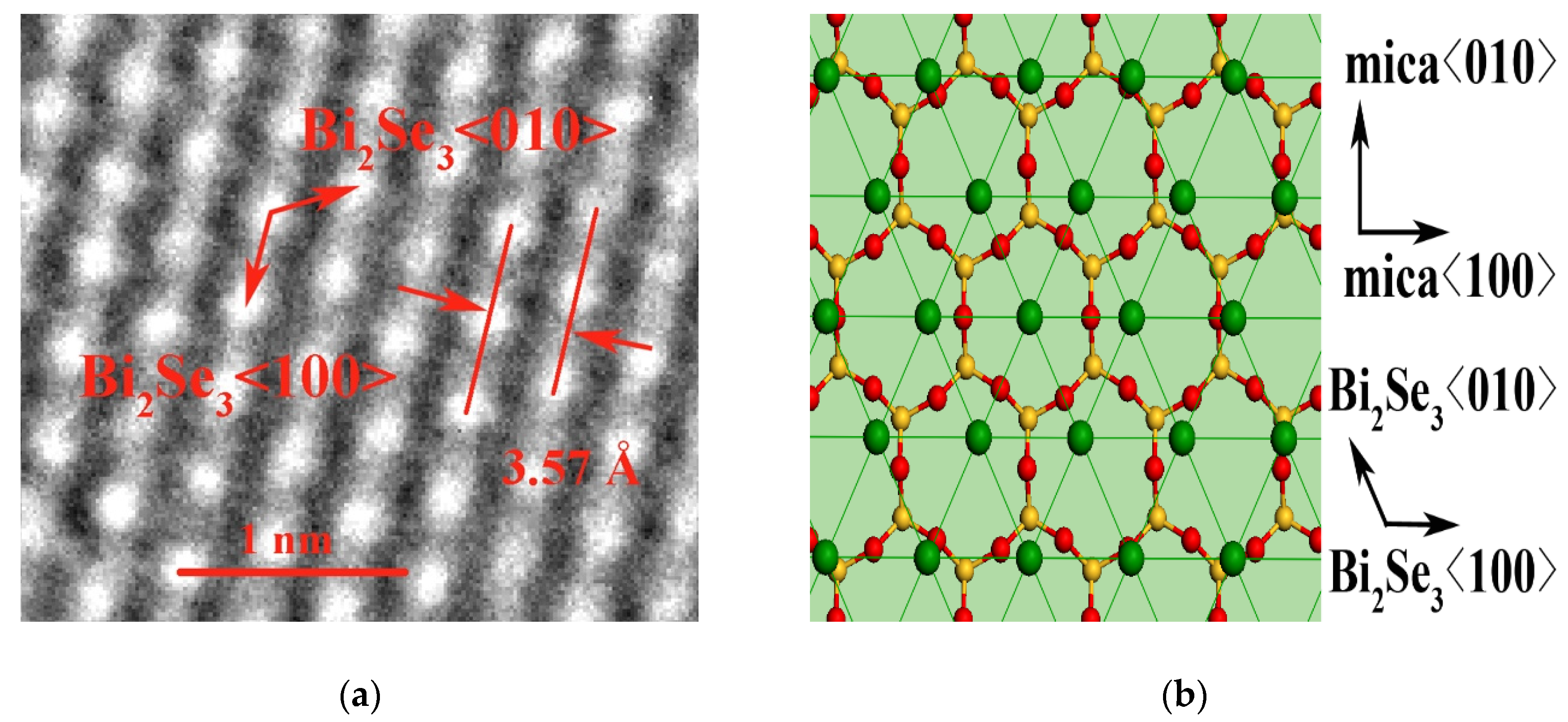

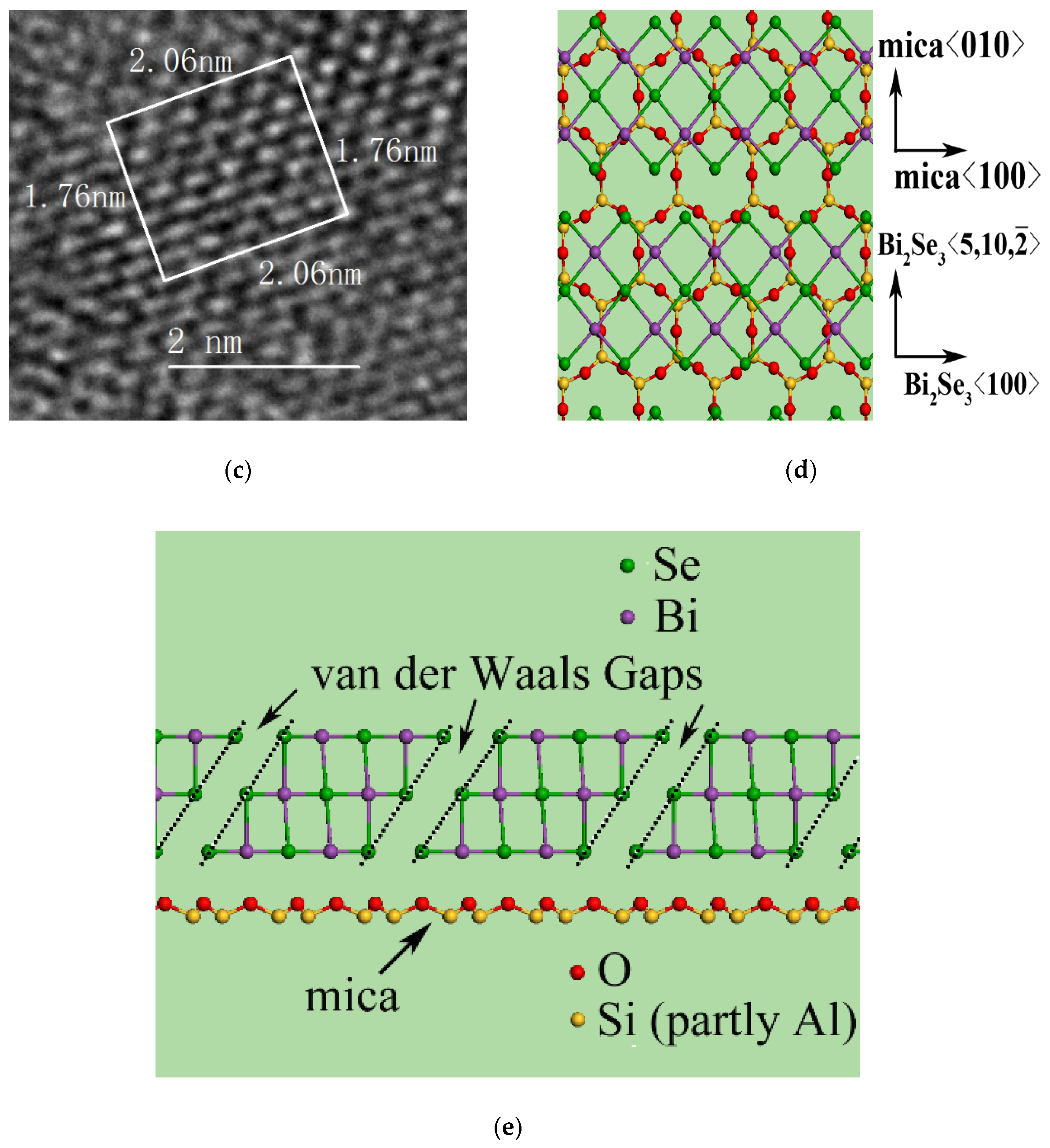

High-resolution TEM measurements were conducted to reveal the Bi

2Se

3 microstructure. The hexagonal atomic arrangement, as shown in

Figure 3a, confirms the c-axis-oriented growth direction of the film. The average distance between the planes is found to be 3.57 Å, as indicated by the red arrows, signifying the lattice constant as

a = 4.12 Å.

Figure 3c shows the atomic arrangement within the vertical planes. The average spacing between the planes indicated by the white rectangle was found to be 2.20 Å, in good agreement with the calculated value of 2.21 Å between planes along the Bi

2Se

3 <

> direction. The distance of 2.06 nm between the five atoms along the longer side of the white rectangle coincided nicely with the lattice along Bi

2Se

3 <500>, in which 5

a = 20.61 Å. These results confirm that the fence-like vertical planes are those that grew along the Bi

2Se

3 (015) normal. The crystallographic relationship of Bi

2Se

3 and the mica (001) surface at these different growth orientations is illustrated by using the interface models, as shown in

Figure 3b,d,e.

For van der Waals epitaxial growth with a large lattice misfit between the epilayer and substrate, the matching condition can be evaluated via the coincidence lattice mismatch [

17], δ, which is defined as (m

depi–n

dsub)/n

dsub, where

depi and

dsub are the atomic distances of the epilayer and substrate, respectively. Lattice coincidence occurs when

depi/

dsub = n/m, where n and m are positive integers and n/m is the smallest non-reducible integral ratio [

24,

25]. Then, the concept of coincidence site lattice unit (CSLU) can be established as CSLU =

nx ×

ny, where

x and

y denote the directions along the substrate lattice vectors

a and

b, respectively. It can be concluded that the smaller the CSLU, the better the lattice match between the epilayer and the substrate, as a small CSLU represents a larger number of coincidence sites per unit area [

17]. For the case of planar growth, as shown in

Figure 3b, the CSLU is 4 × 2 = 8. By contrast, for the vertical growth as illustrated in

Figure 3d,e, the CSLUs are calculated to be 4 × 1 = 4 and 4 × 5 = 20 regardless of and counting the period of van der Waals gaps, respectively. It is apparent that the growth direction along the Bi

2Se

3 <

> direction will develop a larger CSLU size when involving more van der Waals gaps. Therefore, the growth with a smaller CSLU of 4 × 1 will be favored, leading to the preferential growth directions along Bi

2Se

3 <100> and the Bi

2Se

3 (015) normal and producing the fence-like planes.

The fence-like planes make the film surface uneven, e.g., a film 90 nm thick has a root-mean-square (rms) roughness of 17.8 nm on the scale of 5 × 5 μm

2 (see

Figure S1 in the Supplementary Materials). This would bring harm to the fabrication and performance of electronic devices. To eliminate these fence-like vertical planes, a thin amorphous Bi

2Se

3 buffer layer was prepared at room temperature, prior to the Bi

2Se

3 growth at high substrate temperature.

Figure 4 shows the XRD diffraction patterns of Bi

2Se

3 with an amorphous buffer layer on the mica substrate. It was clearly observed that the Bi

2Se

3 {015} diffractions, corresponding to the fence-like vertical planes, totally disappeared. As displayed in the AFM images in

Figure 5, the surface morphology of the prepared Bi

2Se

3 film of ~90 nm with a buffer layer of ~5 nm is greatly improved, reflected by the reduction in the rms roughness to 4.9 nm over an area of 5 × 5 μm

2. Fence-like planes have totally disappeared, and triangular terraces are clearly observed, signifying that only the planar growth along Bi

2Se

3 <001> occurs. The buffer layer presenting as an amorphous state significantly weakens the interaction between the first stacking layer of Bi

2Se

3 and the mica surface, favoring the van der Waals epitaxial growth on top of it. However, it is also because of the much weaker interaction; the lateral growth alignment of van der Waals epitaxies will be weakened as well as reflected by the much broader peaks of the azimuthal phi scan with an average FWHM of 13.8 (see

Figure S2 in the Supplementary Materials), which may contribute a large number of grain boundaries (GBs) in the film.

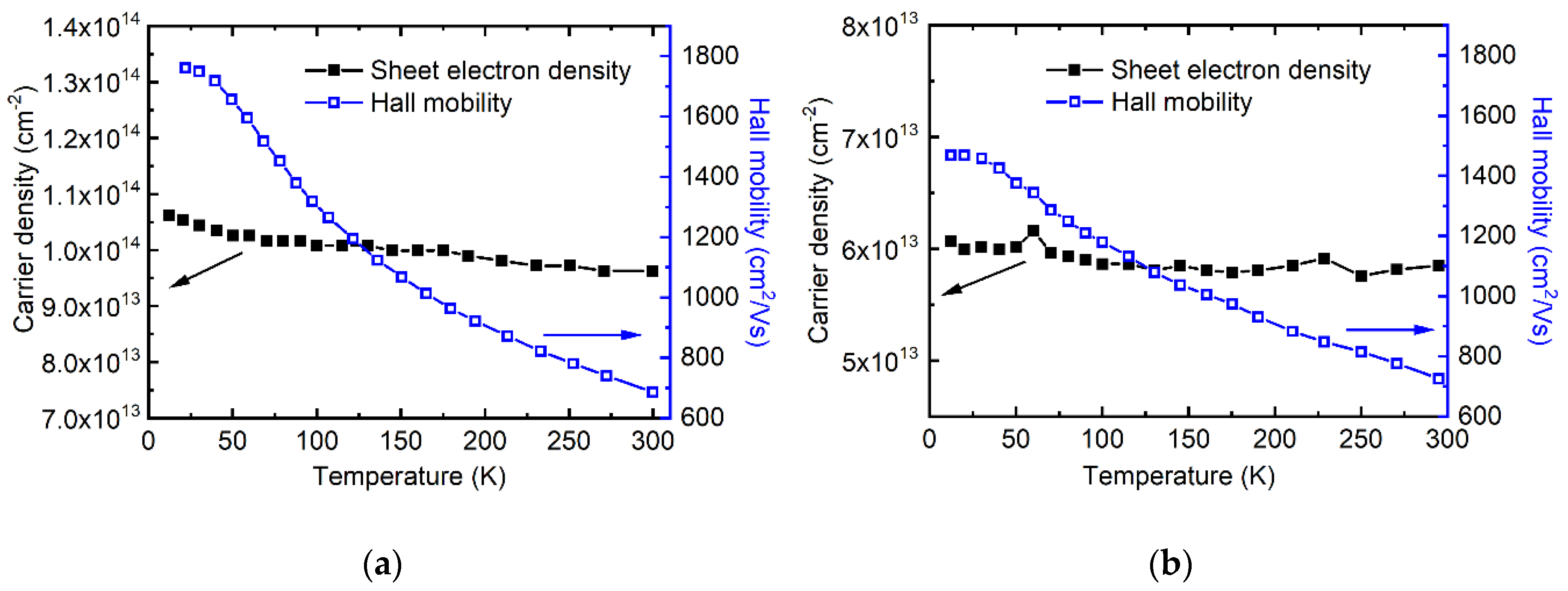

The transport performances of the carrier density and the mobility dependence on temperature for the Bi

2Se

3 thin film were investigated by employing low-temperature Hall measurement.

Figure 6a,b show the electrical properties of 90 nm thick Bi

2Se

3 films on mica without and with a buffer layer, respectively. When grown directly on mica, the Bi

2Se

3 Hall mobility increased from 697 cm

2/(Vs) at room temperature to 1761 cm

2/(Vs) at ~12 K, while the sheet electron density remained nearly constant at about 1.0 × 10

14 cm

−2. By applying an amorphous Bi

2Se

3 buffer layer, the mobility at room temperature was slightly boosted to 726 cm

2/(Vs) with a reduced sheet carrier density of ~5.9 × 10

13 cm

−2. The mobility increased at a near linear trend from 726 to 1469 cm

2/(Vs) as the temperature fell. However, the increase in the mobility of Bi

2Se

3 with the buffer layer lagged that without the buffer layer when the temperature decreased below ~115 K. The fence-like planes in the Bi

2Se

3 film grown directly on mica could contribute to the higher carrier density via introducing a larger surface area. However, the lower the mobility in the low-temperature range of Bi

2Se

3 with the buffer layer can be ascribed to the poor lateral alignment of crystals as discussed above. The weak interaction between the amorphous buffer layer and the Bi

2Se

3 crystals on top, although leading to removal of the fence-like planes, also weakened the lateral growth alignment, which produced a number of GBs mirrored by the misoriented sub-micrometer-sized domains in the AFM images in

Figure 5 and the broad FWHM of the XRD in-plane phi scan in

Figure S2. According to [

26,

27], the GBs play an important role in the mobility decline of 2D MoS

2 by means of interdomain scattering. In this study, the interdomain scattering arising from the misorientation of Bi

2Se

3 crystals on the buffer layer may contribute a lot to the slow rise in mobility with the decrease in temperature in the low-temperature range. By contrast, the lattice scattering may dominate the mobility variation in the Bi

2Se

3 crystals directly grown on mica, as they are perfectly aligned and connected laterally. The electrical transport property of 2D materials requires further investigation.

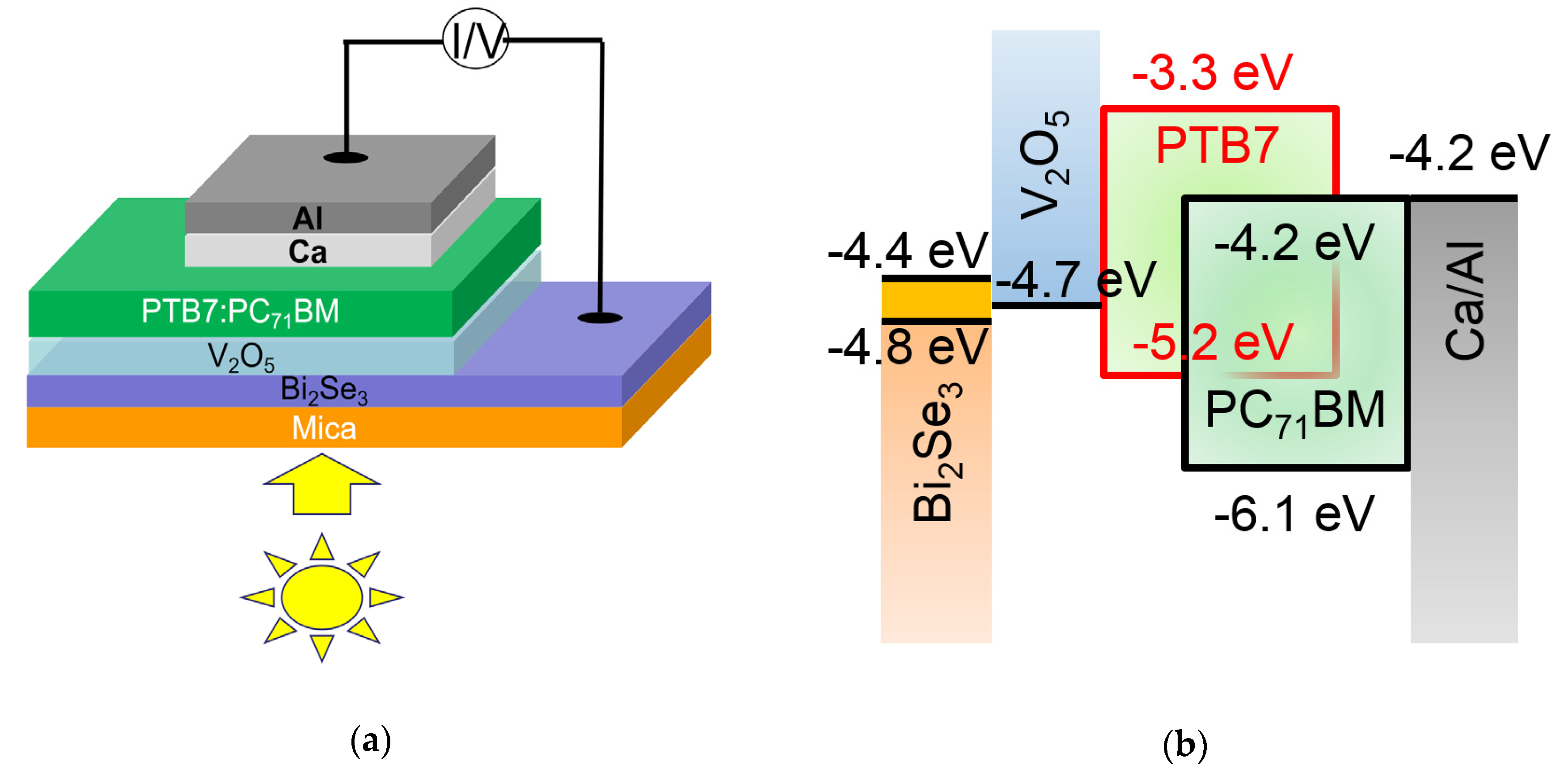

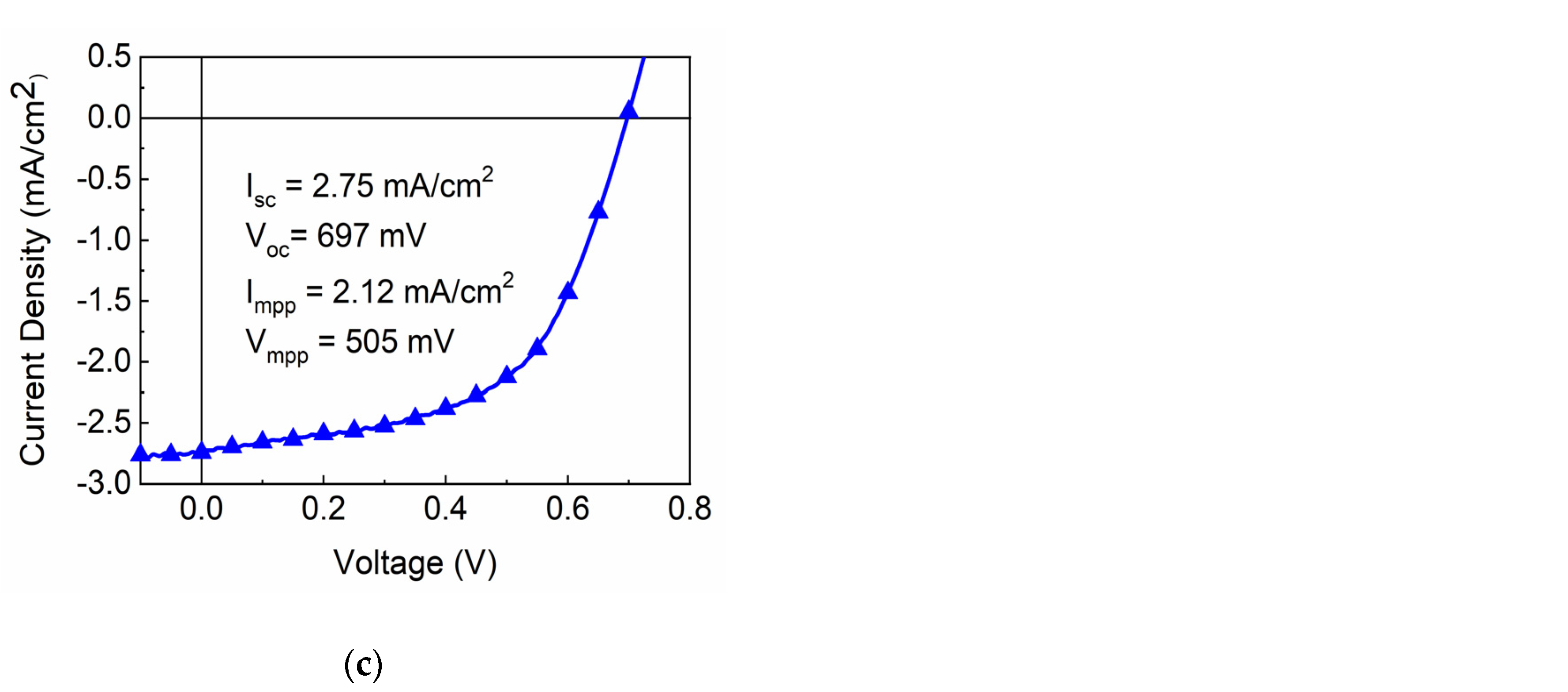

An optoelectronic device comprising the Bi

2Se

3/mica structure and organic absorber was fabricated, as shown in

Figure 7a. The energy band alignment between the device components is illustrated in

Figure 7b, in which the work function of the Bi

2Se

3 thin film is measured as 4.43 eV by using UPS (see

Figure S3 in the Supplementary Materials).

Figure 7c displays the

I–

V characteristics of the device, in which a short-circuit photocurrent of 2.75 mA/cm

2 and an open-circuit voltage of 697 mV are achieved. It is noteworthy that the values of photoelectric parameters are relatively lower compared to the conventional PTB7:PC

71BM-based solar cells, for which TCEs such as ITO coated on glasses are commonly used as the substrates instead of Bi

2Se

3 deposited on the mica. The absorption range of Bi

2Se

3 covers the broad visible light region due to the small bandgap of Bi

2Se

3, causing a reduced amount of light reaching the active layer (PTB7:PC

71BM) of the device to generate photocarriers. To address this issue, the thickness of Bi

2Se

3 should be further optimized or the opaque aluminum electrode should be replaced with transparent electrodes so that the light can be transmitted from both sides. The interface quality of the devices should also be investigated as Bi

2Se

3 coated on flexible mica will exhibit a different strain on the functional layers in the optoelectronic devices compared to the devices using the conventional rigid ITO-coated glass substrates. The presence of interfacial defects leads to carrier recombination, resulting in a poor fill factor of devices. Some interfacial passivation strategies [

28,

29] can be performed to relieve their negative impact on the device performance. Nevertheless, the demonstration of using Bi

2Se

3 in PTB7:PC

71BM-based optoelectronic devices in this work aims to pave the way to explore 2D transition metal dichalcogenides and exhibit their potential in the optoelectronic applications.