Hierarchical Composites with Electrophoretically Deposited Carbon Nanotubes for In Situ Sensing of Deformation and Damage

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Functionalization and Electrophoretic Deposition

2.3. Composites Manufacturing

2.4. Mechanical, Electrical, Thermal, and Microscopic Characterization

3. Results and Discussion

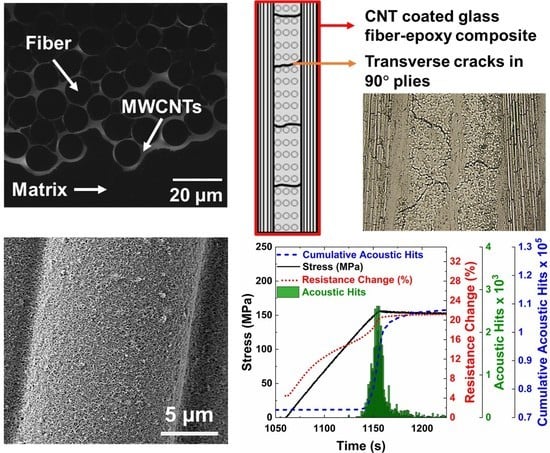

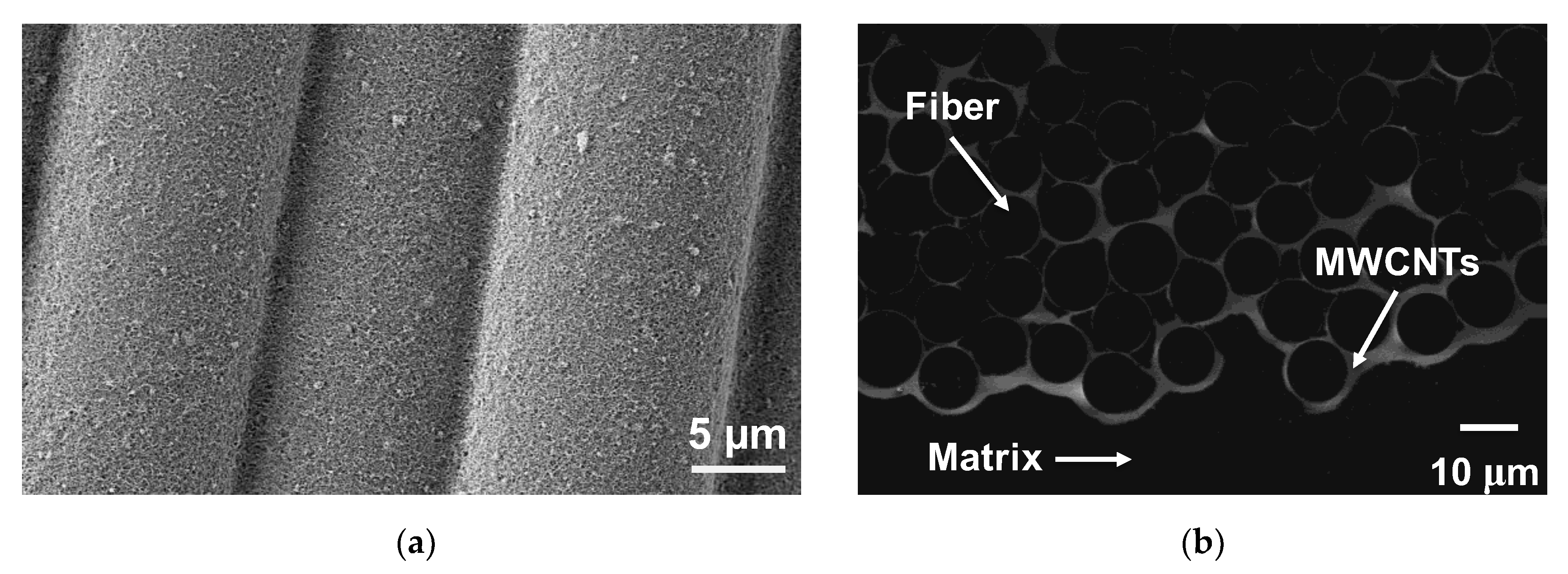

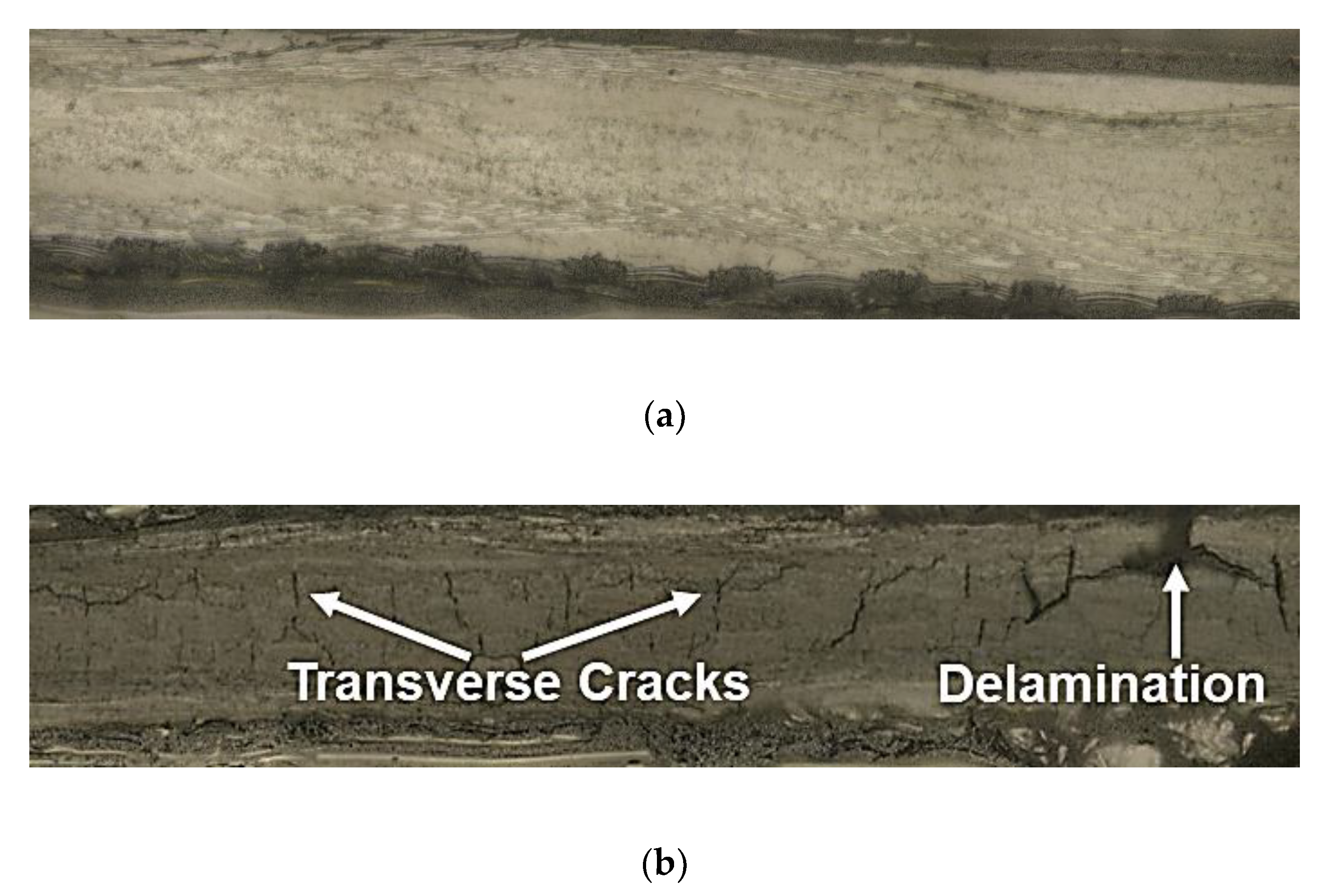

3.1. Composite Microstructure

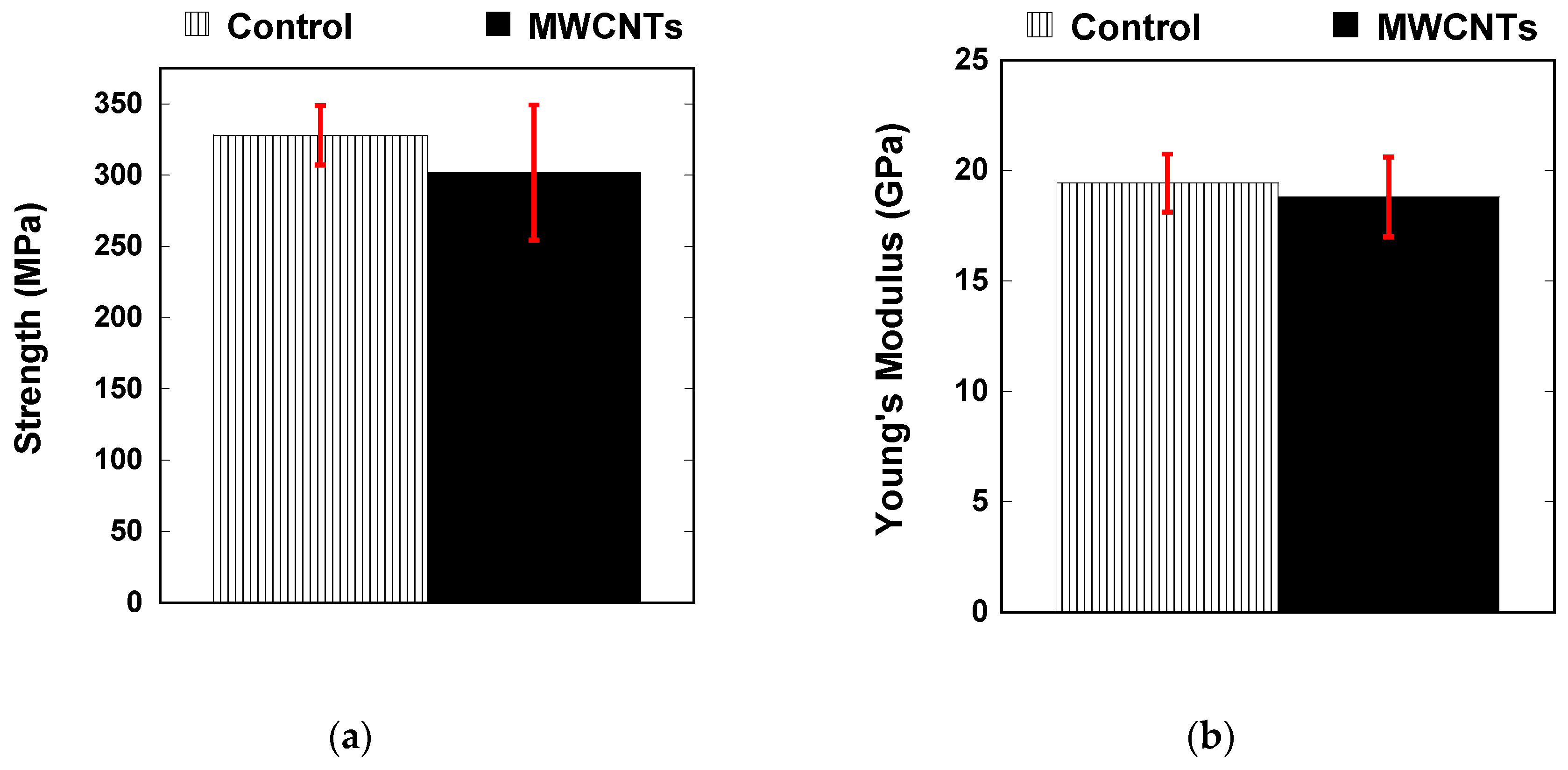

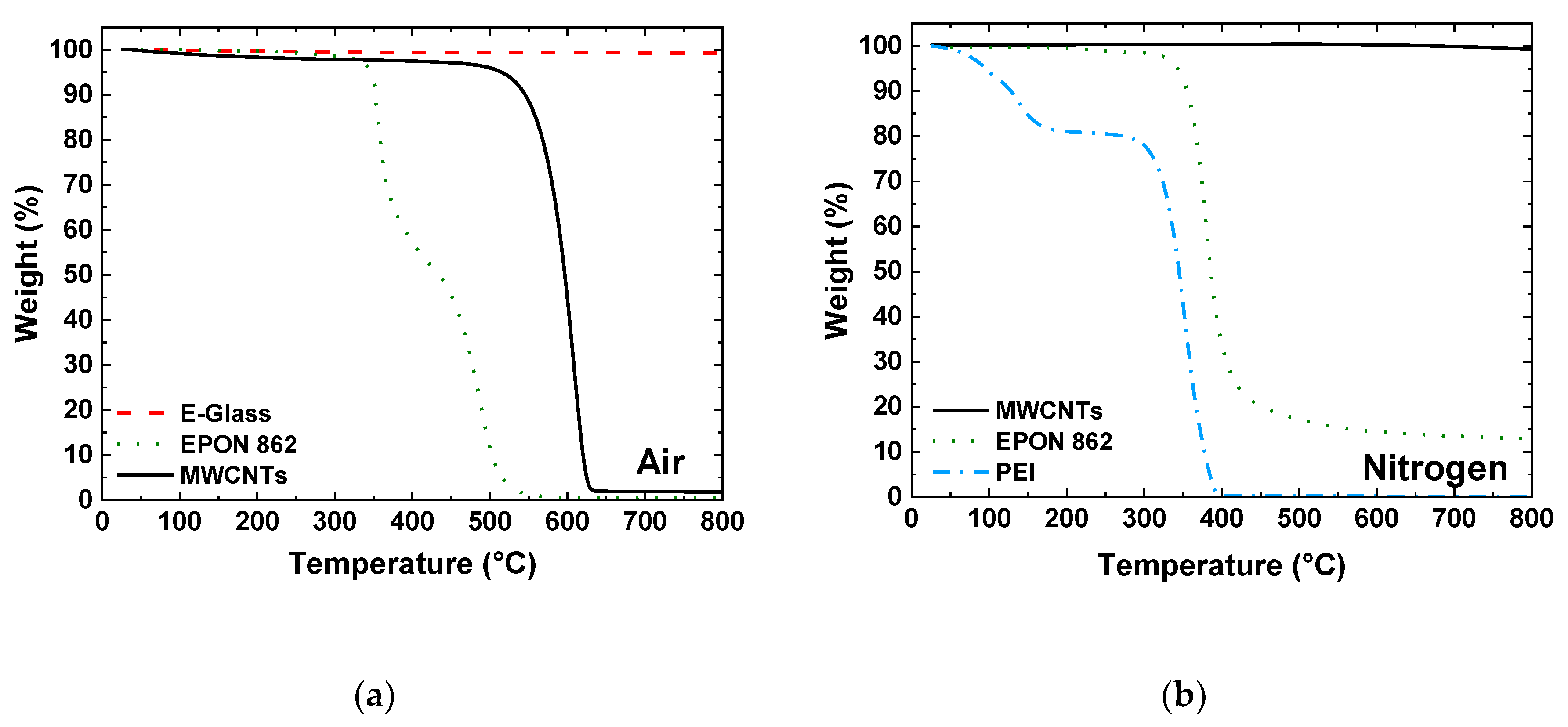

3.2. Mechanical and Thermal Characterization

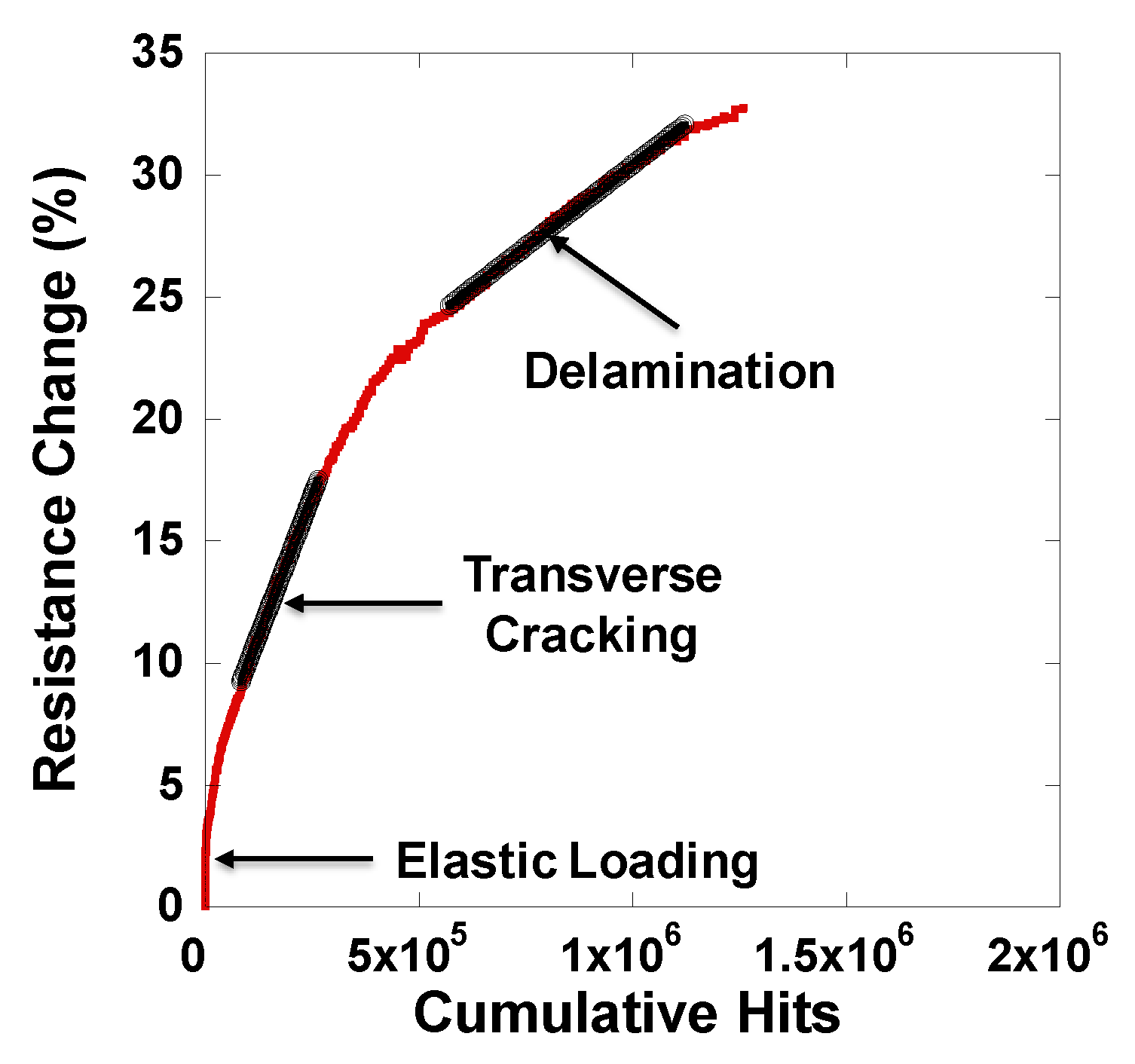

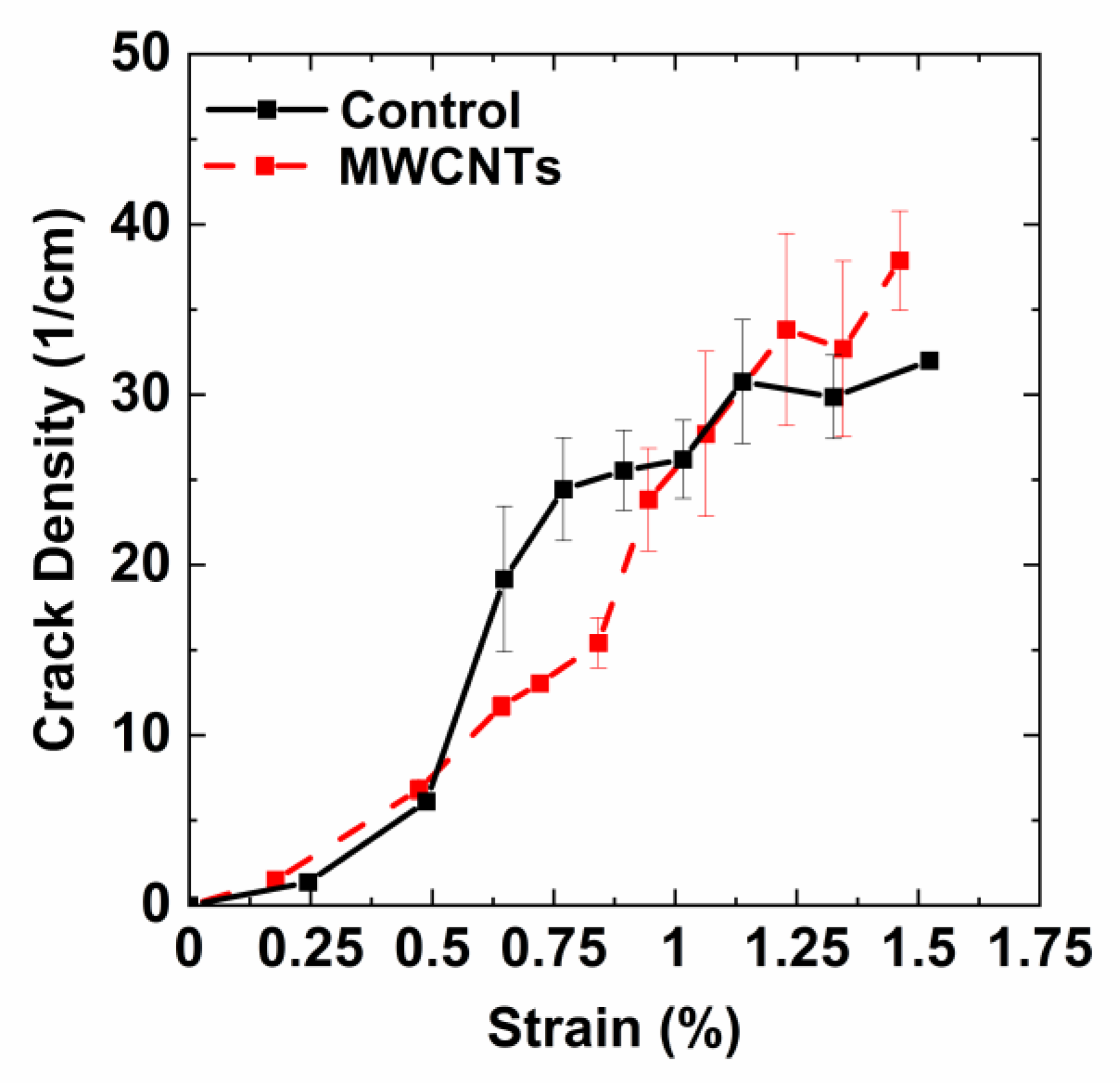

3.3. Damage Sensing under Monotonic Tensile Loading

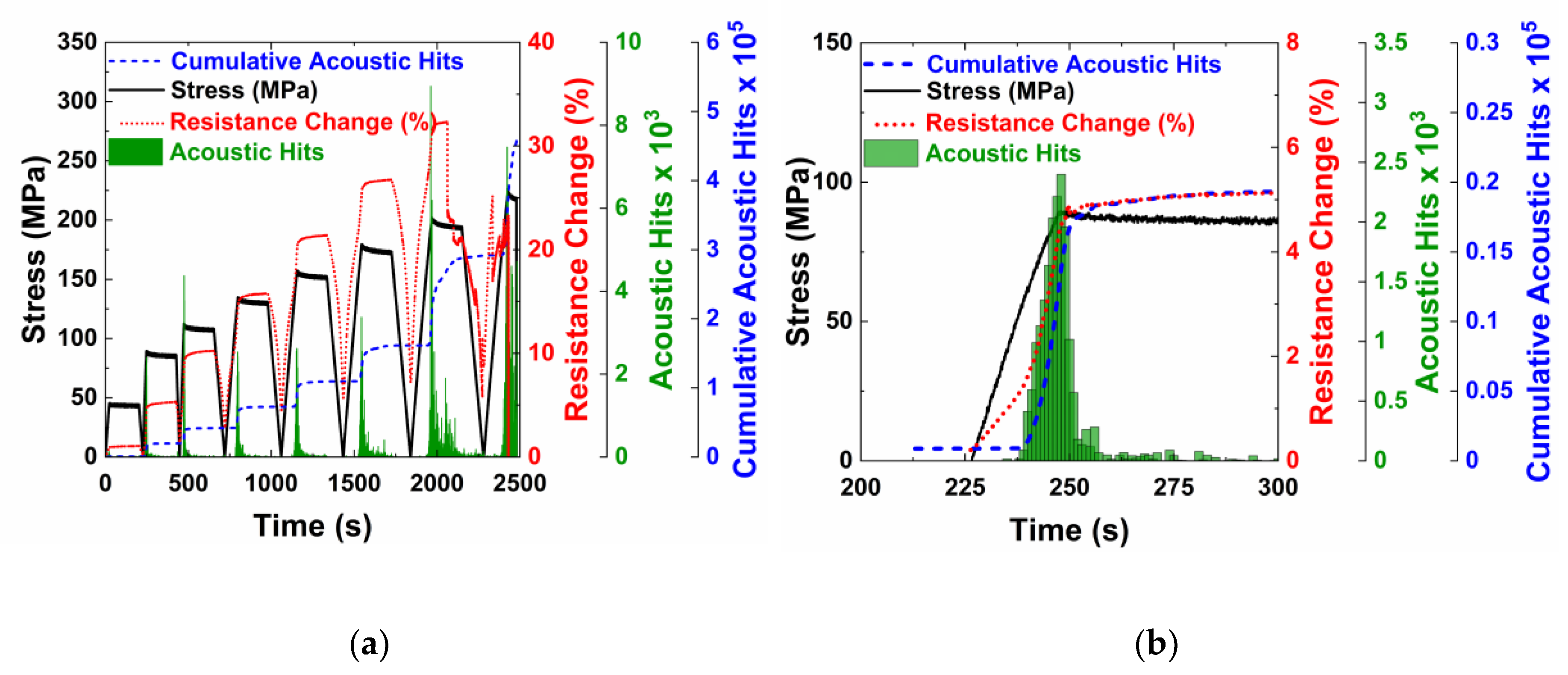

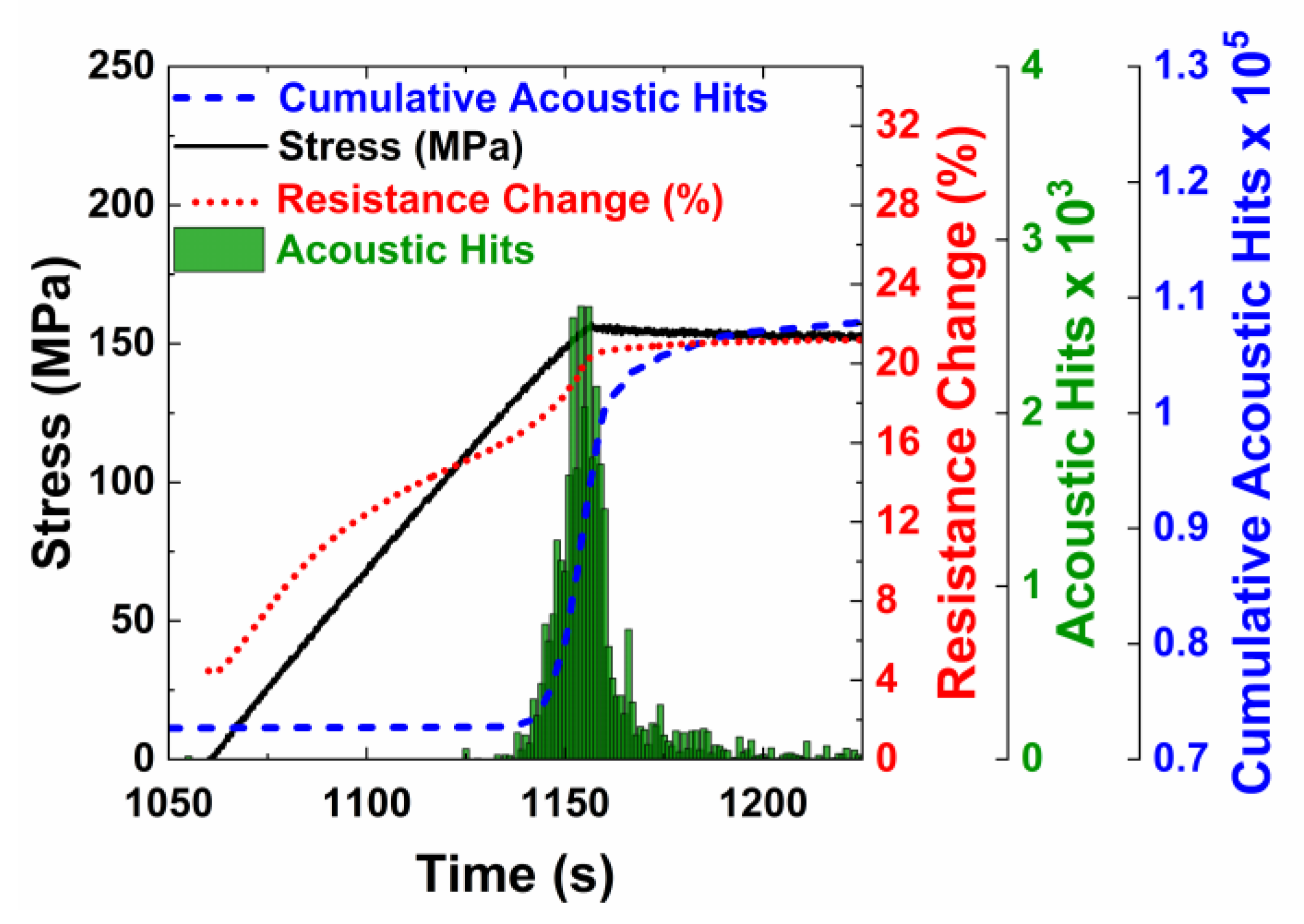

3.4. Damage Accumulation under Progressively Increasing Cyclic Loading

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hahn, H.T.; Kim, R.Y. Fatigue Behavior of Composite Laminate. J. Compos. Mater. 1976, 10, 156–180. [Google Scholar] [CrossRef]

- Liu, B.; Lessard, L.B. Fatigue and damage-tolerance analysis of composite laminates: Stiffness loss, damage-modelling, and life prediction. Compos. Sci. Technol. 1994, 51, 43–51. [Google Scholar] [CrossRef]

- Gholizadeh, S. A review of non-destructive testing methods of composite materials. Procedia Struct. Integr. 2016, 1, 50–57. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T.-W. Real-time in situ sensing of damage evolution in advanced fiber composites using carbon nanotube networks. Nanotechnology 2008, 19, 5713. [Google Scholar] [CrossRef] [PubMed]

- Thostenson, E.T.; Chou, T.W. Carbon nanotube networks: Sensing of distributed strain and damage for life prediction and self healing. Adv. Mater. 2006, 18, 2837–2841. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Chou, T.W. Processing-structure-multi-functional property relationship in carbon nanotube/epoxy composites. Carbon N. Y. 2006, 44, 3022–3029. [Google Scholar] [CrossRef]

- Gojny, F.H.; Wichmann, M.H.G.; Köpke, U.; Fiedler, B.; Schulte, K. Carbon nanotube-reinforced epoxy-composites: Enhanced stiffness and fracture toughness at low nanotube content. Compos. Sci. Technol. 2004, 64, 2363–2371. [Google Scholar] [CrossRef]

- Sánchez, M.; Campo, M.; Jiménez-Suárez, A.; Ureña, A. Effect of the carbon nanotube functionalization on flexural properties of multiscale carbon fiber/epoxy composites manufactured by VARIM. Compos. Part B Eng. 2013, 45, 1613–1619. [Google Scholar] [CrossRef]

- Jiménez-Suárez, A.; Campo, M.; Sánchez, M.; Romón, C.; Ureña, A. Influence of the functionalization of carbon nanotubes on calendering dispersion effectiveness in a low viscosity resin for VARIM processes. Compos. Part B Eng. 2012, 43, 3482–3490. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Li, W.Z.; Wang, D.Z.; Ren, Z.F.; Chou, T.W. Carbon nanotube/carbon fiber hybrid multiscale composites. J. Appl. Phys. 2002, 91, 6034–6037. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, J.; Sager, R.; Dai, L.; Baur, J. Hierarchical composites of carbon nanotubes on carbon fiber: Influence of growth condition on fiber tensile properties. Compos. Sci. Technol. 2009, 69, 594–601. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Y.; Kuwata, M.; Bilotti, E.; Peijs, T. Improved fracture toughness and integrated damage sensing capability by spray coated CNTs on carbon fibre prepreg. Compos. Part A Appl. Sci. Manuf. 2015, 70, 102–110. [Google Scholar] [CrossRef]

- Zhang, H.; Kuwata, M.; Bilotti, E.; Peijs, T. Integrated Damage Sensing in Fibre-Reinforced Composites with Extremely Low Carbon Nanotube Loadings. J. Nanomater. 2015, 2015, 785834. [Google Scholar] [CrossRef]

- Ahmed, S.; Thostenson, E.T.; Schumacher, T.; Doshi, S.M.; McConnell, J.R. Integration of carbon nanotube sensing skins and carbon fiber composites for monitoring and structural repair of fatigue cracked metal structures. Compos. Struct. 2018, 203, 182–192. [Google Scholar] [CrossRef]

- Doshi, S.M.; Lyness, T.B.; Thostenson, E.T. Damage monitoring of adhesively bonded composite-metal hybrid joints using carbon nanotube-based sensing layer. Nanocomposites 2020, 6, 12–21. [Google Scholar] [CrossRef]

- Ahmed, S.; Doshi, S.; Schumacher, T.; Thostenson, E.T.; McConnell, J. Development of a Novel Integrated Strengthening and Sensing Methodology for Steel Structures Using CNT-Based Composites. J. Struct. Eng. 2016, 134, 04016202. [Google Scholar] [CrossRef]

- Doshi, S.M.; Murray, C.; Chaudhari, A.; Thostenson, E.T. Carbon Nanotube Coated Textile Sensors with Ultrahigh Sensitivity for Human Motion Detection. In Proceedings of the IEEE Sensors, Montreal, QC, Canada, 27–30 October 2019; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2019. [Google Scholar]

- Doshi, S.M.; Thostenson, E.T. Thin and Flexible Carbon Nanotube-Based Pressure Sensors with Ultrawide Sensing Range. ACS Sens. 2018, 3, 1276–1282. [Google Scholar] [CrossRef] [PubMed]

- An, Q.; Rider, A.N.; Thostenson, E.T. Hierarchical Composite Structures Prepared by Electrophoretic Deposition of Carbon Nanotubes onto Glass Fibers. ACS Appl. Mater. Interfaces 2013, 5, 2022–2032. [Google Scholar] [CrossRef] [PubMed]

- ASTM D3039/D3039M-17. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. Available online: https://www.astm.org/Standards/D3039 (accessed on 27 May 2020).

- Krishnamurthy, A.; Tao, R.; Senses, E.; Doshi, S.M.; Burni, F.A.; Natarajan, B.; Hunston, D.; Thostenson, E.T.; Faraone, A.; Forster, A.L.; et al. Multiscale Polymer Dynamics in Hierarchical Carbon Nanotube Grafted Glass Fiber Reinforced Composites. ACS Appl. Polym. Mater. 2019, 1, 1905–1917. [Google Scholar] [CrossRef] [PubMed]

- Natarajan, B.; Orloff, N.D.; Ashkar, R.; Doshi, S.; Twedt, K.; Krishnamurthy, A.; Davis, C.; Forster, A.M.; Thostenson, E.; Obrzut, J.; et al. Multiscale metrologies for process optimization of carbon nanotube polymer composites. Carbon N. Y. 2016, 108, 381–393. [Google Scholar] [CrossRef]

| Fiber Volume Fraction | Matrix Volume Fraction | |

|---|---|---|

| Average | 0.466 | 0.534 |

| Standard Deviation | 0.0091 | 0.0091 |

| Coefficient of Variation | 1.96% | 1.71% |

| Carbon Nanotube Density (g/cc) | Matrix Volume Fraction | Nanotube Volume Fraction |

|---|---|---|

| 1.6 | 0.485 | 0.048 |

| 1.85 | 0.492 | 0.042 |

| 2.1 | 0.496 | 0.037 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murray, C.M.; Doshi, S.M.; Sung, D.H.; Thostenson, E.T. Hierarchical Composites with Electrophoretically Deposited Carbon Nanotubes for In Situ Sensing of Deformation and Damage. Nanomaterials 2020, 10, 1262. https://doi.org/10.3390/nano10071262

Murray CM, Doshi SM, Sung DH, Thostenson ET. Hierarchical Composites with Electrophoretically Deposited Carbon Nanotubes for In Situ Sensing of Deformation and Damage. Nanomaterials. 2020; 10(7):1262. https://doi.org/10.3390/nano10071262

Chicago/Turabian StyleMurray, Colleen M., Sagar M. Doshi, Dae Han Sung, and Erik T. Thostenson. 2020. "Hierarchical Composites with Electrophoretically Deposited Carbon Nanotubes for In Situ Sensing of Deformation and Damage" Nanomaterials 10, no. 7: 1262. https://doi.org/10.3390/nano10071262

APA StyleMurray, C. M., Doshi, S. M., Sung, D. H., & Thostenson, E. T. (2020). Hierarchical Composites with Electrophoretically Deposited Carbon Nanotubes for In Situ Sensing of Deformation and Damage. Nanomaterials, 10(7), 1262. https://doi.org/10.3390/nano10071262