Simple Fabrication of Transparent, Colorless, and Self-Disinfecting Polyethylene Terephthalate Film via Cold Plasma Treatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Plasma Treatment

2.2. Characterization

2.3. Antibacterial Test

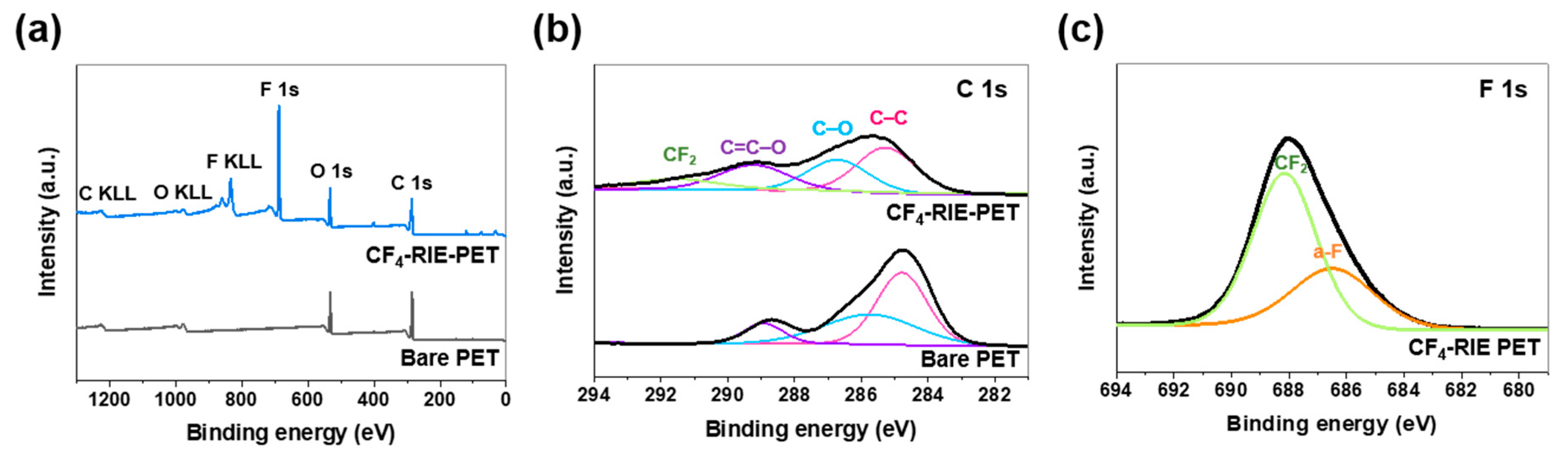

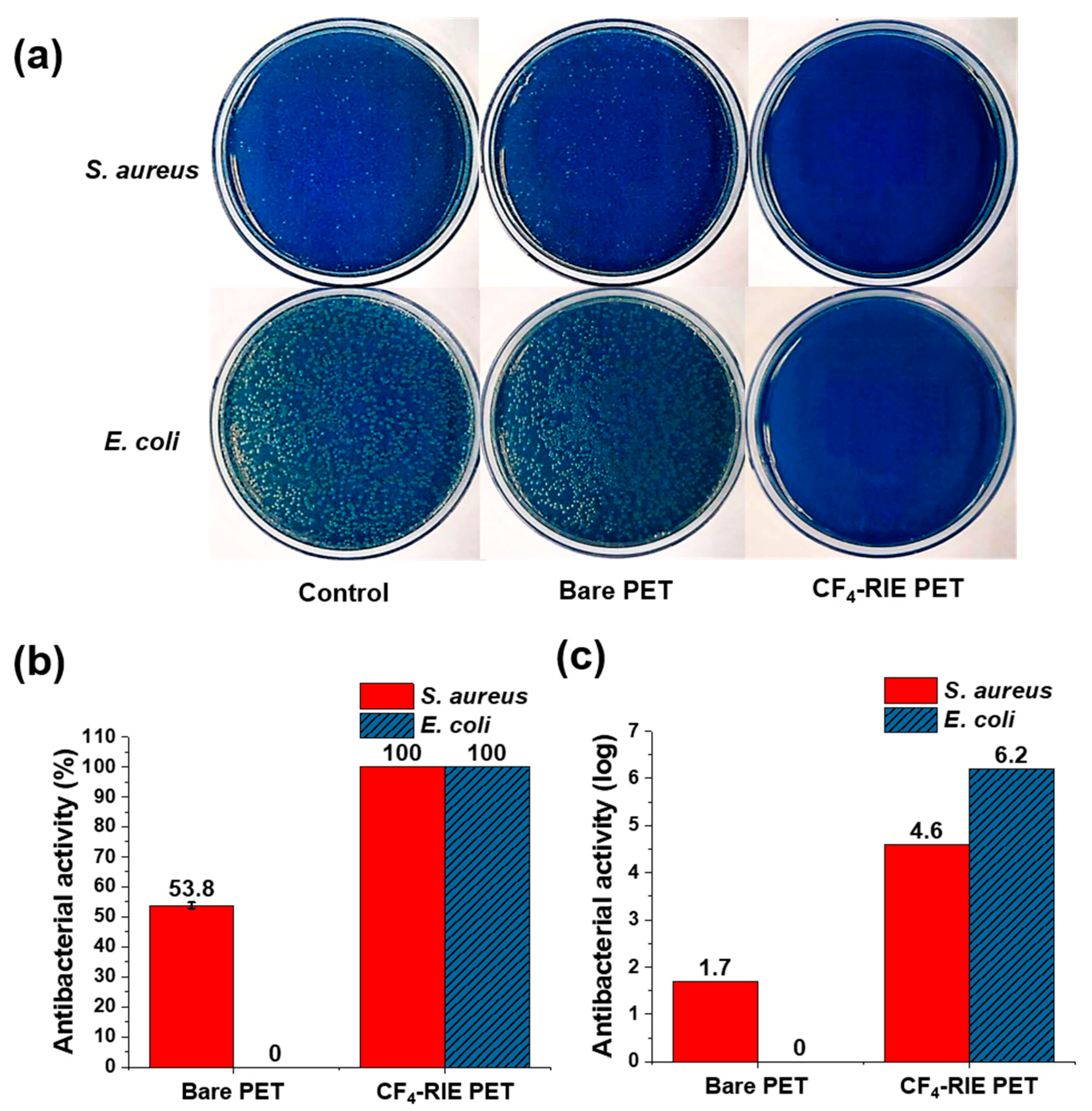

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- NIIR Board of Consultants & Engineers. Handbook on Pet Film and Sheets, Urethane Foams, Flexible Foams, Rigid Foams, Speciality Plastics, Stretch Blow Moulding, Injection Blow Moulding, Injection and Co-Injection Preform Technologie; ASIA PACIFIC BUSINESS PRESS Inc.: New Delhi, Delhi, 2018. [Google Scholar]

- Al-Ghamdi, A.K.; Abdelmalek, S.M.A.; Ashshi, A.M.; Faidah, H.; Shukri, H.; Jiman-Fatani, A.A. Bacterial contamination of computer keyboards and mice, elevator buttons and shopping carts. African J. Microbiol. Res. 2011, 5, 3998–4003. [Google Scholar]

- World Health Organization. Hospital Hygiene and Infection Control; World Health Organization: Geneva, Switzerland, 2014. [Google Scholar]

- Cloutier, M.; Mantovani, D.; Rosei, F. Antibacterial Coatings: Challenges, Perspectives, and Opportunities. Trends Biotechnol. 2015, 33, 637–652. [Google Scholar] [CrossRef] [PubMed]

- Madeira, M.P.; Lobo, A.O.; Viana, B.C.; Silva Filho, E.C.; Osajima, J.A. Systems developed for application as self-cleaning surfaces and/or antimicrobial properties: A short review on materials and production methods. Cerâmica 2019, 65, 477–484. [Google Scholar] [CrossRef]

- Mansouri, J.; Truong, V.K.; MacLaughlin, S.; Mainwaring, D.E.; Moad, G.; Dagley, I.J.; Ivanova, E.P.; Crawford, R.J.; Chen, V. Polymerization-Induced Phase Segregation and Self-Assembly of Siloxane Additives to Provide Thermoset Coatings with a Defined Surface Topology and Biocidal and Self-Cleaning Properties. Nanomaterials 2019, 9, 1610. [Google Scholar] [CrossRef] [PubMed]

- Hu, H.; Siu, V.S.; Gifford, S.M.; Kim, S.; Lu, M.; Meyer, P.; Stolovitzky, G.A. Bio-inspired silicon nanospikes fabricated by metal-assisted chemical etching for antibacterial surfaces. Appl. Phys. Lett. 2017, 111, 253701. [Google Scholar] [CrossRef]

- Gomes, R.N.; Borges, I.; Pereira, A.T.; Maia, A.F.; Pestana, M.; Magalhães, F.D.; Pinto, A.M.; Gonçalves, I.C. Antimicrobial graphene nanoplatelets coatings for silicone catheters. Carbon N. Y. 2018, 139, 635–647. [Google Scholar] [CrossRef]

- Fisher, L.E.; Yang, Y.; Yuen, M.-F.; Zhang, W.; Nobbs, A.H.; Su, B. Bactericidal activity of biomimetic diamond nanocone surfaces. Biointerphases 2016, 11, 011014. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, X.; Zhang, J.; Zheng, Q.; Liu, B. Study on antibacterial property of PMMA denture base materials with negative ion powder. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 301. [Google Scholar]

- Mangadlao, J.D.; Santos, C.M.; Felipe, M.J.L.; De Leon, A.C.C.; Rodrigues, D.F.; Advincula, R.C. On the antibacterial mechanism of graphene oxide (GO) Langmuir-Blodgett films. Chem. Commun. 2015, 51, 2886–2889. [Google Scholar] [CrossRef]

- Jenkins, J.; Nobbs, A.; Verkade, P.; Su, B. Characterisation of bactericidal titanium surfaces using electron microscopy. Microsc. Anal. 2018, 34, 17–22. [Google Scholar]

- Wang, J.; Li, J.; Qian, S.; Guo, G.; Wang, Q.; Tang, J.; Shen, H.; Liu, X.; Zhang, X.; Chu, P.K. Antibacterial surface design of titanium-based biomaterials for enhanced bacteria-killing and cell-assisting functions against periprosthetic joint infection. ACS Appl. Mater. Interfaces 2016, 8, 11162–11178. [Google Scholar] [CrossRef]

- Muñoz-Bonilla, A.; Fernández-García, M. Polymeric materials with antimicrobial activity. Prog. Polym. Sci. 2012, 37, 281–339. [Google Scholar] [CrossRef]

- Muñoz-Bonilla, A.; Fernández-García, M. The roadmap of antimicrobial polymeric materials in macromolecular nanotechnology. Eur. Polym. J. 2015, 65, 46–62. [Google Scholar] [CrossRef]

- Rizzello, L.; Cingolani, R.; Pompa, P.P. Nanotechnology tools for antibacterial materials. Nanomedicine 2013, 8, 807–821. [Google Scholar] [CrossRef] [PubMed]

- Sun, D.; Babar Shahzad, M.; Li, M.; Wang, G.; Xu, D. Antimicrobial materials with medical applications. Mater. Technol. 2015, 30, B90–B95. [Google Scholar] [CrossRef]

- Gunawan, C.; Teoh, W.Y.; Marquis, C.P.; Amal, R. Induced adaptation of Bacillus sp. to antimicrobial nanosilver. Small 2013, 9, 3554–3560. [Google Scholar] [CrossRef] [PubMed]

- Minoura, K.; Yamada, M.; Mizoguchi, T.; Kaneko, T.; Nishiyama, K.; Ozminskyj, M.; Koshizuka, T.; Wada, I.; Suzutani, T. Antibacterial effects of the artificial surface of nanoimprinted moth-eye film. PLoS ONE 2017, 12, e0185366. [Google Scholar] [CrossRef]

- Yi, G.; Riduan, S.N.; Yuan, Y.; Zhang, Y. Microbicide surface nano-structures. Crit. Rev. Biotechnol. 2019, 39, 964–979. [Google Scholar] [CrossRef]

- Elbourne, A.; Crawford, R.J.; Ivanova, E.P. Nano-structured antimicrobial surfaces: From nature to synthetic analogues. J. Colloid Interface Sci. 2017, 508, 603–616. [Google Scholar] [CrossRef]

- Muller, M.P.; MacDougall, C.; Lim, M.; Armstrong, I.; Bialachowski, A.; Callery, S.; Ciccotelli, W.; Cividino, M.; Dennis, J.; Hota, S.; et al. Antimicrobial surfaces to prevent healthcare-associated infections: A systematic review. J. Hosp. Infect. 2016, 92, 7–13. [Google Scholar] [CrossRef]

- Serrano, C.; García-Fernández, L.; Fernández-Blázquez, J.P.; Barbeck, M.; Ghanaati, S.; Unger, R.; Kirkpatrick, J.; Arzt, E.; Funk, L.; Turón, P.; et al. Nanostructured medical sutures with antibacterial properties. Biomaterials 2015, 52, 291–300. [Google Scholar] [CrossRef]

- Orhan, M.; Kut, D.; Gunesoglu, C. Improving the antibacterial property of polyethylene terephthalate by cold plasma treatment. Plasma Chem. Plasma Process. 2012, 32, 293–304. [Google Scholar] [CrossRef]

- Yamada, M.; MinouraI, K.; Mizoguchi, T.; Nakamatsu, K.; Taguchi, T.; Kameda, T.; Sekiguchi, M.; Suzutani, T.; Konno, S. Antibacterial effects of nano-imprinted motheye film in practical settings. PLoS ONE 2018, 13, e0198300. [Google Scholar] [CrossRef] [PubMed]

- Dickson, M.N.; Liang, E.I.; Rodriguez, L.A.; Vollereaux, N.; Yee, A.F. Nanopatterned polymer surfaces with bactericidal properties. Biointerphases 2015, 10, 021010. [Google Scholar] [CrossRef] [PubMed]

- Yu, Q.; Cho, J.; Shivapooja, P.; Ista, L.K.; López, G.P. Nanopatterned smart polymer surfaces for controlled attachment, killing, and release of bacteria. ACS Appl. Mater. Interfaces 2013, 5, 9295–9304. [Google Scholar] [CrossRef] [PubMed]

- Japanese Standards Association. JIS Z 2801:2010 Antibacterial Products–Test for Antibacterial Activity and Efficacy; Japanese Standards Association: Tokyo, Japan, 2010. [Google Scholar]

- Resnik, M.; Zaplotnik, R.; Mozetic, M.; Vesel, A. Comparison of SF6 and CF4 plasma treatment for surface hydrophobization of PET polymer. Materials 2018, 11, 311. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.W.; Cheong, F.C.; Yu, T.; Xu, X.J.; Lim, C.T.; Thong, J.T.L.; Shen, Z.X.; Ong, C.K.; Liu, Y.J.; Wee, A.T.S. Effects of CF4 plasma on the field emission properties of aligned multi-wall carbon nanotube films. Carbon N. Y. 2005, 43, 395–400. [Google Scholar] [CrossRef]

- Nowlin, K.; Boseman, A.; Covell, A.; LaJeunesse, D. Adhesion-dependent rupturing of Saccharomyces cerevisiae on biological antimicrobial nanostructured surfaces. J. R. Soc. Interface 2014, 12, 20140999. [Google Scholar] [CrossRef]

- Gupta, K.; Lin, T.; Wang, R.C.; Liu, C.P. Porosity-induced full-range visible-light photodetection via ultrahigh broadband antireflection in ZnO nanowires. NPG Asia Mater. 2016, 8, e314. [Google Scholar] [CrossRef]

- Cai, J.; Qi, L. Recent advances in antireflective surfaces based on nanostructure arrays. Mater. Horizons 2015, 2, 37–53. [Google Scholar] [CrossRef]

- Zhao, J.; Yu, X.; Zhou, K.; Yang, X.; Yu, Y. Wide-Gamut and Polarization-Independent Structural Color at Optical Sub-diffraction-Limit Spatial Resolution Based on Uncoupled LSPPs. Nanoscale Res. Lett. 2019, 14, 1–7. [Google Scholar] [CrossRef]

- Purtov, J.; Verch, A.; Rogin, P.; Hensel, R. Improved development procedure to enhance the stability of microstructures created by two-photon polymerization. Microelectron. Eng. 2018, 194, 45–50. [Google Scholar] [CrossRef]

- Watson, G.S.; Green, D.W.; Watson, J.A.; Zhou, Z.; Li, X.; Cheung, G.S.P.; Gellender, M. A Simple Model for Binding and Rupture of Bacterial Cells on Nanopillar Surfaces. Adv. Mater. Interfaces 2019, 6, 1801646. [Google Scholar] [CrossRef]

- Li, X. Bactericidal mechanism of nanopatterned surfaces. Phys. Chem. Chem. Phys. 2015, 18, 1311–1316. [Google Scholar] [CrossRef] [PubMed]

- Xue, F.; Liu, J.; Guo, L.; Zhang, L.; Li, Q. Theoretical study on the bactericidal nature of nanopatterned surfaces. J. Theor. Biol. 2015, 385, 1–7. [Google Scholar] [CrossRef]

- Oh, H.G.; Lee, J.Y.; Son, H.G.; Kim, D.H.; Park, S.H.; Kim, C.M.; Jhee, K.H.; Song, K.S. Antibacterial mechanisms of nanocrystalline diamond film and graphene sheet. Results Phys. 2019, 12, 2129–2135. [Google Scholar] [CrossRef]

- Chen, M.; Li, H.; Wang, X.; Qin, G.; Zhang, E. Improvement in antibacterial properties and cytocompatibility of titanium by fluorine and oxygen dual plasma-based surface modification. Appl. Surf. Sci. 2019, 463, 261–274. [Google Scholar] [CrossRef]

- Canal, C.; Gaboriau, F.; Villeger, S.; Cvelbar, U.; Ricard, A. Studies on antibacterial dressings obtained by fluorinated post-discharge plasma. Int. J. Pharm. 2009, 367, 155–161. [Google Scholar] [CrossRef]

- Wang, X.; Lu, P.; Li, Y.; Xiao, H.; Liu, X. Antibacterial activities and mechanisms of fluorinated graphene and guanidine-modified graphene. RSC Adv. 2016, 6, 8763–8772. [Google Scholar] [CrossRef]

- Ivanova, E.P.; Hasan, J.; Webb, H.K.; Gervinskas, G.; Juodkazis, S.; Truong, V.K.; Wu, A.H.F.; Lamb, R.N.; Baulin, V.A.; Watson, G.S.; et al. Bactericidal activity of black silicon. Nat. Commun. 2013, 4, 1–7. [Google Scholar] [CrossRef]

- Kelleher, S.M.; Habimana, O.; Lawler, J.; O’reilly, B.; Daniels, S.; Casey, E.; Cowley, A. Cicada Wing Surface Topography: An Investigation into the Bactericidal Properties of Nanostructural Features. ACS Appl. Mater. Interfaces 2016, 8, 14966–14974. [Google Scholar] [CrossRef]

- Hasan, J.; Raj, S.; Yadav, L.; Chatterjee, K. Engineering a nanostructured “super surface” with superhydrophobic and superkilling properties. RSC Adv. 2015, 5, 44953–44959. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Zuber, F.; Brugger, J.; Maniura-Weber, K.; Ren, Q. Antibacterial Au nanostructured surfaces. Nanoscale 2016, 8, 2620–2625. [Google Scholar] [CrossRef] [PubMed]

- Bhadra, C.M.; Khanh Truong, V.; Pham, V.T.H.; Al Kobaisi, M.; Seniutinas, G.; Wang, J.Y.; Juodkazis, S.; Crawford, R.J.; Ivanova, E.P. Antibacterial titanium nano-patterned arrays inspired by dragonfly wings. Sci. Rep. 2015, 5, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Hizal, F.; Zhuk, I.; Sukhishvili, S.; Busscher, H.J.; Van Der Mei, H.C.; Choi, C.H. Impact of 3D hierarchical nanostructures on the antibacterial efficacy of a bacteria-triggered self-defensive antibiotic coating. ACS Appl. Mater. Interfaces 2015, 7, 20304–20313. [Google Scholar] [CrossRef]

- May, P.W.; Clegg, M.; Silva, T.A.; Zanin, H.; Fatibello-Filho, O.; Celorrio, V.; Fermin, D.J.; Welch, C.C.; Hazell, G.; Fisher, L.; et al. Diamond-coated “black silicon” as a promising material for high-surface-area electrochemical electrodes and antibacterial surfaces. J. Mater. Chem. B 2016, 4, 5737–5746. [Google Scholar] [CrossRef]

- Pogodin, S.; Hasan, J.; Baulin, V.A.; Webb, H.K.; Truong, V.K.; Nguyen, T.H.P.; Boshkovikj, V.; Fluke, C.J.; Watson, G.S.; Watson, J.A. Biophysical model of bacterial cell interactions with nanopatterned cicada wing surfaces. Biophys. J. 2013, 104, 835–840. [Google Scholar] [CrossRef]

- Hui, C.Y.; Jagota, A.; Lin, Y.-Y.; Kramer, E.J. Constraints on microcontact printing imposed by stamp deformation. Langmuir 2002, 18, 1394–1407. [Google Scholar] [CrossRef]

- Roca-Cusachs, P.; Rico, F.; Martinez, E.; Toset, J.; Farré, R.; Navajas, D. Stability of microfabricated high aspect ratio structures in poly (dimethylsiloxane). Langmuir 2005, 21, 5542–5548. [Google Scholar] [CrossRef]

- Davis, B.D.; Dulbecco, R.; Eisen, H.N.; Ginsberg, H.S. Bacterial Physiology: Microbiology, 2nd ed.; Harper and Row: Columbia, MD, USA, 1973. [Google Scholar]

- Rimai, D.S.; DeMejo, L.P.; Mittal, K.L. Fundamentals of Adhesion and Interfaces; VSP: Rancho Cordova, CA, USA, 1995; Volume 8. [Google Scholar]

- Werner Martienssen, H.W. Springer Handbook of Condensed Matter and Materials Data; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Coble, S. Materials Data Book; Cambridge University Engineering Department: Cambridge, UK, 2003. [Google Scholar]

- Sjöström, T.; Nobbs, A.H.; Su, B. Bactericidal nanospike surfaces via thermal oxidation of Ti alloy substrates. Mater. Lett. 2016, 167, 22–26. [Google Scholar] [CrossRef]

- Kim, J.-H.; Ma, J.; Jo, S.; Lee, S.; Kim, C.S. Enhancement of Antibacterial Properties of a Silver Nanowire Film via Electron Beam Irradiation. ACS Appl. Bio Mater. 2020, 3, 2117–2124. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-H.; Mun, C.; Ma, J.; Park, S.-G.; Lee, S.; Kim, C.S. Simple Fabrication of Transparent, Colorless, and Self-Disinfecting Polyethylene Terephthalate Film via Cold Plasma Treatment. Nanomaterials 2020, 10, 949. https://doi.org/10.3390/nano10050949

Kim J-H, Mun C, Ma J, Park S-G, Lee S, Kim CS. Simple Fabrication of Transparent, Colorless, and Self-Disinfecting Polyethylene Terephthalate Film via Cold Plasma Treatment. Nanomaterials. 2020; 10(5):949. https://doi.org/10.3390/nano10050949

Chicago/Turabian StyleKim, Ji-Hyeon, ChaeWon Mun, Junfei Ma, Sung-Gyu Park, Seunghun Lee, and Chang Su Kim. 2020. "Simple Fabrication of Transparent, Colorless, and Self-Disinfecting Polyethylene Terephthalate Film via Cold Plasma Treatment" Nanomaterials 10, no. 5: 949. https://doi.org/10.3390/nano10050949

APA StyleKim, J.-H., Mun, C., Ma, J., Park, S.-G., Lee, S., & Kim, C. S. (2020). Simple Fabrication of Transparent, Colorless, and Self-Disinfecting Polyethylene Terephthalate Film via Cold Plasma Treatment. Nanomaterials, 10(5), 949. https://doi.org/10.3390/nano10050949