Fabrication and Characterization of Solid Composite Yarns from Carbon Nanotubes and Poly(dicyclopentadiene)

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Yarn Fabrication

2.3. Characterization

3. Results

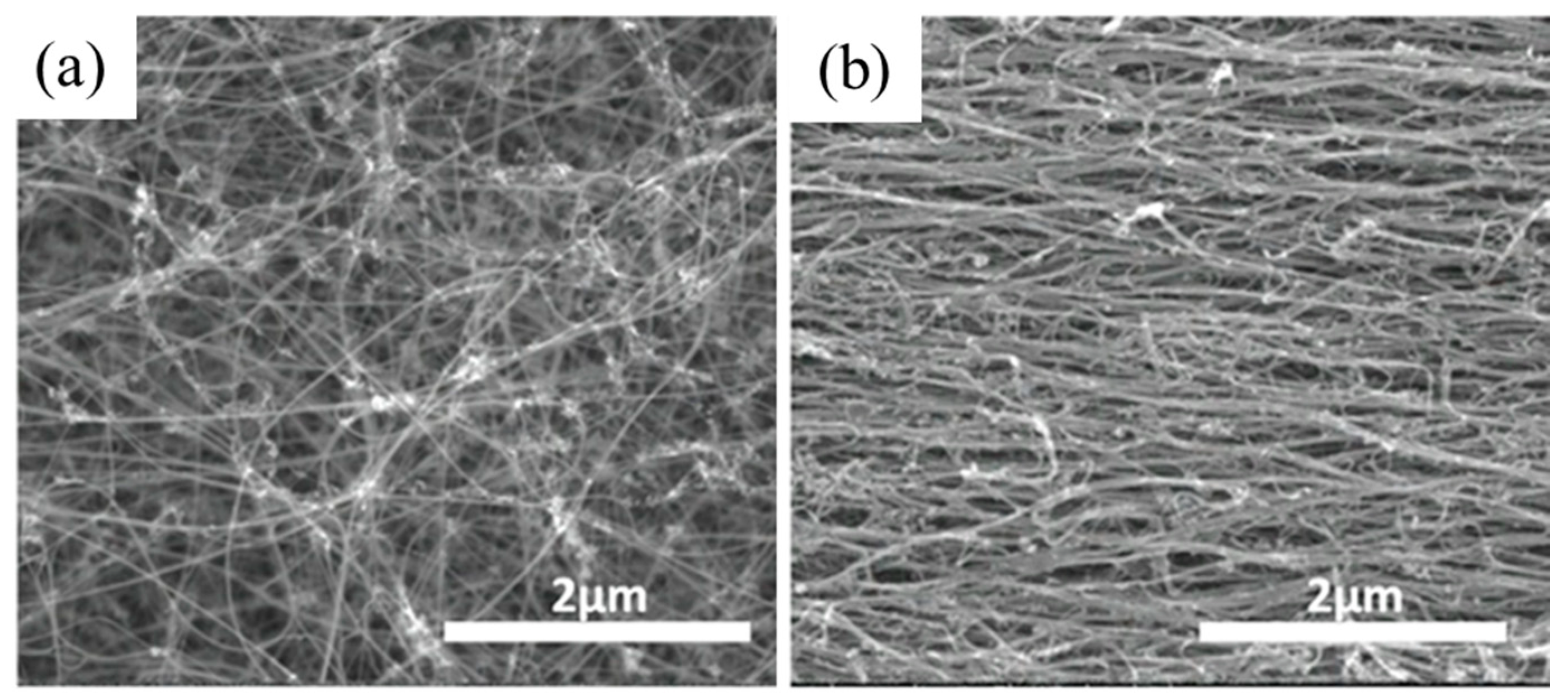

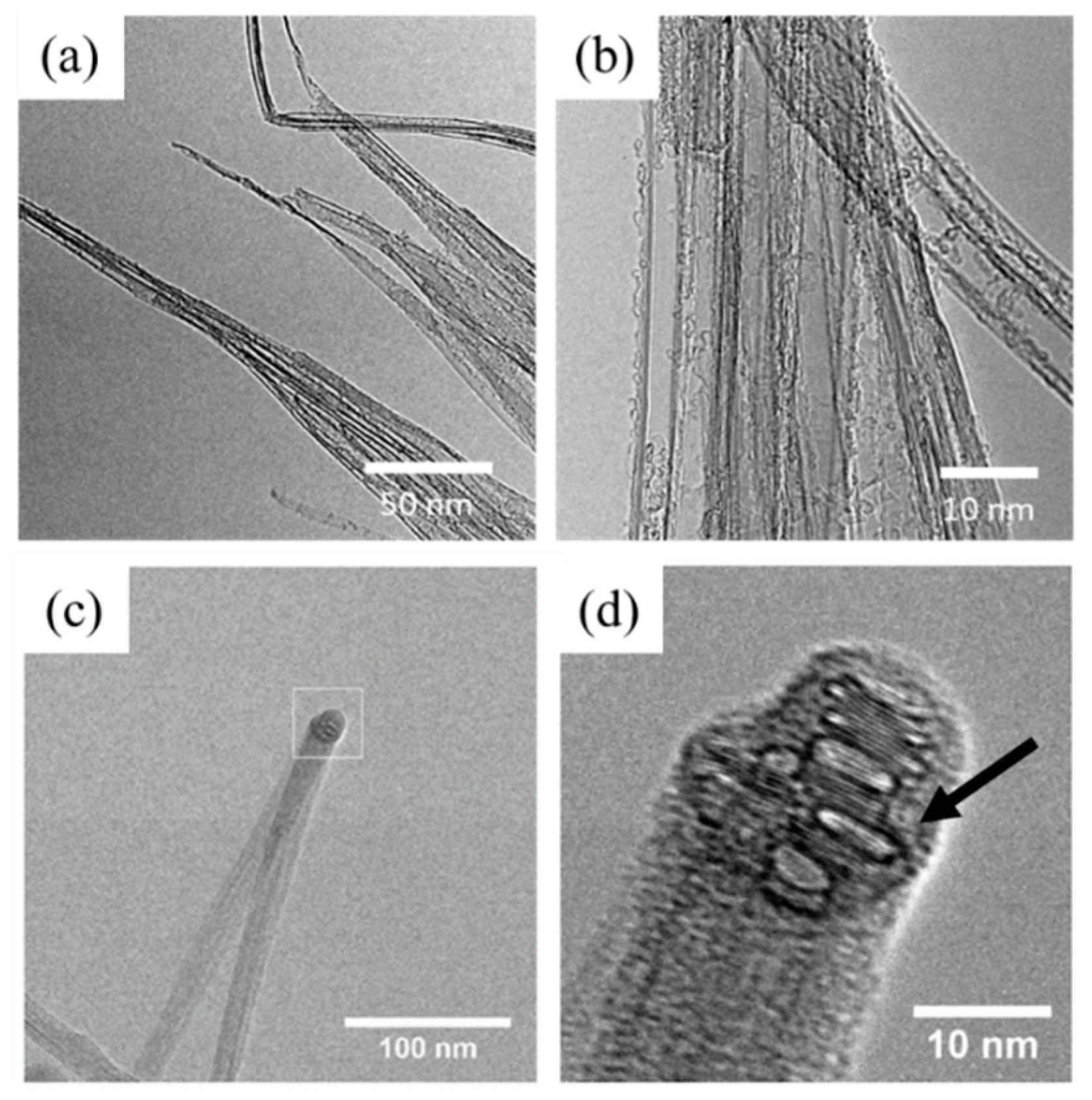

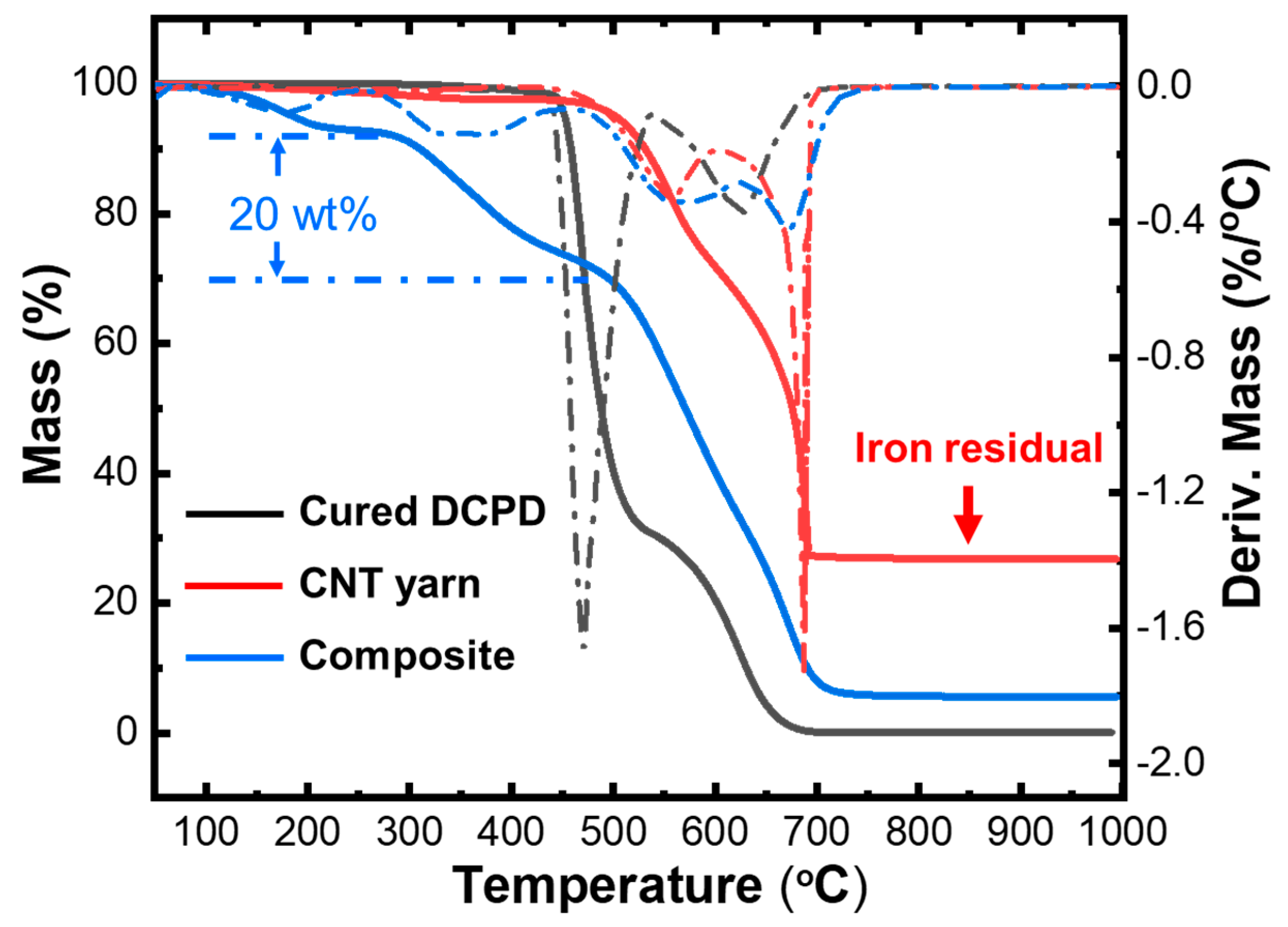

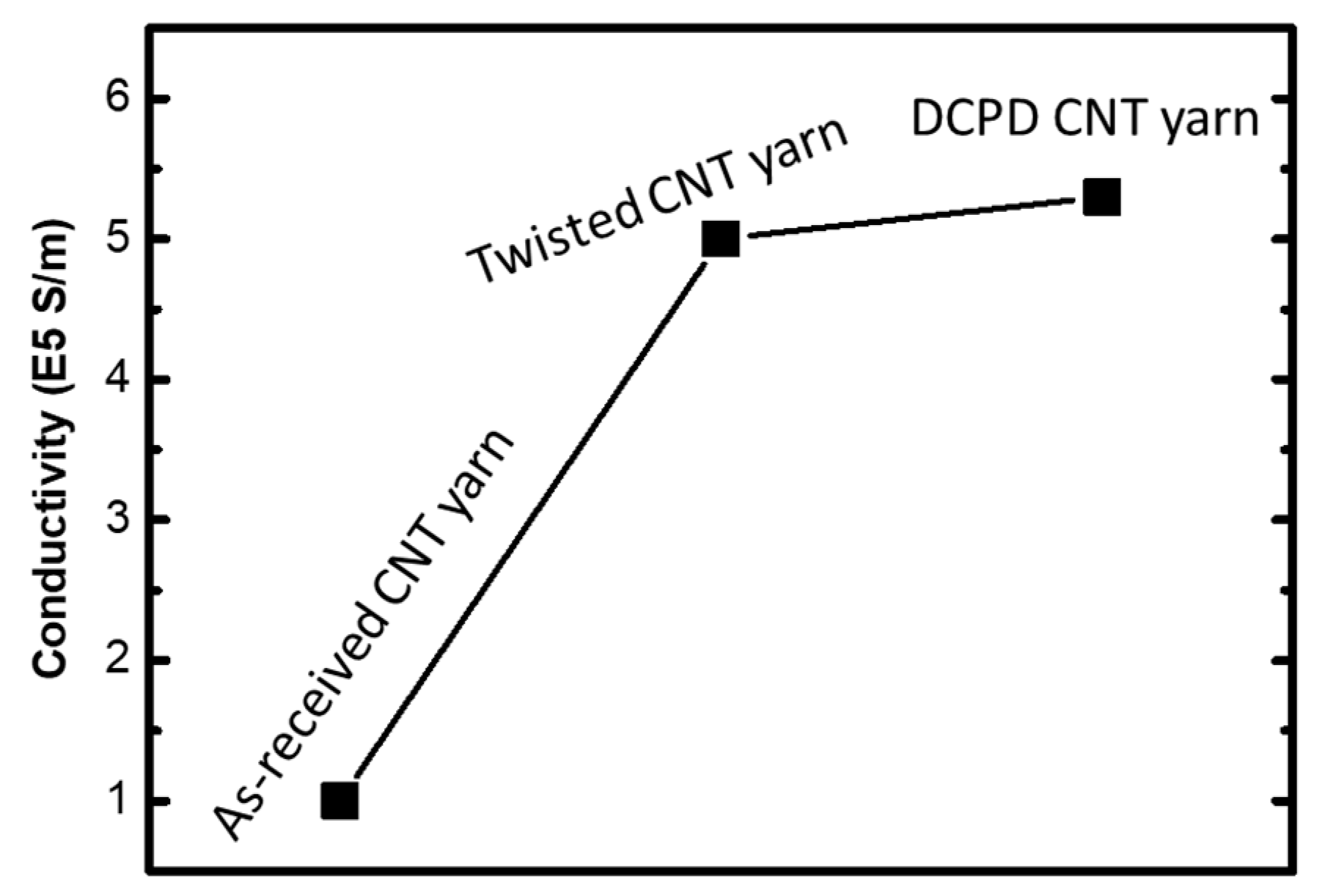

3.1. CNT Assemblies

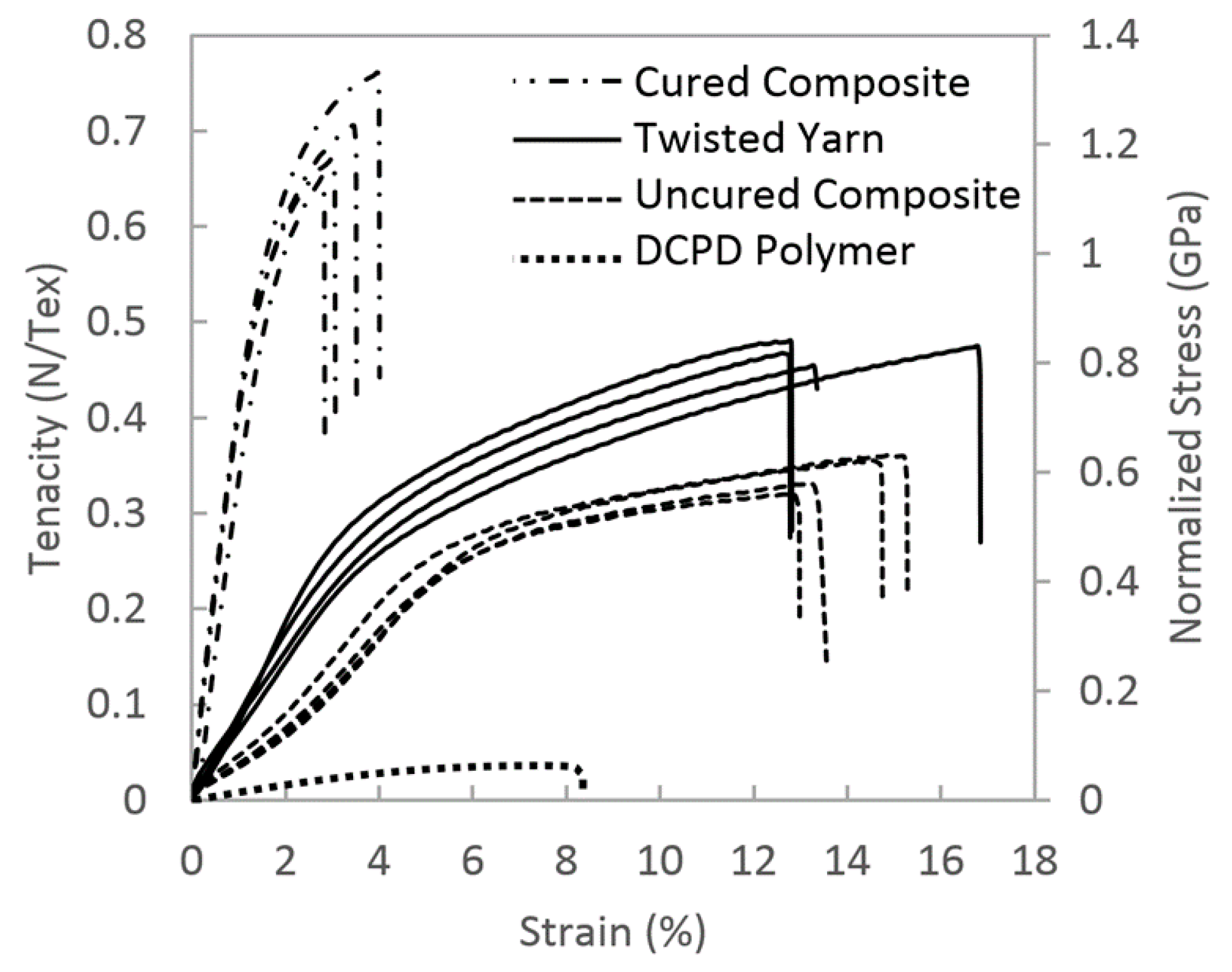

3.2. Composite Yarns

4. Discussion

4.1. Nanotube Assemblies without Resin

4.2. Uncured Composite

4.3. Cured Composite

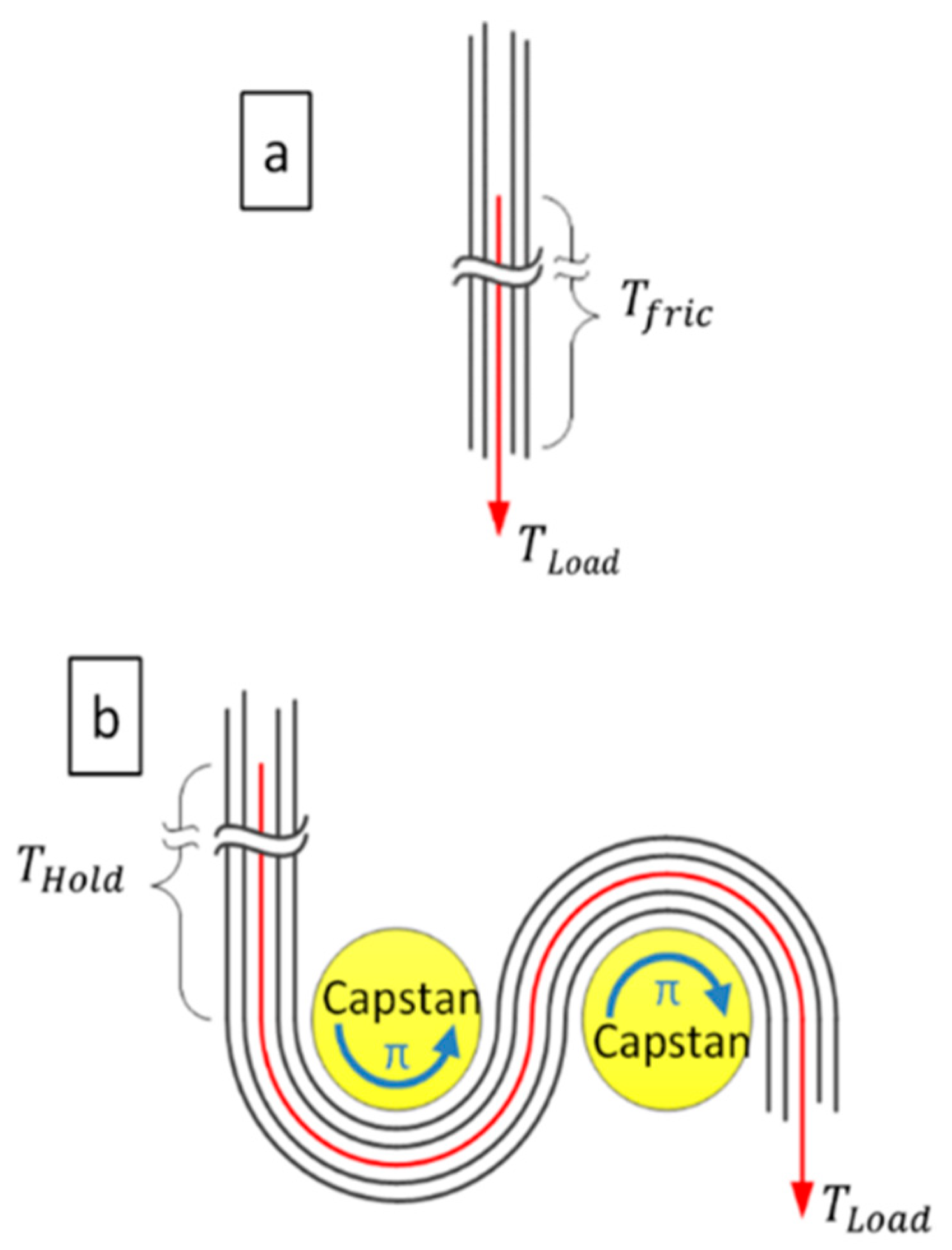

4.4. Strengthening Mechanism

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kim, J.W.; Sauti, G.; Cano, R.J.; Wincheski, R.A.; Ratcliffe, J.G.; Czabaj, M.; Gardner, N.W.; Siochi, E.J. Assessment of carbon nanotube yarns as reinforcement for composite overwrapped pressure vessels. Compos. Part A Appl. Sci. Manuf. 2016, 84, 256–265. [Google Scholar] [CrossRef]

- Xin, W.; Sarasini, F.; Tirillò, J.; Bavasso, I.; Sbardella, F.; Lampani, L.; De Rosa, I.M. Impact and post-impact properties of multiscale carbon fiber composites interleaved with carbon nanotube sheets. Compos. Part B Eng. 2020, 183, 107711. [Google Scholar] [CrossRef]

- Xin, W.; Yang, J.-M.; Li, C.; Goorsky, M.S.; Carlson, L.; De Rosa, I.M. Novel strategy for one-pot synthesis of gold nanoplates on carbon nanotube sheet as an effective flexible SERS substrate. ACS Appl. Mater. Interfaces 2017, 9, 6246–6254. [Google Scholar] [CrossRef] [PubMed]

- De Volder, M.F.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon Nanotubes: Present and Future Commercial Applications. Science 2013, 339, 535. [Google Scholar] [CrossRef] [PubMed]

- Demczyk, B.G.; Wang, Y.M.; Cumings, J.; Hetman, M.; Han, W.; Zettl, A.; Ritchie, R.O. Direct mechanical measurement of the tensile strength and elastic modulus of multiwalled carbon nanotubes. Mater. Sci. Eng. A 2002, 334, 173–178. [Google Scholar] [CrossRef]

- Bai, Y.; Zhang, R.; Ye, X.; Zhu, Z.; Xie, H.; Shen, B.; Cai, D.; Liu, B.; Zhang, C.; Jia, Z.; et al. Carbon nanotube bundles with tensile strength over 80 GPa. Nat. Nanotechnol. 2018, 13, 589–595. [Google Scholar] [CrossRef]

- Qian, D.; Wagner, G.J.; Liu, W.K.; Yu, M.F.; Ruoff, R.S. Mechanics of carbon nanotubes. Appl. Mech. Rev. 2002, 55, 495–533. [Google Scholar] [CrossRef]

- Di, J.; Hu, D.; Chen, H.; Yong, Z.; Chen, M.; Feng, Z.; Zhu, Y.; Li, Q. Ultrastrong, foldable, and highly conductive carbon nanotube film. ACS Nano 2012, 6, 5457–5464. [Google Scholar] [CrossRef]

- Vigolo, B.; Penicaud, A.; Coulon, C.; Sauder, C.; Pailler, R.; Journet, C.; Bernier, P.; Poulin, P. Macroscopic fibers and ribbons of oriented carbon nanotubes. Science 2000, 290, 1331–1334. [Google Scholar] [CrossRef]

- Jiang, K.; Li, Q.; Fan, S. Nanotechnology: Spinning continuous carbon nanotube yarns. Nature 2002, 419, 801. [Google Scholar] [CrossRef]

- Li, Y.L.; Kinloch, I.A.; Windle, A.H. Direct spinning of carbon nanotube fibers from chemical vapor deposition synthesis. Science 2004, 304, 276–278. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Atkinson, K.R.; Baughman, R.H. Multifunctional carbon nanotube yarns by downsizing an ancient technology. Science 2004, 306, 1358–1361. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Bradford, P.D.; Liu, W.; Zhao, H.; Inoue, Y.; Maria, J.P.; Li, Q.; Yuan, F.-G.; Zhu, Y. Mechanical and electrical property improvement in CNT/Nylon composites through drawing and stretching. Compos. Sci. Technol. 2011, 71, 1677–1683. [Google Scholar] [CrossRef]

- Sears, K.; Skourtis, C.; Atkinson, K.; Finn, N.; Humphries, W. Focused ion beam milling of carbon nanotube yarns to study the relationship between structure and strength. Carbon 2010, 48, 4450–4456. [Google Scholar] [CrossRef]

- Xu, W.; Chen, Y.; Zhan, H.; Wang, J.N. High-strength carbon nanotube film from improving alignment and densification. Nano Lett. 2016, 16, 946–952. [Google Scholar] [CrossRef] [PubMed]

- Alvarenga, J.; Jarosz, P.R.; Schauerman, C.M.; Moses, B.T.; Landi, B.J.; Cress, C.D.; Raffaelle, R.P. High conductivity carbon nanotube wires from radial densification and ionic doping. Appl. Phys. Lett. 2010, 97, 182106. [Google Scholar] [CrossRef]

- Bucossi, A.R.; Cress, C.D.; Schauerman, C.M.; Rossi, J.E.; Puchades, I.; Landi, B.J. Enhanced electrical conductivity in extruded single-wall carbon nanotube wires from modified coagulation parameters and mechanical processing. ACS Appl. Mater. Interfaces 2015, 7, 27299–27305. [Google Scholar] [CrossRef]

- Liu, K.; Sun, Y.; Zhou, R.; Zhu, H.; Wang, J.; Liu, L.; Fan, S. Carbon nanotube yarns with high tensile strength made by a twisting and shrinking method. Nanotechnology 2010, 21, 045708. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, W.; Zhou, G.; Li, Q. Understanding the Mechanical and Conductive Properties of Carbon Nanotube Fibers for Smart Electronics. Adv. Mater. 2019, 1902028. [Google Scholar] [CrossRef]

- Tsentalovich, D.E.; Headrick, R.J.; Mirri, F.; Hao, J.; Behabtu, N.; Young, C.C.; Pasquali, M. Influence of carbon nanotube characteristics on macroscopic fiber properties. ACS Appl. Mater. Interfaces 2017, 9, 36189–36198. [Google Scholar] [CrossRef]

- Vilatela, J.J.; Elliott, J.A.; Windle, A.H. A model for the strength of yarn-like carbon nanotube fibers. ACS Nano 2011, 5, 1921–1927. [Google Scholar] [CrossRef] [PubMed]

- Dalton, A.B.; Collins, S.; Munoz, E.; Razal, J.M.; Ebron, V.H.; Ferraris, J.P.; Coleman, J.N.; Kim, B.G.; Baughman, R.H. Super-Tough Carbon-Nanotube Fibres. Nature 2003, 423, 703. [Google Scholar] [CrossRef] [PubMed]

- Ma, W.J.; Liu, L.Q.; Zhang, Z.; Yang, R.; Liu, G.; Zhang, T.H.; An, X.; Yi, X.; Ren, Y.; Niu, Z.; et al. High-strength composite fibers—Realizing true potential of carbon nanotubes in polymer matrix through continuous reticulate architecture and molecular level couplings. Nano Lett. 2009, 9, 2855–2861. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Zhang, X.; Zhao, J.; Meng, F.; Xu, G.; Yong, Z.; Jia, J.; Zhang, Z.; Li, Q. Enhancement of carbon nanotube fibres using different solvents and polymers. Compos. Sci. Technol. 2012, 72, 1402–1407. [Google Scholar] [CrossRef]

- Cheng, Q.; Wang, B.; Zhang, C.; Liang, Z. Functionalized carbon-nanotube sheet/bismaleimide nanocomposites: Mechanical and electrical performance beyond carbon-fiber composites. Small 2010, 6, 763–767. [Google Scholar] [CrossRef]

- Ryu, S.; Lee, Y.; Hwang, J.W.; Hong, S.; Kim, C.; Park, T.G.; Lee, H.; Hong, S.H. High-strength carbon nanotube fibers fabricated by infiltration and curing of mussel-inspired catecholamine polymer. Adv. Mater. 2011, 23, 1971–1975. [Google Scholar] [CrossRef]

- Ryu, S.; Chou, J.B.; Lee, K.; Lee, D.; Hong, S.H.; Zhao, R.; Lee, H.; Kim, S.-G. Direct insulation-to-conduction transformation of adhesive catecholamine for simultaneous increases of electrical conductivity and mechanical strength of CNT fibers. Adv. Mater. 2015, 27, 3250–3255. [Google Scholar] [CrossRef]

- Kessler, M.; Larin, G.; Bernklau, N. Cure characterization and viscosity development of ring-opening metathesis polymerized resins. J. Therm. Anal. Calorim. 2006, 85, 7–12. [Google Scholar] [CrossRef]

- Yao, Z.; Zhou, L.-w.; Dai, B.-b.; Cao, K.J. Ring-opening metathesis copolymerization of dicyclopentadiene and cyclopentene through reaction injection molding process. J. Appl. Polym. Sci. 2012, 125, 2489–2493. [Google Scholar] [CrossRef]

- Knorr, D.B., Jr.; Masser, K.A.; Elder, R.M.; Sirk, T.W.; Hindenlang, M.D.; Yu, J.H.; Richardson, A.D.; Boyd, S.E.; Spurgeon, W.A.; Lenhart, J.L. Overcoming the structural versus energy dissipation trade-off in highly crosslinked polymer networks: Ultrahigh strain rate response in polydicyclopentadiene. Compos. Sci. Technol. 2015, 114, 17–25. [Google Scholar] [CrossRef]

- Sheng, X.; Kessler, M.R.; Lee, J.K. The influence of cross-linking agents on ring-opening metathesis polymerized thermosets. J. Therm. Anal. Calorim. 2007, 89, 459–464. [Google Scholar] [CrossRef]

- He, Z.-L.; Xu, J.-K.; Zhang, L.; Ren, H.-Y.; Fu, S.-Y. Dramatically Enhanced Tensile Strength and Impact Toughness of Polydicyclopentadiene Composites by Covalent Bond Formation between Phenyl-Functionalized Silica and Dicyclopentadiene. Compos. Part B Eng. 2019, 170, 31–40. [Google Scholar] [CrossRef]

- Jeong, W.; Kessler, M.R. Toughness enhancement in ROMP functionalized carbon nanotube/polydicyclopentadiene composites. Chem. Mater. 2008, 20, 7060–7068. [Google Scholar] [CrossRef]

- Lashmore, D.S. Supercapacitors and Methods of Manufacturing Same; Nanocomp Technologies Inc.: Merrimack, NH, USA, 2008; p. 16. [Google Scholar]

- Adanur, S. Wellington Sears Handbook of Industrial Textiles; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Xin, W.; de Rosa, I.M.; Ye, P.; Severino, J.; Li, C.; Yin, X.; Goorsky, M.S.; Carlson, L.; Yang, J.-M. Graphene template-induced growth of single-crystalline gold nanobelts with high structural tunability. Nanoscale 2018, 10, 2764–2773. [Google Scholar] [CrossRef] [PubMed]

- Cornwell, C.F.; Welch, C.R. Very-high-strength (60-GPa) carbon nanotube fiber design based on molecular dynamics simulations. J. Chem. Phys. 2011, 134, 204708. [Google Scholar] [CrossRef]

- Frankland, S.J.V.; Caglar, A.; Brenner, D.W.; Griebel, M. Molecular simulation of the influence of chemical cross-links on the shear strength of carbon nanotube-polymer interfaces. J. Phys. Chem. B 2002, 106, 3046–3048. [Google Scholar] [CrossRef]

- Suekane, O.; Nagataki, A.; Mori, H.; Nakayama, Y. Static friction force of carbon nanotube surfaces. Appl. Phys. Express 2008, 1, 064001. [Google Scholar] [CrossRef]

- Chawla, K.K. Composite Materials: Science and Engineering; Springer: Berlin, Germany, 1998. [Google Scholar]

- Zhang, R.; Ning, Z.; Zhang, Y.; Zheng, Q.; Chen, Q.; Xie, H.; Zhang, Q.; Qian, W.; Wei, F. Superlubricity in centimetres-long double-walled carbon nanotubes under ambient conditions. Nat. Nanotechnol. 2013, 8, 912–916. [Google Scholar] [CrossRef]

- Morton, W.E.; Hearle, J.W.S. Physical Properties of Textile Fibres; Elsevier: Amsterdam, The Netherlands, 1962. [Google Scholar]

- Mylvaganam, K.; Zhang, L.C.; Xiao, K.Q. Origin of friction in films of horizontally oriented carbon nanotubes sliding against diamond. Carbon 2009, 7, 1693–1700. [Google Scholar] [CrossRef]

- Sawyer, W.; Perry, S.; Phillpot, S.; Sinnott, S. Integrating experimental and simulation length and time scales in mechanistic studies of friction. J. Phys. Condens. Matter 2008, 20, 354012. [Google Scholar] [CrossRef]

- Tu, J.P.; Zhu, L.P.; Hou, K.; Guo, S.Y. Synthesis and frictional properties of array film of amorphous carbon nanofibers on anodic aluminum oxide. Carbon 2003, 41, 1257–1263. [Google Scholar] [CrossRef]

| Sample | Modulus | UTS | Strain % | Toughness J/m3 | ||

|---|---|---|---|---|---|---|

| N/Tex | GPa | N/Tex | GPa | |||

| DCPD | -- | 1.5 ± 0.1 | -- | 0.06 ± 0.01 | 8.4 ± 0.7 | 2.5 ± 0.6 |

| Twisted yarn | 12 ± 2 | 14 ± 2 | 0.4 ± 0.05 | 0.8 ± 0.1 | 14.0 ± 1.7 | 65.0 ± 9.8 |

| Uncured composite | 5 ± 1 | 6 ± 1 | 0.3 ± 0.06 | 0.6 ± 0.1 | 13.8 ± 0.9 | 51.0 ± 7.0 |

| Composite yarn | 55 ± 2 | 68 ± 2 | 0.7 ± 0.05 | 1.2 ± 0.1 | 3.4 ± 0.4 | 22.9 ± 5.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xin, W.; Severino, J.; Venkert, A.; Yu, H.; Knorr, D.; Yang, J.-M.; Carlson, L.; Hicks, R.; De Rosa, I. Fabrication and Characterization of Solid Composite Yarns from Carbon Nanotubes and Poly(dicyclopentadiene). Nanomaterials 2020, 10, 717. https://doi.org/10.3390/nano10040717

Xin W, Severino J, Venkert A, Yu H, Knorr D, Yang J-M, Carlson L, Hicks R, De Rosa I. Fabrication and Characterization of Solid Composite Yarns from Carbon Nanotubes and Poly(dicyclopentadiene). Nanomaterials. 2020; 10(4):717. https://doi.org/10.3390/nano10040717

Chicago/Turabian StyleXin, Wenbo, Joseph Severino, Arie Venkert, Hang Yu, Daniel Knorr, Jenn-Ming Yang, Larry Carlson, Robert Hicks, and Igor De Rosa. 2020. "Fabrication and Characterization of Solid Composite Yarns from Carbon Nanotubes and Poly(dicyclopentadiene)" Nanomaterials 10, no. 4: 717. https://doi.org/10.3390/nano10040717

APA StyleXin, W., Severino, J., Venkert, A., Yu, H., Knorr, D., Yang, J.-M., Carlson, L., Hicks, R., & De Rosa, I. (2020). Fabrication and Characterization of Solid Composite Yarns from Carbon Nanotubes and Poly(dicyclopentadiene). Nanomaterials, 10(4), 717. https://doi.org/10.3390/nano10040717