Formation of Thin NiGe Films by Magnetron Sputtering and Flash Lamp Annealing

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

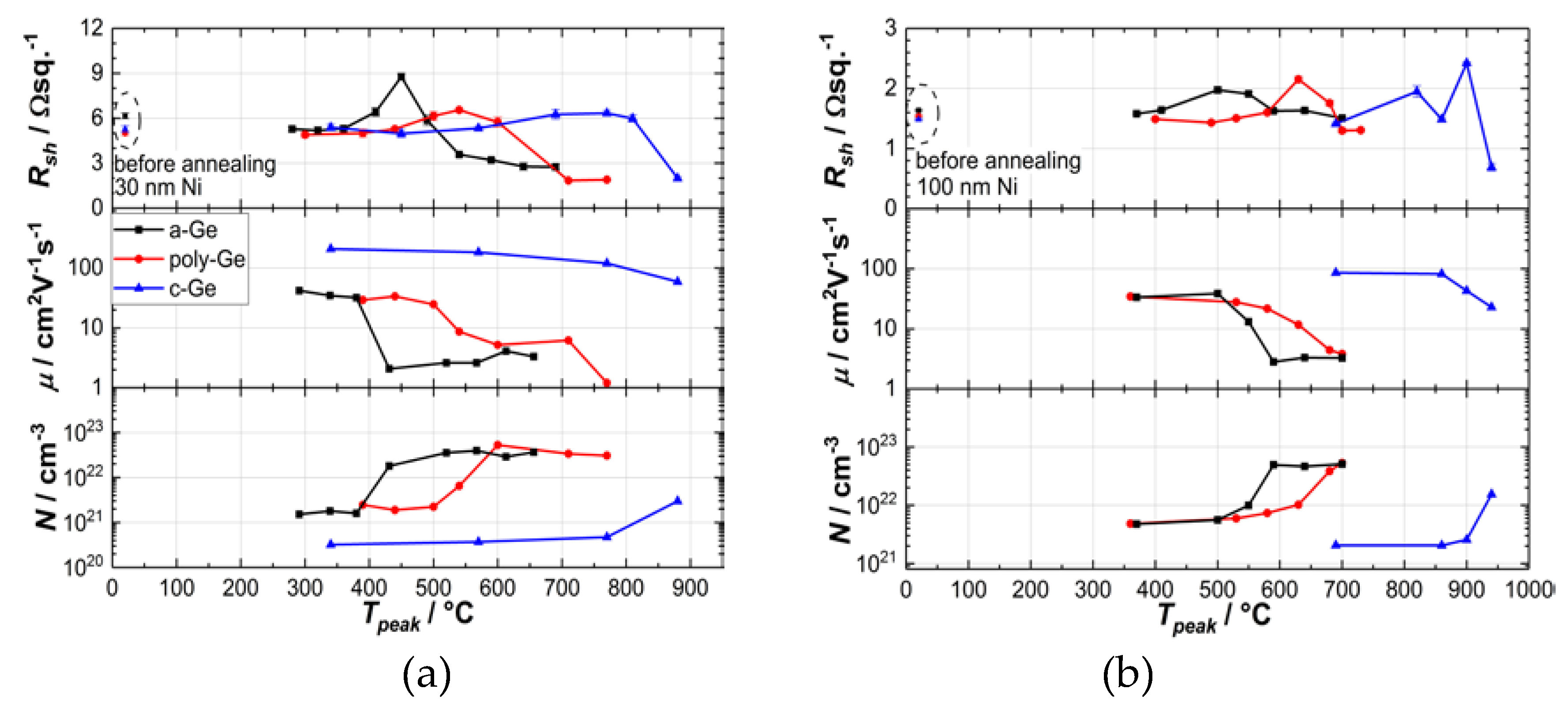

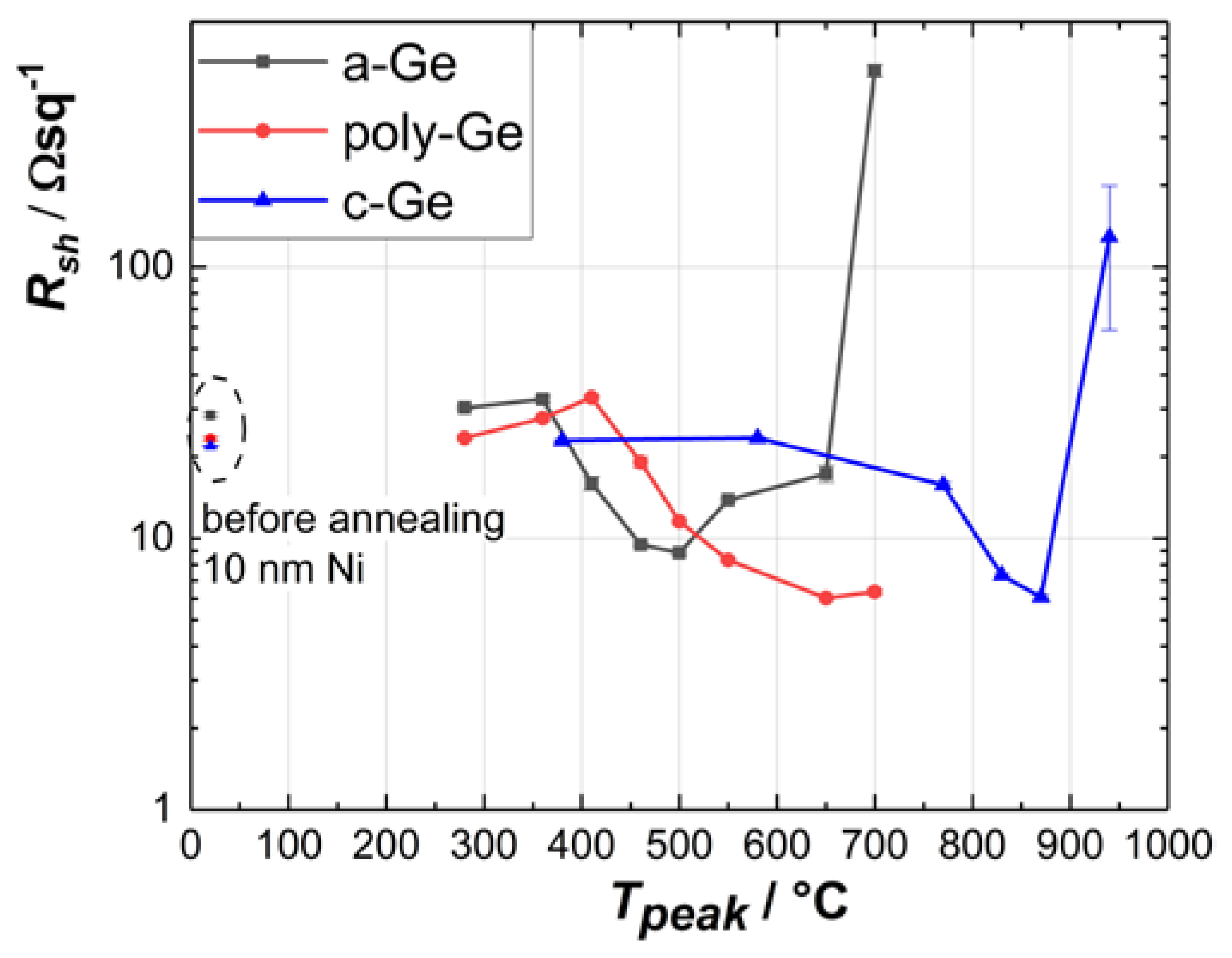

3.1. Electrical Characterization

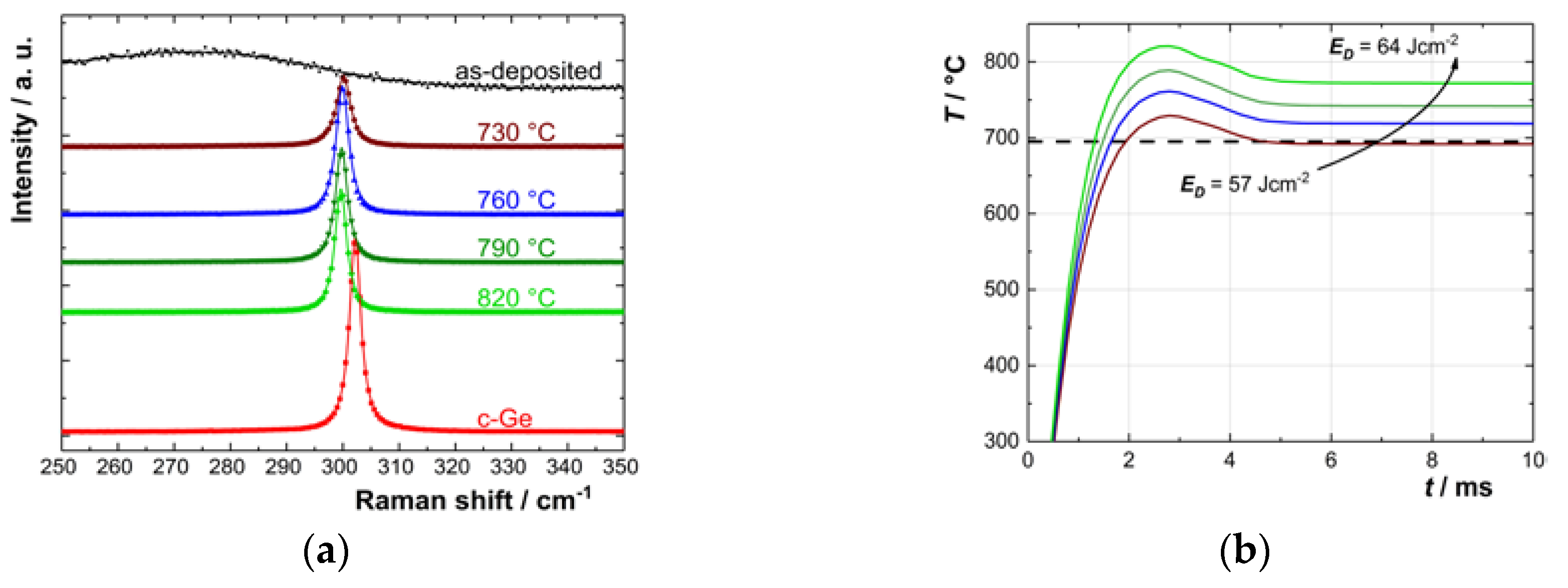

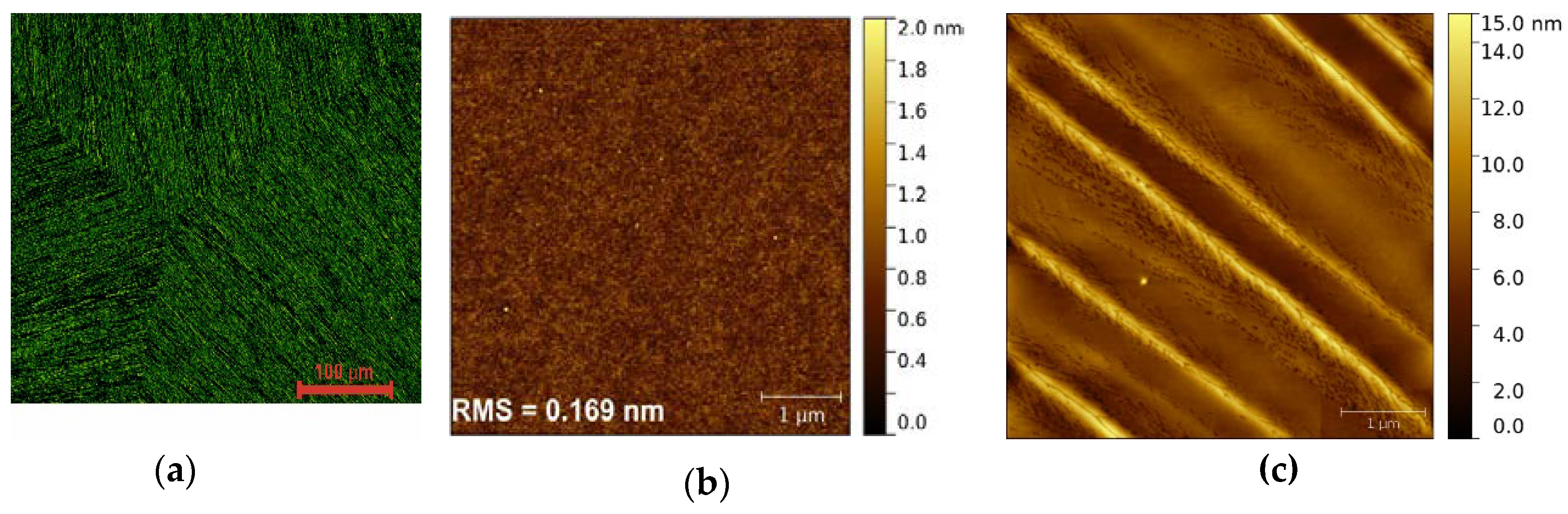

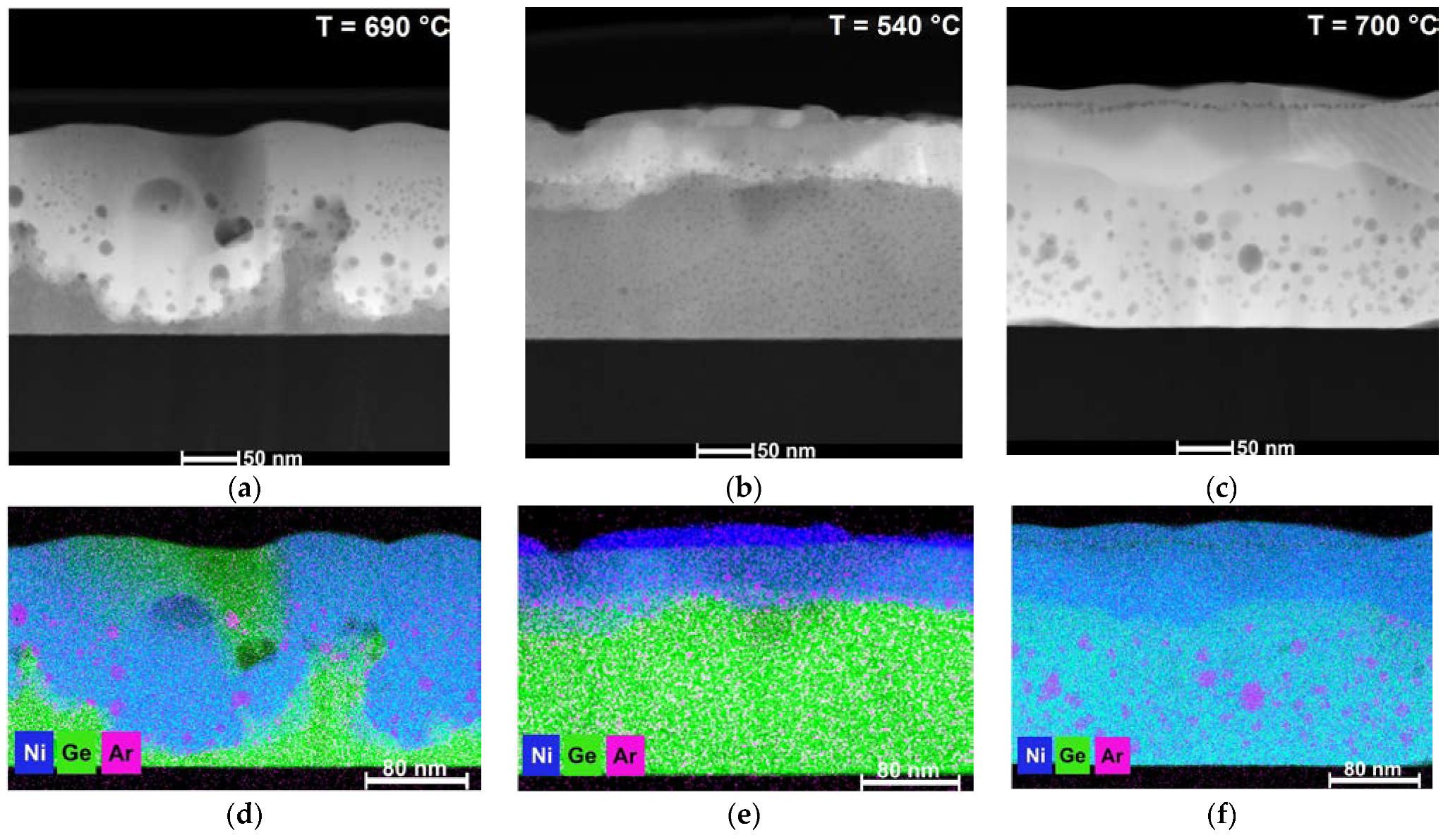

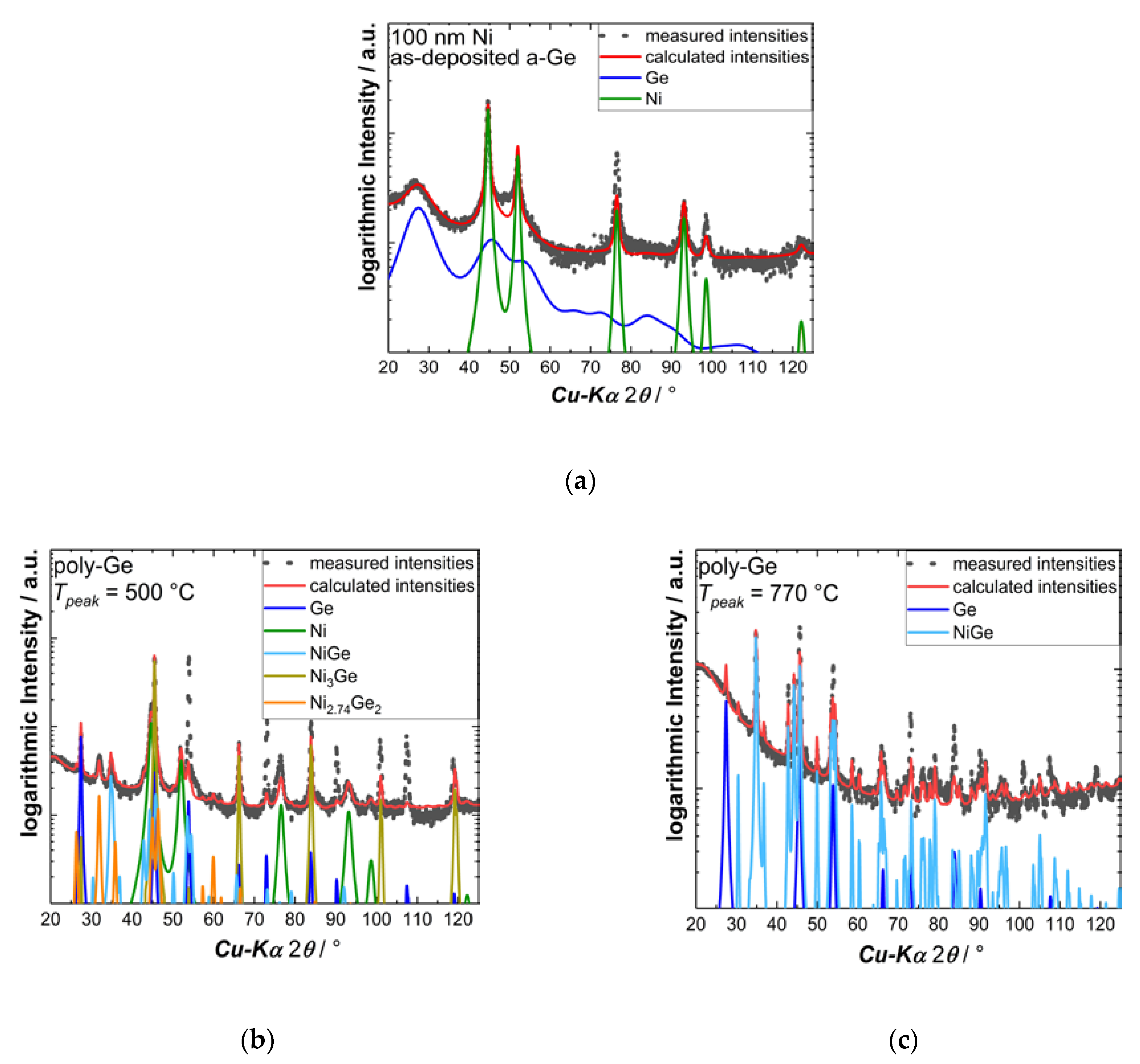

3.2. Structural Characterization

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

Polycrystalline Germanium

| Phase | Peak Position/cm−1 | FWHM/cm−1 | Tpeak/°C |

|---|---|---|---|

| Amorphous | ~270 | ~100 | --- |

| Polycrystalline | 300.1 | 3.0 | 730 |

| 300.1 | 2.8 | 760 | |

| 299.8 | 2.6 | 790 | |

| 299.6 | 2.6 | 820 | |

| Single crystalline | 302.2 | 2.5 | --- |

References

- Goley, P.S.; Hundait, M.K. Germanium Based Field-Effect Transistors: Challenges and Opportunities. Materials 2014, 7, 2301–2339. [Google Scholar] [CrossRef] [PubMed]

- Mitard, J.; De Jaeger, B.; Eneman, G.; Dobbie, A.; Myronov, M.; Kobayashi, M.; Geypen, J.; Bender, H.; Vincent, B.; Krom, R.; et al. High Hole Mobility in 65 nm Strained Ge p-Channel Field Effect Transistors with HfO2 Gate Dielectric. Jpn. J. Appl. Phys. 2011, 50, 04DC17. [Google Scholar] [CrossRef]

- Kobayashi, M.; Mitard, J.; Irisawa, T.; Hoffmann, T.-Y.; Meuris, M.; Saraswat, K.; Nishi, Y.; Heyns, M. On the High-Field Transport and Uniaxial Stress Effect in Ge PFETs. IEEE T. Electron. Dev. 2011, 58, 384–391. [Google Scholar] [CrossRef]

- Selvarkumar, C.R.; Hecht, B. SiGe-Channel n-MOSFET by Germanium Implantation. IEEE Electron Device Lett. 1991, 12, 444–446. [Google Scholar] [CrossRef]

- Brunco, D.P.; De Jaeger, B.; Eneman, G.; Mitard, J.; Hellings, G.; Satta, A.; Terzieva, V.; Souriau, L.; Leys, F.E.; Pourtois, G.; et al. Germanium MOSFET Devices: Advances in Materials Understanding, Process Development, and Electrical Performance. J. Electrochem. Soc. 2008, 155, H552–H561. [Google Scholar] [CrossRef]

- Akatsu, T.; Deguet, C.; Sanchez, L.; Allibert, F.; Rouchon, D.; Signamarcheix, T.; Richtarch, C.; Boussagol, A.; Loup, V.; Mazen, F.; et al. Germanium-on-insulator (GeOI) substrates—A novel engineered substrate for future high performance devices. Mat. Sci. Semicond. Proc. 2006, 9, 444–448. [Google Scholar] [CrossRef]

- Rebohle, L.; Prucnal, S.; Reichel, D. Optical output. In Flash Lamp Annealing: From Basics to Applications, 1st ed.; Springer Nature Switzerland: Cham, Switzerland, 2019; pp. 47–51. [Google Scholar]

- Gaudet, S.; Detavernier, C.; Kellock, A.J.; Desjardins, P.; Lavoie, C. Thin film reaction of transition metals with germanium. J. Vac. Sci. Technol. 2006, 24, 474–485. [Google Scholar] [CrossRef]

- Hsu, S.-L.; Yang, M.-J.; Huang, R.-H.; Shen, S.-W.; Yang, T.-H.; Chien, C.-H.; Leu, C.-C. Study of thermal stability of nickel monogermanide on single- and polycrystalline germanium substrates. Appl. Phys. Lett. 2005, 86, 1–3. [Google Scholar] [CrossRef]

- Spann, J.; Anderson, R.; Thornton, T.; Harris, G.; Thomas, S.; Tracy, C. Characterization of Nickel Germanide Thin Films for Use as Contacts to p-Channel Germanium MOSFETs. IEEE Electron Device Lett. 2005, 26, 151–153. [Google Scholar] [CrossRef]

- Zhu, S.; Nakajima, A. Annealing Temperature Dependence on Nickel-Germanium Solid-State Reaction. Jpn. J. Appl. Phys. 2005, 24, L753–L755. [Google Scholar] [CrossRef]

- Seger, J.; Zhang, S.-L. Increased nucleation temperature of NiSi2 in the reaction of Ni thin films with Si1-xGex. Appl. Phys. Lett. 2002, 81, 1978–1980. [Google Scholar] [CrossRef]

- Li, M.; Shin, G.; Lee, J.; Oh, J.; Lee, H.-D. Low contact resistance of NiGe/p-Ge by indium segregation during Ni germanidation. AIP Adv. 2018, 8, 065312. [Google Scholar] [CrossRef]

- Miyoshi, H.; Ueno, T.; Akiyama, K.; Hirota, Y.; Kaitsuka, T.; Ueno, T.; Akiyama, K.; Hirota, Y. In-situ contact formation for ultra-low contact resistance NiGe using carrier activation enhancement (CAE) techniques for Ge CMOS. In Proceedings of the 2014 Symposium on VLSI Technology (VLSI-Technology): Digest of Technical Papers, Honolulu, HI, USA, 9–12 June 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 1–2. [Google Scholar]

- Gallacher, K.; Velha, P.; Paul, D.J.; MacLaren, I.; Myronov, M.; Leadley, D. Ohmic contacts to n-type germanium with low specific contact resistivity. Appl. Phys. Lett. 2012, 100, 02213. [Google Scholar] [CrossRef]

- Patterson, J.; Park, B.; Ritley, K.; Xiao, H.; Allen, L.; Rockett, A. Kinetics of Ni/a-Ge bilayer reactions. Thin Solid Films 1994, 253, 456–461. [Google Scholar] [CrossRef]

- Jensen, J.M.; Ly, S.; Johnson, D.C. Low-Temperature Preparation of High-Temperature Nickel Germanides Using Multilayer Reactants. Chem. Mater. 2003, 15, 4200–4204. [Google Scholar] [CrossRef]

- Li, J.; Hong, Q.Z.; Mayer, J.W.; Rathbun, L. Interfacial reaction between a Ni/Ge bilayer and silicon (100). J. Appl. Phys. 1989, 67, 2506–2511. [Google Scholar] [CrossRef]

- Prucnal, S.; Frigerio, J.; Napolitani, E.; Ballabio, A.; Berencén, Y.; Rebohle, L.; Wang, M.; Böttger, R.; Voelskow, M.; Isella, G.; et al. In situ ohmic contact formation for n-type Ge via non-equilibrium processing. Semicond. Sci. Technol. 2017, 32, 1–7. [Google Scholar] [CrossRef]

- Habuka, H.; Hara, A.; Karasawa, T.; Yoshioka, M. Heat Transport Analysis for Flash Lamp Annealing. Jpn. J. Appl. Phys 2007, 46, 937–942. [Google Scholar] [CrossRef]

- Rebohle, L.; Neubert, M.; Schumann, T.; Skorupa, W. Determination of the thermal cycle during flash lamp annealing without a direct temperature measurement. Int. J. Heat Mass Transf. 2018, 126, 1–8. [Google Scholar] [CrossRef]

- Chen, Y.-Y.; Juang, J.-Y. Finite element analysis and equivalent parallel-resistance model for conductive multilayer thin films. Meas. Sci. Technol. 2016, 27, 1–7. [Google Scholar] [CrossRef]

- Volkov, V.; Levashov, V.; Matveev, V.; Matveeva, L.; Khodos, I.; Kasumov, Y. Extraordinary Hall effect in nanoscale nickel films. Thin Solid Films 2011, 519, 4329–4333. [Google Scholar] [CrossRef]

- Jablonka, L.; Kubart, T.; Primetzhofer, D.; Abedin, A.; Hellstrom, P.-E.; Östling, M.; Jordan-Sweet, J.; Lavoie, C.; Zhang, S.-L.; Zhang, Z. Formation of nickel germanides from Ni layers with thickness below 10 nm. J. Vac. Sci. Technol. B 2017, 35, 020602. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, D.; Du, Y. Thermodynamic modeling of the germanium-nickel system. J. Alloys Compd. 2010, 491, 63–71. [Google Scholar] [CrossRef]

- De Schutter, B.; Devulder, W.; Schrauwen, A.; Van Stiphout, K.; Perkisas, T.; Bals, S.; Vantomme, A.; Detavernier, C. Phase formation in intermixed Ni–Ge thin films: Influence of Ge content and low-temperature nucleation of hexagonal nickel germanides. Microelectron. Eng. 2014, 120, 168–173. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, N.; Osipowicz, T.; Bera, L.K.; Zhu, C. Formation and thermal stability of nickel germanide on germanium substrate. Jpn. J. Appl. Phys. 2005, 44, L1389–L1391. [Google Scholar] [CrossRef]

- Tang, J.; Wang, C.-Y.; Xiu, F.; Lang, M.; Chu, L.-W.; Tsai, C.-J.; Chueh, Y.-L.; Chen, L.J.; Wang, K.L. Oxide-Confined Formation of Germanium Nanowire Heterostructure for High-Performance Transistors. ACS Nano 2011, 5, 6008–6015. [Google Scholar] [CrossRef]

- Knaepen, W.; Gaudet, S.; Detavernier, C.; Van Meirhaeghe, R.; Sweet, J.J.; Lavoie, C. In situ X-ray diffraction study of metal induced crystallization of amorphous germanium. J. Appl. Phys. 2009, 105, 1–7. [Google Scholar] [CrossRef]

- Habanyama, A.; Comrie, C. Intermetallic Compounds: Formation and Applications; Intechopen Limited: London, UK, 2018; p. 141. [Google Scholar]

- Donovan, E.P.; Spaepen, F.; Turnbull, D.; Poate, J.M.; Jacobson, D.C. Calorimetric studies of crystallization and relaxation of amorphous Si and Ge prepared by ion implantation. J. Appl. Phys. 1985, 57, 1795–1804. [Google Scholar] [CrossRef]

- Gouadec, G.; Colomban, P. Raman Spectroscopy of nanomaterials: How spectra relate to disorder, particle size and mechanical properties. Prog. Cryst. Growth Charact. Mater. 2007, 53, 1–56. [Google Scholar] [CrossRef]

- Geiler, H.; Glaser, E.; Gotz, G.; Wagner, M. Explosive crystallization in silicon. J. Appl. Phys. 1986, 59, 3091–3099. [Google Scholar] [CrossRef]

- Ohdaira, K.; Fujiwara, T.; Endo, Y.; Nishizaki, S.; Matsumura, H. Explosive crystallization of amorphous silicon films by flash lamp annealing. J. Appl. Phys. 2009, 106, 044907. [Google Scholar] [CrossRef]

- Ohdaira, K.; Matsumura, H. Flash-lamp-induced explosive crystallization of amorphous germanium films leaving behind periodic microstructures. Thin Solid Films 2012, 524, 161–165. [Google Scholar] [CrossRef]

- Matsukura, Y. Grain Boundary States in Silicon and Germanium. Jpn. J. Appl. Phys. 1963, 2, 91–98. [Google Scholar] [CrossRef]

| Ge Phase | Initial Ni Layer Thickness/nm | Rsh/Ω·sq−1 | Calculated ρ/μΩ·cm | Tpeak/°C |

|---|---|---|---|---|

| Amorphous | 10 | 8.86 ± 0.17 | 21.6 ± 0.4 | 500 |

| 30 | 2.74 ± 0.19 | 20.1 ± 1.4 | 690 | |

| 100 | 1.51 ± 0.03 | --- | 720 | |

| Polycrystalline | 10 | 6.04 ± 0.11 | 14.8 ± 0.3 | 650 |

| 30 | 1.84 ± 0.02 | 13.5 ± 0.2 | 710 | |

| 100 | 1.31 ± 0.02 | --- | 700 | |

| Single-crystalline | 10 | 6.08 ± 0.12 | 14.9 ± 0.3 | 870 |

| 30 | 1.99 ± 0.09 | 14.6 ± 0.7 | 880 | |

| 100 | 0.69 ± 0.06 | --- | 940 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Begeza, V.; Mehner, E.; Stöcker, H.; Xie, Y.; García, A.; Hübner, R.; Erb, D.; Zhou, S.; Rebohle, L. Formation of Thin NiGe Films by Magnetron Sputtering and Flash Lamp Annealing. Nanomaterials 2020, 10, 648. https://doi.org/10.3390/nano10040648

Begeza V, Mehner E, Stöcker H, Xie Y, García A, Hübner R, Erb D, Zhou S, Rebohle L. Formation of Thin NiGe Films by Magnetron Sputtering and Flash Lamp Annealing. Nanomaterials. 2020; 10(4):648. https://doi.org/10.3390/nano10040648

Chicago/Turabian StyleBegeza, Viktor, Erik Mehner, Hartmut Stöcker, Yufang Xie, Alejandro García, Rene Hübner, Denise Erb, Shengqiang Zhou, and Lars Rebohle. 2020. "Formation of Thin NiGe Films by Magnetron Sputtering and Flash Lamp Annealing" Nanomaterials 10, no. 4: 648. https://doi.org/10.3390/nano10040648

APA StyleBegeza, V., Mehner, E., Stöcker, H., Xie, Y., García, A., Hübner, R., Erb, D., Zhou, S., & Rebohle, L. (2020). Formation of Thin NiGe Films by Magnetron Sputtering and Flash Lamp Annealing. Nanomaterials, 10(4), 648. https://doi.org/10.3390/nano10040648