1. Introduction

With the extremely increasing loading and aggravation of axis load in the pavement industry, damages such as rutting, cracking etc., are happening more frequently on highways and urban roads [

1,

2,

3,

4]. Asphalt modification technology has been considered a practical approach to resolve these concerns by enhancing the durability of asphalt pavements. Crumb rubber (CRM), styrene-butadiene-rubber (SBR) and styrene-butadiene-styrene (SBS) are the three most widely applied modifiers, which are regarded as effective adhesive and cohesive performance enhancers of asphalt [

5,

6,

7,

8,

9]. However, the storage stability concern of modified asphalt has limited its widespread application. Engineers from asphalt plants have always worried about the separation of the modifier and asphalt during the storage and transportation process in elevated temperatures.

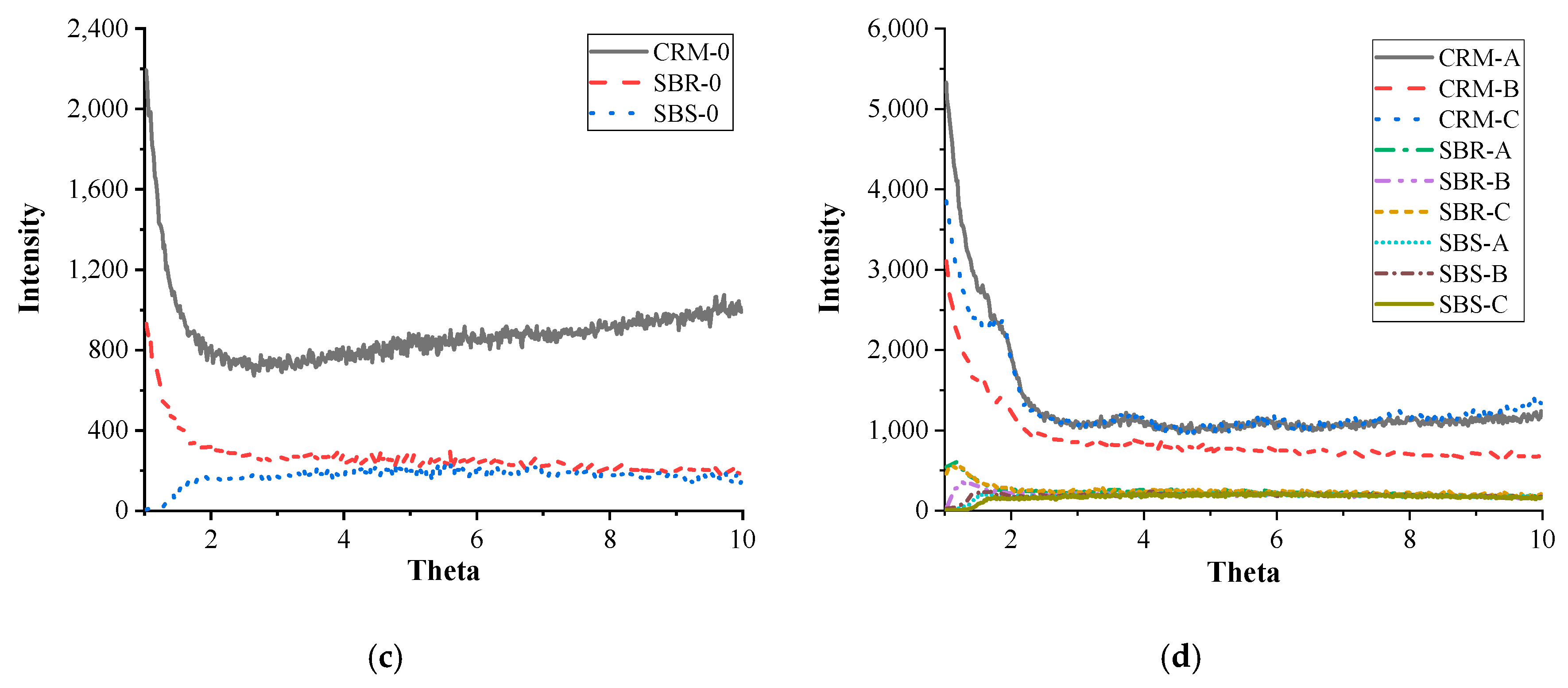

According to Stoke’s law, the phase separation phenomenon can be governed by the following equation [

10,

11,

12]:

where

vt is the settling velocity of dispersed particles,

α is the radius of dispersed particles, Δ

ρ is the density difference between two different phases,

g is gravitational acceleration, and

η is the dynamic viscosity of liquid medium.

Among different asphalt modifiers, CRM tends to sink in the liquid phase of modified asphalt during the storage process due to higher density compared to virgin asphalt, while SBR and SBS additives with lower density values tend to float in the upper part of liquid phase. The separation of modifier and raw asphalt results in a huge difference in composition and rheological properties between top and bottom portions of the polymer modified asphalt after storage. Previous studies indicate that this concern can be alleviated by adjusting the liquid asphalt density using bio-modification [

13,

14] or activating the crumb rubber [

15]. However, the improvement effect is not very satisfactory. Therefore, one potential method is addressed in this study by incorporating nanoclay into the polymer-modified asphalt, which can reduce the phase separation phenomenon by decreasing the migration velocity of insoluble additive of polymers in the liquid phase [

16,

17].

Nanoclay is a type of natural mineral mainly including kaolinite clay (KC), vermiculite (VMT) and montmorillonite (MMT), which has a 2:1 layered structure with two silica tetrahedral sheets sandwiching an alumina octahedral sheet. Nowadays, nanomaterials have been popularly applied as modifiers for construction materials [

12,

18,

19,

20]. Especially, the importance of layered clay minerals, also known as nanoclays, in terms of asphalt modification is gradually increasing. Nanoclays’ remarkable improvement on the rheological properties of asphalt has been widely reported by previous studies. Vargas et al., [

18] discovered that Organo-nanocomposite modified-asphalt can generate an intercalated structure using X-ray diffraction (XRD) and transmission electron microscopy (TEM). This indicates that the enhanced rheological properties may ascribe to the interaction behavior of the polymer chains in asphalt binder into the interlayer of clay. Yu et al., [

21] enhanced the storage stability of asphalt rubber by incorporating three types of nanoclays and improved the rheological properties through modification. Leng et al., [

22] found that clay/SBS modified bitumen composites have acceptable storage performance. The composites also showed better resistance to aging by reducing the oxidation of bitumen and the degradation of SBS. Galooyak et al., [

23] proved the improvement of nanoclays on the storage stability of SBS modified asphalt and confirmed the conclusion through morphological analysis. Thus, nanoclay was expected by the asphalt industry to serve as the storage stability improver of PMAs.

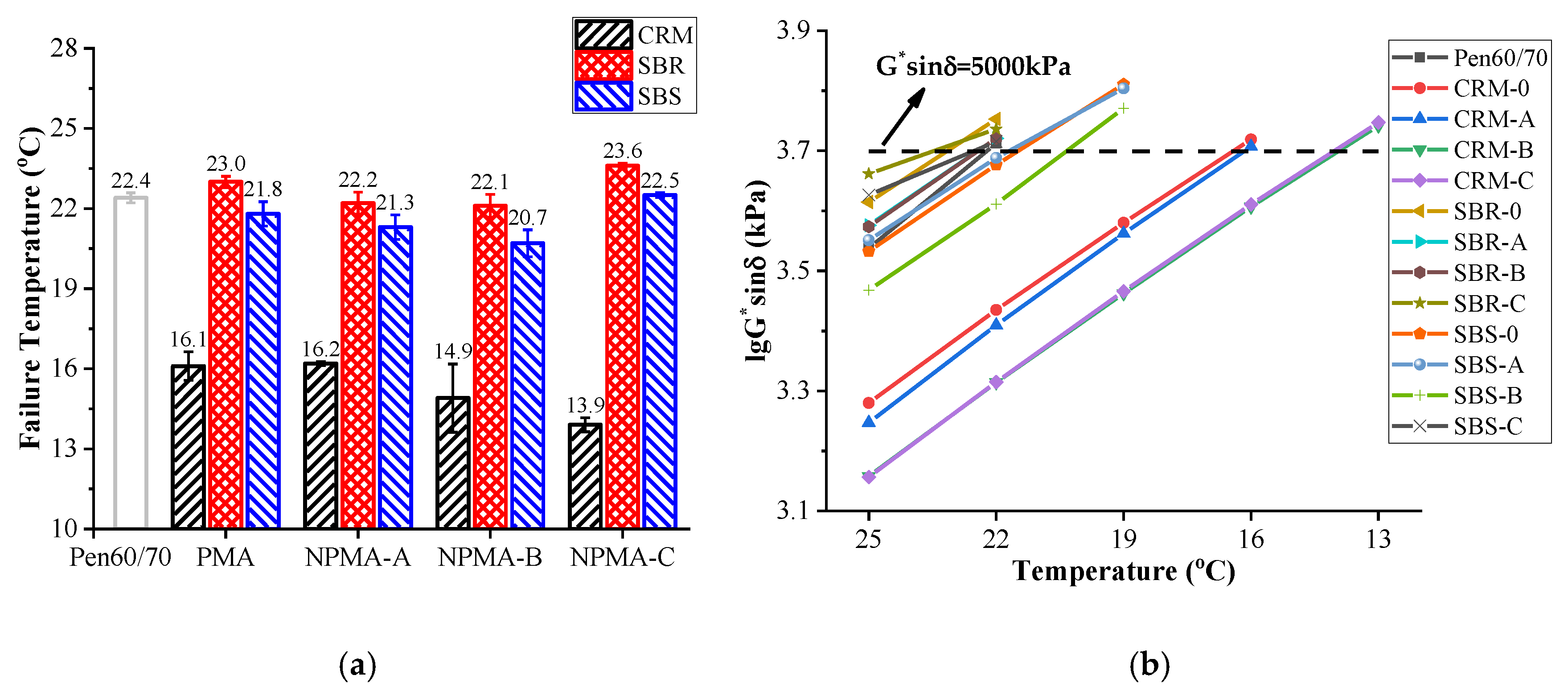

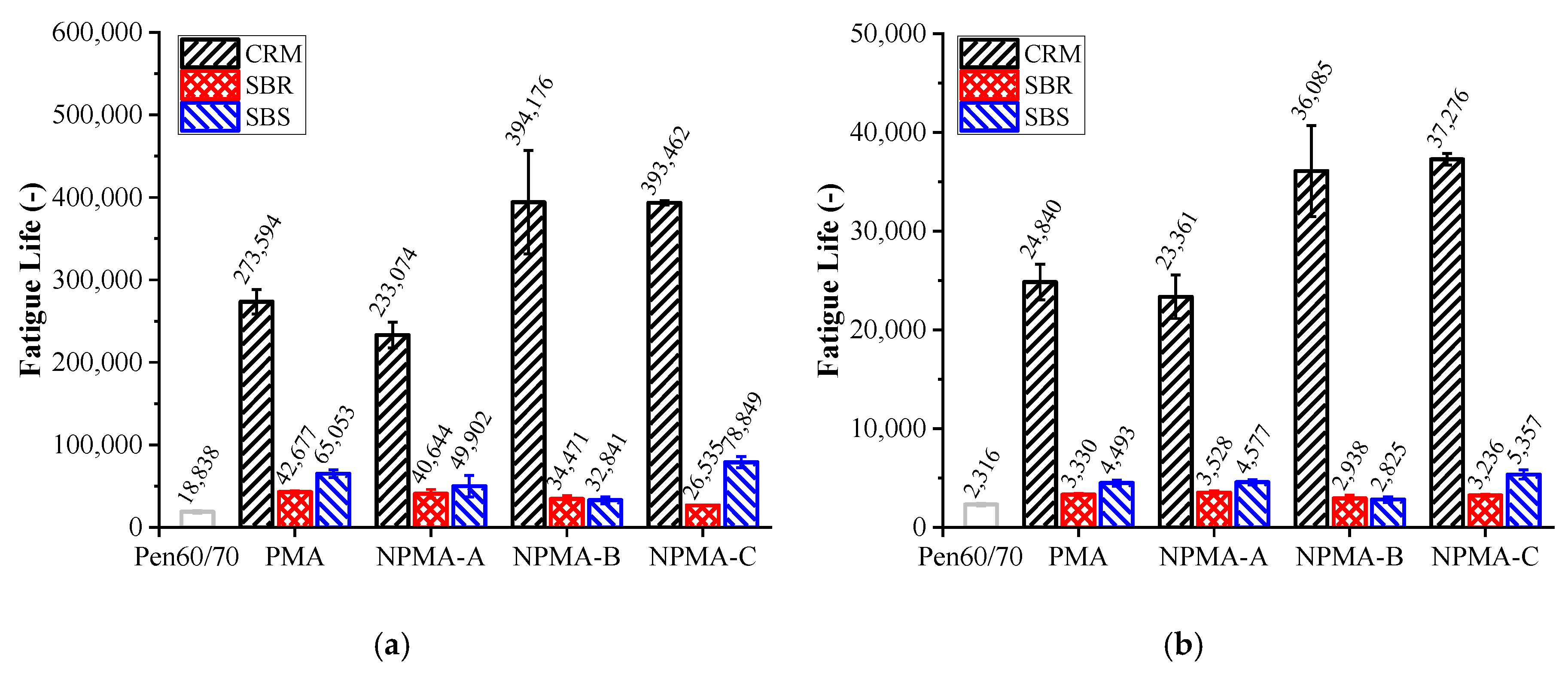

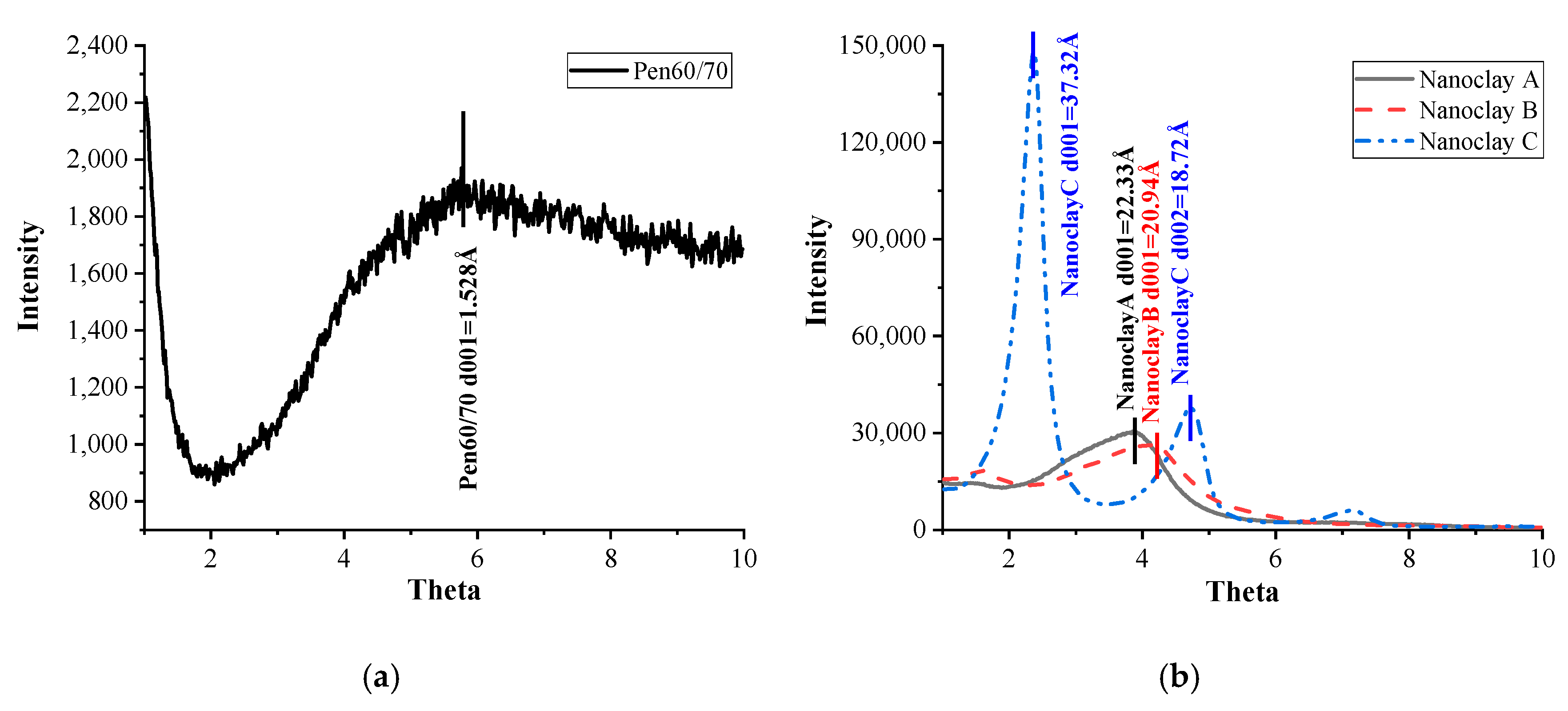

The objective of this study was to evaluate the feasibility of alleviating the storage stability concern of polymer-modified asphalt by incorporating nano-montmorillonite. To this end, three different types of nano-montmorillonites and three types of modifiers, i.e., CRM, SBR and SBS, were selected to prepare NPMAs. The rheological tests were performed to evaluate mechanical properties of NPMA binders when applied to pavement industry, among which the Superpave rutting factor test was chosen to control the content of these three modifiers. With the same PG82 grade, the content of modifier applied in each PMA binder was high enough to simulate the most unfavorable situation after storing in high temperature. In addition, the storage stability of modified binders was quantitatively analyzed through characterizing the differences in softening point, complex moduli and absorbance ratio of CRM/SBR/SBS in the infrared spectrum between the top and bottom portions of the sample after a lab-simulated storage process. Finally, an X-ray diffraction (XRD) test was conducted to investigate the layer gap distance variation of nano-montmorillonite to reveal the modification mechanism.

2. Materials and Methods

2.1. Materials and Sample Preparation

A Pen 60/70 virgin asphalt, with a penetration grade of 60/70, was used to prepare NPMA binders. In this study, all modified binders including polymer-modified asphalts, nano-montmorillonite-modified asphalts (NMA) and nano-montmorillonite-polymer modified asphalts were prepared by 10,000 rpm high shear incorporating modifiers with a certain dosage into virgin asphalt at 180 °C for 1 h. The selected dosages were 20 wt %, 7 wt % and 6 wt % by virgin asphalt for CRM (40-mesh), SBR and SBS, respectively, then a certain dosage of nano-montmorillonite (3 wt % by virgin asphalt) was adopted to prepare NPMA binders.

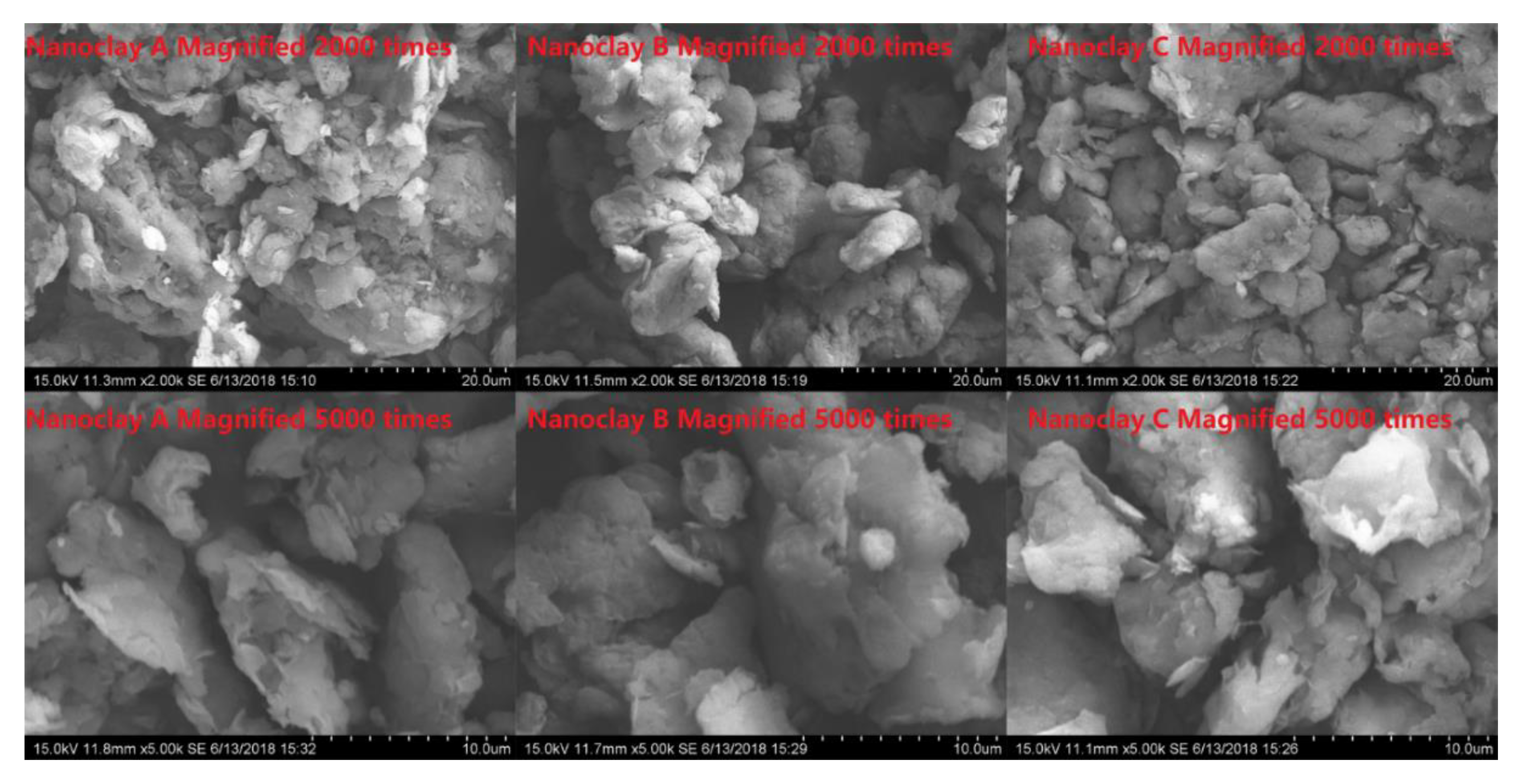

Three different types of nano-montmorillonites, labelled as A, B and C, were applied for asphalt modification. The nano-montmorillonite samples used in this study are organomodified nanoclay particles (provided by the Zhejiang Fenghong Clay Chemical Co., Ltd., Huzhou, China). The nanoclay samples are high-quality montmorillonite with high purity (at least 95% montmorillonite content). Besides, the nano-montmorillonite layer was forgeable due to the large specific surface area (750 m

2/g) and the unique layered one-dimensional nanostructure and morphology. Among the three nanoclays, A is pure montmorillonite with Na

+ inorganic group, while B and C are montmorillonites having inorganic groups exchanged with different alkyl ammonium ions. The ranking of their surface hydrophilic properties from high to low is A, B and C. Different from other two-dimensional and three-dimensional inorganic nanoparticles, the specific structure and morphology might lead to excellent mechanical properties, thermal properties, functional properties and physical properties of nano-montmorillonite-polymer modified asphalts. The morphologies of nano-montmorillonites were presented in

Figure 1, and the physical properties of different nano-montmorillonites were shown in

Table 1.

Table 2 detailed the information of each test sample.

2.2. Testing Program

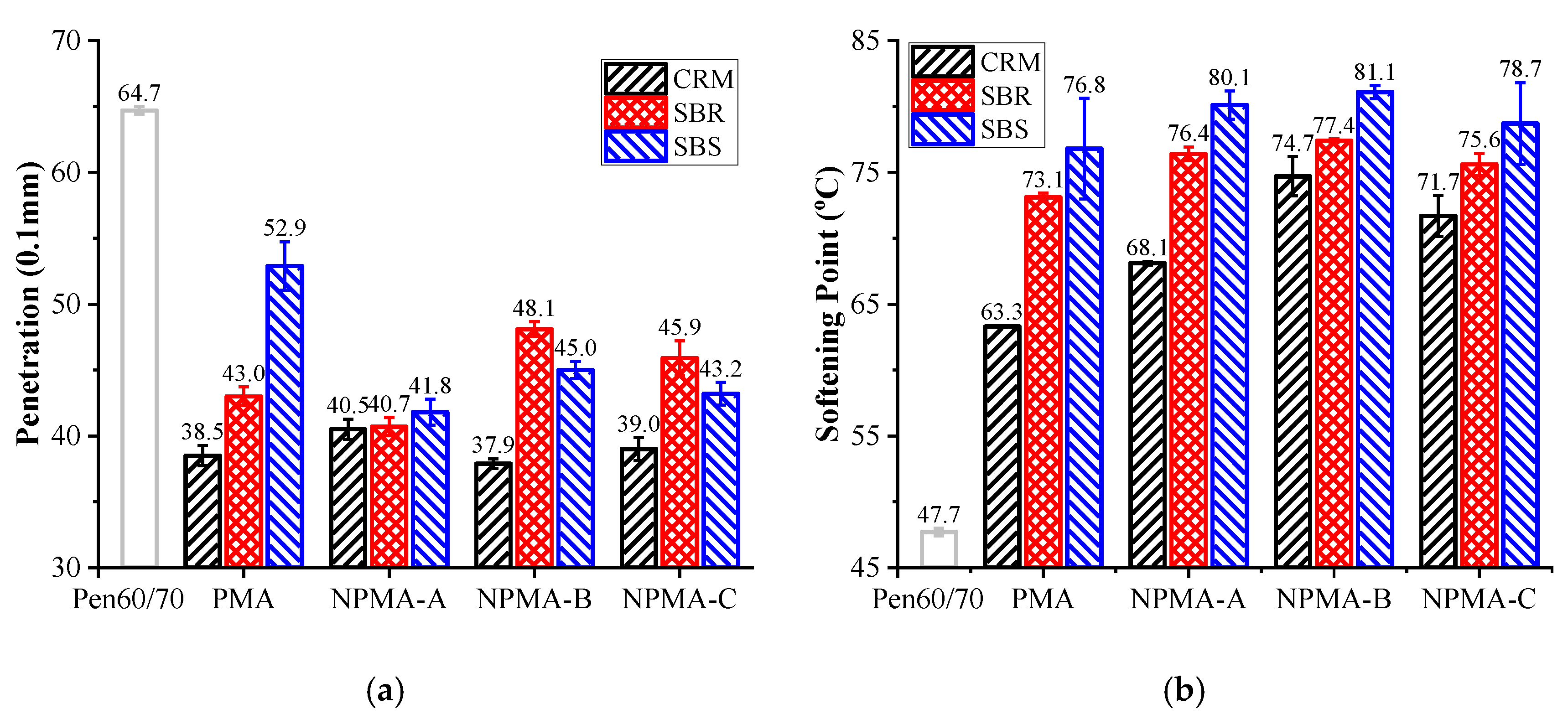

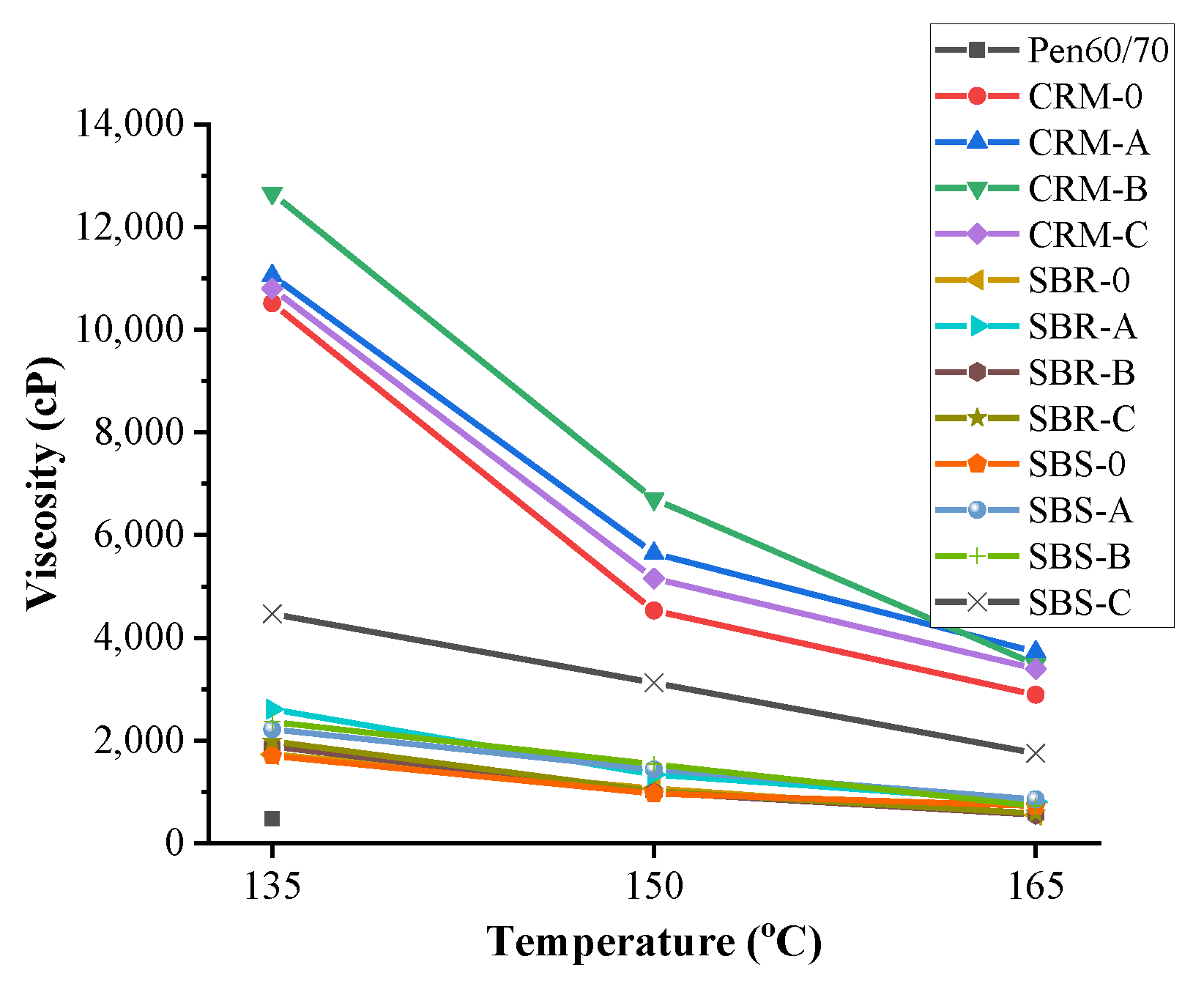

The conventional physical properties, including penetration and softening point, were selected as the indicators for the general properties of test binders. The workability was evaluated using a Brookfield viscometer (RVD VII+) through measuring rotational viscosities of asphalt specimen at three different temperatures.

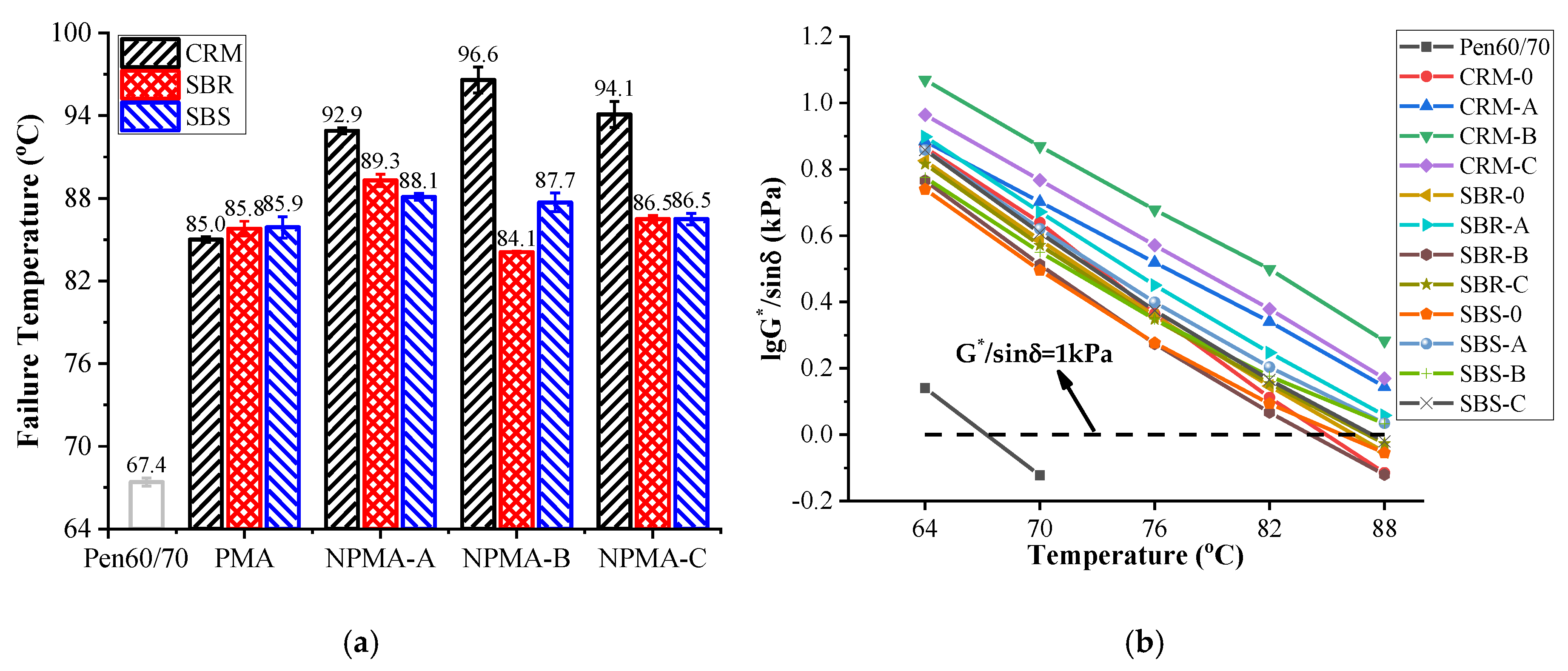

The rheological properties of modified binders were characterized using a dynamic shear rheometer (DSR, Malvern Kinexus Lab+, Malvern analytical Company, UK). The Superpave rutting factor (G*/sin δ) test and multiple stress creep recovery (MSCR) tests were conducted to evaluate the high temperature rutting resistance of asphalt samples, while the intermediate temperature fatigue resistance was analyzed through the Superpave fatigue factor (G*sin δ) test and linear amplitude sweep (LAS) test. The test binders for the MSCR test were aged by the standard rolling thin film oven (RTFO) process, while those for the fatigue test were aged by both RTFO and pressure aging vessel (PAV) processes. The bending beam rheometer (BBR) test was also performed to evaluate the low temperature cracking resistance performance of the RTFO + PAV aged samples.

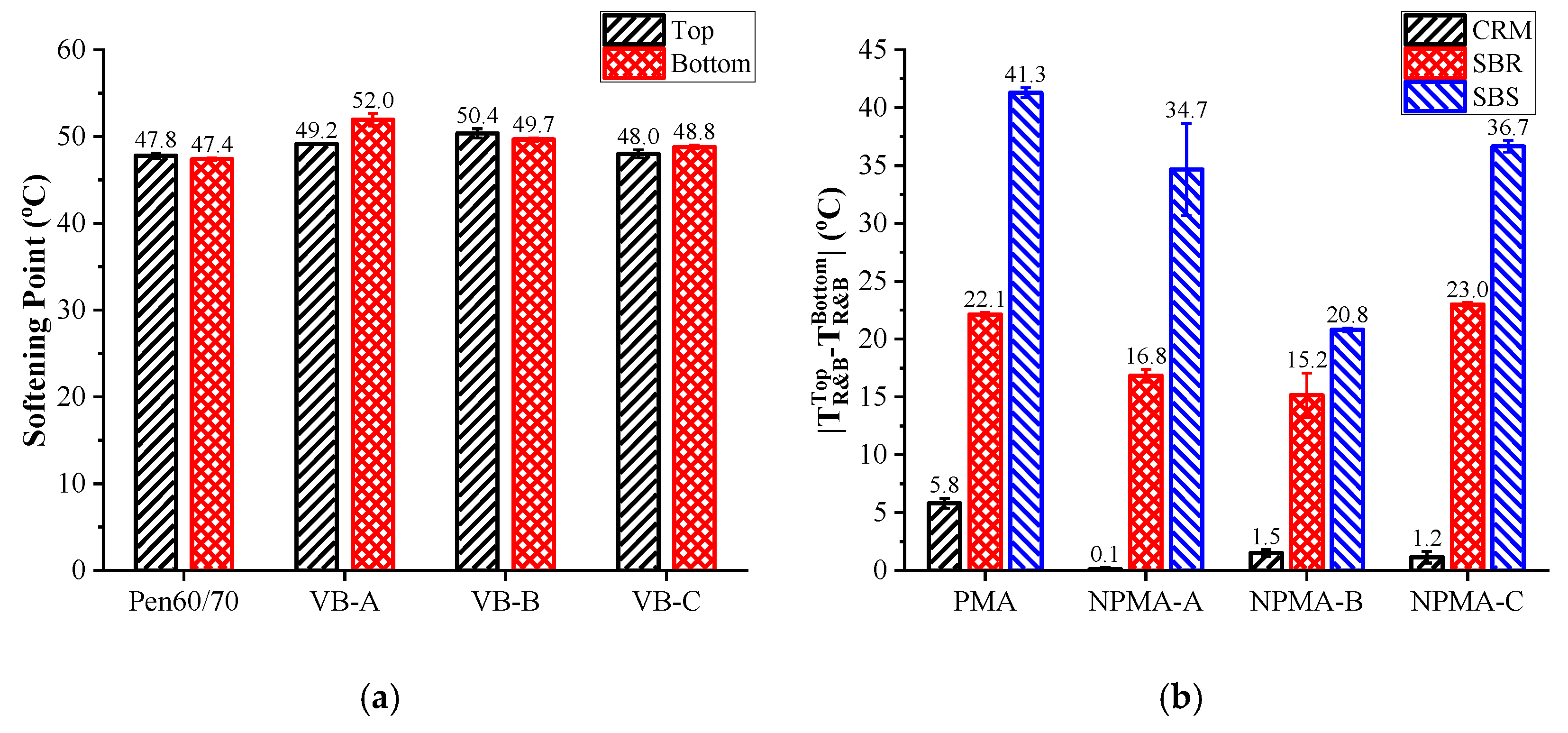

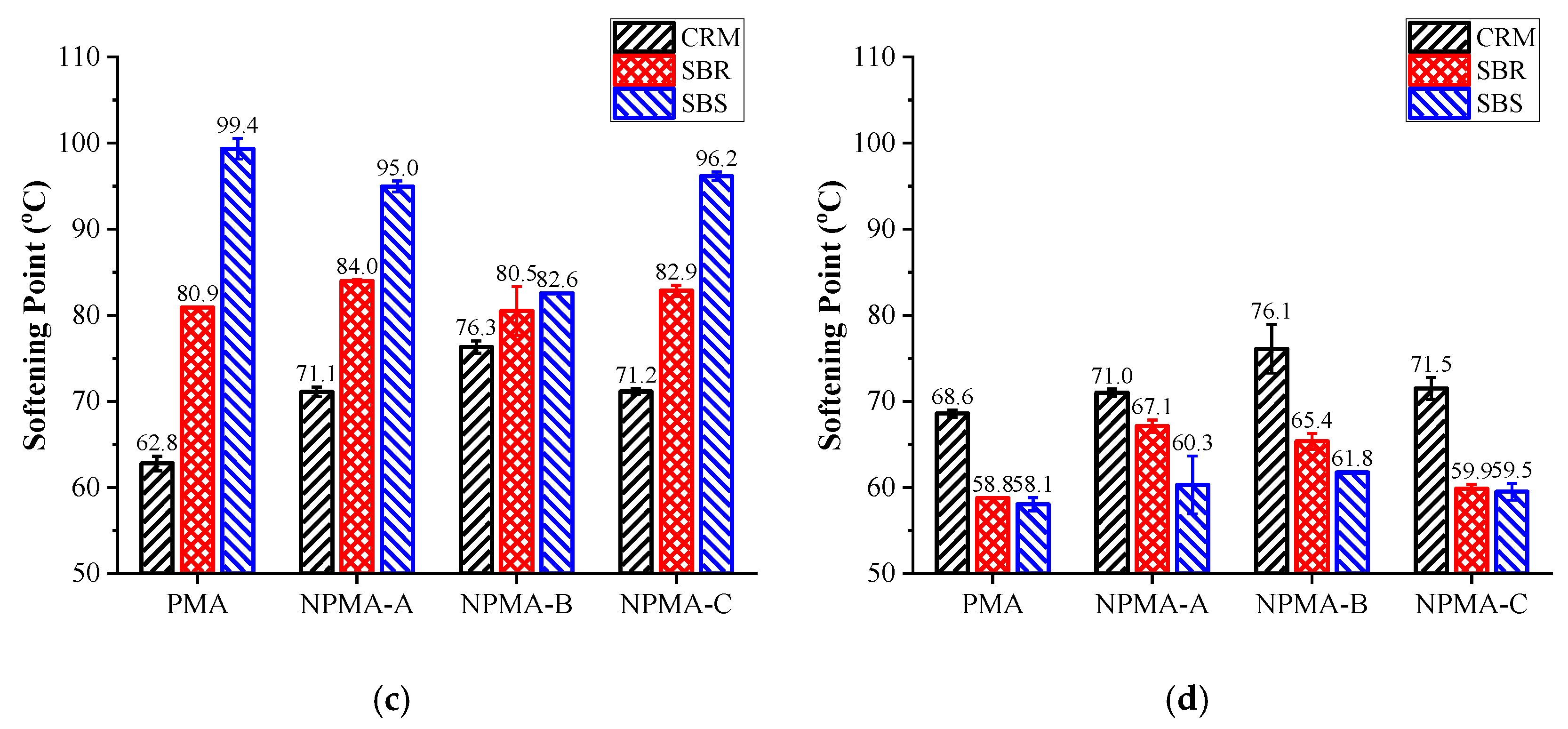

The storage stability of modified binders was quantitatively analyzed through characterizing the differences in softening point [

16,

17], complex moduli [

24,

25,

26] and absorbance ratio of CRM/SBR/SBS in the infrared spectrum between the top and bottom portions of the sample after storing. For FTIR tests, the test binder with a thickness of approximately 1 mm was placed in a transmission holder and scanned in order to obtain infrared spectroscopy ranging from 4,000 to 400 cm

−1. According to ASTM 7173 [

27], to simulate the high temperature storing process in the laboratory, about 70 g of hot asphalt was poured into an aluminum tube with a diameter of 25 mm. Before cutting the tube into three equal parts horizontally, it was being stored at 163 °C for 48 h followed by cooling down at −5 °C.

To investigate the modification mechanism of nano-montmorillonite on storage stability, X-ray diffraction (XRD) tests were conducted to investigate the layer gap distance variation.

Table 3 shows the detailed information of conducted tests in this study.

4. Conclusions

This study evaluated the effect of nano-montmorillonite on the properties of modified asphalt with different polymers including CRM, SBR and SBS. Rheological and chemical tests were conducted to characterize the rheological properties of obtained NPMA binders and reveal the modification mechanism of nano-montmorillonite on the storing performance. According to test results, the findings are obtained as follows.

Adding nano-montmorillonite slightly improved the viscosity of PMA binders, and had insignificant effects on their rheological properties.

The incorporation of all three types of nano-montmorillonites effectively alleviates the storage stability concern of CRM-0, while having a limited positive effect on SBR-0 and SBS-0.

Nanoclay B, pure montmorillonite with Hydroxyl organic ammonium, exhibited the most obvious effect in improving the storage stability of the three selected PMA binders.

This study suggests that nano-montmorillonite is a promising modifier to alleviate the storage stability concern for asphalt with polymer modifiers. Future studies will focus on investigating the interaction mechanism among nano-montmorillonite, virgin asphalt and different modifiers, as well as the effects of nano-montmorillonites on the engineering performance of asphalt mixture.