Abstract

Thin-film transistor (TFT) devices composed of metal oxide semiconductors have attracted tremendous research attention globally in recent years. Owing to their ability to offer mobility, metal oxide semiconductor materials can enable high-performance TFTs for next-generation integrated display devices. Nevertheless, further breakthroughs of metal oxide TFTs are mainly obstructed by their long-term variability, the reason for which is not yet fully understood. Herein, TFTs based on InSnZnO (ITZO) with various thicknesses (TITZO) were prepared and their long-term stabilities under test temperatures and drain current stress were investigated. The results indicate that ITZO TFTs exhibit outstanding electrical properties regardless of the TITZO, including a high saturated mobility of over 35 cm2V−1s−1 and sharp subthreshold swing. Note that the transfer and output characteristic curves of the device with a thick TITZO of 100 nm express an abnormal current surge when high gate and drain voltages are exerted, which is attributed to the floating body effect, caused when the imposed electric field induces impact ionization near the drain side. More interestingly, these drain current stress results further suggest that the abnormal shift behavior of the electrical properties of the ITZO TFTs with a TITZO of greater than 75 nm is observed to deteriorate gradually with increasing temperature and drain current bias. This study addresses that such a degradation effect should be restrained for the operation of high-mobility devices.

1. Introduction

Metal oxide semiconductors have recently emerged as extremely sought-after materials for thin-film transistor (TFT) applications [1,2,3,4,5,6]. Over the past decade, the mobility (μ) of TFTs employing these semiconductors, such as InGaZnO, has greatly increased, and is comparable to that of polysilicon-based devices [7]. These metal oxide semiconductors also possess promise for various optoelectronic applications, including photodetectors and solar cells [8,9,10,11]. Inspired by the achievement of metal oxide films, another category of these materials, called InSnZnO (ITZO), was studied by our group in 2012 [12]. From the perspective of potential applications in flat panel displays (FPDs), the ITZO TFTs have been gifted with desirable electrical properties, especially the high μ of >30 cm2V−1s−1, which originates from the 5 s orbital overlaps of In and Sn atoms [13].

Besides the tremendous developments of metal oxide semiconductors and TFT structures, an intensive understanding of the charge-carrier transport processes is beneficial to further improving the TFT characteristics. In addition, the systematic carrier motion model extending to the internal active layer, which is the core of operating TFT devices, still needs to be studied. Adjusting the metal oxide thickness is an intuitive and effective parameter of the model to investigate the charge transport processes in the bulk of the active layer with [14,15,16], while leaving the condition of the adjacent interfaces almost unchanged. Apart from the design and fabrication of TFT architectures, the measurement approach is also a crucial step to set up the fundamental physical framework [17]. In addition, in terms of TFT devices, the long-term stabilities are critical to drive TFT-contained integrated circuits in FPDs [18,19]. Moreover, the drain current stress is a common working procedure in current-biased TFTs [20].

In this regard, here the typical TFT device structure is considered to verify the universality of the overall framework. On the basis of the device’s architecture, channel layers with different thicknesses (TITZO) are then designed. To evaluate the device’s stability, the measurement conditions and working environment are taken into consideration. More importantly, to understand the carrier transport mechanism in the devices, both the channel layer thickness and drain current stress (DCS) should be fully considered.

2. Experimental

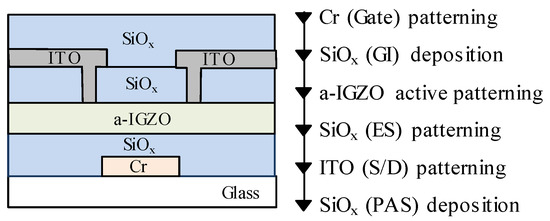

Figure 1 displays the device architecture and fabrication procedure of ITZO-based TFT, which refers to our previous publication [21]. The chromium gate electrode was prepared on the glass substrate, and the SiOx gate insulator with a thickness of 150 nm was formed by plasma-enhanced chemical vapor deposition (PECVD). For the active layers, ITZO films with the thicknesses of 45, 75, and 100 nm were prepared by DC magnetron sputtering with a mixed gas of Ar/O2 = 15/15 sccm at a deposition pressure of 1 Pa. Then, a 200 nm thick SiOx etch-stopper was deposited by PECVD, and indium-tin-oxide source and drain electrodes were formed. Finally, a SiOx passivation layer was fabricated by PECVD. After the fabrication of devices with channel widths of 50 μm and lengths of 20 μm, the TFTs were post-treated in a nitrogen atmosphere at 350 °C for 1 h. All the current–voltage (I–V) results were evaluated by an Agilent 4156C precision semiconductor parameter analyzer in air.

Figure 1.

Device architecture and preparation process of the ITZO TFT.

3. Results and Discussion

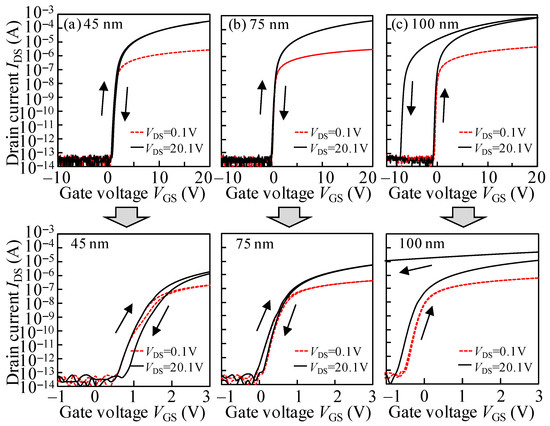

The transfer curves of TFT devices with different TITZO were evaluated at a drain voltage (VDS) of 0.1 and 20.1 V, as shown in Figure 2. The linear (μlin) and saturated (μsat) mobilities were estimated on the basis of previous literature [21]. The turn-on voltage (VON) was extracted from the gate voltage (VGS) at a drain current (IDS) of 1 nA. The hysteresis (ΔVH) was calculated from the VON difference value between the forward and reverse scans of the transfer curves. The subthreshold swing (SS) was defined to be dVGS/dlog10(IDS). The respective parameters were extracted from the forward sweep, as tabulated in Table 1.

Figure 2.

Transfer characteristics of TFT devices with different TITZO of (a) 45, (b) 75, and (c) 100 nm evaluated at a VDS of 0.1 and 20.1 V.

Table 1.

The electrical parameters of a-ITZO TFTs with various TITZO extracted from the forward sweep.

For the device with a 45 nm TITZO, a μlin of 28.76 cm2V−1s−1, μsat of 35.23 cm2V−1s−1, VON of 1.19 V, ΔVH of 0.22 V, and SS of 169 mV/dec. were calculated. The observed results indicate that ITZO-based TFTs exhibit outstanding electrical characteristics which are generally superior to the results of IGZO-based TFT devices [22]. The μlin gradually rose to 33.27 and 46.36 cm2∙V−1∙s−1 when the TITZO thickened to 75 and 100 nm, respectively. For the mobility extracted from the saturation region, the μsat significantly increased to 46.90 cm2∙V−1∙s−1 for the 75 nm TITZO device, and sharply soared to 130.10 cm2∙V−1∙s−1 as the TITZO further thickened to 100 nm. It was found that the IDS values significantly increased with the increase in TITZO. In general, the increase in the μ and IDS of the thicker channel TFT was attributed to the increase in carrier concentration and decrease in the density of subgap states, which were based on the percolation conduction and multiple trapping and release model [23,24]. Combined with the transfer curves observed from the 100 nm TITZO TFT measured with a VDS of 20.1 V and VGS of ~20 V, we can conclude that the calculated μsat hardly represents the intrinsic properties of the ITZO material. In the sections of DCS-induced instabilities, for the devices with thicker TITZO TFT and measurement modes with a high VDS and VGS bias, this conclusion of the sudden increase in the μsat was further confirmed. In addition, the VON slightly shifted to 0.43 and −0.33 V as the TITZO gradually thickened to 75 and 100 nm, respectively. Because the free carrier content in the bulk is directly proportional to the thickness of samples [25], the VON changed in the negative VGS direction with the increase in the TITZO. The negligible clockwise hysteresis was observed for the devices with a TITZO of 45 and 75 nm. As the TITZO was enlarged to 100 nm, an abnormal anticlockwise hysteresis of −6.38 V was obtained. In other words, the VGS was swept forward from −10 to 20 V with 20.1 V VDS.

On the basis of the previous publication [26], high-μ TFTs experiencing drain current stress may induce the floating body effect that impacts ionization, producing electron-hole pairs in the drain side. The generated holes drift to the ITZO/etch-stopper interface due to the longitudinal electric field and flow to the source region due to the transverse electric field. Furthermore, for the TFTs with a thick TITZO, superfluous holes are trapped in the source area of the back-channel interface, naturally causing the transfer curve’s negative shift. Therefore, in terms of 100-nm-thick ITZO TFTs, a tremendous shift in the negative VGS direction was observed in the transfer properties, leading to the great hysteresis. Interestingly, the SS values manifest the gradient descent as 130 and 88 mV/dec. as the TITZO increases to 75 and 100 nm, respectively. This behavior is due to the fact that the densities of interface traps at the ITZO/etch-stopper area are lessened as the TITZO increases [27]. It is commonly known that the SS is the direct parameter by which to evaluate the integration of trap state densities in the ITZO film and corresponding interfaces [28]. The results further imply that the interface quality is directly related to the device properties.

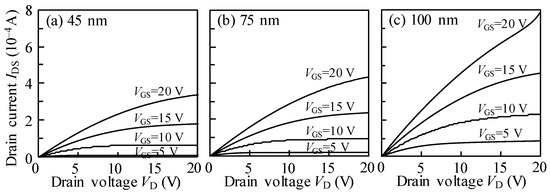

Figure 3 plots the typical output curves of ITZO TFTs with various TITZO. The VGS was altered from 5 to 20 V in increments of 5 V. All devices exhibited standard n-type field-effect transistor behavior. When the TFTs were switched on, the output properties presented enhancement-mode operation with a clear pinch-off phenomenon regardless of the TITZO. For the devices based on 45 and 75 nm TITZO, the current saturation response was evidently observed. The saturation current under the identical VGS and VDS biases gradually increased with the TITZO. For 100 nm TITZO TFT, a similar current saturation response was also obtained when the VGS was controlled below 15 V. However, the output characteristics expressed a current increase under high drain and source voltages of 20 V. This phenomenon can be explained by the kink effect that impacts ionization-induced hole flow towards the source side. Moreover, electrons were injected into the channel from the source side and collected at the drain region. The extra drain current accelerated the impact ionization probability. Consequently, this effect led to a sharp rise in the output characteristics, which was in agreement with the results for the transfer characteristics.

Figure 3.

Output characteristics of TFT devices with various TITZO of (a) 45, (b) 75, and (c) 100 nm.

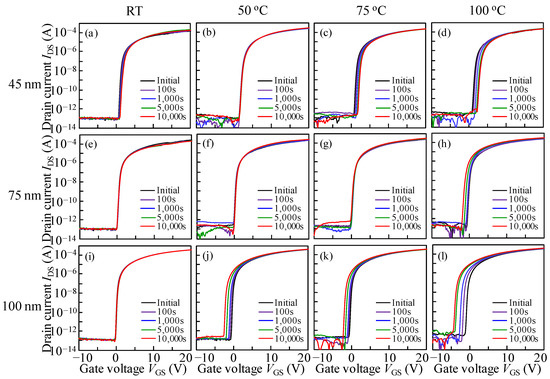

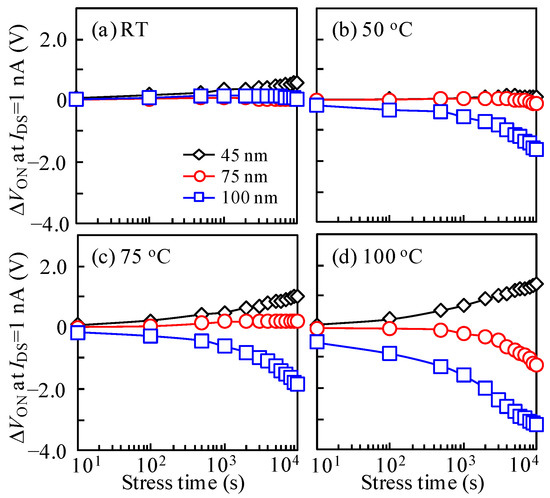

To comprehend the influence of measurement temperatures on the DCS-induced instability of ITZO TFTs with various TITZO, the test platform temperatures were set to 25, 50, 75, and 100 °C, and the DCS of VGS = VDS = 10 V was fixed for 104 s. To avoid the abnormal transfer curve shift occurring, a VDS of 10.1 V was chosen. The variations in the transfer properties of ITZO TFTs with different TITZO were studied under DCS at various test temperatures (Figure 4). Correspondingly, the changes in VON (ΔVON) accompanied by DCS time under various test temperatures are shown in Figure 5. It is noted that the current fluctuations in the OFF-current region are observed in some I-V curves. This phenomenon may be due to the poor shielding effect of the test platform during the measurement process. Even so, a current level of below 10−13 A had no effect on the DCS evaluation. For the devices measured at room temperature, all of the transfer curves exhibited stable behaviors even throughout a long-term duration, suggesting that a high quality GI layer has been fabricated, and the electrons were seldom captured at the ITZO/GI interface. As the test temperature was raised to 50 °C, the electrical properties of 45 and 75 nm TITZO TFTs still presented a steady state. However, in terms of the device with a thick TITZO of 100 nm, a parallel shift in the transfer characteristics with a ΔVON of −1.60 V was observed after the DCS duration. The results indicate that a high temperature promotes thermal movement of the electron, contributing to the occurrence probability of impact ionization. As the temperature was further adjusted to 75 °C, the transfer curves of the TFT with 45 nm TITZO shifted by 1.02 V towards a positive VGS direction with unchanged SS during the 104 s stress time, demonstrating that the generated electrons induced by thermal activation were trapped at the front interface. It was noted that the device with a 75 nm TITZO still maintained excellent electrical stability. In the case of the 100 nm TITZO device, the motion behavior was enlarged and the ΔVON was aggravated to −1.85 V. When the platform temperature was increased to a harsh condition of 100 °C, the transfer curves of the TFT with a 45 nm TITZO continually changed by 1.40 V after the DCS duration. In contrast, for the TITZO thicknesses of 75 and 100 nm, the transfer characteristics showed parallel movement in a negative way and the ΔVON values were respectively exacerbated to −1.27 and −3.18 V over the whole DCS time. These results state that temperature plays a key role in exciting electron movement, thereby concretizing and enlarging electron-related effects.

Figure 4.

Evolution of transfer characteristics as a function of DCS (VGS = VDS = 10 V) duration for 104 s for the devices with a TITZO of 45 nm measured at test temperatures of (a) 25, (b) 50, (c) 75, and (d) 100 °C; with a TITZO of 75 nm measured at test temperatures of (e) 25, (f) 50, (g) 75, and (h) 100 °C; and with a TITZO of 100 nm measured at test temperatures of (i) 25, (j) 50, (k) 75, and (l) 100 °C.

Figure 5.

Variation in the ΔVON with DCS duration for the TFT devices measured at test temperatures of (a) RT, (b) 50, (c) 75, and (d) 100 °C.

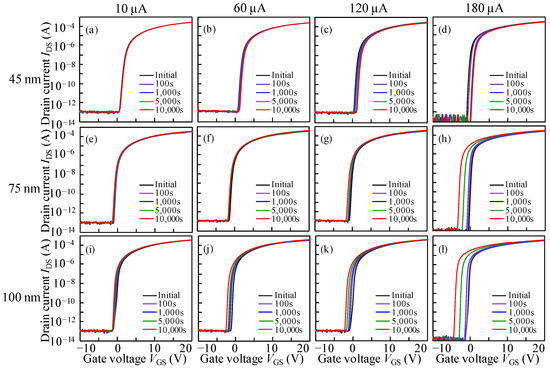

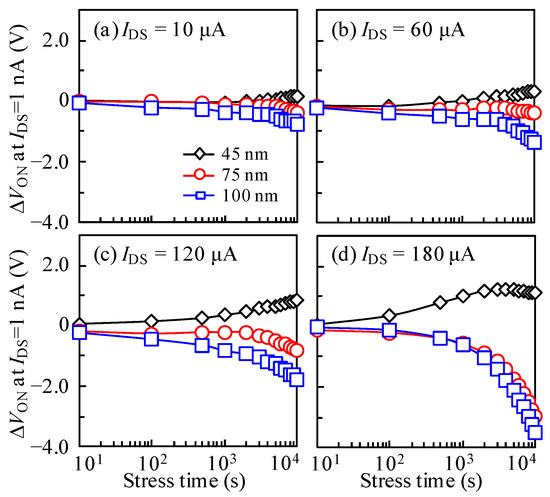

To further study DCS-caused instability of the ITZO TFTs with various TITZO, the IDS values of 10, 60, 120, and 180 μA adjusted by the gate and drain voltages (VGS = VDS) were applied at 50 °C up to the stress duration of 104 s. It should be noted that these IDS values are much higher than those applied in conventional active-matrix organic light-emitting diodes displays (~2 μA) [29]. Figure 6 displays the corresponding variation in the transfer curves of the devices. Note that the transfer characteristics of all TFTs under various IDS stresses exhibit a parallel shift without SS degradation. The corresponding ΔVON fluctuations are plotted in Figure 7. All devices exhibit acceptable reliability under 10 μA DCS irrespective of the TITZO, implying that few electron trapping sites exist in the ITZO bulk and at the ITZO/GI interface. Interestingly, with the increase in the IDS stress, a ΔVON with a significant TITZO dependence was observed. For the 45 nm TITZO TFT, the VON positively shifted with the increase in the IDS stress. The positive shift behavior was enlarged by increasing the stress duration. For the 180 μA IDS stress, the transfer curves parallel shifted by 1.21 V towards the positive VGS direction under the stress duration of 3000 s. In the subsequent stress time, the ΔVON shift was saturated in a short stress time, and then slightly moved back to 1.10 V. In contrast, when the thickness increased to 75 and 100 nm, the transfer curves completely changed in the negative VGS direction irrespective of the IDS stress. Under the 180 μA IDS stress, the ΔVON of the TFTs with TITZO of 75 and 100 nm decreased by −2.98 and −3.50 V, respectively. The results demonstrate that, under identical IDS stress, the negative VON shift is accelerated with the increase in TITZO.

Figure 6.

Evolution of transfer characteristics as a function of 104 s DCS duration with the test temperature of 50 °C for the devices with a TITZO of 45 nm under IDS stresses of (a) 10, (b) 60, (c) 120, and (d) 180 μA; with a TITZO of 75 nm under IDS stresses of (e) 10, (f) 60, (g) 120, and (h) 180 μA; and with a TITZO of 100 nm under IDS stresses of (i) 10, (j) 60, (k) 120, and (l) 180 μA.

Figure 7.

Variation in the ΔVON with DCS duration for the TFT devices measured at IDS stresses of (a) 10, (b) 60, (c) 120, and (d) 180 μA.

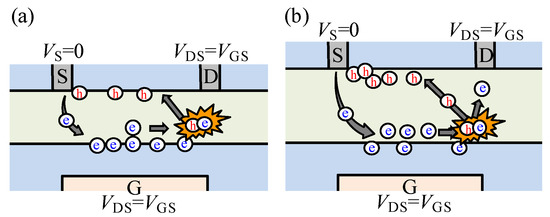

Generally, the positive VON shift was due to electron trapping at the front-channel interface, while the VON shift to the negative VGS direction was due to hole trapping at the active layer/etch-stopper interface under the IDS stress. For the 45 nm TITZO device under low IDS (< 180 μA) stress (VDS = VGS), electrons drifted to the gate insulator/ITZO region. Simultaneously, electron trapping occurred immediately at the gate insulator/ITZO interface, as illustrated in the corresponding schematic diagram (Figure 8a).

Figure 8.

The schematic diagram of impact ionization mechanism of DCS-originated instability in the devices with a TITZO of (a) 45 and (b) 75 and 100 nm.

As the IDS stress increases, the electron trapping probability is enhanced. When the IDS increases to 180 μA, electron trapping is the main origin of the positive VON shift within the stress duration of 1000 s. Consequently, a saturated trapping behavior is then observed. When the stress time exceeds 3000 s, hole trapping seems to become a major reason for the slightly negative VON shift. It can be explained by the impact ionization phenomenon [21], which induces the generation of an electron-hole pair. Consequently, the excited charges are trapped at the front- and back-channel interfaces. However, the electron trapping seems to become saturated at the gate insulator/ITZO region. Therefore, the extra electrons are drained from the drain electrode. The holes generated near the drain side migrate to the source region along the back-channel interface and accumulate near the source region. As a result, the VON shifts from a positive to negative VGS direction. When the TITZO increases to 75 nm and more, a clear negative VON shift is observed under various IDS stresses, demonstrating that hole trapping at the ITZO/etch-stopper interface is the main cause of the negative VON shift. With the increase in the TITZO, the negative VON shift is accelerated under the identical IDS stress. The results demonstrate that, for the thicker TITZO TFTs, electrons injected from the source will experience a longer duration prior to reaching the gate insulator/ITZO interface under the vertical electric field. Simultaneously, electrons are subjected to a driving force from the lateral electric field. It is noted that the identical IDS bias is controlled with different VGS = VDS values for various TITZO TFTs. Therefore, the probability of electron-induced impact ionization is greatly increased with sufficient space and time, contributing to more excited carriers (Figure 8b). It is noted that the forward and reverse transfer curves were compared after DCS, and the similar transfer curves were obtained without SS degradation. Therefore, the results suggest that the observed phenomenon is hard to attribute to the increase in the donor-like states near the source side of the TFTs.

On the basis of the above-mentioned discussions, the obtained results suggest that, in the high-μ devices, the DCS-induced impact ionization is dependent on the generation of electron-hole pairs, which is closely proportional to the channel layer thickness, test temperature, applied electric field, and drain current density. In other words, the structural design of the devices and the control of test conditions should be well considered to promote the stability performance of the devices.

4. Conclusions

In summary, the ITZO TFTs with various TITZO were fabricated and the DCS-induced instabilities under different test temperatures and IDS values were investigated. All the TFT devices possessed excellent electrical properties irrespective of the TITZO, including a high μsat of >35 cm2V−1s−1 and steep SS. For 100 nm TITZO devices evaluated at high VGS and VDS values, the transfer and output characteristics exhibited an abnormal rise in current. This phenomenon can be ascribed to the floating body effect that impacts ionization occurring near the drain region. More importantly, with the variation in the TITZO, the synergistic effects of temperature and IDS value on DCS-induced instability were well understood. The results further demonstrate that the abnormal negative shift behavior in TFT devices with the TITZO of greater than 75 nm is gradually enlarged with the increase in temperature and IDS values. This study provides a method with which to comprehend the DCS-originating degradations for high-performance ITZO-based TFT devices.

Author Contributions

Conceptualization, M.F. and D.W.; Methodology, D.W., S.T., and K.Y.; Validation, M.F. and D.W.; Formal Analysis, D.W.; Writing-Original Draft Preparation, D.W.; Writing-Review & Editing, M.F. and D.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key Research and Development Program of China (2016YFA0202403), the National Nature Science Foundation of China (61674098, 91733301), the Fundamental Research Funds for the Central Universities (GK201903052), the Changjiang Scholar and the Innovative Research Team (IRT_14R33), the 111 Project (B14041), and the Chinese National 1000-talent-plan program (Grant No. 111001034). This work was partly supported by JSPS KAKENHI Grant Number 16K06309.

Acknowledgments

The authors would like to thank Idemitsu Kosan Co. Ltd., for their support throughout this work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nomura, K.; Ohta, H.; Takagi, A.; Kamiya, T.; Hirano, M.; Hosono, H. Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 2004, 432, 488–492. [Google Scholar] [CrossRef] [PubMed]

- Hirao, T.; Furuta, M.; Hiramatsu, T.; Matsuda, T.; Li, C.; Furuta, H.; Hokari, H.; Yoshida, M.; Ishii, H.; Kakegawa, M. Bottom-gate zinc oxide thin-film transistors (ZnO TFTs) for AM-LCDs. IEEE Trans. Electron Devices 2008, 55, 3136–3142. [Google Scholar] [CrossRef]

- Shin, K.Y.; Tak, Y.J.; Kim, W.-G.; Hong, S.; Kim, H.J. Improvement of Electrical Characteristics and Stability of Amorphous Indium Gallium Zinc Oxide Thin Film Transistors Using Nitrocellulose Passivation Layer. ACS Appl. Mater. Interfaces 2019, 9, 13278–13285. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.L.; Lee, C.H.; Nam, T.; Lee, S.; Oh, I.-K.; Yang, J.Y.; Choi, D.W.; Yoo, C.; Kim, H.-J.; Kim, W.-H.; et al. Hydrogen barrier performance of sputtered La2O3 films for InGaZnO thin-film transistor. J. Mater. Sci. 2019, 54, 11145–11156. [Google Scholar] [CrossRef]

- Wang, C.-J.; You, H.-C.; Ou, J.-H.; Chu, Y.-Y.; Ko, F.-H. Ultraviolet Photodetecting and Plasmon-to-Electric Conversion of Controlled Inkjet-Printing Thin-Film Transistors. Nanomaterials 2020, 10, 458. [Google Scholar] [CrossRef]

- Barros, R.; Saji, K.J.; Waerenborgh, J.C.; Barquinha, P.; Pereira, L.; Carlos, E.; Martins, R.; Fortunato, E. Role of Structure and Composition on the Performances of P-Type Tin Oxide Thin-Film Transistors Processed at Low-Temperatures. Nanomaterials 2019, 9, 320. [Google Scholar] [CrossRef]

- Zan, H.-W.; Yeh, C.-C.; Meng, H.-F.; Tsai, C.-C.; Chen, L.H. Achieving High Field-Effect Mobility in Amorphous Indium-Gallium-Zinc Oxide by Capping a Strong Reduction Layer. Adv. Mater. 2012, 24, 3509–3514. [Google Scholar] [CrossRef]

- Wang, C.-J.; You, H.-C.; Lin, K.; Ou, J.-H.; Chao, K.-H.; Ko, F.-H. Highly Transparent and Surface-Plasmon-Enhanced Visible-Photodetector Based on Zinc Oxide Thin-Film Transistors with Heterojunction Structure. Materials 2019, 12, 3639. [Google Scholar] [CrossRef]

- Zhou, C.; Ai, Q.; Chen, X.; Gao, X.; Liu, K.; Shen, D. Ultraviolet photodetectors based on wide bandgap oxide semiconductor films. Chin. Phys. B 2019, 28, 048503. [Google Scholar] [CrossRef]

- Zhao, W.; Li, H.; Li, D.; Liu, Z.; Wang, D.; Liu, S. Comprehensive investigation of sputtered and spin-coated zinc oxide electron transport layers for highly efficient and stable planar perovskite solar cells. J. Power Sources 2019, 427, 223–230. [Google Scholar] [CrossRef]

- Li, H.; Li, D.; Zhao, W.; Yuan, S.; Liu, Z.; Wang, D.; Liu, S. NaCl-Assisted Defect Passivation in the Bulk and Surface of TiO2 Enhancing Efficiency and Stability of Planar Perovskite Solar Cells. J. Power Sources 2020, 448, 227586. [Google Scholar] [CrossRef]

- Wang, D.; Li, C.; Furuta, M. Influence of Active Layer Thickness on Performance and Reliability of InSnZnO Thin-film Transistors. In Proceedings of the 19th International Workshop on AM-FPD, Kyoto, Japan, 4–6 July 2012; pp. 159–162. [Google Scholar]

- Nakata, M.; Zhao, C.; Kanicki, J. DC sputtered amorphous In–Sn–Zn–O thin-film transistors: Electrical properties and stability. Solid State Electron. 2016, 116, 22–29. [Google Scholar] [CrossRef]

- Park, H.-W.; Park, K.; Kwon, J.-Y.; Choi, D.; Chung, K.-B. Effect of active layer thickness on device performance of tungsten-doped InZnO thin-film transistor. IEEE Trans. Electron Devices 2016, 64, 159–163. [Google Scholar] [CrossRef]

- Park, J.; Kim, Y.S.; Kim, J.H.; Park, K.; Park, Y.C.; Kim, H.-S. The effects of active layer thickness and annealing conditions on the electrical performance of ZnON thin-film transistors. J. Alloy. Compd. 2016, 688, 666–671. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, J.; Meng, T.; Qu, M.; Zhang, Q. Influence of channel layer thickness on the stability of amorphous indium zinc oxide thin film transistors. Mater. Lett. 2016, 166, 46–50. [Google Scholar] [CrossRef]

- Wang, D.; Hung, M.P.; Jiang, J.; Toda, T.; Furuta, M. Suppression of degradation induced by negative gate bias and illumination stress in amorphous InGaZnO thin-film transistors by applying negative drain bias. ACS Appl. Mater. Interfaces 2014, 6, 5713–5718. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, J.; Li, Y.; Wilson, J.; Ma, X.; Xin, Q.; Song, A. High performance complementary circuits based on p-SnO and n-IGZO thin-film transistors. Materials 2017, 10, 319. [Google Scholar] [CrossRef]

- Lee, S.; Chen, Y.; Kim, J.; Kim, H.-M.; Jang, J. Transparent AMOLED display driven by split oxide TFT backplane. J. Soc. Inf. Disp. 2018, 26, 164–168. [Google Scholar] [CrossRef]

- Chen, Y.; Geng, D.; Jang, J. Integrated Active-Matrix Capacitive Sensor Using a-IGZO TFTs for AMOLED. IEEE J. Electron Devices Soc. 2018, 6, 214–218. [Google Scholar] [CrossRef]

- Wang, D.; Zhao, W.; Li, H.; Furuta, M. Drain Current Stress-Induced Instability in Amorphous InGaZnO Thin-Film Transistors with Different Active Layer Thicknesses. Materials 2018, 11, 559. [Google Scholar] [CrossRef]

- Yue, L.; Pu, H.-F.; Li, H.-L.; Pang, S.-J.; Zhang, Q. Effect of active layer thickness on device performance of a-LZTO thin-film transistors. Superlattice Microstruct. 2013, 57, 123–128. [Google Scholar] [CrossRef]

- Lee, S.; Jeon, S.; Nathan, A. Modeling Sub-Threshold Current–Voltage Characteristics in Thin Film Transistors. J. Disp. Technol. 2013, 9, 883–889. [Google Scholar]

- Kamiya, T.; Hosono, H. Material characteristics and applications of transparent amorphous oxide semiconductors. NPG Asia Mater. 2010, 2, 15–22. [Google Scholar] [CrossRef]

- Choi, H.-S.; Jeon, S.; Kim, H.; Shin, J.; Kim, C.; Chung, U.I. The impact of active layer thickness on low-frequency noise characteristics in InZnO thin-film transistors with high mobility. Appl. Phys. Lett. 2012, 100, 173501. [Google Scholar] [CrossRef]

- Valdinoci, M.; Colalongo, L.; Baccarani, G.; Fortunato, G.; Pecora, A.; Policicchio, I. Floating body effects in polysilicon thin-film transistors. IEEE Trans. Electron Devices 1997, 44, 2234–2241. [Google Scholar] [CrossRef]

- Jiang, J.; Wang, D.; Matsuda, T.; Kimura, M.; Liu, S.; Furuta, M. Influence of Interface Traps on the Electrical Properties of Oxide Thin-Film Transistors with Different Channel Thicknesses. J. Nano Res. 2017, 46, 93–99. [Google Scholar] [CrossRef]

- Li, Y.; Pei, Y.L.; Hu, R.Q.; Chen, Z.M.; Zhao, Y.; Shen, Z.; Fan, B.F.; Liang, J.; Wang, G. Effect of channel thickness on electrical performance of amorphous IGZO thin-film transistor with atomic layer deposited alumina oxide dielectric. Curr. Appl. Phys. 2014, 14, 941–945. [Google Scholar] [CrossRef]

- Lee, H.; Lin, Y.-C.; Shieh, H.P.D.; Kanicki, J. Current-scaling a-Si:H TFT pixel-electrode circuit for AM-OLEDs: Electrical properties and stability. IEEE Trans. Electron Devices 2007, 54, 2403–2410. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).