Self-Compliance and High Performance Pt/HfOx/Ti RRAM Achieved through Annealing

Abstract

1. Background

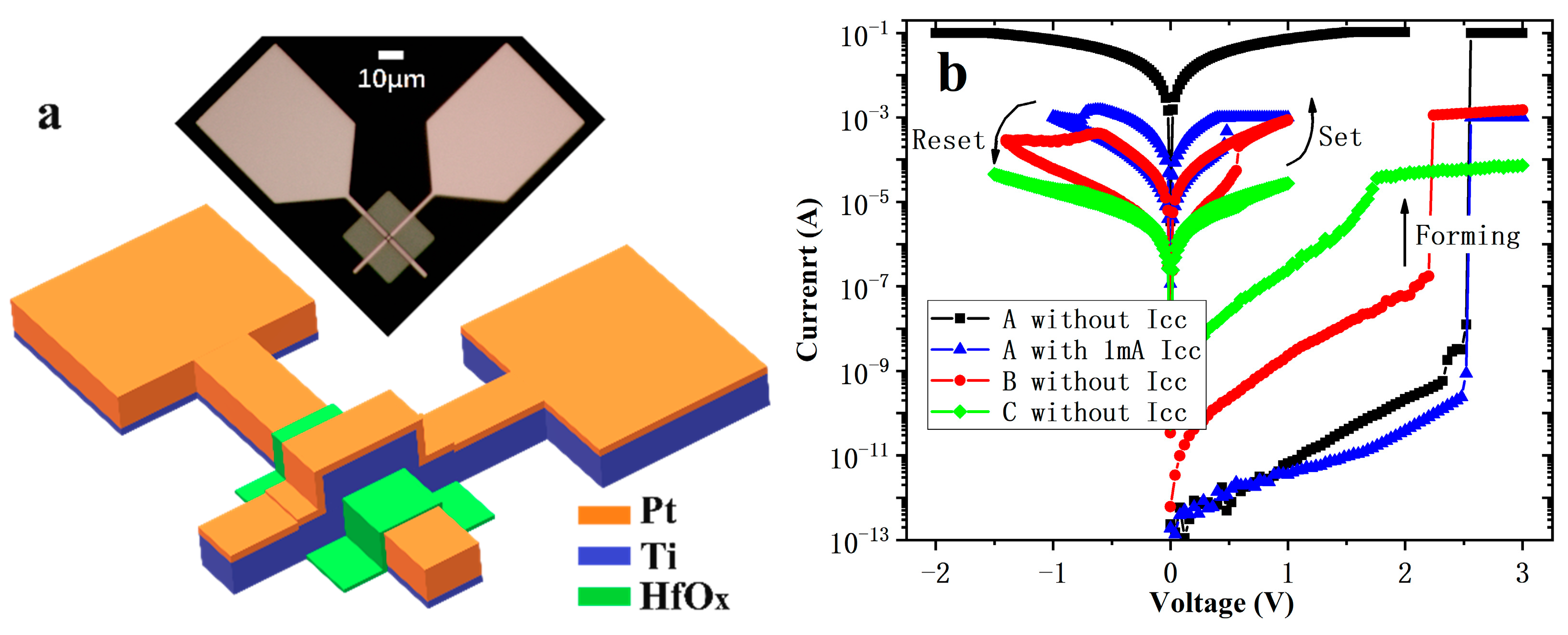

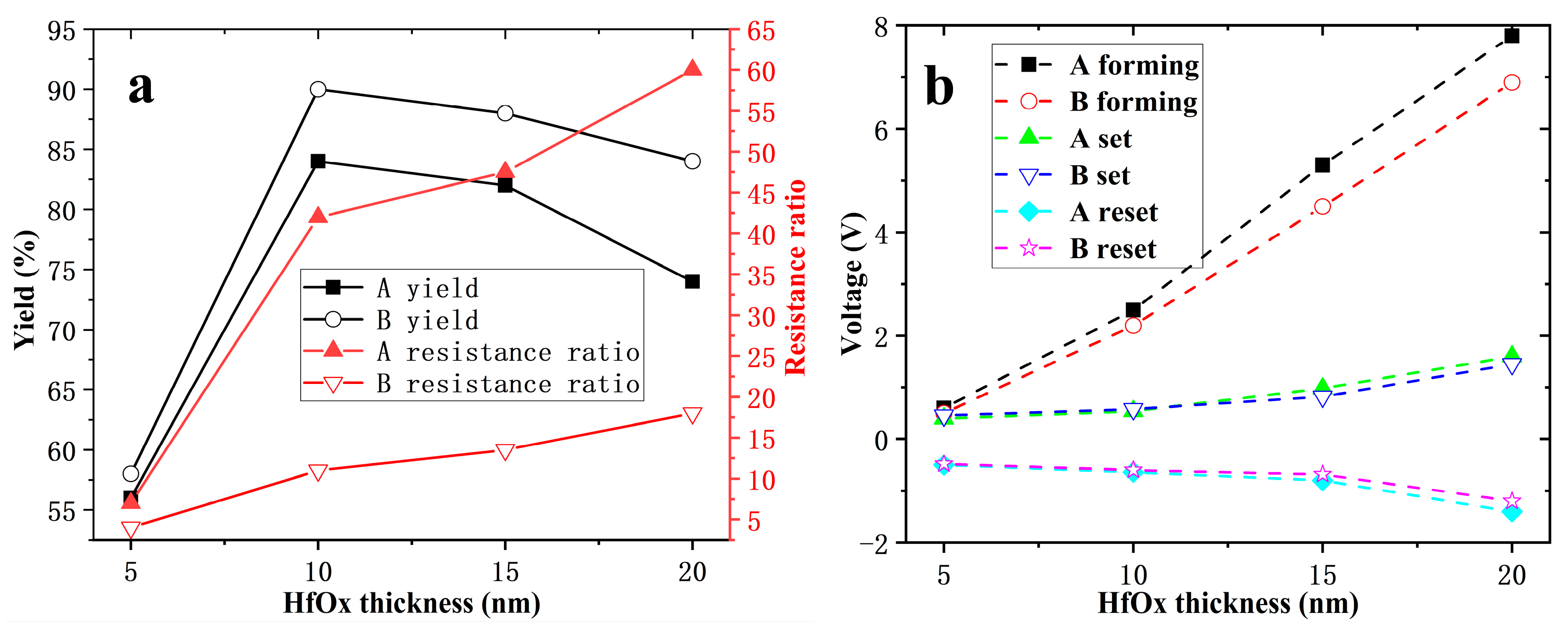

2. Methods

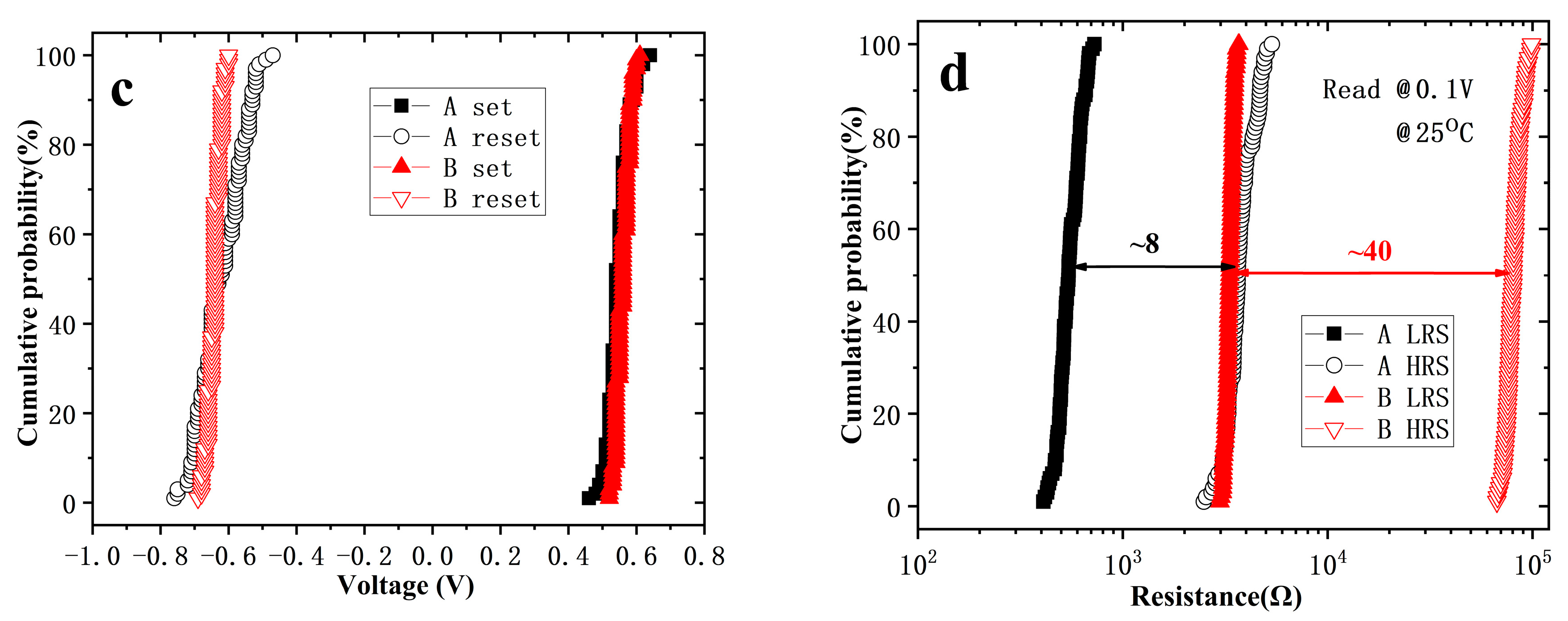

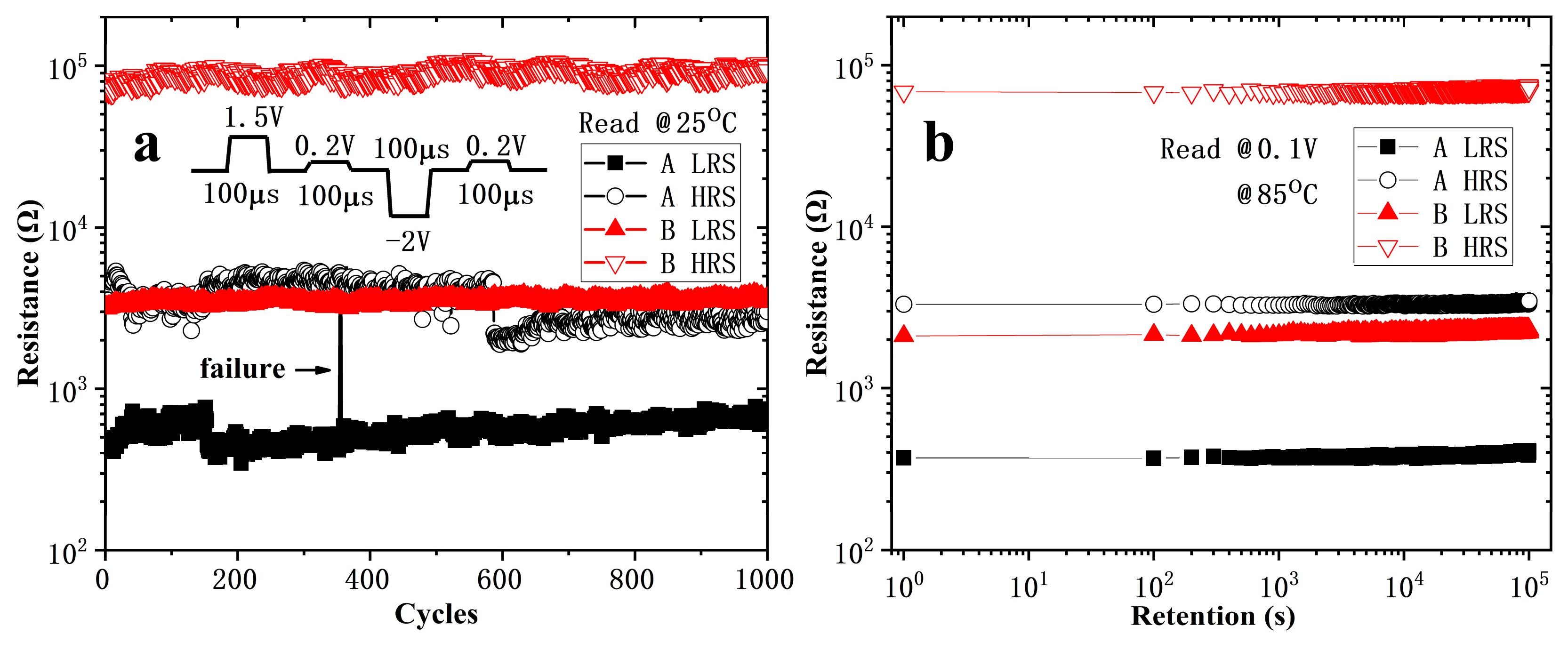

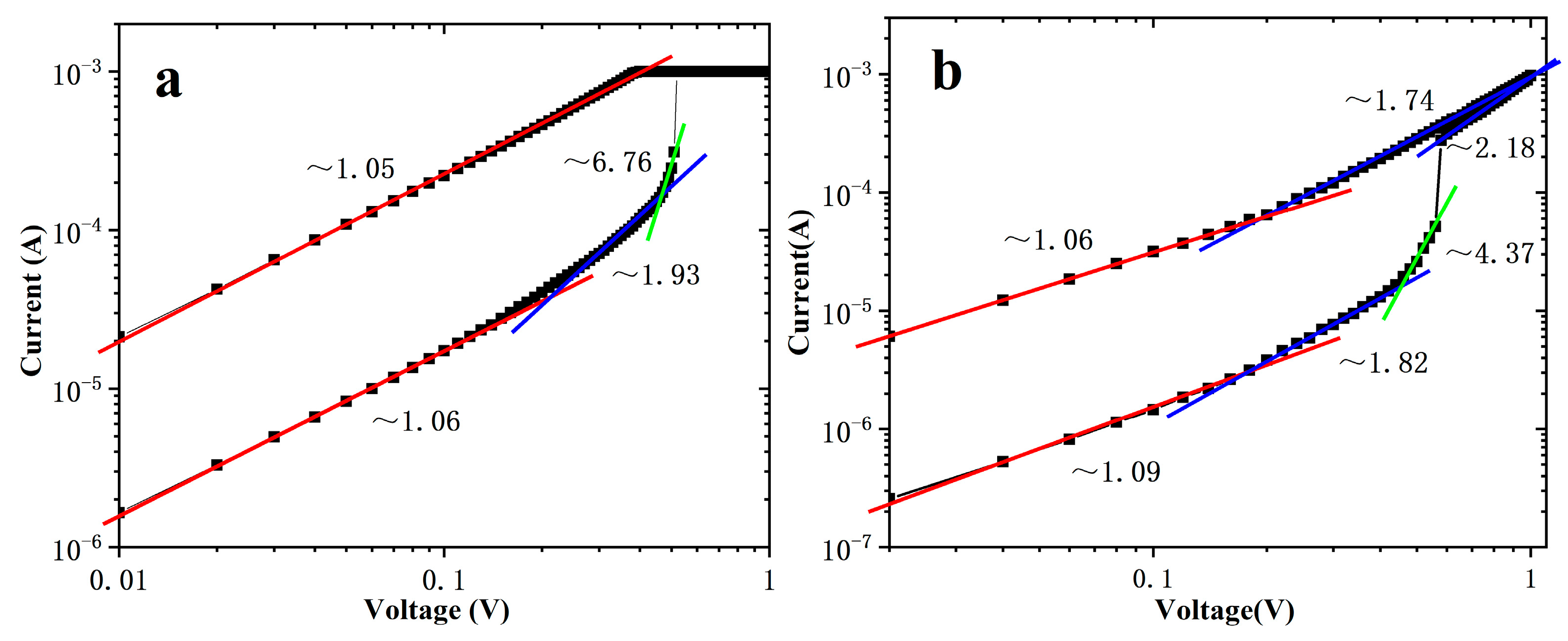

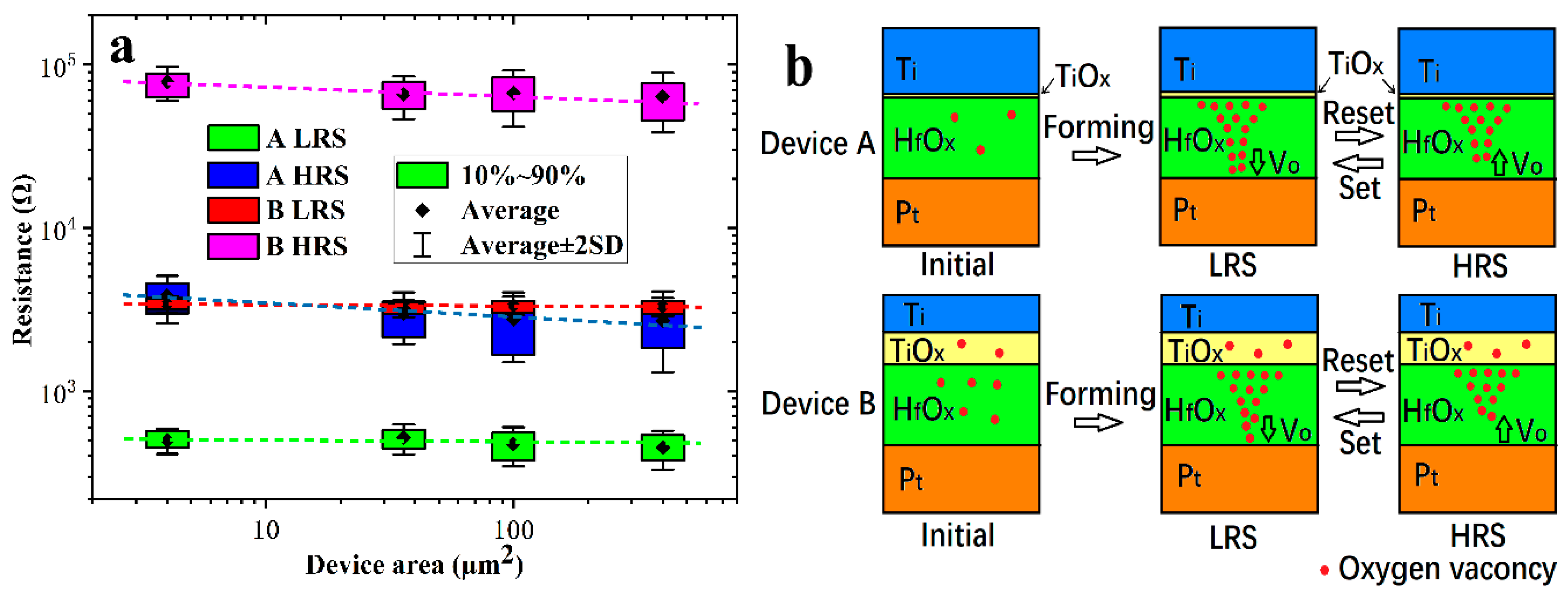

3. Results and Discussion

4. Conclusion

Author Contributions

Funding

Conflicts of Interest

References

- Scott, J.C. Is there an immortal memory? Science 2004, 304, 62–63. [Google Scholar] [CrossRef]

- Kim, K.H.; Gaba, S.; Wheeler, D.; Cruz-Albrecht, J.M.; Hussain, T.; Srinivasa, N.; Lu, W. A functional hybrid memristor crossbar-array/CMOS system for data storage and neuromorphic applications. Nano Lett. 2011, 12, 389–395. [Google Scholar] [CrossRef]

- Yang, J.J.; Pickett, M.D.; Li, X.; Ohlberg, D.A.; Stewart, D.R.; Williams, R.S. Memristive switching mechanism for metal/oxide/metal nanodevices. Nat. Nanotechnol. 2008, 3, 429–433. [Google Scholar] [CrossRef] [PubMed]

- Chang, T.C.; Chang, K.C.; Tsai, T.M.; Chu, T.J.; Sze, S.M. Resistance random access memory. Mater. Today 2016, 19, 254–264. [Google Scholar] [CrossRef]

- Chang, K.C.; Chang, T.C.; Tsai, T.M.; Zhang, R.; Hung, Y.C.; Syu, Y.E.; Chang, Y.F.; Chen, M.C.; Chu, T.J.; Chen, H.L.; et al. Physical and chemical mechanisms in oxide-based resistance random access memory. Nanoscale Res. Lett. 2015, 10, 120. [Google Scholar] [CrossRef] [PubMed]

- Akinaga, H.; Shima, H. Resistive random access memory (ReRAM) based on metal oxides. Proc. IEEE 2010, 98, 2237–2251. [Google Scholar] [CrossRef]

- Li, Y.; Long, S.; Liu, Q.; Lv, H.; Liu, M. Resistive Switching Performance Improvement via Modulating Nanoscale Conductive Filament, Involving the Application of Two-Dimensional Layered Materials. Small 2017, 13, 1604306:1–1604306:35. [Google Scholar] [CrossRef]

- Ahn, E.C.; Wong, H.S.P.; Pop, E. Carbon nanomaterials for non-volatile memories. Nat. Rev. Mater. 2018, 3, 18009. [Google Scholar] [CrossRef]

- Huang, Y.J.; Lee, S.C. Graphene/h-BN Heterostructures for Vertical Architecture of RRAM Design. Sci. Rep. 2017, 7, 9679:1–9679:9. [Google Scholar] [CrossRef] [PubMed]

- Cai, Y.; Tan, J.; YeFan, L.; Lin, M.; Huang, R. A flexible organic resistance memory device for wearable biomedical applications. Nanotechnology 2016, 27, 275206:1–275206:6. [Google Scholar] [CrossRef]

- Ling, H.; Yi, M.; Nagai, M.; Xie, L.; Wang, L.; Hu, B.; Huang, W. Controllable Organic Resistive Switching Achieved by One-Step Integration of Cone-Shaped Contact. Adv. Mater. 2017, 29, 1701333:1–1701333:9. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Niu, G.; Roy, S.; Wang, Y.; Zhang, Y.; Wu, H.; Zhai, S.; Bai, W.; Shi, P.; Song, S.; et al. Interface-engineered reliable HfO2-based RRAM for synaptic simulation. J. Mater. Chem. C 2019, 7, 12682–12687. [Google Scholar] [CrossRef]

- Qi, M.; Tao, Y.; Wang, Z.; Xu, H.; Zhao, X.; Liu, W.; Ma, J.; Liu, Y. Highly uniform switching of HfO2−x based RRAM achieved through Ar plasma treatment for low power and multilevel storage. Appl. Surf. Sci. 2018, 458, 216–221. [Google Scholar] [CrossRef]

- Hong, X.L.; Loy, D.J.; Dananjaya, P.A.; Tan, F.; Ng, C.; Lew, W. Oxide-based RRAM materials for neuromorphic computing. J. Mater. Sci. 2018, 53, 8720–8746. [Google Scholar] [CrossRef]

- Liu, C.F.; Tang, X.G.; Wang, L.Q.; Tang, H.; Jiang, Y.P.; Liu, Q.X.; Li, W.H.; Tang, Z.H. Resistive switching characteristics of HfO2 thin films on mica substrates prepared by Sol-Gel process. Nanomaterials 2019, 9, 1124:1–1124:11. [Google Scholar] [CrossRef]

- Wilk, G.D.; Wallace, R.M.; Anthony, J.M. High-κ gate dielectrics: Current status and materials properties considerations. J. Appl. Phys. 2001, 89, 5243–5275. [Google Scholar] [CrossRef]

- Kingon, A.I.; Maria, J.P.; Streiffer, S.K. Alternative dielectrics to silicon dioxide for memory and logic devices. Nature 2000, 406, 1032–1038. [Google Scholar] [CrossRef]

- Chang, T.C.; Jian, F.Y.; Chen, S.C.; Tsai, Y.T. Developments in nanocrystal memory. Mater. Today 2011, 14, 608–615. [Google Scholar] [CrossRef]

- Li, Y.; Lv, H.; Liu, Q.; Long, S.; Wang, M.; Xie, H.; Zhang, K.; Huo, Z.; Liu, M. Bipolar one diode–one resistor integration for high-density resistive memory applications. Nanoscale 2013, 5, 4785–4789. [Google Scholar] [CrossRef]

- Zheng, H.X.; Chang, T.C.; Xue, K.H.; Su, Y.T.; Wu, C.H.; Shih, C.C.; Tseng, Y.T.; Chen, W.C.; Huang, W.C.; Chen, C.K.; et al. Reducing Forming Voltage by Applying Bipolar Incremental Step Pulse Programming in a 1T1R Structure Resistance Random Access Memory. IEEE Electron. Device Lett. 2018, 39, 815–818. [Google Scholar] [CrossRef]

- Gao, X.P.; Fu, L.P.; Chen, C.B.; Yuan, P.; Li, Y.T. Self-compliance multilevel storage characteristic in HfO2-based device. Chin. Phys. B 2016, 25, 106102:1–106102:3. [Google Scholar] [CrossRef]

- Jeong, S.W.; Lee, H.J.; Kim, K.S.; You, M.T.; Roh, Y.; Noguchi, T.; Xiaoyu, W.; Jung, J. Effects of annealing temperature on the characteristics of ALD-deposited HfO2 in MIM capacitors. Thin Solid Films 2006, 515, 526–530. [Google Scholar] [CrossRef]

- Tao, Q.; Jursich, G.M.; Takoudis, C. Investigation of Surface Sputtering and Post Annealing Effects on Atomic Layer Deposited HfO2 and TiO2. IEEE Trans. Semicond. Manuf. 2011, 24, 139–144. [Google Scholar] [CrossRef]

- Wright, G.T. Mechanisms of space-charge-limited current in solids. Solid State Electron. 1961, 2, 165–189. [Google Scholar] [CrossRef]

- De Boer, R.W.I.; Morpurgo, A.F. Influence of surface traps on space-charge limited current. Phys. Rev. B 2005, 72, 073207:1–073207:4. [Google Scholar] [CrossRef]

- Xia, Y.; He, W.; Chen, L.; Meng, X.; Liu, Z. Field-induced resistive switching based on space-charge-limited current. Appl. Phys. Lett. 0229, 90, 022907:1–022907:3. [Google Scholar] [CrossRef]

- Sowinska, M.; Bertaud, T.; Walczyk, D.; Thiess, S.; Schubert, M.A.; Lukosius, M.; Drube, W.; Walczyk, Ch.; Schroeder, T. Hard x-ray photoelectron spectroscopy study of the electroforming in Ti/ HfO2-based resistive switching structures. Appl. Phys. Lett. 2012, 100, 233509:1–233509:5. [Google Scholar] [CrossRef]

- Brivio, S.; Tallarida, G.; Cianci, E.; Spiga, S. Formation and disruption of conductive filaments in a HfO2/TiN structure. Nanotechnology 2014, 25, 385705:1–385705:7. [Google Scholar] [CrossRef]

- Goux, L.; Wang, X.P.; Chen, Y.Y.; Pantisano, L.; Jossart, N.; Govoreanu, B.; Kittl, J.A.; Jurczak, M.; Altimime, L.; Wouters, D.J. Roles and effects of TiN and Pt electrodes in resistive-switching HfO2 systems. Electrochem. Solid State Lett. 2011, 14, H244–H246. [Google Scholar] [CrossRef]

- Lin, Y.S.; Zeng, F.; Tang, S.G.; Liu, H.Y.; Chen, C.; Gao, S.; Wang, Y.G.; Pan, F. Resistive switching mechanisms relating to oxygen vacancies migration in both interfaces in Ti/HfOx/Pt memory devices. J. Appl. Phys. 2013, 113, 064510:1–064510:5. [Google Scholar] [CrossRef]

- Lee, C.B.; Kang, B.S.; Benayad, A.; Lee, M.J.; Ahn, S.E.; Kim, K.H.; Stefanovich, G.; Park, Y.; Yoo, I.K. Effects of metal electrodes on the resistive memory switching property of NiO thin films. Appl. Phys. Lett. 2008, 93, 042115:1–042115:3. [Google Scholar] [CrossRef]

- Kim, H.; McIntyre, P.C.; Chui, C.O.; Saraswat, K.C.; Stemmer, S. Engineering chemically abrupt high-k metal oxide/silicon interfaces using an oxygen-gettering metal overlayer. J. Appl. Phys. 2004, 96, 3467–3472. [Google Scholar] [CrossRef]

- Lee, H.Y.; Chen, P.S.; Wu, T.Y.; Chen, Y.S.; Chen, F.; Wang, C.C.; Tzeng, P.J.; Lin, C.H.; Tsai, M.J.; Lien, C. HfOx Bipolar Resistive Memory with Robust Endurance Using AlCu as Buffer Electrode. IEEE Electr. Device Lett. 2009, 30, 703–705. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, L.; Liu, H.; Lin, J.; Wang, S. Self-Compliance and High Performance Pt/HfOx/Ti RRAM Achieved through Annealing. Nanomaterials 2020, 10, 457. https://doi.org/10.3390/nano10030457

Wu L, Liu H, Lin J, Wang S. Self-Compliance and High Performance Pt/HfOx/Ti RRAM Achieved through Annealing. Nanomaterials. 2020; 10(3):457. https://doi.org/10.3390/nano10030457

Chicago/Turabian StyleWu, Lei, Hongxia Liu, Jinfu Lin, and Shulong Wang. 2020. "Self-Compliance and High Performance Pt/HfOx/Ti RRAM Achieved through Annealing" Nanomaterials 10, no. 3: 457. https://doi.org/10.3390/nano10030457

APA StyleWu, L., Liu, H., Lin, J., & Wang, S. (2020). Self-Compliance and High Performance Pt/HfOx/Ti RRAM Achieved through Annealing. Nanomaterials, 10(3), 457. https://doi.org/10.3390/nano10030457