Flux-Free Diffusion Joining of SiCp/6063 Al Matrix Composites Using Liquid Gallium with Nano-Copper Particles in Atmosphere Environment

Abstract

1. Introduction

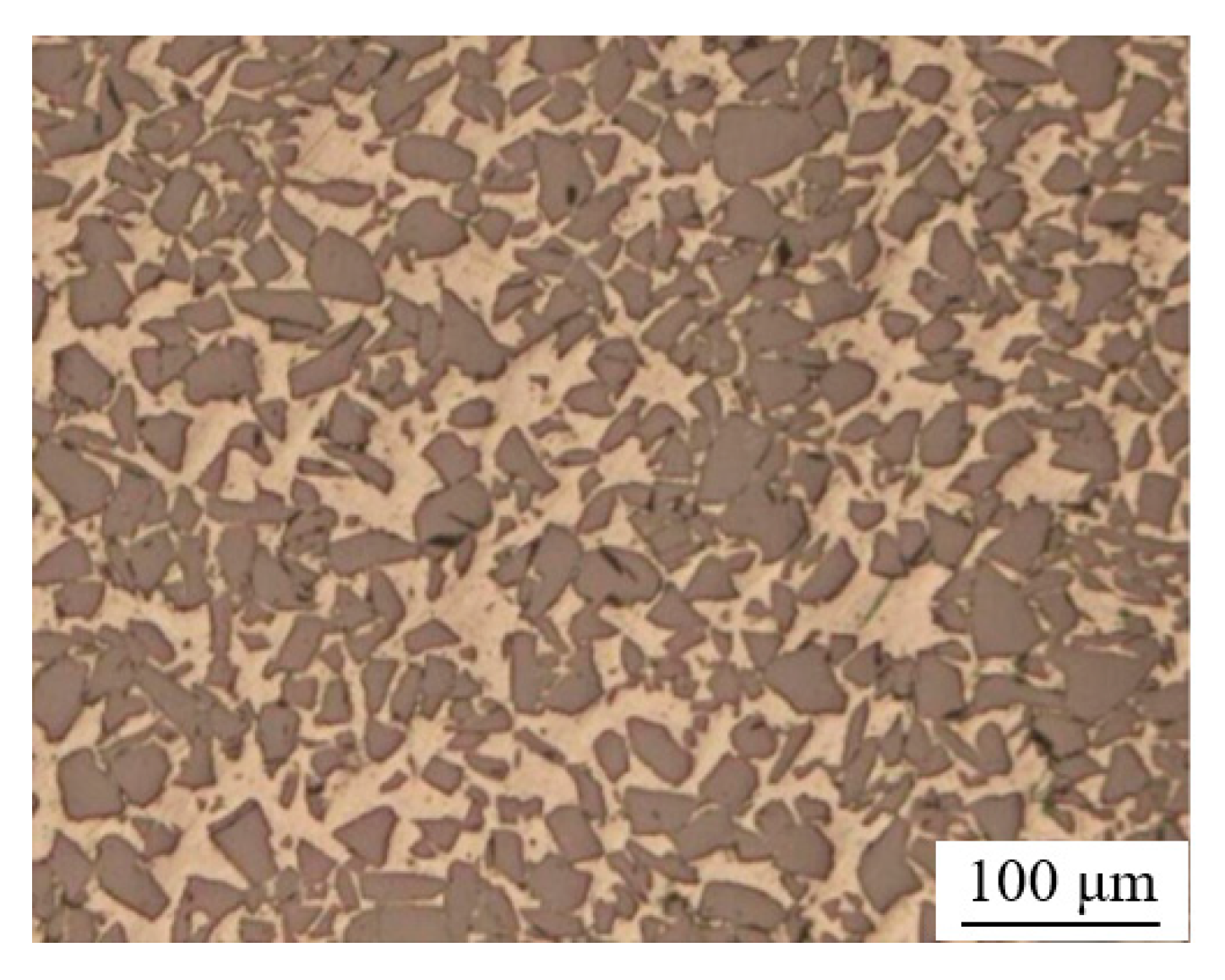

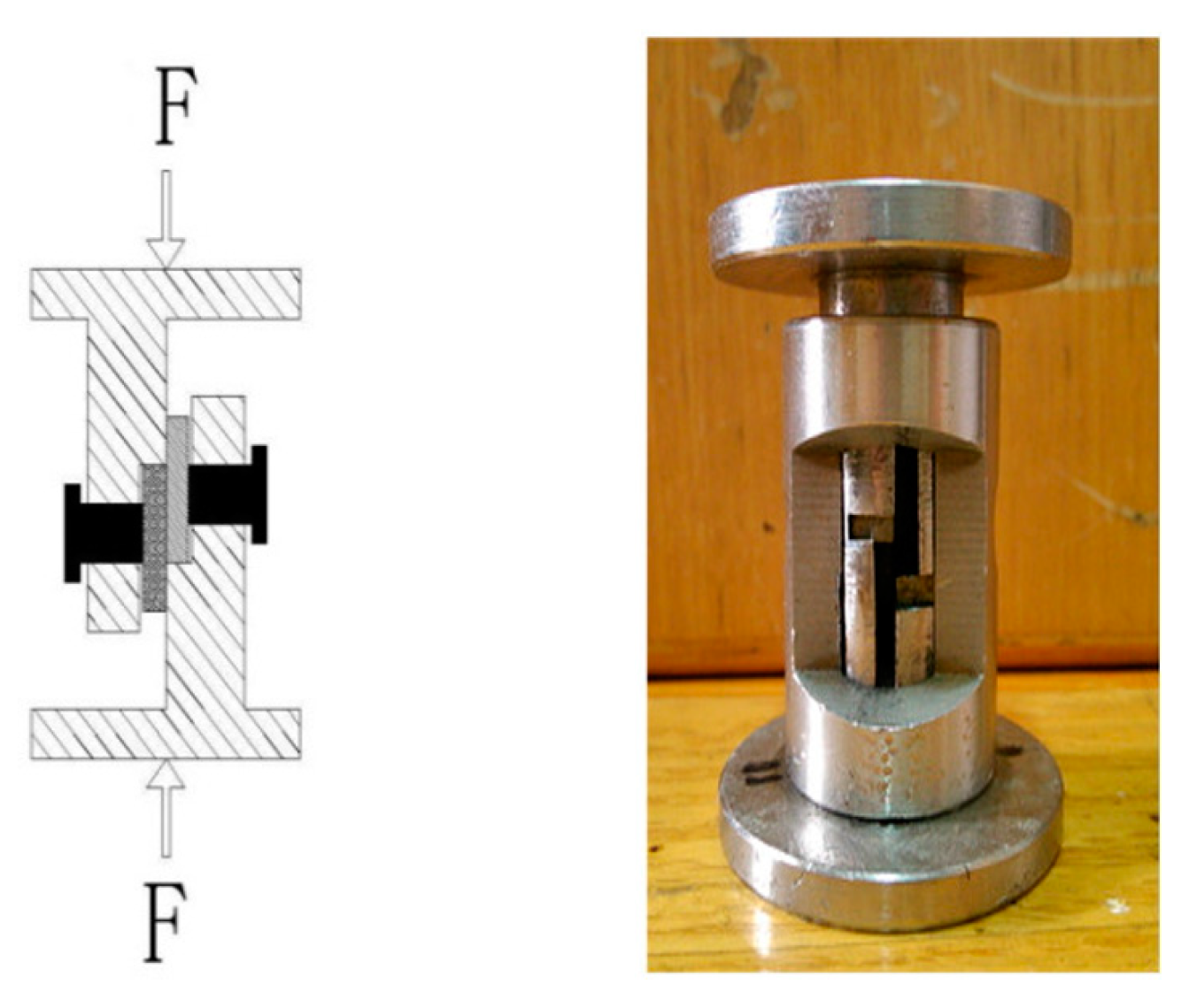

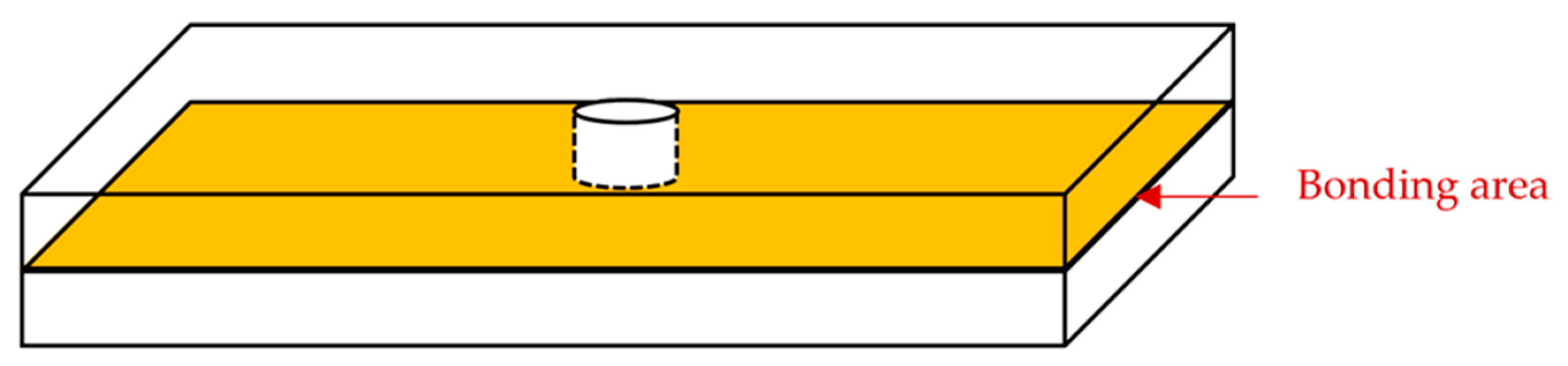

2. Materials and Methods

3. Results and Discussion

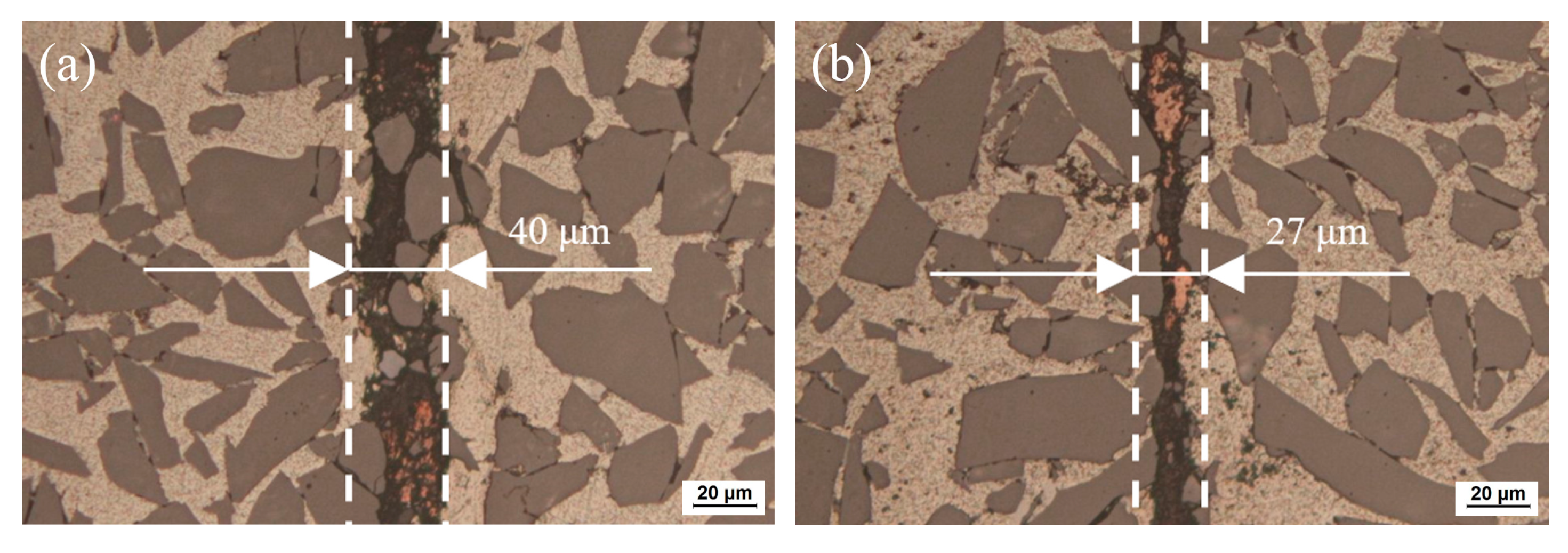

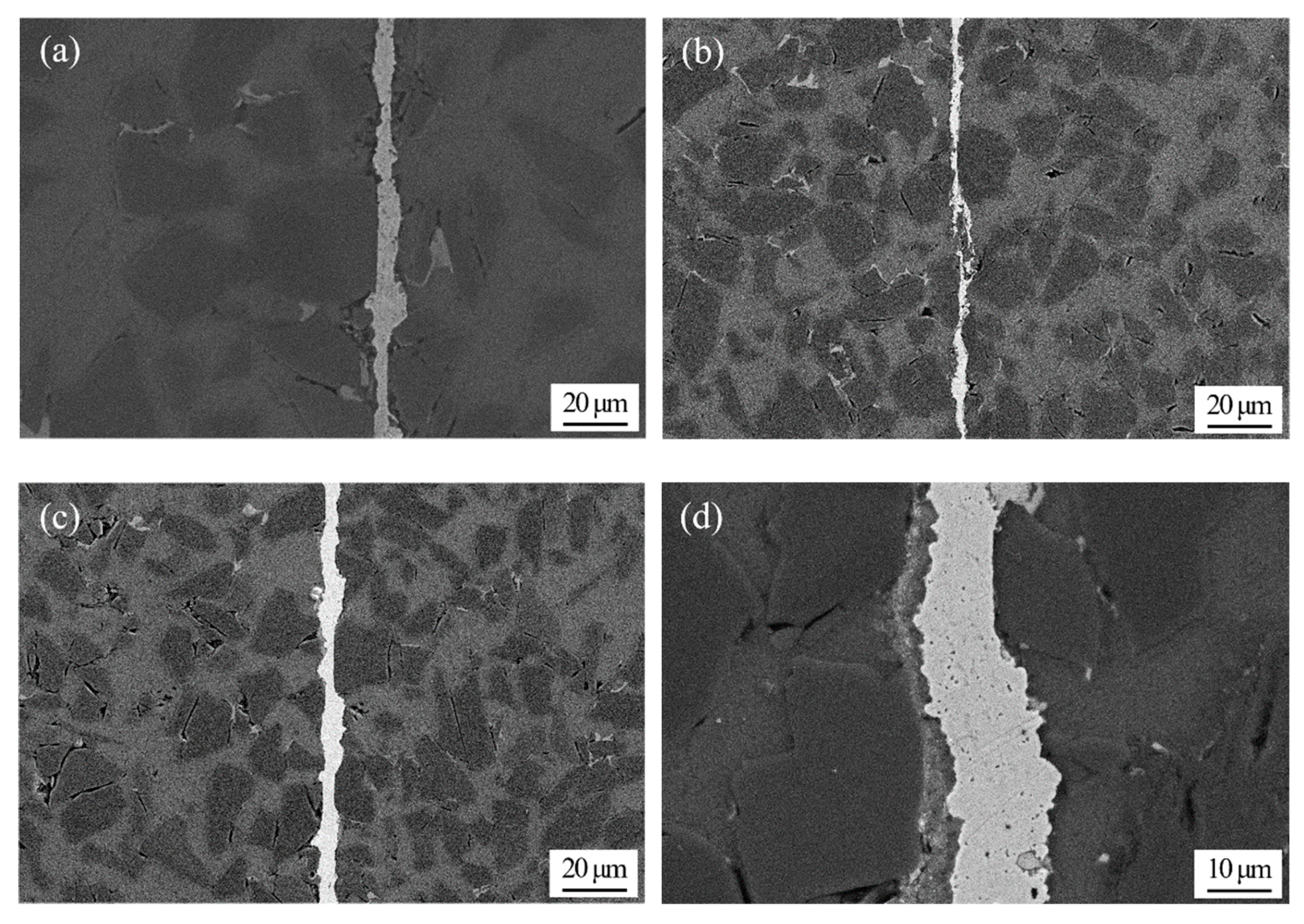

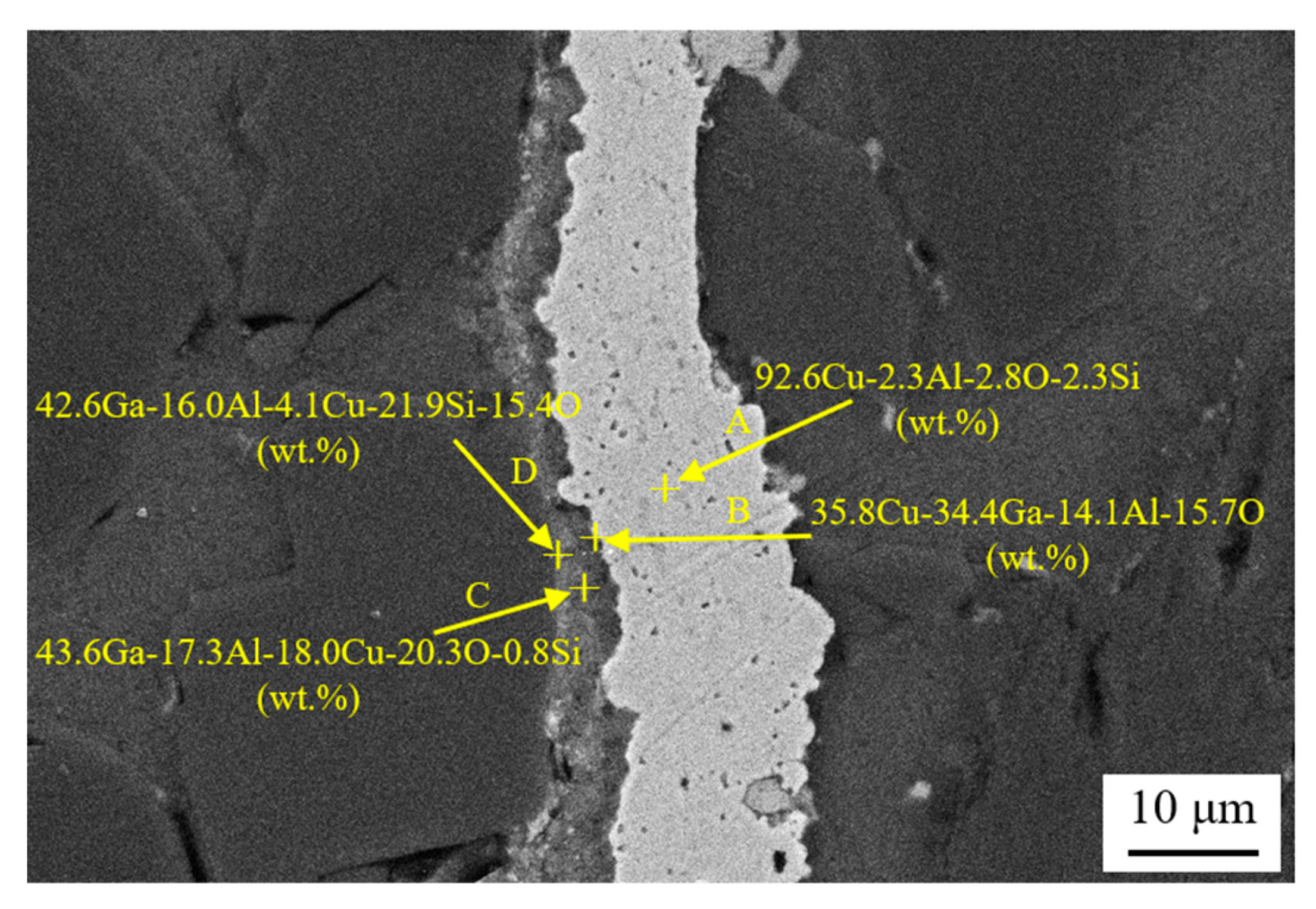

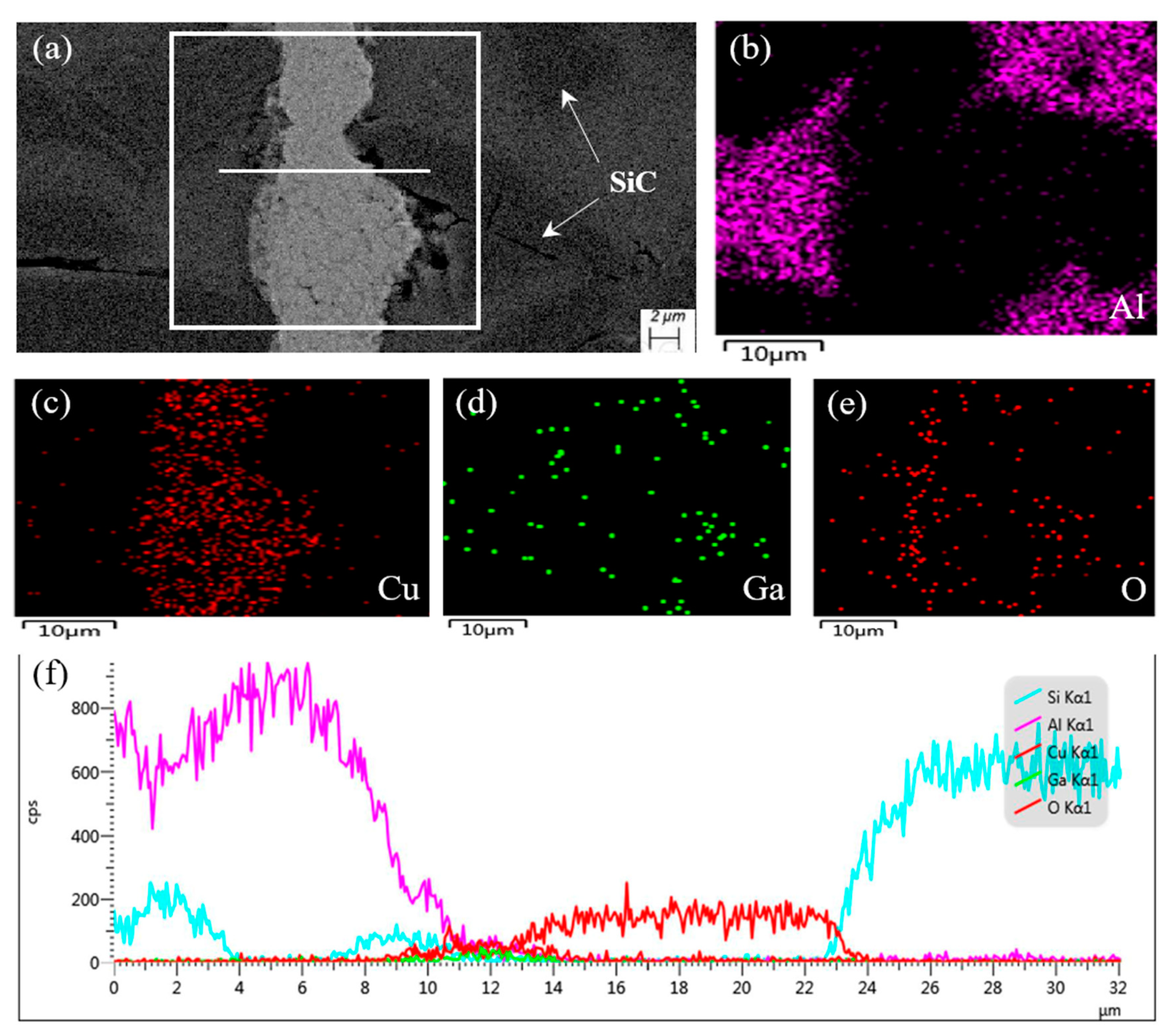

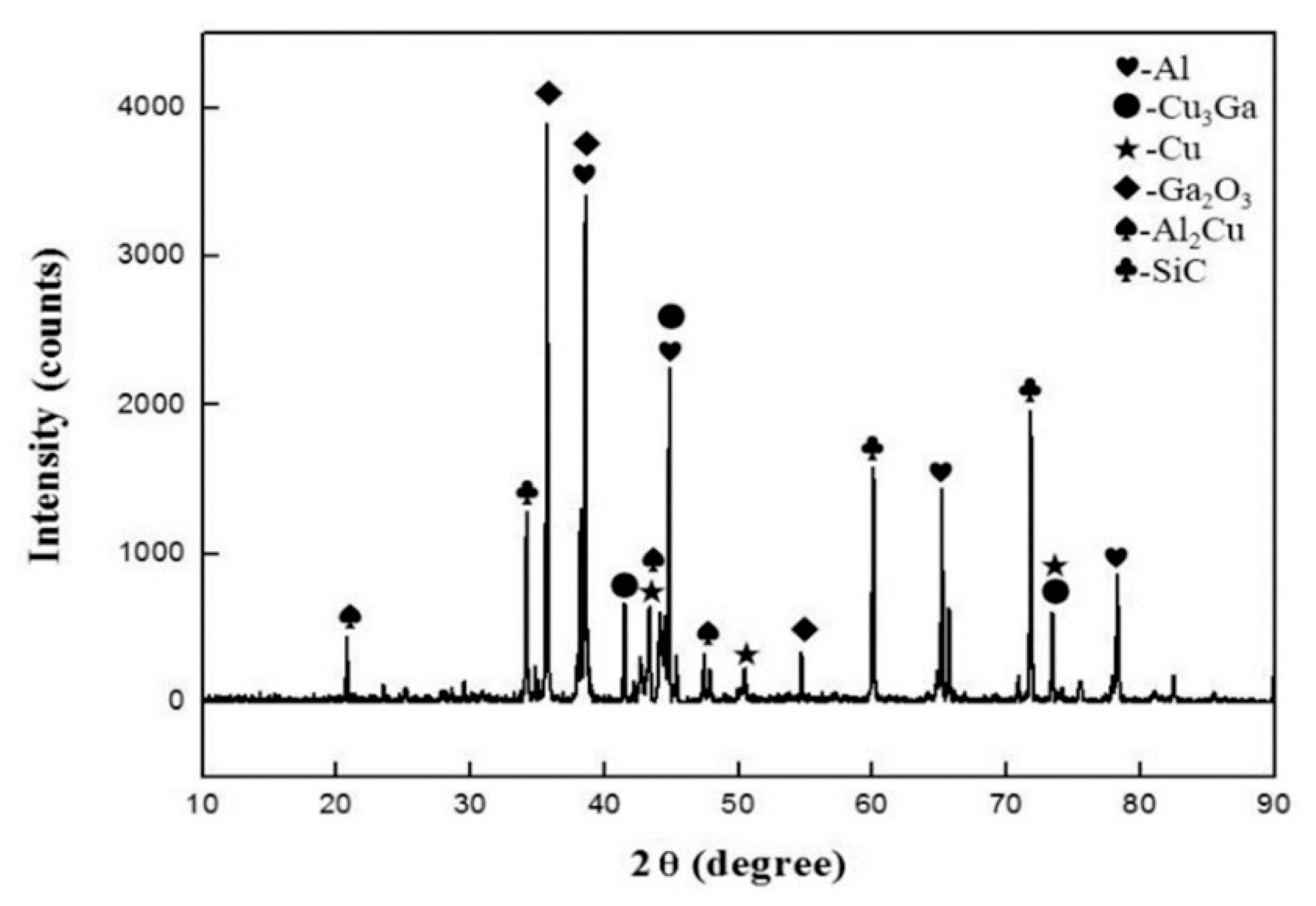

3.1. Microstructure and Element Distribution Analysis of Diffusion Joints

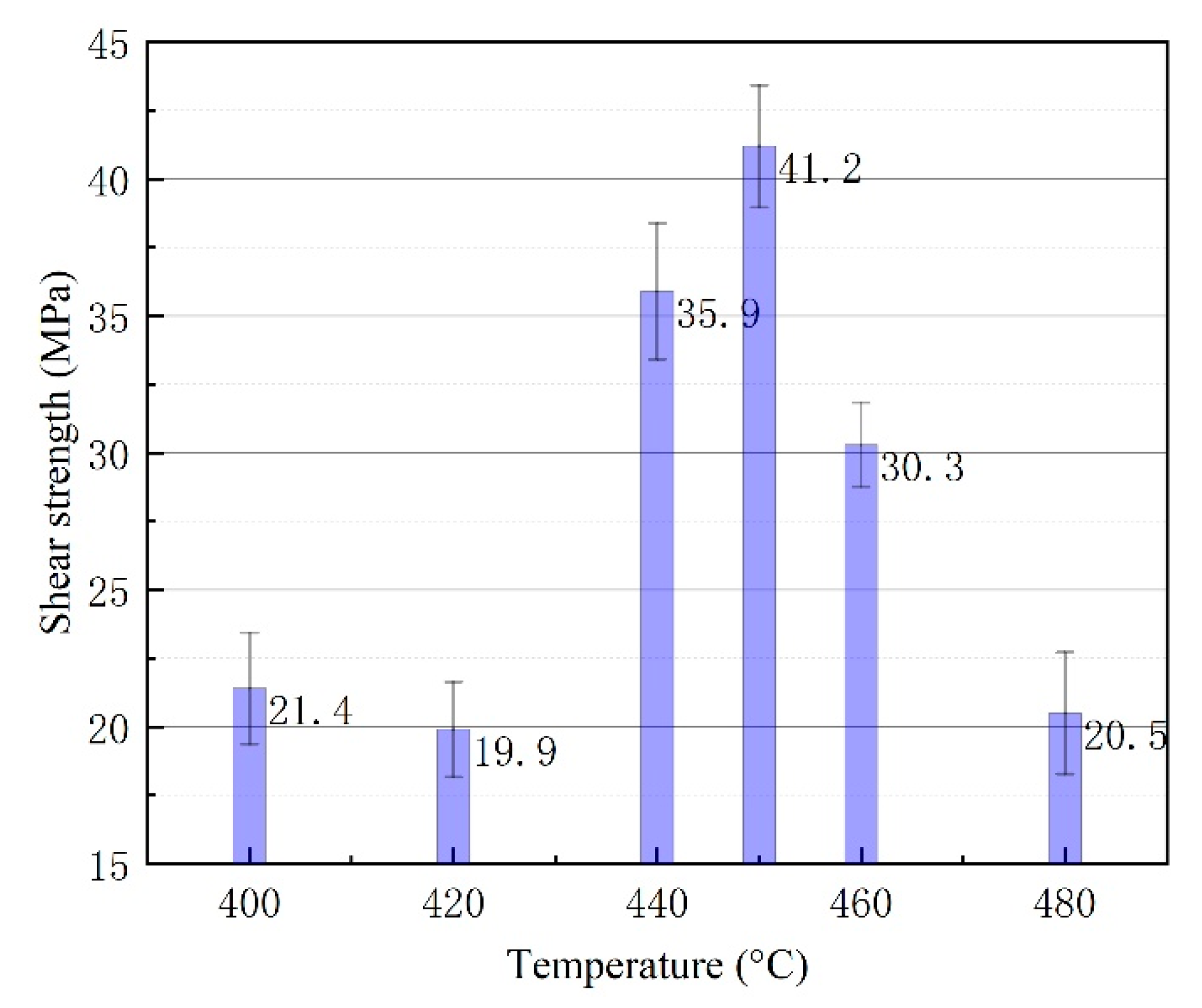

3.2. Mechanical Properties of Diffusion Joints

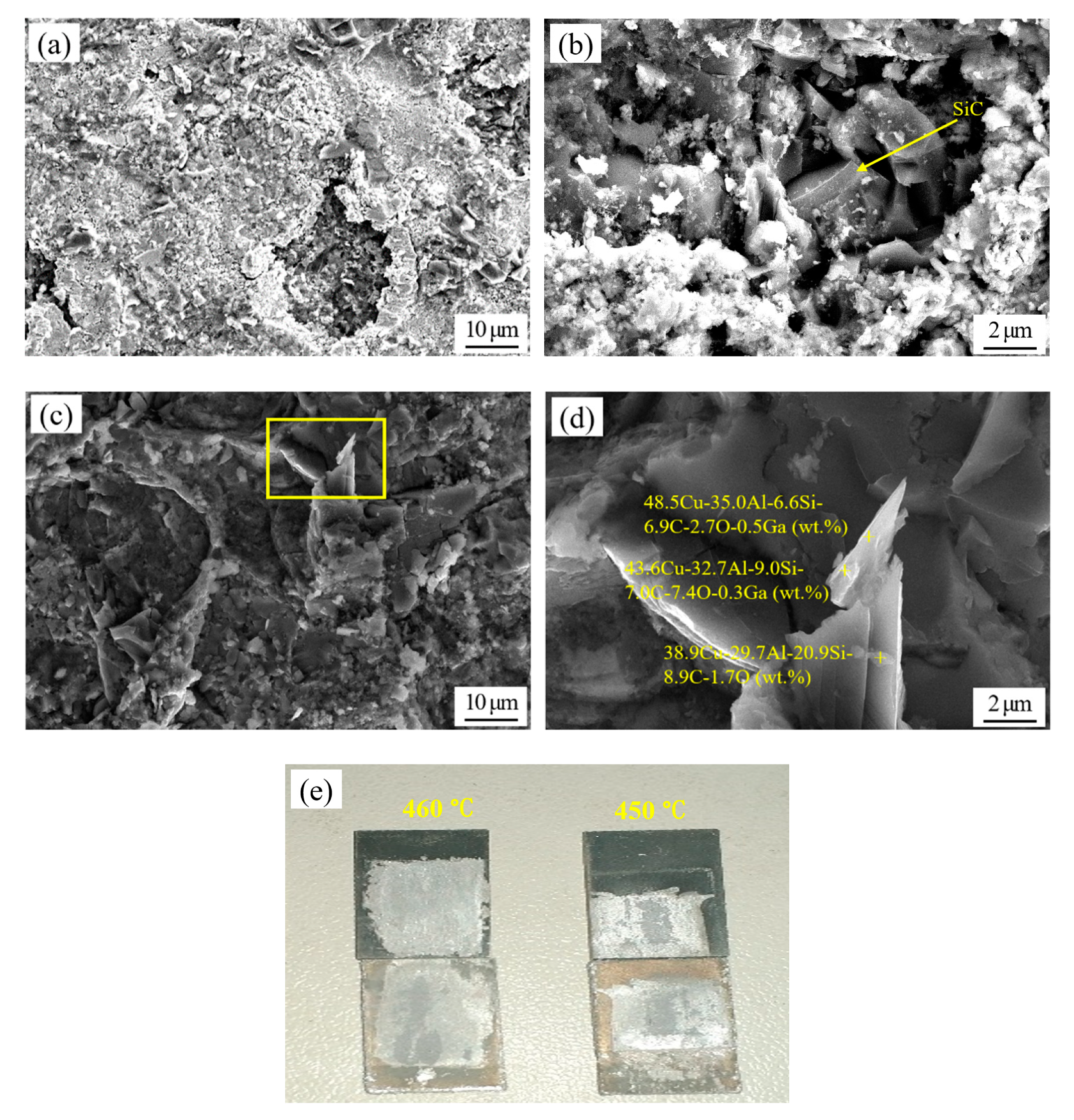

3.3. Fracture Analysis of Diffusion Joints

3.4. Gas Tightness of Joints Produced at Different Diffusion Temperatures

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gu, X.F.; Zhang, L.M.; Yang, M.J.; Zhang, D.M. Fabrication by SPS and thermophysical properties of high volume n fraction SiCp/Al matrix composites. Key Eng. Mater. 2006, 313, 171–176. [Google Scholar] [CrossRef]

- Bai, W.; Roy, A.; Sun, R.; Silberschmidt, V.V. Enhanced machinability of SiC-reinforced metal-matrix composite with hybrid turning. J. Mater. Process. Technol. 2019, 268, 149–161. [Google Scholar] [CrossRef]

- Li, Q.; Qiu, F.; Dong, B.; Geng, R.; Lv, M.; Zhao, Q.; Jiang, Q.-C. Fabrication, microstructure refinement and strengthening mechanisms of nanosized SiCP/Al composites assisted ultrasonic vibration. Mater. Sci. Eng. A 2018, 735, 310–317. [Google Scholar] [CrossRef]

- Zhang, J.F.; Zhang, X.X.; Wang, Q.Z.; Xiao, B.L.; Ma, Z.Y. Simulations of deformation and damage processes of SiCp/Al composites during tension. J. Mater. Sci. Technol. 2018, 34, 627–634. [Google Scholar] [CrossRef]

- Zhang, Z.-M.; Xiang, D.-H.; Wu, B.-F.; Feng, H.-R.; Shi, Z.-L.; Hu, Y.-W.; Zhao, B. Finite element simulation study of ultrasonic vibration-assisted tensile high-volume fraction SiCp/Al composite. Materials 2019, 12, 3841. [Google Scholar] [CrossRef]

- Jayakumar, K.; Mathew, J.; Joseph, M.A. An investigation of cutting force and tool-work interface temperature in milling of Al-SiCp metal matrix composite. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2013, 227, 362–374. [Google Scholar] [CrossRef]

- Xia, J.; Lewandowski, J.J.; Willard, M.A. Tension and fatigue behavior of Al-2124A/SiC-particulate metal matrix composites. Mater. Sci. Eng. A 2020, 770. [Google Scholar] [CrossRef]

- Li, X.; Bai, F.; Fu, Y. The small hole helical mill-grinding process and application in high volume fraction SiCp/Al MMCs. Int. J. Adv. Manuf. Technol. 2017, 91, 3007–3014. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, G.; Chen, G.; Jiang, L.; Luan, B. The thermal expansion and mechanical properties of high reinforcement content SiCp/Al composites fabricated by squeeze casting technology. Compos. Part A Appl. Sci. Manuf. 2003, 34, 1023–1027. [Google Scholar] [CrossRef]

- Amirkhanlou, S.; Niroumand, B. Effects of reinforcement distribution on low and high temperature tensile properties of Al356/SiCp cast composites produced by a novel reinforcement dispersion technique. Mater. Sci. Eng. A 2011, 528, 7186–7195. [Google Scholar] [CrossRef]

- Hu, S.-Q.; Wan, S.-P.; Liu, Y.-Y.; Shu, Y.-H.; Tan, C.-L. SiCp/Al composites for electronic packaging prepared by microwave sintering and vacuum pressure infiltration. Mater. Sci. Technol. 2012, 20, 78–82. [Google Scholar]

- Tolochko, O.V.; Koltsova, T.S.; Bobrynina, E.V.; Rudskoy, A.I.; Zemtsova, E.G.; Kirichenko, S.O.; Smirnov, V.M. Conditions for Production of Composite Material Based on Aluminum and Carbon Nanofibers and Its Physic-Mechanical Properties. Nanomaterials 2019, 9, 550. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.Q.; Zhang, B.G.; Liu, L.Y.; Feng, J.C. Electron beam welding of SiCp/Al composite to Ti-6Al-4V. Mater. Res. Innov. 2015, 19, S51309–S51312. [Google Scholar] [CrossRef]

- McCay, M.H.; McCay, T.D.; Dahotre, N.B.; Sharp, C.M. Fusion zone structures in laser welded Al-SiC composites. J. Laser Appl. 1991, 3, 35. [Google Scholar] [CrossRef]

- Long, J.; Zhang, L.-J.; Zhang, L.-L.; Wang, X.; Zhang, G.-F.; Zhang, J.-X.; Na, S.-J. Effects of minor Zr addition on the microstructure and mechanical properties of laser welded joint of Al/SiCp metal-matrix composite. J. Manuf. Process. 2020, 49, 373–384. [Google Scholar] [CrossRef]

- Gurler, R. Fusion welding of SiC particulate-reinforced aluminum 392 metal matrix composite. J. Mater. Sci. Lett. 1998, 17, 1543–1544. [Google Scholar] [CrossRef]

- Tong, H.; Qiu, F.; Zuo, R.; Shen, P.; Cong, X.; Liu, J.; Yang, H.; Jiang, Q. The effect and mechanism of alloying elements on Al/SiC interfacial reaction in Al melt. Appl. Surf. Sci. 2020, 501. [Google Scholar] [CrossRef]

- Muratoğlu, M.; Yilmaz, O.; Aksoy, M. Investigation on diffusion bonding characteristics of aluminum metal matrix composites (Al/SiCp) with pure aluminum for different heat treatments. J. Mater. Process. Technol. 2006, 178, 211–217. [Google Scholar] [CrossRef]

- Guo, W.; Niu, J.; Zhai, J.; Wang, C.; Yu, J.; Zhou, G. Study on non-interlayer liquid phase diffusion bonding for SiCp/ZL101 aluminum matrix composite. J. Mater. Sci. Technol. 2003, 19, 88–90. [Google Scholar]

- Xiao, J.; Li, S.; Bai, S.; Yan, J.; Xiong, D.; Tang, Y. Compression Brazing of SiCp/Al Composite Using a Semisolid Zn-Al-Cu Filler Metal Based on the Strain-Induced Melt Activation Process. JOM 2019, 71, 4931–4939. [Google Scholar] [CrossRef]

- Li, J.; Qin, Q.; Long, Q.; Zhang, Y. Influence of the filler metals’ forms on semi-solid pressure reaction brazing joints. Trans. China Weld. Inst. 2019, 40, 139–144. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, G. Effect of Zn and mechanical vibration agitation on the microstructure evolution in brazed joint of SiC particle-reinforced aluminum matrix composites. Weld. World 2019, 63, 1841–1850. [Google Scholar] [CrossRef]

- Ferchaud, E.; Christien, F.; Barnier, V.; Paillard, P. Characterisation of Ga-coated and Ga-brazed aluminium. Mater. Charact. 2012, 67, 17–26. [Google Scholar] [CrossRef]

- Sumigawa, T.; Shishido, T.; Murakami, T.; Iwasaki, T.; Kitamura, T. Evaluation on plastic deformation property of copper nano-film by nano-scale cantilever specimen. Thin Solid Films 2010, 518, 6040–6047. [Google Scholar] [CrossRef]

- Hsu, Q.C.; Cheng, Y.Y.; Liu, B.H. Study on bonding properties of copper and aluminum in nano scale using molecular dynamics simulation. Appl. Mech. Mater. 2012, 152, 183–187. [Google Scholar] [CrossRef]

- Chu, G. Characterisation of microstructure and properties of nano-copper powders prepared by flow levitation method. Powder Metall. 2009, 52, 84–86. [Google Scholar] [CrossRef]

- Kassam, T.A.; Babu, N.H.; Ludford, N.; Yan, S.; Howkins, A. Secondary Phase Interaction at Interfaces of High-Strength Brazed Joints made using Liquid Phase Sintered Alumina Ceramics and Ag-Cu-Ti Braze Alloys. Sci. Rep. 2018, 8. [Google Scholar] [CrossRef]

- Akhtar, T.S.; Cooke, K.O.; Khan, T.I.; Shar, M.A. Nanoparticle Enhanced Eutectic Reaction during Diffusion Brazing of Aluminium to Magnesium. Nanomaterials 2019, 9, 370. [Google Scholar] [CrossRef]

| Element | Si | Mg | Fe | Cu | Mn | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | 0.20–0.60 | 0.45–0.90 | 0.35 | 0.10 | 0.10 | 0.10 | 0.10 | 0.10 | Balance |

| Temperature (°C) | 400 | 420 | 440 | 450 | 460 | 480 |

|---|---|---|---|---|---|---|

| Leak rate after diffusion joining (Pa·m3/s) | 10−6 | 10−6 | 10−10 | 10−10 | 10−10 | 10−10 |

| Leak rate after one week (Pa·m3/s) | 10−6 | 10−6 | 10−10 | 10−10 | 10−10 | 10−10 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Z.; Yang, H.; Feng, J.; Ji, F.; Niu, J.; Brnic, J. Flux-Free Diffusion Joining of SiCp/6063 Al Matrix Composites Using Liquid Gallium with Nano-Copper Particles in Atmosphere Environment. Nanomaterials 2020, 10, 437. https://doi.org/10.3390/nano10030437

Gao Z, Yang H, Feng J, Ji F, Niu J, Brnic J. Flux-Free Diffusion Joining of SiCp/6063 Al Matrix Composites Using Liquid Gallium with Nano-Copper Particles in Atmosphere Environment. Nanomaterials. 2020; 10(3):437. https://doi.org/10.3390/nano10030437

Chicago/Turabian StyleGao, Zeng, Huanyu Yang, Jianguang Feng, Fei Ji, Jitai Niu, and Josip Brnic. 2020. "Flux-Free Diffusion Joining of SiCp/6063 Al Matrix Composites Using Liquid Gallium with Nano-Copper Particles in Atmosphere Environment" Nanomaterials 10, no. 3: 437. https://doi.org/10.3390/nano10030437

APA StyleGao, Z., Yang, H., Feng, J., Ji, F., Niu, J., & Brnic, J. (2020). Flux-Free Diffusion Joining of SiCp/6063 Al Matrix Composites Using Liquid Gallium with Nano-Copper Particles in Atmosphere Environment. Nanomaterials, 10(3), 437. https://doi.org/10.3390/nano10030437

.JPG)