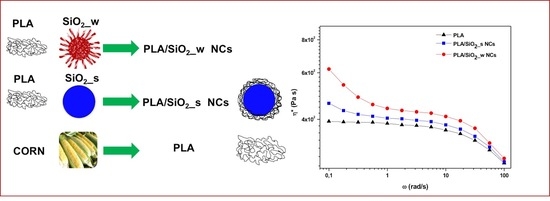

Improving Interaction at Polymer–Filler Interface: The Efficacy of Wrinkle Texture

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

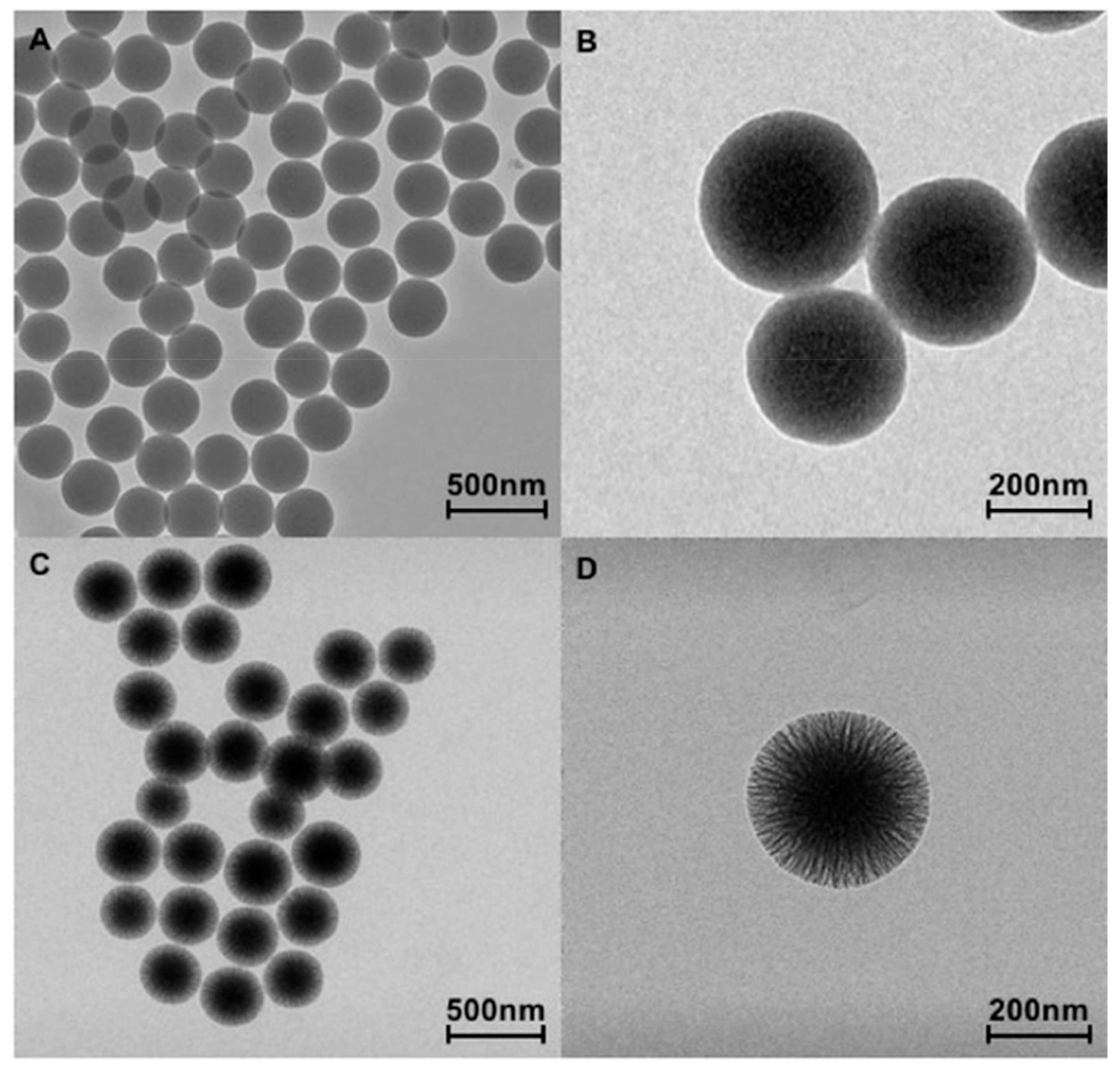

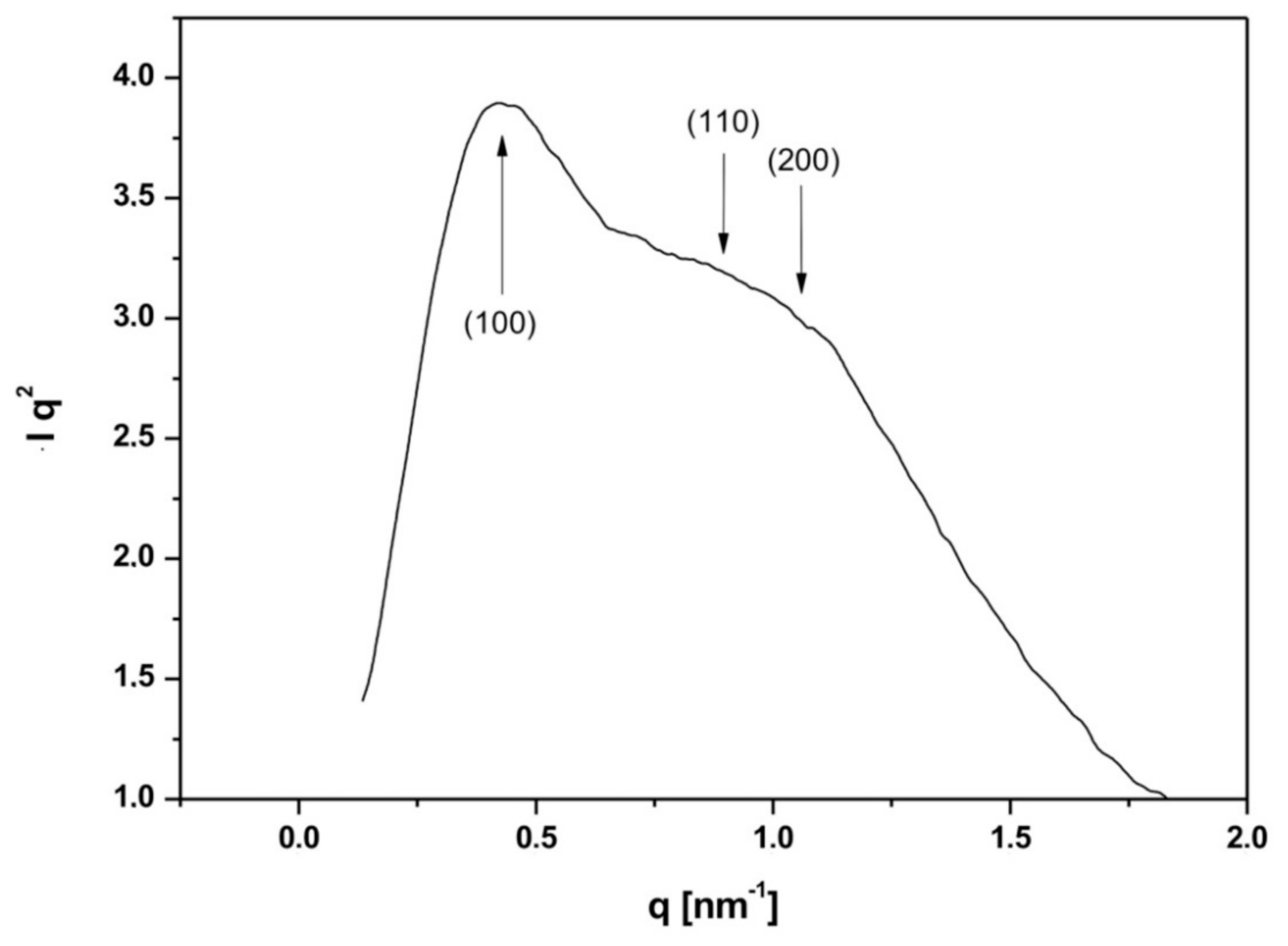

2.2. Synthesis of SiO2 Nanoparticles

2.3. Synthesis of PLA-Modified SiO2 Nanoparticles

2.4. Synthesis of PLA-SiO2 Nanocomposites

2.5. Characterization Techniques

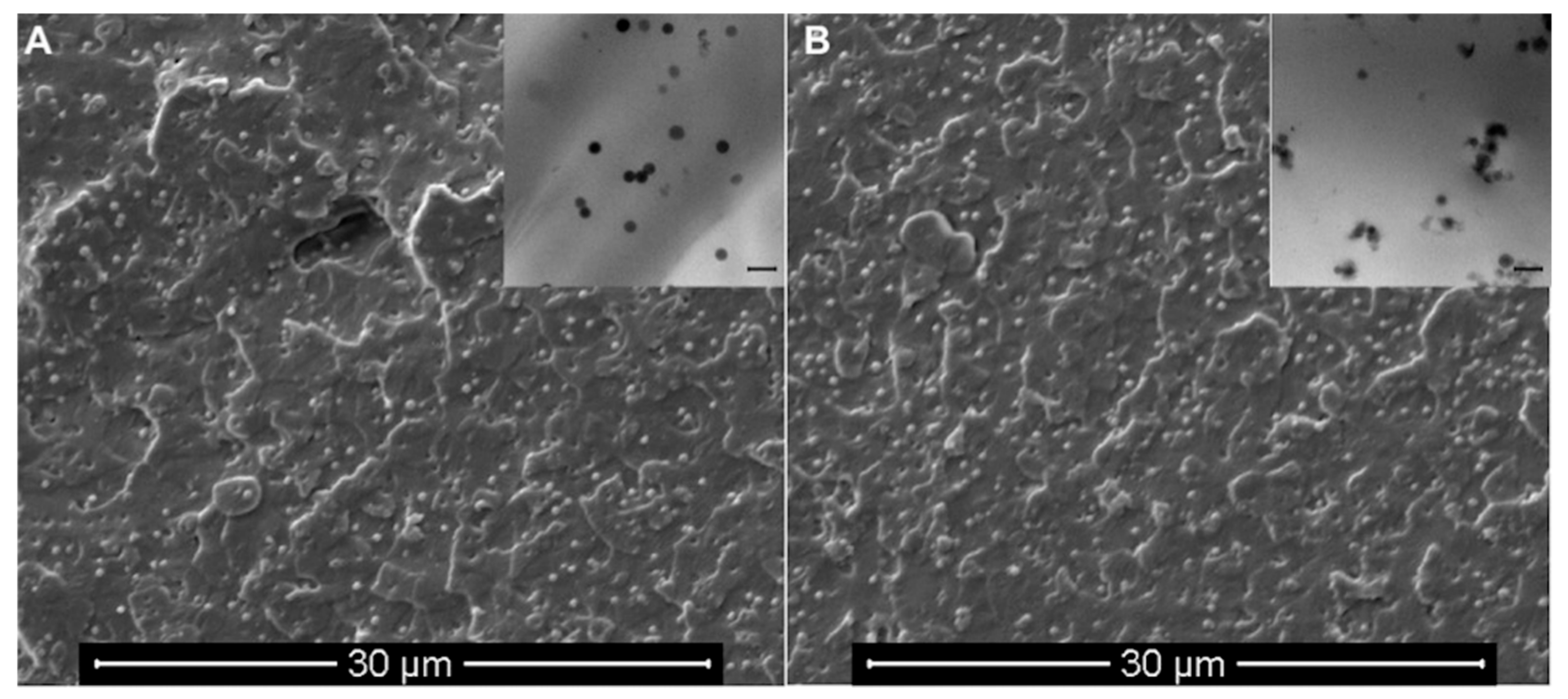

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Murariu, M.; Dubois, P. PLA composites. From production to properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef]

- Hao, X.; Kaschta, J.; Schubert, D.W. Viscous and elastic properties of polylactide melts filled with silica particles. Effect of particle size and concentration. Compos part B-eng. 2016, 89, 44–53. [Google Scholar] [CrossRef]

- Dil, E.J.; Virgilio, N.; Favis, B.D. The effect of the interfacial assembly of nano-silica in poly (lactic acid)/poly (butylene adipate-co-terephthalate) blends on morphology, rheology and mechanical properties. Eur. Polym. J. 2016, 85, 635–646. [Google Scholar]

- Moussaif, N.; Crespo, C.; Meier, J.G.; Jimenez, M.A. Synergistic reinforcement of nanoclay and mesoporous silicate fillers in polycaprolactone. the effect of nanoclay on the compatibility of the components. Polymer 2012, 53, 3741–3748. [Google Scholar] [CrossRef]

- Basu, A.; Nazarkovsky, M.; Ghadi, R.; Khan, W.; Domb, A.J. Poly (lactic acid)-based nanocomposites. Polym. Adv. Technol. 2017, 28, 919–930. [Google Scholar] [CrossRef]

- Bourbigot, S.; Fontaine, G.; Gallos, A.; Bellayer, S. Reactive extrusion of PLA and of PLA/carbon nanotubes nanocomposite. processing, characterization and flame retardancy. Polym. Adv. Technol. 2011, 22, 30–37. [Google Scholar] [CrossRef]

- Zhou, Y.; Lei, L.; Yang, B.; Li, J.; Ren, J. Preparation and characterization of polylactic acid (PLA) carbon nanotube nanocomposites. Polm. Test. 2018, 68, 34–38. [Google Scholar] [CrossRef]

- Park, S.H.; Lee, S.G.; Kim, S.H. Isothermal crystallization behavior and mechanical properties of polylactide/carbon nanotube nanocomposites. Compos. Part A-Appl. S. 2013, 46, 11–18. [Google Scholar] [CrossRef]

- Pinto, A.M.; Cabral, J.; Tanaka, D.A.P.; Mendes, A.M.; Magalhães, F.D. Effect of incorporation of graphene oxide and graphene nanoplatelets on mechanical and gas permeability properties of poly (lactic acid) films. Polym. Int. 2013, 62, 33–40. [Google Scholar] [CrossRef]

- Sabzi, M.; Jiang, L.; Nikfarjam, N. Graphene nanoplatelets as rheology modifiers for polylactic acid. Graphene aspect-ratio-dependent nonlinear rheological behavior. Ind. Eng. Chem. Res. 2015, 54, 8175–8182. [Google Scholar] [CrossRef]

- Musto, P.; La Manna, P.; Cimino, F.; Mensitieri, G.; Russo, P. Morphology, molecular interactions and H2O diffusion in a poly (lactic-acid)/graphene composite. A vibrational spectroscopy study. Spectrochim. Acta A 2019, 218, 40–50. [Google Scholar] [CrossRef] [PubMed]

- Jaratrotkamjorn, R.; Khaokong, C.; Tanrattanakul, V. Toughness enhancement of poly (lactic acid) by melt blending with natural rubber. J. Appl. Polym. Sci. 2012, 124, 5027–5036. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, K.; Xu, C.; Chen, Y. Supertoughened biobased poly (lactic acid)–epoxidized natural rubber thermoplastic vulcanizates. fabrication, co-continuous phase structure, interfacial in situ compatibilization, and toughening mechanism. J. Phys. Chem. B. 2015, 119, 12138–12146. [Google Scholar] [CrossRef] [PubMed]

- Ayutthaya, W.D.N.; Poompradub, S. Thermal and mechanical properties of poly (lactic acid)/natural rubber blend using epoxidized natural rubber and poly (methyl methacrylate) as co-compatibilizers. Macromol. Res. 2014, 22, 686–692. [Google Scholar] [CrossRef]

- Mohapatra, A.K.; Mohanty, S.; Nayak, S.K. Poly (lactic acid) and layered silicate nanocomposites prepared by melt mixing. Thermomechanical and morphological properties. Polym. Compos. 2012, 33, 2095–2104. [Google Scholar] [CrossRef]

- Tehrani, M.A.; Akbari, A.; Majumder, M. Handbook of Polymernanocomposites. Processing, Performance and Application; Springer: Berlin, Germany, 2014; pp. 53–67. [Google Scholar]

- Frone, A.N.; Berlioz, S.; Chailan, J.F.; Panaitescu, D.M. Morphology and thermal properties of PLA–cellulose nanofibers composites. Carbohydr. Polym. 2013, 91, 377–384. [Google Scholar] [CrossRef]

- Awal, A.; Rana, M.; Sain, M. Thermorheological and mechanical properties of cellulose reinforced PLA bio-composites. Mech. Mater. 2015, 80, 87–95. [Google Scholar] [CrossRef]

- Yang, W.; Fortunati, E.; Dominici, F.; Giovanale, G.; Mazzaglia, A.; Balestra, G.M.; Kenny, J.M.; Puglia, D. Synergic effect of cellulose and lignin nanostructures in PLA based systems for food antibacterial packaging. Eur. Polym. J. 2016, 79, 1–12. [Google Scholar] [CrossRef]

- Lv, H.; Song, S.; Sun, S.; Ren, L.; Zhang, H. Enhanced properties of poly (lactic acid) with silica nanoparticles. Polymers for Advanced Technologies. 2016, 27, 1156–1163. [Google Scholar] [CrossRef]

- Branda, F.; Silvestri, B.; Costantini, A.; Luciani, G. Effect of exposure to growth media on size and surface charge of silica based Stöber nanoparticles. a DLS and ζ-potential study. J. Solgel Sci. Technol. 2015, 73, 54–61. [Google Scholar] [CrossRef]

- Silvestri, B.; Pezzella, A.; Luciani, G.; Costantini, A.; Tescione, F.; Branda, F. Heparin conjugated silica nanoparticle synthesis. Mater. Sci. Eng. C 2012, 32, 2037–2041. [Google Scholar] [CrossRef]

- Silvestri, B.; Guarnieri, D.; Luciani, G.; Costantini, A.; Netti, P.A.; Branda, F. Fluorescent (rhodamine), folate decorated and doxorubicin charged, PEGylated nanoparticles synthesis. J. Mater. Sci: Mater. Med. 2012, 23, 1697–1704. [Google Scholar] [CrossRef] [PubMed]

- Silvestri, B.; Armanetti, P.; Sanità, G.; Vitiello, G.; Lamberti, A.; Calì, G.; Pezzella, A.; Luciani, G.; Menichetti, L.; Luin, S.; et al. Silver-nanoparticles as plasmon-resonant enhancers for eumelanin’s photoacoustic signal in a self-structured hybrid nanoprobe. Mater. Sci. Eng. C 2019, 102, 788–797. [Google Scholar] [CrossRef] [PubMed]

- Russo, P.; Costantini, A.; Luciani, G.; Tescione, F.; Lavorgna, M.; Branda, F.; Silvestri, B. Thermo-mechanical behavior of poly (butylene terephthalate)/silica nanocomposites. J. Appl. Polym. Sci. 2018, 135, 46006. [Google Scholar] [CrossRef]

- Silvestri, B.; Costantini, A.; Speranza, V.; Luciani, G.; Branda, F.; Russo, P. Agglomeration-free silica NPs in dry storage for PBT nanocomposite. J. Solgel Sci. Technol. 2016, 78, 531–538. [Google Scholar] [CrossRef]

- Luciani, G.; Costantini, A.; Silvestri, B.; Tescione, F.; Branda, F.; Pezzella, A. Synthesis, structure and bioactivity of pHEMA/SiO 2 hybrids derived through in situ sol–gel process. J. Solgel Sci. Technol. 2008, 46, 166. [Google Scholar] [CrossRef]

- Robles, E.; Urruzola, I.; Labidi, J.; Serrano, L. Surface-modified nano-cellulose as reinforcement in poly (lactic acid) to conform new composites. Ind. Crops Prod. 2015, 71, 44–53. [Google Scholar] [CrossRef]

- Miao, C.; Hamad, W.Y. In-situ polymerized cellulose nanocrystals (CNC)—poly (l-lactide)(PLLA) nanomaterials and applications in nanocomposite processing. Carbohydr. Polym. 2016, 153, 549–558. [Google Scholar] [CrossRef]

- Bondeson, D.; Oksman, K. Polylactic acid/cellulose whisker nanocomposites modified by polyvinyl alcohol. Compos. Part A-Appl. S. 2007, 38, 2486–2492. [Google Scholar] [CrossRef]

- Petersson, L.; Kvien, I.; Oksman, K. Structure and thermal properties of poly (lactic acid)/cellulose whiskers nanocomposite materials. Compos. Sci. Technol. 2007, 67, 2535–2544. [Google Scholar] [CrossRef]

- De Paula, E.L.; Roig, F.; Mas, A.; Habas, J.P.; Mano, V.; Pereira, F.V.; Robin, J.J. Effect of surface-grafted cellulose nanocrystals on the thermal and mechanical properties of PLLA based nanocomposites. Eur. Polym. J. 2016, 84, 173–187. [Google Scholar] [CrossRef]

- Raquez, J.M.; Habibi, Y.; Murariu, M.; Dubois, P. Polylactide (PLA)-based nanocomposites. Prog. Polym. Sci. 2013, 38, 1504–1542. [Google Scholar] [CrossRef]

- Hajibeygi, M.; Shafiei-Navid, S. Design and preparation of poly (lactic acid) hydroxyapatite nanocomposites reinforced with phosphorus-based organic additive: Thermal, combustion, and mechanical properties studies. Polym. Adv. Technol. 2019. [Google Scholar] [CrossRef]

- Pal, N.; Banerjee, S.; Roy, P.; Pal, K. Melt-blending of unmodified and modified cellulose nanocrystals with reduced graphene oxide into PLA matrix for biomedical application. Polym. Adv. Technol. 2019. [Google Scholar] [CrossRef]

- Wu, S.H.; Mou, C.Y.; Lin, H.P. Synthesis of mesoporous silica nanoparticles. Chem. Soc. Rev. 2013, 42, 3862–3875. [Google Scholar] [CrossRef]

- Maiti, M.; Basak, G.C.; Srivastava, V.K.; Jasra, R.V. Mesoporous silica reinforced polybutadiene rubber hybrid composite. Int. J. Ind. Chem. 2016, 7, 131–141. [Google Scholar] [CrossRef]

- Wang, N.; Fang, Q.; Zhang, J.; Chen, E.; Zhang, X. Incorporation of nano-sized mesoporous MCM-41 material used as fillers in natural rubber composite. Mater. Sci. Eng. A 2011, 528, 3321–3325. [Google Scholar] [CrossRef]

- Califano, V.; Sannino, F.; Costantini, A.; Avossa, J.; Cimino, S.; Aronne, A. Wrinkled silica nanoparticles: efficient matrix for β-glucosidase immobilization. J. Phys. Chem. C. 2018, 122, 8373–8379. [Google Scholar] [CrossRef]

- Stöber, W.; Fink, A.; Bohn, E. Controlled growth of monodisperse silica spheres in the micron size range. J. Colloid Interface Sci. 1968, 26, 62–69. [Google Scholar] [CrossRef]

- Yang, Z.; Chen, G.; Weng, H.; Shen, W.; Huang, Z.; Lin, M. Efficient and selective separation of U (VI) and Th (IV) from rare earths using functionalized hierarchically mesoporous silica. J. Mater. Sci. 2018, 53, 3398–3416. [Google Scholar] [CrossRef]

- Pauw, B.R. Everything SAXS: Small-angle scattering pattern collection and correction. J. Phys. Condens. Mat. 2013, 25, 383201. [Google Scholar] [CrossRef] [PubMed]

- Yano, S.; Iwata, K.; Kurita, K. Biomimetic materials, sensors and systems. Mat. Sci. Eng. C. 1998, 6, 75–90. [Google Scholar] [CrossRef]

- Du, X.; He, J. Hierarchically mesoporous silica nanoparticles: extraction, amino-functionalization, and their multipurpose potentials. Langmuir 2011, 27, 2972–2979. [Google Scholar] [CrossRef] [PubMed]

- Yi, Z.; Dumée, L.F.; Garvey, C.J.; Feng, C.; She, F.; Rookes, J.E.; Mudie, S.; Cahill, D.M.; Kong, L. A new insight into growth mechanism and kinetics of mesoporous silica nanoparticles by in situ small angle X-ray scattering. Langmuir 2015, 31, 8478–8487. [Google Scholar] [CrossRef] [PubMed]

- Morales, D.M.; Frenzel, R.A.; Romanelli, G.P.; Pizzio, L.R. Synthesis and characterization of nanoparticulate silica with organized multimodal porous structure impregnated with 12-phosphotungstic acid for its use in heterogeneous catalysis. Mol. Catal. 2018. [Google Scholar] [CrossRef]

- Cho, W.; Lee, H.I.; Shim, B.S.; Cha, B.J.; Kim, J.M.; Char, K. Tunable synthesis of hierarchical mesoporous silica via porogen-carrying organosilicates. Micropor. Mesopor. Mat. 2017, 239, 409–415. [Google Scholar] [CrossRef]

- Patti, A.; Russo, P.; Acierno, D.; Acierno, S. The effect of filler functionalization on dispersion and thermal conductivity of polypropylene/multi wall carbon nanotubes composites. Comp. Part B Eng. 2016, 94, 350–359. [Google Scholar] [CrossRef]

- Di Maio, L.; Garofalo, E.; Scarfato, P.; Incarnato, L. Effect of polymer/organoclay composition on morphology and rheological properties of polylactide nanocomposites. Polym. Comp. 2015, 36, 1135–1144. [Google Scholar] [CrossRef]

- Dorigato, A.; Pegoretti, A.; Penati, A. Linear low-density polyethylene/silica micro- and nanocomposites: dynamic rheological measurements and modelling. eXpress Polym. Lett. 2010, 4, 115–129. [Google Scholar] [CrossRef]

- Sumfleth, J.; Bushhorn, S.T.; Schulte, K. Comparison of rheological and electrical percolation phenomena in carbon black and carbon nanotube filled epoxy polymers. J. Mater. Sci. 2011, 46, 659–669. [Google Scholar] [CrossRef]

- Palade, L.I.; Lehermeier, H.J.; Dorgan, J.R. Melt rheology of high l-content poly(lactic acid). Macromolecules 2001, 34, 1384–1390. [Google Scholar] [CrossRef]

- Wen, X.; Lin, Y.; Han, C.Y.; Zhang, K.Y.; Ran, X.H.; Li, Y.S.; Dong, L.S. Thermomechanical and optical properties of biodegradable poly(L-lactide)/silica nanocomposites by melt compounding. J. Appl. Polym. Sci. 2009, 114, 3379–3388. [Google Scholar] [CrossRef]

- Wu, D.F.; Wu, L.; Zhang, M.; Zhao, Y.L. Viscoelasticity and thermal stability of polylactide composites with various functionalized carbon nanotubes. Polym. Degrad. Stab. 2008, 93, 1577–1584. [Google Scholar] [CrossRef]

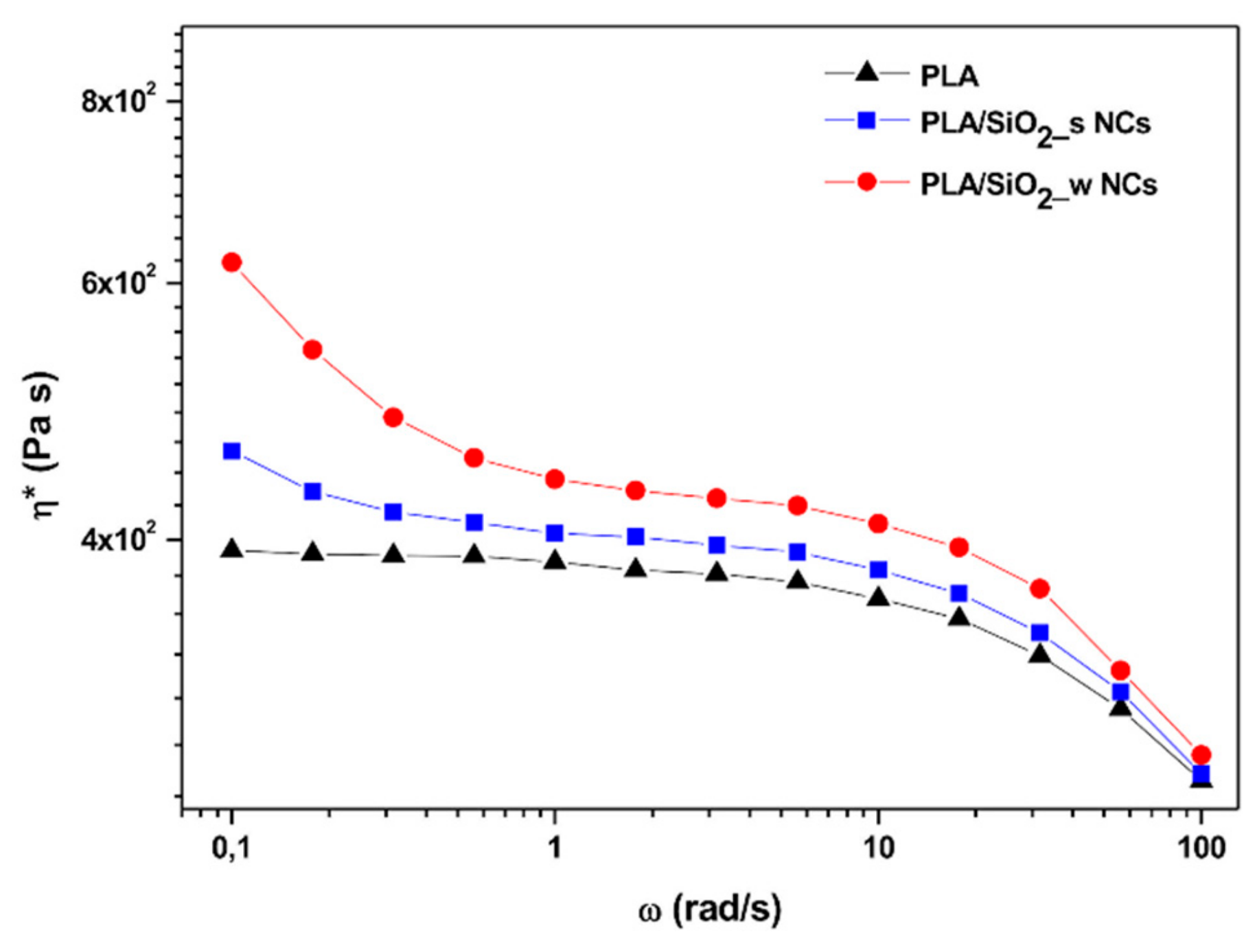

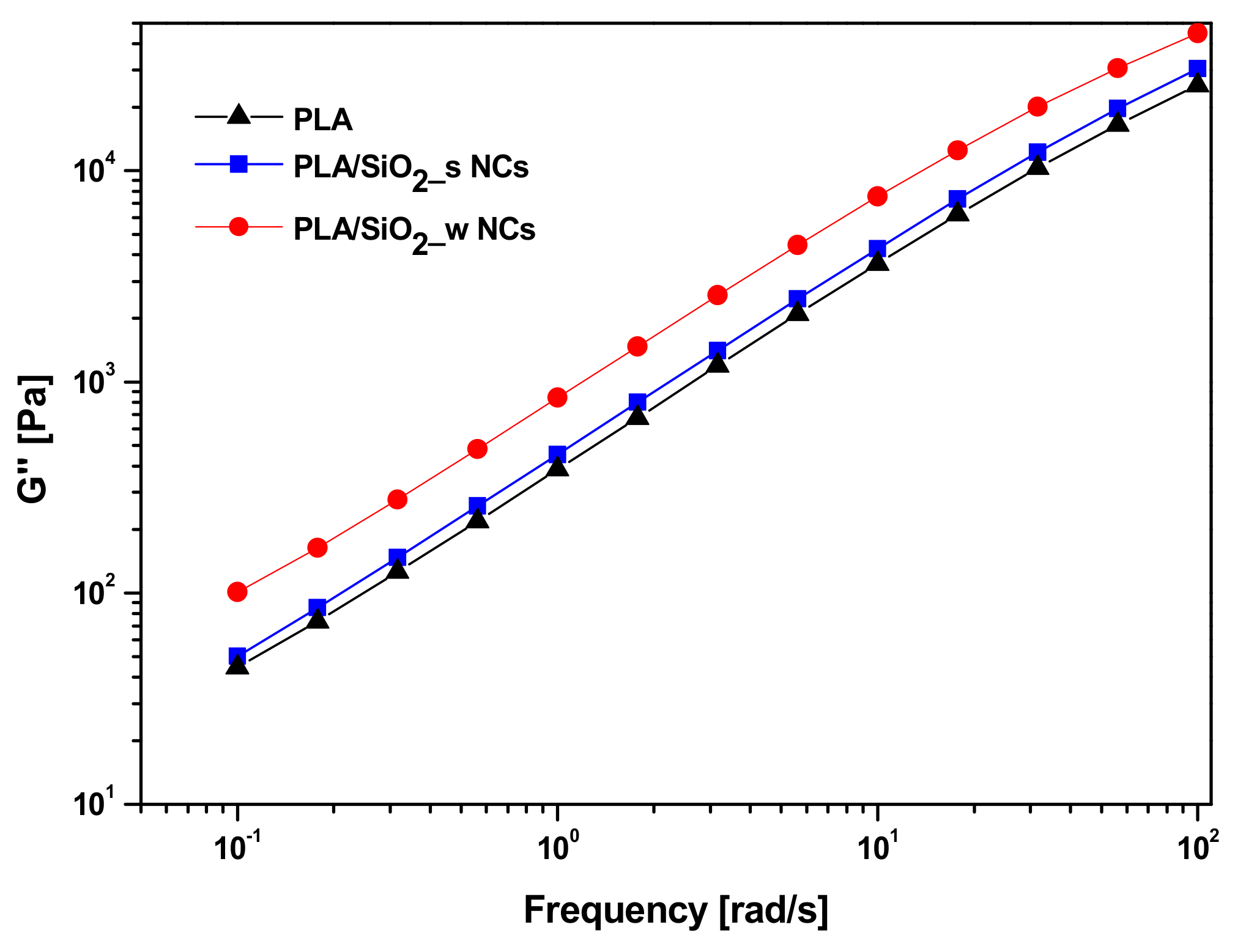

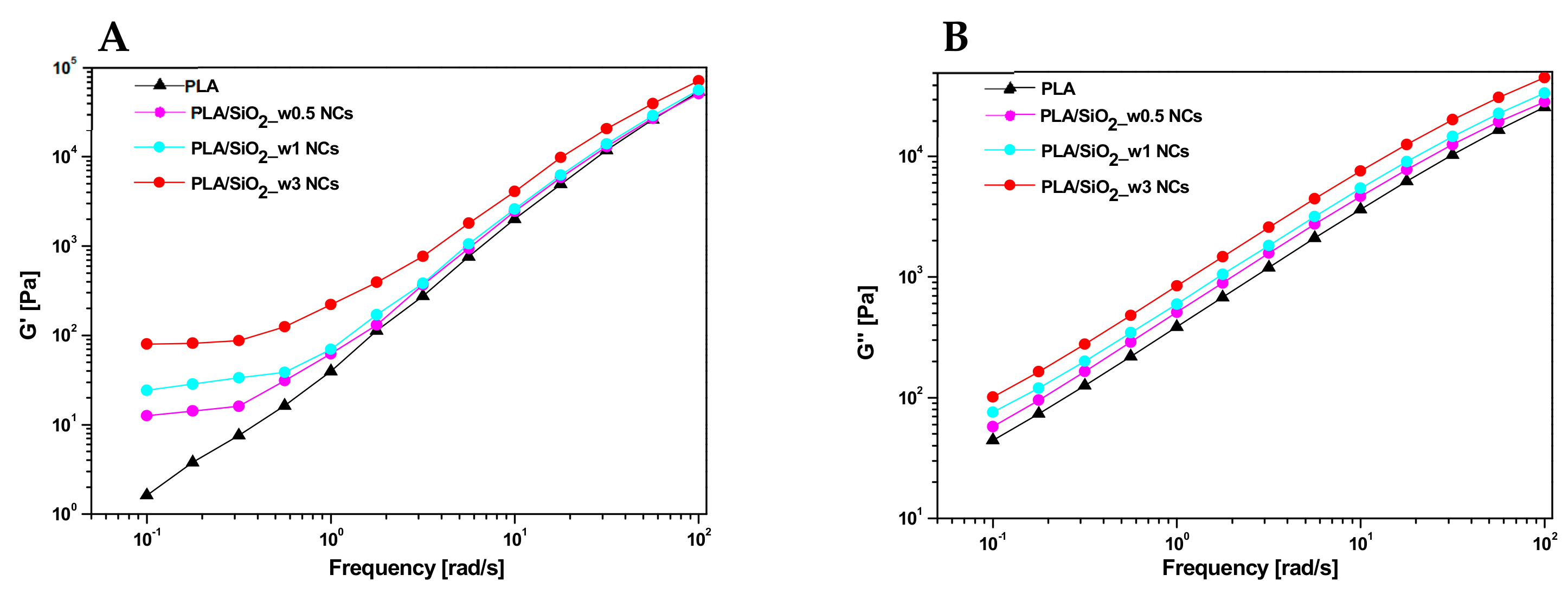

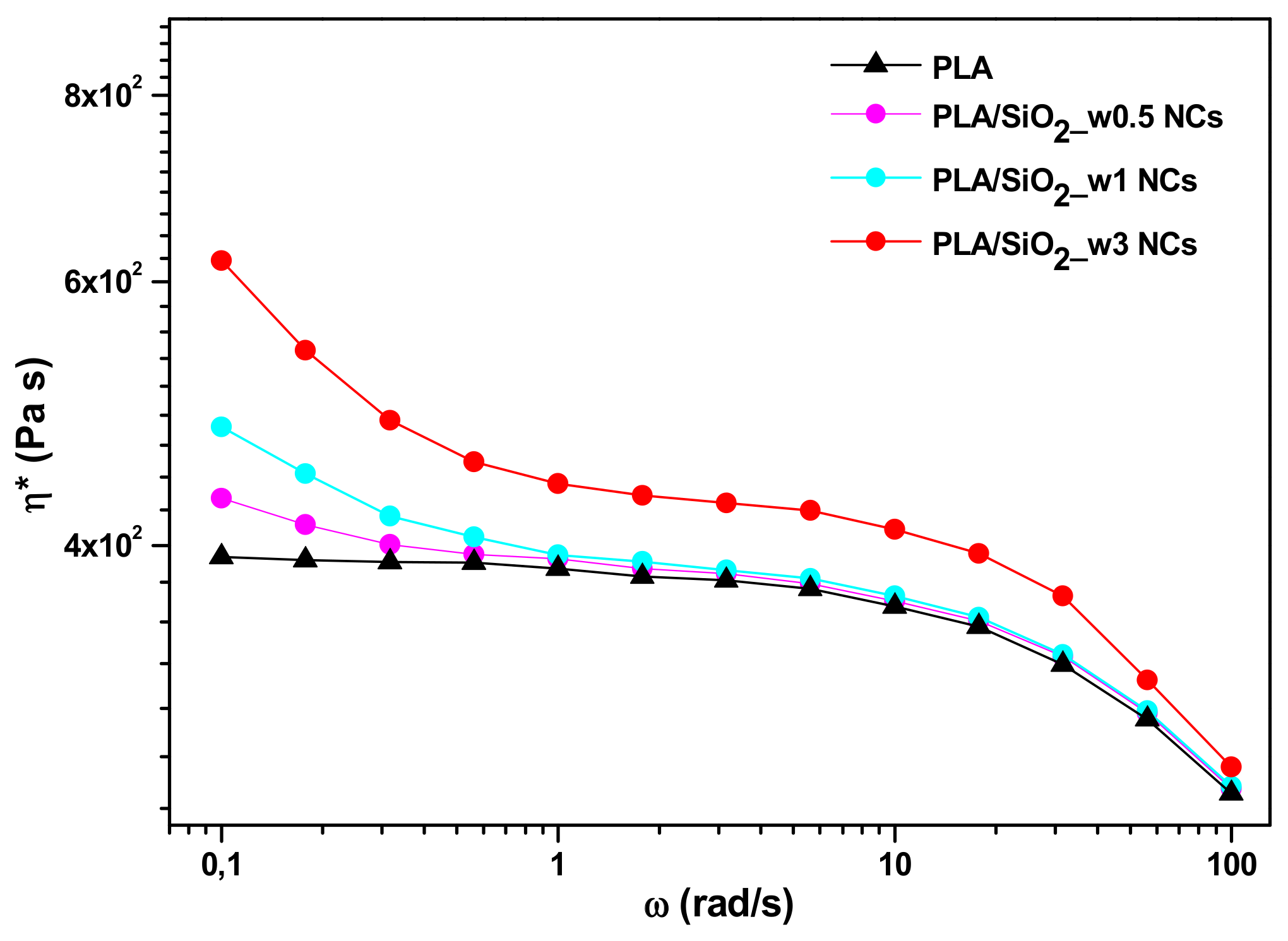

| Sample | n |

|---|---|

| PLA | 1.320 |

| PLA/SiO2_s NCs | 0.602 |

| PLA/SiO2_w NCs | 0.074 |

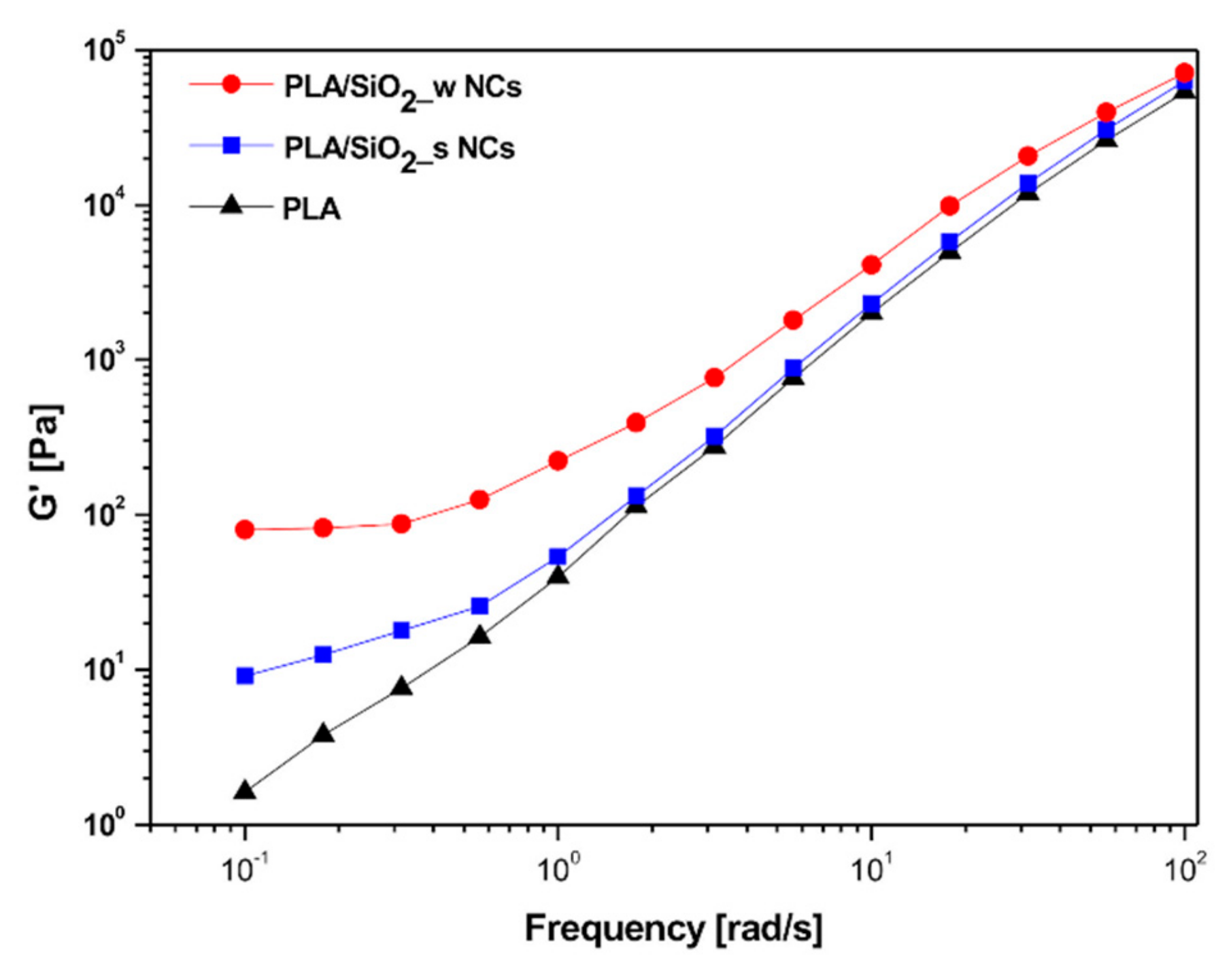

| Sample | G’0.01Hz (Pa) | η*0.01Hz (Pa*s) | λ (s) |

|---|---|---|---|

| PLA | 1.6 | 400 | 40 |

| PLA/SiO2_s NCs | 9.1 | 460 | 198 |

| PLA/SiO2_w NCs | 80 | 620 | 1290 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Russo, P.; Venezia, V.; Tescione, F.; Avossa, J.; Luciani, G.; Silvestri, B.; Costantini, A. Improving Interaction at Polymer–Filler Interface: The Efficacy of Wrinkle Texture. Nanomaterials 2020, 10, 208. https://doi.org/10.3390/nano10020208

Russo P, Venezia V, Tescione F, Avossa J, Luciani G, Silvestri B, Costantini A. Improving Interaction at Polymer–Filler Interface: The Efficacy of Wrinkle Texture. Nanomaterials. 2020; 10(2):208. https://doi.org/10.3390/nano10020208

Chicago/Turabian StyleRusso, Pietro, Virginia Venezia, Fabiana Tescione, Joshua Avossa, Giuseppina Luciani, Brigida Silvestri, and Aniello Costantini. 2020. "Improving Interaction at Polymer–Filler Interface: The Efficacy of Wrinkle Texture" Nanomaterials 10, no. 2: 208. https://doi.org/10.3390/nano10020208

APA StyleRusso, P., Venezia, V., Tescione, F., Avossa, J., Luciani, G., Silvestri, B., & Costantini, A. (2020). Improving Interaction at Polymer–Filler Interface: The Efficacy of Wrinkle Texture. Nanomaterials, 10(2), 208. https://doi.org/10.3390/nano10020208