Microstructure-Induced Anisotropic Optical Properties of YF3 Columnar Thin Films Prepared by Glancing Angle Deposition

Abstract

1. Introduction

2. Theory and Optical Modeling

3. Experimental Details

3.1. Materials and Sample Preparation

3.2. Characterizations

4. Results and Discussion

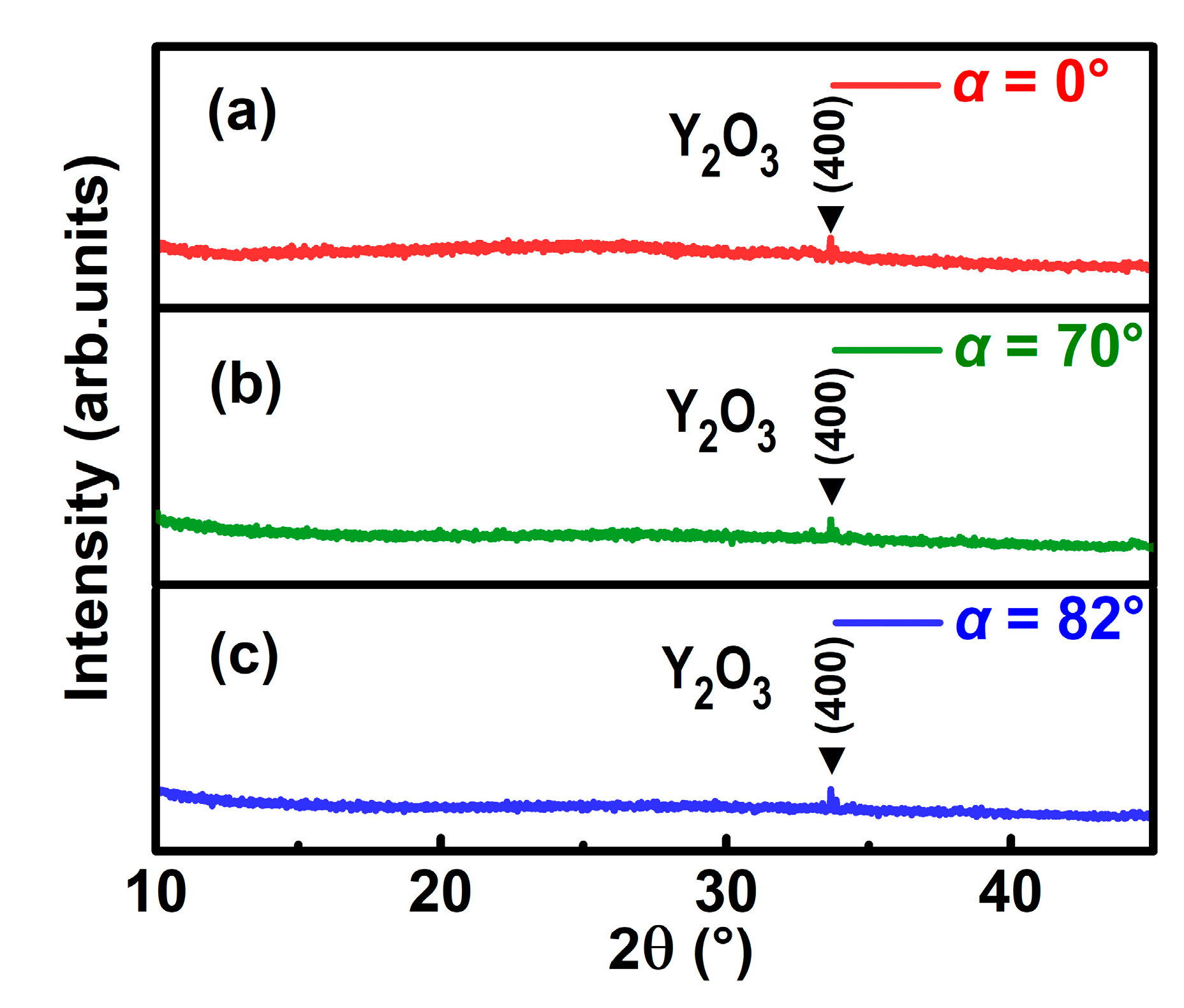

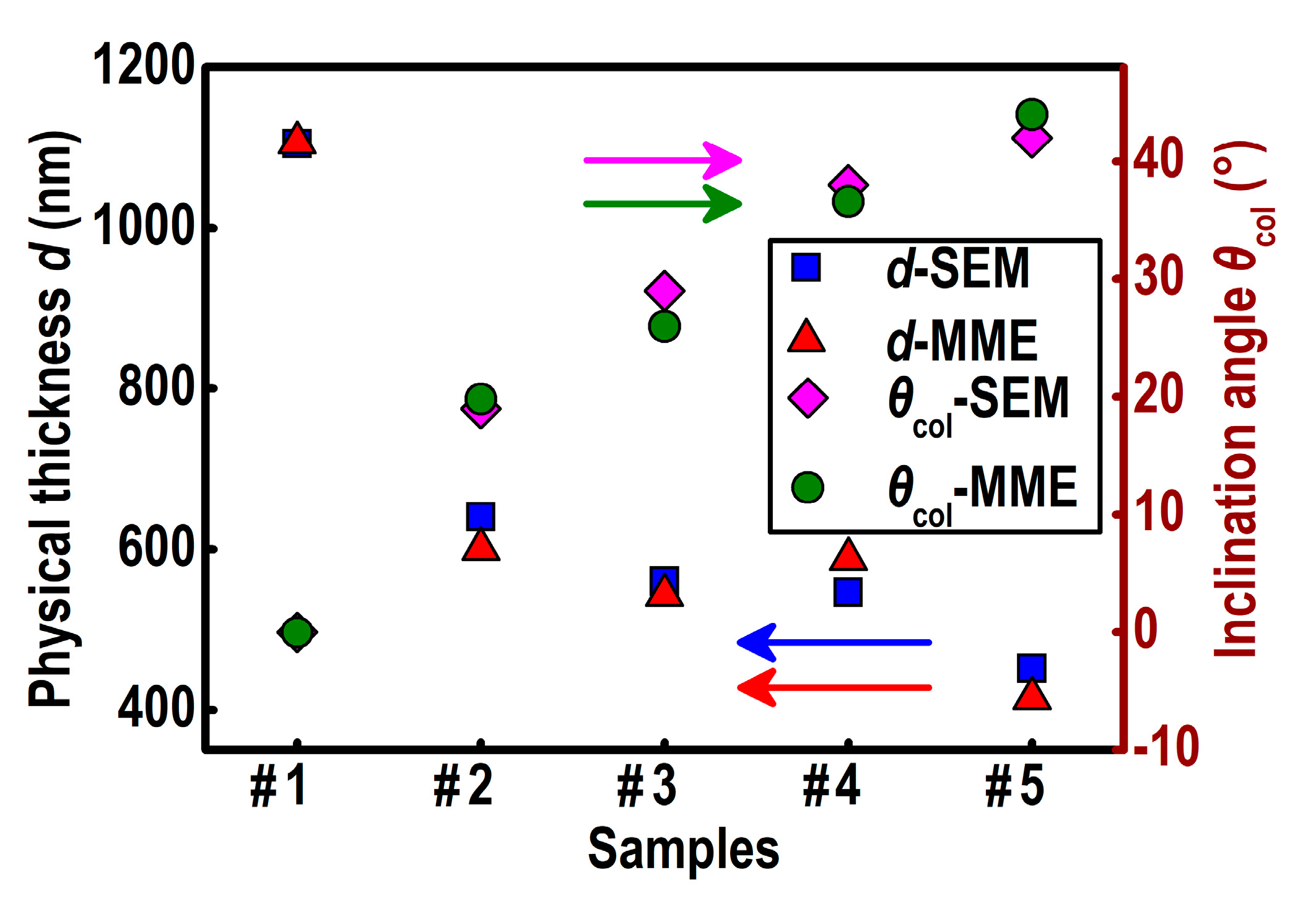

4.1. Microstructure of YF3 CTFs

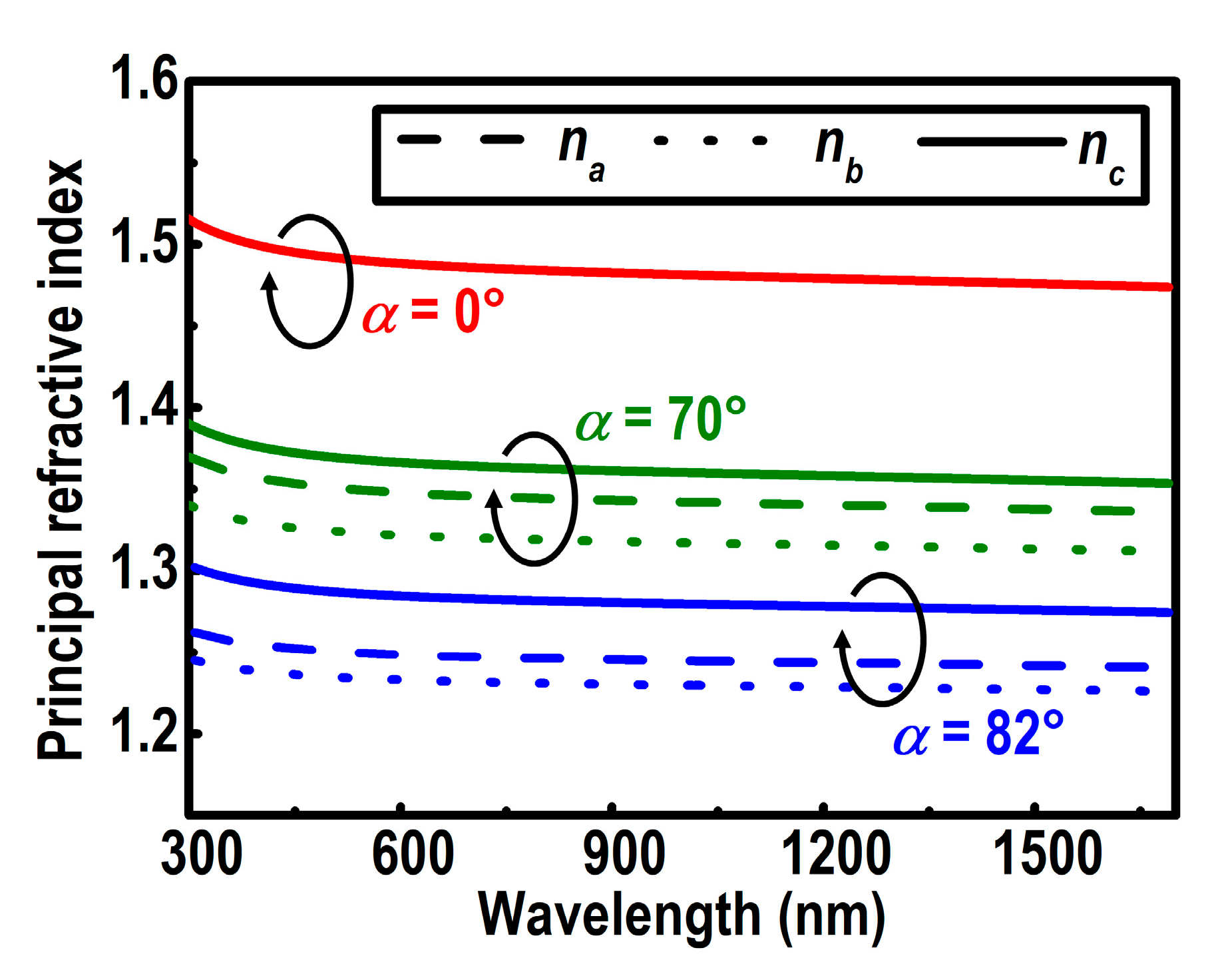

4.2. Optical Properties of YF3 CTFs

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Barabasi, A.L.; Stanley, H.E. Fractal Concepts in Surface Growth; Cambridge U.P.: Cambridge, UK, 1995. [Google Scholar]

- Young, N.O.; Kowal, J. Optically active fluorite films. Nature 1959, 183, 104–105. [Google Scholar] [CrossRef]

- Petrov, I.; Barna, P.B.; Hultman, L.; Greene, J.E. Microstructural evolution during film growth. J. Vac. Sci. Technol. A 2003, 21, S117–S128. [Google Scholar] [CrossRef]

- Barranco, A.; Borras, A.; Gonzalez-Elipe, A.R.; Palmero, A. Perspectives on oblique angle deposition of thin films: From fundamentals to devices. Prog. Mater. Sci. 2016, 76, 59–153. [Google Scholar] [CrossRef]

- Vick, D.; Friedrich, L.J.; Dew, S.K.; Brett, M.J.; Robbie, K.; Seto, M.; Smy, T. Self-shadowing and surface diffusion effects in obliquely deposited thin films. Thin Solid Films 1999, 339, 88–94. [Google Scholar] [CrossRef]

- Kranenburg, H.; Lodder, C. Tailoring growth and local composition by oblique-incidence deposition: A review and new experimental data. Mater. Sci. Eng. R 1994, 11, 295–354. [Google Scholar] [CrossRef]

- Kuo, M.-L.; Poxson, D.J.; Kim, Y.S.; Mont, F.W.; Kim, J.K.; Schubert, E.F.; Lin, S.-Y. Realization of a near-perfect antireflection coating for silicon solar energy utilization. Opt. Lett. 2008, 33, 2527–2529. [Google Scholar] [CrossRef]

- Xi, J.Q.; Schubert, M.F.; Kim, J.K.; Schubert, E.F.; Chen, M.; Lin, S.-Y.; Liu, W.; Smart, J.A. Optical thin-film materials with low refractive index for broadband elimination of Fresnel reflection. Nat. Photonics 2007, 1, 176–179. [Google Scholar] [CrossRef]

- Khudhayer, W.J.; Kariuki, N.N.; Wang, X.; Myers, D.J.; Shaikh, A.U.; Karabacak, T. Oxygen reduction reaction electrocatalytic activity of glancing angle deposited platinum nanorod arrays. J. Electrochem. Soc. 2011, 158, B1029–B1041. [Google Scholar] [CrossRef]

- Yuan, J.; Wang, B.; Wang, H.; Chai, Y.; Jin, Y.; Qi, H.; Shao, J. Electrochromic behavior of WO3 thin films prepared by GLAD. Appl. Surf. Sci. 2018, 447, 471–478. [Google Scholar] [CrossRef]

- Sun, Y.; Xiao, X.; Xu, G.; Dong, G.; Chai, G.; Zhang, H.; Liu, P.; Zhu, H.; Zhan, Y. Anisotropic vanadium dioxide sculptured thin films with superior thermochromic properties. Sci. Rep. 2013, 3, 1–10. [Google Scholar] [CrossRef]

- Xiao, X.; Dong, G.; Xu, C.; He, H.; Qi, H.; Fan, Z.; Shao, J. Structure and optical properties of Nb2O5 sculptured thin films by glancing angle deposition. Appl. Surf. Sci. 2008, 255, 2192–2195. [Google Scholar] [CrossRef]

- Motohiro, T.; Taga, Y. Thin film retardation plate by oblique deposition. Appl. Opt. 1989, 28, 2466–2482. [Google Scholar] [CrossRef]

- Hodgkinson, I.; Wu, Q.H. Birefringent thin-film polarizers for use at normal incidence and with planar technologies. Appl. Phys. Lett. 1999, 74, 1794–1796. [Google Scholar] [CrossRef]

- Kaminska, K.; Robbie, K. Birefringent omnidirectional reflector. Appl. Opt. 2004, 43, 1570–1576. [Google Scholar] [CrossRef]

- Toader, O.; John, S. Proposed square spiral microfabrication architecture for large three-dimensional photonic band gap crystals. Science 2001, 292, 1133–1135. [Google Scholar] [CrossRef]

- Chen, G.; Qiu, H.; Fan, R.; Hao, S.; Tan, S.; Yang, C.; Han, G. Lanthanide-doped ultrasmall yttrium fluoride nanoparticles with enhanced multicolor upconversion photoluminescence. J. Mater. Chem. 2012, 22, 20190–20196. [Google Scholar] [CrossRef]

- Condorelli, G.G.; Anastasi, G.; Fragalà, I.L. MOCVD of YF3 and Y1–xErxF3 thin films from precursors synthesized in Situ. Chem. Vap. Depos. 2005, 11, 324–329. [Google Scholar] [CrossRef]

- Barrioz, V.; Irvine, S.J.C.; Jones, D.P. In situ and ex situ stress measurements of YF3 single layer optical coatings deposited by electron beam evaporator. J. Mater. Sci. Mater. Electron. 2003, 14, 559–566. [Google Scholar] [CrossRef]

- Pilvi, T.; Puukilainen, E.; Munnik, F.; Leskelä, M.; Ritala, M. ALD of YF3 thin films from TiF4 and Y(thd)3 precursors. Chem. Vap. Depos. 2009, 15, 27–32. [Google Scholar] [CrossRef]

- Chindaudom, P.; Vedam, K. Characterization of inhomogeneous transparent thin films on transparent substrates by spectroscopic ellipsometry: Refractive indices n(λ) of some fluoride coating materials. Appl. Opt. 1994, 33, 2664–2671. [Google Scholar] [CrossRef]

- Pellicori, S.F.; Colton, E. Fluoride compounds for IR coatings. Thin Solid Films 1992, 209, 109–115. [Google Scholar] [CrossRef]

- Lemarquis, F.; Marchand, G.; Amra, C. Design and manufacture of low-absorption ZnS–YF3 antireflection coatings in the 3.5–16-μm spectral range. Appl. Opt. 1998, 37, 4239–4244. [Google Scholar] [CrossRef] [PubMed]

- Goldstein, D.H. Mueller matrix dual-rotating retarder polarimeter. Appl. Opt. 1992, 31, 6676–6683. [Google Scholar] [CrossRef]

- Huang, C.Y.T.; Kargar, F.; Debnath, T.; Debnath, B.; Valentin, M.D.; Synowicki, R.; Schoeche, S.; Lake, R.K.; Balandin, A.A. Phononic and photonic properties of shape-engineered silicon nanoscale pillar arrays. Nanotechnology 2020, 31, 30LT01. [Google Scholar] [CrossRef]

- Robbie, K.; Brett, M.J.; Lakhtakia, A. Chiral sculptured thin films. Nature 1996, 384, 616. [Google Scholar] [CrossRef]

- Tompkins, H.G.; Eugene, A.I. Handbook of Ellipsometry; William Andrew Inc.: New York, NY, USA, 2005. [Google Scholar]

- Arwin, H.; Berlind, T.; Johs, B.; Järrendahl, K. Cuticle structure of the scarab beetle Cetonia aurata analyzed by regression analysis of Mueller-matrix ellipsometric data. Opt. Express 2013, 21, 22645–22656. [Google Scholar] [CrossRef]

- Berreman, D.W. Optics in stratified and anisotropic media: 4×4-matrix formulation. J. Opt. Soc. Am. 1972, 62, 502–510. [Google Scholar] [CrossRef]

- Schubert, M. Polarization-dependent optical parameters of arbitrarily anisotropic homogeneous layered systems. Phys. Rev. B 1996, 53, 4265–4274. [Google Scholar] [CrossRef]

- Lei, P.; Zhu, J.; Zhu, Y.; Han, J. Preparation and optical properties of sputtered-deposition yttrium fluoride film. Nucl. Instrum. Methods Phys. Res. Sect. B 2013, 307, 429–433. [Google Scholar]

- Gospodyn, J.; Sit, J.C. Characterization of dielectric columnar thin films by variable angle Mueller matrix and spectroscopic ellipsometry. Opt. Mater. 2006, 29, 318–325. [Google Scholar] [CrossRef]

- Spanier, J.E.; Herman, I.P. Use of hybrid phenomenological and statistical effective-medium theories of dielectric functions to model the infrared reflectance of porous SiC films. Phys. Rev. B 2000, 61, 10437–10450. [Google Scholar] [CrossRef]

- Wang, X.J.; Abell, J.L.; Zhao, Y.P.; Zhang, Z.M. Angle-resolved reflectance of obliquely aligned silver nanorods. Appl. Opt. 2012, 51, 1521–1531. [Google Scholar] [CrossRef]

- Polder, D.; van Santeen, J.H. The effective permeability of mixtures of solids. Physica 1946, 12, 257–271. [Google Scholar] [CrossRef]

- Aspnes, D.E. Optical properties of thin films. Thin Solid Films 1982, 89, 249–262. [Google Scholar] [CrossRef]

- Hodgkinson, I.; Wu, Q.h.; Hazel, J. Empirical equations for the principal refractive indices and column angle of obliquely deposited films of tantalum oxide, titanium oxide, and zirconium oxide. Appl. Opt. 1998, 37, 2653–2659. [Google Scholar] [CrossRef]

- Tait, R.N.; Smy, T.; Brett, M.J. Modelling and characterization of columnar growth in evaporated films. Thin Solid Films 1993, 226, 196–201. [Google Scholar] [CrossRef]

- Charles, C.; Martin, N.; Devel, M.; Ollitrault, J.; Billard, A. Correlation between structural and optical properties of WO3 thin films sputter deposited by glancing angle deposition. Thin Solid Films 2013, 534, 275–281. [Google Scholar] [CrossRef]

- Hossain, M.M.; Gu, M. Radiative cooling: Principles, progress, and potentials. Adv. Sci. 2016, 3, 1500360. [Google Scholar] [CrossRef]

- Chaffar Akkari, F.; Ben Jbara, H.; Abdelkader, D.; Gallas, B.; Kanzari, M. Effect of angle deposition γ on the structural, optical and electrical properties of copper oxide zigzag (+γ, −γ) nanostructures elaborated by glancing angle deposition. Thin Solid Films 2018, 657, 61–69. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shan, Y.; Liu, P.; Chen, Y.; Zhang, H.; Tu, H.; Zheng, Y.; Zhang, R.; Wang, S.; Li, J.; Chen, L. Microstructure-Induced Anisotropic Optical Properties of YF3 Columnar Thin Films Prepared by Glancing Angle Deposition. Nanomaterials 2020, 10, 2413. https://doi.org/10.3390/nano10122413

Shan Y, Liu P, Chen Y, Zhang H, Tu H, Zheng Y, Zhang R, Wang S, Li J, Chen L. Microstructure-Induced Anisotropic Optical Properties of YF3 Columnar Thin Films Prepared by Glancing Angle Deposition. Nanomaterials. 2020; 10(12):2413. https://doi.org/10.3390/nano10122413

Chicago/Turabian StyleShan, Yao, Pian Liu, Yao Chen, Haotian Zhang, Huatian Tu, Yuxiang Zheng, Rongjun Zhang, Songyou Wang, Jing Li, and Liangyao Chen. 2020. "Microstructure-Induced Anisotropic Optical Properties of YF3 Columnar Thin Films Prepared by Glancing Angle Deposition" Nanomaterials 10, no. 12: 2413. https://doi.org/10.3390/nano10122413

APA StyleShan, Y., Liu, P., Chen, Y., Zhang, H., Tu, H., Zheng, Y., Zhang, R., Wang, S., Li, J., & Chen, L. (2020). Microstructure-Induced Anisotropic Optical Properties of YF3 Columnar Thin Films Prepared by Glancing Angle Deposition. Nanomaterials, 10(12), 2413. https://doi.org/10.3390/nano10122413