Making van der Waals Heterostructures Assembly Accessible to Everyone

Abstract

1. Introduction

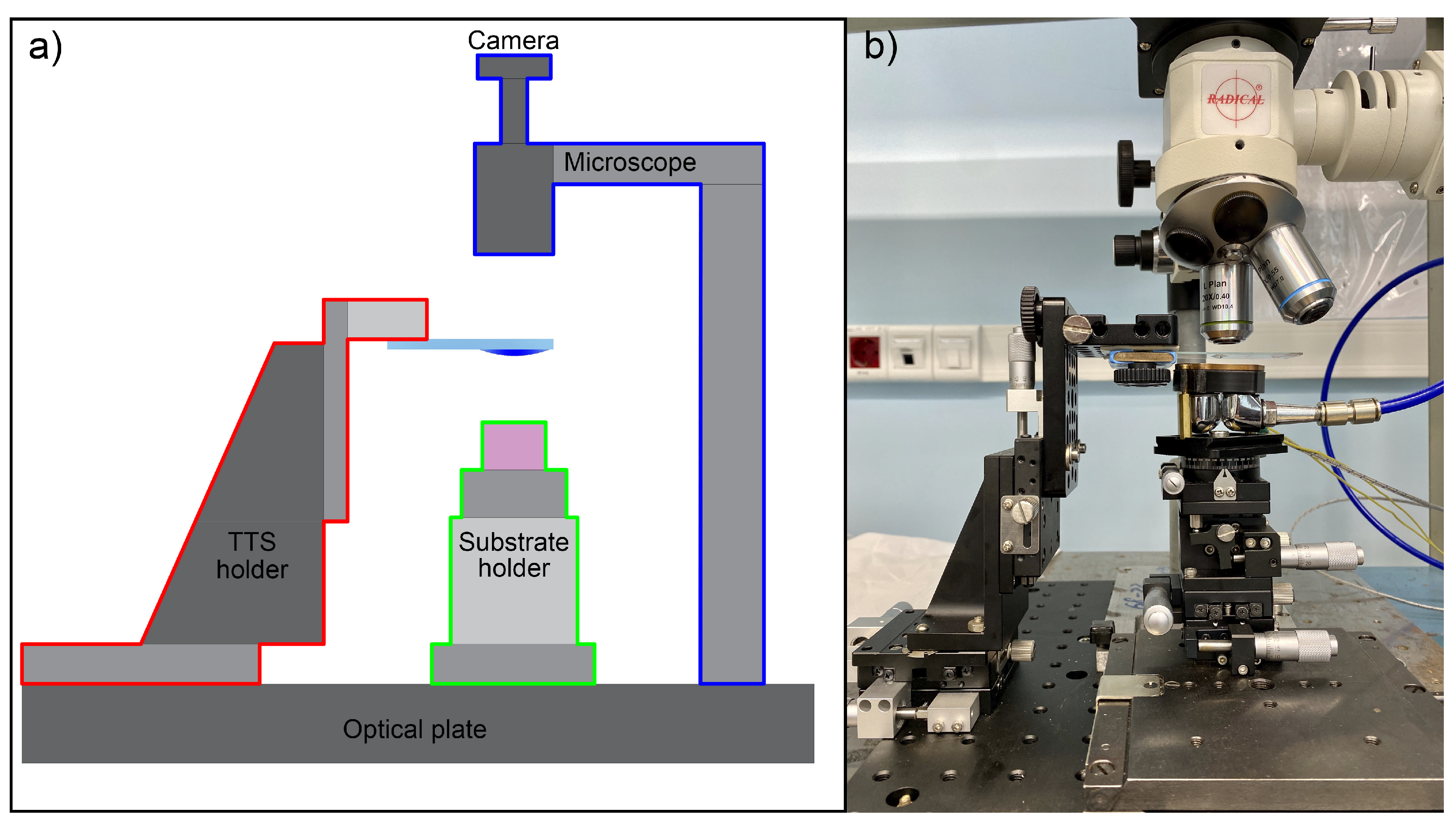

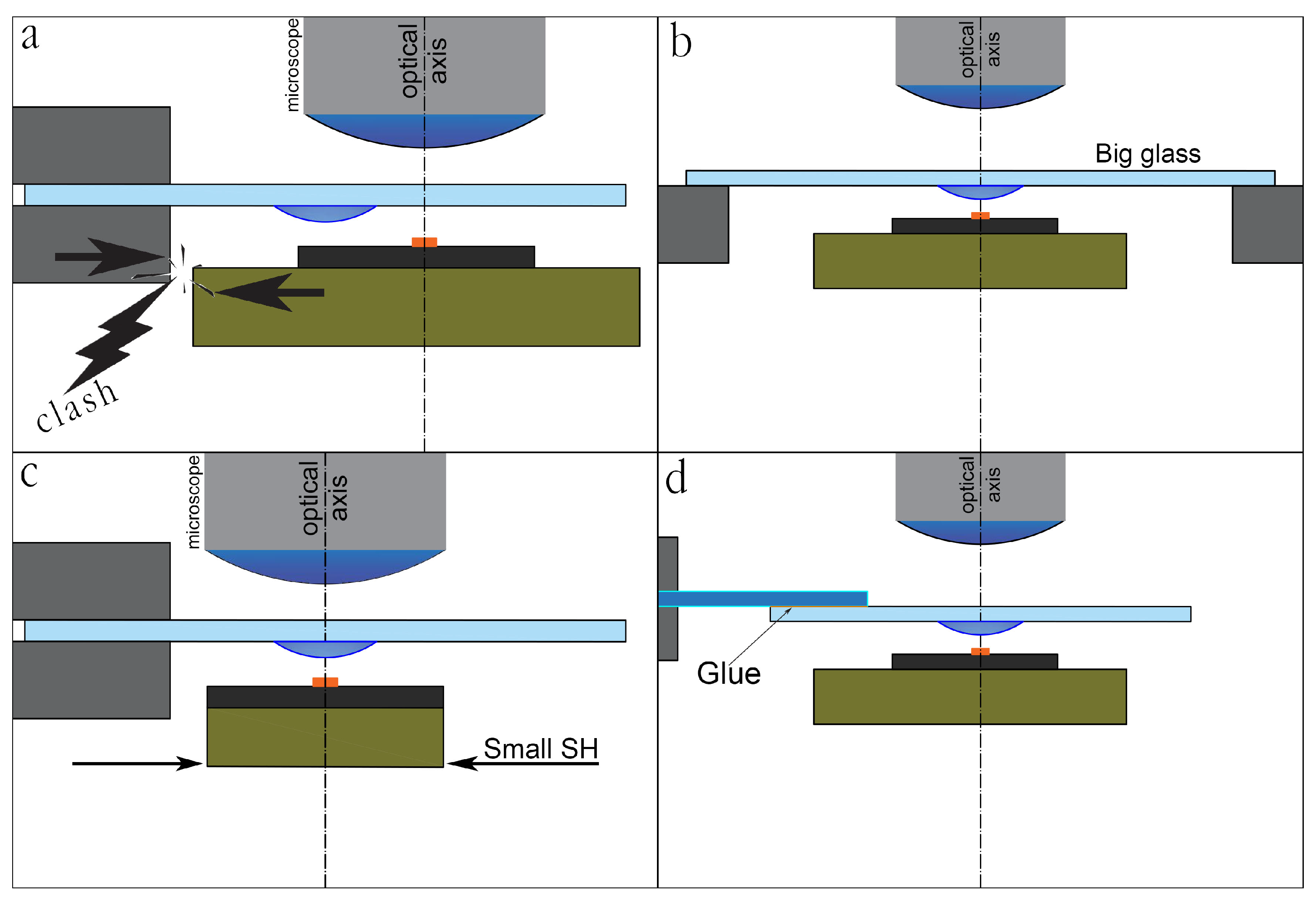

2. Design of the Transfer Machine: Guiding Principles

- Substrate holder

- TTS holder

- Microscope

2.1. Microscope

2.2. Transparent Temporary Substrate Holder

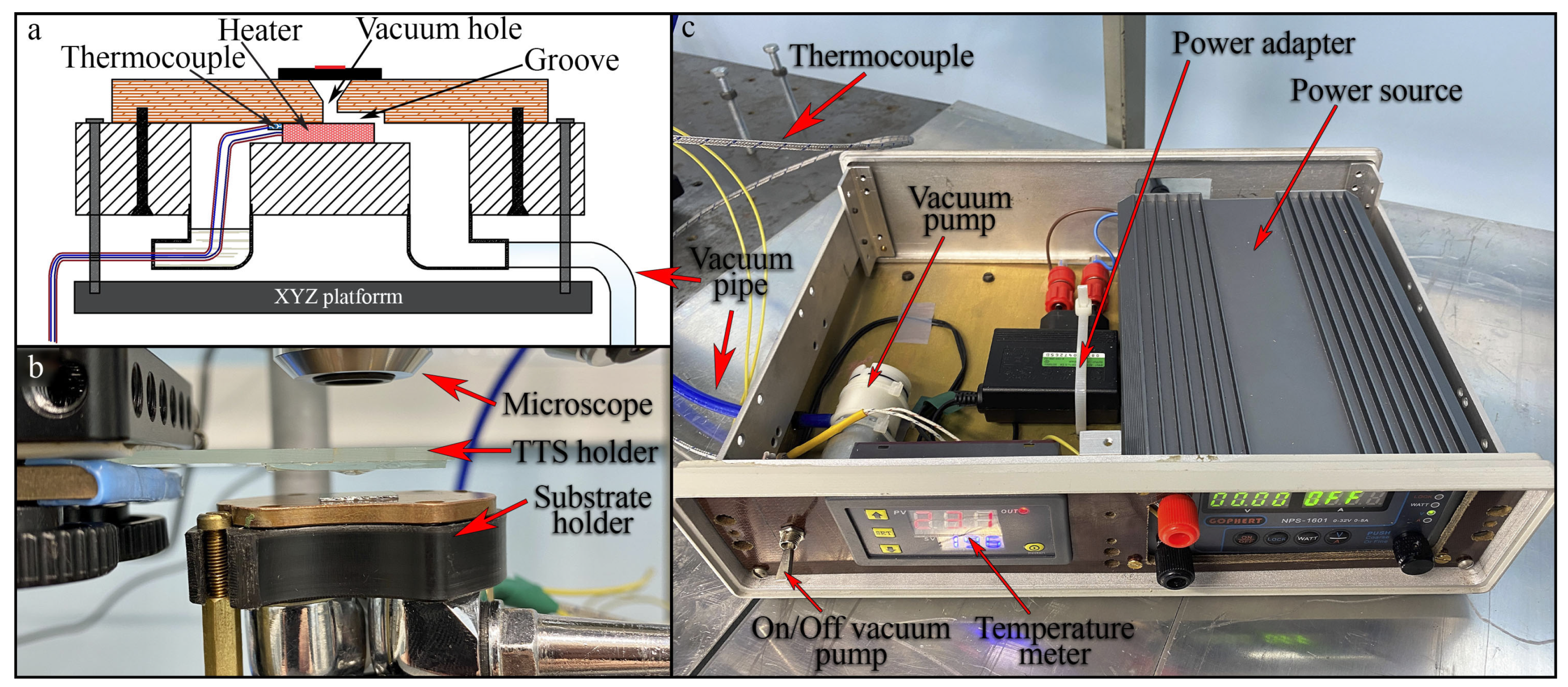

2.3. Substrate Holder

- A vacuumed holder with metallic polished top plate drilled for vacuum fixation of the the substrate.

- A heater to change the sample temperature.

- A thermocouple to control these changes.

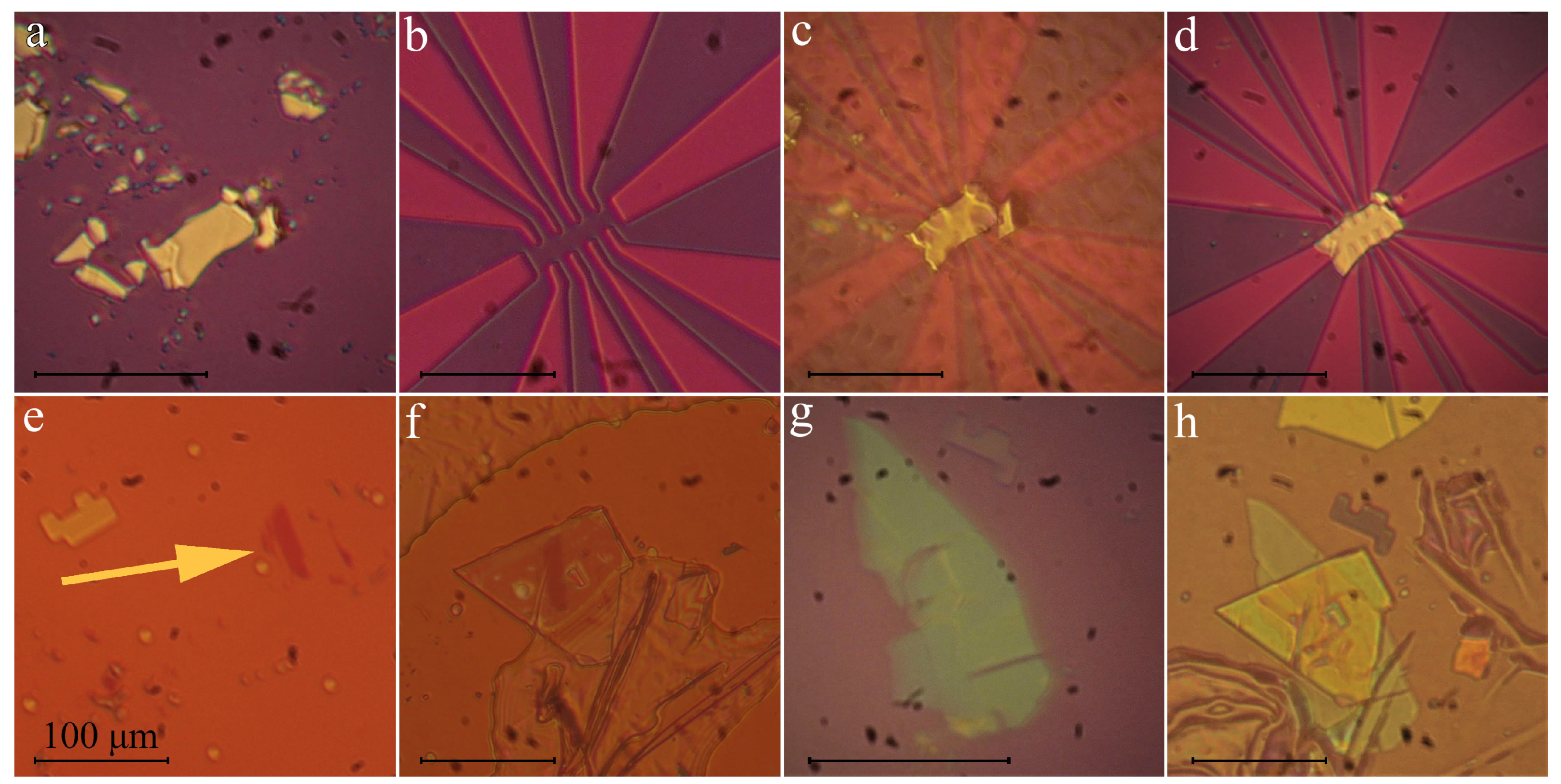

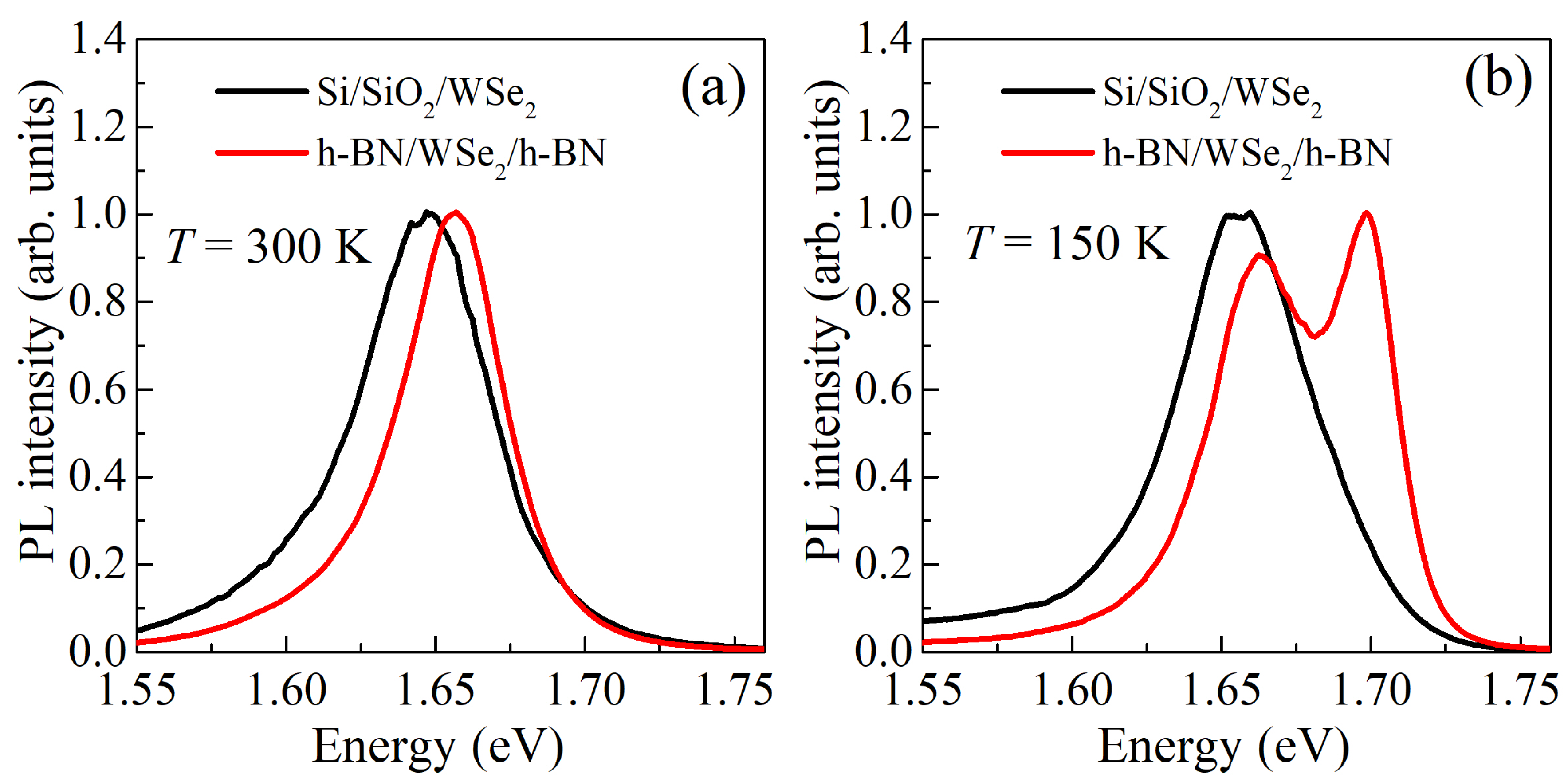

3. Examples of Operation

4. Discussion

- Independent and precise positioning of all three components of the machine (microscope, TTS holder, substrate holder);

- Presence of microobjectives with different magnification for transfer, location and analysis;

- Vacuum chuck and temperature control on the substrate holder.

- Compact size for easy integration into a glovebox;

- Low cost, about 1 k$ for all components;

- Modular design of the device;

- Cheap and compact substrate holder table;

- Convenient substrate replacement without touching the TTS holder and the microscope.

- Vacuum sealing of the substrate is never perfect, there is some air flow under the substrate that cools the sample down making a thermometer misleading. This effect should be taken into account.

- It is highly desirable not to lose a focus during the substrate positioning and rotation. Therefore the sample holder table plane and microscope plane of view should be parallel and aligned perpendicularly to the rotational axis of the holder. The later axis should be rather close to the optical axis, otherwise it will take extra time to find the flakes after the rotation.

- The construction by www.hqgraphene.com is a bit different from the one considered in this paper as its -manipulator (TTS Holder) is placed onto another bigger manipulator (substrate holder). Such a placement is fruitful idea, as it suppresses mutual vibrations of the substrate and the TTS and can help to avoid extra degrees of freedom.

- Note that the machine is assembled out of very cheap components because there is no need in sub-micrometer resolution positioning. For our machine we estimate the precision of flakes alignment as 2 micrometers, that comes from diffraction limit of the microscope, vibrations and viscoelastic properties of PDMS, those lead to slight shift of flakes in the process of TTS-to-substrate contact.

- The transfer with the optimized machine might be very fast and takes just a few minutes provided that the TTS is well prepared. One drop of PDMS might be used many times. However, sometimes the transfer might be unsuccessful. This is because there are hidden controlling parameters those crucially affect the properties of the thermosensitive polymer, such as humidity, thickness of the polymer layer, freshness of the PDMS drop, preparation of the substrate surface etc. These parameters determine the optimal temperature regime and should be maintained stable for a reproducible process. Searching for flakes and controlling these parameters takes much more time than the transfer itself.

- In refs. [17,23] a Peltier element, easily available from www.aliexpress.com, is used instead of resistive heater. This element is faster, though it is not compatible with vacuum fixation, and the authors have to use the double-sided scotch-tape. The temperature range for the Peltier element is also smaller (between 10 °C and 80 °C).

- Concerning the price. Similarly to our setup ref. [33] reports 1 k$ transfer machine. That machine however lacks for temperature-controlled table and therefore does not allow pick-up process. We believe that this price is close to absolute minimum and there is no need to further optimize it, because mechanical elements could hardly be made cheaper than 400 $ and the microscope absolute minimum is close to 600 $. In fact such a price means that transfer machine, equipped with all possible degrees of freedom, becomes available for any laboratory or even person, that is the main message of this paper.

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| SH | Substrate holder |

| TTS | Transparent temporay substrate |

| PVA | Polyvinylalcohol |

| CVD | chemical vapour deposition |

| PPC | Poly-propilene carbonate |

| PID | Proportional-integral-differential (controller) |

| PVC | poly-vinyl chloride |

| PMMA | poly-methyl meta acrylate |

| PC | personal computer |

| PL | photoluminescence |

| NIMS | National Institute of Materials Science in Tsukuba, Japan |

References

- Geim, A.K.; Grigorieva, I.V. Van der Waals Heterostructures. Nature 2013, 499, 419–425. [Google Scholar] [CrossRef] [PubMed]

- Novoselov, K.; Mishchenko, A.; Carvalho, A.; Castro Neto, A.H. 2D materials and van der Waals heterostructures. Science 2016, 353, aac9439. [Google Scholar] [CrossRef] [PubMed]

- Frisenda, R.; Navarro-Moratalla, E.; Gant, P.; De Lara, D.P.; Jarillo-Herrero, P.; Gorbachev, R.V.; Castellanos-Gomez, A. Recent progress in the assembly of nanodevices and van der Waals heterostructures by deterministic placement of 2D materials. Chem. Soc. Rev. 2018, 47, 53–68. [Google Scholar] [CrossRef] [PubMed]

- Qi, H.; Wang, L.; Sun, J.; Long, Y.; Hu, P.; Liu, F.; He, X. Production Methods of Van der Waals Heterostructures Based on Transition Metal Dichalcogenides. Crystals 2018, 8, 35. [Google Scholar] [CrossRef]

- Li, J.; Chen, X.; Zhang, D.; Zhou, P. Van der Waals Heterostructure Based Field Effect Transistor Application. Crystals 2018, 8, 8. [Google Scholar] [CrossRef]

- Liang, S.J.; Cheng, B.; Cui, X.; Miao, F. Van der Waals Heterostructures for High-Performance Device Applications: Challenges and Opportunities. Adv. Mater. 2019, 2019, 1903800. [Google Scholar] [CrossRef]

- Shen, P.; Lin, Y.; Wang, H.; Park, J.; Leong, W.S.; Lu, A.; Palacios, T.; Kong, J. CVD Technology for 2-D Materials. IEEE Trans. Electron Devices 2018, 65, 4040–4052. [Google Scholar] [CrossRef]

- Cai, Z.; Liu, B.; Zou, X.; Chen, H.M. Chemical Vapor Deposition Growth and Applications of Two-Dimensional Materials and Their Heterostructures. Chem. Rev. 2018, 118, 6091–6133. [Google Scholar] [CrossRef]

- Walsh, L.; Hinkle, C. van der Waals epitaxy: 2D materials and topological insulators. Appl. Mater. Today 2017, 9, 504–515. [Google Scholar] [CrossRef]

- Ai, R.; Guan, X.; Li, J.; Yao, K.; Chen, P.; Zhang, Z.; Duan, X.; Duan, X. Growth of Single-Crystalline Cadmium Iodide Nanoplates, CdI2/MoS2 (WS2, WSe2) Van der Waals Heterostructures, and Patterned Arrays. ACS Nano 2017, 11, 3413–3419. [Google Scholar] [CrossRef]

- Garoli, D.; Mosconi, D.; Miele, E.; Maccaferri, N.; Ardini, M.; Giovannini, G.; Dipalo, M.; Agnoli, S.; De Angelis, F. Hybrid plasmonic nanostructures based on controlled integration of MoS2 flakes on metallic nanoholes. Nanoscale 2018, 10, 17105–17111. [Google Scholar] [CrossRef] [PubMed]

- Mosconi, D.; Giovannini, G.; Jacassi, A.; Ponzellini, P.; Maccaferri, N.; Vavassori, P.; Serri, M.; Dipalo, M.; Darvill, D.; De Angelis, F.; et al. Site-Selective Integration of MoS2 Flakes on Nanopores by Means of Electrophoretic Deposition. ACS Omega 2019, 4, 9294–9300. [Google Scholar] [CrossRef] [PubMed]

- Mosconi, D.; Giovannini, G.; Maccaferri, N.; Serri, M.; Agnoli, S.; Garoli, D. Electrophoretic Deposition of WS2 Flakes on Nanoholes Arrays—Role of Used Suspension Medium. Materials 2019, 12, 3286. [Google Scholar] [CrossRef] [PubMed]

- Burzurí, E.; Vera-Hidalgo, M.; Giovanelli, E.; Villalva, J.; Castellanos-Gomez, A.; Pérez, E. Simultaneous assembly of van der Waals heterostructures into multiple nanodevices. Nanoscale 2018, 10, 7966–7970. [Google Scholar] [CrossRef]

- Huo, C.; Yan, Z.; Song, X.; Zeng, H. 2D materials via liquid exfoliation: A review on fabrication and applications. Sci. Bull. 2015, 60, 1994–2008. [Google Scholar] [CrossRef]

- Blake, P.; Hill, E.W.; Castro Neto, A.H.; Novoselov, K.; Jiang, D.; Yang, R.; Booth, T.J.; Geim, A.K. Making graphene visible. Appl. Phys. Lett. 2007, 91, 063124. [Google Scholar] [CrossRef]

- Uwanno, T.; Hattori, Y.; Taniguchi, T.; Watanabe, K.; Nagashio, K. Fully dry PMMA transfer of graphene on h-BN using a heating/cooling system. 2D Mater. 2015, 2, 041002. [Google Scholar] [CrossRef]

- Kretinin, A.V.; Cao, Y.; Tu, J.S.; Yu, G.; Jalil, R.; Novoselov, K.; Haigh, S.J.; Gholinia, A.; Mishchenko, A.; Lozada, M.; et al. Electronic Properties of Graphene Encapsulated with Different Two-Dimensional Atomic Crystals. Nano Lett. 2014, 14, 3270–3276. [Google Scholar] [CrossRef]

- Zomer, P.; Guimarães, M.H.D.; Brant, J.C.; Tombros, N.; van Wees, B. Fast pick up technique for high quality heterostructures of bilayer graphene and hexagonal boron nitride. Appl. Phys. Lett. 2014, 105, 013101. [Google Scholar] [CrossRef]

- Castellanos-Gomez, A.; Buscema, M.; Molenaar, R.; Singh, V.; Janssen, L.; van der Zant, H.S.J.; Steele, G. Deterministic transfer of two-dimensional materials by all-dry viscoelastic stamping. 2D Mater. 2014, 1, 011002. [Google Scholar] [CrossRef]

- Pizzocchero, F.; Gammelgaard, L.; Jessen, B.; Caridad, J.; Wang, L.; Hone, J.; Bøggild, P.; Booth, T. The hot pick-up technique for batch assembly of van der Waals heterostructures. Nat. Commun. 2016, 7, 11894. [Google Scholar] [CrossRef] [PubMed]

- Kinoshita, K.; Moriya, R.; Onodera, M.; Wakafuji, Y.; Masubuchi, S.; Watanabe, K.; Taniguchi, T.; Machida, T. Dry release transfer of graphene and few-layer h-BN by utilizing thermoplasticity of polypropylene carbonate. NPJ 2D Mater. Appl. 2019, 3, 22. [Google Scholar] [CrossRef]

- Toyoda, S.; Uwanno, T.; Taniguchi, T.; Watanabe, K.; Nagashio, K. Pinpoint pick-up and bubble-free assembly of 2D materials using PDMS/PMMA polymers with lens shapes. Appl. Phys. Express 2019, 12, 055008. [Google Scholar] [CrossRef]

- Reina, A.; Son, H.; Jiao, L.; Fan, B.; Dresselhaus, M.S.; Liu, Z.; Kong, J. Transferring and Identification of Single- and Few-Layer Graphene on Arbitrary Substrates. J. Phys. Chem. C 2008, 112, 17741–17744. [Google Scholar] [CrossRef]

- Schneider, G.; Calado, V.; Zandbergen, H.; Vandersypen, L.; Dekker, C. Wedging Transfer of Nanostructures. Nano Lett. 2010, 10, 1912–1916. [Google Scholar] [CrossRef]

- Dean, C.R.; Young, A.F.; Meric, I.; Lee, C.; Wang, L.; Sorgenfrei, S.; Watanabe, K.; Taniguchi, T.; Kim, P.; Shepard, K.L.; et al. Boron nitride substrates for high-quality graphene electronics. Nat. Nanotechnol. 2010, 5, 722726. [Google Scholar] [CrossRef]

- Leong, W.; Wang, H.; Yeo, J.; Martin-Martinez, F.; Zubair, A.; Shen, P.C.; Mao, Y.; Palacios, T.; Buehler, M.; Hong, J.Y.; et al. Paraffin-enabled graphene transfer. Nat. Commun. 2019, 10, 867. [Google Scholar] [CrossRef]

- Li, H.; Wu, J.; Huang, X.; Yin, Z.; Liu, J.; Zhang, H. A Universal, Rapid Method for Clean Transfer of Nanostructures onto Various Substrates. ACS Nano 2014, 8, 6563–6570. [Google Scholar] [CrossRef]

- Fan, S.; Vu, Q.A.; Tran, M.D.; Adhikari, S.; Lee, Y.H. Transfer assembly for two-dimensional van der Waals heterostructures. 2D Mater. 2020, 7, 022005. [Google Scholar] [CrossRef]

- Wakafuji, Y.; Moriya, R.; Masubuchi, S.; Watanabe, K.; Taniguchi, T.; Machida, T. 3D Manipulation of 2D Materials Using Microdome Polymer. Nano Lett. 2020, 20, 2486–2492. [Google Scholar] [CrossRef]

- Jain, A.; Bharadwaj, P.; Heeg, S.; Parzefall, M.; Taniguchi, T.; Watanabe, K.; Novotny, L. Minimizing residues and strain in 2D materials transferred from PDMS. Nanotechnology 2018, 29, 265203. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Yankovitz, M.; Fallahazad, B.; Kang, S.; Movva, H.C.P.; Huang, S.; Larentis, S.; Corbet, C.M.; Taniguchi, T.; Watanabe, K.; et al. Van der Waals Heterostructures with High Accuracy Rotational Alignment. Nano Lett. 2016, 16, 1989–1995. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Q.; Wang, T.; Ryu, Y.K.; Frisenda, R.; Castellanos-Gomez, A. An inexpensive system for the deterministic transfer of 2D materials. J. Phys. Mater. 2020, 3, 016001. [Google Scholar] [CrossRef]

- Masubuchi, S.; Morimoto, S.; Onodera, M.; Asakawa, Y.; Watanabe, K.; Taniguchi, T.; Machida, T. Autonomous robotic searching and assembly of two-dimensional crystals to build van der Waals superlattices. Nat. Commun. 2018, 9, 1413. [Google Scholar] [CrossRef] [PubMed]

- Boddison-Chouinard, J.; Plumadore, R.; Luican-Mayer, A. Fabricating van der Waals Heterostructures with Precise Rotational Alignment. Jove J. Vis. Exp. 2019, 149, e59727. [Google Scholar] [CrossRef] [PubMed]

- Gant, P.; Carrascoso, F.; Zhao, Q.; Ryu, Y.; Seitz, M.; Prins, F.; Frisenda, R.; Castellanos-Gomez, A. A system for the deterministic transfer of 2D materials under inert environmental conditions. 2D Mater. 2020, 7, 025034. [Google Scholar] [CrossRef]

- Onodera, M.; Masubuchi, S.; Moriya, R.; Machida, T. Assembly of van der Waals heterostructures: Exfoliation, searching, and stacking of 2D materials. Jpn. J. Appl. Phys. 2020, 59, 010101. [Google Scholar] [CrossRef]

- Zastrow, M. Meet the crystal growers who sparked a revolution in graphene electronics. Nature 2019, 572, 429–432. [Google Scholar] [CrossRef]

- Iwasaki, T.; Endo, K.; Watanabe, E.; Tsuya, D.; Morita, Y.; Nakaharai, S.; Noguchi, Y.; Watanabe, K.; Taniguchi, T.; Moriyama, S. Bubble-Free Transfer Technique for High-Quality Graphene/Hexagonal Boron Nitride van der Waals Heterostructures. ACS Appl. Mater. Interfaces 2020, 12, 8533–8538. [Google Scholar] [CrossRef]

- Cao, Y.; Fatemi, V.; Fang, S.; Watanade, K.; Taniguchi, T.; Kaxiras, E.; Jarillo-Herrero, P. Unconventional superconductivity in magic-angle graphene superlattices. Nature 2018, 556, 43–50. [Google Scholar] [CrossRef]

- Kuntsevich, A.Y.; Bryzgalov, M.A.; Prudkoglyad, V.A.; Martovitskii, V.P.; Selivanov, Y.G.; Chizhevskii, E.G. Structural distortion behind the nematic superconductivity in SrxBi2Se3. New J. Phys. 2018, 20, 103022. [Google Scholar] [CrossRef]

- Kuntsevich, A.Y.; Martovitskii, V.P.; Rybalchenko, G.V.; Selivanov, Y.G.; Bannikov, M.I.; Sobolevskiy, O.A.; Chigevskii, E.G. Superconductivity in Cu Co-Doped SrxBi2Se3 Single Crystals. Materials 2019, 12, 3899. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Wu, W.; Bai, Y.; Chae, S.H.; Li, Q.; Wang, J.; Hone, J.; Zhu, X.Y. Disassembling 2D van der Waals crystals into macroscopic monolayers and reassembling into artificial lattices. Science 2020, 367, 903–906. [Google Scholar] [CrossRef] [PubMed]

- Cadiz, F.; Courtade, E.; Robert, C.; Wang, G.; Shen, Y.; Cai, H.; Taniguchi, T.; Watanabe, K.; Carrere, H.; Lagarde, D.; et al. Excitonic Linewidth Approaching the Homogeneous Limit in MoS2-Based van der Waals Heterostructures. Phys. Rev. X 2017, 7, 021026. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martanov, S.G.; Zhurbina, N.K.; Pugachev, M.V.; Duleba, A.I.; Akmaev, M.A.; Belykh, V.V.; Kuntsevich, A.Y. Making van der Waals Heterostructures Assembly Accessible to Everyone. Nanomaterials 2020, 10, 2305. https://doi.org/10.3390/nano10112305

Martanov SG, Zhurbina NK, Pugachev MV, Duleba AI, Akmaev MA, Belykh VV, Kuntsevich AY. Making van der Waals Heterostructures Assembly Accessible to Everyone. Nanomaterials. 2020; 10(11):2305. https://doi.org/10.3390/nano10112305

Chicago/Turabian StyleMartanov, Sergey G., Natalia K. Zhurbina, Mikhail V. Pugachev, Aliaksandr I. Duleba, Mark A. Akmaev, Vasilii V. Belykh, and Aleksandr Y. Kuntsevich. 2020. "Making van der Waals Heterostructures Assembly Accessible to Everyone" Nanomaterials 10, no. 11: 2305. https://doi.org/10.3390/nano10112305

APA StyleMartanov, S. G., Zhurbina, N. K., Pugachev, M. V., Duleba, A. I., Akmaev, M. A., Belykh, V. V., & Kuntsevich, A. Y. (2020). Making van der Waals Heterostructures Assembly Accessible to Everyone. Nanomaterials, 10(11), 2305. https://doi.org/10.3390/nano10112305