Manufacture of Contact Lens of Nanoparticle-Doped Polymer Complemented with ZEMAX

Abstract

1. Introduction

2. Analysis Criteria

2.1. Modulation Transfer Function

2.2. Root Mean Square (RMS)

3. Materials and Methods

3.1. PMMA Preparation

3.2. PMMA-TiO2 Preparation

3.3. Optical Modeling

4. Results and Discussion

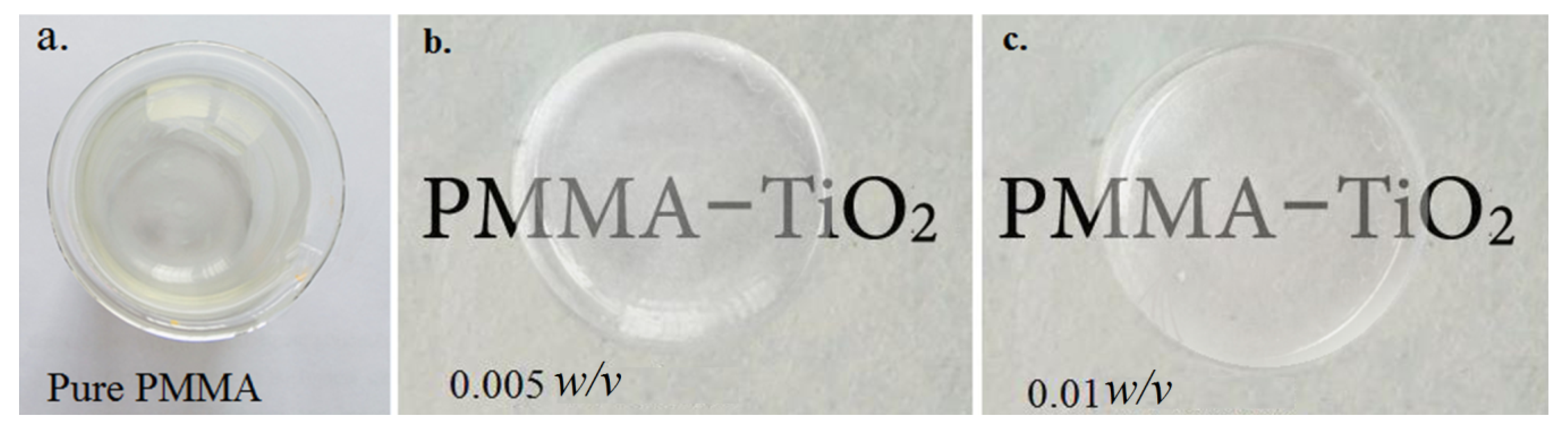

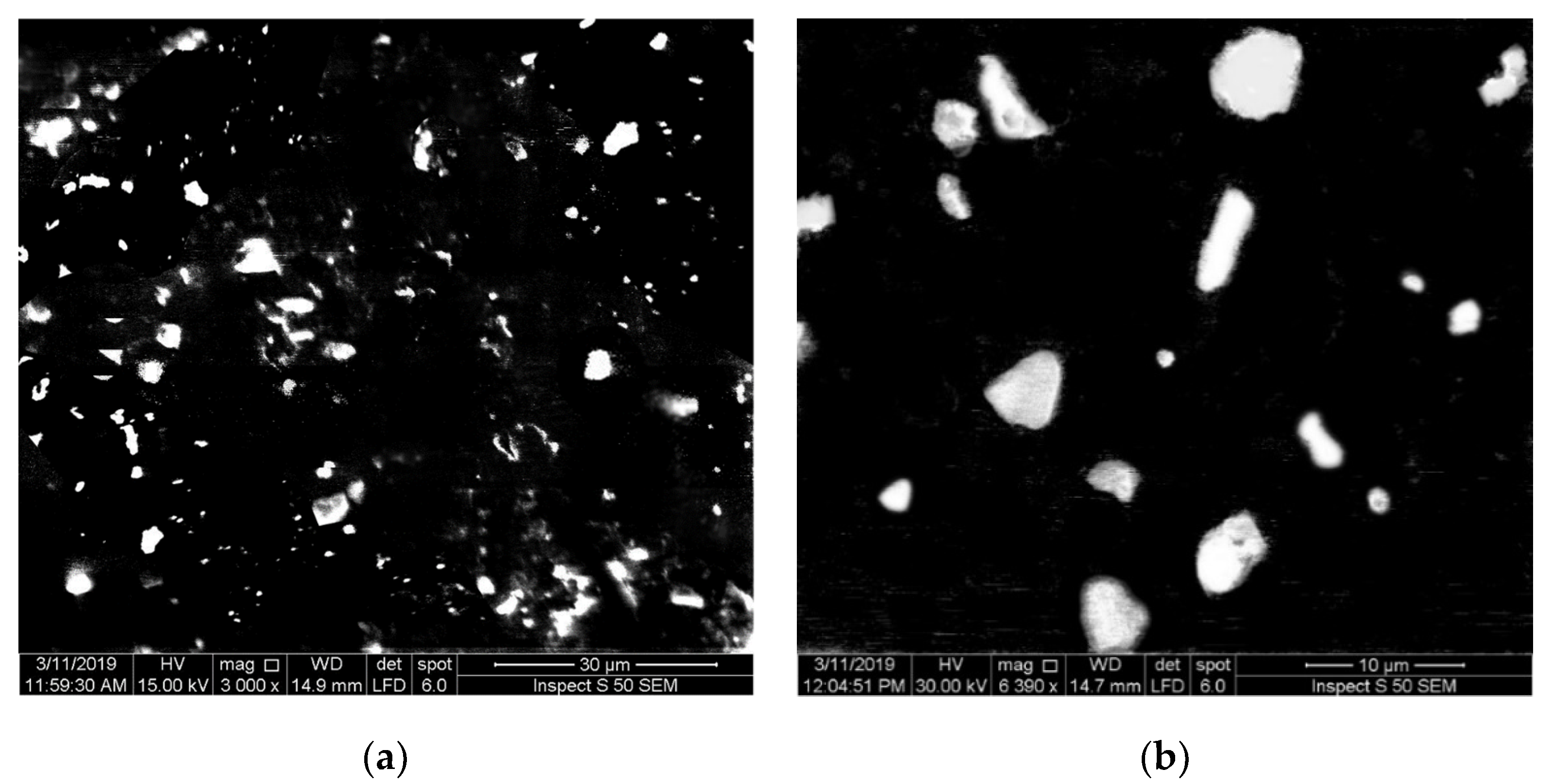

4.1. Morphological Properties

4.2. UV-Vis Transmission Spectrum

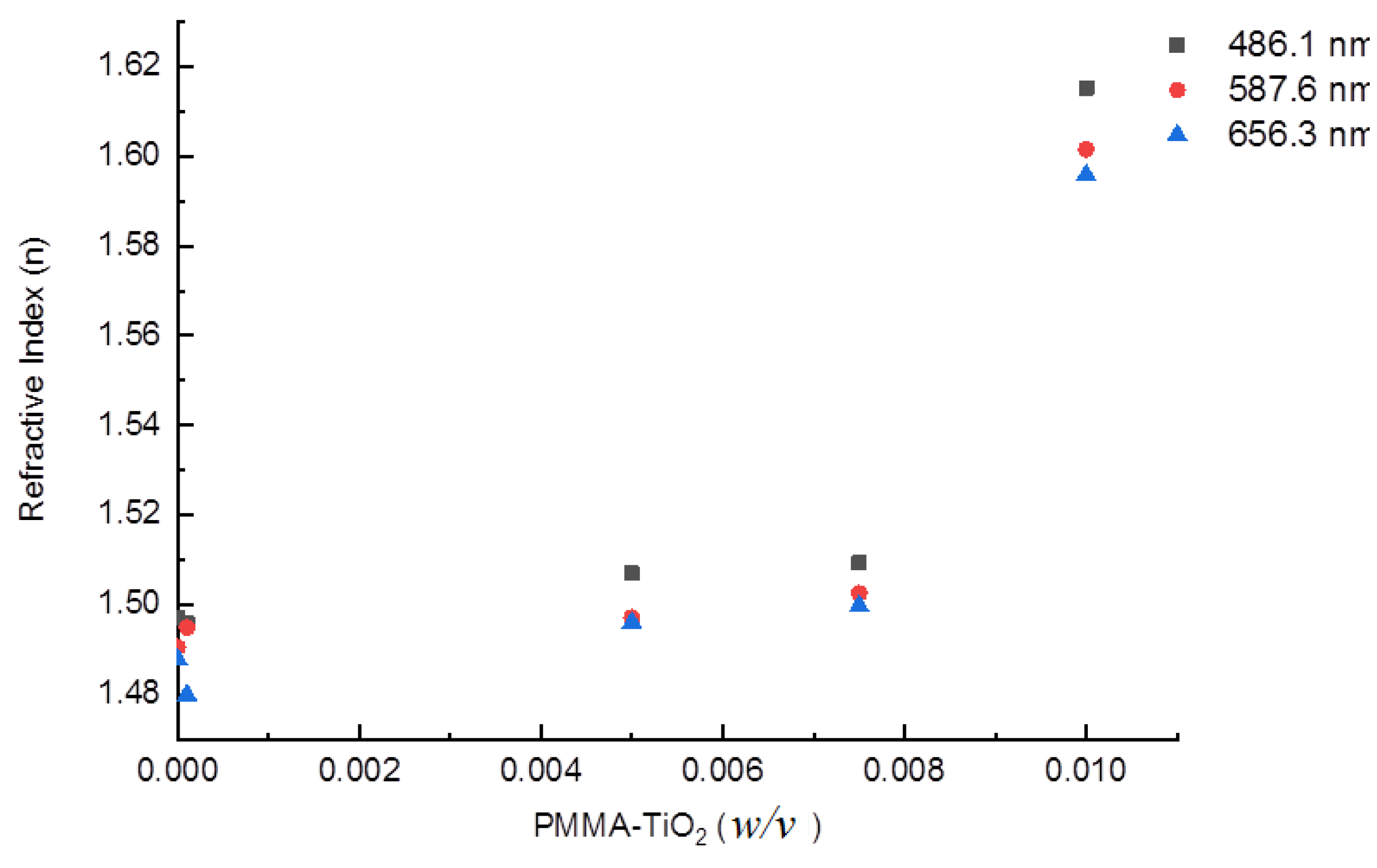

4.3. Refractive Index and Abbe Number

4.4. Polychromatic MTF

4.5. Spot Diagram

4.6. Image Simulation

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Goda, T.; Ishihara, K. Soft contact lens biomaterials from bioinspired phospholipid polymers. Expert Rev. Med. Devices 2006, 3, 167–174. [Google Scholar] [CrossRef] [PubMed]

- Gaaz, T.S.; Sulong, A.B.; Kadhum, A.A.H.; Ba-Abbad, M.; Al-Amiery, A.A. Enhancement of physical and chemical properties of halloysite nanotubes using sulfuric acid. Wulfenia 2015, 22, 264–284. [Google Scholar]

- Tummala, G.K.; Rojas, R.; Mihranyan, A. Poly(vinyl alcohol) Hydrogels Reinforced with Nanocellulose for Ophthalmic Applications: General Characteristics and Optical Properties. J. Phys. Chem. B 2016, 120, 13094–13101. [Google Scholar] [CrossRef] [PubMed]

- Gaaz, T.S.; Al-Amiery, A.A.; Hussein, E.K. Physical Properties of Halloysite Nanotubes-Polyvinyl Alcohol Nanocomposites using Malonic Acid Crosslinked. J. Kejuruter. 2017, 29, 71–77. [Google Scholar] [CrossRef][Green Version]

- Kita, M.; Ogura, Y.; Honda, Y.; Hyon, S.-H.; Cha, W.-I.; Ikada, Y. Evaluation of polyvinyl alcohol hydrogel as a soft contact lens material. Graefe’s Arch. Clin. Exp. Ophthalmol. 1990, 228, 533–537. [Google Scholar] [CrossRef] [PubMed]

- Maldonado-Codina, C.; Efron, N. Dynamic wettability of pHEMA-based hydrogel contact lenses. Ophthalmic Physiol. Opt. 2006, 26, 408–418. [Google Scholar] [CrossRef] [PubMed]

- Seo, E.; Kumar, S.; Lee, J.; Jang, J.; Park, J.H.; Chang, M.C.; Kwon, I.; Lee, J.-S.; Huh, Y.-I. Modified hydrogels based on poly(2-hydroxyethyl methacrylate) (pHEMA) with higher surface wettability and mechanical properties. Macromol. Res 2017, 25, 704–711. [Google Scholar] [CrossRef]

- Shokrollahzadeh, F.; Hashemi, H.; Jafarzadehpur, E.; Mirzajani, A. Corneal aberration changes after rigid gas permeable contact lens wear. J. Curr. Ophthalmol. 2016, 20, 1–5. [Google Scholar]

- Thai, L.C.; Tomlinson, A.; Doane, M.G. Effect of Contact Lens Materials on Tear Physiology. Am. Acad. Optom. 2004, 81, 194–204. [Google Scholar] [CrossRef] [PubMed]

- Gaaz, T.S.; Sulong, A.B.; Kadhum, A.A.H.; Al-Amiery, A.A.; Nassir, M.H.; Jaaz, A.H. The Impact of Halloysite on the Thermo-Mechanical Properties of Polymer Composites. Molecules 2017, 22, 838. [Google Scholar] [CrossRef]

- Benhabiles, O.; Galiano, F.; Marino, T.; Mahmoudi, H.; Lounici, H.; Figoli, A. Preparation and Characterization of TiO2-PVDF/PMMA Blend Membranes Using an Alternative Non-Toxic Solvent for UF/MF and Photocatalytic Application. Molecules 2019, 24, 724. [Google Scholar] [CrossRef] [PubMed]

- Sathish, S.; Shekar, B.C.; Bhavyasree, B.T. Nano composite PVA–TiO2 thin films for OTFTs. Adv. Mater. Res. 2013, 678, 335–342. [Google Scholar] [CrossRef]

- Demir, M.M.; Koynov, K.; Bubeck, C.; Park, I.; Lieberwirth, I.; Wegner, G. Optical Properties of Composites of PMMA and Surface-Modified Zincite Nanoparticles. Macromolecules 2007, 40, 1089–1100. [Google Scholar] [CrossRef]

- Ba-Abbad, M.M.; Kadhum, A.A.H.; Al-Amiery, A.A.; Mohamad, A.B.; Takriff, M.S. Toxicity evaluation for low concentration of chlorophenols under solar radiation using zinc oxide (ZnO) nanoparticles. Int. J. Phys. Sci. 2012, 7, 48–52. [Google Scholar]

- Xu, J.; Zhang, Y.; Zhu, W.; Cui, Y. Synthesis of Polymeric Nanocomposite Hydrogels Containing the Pendant ZnS Nanoparticles: Approach to Higher Refractive Index Optical Polymeric Nanocomposites. Macromolecules 2018, 51, 2672–2681. [Google Scholar] [CrossRef]

- Xia, Y.; Zhang, C.; Wang, J.X.; Wang, D.; Zeng, X.F.; Chen, J.F. Synthesis of Transparent Aqueous ZrO2 Nanodispersion with a Controllable Crystalline Phase without Modification for a High-Refractive-Index Nanocomposite Film. Langmuir 2018, 34, 6806–6813. [Google Scholar] [CrossRef]

- Cai, B.; Kaino, T.; Sugihara, O. Sulfonyl-containing polymer and its alumina nanocomposite with high Abbe number and high refractive index. Opt. Mater. Express 2015, 5, 1210. [Google Scholar] [CrossRef]

- Jassim, H.A.; Khadhim, A.; Al-Amiery, A.A. Photo catalytic degradation of methylene blue by using CuO nanoparticles. Int. J. Comput. Appl. Sci. 2016, 1, 1–4. [Google Scholar] [CrossRef]

- Wasmi, B.; Al-Amiery, A.A.; Kadhum, A.A.H.; Takriff, M.S.; Mohamad, A.B. Synthesis of vanadium pentoxide nanoparticles as catalysts for the ozonation of palm oil. Ozone Sci. Eng. 2016, 38, 36–41. [Google Scholar] [CrossRef]

- Hecht, E. Geometrical Optics. In Optics, 5th ed.; Pearson Education Limited: London, UK, 2017; p. 216. [Google Scholar]

- Schaub, M.; Schwiegerling, J.; Fest, E.C.A.; Shepard, R.H. Molded Optics: Design and Manufacture; Taylor and Francis Group LLC: Boca Raton, FL, USA, 2011; pp. 128–129. [Google Scholar]

- Geary, J.M. Introduction to Lens Design with Zemax; Scientific Research; Willmann-Bell Inc.: Richmond, VA, USA, 2002. [Google Scholar]

- Kamil, F.; Hubiter, K.A.; Abed, T.K.; Al-Amiery, A.A. Synthesis of Aluminum and Titanium Oxides Nanoparticles via Sol-Gel Method: Optimization for the Minimum Size. J. Nanosci. Technol. 2016, 2, 37–39. [Google Scholar]

- Liou, H.L.; Brennan, N.A. Anatomically accurate, finite model eye for optical modeling. J. Opt. Soc. Am. A Opt. Image Sci. Vis. 1997, 14, 1684–1695. [Google Scholar] [CrossRef] [PubMed]

- Westheimer, G. Image Quality in the Human Eye. Opt. Acta Int. J. Opt. 1970, 17, 37–41. [Google Scholar] [CrossRef] [PubMed]

- Dua, S.; Acharya, R.; Ng, E.Y.K. Computational Analysis of the Human Eye with Applications; World Scientific: Singapore, 2011; pp. 12–13. [Google Scholar]

- Sugumaran, S.; Bellan, C.S. Transparent nano composite PVA-TiO2 and PMMA-TiO2 thin films: Optical and dielectric properties. Optik 2014, 125, 5128–5133. [Google Scholar] [CrossRef]

- Jin, J.; Qi, R.; Su, Y.; Tong, M.; Zhu, J. Preparation of high-refractive-index PMMA/TiO2 nanocomposites by one-step in situ solvothermal method. Iran. Polym. J. 2013, 22, 767–774. [Google Scholar] [CrossRef]

- Yuwono, A.H.; Xue, J.; Wang, J.; Elim, I.; Ji, W. Transparent nanohybrids of nanocrystalline TiO2 in PMMA with unique nonlinear optical behavior. J. Mater. Chem. 2003, 13, 1475–1479. [Google Scholar] [CrossRef]

- Tao, P.; Viswanath, A.; Li, Y.; Rungta, A.; Benicewicz, B.C.; Siegel, R.W.; Schadler, L.S. Refractive Index Engineering of Polymer Nanocomposites Prepared by End-grafted Polymer Chains onto Inorganic Nanoparticles. Mater. Res. Soc. 2011, 1359, 163–168. [Google Scholar] [CrossRef]

- Castejo’n-Mocho’n, J.; Lo’pez-Gil, N.; Benito, A.; Artal, P. Ocular wave-front aberration statistics in a normal young population. Vis. Res. 2002, 42, 1611–1617. [Google Scholar] [CrossRef]

- Thibos, L.N.; Bradley, A.; Zhang, X. Effect of ocular chromatic aberration on monocular visual performance. Optom. Vis. Sci. 1991, 68, 599–607. [Google Scholar] [CrossRef]

| Surface | Radius (mm) | Thickness (mm) | RI | νd | Conic | PD (mm) |

|---|---|---|---|---|---|---|

| Cornea (anterior cornea) | 7.77 | 0.55 | 1.376 | 50.23 | −0.18 | 10 |

| Aqueous (posterior cornea) | 6.40 | 3.16 | 1.336 | 50.23 | −0.6 | 10 |

| Pupil | Infinity | 0 | 1.34 | 50.23 | 0 | 4 |

| Lens—front surface | 12.40 | 1.59 | - | - | 0 | 10 |

| Lens—back surface | Infinity | 2.43 | - | - | 0 | 10 |

| Vitreous humor | −8.1 | 16.24 | 1.336 | 50.23 | 0.96 | 10 |

| Retina | −12 | - | - | - | 0 | 10 |

| PMMA-TiO2 (w/v) | 486.1 nm | 587.6 nm | 656.3 nm | νd |

|---|---|---|---|---|

| 0 | 1.497 | 1.491 | 1.488 | 53.32 |

| 0.005 | 1.507 | 1.497 | 1.496 | 45.61 |

| 0.01 | 1.615 | 1.602 | 1.596 | 31.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shaker, L.M.; Al-Amiery, A.A.; Kadhum, A.A.H.; Takriff, M.S. Manufacture of Contact Lens of Nanoparticle-Doped Polymer Complemented with ZEMAX. Nanomaterials 2020, 10, 2028. https://doi.org/10.3390/nano10102028

Shaker LM, Al-Amiery AA, Kadhum AAH, Takriff MS. Manufacture of Contact Lens of Nanoparticle-Doped Polymer Complemented with ZEMAX. Nanomaterials. 2020; 10(10):2028. https://doi.org/10.3390/nano10102028

Chicago/Turabian StyleShaker, Lina M., Ahmed A. Al-Amiery, Abdul Amir H. Kadhum, and Mohd S. Takriff. 2020. "Manufacture of Contact Lens of Nanoparticle-Doped Polymer Complemented with ZEMAX" Nanomaterials 10, no. 10: 2028. https://doi.org/10.3390/nano10102028

APA StyleShaker, L. M., Al-Amiery, A. A., Kadhum, A. A. H., & Takriff, M. S. (2020). Manufacture of Contact Lens of Nanoparticle-Doped Polymer Complemented with ZEMAX. Nanomaterials, 10(10), 2028. https://doi.org/10.3390/nano10102028