Microstructure and Mechanical Performance of Graphene Nanosheets Reinforced Nickel-Based Superalloy FGH95 Composite

Abstract

1. Introduction

2. Experimental

3. Results and Discussion

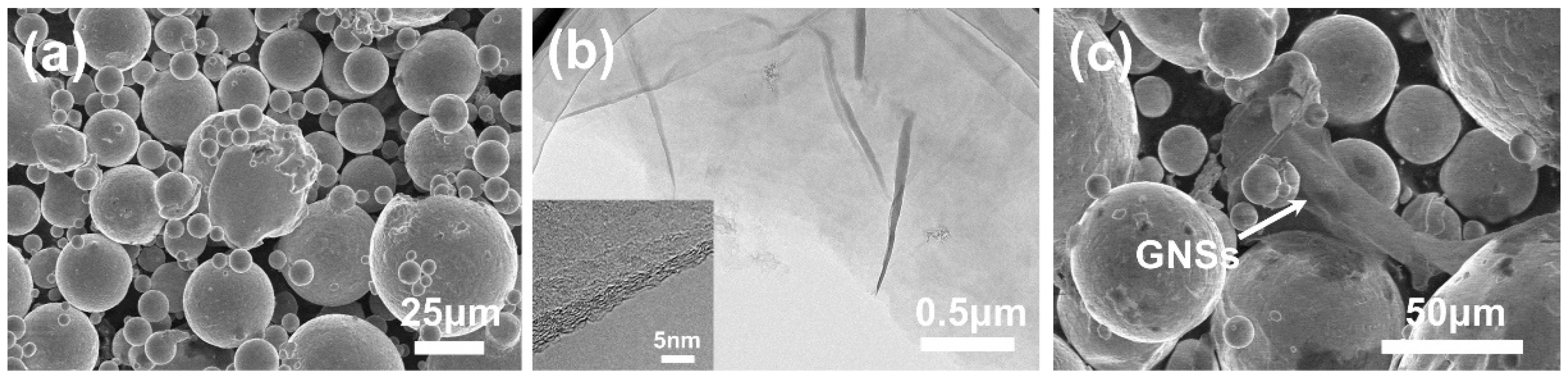

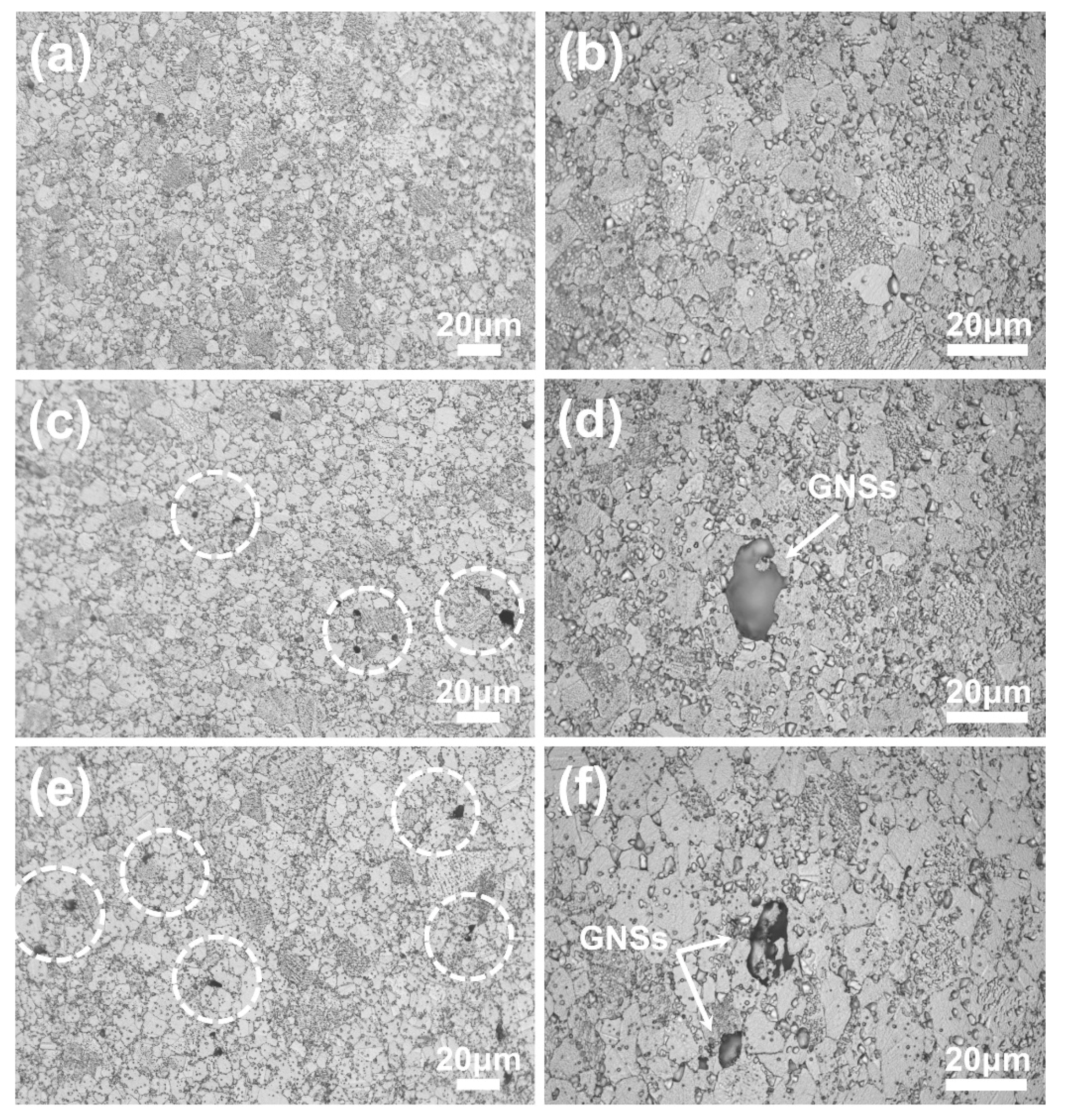

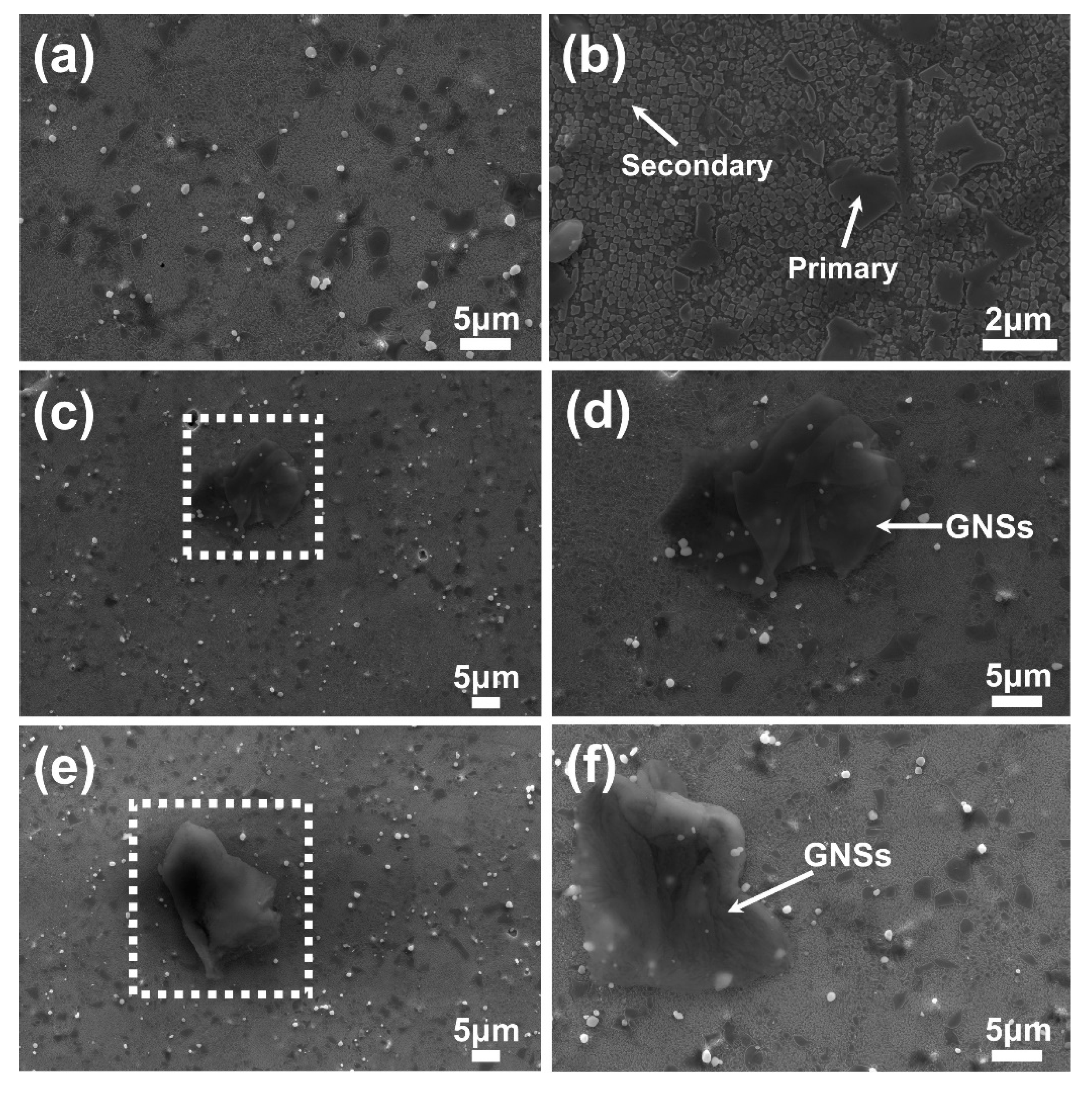

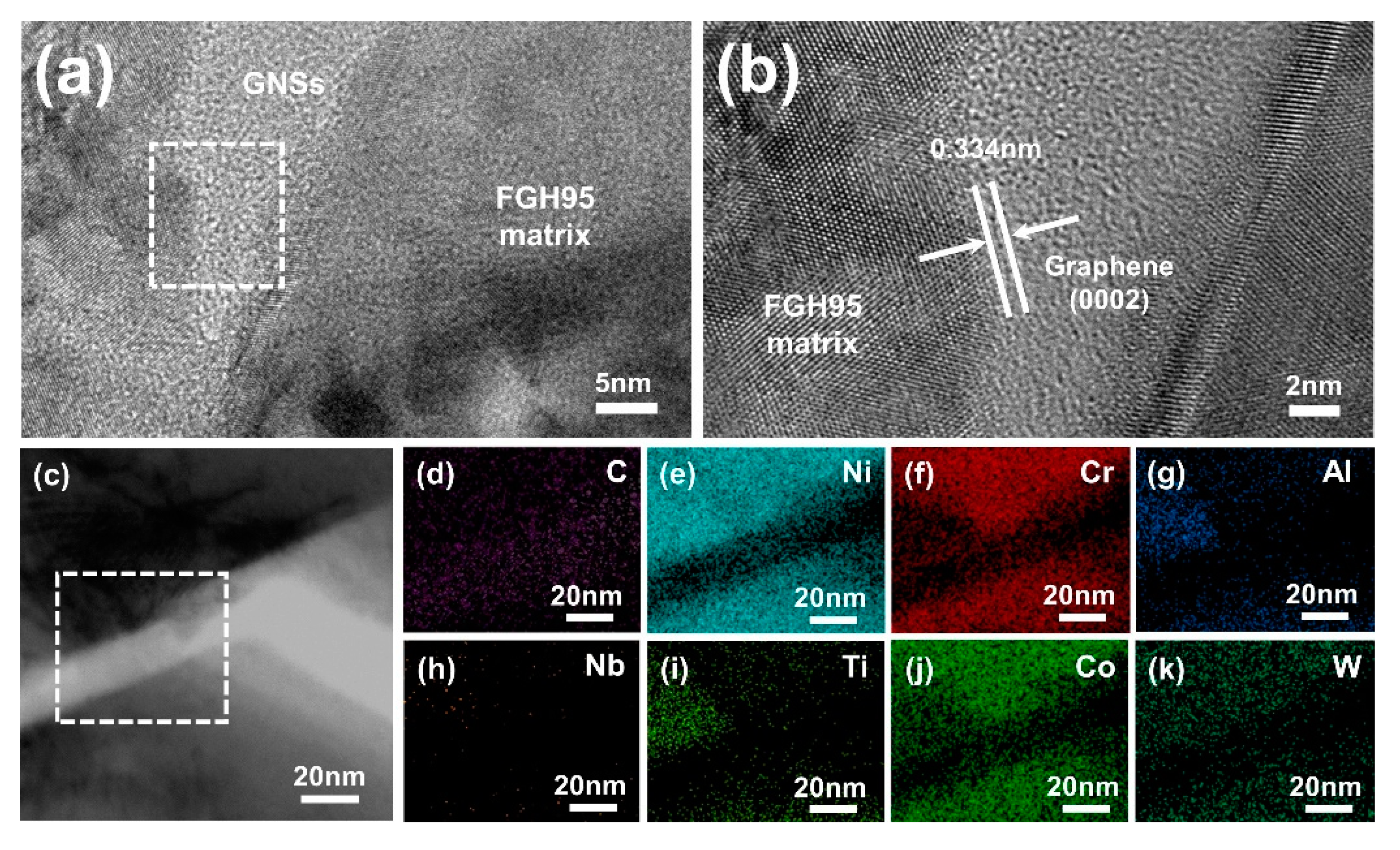

3.1. Microstructures of Graphene Nanosheets (GNSs)/FGH95 Composite

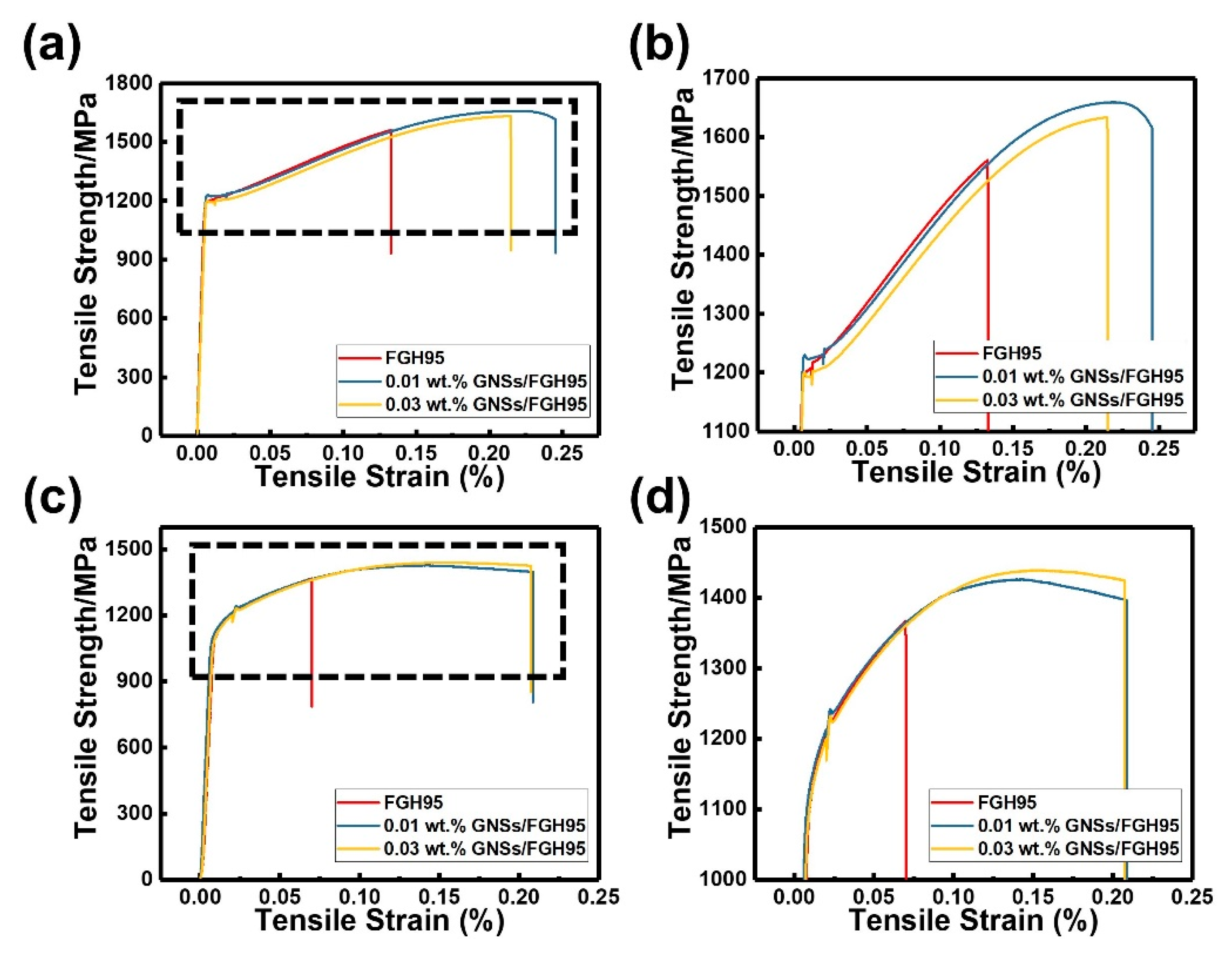

3.2. Mechanical Properties of GNSs/FGH95 Composite

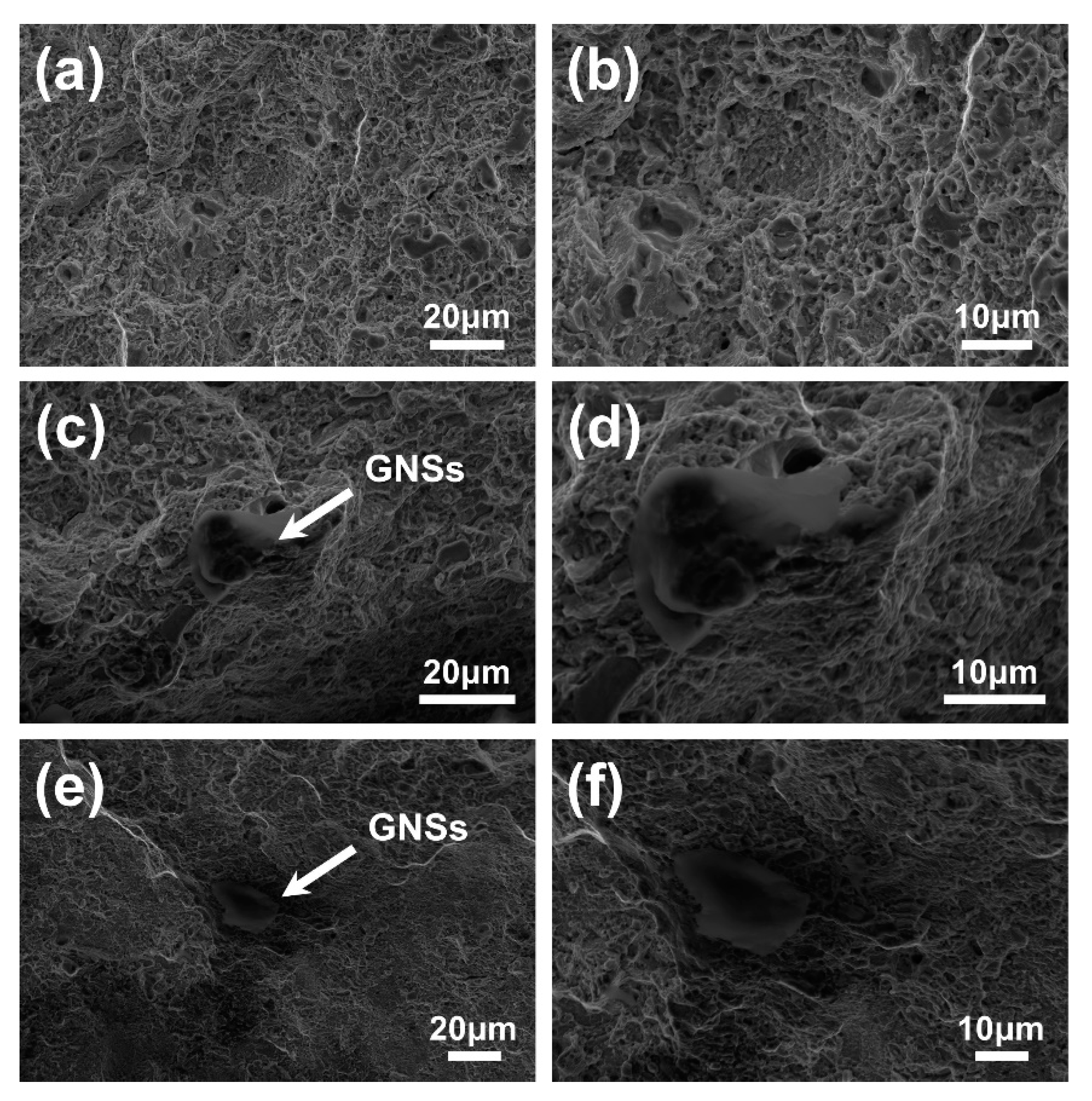

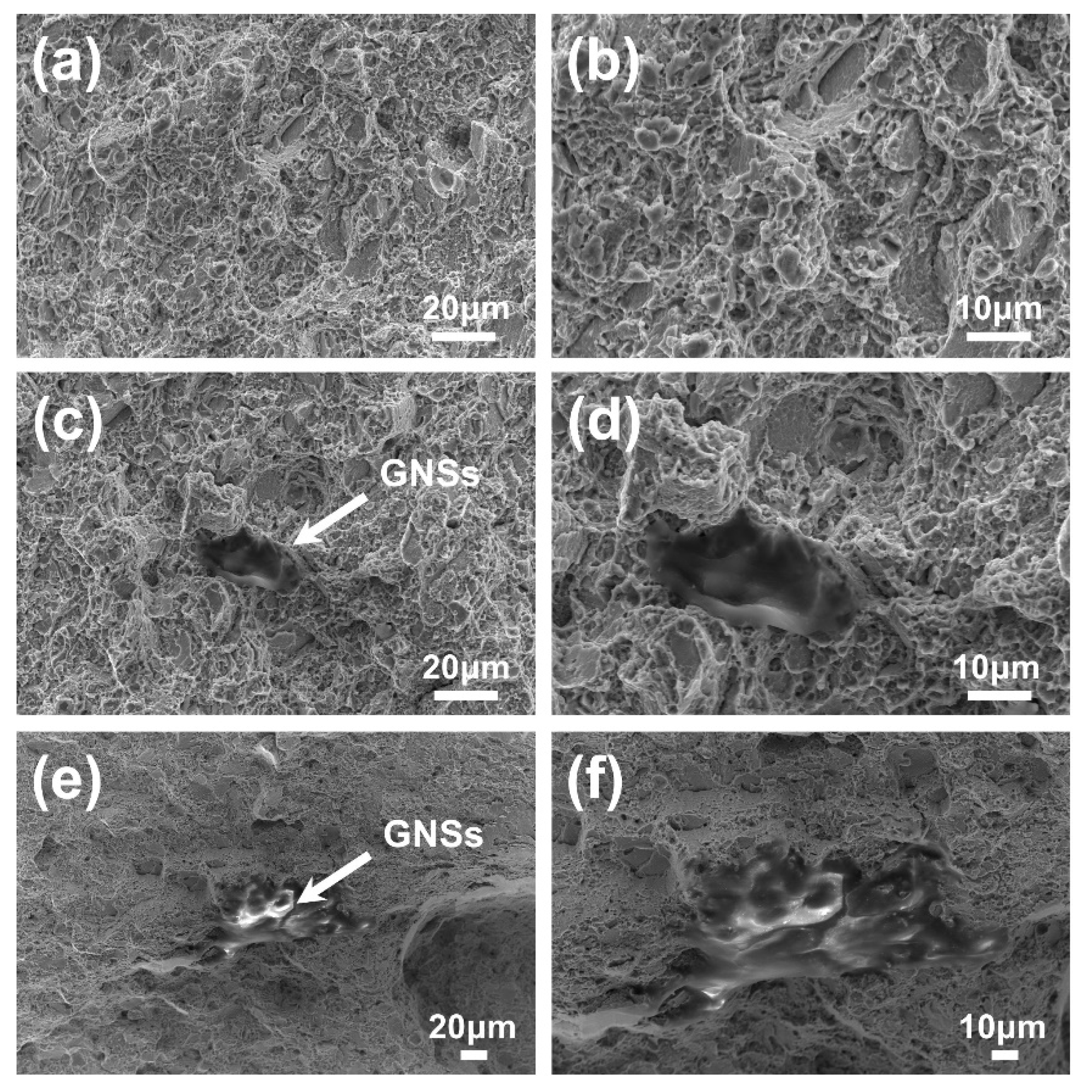

3.3. Fracture Behavior and Failure Mechanisms at Different Temperature

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Qi, X.; Boey, F.; Zhang, H. Graphene-based composites. Chem. Soc. Rev. 2012, 41, 666–686. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.; Tong, G.; Lin, D.; Chen, C.; Guo, H.; Xu, J.; Zhou, L. Graphene-reinforced metal matrix nanocomposites—A review. Mater. Sci. Technol. Lond. 2016, 32, 930–953. [Google Scholar] [CrossRef]

- Kim, H.; Abdala, A.A.; Macosko, C.W. Graphene/Polymer Nanocomposites. Macromolecules 2010, 43, 6515–6530. [Google Scholar] [CrossRef]

- Kuila, T.; Bose, S.; Mishra, A.K.; Khanra, P.; Kim, N.H.; Lee, J.H. Chemical functionalization of graphene and its applications. Prog. Mater. Sci. 2012, 57, 1061–1105. [Google Scholar] [CrossRef]

- Nieto, A.; Bisht, A.; Lahiri, D.; Zhang, C.; Agarwal, A. Graphene reinforced metal and ceramic matrix composites: A review. Int. Mater. Rev. 2016, 62, 241–302. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Dommett, G.H.B.; Kohlhaas, K.M.; Zimney, E.J.; Stach, E.A.; Piner, R.D.; Nguyen, S.T.; Ruoff, R.S. Graphene-based composite materials. Nature 2006, 442, 282–286. [Google Scholar] [CrossRef]

- Zhang, Z.W.; Liu, Z.Y.; Xiao, B.L.; Ni, D.R.; Ma, Z.Y. High efficiency dispersal and strengthening of graphene reinforced aluminum alloy composites fabricated by powder metallurgy combined with friction stir processing. Carbon 2018, 135, 215–223. [Google Scholar] [CrossRef]

- Ramanathan, T.; Abdala, A.A.; Stankovich, S.; Dikin, D.A.; Herrera Alonso, M.; Piner, R.D.; Adamson, D.H.; Schniepp, H.C.; Chen, X.; Ruoff, R.S.; et al. Functionalized graphene sheets for polymer nanocomposites. Nat. Nano 2008, 3, 327–331. [Google Scholar] [CrossRef]

- Tjong, S.C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets. Mater. Sci. Eng. R Rep. 2013, 74, 281–350. [Google Scholar] [CrossRef]

- Wang, J.; Li, Z.; Fan, G.; Pan, H.; Chen, Z.; Zhang, D. Reinforcement with graphene nanosheets in aluminum matrix composites. Scr. Mater. 2012, 66, 594–597. [Google Scholar] [CrossRef]

- Mileiko, S.T. High temperature oxide-fibre/metal-matrix composites. Mater. Chem. Phys. 2018, 210, 353–361. [Google Scholar] [CrossRef]

- Zhang, X.; Shi, C.; Liu, E.; Zhao, N.; He, C. High-strength graphene network reinforced copper matrix composites achieved by architecture design and grain structure regulation. Mater. Sci. Eng. A Struct. 2019, 762, 138063. [Google Scholar] [CrossRef]

- Lin, D.; Richard Liu, C.; Cheng, G.J. Single-layer graphene oxide reinforced metal matrix composites by laser sintering: Microstructure and mechanical property enhancement. Acta Mater. 2014, 80, 183–193. [Google Scholar] [CrossRef]

- Jiang, Y.; Xu, R.; Tan, Z.; Ji, G.; Fan, G.; Li, Z.; Xiong, D.-B.; Guo, Q.; Li, Z.; Zhang, D. Interface-induced strain hardening of graphene nanosheet/aluminum composites. Carbon 2019, 146, 17–27. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Hu, H.; Asif, M.; Hussain, S.; She, J. Enhanced tensile properties of magnesium composites reinforced with graphene nanoplatelets. Mater. Sci. Eng. A Struct. 2015, 630, 36–44. [Google Scholar] [CrossRef]

- Wang, M.; Zhao, Y.; Wang, L.-D.; Zhu, Y.-P.; Wang, X.-J.; Sheng, J.; Yang, Z.-Y.; Shi, H.-L.; Shi, Z.-D.; Fei, W.-D. Achieving high strength and ductility in graphene/magnesium composite via an in-situ reaction wetting process. Carbon 2018, 139, 954–963. [Google Scholar] [CrossRef]

- Yang, W.; Chen, G.; Qiao, J.; Liu, S.; Xiao, R.; Dong, R.; Hussain, M.; Wu, G. Graphene nanoflakes reinforced Al-20Si matrix composites prepared by pressure infiltration method. Mat. Sci. Eng. A Struct. 2017, 700, 351–357. [Google Scholar] [CrossRef]

- Khobragade, N.; Sikdar, K.; Kumar, B.; Bera, S.; Roy, D. Mechanical and electrical properties of copper-graphene nanocomposite fabricated by high pressure torsion. J. Alloys Compd. 2019, 776, 123–132. [Google Scholar] [CrossRef]

- Mu, X.N.; Cai, H.N.; Zhang, H.M.; Fan, Q.B.; Wang, F.C.; Cheng, X.W.; Zhang, Z.H.; Li, J.B.; Jiao, X.L.; Ge, Y.X.; et al. Size effect of flake Ti powders on the mechanical properties in graphene nanoflakes/Ti fabricated by flake powder metallurgy. Compos. Part A Appl. Sci. 2019, 123, 86–96. [Google Scholar] [CrossRef]

- Li, J.; Zhang, X.; Geng, L. Effect of heat treatment on interfacial bonding and strengthening efficiency of graphene in GNP/Al composites. Compos. Part A Appl. Sci. 2019, 121, 487–498. [Google Scholar] [CrossRef]

- Ferreira, F.; Ferreira, I.; Camacho, E.; Lopes, F.; Marques, A.C.; Velhinho, A. Graphene oxide-reinforced aluminium-matrix nanostructured composites fabricated by accumulative roll bonding. Compos. Part B Eng. 2019, 164, 265–271. [Google Scholar] [CrossRef]

- Isaza Merino, C.A.; Ledezma Sillas, J.E.; Meza, J.M.; Herrera Ramirez, J.M. Metal matrix composites reinforced with carbon nanotubes by an alternative technique. J. Alloys Compd. 2017, 707, 257–263. [Google Scholar] [CrossRef]

- Tjong, S.C.; Ma, Z.Y. Microstructural and mechanical characteristics of in situ metal matrix composites. Mater. Sci. Eng. R 2000, 29, 49–113. [Google Scholar] [CrossRef]

- Fu, K.; Zhang, X.; Shi, C.; Liu, E.; He, F.; Li, J.; Zhao, N.; He, C. An approach for fabricating Ni@graphene reinforced nickel matrix composites with enhanced mechanical properties. Mater. Sci. Eng. A Struct. 2018, 715, 108–116. [Google Scholar] [CrossRef]

- Ma, S.; Yang, Y.; Li, A.; Zhou, S.; Shi, L.; Wang, S.; Liu, M. Effects of temperature on microstructure and mechanical properties of IN718 reinforced by reduced graphene oxide through spark plasma sintering. J. Alloys Compd. 2018, 767, 675–681. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, J.; Yeom, M.S.; Shin, J.W.; Kim, H.; Cui, Y.; Kysar, J.W.; Hone, J.; Jung, Y.; Jeon, S.; et al. Strengthening effect of single-atomic-layer graphene in metal-graphene nanolayered composites. Nat. Commun. 2013, 4, 2114. [Google Scholar] [CrossRef]

- Chen, Z.; Wei, P.; Zhang, S.; Lu, B.; Zhang, L.; Yang, X.; Huang, K.; Huang, Y.; Li, X.; Zhao, Q. Graphene reinforced nickel-based superalloy composites fabricated by additive manufacturing. Mater. Sci. Eng. A Struct. 2020, 769, 138484. [Google Scholar] [CrossRef]

- Chen, Y.; Lu, F.; Zhang, K.; Nie, P.; Elmi Hosseini, S.R.; Feng, K.; Li, Z. Laser powder deposition of carbon nanotube reinforced nickel-based superalloy Inconel 718. Carbon 2016, 107, 361–370. [Google Scholar] [CrossRef]

- Deng, P.; Yao, C.; Feng, K.; Huang, X.; Li, Z.; Li, Y.; Zhao, H. Enhanced wear resistance of laser cladded graphene nanoplatelets reinforced Inconel 625 superalloy composite coating. Surf. Coat. Technol. 2018, 335, 334–344. [Google Scholar] [CrossRef]

- Cao, M.; Xiong, D.B.; Yang, L.; Li, S.; Xie, Y.; Guo, Q.; Li, Z.; Adams, H.; Gu, J.; Fan, T.; et al. Ultrahigh Electrical Conductivity of Graphene Embedded in Metals. Adv. Funct. Mater. 2019, 29, 1806792. [Google Scholar] [CrossRef]

- Hu, Z.; Wang, D.; Chen, C.; Wang, X.; Chen, X.; Nian, Q. Bulk titanium–graphene nanocomposites fabricated by selective laser melting. J. Mater. Res. 2019, 34, 1744–1753. [Google Scholar] [CrossRef]

- Cao, M.; Luo, Y.; Xie, Y.; Tan, Z.; Fan, G.; Guo, Q.; Su, Y.; Li, Z.; Xiong, D.B. The Influence of Interface Structure on the Electrical Conductivity of Graphene Embedded in Aluminum Matrix. Adv. Mater. Interfaces 2019, 6, 1900468. [Google Scholar] [CrossRef]

- Yang, L.; Ren, X.; Ge, C.; Yan, Q. Status and development of powder metallurgy nickel-based disk superalloys. Int. J. Mater. Res. 2019, 110, 901–910. [Google Scholar] [CrossRef]

- Hummers, W.S.; Offeman, R.E. Preparation of Graphitic Oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Geim, A.K. Graphene: Status and Prospects. Science 2009, 324, 1530. [Google Scholar] [CrossRef] [PubMed]

- Yoo, S.C.; Lee, J.; Hong, S.H. Synergistic outstanding strengthening behavior of graphene/copper nanocomposites. Compos. Part B Eng. 2019, 176, 107235. [Google Scholar] [CrossRef]

- Jiang, Y.; Tan, Z.; Xu, R.; Fan, G.; Xiong, D.-B.; Guo, Q.; Su, Y.; Li, Z.; Zhang, D. Tailoring the structure and mechanical properties of graphene nanosheet/aluminum composites by flake powder metallurgy via shift-speed ball milling. Compos. Part A Appl. Sci. 2018, 111, 73–82. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 2008, 321, 385. [Google Scholar] [CrossRef]

- Chu, K.; Wang, F.; Li, Y.-B.; Wang, X.-H.; Huang, D.-J.; Zhang, H. Interface structure and strengthening behavior of graphene/CuCr composites. Carbon 2018, 133, 127–139. [Google Scholar] [CrossRef]

- Chu, K.; Wang, J.; Liu, Y.-P.; Li, Y.-B.; Jia, C.-C.; Zhang, H. Creating defects on graphene basal-plane toward interface optimization of graphene/CuCr composites. Carbon 2019, 143, 85–96. [Google Scholar] [CrossRef]

- Estrin, Y.; Gottstein, G.; Shvindlerman, L.S. Diffusion controlled creep in nanocrystalline materials under grain growth. Scr. Mater. 2004, 50, 993–997. [Google Scholar] [CrossRef]

- Mokdad, F.; Chen, D.L.; Liu, Z.Y.; Ni, D.R.; Xiao, B.L.; Ma, Z.Y. Hot deformation and activation energy of a CNT-reinforced aluminum matrix nanocomposite. Mater. Sci. Eng. A Struct. 2017, 695, 322–331. [Google Scholar] [CrossRef]

- Jiang, R.; Zhou, X.; Fang, Q.; Liu, Z. Copper-graphene bulk composites with homogeneous graphene dispersion and enhanced mechanical properties. Mater. Sci. Eng. A Struct. 2016, 654, 124–130. [Google Scholar] [CrossRef]

- Chu, K.; Wang, F.; Wang, X.-H.; Li, Y.-B.; Geng, Z.-R.; Huang, D.-J.; Zhang, H. Interface design of graphene/copper composites by matrix alloying with titanium. Mater. Des. 2018, 144, 290–303. [Google Scholar] [CrossRef]

- Shin, S.E.; Ko, Y.J.; Bae, D.H. Mechanical and thermal properties of nanocarbon-reinforced aluminum matrix composites at elevated temperatures. Compos. Part B Eng. 2016, 106, 66–73. [Google Scholar] [CrossRef]

| Sample | Temperature (°C) | UTS (MPa) | YS (MPa) | Elongation (%) | R/A (%) |

|---|---|---|---|---|---|

| FGH95 | 23 | 1561 ± 15 | 1167 ± 13 | 10.8 ± 1.3 | 12.0 ± 1.2 |

| 0.01 wt.% GNSs/FGH95 | 1660 ± 17 | 1229 ± 11 | 22.2 ± 1.5 | 29.9 ± 1.6 | |

| 0.03 wt.% GNSs/FGH95 | 1634 ± 14 | 1198 ± 16 | 19.2 ± 1.1 | 21.5 ± 1.0 | |

| FGH95 | 650 | 1367 ± 16 | 1068 ± 11 | 8.1 ± 1.5 | 10.9 ± 1.3 |

| 0.01 wt.% GNSs/FGH95 | 1426 ± 14 | 1110 ± 13 | 19.4 ± 0.9 | 20.1 ± 1.1 | |

| 0.03 wt.% GNSs/FGH95 | 1439 ± 11 | 1106 ± 13 | 21.3 ± 1.1 | 21.9 ± 1.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Zou, J.; Wang, X.; Wang, X.; Yang, J.; Wang, H. Microstructure and Mechanical Performance of Graphene Nanosheets Reinforced Nickel-Based Superalloy FGH95 Composite. Nanomaterials 2020, 10, 100. https://doi.org/10.3390/nano10010100

Gao Y, Zou J, Wang X, Wang X, Yang J, Wang H. Microstructure and Mechanical Performance of Graphene Nanosheets Reinforced Nickel-Based Superalloy FGH95 Composite. Nanomaterials. 2020; 10(1):100. https://doi.org/10.3390/nano10010100

Chicago/Turabian StyleGao, Yuxi, Jinwen Zou, Xuqing Wang, Xiaofeng Wang, Jie Yang, and Huaming Wang. 2020. "Microstructure and Mechanical Performance of Graphene Nanosheets Reinforced Nickel-Based Superalloy FGH95 Composite" Nanomaterials 10, no. 1: 100. https://doi.org/10.3390/nano10010100

APA StyleGao, Y., Zou, J., Wang, X., Wang, X., Yang, J., & Wang, H. (2020). Microstructure and Mechanical Performance of Graphene Nanosheets Reinforced Nickel-Based Superalloy FGH95 Composite. Nanomaterials, 10(1), 100. https://doi.org/10.3390/nano10010100