Factors Affecting the Color Change of Monolithic Zirconia Ceramics: A Narrative Review

Abstract

1. Introduction

2. Factors Affecting the Color Change in Monolithic Zirconia Ceramics

2.1. Effects of Cement Type and Cement Color on the Color Change in Monolithic Zirconia Ceramics

2.2. Effect of Restoration Thickness on the Color Change in Monolithic Zirconia Ceramics

2.3. Effect of Substrate Color on the Color Change in Monolithic Zirconia Ceramics

2.4. Effect of Sinterization on the Color Change in Monolithic Zirconia Ceramics

2.5. Effect of Aging on the Color Change in Monolithic Zirconia Ceramics

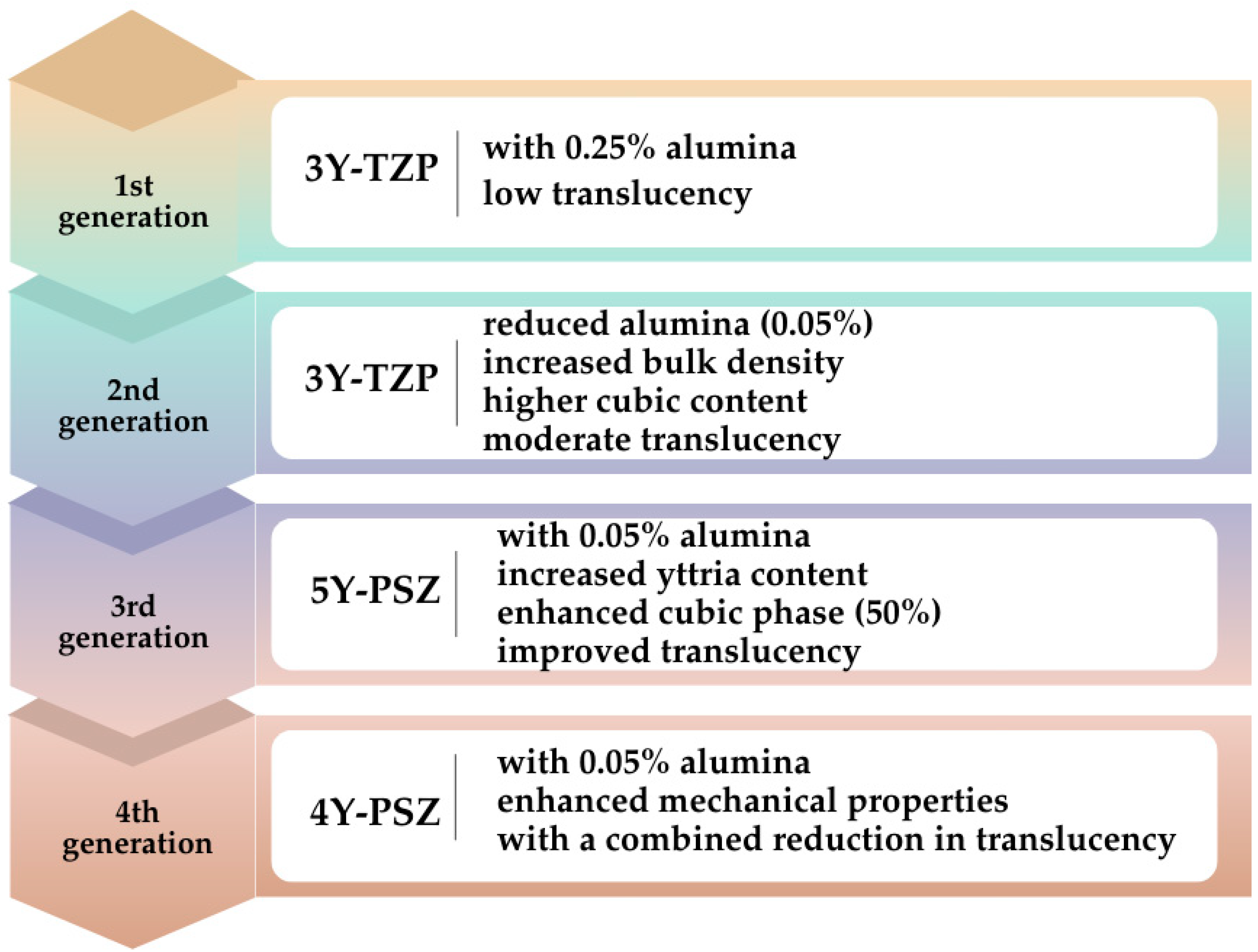

2.6. Effect of Zirconia Type on the Color Change in Monolithic Zirconia Ceramics

3. Conclusions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Y-TZP | Yttria-stabilized tetragonal zirconia polycrystals |

| Y-PSZ | Yittria-partially stabilized zirconia |

| wt. | weight |

| CAD-CAM | Computer-aided design-Computer-aided manufacturing |

| TP | Translucency parameter |

| UTML | Ultra translucent multi-layered |

| LTD | Low-temperature degradation |

References

- Alrabeah, G.; Al-Sowygh, A.H.; Almarshedy, S. Use of ultra-translucent monolithic zirconia as esthetic dental restorative material: A narrative review. Ceramics 2024, 7, 264–275. [Google Scholar] [CrossRef]

- Nistor, L.; Grădinaru, M.; Rîcă, R.; Mărășescu, P.; Stan, M.; Manolea, H.; Ionescu, A.; Moraru, I. Zirconia use in dentistry—manfacturing and properties. Curr. Health Sci. J. 2019, 45, 28–35. [Google Scholar] [CrossRef]

- Kim, H.K.; Kim, S.H. Optical properties of pre-colored dental monolithic zirconia ceramics. J. Dent. 2016, 55, 75–81. [Google Scholar] [CrossRef] [PubMed]

- Ban, S. Development and characterization of ultra-high translucent zirconia using new manufacturing technology. Dent. Mater. J. 2023, 42, 1–10. [Google Scholar] [CrossRef]

- Giordano, R., II. Ceramics overview. Br. Dent. J. 2022, 232, 658–663. [Google Scholar] [CrossRef] [PubMed]

- Huang, B.; Chen, M.; Wang, J.; Zhang, X. Advances in zirconia-based dental materials: Properties, classification, applications, and future prospects. J. Dent. 2024, 147, 105111. [Google Scholar] [CrossRef] [PubMed]

- Alqutaibi, A.Y.; Ghulam, O.; Krsoum, M.; Binmahmoud, S.; Taher, H.; Elmalky, W.; Zafar, M.S. Revolution of current dental zirconia: A comprehensive review. Molecules 2022, 27, 1699. [Google Scholar] [CrossRef] [PubMed]

- Ban, S. Classification and properties of dental zirconia as implant fixtures and superstructures. Materials 2021, 14, 4879. [Google Scholar] [CrossRef] [PubMed]

- Ghodsi, S.; Jafarian, Z. A Review on Translucent Zirconia. Eur. J. Prosthodont. Restor. Dent. 2018, 26, 62–74. [Google Scholar] [CrossRef] [PubMed]

- Pekkan, G.; Özcan, M.; Subaşı, M.G. Clinical factors affecting the translucency of monolithic Y-TZP ceramics. Odontology 2020, 108, 526–531. [Google Scholar] [CrossRef] [PubMed]

- Denry, I.; Kelly, J.R. State of the art of zirconia for dental applications. Dent. Mater. 2008, 24, 299–307. [Google Scholar] [CrossRef] [PubMed]

- Güth, J.F.; Stawarczyk, B.; Edelhoff, D.; Liebermann, A. Zirconia and its novel compositions: What do clinicians need to know? Quintessence Int. 2019, 50, 512–520. [Google Scholar] [CrossRef] [PubMed]

- Kui, A.; Manziuc, M.; Petruțiu, A.; Buduru, S.; Labuneț, A.; Negucioiu, M.; Chisnoiu, A. Translucent zirconia in fixed prosthodontics—An integrative overview. Biomedicines 2023, 11, 3116. [Google Scholar] [CrossRef]

- Daneshpooy, M.; Pournaghi Azar, F.; Alizade Oskoee, P.; Bahari, M.; Asdagh, S.; Khosravani, S.R. Color agreement between try-in paste and resin cement: Effect of thickness and regions of ultra-translucent multilayered zirconia veneers. J. Dent. Res. Dent. Clin. Dent. Prospect. 2019, 13, 61–67. [Google Scholar] [CrossRef]

- Abdulmajeed, A.; Sulaiman, T.A.; Abdulmajeed, A.A.; Närhi, T.O. Strength and phase transformation of different zirconia types after chairside adjustment. J. Prosthet. Dent. 2024, 132, 455–463. [Google Scholar] [CrossRef] [PubMed]

- Vardhaman, S.; Borba, M.; Kaizer, M.R.; Kim, D.K.; Zhang, Y. Optical and mechanical properties of the multi-transition zones of a translucent Zirconia. J. Esthet. Restor. Dent. 2024, 1–8. [Google Scholar] [CrossRef]

- Arellano Moncayo, A.M.; Peñate, L.; Arregui, M.; Giner-Tarrida, L.; Cedeño, R. State of the art of different zirconia materials and their indications according to evidence-based clinical performance: A narrative review. Dent. J. 2023, 11, 18. [Google Scholar] [CrossRef]

- Malallah, A.D.; Hasan, N.H. Thickness and yttria percentage influence the fracture resistance of laminate veneer zirconia restorations. Clin. Exp. Dent. Res. 2022, 8, 1413–1420. [Google Scholar] [CrossRef] [PubMed]

- Kongkiatkamon, S.; Rokaya, D.; Kengtanyakich, S.; Peampring, C. Current classification of zirconia in dentistry: An updated review. PeerJ 2023, 11, e15669. [Google Scholar] [CrossRef]

- Tabatabaian, F. Color in zirconia-based restorations and related factors: A literature review. J. Prosthodont. 2018, 27, 201–211. [Google Scholar] [CrossRef] [PubMed]

- Pekkan, G.; Pekkan, K.; Bayindir, B.Ç.; Özcan, M.; Karasu, B. Factors affecting the translucency of monolithic zirconia ceramics: A review from materials science perspective. Dent. Mater. J. 2020, 39, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Paravina, R.D.; Ghinea, R.; Herrera, L.J.; Bona, A.D.; Igiel, C.; Linninger, M.; Mar Perez, M.D. Color difference thresholds in dentistry. J. Esthet. Restor. Dent. 2015, 27, S1–S9. [Google Scholar] [CrossRef] [PubMed]

- Jouhar, R.; Ahmed, M.A.; Khurshid, Z. An overview of shade selection in clinical dentistry. Appl. Sci. 2022, 12, 6841. [Google Scholar] [CrossRef]

- Paravina, R.D. Performance assessment of dental shade guides. J. Dent. 2009, 37, e15–e20. [Google Scholar] [CrossRef]

- Lehmann, K.M.; Devigus, A.; Igiel, C.; Wentaschek, S.; Azar, M.S.; Scheller, H. Repeatability of color-measuring devices. Eur. J. Esthet. Dent. 2011, 6, 428–435. [Google Scholar]

- Tabatabaian, F.; Beyabanaki, E.; Alirezaei, P.; Epakchi, S. Visual and digital tooth shade selection methods, related effective factors and conditions, and their accuracy and precision: A literature review. J. Esthet. Restor. Dent. 2021, 33, 1084–1104. [Google Scholar] [CrossRef] [PubMed]

- Mahajan, N.R.; Bansod, A.; Reche, A.; Dubey, S.A. Aesthetic and functional rehabilitation for dentogingival asymmetry using zirconia restorations. Cureus 2024, 16, e63558. [Google Scholar] [CrossRef]

- Çakmak, G.; Donmez, M.B.; Kashkari, A.; Johnston, W.M.; Yilmaz, B. Effect of thickness, cement shade, and coffee thermocycling on the optical properties of zirconia reinforced lithium silicate ceramic. J. Esthet. Restor. Dent. 2021, 33, 1132–1138. [Google Scholar] [CrossRef] [PubMed]

- Comba, A.; Paolone, G.; Baldi, A.; Vichi, A.; Goracci, C.; Bertozzi, G.; Scotti, N. Effects of substrate and cement shade on the translucency and color of CAD/CAM lithium-disilicate and zirconia ceramic materials. Polymers 2022, 14, 1778. [Google Scholar] [CrossRef]

- Ayash, G.; Osman, E.; Segaan, L.; Rayyan, M.; Joukhadar, C. Influence of resin cement shade on the color and translucency of zirconia crowns. J. Clin. Exp. Dent. 2020, 12, e257–e263. [Google Scholar] [CrossRef]

- Mekled, S.; Elwazeer, S.; Jurado, C.A.; White, J.; Faddoul, F.; Afrashtehfar, K.I.; Fischer, N.G. Ultra-translucent zirconia laminate veneers: The influence of restoration thickness and stump tooth-shade. Materials 2023, 16, 3030. [Google Scholar] [CrossRef] [PubMed]

- Manziuc, M.M.; Gasparik, C.; Negucioiu, M.; Constantiniuc, M.; Burde, A.; Vlas, I.; Dudea, D. Optical properties of translucent zirconia: A review of the literature. EuroBiotech J. 2019, 3, 45–51. [Google Scholar] [CrossRef]

- Batista, A.; Palacios, N.; Ricardo, A.J.O. Zirconia cementation: A systematic review of the most currently used protocols. Open Dent. J. 2024, 18, e18742106300869. [Google Scholar] [CrossRef]

- Gomes, A.L.; Castillo-Oyagüe, R.; Lynch, C.D.; Montero, J.; Albaladejo, A. Influence of sandblasting granulometry and resin cement composition on microtensile bond strength to zirconia ceramic for dental prosthetic frameworks. J. Dent. 2013, 41, 31–41. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.A.; Al Kheraif, A.; Jamaluddin, S.; Elsharawy, M.; Divakar, D.D. Recent trends in surface treatment methods for bonding composite cement to zirconia: A review. J. Adhes. Dent. 2017, 19, 7–19. [Google Scholar] [CrossRef]

- Chen, Z.; Zhou, Y.; Li, D.; Zhang, M.; Zhou, B.; Hao, P. Does the internal surface treatment technique for enhanced bonding affect the color, transparency, and surface roughness of ultra-transparent zirconia? Clin. Oral Investig. 2024, 28, 473. [Google Scholar] [CrossRef] [PubMed]

- Shahmiri, R.; Standard, O.C.; Hart, J.N.; Sorrell, C.C. Optical properties of zirconia ceramics for esthetic dental restorations: A systematic review. J. Prosthet. Dent. 2018, 119, 36–46. [Google Scholar] [CrossRef]

- Turgut, S.; Bagis, B. Effect of resin cement and ceramic thickness on final color of laminate veneers: An in vitro study. J. Prosthet. Dent. 2013, 109, 179–186. [Google Scholar] [CrossRef]

- Malkondu, O.; Tinastepe, N.; Kazazoglu, E. Influence of type of cement on the color and translucency of monolithic zirconia. J. Prosthet. Dent. 2016, 116, 902–908. [Google Scholar] [CrossRef]

- Bayindir, F.; Koseoglu, M. The effect of restoration thickness and resin cement shade on the color and translucency of a high-translucency monolithic zirconia. J. Prosthet. Dent. 2020, 123, 149–154. [Google Scholar] [CrossRef] [PubMed]

- Tabatabaian, F.; Habib Khodaei, M.; Namdari, M.; Mahshid, M. Effect of cement type on the color attributes of a zirconia ceramic. J. Adv. Prosthodont. 2016, 8, 449–456. [Google Scholar] [CrossRef] [PubMed]

- Khosravani, S.R.; Kahnamoui, M.A.; Kimyai, S.; Navimipour, E.J.; Mahounak, F.S.; Azar, F.P. Final colour of ultra translucent multilayered zirconia veneers, effect of thickness, and resin cement shade. Biomed Res. Int. 2022, 2022, 2555797. [Google Scholar] [CrossRef] [PubMed]

- Sakrana, A.A.; Laith, A.; Elsherbini, A.; Elerian, F.A.; Özcan, M.; Al-Zordk, W. Influence of resin cement on color stability when luting lithium disilicate and zirconia restorations. Int. J. Esthet. Dent. 2023, 18, 114–126. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.K.; Kim, S.H.; Lee, J.B.; Han, J.S.; Yeo, I.S.; Ha, S.R. Effect of the amount of thickness reduction on color and translucency of dental monolithic zirconia ceramics. J. Adv. Prosthodont. 2016, 8, 37–42. [Google Scholar] [CrossRef]

- Tabatabaian, F.; Aflatoonian, K.; Namdari, M. Effects of veneering porcelain thickness and background shade on the shade match of zirconia-based restorations. J. Dent. Res. Dent. Clin. Dent. Prospect. 2019, 13, 68–74. [Google Scholar] [CrossRef] [PubMed]

- Oh, S.H.; Kim, S.G. Effect of abutment shade, ceramic thickness, and coping type on the final shade of zirconia all-ceramic restorations: In vitro study of color masking ability. J. Adv. Prosthodont. 2015, 7, 368–374. [Google Scholar] [CrossRef] [PubMed]

- Tabatabaian, F.; Khaledi, Z.; Namdari, M. Effect of ceramic thickness and cement type on the color match of high-translucency monolithic zirconia restorations. Int. J. Prosthodont. 2021, 34, 334–340. [Google Scholar] [CrossRef]

- Kang, C.M.; Peng, T.Y.; Huang, H.H. Effects of thickness of different types of high-translucency monolithic multilayer precolored zirconia on color accuracy: An in vitro study. J. Prosthet. Dent. 2021, 126, 587.e1–587.e8. [Google Scholar] [CrossRef] [PubMed]

- Suputtamongkol, K.; Tulapornchai, C.; Mamani, J.; Kamchatphai, W.; Thongpun, N. Effect of the shades of background substructures on the overall color of zirconia-based all-ceramic crowns. J. Adv. Prosthodont. 2013, 5, 319–325. [Google Scholar] [CrossRef] [PubMed]

- Sonza, Q.N.; Della Bona, A.; Pecho, O.E.; Borba, M. Effect of substrate and cement on the final color of zirconia-based all-ceramic crowns. J. Esthet. Restor. Dent. 2021, 33, 891–898. [Google Scholar] [CrossRef]

- Tabatabaian, F.; Masoomi, F.; Namdari, M.; Mahshid, M. Effect of three different core materials on masking ability of a zirconia ceramic. J. Dent. 2016, 13, 340–348. [Google Scholar]

- Ansarifard, E.; Taghva, M.; Mosaddad, S.A.; Akhlaghian, M. The impact of various substrates, ceramic shades, and brands on the ultimate color and masking capacity of highly translucent monolithic zirconia: An in vitro study. Odontology 2024. [Google Scholar] [CrossRef] [PubMed]

- Ghoveizi, R.; Baghaei, M.; Tavakolizadeh, S.; Tabatabaian, F. Color match of ultra-translucency multilayer zirconia restorations with different designs and backgrounds. J. Prosthodont. 2024, 33, 382–388. [Google Scholar] [CrossRef] [PubMed]

- Skienhe, H.; Habchi, R.; Ounsi, H.; Ferrari, M.; Salameh, Z. Evaluation of the effect of different types of abrasive surface treatment before and after zirconia sintering on its structural composition and bond strength with resin cement. Biomed Res. Int. 2018, 2018, 1803425. [Google Scholar] [CrossRef] [PubMed]

- Juntavee, N.; Juntavee, A.; Jaralpong, C. Color characteristics of high yttrium oxide-doped monochrome and multilayer partially stabilized zirconia upon different sintering parameters. Eur. J. Dent. 2024, 19, 227–239. [Google Scholar] [CrossRef] [PubMed]

- Ebeid, K.; Wille, S.; Hamdy, A.; Salah, T.; El-Etreby, A.; Kern, M. Effect of changes in sintering parameters on monolithic translucent zirconia. Dent. Mater. 2014, 30, e419–e424. [Google Scholar] [CrossRef] [PubMed]

- Vafaei, F.; Shahbazi, A.; Hooshyarfard, A.; Najafi, A.H.; Ebrahimi, M.; Farhadian, M. Effect of sintering temperature on translucency parameter of zirconia blocks. Dent. Res. J. 2022, 19, 82. [Google Scholar]

- Kilinc, H.; Sanal, F.A. Effect of sintering and aging processes on the mechanical and optical properties of translucent zirconia. J. Prosthet. Dent. 2021, 126, 129.e1–129.e7. [Google Scholar] [CrossRef] [PubMed]

- Salah, K.; Sherif, A.H.; Mandour, M.H.; Nossair, S.A. Optical effect of rapid sintering protocols on different types of zirconia. J. Prosthet. Dent. 2023, 130, 253.e1–253.e7. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Zhang, L.; Yang, M.; Chen, J.; Xing, W. The effect of deviations in sintering temperature on the translucency and color of multi-layered zirconia. BMC Oral Health 2024, 24, 471. [Google Scholar] [CrossRef] [PubMed]

- Giti, R.; Mosallanezhad, S. Effect of sintering temperature on color stability and translucency of various zirconia systems after immersion in coffee solution. PLoS ONE 2024, 19, e0313645. [Google Scholar] [CrossRef] [PubMed]

- Hassan Shohdy, E.I.; Sabet, A.; Sherif, A.H.; Salah, T. The effect of speed sintering on the optical properties and microstructure of multi-layered cubic zirconia. J. Prosthodont. 2024. [Google Scholar] [CrossRef] [PubMed]

- Engler, M.L.P.D.; Kauling, A.E.C.; Silva, J.; Rafael, C.F.; Liebermann, A.; Volpato, C.A.M. Influence of sintering temperature and aging on the color and translucency of zirconia. J. Prosthet. Dent. 2025. [Google Scholar] [CrossRef]

- Aly, Y.M.; Shahin, H.; Halawani, M. Effect of sintering technıque on the color coordınates of a translucent zirconium ceramic material. Alex. Dent. J. 2024, 49, 134–140. [Google Scholar] [CrossRef]

- de Araújo-Júnior, E.N.S.; Bergamo, E.T.P.; Bastos, T.M.C.; Benalcázar Jalkh, E.B.; Lopes, A.C.O.; Monteiro, K.N.; Cesar, P.F.; Tognolo, F.C.; Migliati, R.; Tanaka, R.; et al. Ultra-translucent zirconia processing and aging effect on microstructural, optical, and mechanical properties. Dent. Mater. 2022, 38, 587–600. [Google Scholar] [CrossRef] [PubMed]

- De Souza, G.M.; Zykus, A.; Ghahnavyeh, R.R.; Lawrence, S.K.; Bahr, D.F. Effect of accelerated aging on dental zirconia-based materials. J. Mech. Behav. Biomed. Mater. 2017, 65, 256–263. [Google Scholar] [CrossRef] [PubMed]

- Fathy, S.M.; El-Fallal, A.A.; El-Negoly, S.A.; El Bedawy, A.B. Translucency of monolithic and core zirconia after hydrothermal aging. Acta Biomater Odontol Scand 2015, 1, 86–92. [Google Scholar] [CrossRef] [PubMed]

- Angela Mazıero Volpato, C.; Francısco Cesar, P.; Antônıo Bottıno, M. Influence of accelerated aging on the color stability of dental zirconia. J. Esthet. Restor. Dent. 2016, 28, 304–312. [Google Scholar] [CrossRef] [PubMed]

- Papageorgiou-Kyrana, K.; Fasoula, M.; Kontonasaki, E. Translucency of monolithic zirconia after hydrothermal aging: A review of in vitro studies. J. Prosthodont. 2020, 29, 489–500. [Google Scholar] [CrossRef]

- Kim, H.K.; Kim, S.H. Effect of hydrothermal aging on the optical properties of precolored dental monolithic zirconia ceramics. J. Prosthet. Dent. 2019, 121, 676–682. [Google Scholar] [CrossRef] [PubMed]

- Miura, S.; Shinya, A.; Koizumi, H.; Vallittu, P.; Lassila, L.; Fujisawa, M. Effect of low-temperature degradation and sintering protocols on the color of monolithic zirconia crowns with different yttria contents. Dent. Mater. J. 2024, 43, 164–171. [Google Scholar] [CrossRef]

- Arindham, R.S.; Nandini, V.V.; Boruah, S.; Marimuthu, R.; Surya, R.; Lathief, J. Evaluation of the surface roughness and color stability of two types of milled zirconia before and after immersion in alcoholic beverages: An in vitro study. Cureus 2024, 16, e64695. [Google Scholar] [CrossRef]

- Abounassif, F.M.; Alfaraj, A.; Gadah, T.; Yang, C.C.; Chu, T.G.; Lin, W.S. Color stability of precolored and extrinsically colored monolithic multilayered polychromatic zirconia: Effects of surface finishing and aging. J. Prosthodont. 2024. [Google Scholar] [CrossRef] [PubMed]

- Park, M.G. Effect of low-temperature degradation treatment on hardness, color, and translucency of single layers of multilayered zirconia. J. Prosthet. Dent. 2025, 133, 258–263. [Google Scholar] [CrossRef]

- Khanlar, L.N.; Salazar Rios, A.; Tahmaseb, A.; Zandinejad, A. Additive Manufacturing of Zirconia Ceramic and Its Application in Clinical Dentistry: A Review. Dent. J. 2021, 9, 104. [Google Scholar] [CrossRef]

- Shahin, A.; Al-Wahadni, A.; Masri, R. Zirconia-based restorations: Literature review. Int. J. Med. Res. Prof. 2017, 3, 253–260. [Google Scholar] [CrossRef]

- Ramezani, M.; Mohd Ripin, Z. 4D printing in biomedical engineering: Advancements, challenges, and future directions. J. Funct. Biomater. 2023, 14, 347. [Google Scholar] [CrossRef] [PubMed]

- Revilla-León, M.; Meyer, M.J.; Zandinejad, A.; Özcan, M. Additive manufacturing technologies for processing zirconia in dental applications. Int. J. Comput. Dent. 2020, 23, 27–37. [Google Scholar]

- Alghauli, M.; Alqutaibi, A.Y.; Wille, S.; Kern, M. 3D-printed versus conventionally milled zirconia for dental clinical applications: Trueness, precision, accuracy, biological and esthetic aspects. J. Dent. 2024, 144, 104925. [Google Scholar] [CrossRef] [PubMed]

- Revilla-León, M.; Husain, N.A.H.; Ceballos, L.; Özcan, M. Flexural strength and Weibull characteristics of stereolithography additive manufactured versus milled zirconia. J. Prosthet. Dent. 2021, 125, 685–690. [Google Scholar] [CrossRef]

- Revilla-León, M.; Mostafavi, D.; Methani, M.M.; Zandinejad, A. Manufacturing accuracy and volumetric changes of stereolithography additively manufactured zirconia with different porosities. J. Prosthet. Dent. 2022, 128, 211–215. [Google Scholar] [CrossRef]

- Nakai, H.; Inokoshi, M.; Nozaki, K.; Komatsu, K.; Kamijo, S.; Liu, H.; Shimizubata, M.; Minakuchi, S.; Van Meerbeek, B.; Vleugels, J.; et al. Additively manufactured zirconia for dental applications. Materials 2021, 14, 3694. [Google Scholar] [CrossRef]

- Wang, W.; Sun, J. Dimensional accuracy and clinical adaptation of ceramic crowns fabricated with the stereolithography technique. J. Prosthet. Dent. 2021, 125, 657–663. [Google Scholar] [CrossRef] [PubMed]

- Branco, A.C.; Colaço, R.; Figueiredo-Pina, C.G.; Serro, A.P. Recent advances on 3D-printed zirconia-based dental materials: A review. Materials 2023, 16, 1860. [Google Scholar] [CrossRef] [PubMed]

- Vafaei, F.; Izadi, A.; Abbasi, S.; Farhadian, M.; Bagheri, Z. Comparison of optical properties of laminate veneers made of Zolid FX and Katana UTML zirconia and lithium disilicate ceramics. Front. Dent. 2019, 16, 357–368. [Google Scholar] [CrossRef] [PubMed]

- Kang, C.M.; Peng, T.Y.; Shimoe, S. Color accuracy of different types of monolithic multilayer precolored zirconia ceramics. J. Prosthet. Dent. 2020, 124, 789.e1–789.e7. [Google Scholar] [CrossRef]

- Kang, C.M.; Peng, T.Y.; Wu, Y.A.; Hsieh, C.F.; Chi, M.C.; Wu, H.Y.; Lin, Z.C. Comparison of optical properties and fracture loads of multilayer monolithic zirconia crowns with different yttria levels. J. Funct. Biomater. 2024, 15, 228. [Google Scholar] [CrossRef] [PubMed]

| Authors | Aim | Cement Type and/or Color | Study Design | Result |

|---|---|---|---|---|

| Malkondu et al. [39] | The aim of this study was to evaluate color changes regarding the perceptibility and acceptability of monolithic zirconia-and-cement combinations with two monolithic zirconia thicknesses and three types of cement. | Conventional glass ionomer cement, resin-modified glass ionomer cement, and resin cement from the same manufacturer were applied to the surfaces of the specimens. | Monolithic zirconia material (5Y-PSZ) (Ceramill Zolid; Amann Girrbach, Koblach, Austria) was used in two different thicknesses (0.6 mm, 1 mm) and with three different types of cement: RelyX U200 [3M ESPE, St. Paul, MN, USA] resin cement, RelyX Luting [3M ESPE, USA] resin-modified glass ionomer cement, and Ketac Cem Radiopaque [3M ESPE, USA] conventional glass ionomer cement. Color differences (∆Eab) were calculated using the L, a, and b values obtained from the specimens. | Specimen thickness and cement type significantly affected the ∆L, ∆a, ∆b, and ∆Eab values (p ˂ 0.05). The smallest color change was observed in the 1 mm thickness group with resin-modified glass ionomer cement (∆E = 2.23), while the greatest color change was observed in the 0.6 mm thickness group with resin cement (∆E = 5.64). |

| Bayındır et al. [40] | The aim of this in vitro study was to examine the effects of different resin cement colors and material thicknesses on the color and translucency of high-translucency monolithic zirconia. | A transparent and opaque self-etch adhesive resin cements were tested. | Eighty disk-shaped monolithic zirconia specimens (3Y-TZP) (Kuraray Noritake Dental, Okayama, Japan) with a 10 mm diameter were fabricated in four different thicknesses (0.5 mm, 1 mm, 1.5 mm, and 2 mm). The specimens were divided into two subgroups per thickness based on the use of either transparent or opaque self-etch adhesive resin cement (Panavia V5, Kuraray Noritake Dental Inc., Okayama, Japan). Color measurements (CIE L*, a*, and b*) were taken before and after cementation using a spectrophotometer. The translucency parameter (TP) and color change (ΔEab) were then calculated. | Statistical analyses revealed that thickness and cement opacity significantly influenced translucency parameter (TP) and color change values (ΔEab), with thinner specimens exhibiting more excellent translucency and more noticeable color changes due to cement opacity. Monolithic zirconia-clear cement had the lowest value (1.19 for 2 mm), while monolithic zirconia-opaque cement had the highest ΔE value (8.05 for 0.5 mm). These findings highlight the combined effects of material thickness and cement type on the esthetic outcomes of zirconia restorations. |

| Tabatabaian et al. [41] | The aim of this study was to evaluate the effects of four different cements on the color attributes of a zirconia ceramic. | Four types of cements were used: glass ionomer, Panavia F 2.0, zinc phosphate, and TempBond. |

Forty zirconia ceramic disk specimens (Luminesse High Strength 98 mm Discs #5113, Talladium, Valencia, CA, USA) were fabricated and cemented to composite substrates using four different types of cement (glass ionomer, Panavia F 2.0 zinc phosphate, and TempBond). A spectrophotometer measured the specimens’ L, a, and b values before and after cementation. ΔEab values were compared to the perceptibility threshold of ΔEab = 3.3. | Cement type affected the color of zirconia ceramic. ΔEab values of zinc phosphate and Tempbond cement were found to be beyond the perceptibility threshold. However, ΔEab values of glass ionomer and Panavia F 2.0 cement were within the perceptibility threshold. |

| Khosravani et al. [42] | The aim of this study was to evaluate the effect of ceramic thickness and resin cement shade on the final color of different layers of ultra-translucent multilayered (UTML) zirconia veneers. | The specimens of each thickness were divided into five groups based on resin cement shade: universal, clear, brown, white, and opaque. | Monolithic zirconia blocks of A1 shade Katana UTML (5Y-PSZ) (Kuraray Noritake Dental, Okayama, Japan) were prepared in 0.7 mm and 0.5 mm thicknesses, with 45 specimens in each group. The specimens were divided into five groups according to the cement color (universal, transparent, brown, white, and opaque). Each cement was applied to the ceramic specimens and the composite substrate, and the color values were recorded before and after the cement application. The color difference for each specimen was calculated using the ΔE00 formula. | ΔE00 values were significantly influenced by resin cement shade, ceramic thickness, and different layers. In 0.5 and 0.7 mm thick ceramics, the brown shade exhibited the highest ΔE00 values (4.49 ± 0.72 and 3.07 ± 0.81, respectively). White and clear shades showed the lowest ΔE00 values (0.5 mm: 2.44 ± 1.62, 0.7 mm: 2.22 ± 0.94, respectively). |

| Sakrana et al. [43] | The aim of the study was to evaluate the effect of resin cement on the color stability of lithium disilicate and zirconia restorations immersed in coffee after aging. | The resin cement types, G-CEM LinkForce (GC Corporation, Tokyo, Japan) and Panavia SA Cement Plus Automix (Kuraray Noritake Dental, Okayama, Japan) were tested. | Eighty maxillary premolars were prepared for lithium disilicate or zirconia restorations (high translucent zirconia), which were bonded with different types of resin cement (G-CEM LinkForce or Panavia SA Cement Plus Automix). All specimens were aged (240,000 loading cycles followed by 10,000 thermal cycles) and then immersed in coffee (for 18 h). The preheating temperature is 25 °C or 54 °C). Color differences were measured using a reflectance spectrophotometer. The ΔE00 values were calculated. | Cement type significantly affected the color stability of lithium disilicate and zirconia restorations. A significant difference (p = 0.047) was observed between LinkForce (2.28 ± 0.48) and Panavia SA (2.15 ± 0.46) cement. A preheating temperature of 54 °C enhanced the color stability of the zirconia and lithium disilicate. |

| Authors | Aim | Tested Thicknesses | Study Design | Results |

|---|---|---|---|---|

| Tabatabaian et al. [45] | The aim of the study was to evaluate the effects of veneering porcelain thickness and background shade on the shade match of zirconia-based restorations. | Veneering porcelain thicknesses of 1.6, 1.8, 2.0, and 2.2 mm were tested. | Zirconia blanks 3Y-TZP (VITA YZ T, VITA Zahnfabrik, Bad Säckingen, Germany) of four different thicknesses (1.6, 1.8, 2.0, and 2.2 mm) were placed on three different backgrounds: A2-shaded composite resin, nickel-chromium alloy (NC), and amalgam (AM). The color of the specimens was measured using a spectrophotometer, and the CIELab values were recorded. The color differences ΔEab between the specimens and the A2 VITA classical shade were calculated. These ΔEab values were compared to the acceptability threshold of ΔEab = 3.7. | ΔEab was influenced by the thickness of the veneering porcelain, the background shade, and their interaction (p < 0.05). The minimum veneering porcelain thickness required was 2 mm for NC and 1.8 mm for AM to achieve a proper shade match. |

| Oh et al. [46] | The aim of the study was to evaluate the effect of abutment shade, ceramic thickness, and coping type on the final shade of zirconia all-ceramic restorations. | Three types of disk-shaped zirconia coping specimens were fabricated and veneered with IPS e.max Press Ceram (shade A2) for 1 mm and 1.5 mm total thicknesses. | Zirconia coping specimens were fabricated from three different materials: Lava (3Y-TZP, 3M ESPE, St. Paul, MN, USA), Cercon (3Y-TZP, (Degudent GmbH, Hanau, Germany)), and Zirkonzahn (3Y-TZP, Zirkonzahn, Gais, Italy). These copings were veneered with IPS e.max Press Ceram (Ivoclar Vivadent, Schaan, Liechtenstein) (A2) to achieve total thicknesses of 1 mm and 1.5 mm. Abutment specimens were made from gold alloy, base metal (nickel-chromium) alloy, and composite resin in four shades (A1, A2, A3, A4). The color difference (ΔEab) was calculated using the CIELab formula. | The abutment shade, ceramic thickness, and coping material significantly influenced the final shade of the zirconia restorations. The highest ∆E value (>2.6) was observed between the gold alloy and A2 resin abutments for the 1 mm-thick zirconia specimens. |

| Tabatabaian et al. [47] | The aim of this study was to find proper ceramic thickness-cement combinations for color matching of high-translucency monolithic zirconia restorations. | Six different thicknesses of 0.7, 0.9, 1.1, 1.4, 1.6, and 1.8 mm were tested. | Five types of cement were used to bond three hundred A2-shade high-translucency zirconia (5Y-PSZ) disk specimens, with thicknesses of 0.7, 0.9, 1.1, 1.4, 1.6, and 1.8 mm, to A3.5 shade composite resin backgrounds. Color parameters were measured before and after cementation and ΔE00 values were calculated to assess the color differences: ∆E1 between before and after cementation, ∆E2 between the A2 VITA classical shade (target) and specimens before cementation, ∆E3 and between the target and specimens after cementation. | Opaque cement and adequate ceramic thicknesses matched the color for high-translucency monolithic zirconia restorations against A3.5-shade backgrounds. |

| Kang et al. [48] | The aim of this in vitro study was to characterize the effect of thickness on the color accuracy of high-translucency monolithic multilayer pre-colored zirconia. | Four thicknesses were tested: 0.5, 1.0, 1.5, and 2.0 mm. | Plate-shaped, A2 shade high-translucency monolithic multilayer pre-colored zirconia specimens (SHT Multilayer 3Y-TZP, AT Multilayer 5Y-PSZ, and 3D Multilayer 4Y-PSZ + 5Y-PSZ) were tested in 0.5, 1.0, 1.5, and 2 mm thicknesses. The color attributes of these specimens against gray or A2 substrates were measured to assess color accuracy, including color differences (ΔE00) compared to the Vita shade guide and chroma. | The thickness influenced the color accuracy of various high-translucency monolithic multilayer pre-colored zirconia types. The optimal thickness for color accuracy was found to be 1.0 mm. |

| Authors | Aim | Substrate Color | Study Design | Results |

|---|---|---|---|---|

| Comba et al. [29] | The aim of this in vitro study was to evaluate the effects of substrate and cement shades on the translucency and color of lithium-disilicate and zirconia ceramics. | A nanofilled resin-based composite marked Filtek Supreme XTE (3M ESPE, St. Paul, MN, USA) in A2 and A4 shades has been used as the base material. | Two light-cured resin types of cement (RelyX Veneer Cement; 3M, USA; Choice 2 Veneer Cement; Bisco Dental, Schaumburg, IL, USA) with a 0.1 mm thickness were tested. Two monolithic ceramics (3Y-TZP zirconia, lithium disilicate glass-ceramic) and different colored composite substrates were used for 12 combinations. L, a, and b color parameters were measured, and the ΔE00 formula was used to calculate the color differences in the study. | Statistically significant effects were found for ceramic material, cement shade, and substrate color (p < 0.05). Opacity was notably higher with the use of white opaque cement. The ceramic type and cement shade significantly impacted the L, a, and b values. Therefore, these factors can influence ceramic restorations’ final translucency and color. |

| Suputtamongkol et al. [49] | The aim of the study was to determine the effect of the background substructure color on the overall color of a zirconia-based all-ceramic crown. | Abutments with metal post and core, abutments with a prefabricated post, and composite core build-up were tested. | Seven premolar and six molar zirconia crowns were cemented onto abutments with metal posts and cores in the first and second groups. Eight molar zirconia crowns were cemented onto abutments in the third group, which included a prefabricated post and composite core build-up. Color measurements of all ceramic crowns were recorded before try-in and before and after cementation. The CIELab (ΔEab) formula was used to calculate the color differences. | No significant differences were found in the L, a, and b values of zirconia crowns cemented onto either metal cast posts and cores or prefabricated posts and composite cores. However, the color of the background substructure can influence the overall color of posterior zirconia restorations, even with clinically recommended core thickness. |

| Sonza et al. [50] | The aim of the study was to evaluate the influence of the substrate and cement on the final color of ceramic crowns. | Metal (M) and resin (R) were the tested substrate abutments. | Crowns were fabricated using two all-ceramic systems (YZ, 3 mol% yttria-stabilized tetragonal zirconia (3Y-TZP); IZ, alumina-based zirconia-reinforced glass-infiltrated ceramic) and one metal-ceramic system (MC; n = 8). Metal (M) and resin (R) were the substrate abutments. For the resin substrate, crowns were evaluated in both seated (R) and cemented (R-C) conditions. CIELab color coordinates were obtained for the experimental groups, and three different color-difference metrics were used: ΔE*ab, ΔE00 (1:1:1), and ΔE00 (2:1:1). | The substrate and cement affected the final color of zirconia-based ceramic crowns, but the color differences corresponded to an acceptable match. |

| Tabatabaian et al. [51] | The aim of this study was to evaluate the effect of three different core materials on the masking ability of zirconia ceramic. | A white teflon material (W, white), nickel-chromium alloy (NCA), non-precious gold alloy (NPGA), and zirconia ceramic (ZRC) were tested. | Ten zirconia disk specimens (Luminesse High Strength/Low Translucency, 98 mm Discs #5113; Talladium, Valencia, CA, USA) were fabricated, each 0.5 mm thick and 10 mm in diameter. They were placed on four different substrates: A white (W) substrate (control) and substrates of nickel-chromium alloy (NCA), non-precious gold alloy (NPGA), and ZRC. ΔE values were calculated to assess color differences. Using a spectrophotometer, the study measured the specimens’ L*, a*, and b* values. The color change (ΔEab) values were calculated to determine the color differences between the test and control groups and then compared with the perceptual threshold (ΔE = 2.6). | Statistical analysis showed significant differences between the groups’ L, a, b, and ΔE values. ZRC could not mask the examined core materials well. |

| Ansarifard et al. [52] | The aim of this study was to examine the impact of substrates, ceramic shades, and brands on the color and masking ability of highly translucent monolithic zirconia (HTMZ). | Non-precious gold alloy (NPG) Nickel–chromium alloy (Ni-Cr) composite resin (shade A2) and zirconia (shade A2) were tested. | One hundred and fifty-six 1 mm-thick highly translucent monolithic zirconia disks in shades A1, A2, and A3 were fabricated from Dental Direkt and Kerox zirconia (3 mol% yttria-stabilized tetragonal zirconia polycrystalline (3Y-TZP) high translucent monolithic zirconia (A1, A2, A3). The disks were placed over four 3 mm-thick substrates (nickel-chromium alloy, non-precious gold alloy, zirconia A2, and resin composite A2), and color measurements were taken with a spectrophotometer. The study analyzed color differences (ΔE) using ΔEab and ΔE00 formulas. | The results showed that substrate type and shade significantly influenced ΔEab (color change values), while ΔE00 (ΔE2000; CIEDE2000 color differences) was additionally affected by the ceramic brand. Most ceramic-substrate groups demonstrated color differences within clinically acceptable and perceptible ranges (clinically perceptible: ΔEab ≥ 1.3 and ΔE00 ≥ 0.8; clinically acceptable: 0.8 < ΔE00 ≤ 1.8 and 1.3 < ΔEab ≤ 2.7). However, the non-precious gold alloy (NPG) substrate exceeded the perceptible range, with ΔE00 values from 1.1 ± 0.11 to 1.8 ± 0.31 and ΔEab values from 1.61 ± 0.15 to 2.16 ± 0.36. A strong correlation (r = 0.974, p < 0.001) was observed between ΔEab and ΔE00, indicating that both metrics are reliable for assessing color differences. Variations in ceramic brands and shades caused notable ΔE changes, but the overall color differences remained clinically acceptable. |

| Ghoveizi et al. [53] | The purpose of this in vitro study was to assess the color match of ultra translucency multilayer zirconia restorations with different designs and backgrounds. | The specimens were seated on five different backgrounds: shade B2 composite resin, shade B2 zirconia, copper-colored metal alloy, silver-colored metal alloy, and the prepared central incisor. | Thirty ultra-translucent multilayer zirconia crowns in VITA classical shade B2 were prepared. The crowns were divided into three groups: veneered zirconia with a trestle design (VZT), veneered zirconia with a dentin core design (VZD), and full-contour zirconia (FCZ). In VZT and VZD groups, zirconia was layered with feldspathic veneering ceramic. The crowns were placed on five backgrounds: Composite resin, zirconia, copper-colored metal, silver-colored metal, and the prepared central incisor. CIELab values of the labial middle sections were measured, and color differences (ΔE*ab) were calculated compared to a shade B2 VITA tab, with a clinically acceptable threshold of ΔE*ab = 3.7. | Mean ΔE*ab values ranged from 1.17 to 8.48, with significant effects from restoration design, background type, and their interaction (p < 0.001). VZT on all backgrounds and VZD on silver-colored metal showed color mismatches, while VZD on other backgrounds and FCZ on all backgrounds achieved acceptable color matches. |

| Authors | Aim | Sinterization Process | Study Design | Result |

|---|---|---|---|---|

| Juntavee et al. [55] | The aim of this study was to investigate the effect of sintering temperature and time on the color characteristics of monochrome (Mo) and multilayer (Mu) 5 mol% yttria-partially stabilized zirconia (5Y-PSZ). | The specimens were sintered at three different temperatures: decreasing (Td: 1450 °C), regular (Tr: 1500 °C), and increasing (TI: 1550 °C), combined with four sintering durations: extremely short (He: 10 min), ultrashort (Hu: 15 min), short (Hs: 30 min), and regular (Hr: 135 min). | A total of 300 specimens (dimensions: 10 mm × 20 mm × 2 mm) were prepared from two 5Y-PSZ ceramics, monochromatic and multilayered, with cervical (C), middle (M), and incisal (I) regions represented. These specimens were sintered at three different temperatures combined with four sintering durations. Each group consisted of 15 specimens. The color properties, including whiteness index (EW), translucency parameter (TP), contrast ratio (CR), opalescence parameter (OP), and color difference (ΔEdiff), were analyzed using the CIELab system. | Significant differences in color parameters were observed based on the zirconia type, sintering temperature, sintering time, and their interactions (p < 0.05). Higher sintering temperatures and longer times resulted in larger grain sizes, reduced tetragonal-to-monoclinic phase transformation, and significantly increased translucency parameter (TP) and opalescence parameter (OP). They decreased contrast ratio (CR) and color difference (ΔEdiff) (p < 0.05). Lower sintering temperatures and shorter sintering times led to clinically unacceptable color outcomes. Higher sintering temperatures and longer sintering times are recommended for optimal optical properties. |

| Ebeid et al. [56] | The aim of this study was to evaluate the effect of different sintering parameters on color reproduction, translucency, and biaxial flexural strength of monolithic zirconia. | The specimens were divided into three groups based on different sintering temperatures (1460 °C, 1530 °C, and 1600 °C). Each group was further divided into three subgroups, which were exposed to sintering holding times of 1, 2, and 4 h. | Translucent zirconia disks (4Y-PSZ) with a diameter of 15 mm, a thickness of 1 mm, and shade A3 were milled and categorized based on different sintering temperatures (1460 °C, 1530 °C, and 1600 °C) into three groups. Each group was further subdivided into three subgroups (n = 10), which were exposed to sintering holding times of 1, 2, and 4 h. The specimens were placed on a neutral gray background, and the CIELab coordinates were measured using a spectrophotometer. ΔE00 values below 3.0 were considered “clinically imperceptible”, ΔE00 values between 3.0 and 5.0 were considered “clinically acceptable”, and ΔE00 values above 5.0 were considered “clinically unacceptable”. | There was no significant difference in the ΔE00 value between the 2 h and 4 h sintering times, while both times showed a significant decrease compared to the 1 h sintering time. All subgroups showed acceptable color results, and the 1600 °C sintering temperature provided clinically indistinguishable color outcomes. |

| Salah et al. [59] | The aim of this in vitro study was to investigate the effect of different rapid sintering protocols on the color and translucency of cubic and tetragonal zirconia ceramics. | Each zirconia type was divided into three groups based on sintering protocols: conventional (control), speed, and super speed. | Sixty disk-shaped zirconia specimens (1 mm thick) were made from cubic (DD CubeX2) (5Y-PSZ) and tetragonal (DD Bio ZX2) zirconia (5Y-PSZ). Each zirconia type was divided into three groups based on sintering protocols. The translucency of each group was evaluated using the translucency parameter and contrast ratio, with color differences calculated relative to the conventional sintering group. The ΔEab threshold values were set at 1.2 for perceptibility and 2.7 for acceptability. | Speed and superspeed sintering protocols significantly reduced the translucency of cubic and tetragonal zirconia (p < 0.001), with superspeed sintering causing more significant color changes than speed sintering (p < 0.001). When speed sintering was performed, the color difference between cubic (ΔEab = 1.44) and tetragonal (ΔEab = 1.61) zirconia was acceptable compared to their conventionally sintered counterparts. However, with super-speed sintering, the ΔEab for cubic and tetragonal zirconia was measured as 17.79 and 5.6, respectively, indicating a perceivable and unacceptable color change. The study concluded that rapid sintering protocols substantially affected the color and translucency of these zirconia types. |

| Yang et al. [60] | The aim of this study was to investigate the changes in the translucency and color of four different multilayered zirconia materials when the sintering temperature were inaccurate. | Each zirconia type was divided into five subgroups based on sintering temperature: L1 (5% lower), L2 (2.5% lower), R (recommended), H2 (2.5% higher), and H1 (5% higher). | Two hundred zirconia specimens (11 × 11 × 1.0 mm) were prepared from four multilayered zirconia types (5Y-PSZ): Upcera TT-GT (UG), Upcera TT-ML (UM), Cercon xt ML (CX), and Lava Esthetic (LE), and were divided into five subgroups based on sintering temperature. After sintering, color coordinates were measured, and translucency parameter (TP) values and color differences (ΔE) between non-recommended and recommended sintering temperatures were calculated. Mean ΔE00 values below 1.25 were assumed “clinically imperceptible”, while mean ΔE00 values above 2.23 were assumed “clinically unacceptable”. | Sintering temperature deviations significantly impacted multilayered zirconia ceramics’ translucency (TP) and color (ΔE00). TP values varied with temperature, except in the cervical and body sections of UG, with higher temperatures increasing TP for CX but decreasing it for LE. ΔE00 values were clinically imperceptible for UM and CX at the most inaccurate temperatures and clinically acceptable for all materials (ΔE00 < 2.23). |

| Giti et al. [61] | The aim of this study was to evaluate the effect of sintering temperature on color stability and translucency in zirconia systems with low, high, and ultra-high translucencies. | Each group was divided into subgroups sintered at 1450 °C or 1550 °C. | Sixty zirconia disks: DD Bio ZW (3Y-TZP), DD Bio ZX2 98 (3Y-TZP), and DD CubeX2 (5Y-PSZ) with low, high, and ultra-high translucencies were prepared, and each group was divided into subgroups sintered at 1450 °C or 1550 °C. Baseline color and translucency parameters were recorded, followed by 30 days of coffee immersion, after which measurements were repeated. Color changes (ΔEab) and translucency changes (ΔTP) were calculated using the CIELAB formula. | Results showed significant differences in ΔE among zirconia translucencies (p < 0.001) but no differences between sintering temperatures (p = 0.712). Low-translucency zirconia had higher ΔE values than high- and ultra-high-translucency groups (p < 0.05), which were not significantly different. Sintering temperature did not impact color or translucency changes after coffee immersion. Higher-translucency zirconia showed better color stability. |

| Hassan Shohdy et al. [62] | The aim of this study was to investigate the influence of speed sintering on the microstructure and optical properties of ultra-translucent multilayered cubic zirconia. | The specimens were divided into two groups based on the conventional (control) and speed sintering techniques. The conventional sintering was performed at 1550 °C for 2 h, while the speed sintering was performed at 1560 °C for 0.5 h. | Ultra-translucent cubic zirconia 5Y-PSZ (Katana UTML; Kuraray Noritake Dental Inc., Aichi, Japan) was sectioned into 80 specimens, with 20 specimens from each blank layer. The specimens were categorized into two groups: speed sintering and conventional sintering. Measurements of translucency, opalescence, chromaticity, and color differences were obtained using a spectrophotometer. The study recorded L*, a*, and b* color values, and the color software application (Cary Win UV; Agilent Technologies, Santa Clara, CA, USA) was used for this process. TP, OP, C*ab, and ΔEab values were calculated. | Results indicated that speed sintering significantly reduced translucency and opalescence, except the dentin layer’s opalescence. Chromaticity decreased in less chromatic layers and increased in more chromatic layers with speed sintering. The mean color change ranged from 0.65 to 1.25 across different layers, and crystal size decreased with speed sintering. However, no clinically noticeable color change was observed compared to conventional sintering. |

| Engler et al. [63] | The aim of this in vitro study was to evaluate the color and translucency of zirconia subjected to different sintering temperatures and aging. | All specimens were divided according to the sintering temperature: 1400 °C, 1450 °C, and 1500 °C. | One-hundred-and-eighty disk-shaped (1.5 mm-thick) specimens were produced from translucent zirconia blocks: 5Y-TZP (DD cubeX2 white, DD cubeX2 A2 shade), 3Y-TZP (DD Bio ZX2 white), and 3Y-TZP (Lava Plus white). All disks were divided according to the sintering temperature: 1400 °C, 1450 °C, and 1500 °C. The specimens were subjected to an aging protocol in an autoclave for 5 h and 20 h. ΔE00, ∆L′, ∆C′, ∆H′, and TP were calculated using CIEDE2000, and CR was obtained using CIEXYZ. | The experimental sintering temperatures (1400 °C and 1500 °C) promoted color changes in almost all the materials evaluated. The most significant ∆E00 was found at 1400 °C, with the most remarkable difference in the Lava Plus A2 group (5.25), followed by the DD Bio ZX2 White group (4.80). Opacity and saturation values were increased at 1400 °C. |

| Aly et al. [64] | The aim of this study was to evaluate the effect of different sintering techniques on the color parameters of zirconia ceramic restorations. | Zirconia specimens were divided into three groups: microwave sintering (MS), speed sintering (SS), and conventional sintering (CS). MS involved heating to 1500 °C for 2 h, SS to 1550 °C for 30 min, and CS to 1500 °C for 2 h. | Thirty Zenostar Translucent zirconia (3Y-TZP), shade T2 specimens were prepared (10 mm × 2 mm, thickness). Three groups were created. The color difference (ΔEab) was calculated by using a spectrophotometer. | The sintering process affected the optical and color parameters of zirconia specimens. When comparing each group specimen to known shade tabs (A1, A2, B1, B2, C1), the lowest mean ∆Eab value was recorded for MS (2.50 ± 0.31) when compared with shade tab A1; however, there was no significant difference when compared with group CS (2.75 ± 0.50). The highest ∆Eab (3.72 ± 0.75) was found between SS and MS. However, this difference is considered within the clinically acceptable range (∆Eab 3–5). |

| Authors | Aim | Aging Process | Study Design | Result |

|---|---|---|---|---|

| Ângela Mazıero Volpato et al. [68] | The aim of this study was to evaluate the influence of different aging times on the color stability of zirconia that is either veneered or not by ceramic. | All specimens underwent the same accelerated aging protocol. They were aged in an autoclave at 134 °C for 1 h (T2), 2 h (T3), and 4 h (T4), with all procedures performed consecutively on the same day. | Fifteen zirconia disks (3Y-TZP) were fabricated (12.0 mm diameter and 1.0 mm thick) and divided into three groups (n = 5). Group 1 did not receive a veneering ceramic layer; group 2 veneered with a 1.0 mm ceramic layer, and group 3 veneered with a 1.5 mm ceramic layer. Color differences in specimens were calculated after 1 h, 2 h, and 4 h of aging. Color differences (ΔE00), lightness (ΔL0), chroma (ΔC0), and hue (ΔH0) were calculated using the CIEDE2000 color difference formula among standard averages, aging times, and tested thicknesses. | In the G1 group, statistically significant differences were observed in lightness (ΔL0), chroma (ΔC0), and hue (ΔH0) (p = 0.0001), with a particularly notable increase in chroma difference (ΔC0). Distinct color changes (ΔE00) = 0.95 were recorded after 4 h of aging. In conclusion, after prolonged aging, discrete color changes can occur in zirconia, mainly when it is in contact with the oral environment, as in abutments and monolithic crowns. |

| Kim et al. [70] | The aim of this in vitro study was to evaluate the effect of hydrothermal aging on the optical properties, phase transformation, and surface topography of pre-colored monolithic zirconia ceramics. | The specimens were artificially aged in an autoclave at 134 °C under 0.2 MPa for 0, 1, 3, 5, or 10 h (n = 10). | Pre-colored monolithic zirconia specimens (3Y-TZP, 4Y-PSZ) (17 × 17 × 1.5 mm, n = 50) and lithium disilicate glass-ceramic specimens (16 × 16 × 1.5 mm, n = 50) were artificially aged in an autoclave at 134 °C under 0.2 MPa for 0, 1, 3, 5, or 10 h. CIELab color parameters were obtained from spectral measurements. The translucency parameter (TP) and CIEDE2000 color differences (ΔE00) were calculated. | Significant interactions were found between aging time and ceramic material on L, a, b values and TP (p < 0.001), with the most critical effect on b*. TP values increased for Katana (p < 0.014) and in e.max as a function of aging time (p < 0.001). TP increased after aging for zirconia (p < 0.014) except at 10 h (p = 0.389) and for lithium disilicate (p < 0.001). TP increased after aging for zirconia (p < 0.014) except at 10 h (p = 0.389) and for lithium disilicate (p < 0.001). Hydrothermal aging affected the optical properties and microstructures of pre-colored monolithic zirconia ceramics, and translucency increased slightly with aging time. In ΔE00 analysis, Katana exhibited clinically unacceptable color changes compared to baseline (2.03–2.52 ΔE00), while e.max demonstrated stable color matching (0.07–0.23 ΔE00). |

| Miura et al. [71] | The aim of this study was to investigate the effects of low-temperature degradation (LTD) on the L*, a*, and b* values of highly translucent zirconia crowns. | In an autoclave, LTD treatment was applied for 5 h at 134 °C and 0.2 MPa. | Four types of zirconia disks with varying yttria contents IPS e.max ZirCAD LT (3Y-TZP), IPS e.max ZirCAD MT (4Y-PSZ), IPS e.max ZirCAD MT Multi (4Y-PSZ, 5Y-PSZ), IPS e.max ZirCAD Prime (3Y-TZP, 5Y-PSZ) and two shades (A2 and BL) were used to manufacture crowns. The color difference (ΔE00) before and after LTD was calculated from each area’s L*, a*, and b* values using the CIEDE2000 formula. Color measurements were taken before and after LTD treatment. The color difference (ΔE00) was calculated. | L*, a*, b*, and ΔE00 values of four zirconia types were influenced by LTD treatment. Highly translucent zirconia crowns with varying yttria contents showed more significant changes in a* and b* values than in L* after LTD, regardless of shade. Multi2 crowns with 3 and 5 mol% yttria exhibited noticeable color changes due to LTD treatment. |

| Arindham et al. [72] | The aim of this study was to evaluate the effects of immersion in alcoholic beverages on the surface roughness and color stability of two types of milled zirconia. | The specimens were sintered at 1500 °C for eight hours and then immersed in artificial saliva, red wine, and whiskey three times daily for 30 days. | Sixty cuboid-shaped specimens from two types of milled 3Y-TZP zirconia. (Z1: NexxZr T, Sagemax®, Ivoclar Vivadent, Amherst, NY, USA, and Z2: and Cercon®ht, Dentsply Sirona, Charlotte, NC, USA) were sintered at 1500 °C for eight hours and immersed in artificial saliva, red wine, and whiskey three times daily for 30 days. Surface roughness and color changes were measured using AFM and a spectrophotometer. Color stability (ΔE) values were measured using the CIE L*a* b system. | Results showed that whiskey caused the highest surface roughness increase in Z1 (137.09 nm) and Z2 (86.15 nm), while red wine led to the most discoloration in both Z1 (2.41) and Z2 (1.94). Whiskey, red wine, and artificial saliva increased surface roughness with no significant differences in color changes. |

| Abounassif et al. [73] | The aim of this study was to explore the impact of zirconia types, coloring methods, and surface finishing on the color stability of monolithic multilayered polychromatic zirconia after artificial aging, including thermocycling and simulated toothbrushing. | The specimens were subjected to 5000 cycles at 5 °C and 55 °C for 15 s each for thermal cycling. In the tooth brushing simulation, 5000 cycles were performed using a soft toothbrush and a cleaning slurry prepared from a specific mixture. | Eighty square-shaped zirconia specimens were categorized into two types (M3Y-TZP and M6Y-PSZ), with further divisions based on coloring methods (pre-colored and extrinsically colored) and surface finishing techniques (mechanical polishing or glazing). Color stability was evaluated using the CIEDE2000 formula, with thermocycling and toothbrushing simulating artificial aging. Spectrophotometer measurements determined post-aging color changes (ΔE00). A value of 0.8 was set for the 50:50% PT, and 1.8 was set for the 50:50% AT to compare changes in ΔE00. | The study found significant differences in color stability based on zirconia type, coloring method, and surface finishing. M6Y groups showed more substantial color changes (6.61 ± 1.63) compared to M3Y groups (3.40 ± 2.24), with extrinsically colored specimens exhibiting higher ΔE00 when mechanically polished (p = 0.004). Surface finishing did not significantly affect ΔE00 in pre-colored specimens (p = 1.000). The extrinsic coloring paired with glazing is recommended for maintaining color stability in multilayered zirconia restorations, while for pre-colored zirconia, both glazing and mechanical polishing are effective. |

| Park et al. [74] | The purpose of this in vitro study was to analyze the changes in color, translucency, and hardness of a single layer of multilayered zirconia after an LTD treatment. | Lava Esthetic Zirconia containing 5 mol% yttria (5Y-PSZ) was tested. | Ninety 10 × 10 × 1.0 mm multilayered zirconia specimens (3M Lava Esthetic) were prepared and divided into six groups (n = 15) based on the LTD (no treatment, LTD), and the inherent layer type (incisal, transition, and body) (CIELab) parameters were calculated by spectral reflectance. Color differences (ΔEab) and TP values were measured. | Optical properties were not affected by LTD treatment. Increasing red and yellow and decreasing brightness from the incisal layer to the body layer were observed. |

| Authors | Aim | Type of Zirconia | Study Design | Result |

|---|---|---|---|---|

| Vafaei et al. [85] | The aim of this study was to compare the optical properties of Zolid FX, Katana UTML and lithium disilicate laminate veneers. | 5Y-TZP (Katana UTML, Kuraray Noritake Dental Inc., Miyoshi, Japan and Zolid FX, (Amann Girrbach AG, Koblach, Austria) was tested. | The maxillary left lateral incisor of a phantom received a laminate veneer preparation. Ten dies were fabricated from a composite resin with A1, A2, and A3 shades. Laminate veneers were fabricated using an A1 shade of Katana UTML, Zolid FX, and IPS e.max CAD ceramics and placed on composite abutments using bleach and white colors of trial insertion paste (TIP). The optical properties of the specimens were measured at the incisal, middle, and cervical thirds. The mean values of L*, a*, and b* color parameters (ΔEab) were calculated based on the laminate material, TIP color, and composite abutment shade in the cervical, middle, and incisal thirds. | The effect of laminate material on the color parameters was significant in all areas (p < 0.001) except for the L parameter in the middle and cervical thirds. The composite abutment shade, TIP color, and laminate material should be carefully selected for optimal laminate veneers’ esthetics. |

| Kang et al. [86] | The aim of this in vitro study was to determine the color accuracy of different types of monolithic multilayer pre-colored zirconia ceramics of varying thicknesses. | 3Y-TZP + 5Y-PSZ, 5Y-PSZ, 4Y-PSZ + 5Y-PSZ, and 4Y-PSZ + 5Y-PSZ ceramics were tested. | Eighty specimens with A2 shade, two different thicknesses (1.0 mm and 1.5 mm), and four different zirconia brands (UPCERA EXPLORE [UPEX], KATANA Zirconia STML [STML], Enamel ZR Multi-5 [EZM5], and Aidite 3D Pro Zir [A3DM]) were fabricated and measured using a spectrophotometer against gray, transparent, and A2 backgrounds. The color difference (ΔE*ab), translucency parameter (TP), and chroma (C) values for each group were calculated. | The (ΔE*ab) values for UPEX and STML zirconia brands exceeded the clinically acceptable threshold values for gray and transparent backing substrates (ΔE > 3.7). In contrast, A3DM zirconia had clinically acceptable (ΔE*ab) values for all backing substrates. Color accuracy was mainly affected by the monolithic multilayer pre-colored zirconia ceramic type, and the high transparency of ceramics caused color differences. |

| Kang et al. [87] | The aim of this study was to investigate variations in yttria levels and thicknesses that affected multilayer monolithic zirconia’s optical properties and fracture loads. | Two types of multilayer monolithic zirconia in the Vita A1 shade were used, each composed of different yttria levels: one was uniformly composed of 3Y with 4.5 to 5.5 wt.% of Y2O3 (Superfectzir; Aidite Technology, Qinhuangdao, China; denoted as SZ), and the other was a combination of 4Y and 5Y with 4.0 to 10.0 wt.% of Y2O3 (Aizir; Aidite Technology; denoted as AZ). | Specimens in the Vita A1 shade were tested using 3Y-TZP (SZ) and a combination of 4Y- and 5Y-PSZ (AZ). Optical properties, including color difference (ΔEWS) and translucency parameter (TP00), were evaluated with a digital colorimeter. For testing optical properties, 15 multilayer monolithic zirconia plate specimens (10 mm × 10 mm) were prepared in four thicknesses: 0.5, 1.0, 1.5, and 2.0 mm. To confirm color accuracy, ∆EWS was calculated based on the color attributes measured on a white substrate. | For ΔEWS values, SZ ranged from 3.6 to 4.0, while AZ exhibited a ΔEWS of 3.9 at 0.5 mm and less than 2.6 at greater thicknesses. TP00 values decreased as thickness increased, with AZ generally demonstrating higher translucency than SZ. Multilayer monolithic zirconia with combined yttria levels of 4Y + 5Y (AZ) demonstrated high translucency and accurate color matching. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Binici Aygün, E.; Kaynak Öztürk, E.; Tülü, A.B.; Turhan Bal, B.; Karakoca Nemli, S.; Bankoğlu Güngör, M. Factors Affecting the Color Change of Monolithic Zirconia Ceramics: A Narrative Review. J. Funct. Biomater. 2025, 16, 58. https://doi.org/10.3390/jfb16020058

Binici Aygün E, Kaynak Öztürk E, Tülü AB, Turhan Bal B, Karakoca Nemli S, Bankoğlu Güngör M. Factors Affecting the Color Change of Monolithic Zirconia Ceramics: A Narrative Review. Journal of Functional Biomaterials. 2025; 16(2):58. https://doi.org/10.3390/jfb16020058

Chicago/Turabian StyleBinici Aygün, Ebru, Esra Kaynak Öztürk, Ayşe Bilge Tülü, Bilge Turhan Bal, Seçil Karakoca Nemli, and Merve Bankoğlu Güngör. 2025. "Factors Affecting the Color Change of Monolithic Zirconia Ceramics: A Narrative Review" Journal of Functional Biomaterials 16, no. 2: 58. https://doi.org/10.3390/jfb16020058

APA StyleBinici Aygün, E., Kaynak Öztürk, E., Tülü, A. B., Turhan Bal, B., Karakoca Nemli, S., & Bankoğlu Güngör, M. (2025). Factors Affecting the Color Change of Monolithic Zirconia Ceramics: A Narrative Review. Journal of Functional Biomaterials, 16(2), 58. https://doi.org/10.3390/jfb16020058