Mechanical Consequences of Dynamically Loaded NiTi Wires under Typical Actuator Conditions in Rehabilitation and Neuroscience

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization Methodology

3. Results

3.1. Differential Scanning Calorimetry (DSC)

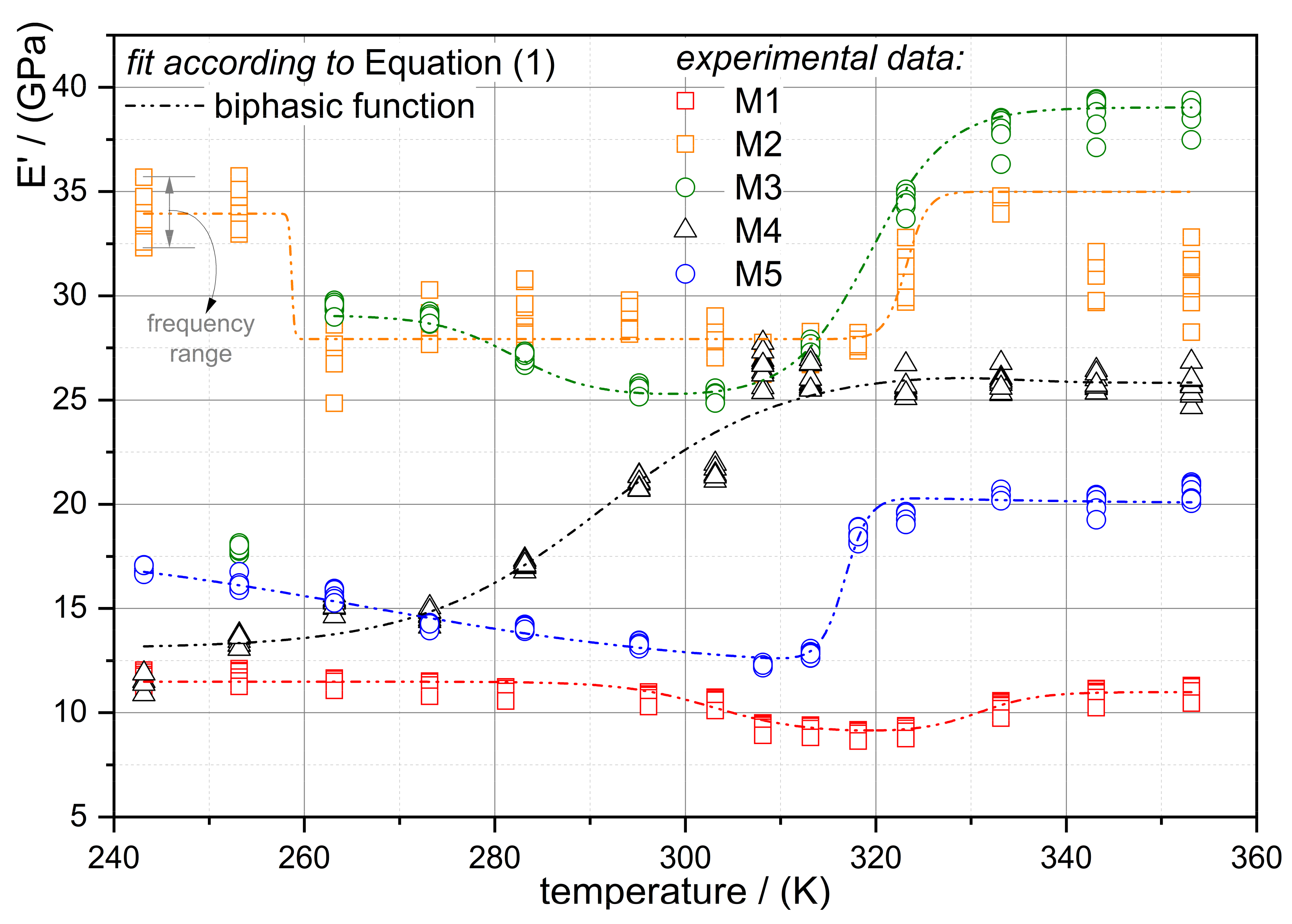

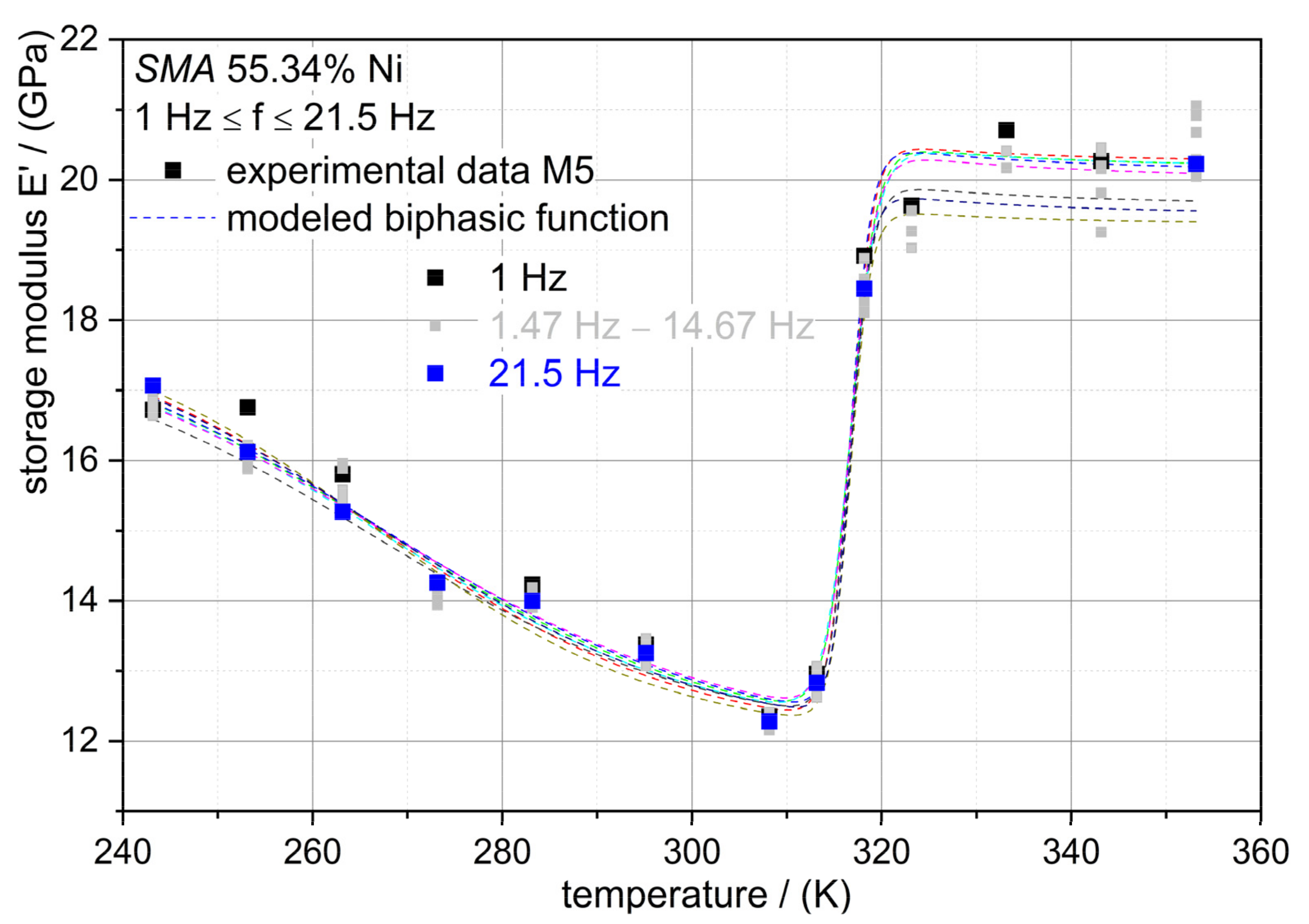

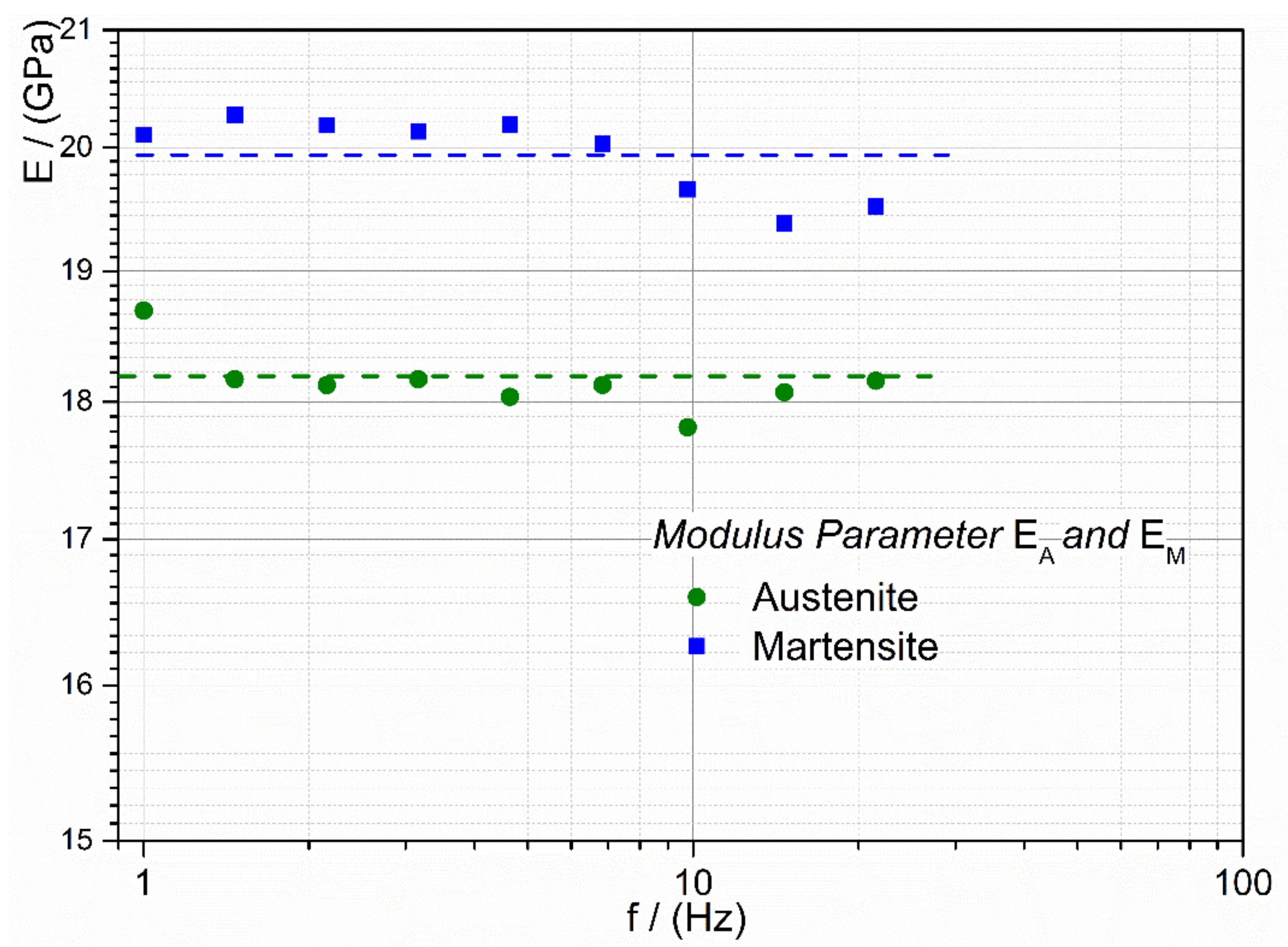

3.2. Dynamic Thermomechanical Analysis (DTMA)

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pittacio, S.; Viscuso, S. Shape Memory Actuators for Medical Rehabilitation and Neuroscience. In Smart Actuation and Sensing Systems-Recent Advances and Future Challenges; IntechOpen: London, UK, 2012; pp. 83–120. [Google Scholar]

- Hesse, S. Treadmill training with partial body weight support after stroke: A review. Neuro Rehabil. 2008, 23, 55–65. [Google Scholar] [CrossRef]

- Krebs, H.; Rossi, S.; Kim, S.; Artemiadis, P.; Williams, D.; Castelli, E.; Cappa, P. Pediatric anklebot. IEEE Int. Conf. Rehabil. Robot 2011, 1–5. [Google Scholar] [CrossRef]

- Boonstra, T.; Clairbois, H.; Daffertshofer, A.; Verbunt, J.; van Dijk, B.; Beek, P. MEG-compatible force sensor. J. Neurosci. Methods 2005, 144, 193–196. [Google Scholar] [CrossRef]

- Onishi, H.; Oyama, M.; Soma, T.; Kubo, M.; Kirimoto, H.; Murakami, H.; Kameyama, S. Neuromagnetic activation of primary and secondary somatosensory cortex following tactile-on and tactile-off stimulation. Clin. Neurophysiol. 2010, 121, 588–593. [Google Scholar] [CrossRef] [PubMed]

- Hollnagel, C.; Brügger, M.; Vallery, H.; Wolf, P.; Dietz, V.; Kollias, S.; Riener, R. Brain activity during stepping: A novel MRI-compatible device. J. Neurosci. Methods 2011, 201, 124–130. [Google Scholar] [CrossRef] [PubMed]

- Schetky, L.M. Shape Memory Alloys. Sci. Am. 1979, 241, 74–82. [Google Scholar] [CrossRef]

- Katsiropoulos, C.V.; Pappas, P.; Koutroumanis, N.; Kokkinos, A.; Galiotis, C. Improving the damping behavior of fiber-reinforced polymer composites with embedded superelastic shape memory alloys (SMA). Smart Mater. Struct. 2020, 29, 25006. [Google Scholar] [CrossRef]

- Nascimento, M.; Inácio, P.; Paixão, T.; Camacho, E.; Novais, S.; Santos, T.G.; Fernandes, F.M.B.; Pinto, J.L. Embedded Fiber Sensors to Monitor Temperature and Strain of Polymeric Parts Fabricated by Additive Manufacturing and Reinforced with NiTi Wires. Sensors 2020, 20, 1122. [Google Scholar] [CrossRef]

- López-Walle, B.; López-Cuellar, E.; Reyes-Melo, E.; Lomas-González, O.; De Castro, W.B. A Smart Polymer Composite Based on a NiTi Ribbon and a Magnetic Hybrid Material for Actuators with Multiphysic Transduction. Actuators 2015, 4, 301–313. [Google Scholar] [CrossRef]

- Zheng, Y.; Cui, L.; Schrooten, J. Temperature memory effect of a nickel–titanium shape memory alloy. Appl. Phys. Lett. 2004, 84, 31–33. [Google Scholar] [CrossRef]

- Bhattacharya, K. Microstructure of Martensite, Why It Forms and How It Gives Rise to the Shape-Memory Effect; Oxford University Press: Oxford, UK, 2003. [Google Scholar]

- Aalito, I.; Mohanchandra, K.P.; Hezcko, O.; Lahelin, M.; Ge, Y.; Carman, G.P.; Söderberg, O.; Löfgren, B.; Seppälä, J.; Hannula, S.-P. Temperature dependence of mechanical damping in Ni-Mn-Ga austenite and non-modulated martensite. Scr. Mater. 2008, 59, 550–553. [Google Scholar]

- Otsuka, K.; Saxena, A.; Deng, J.; Ren, X. Mechanism of shape memory effect in martensitic alloys: An assessment. Philos. Mag. 2011, 91, 4514–4535. [Google Scholar] [CrossRef]

- Oberaigner, E.R.; Fischlschweiger, M. A statistical mechanics approach describing martensitic phase transformation. Mech. Mater. 2011, 43, 467–475. [Google Scholar] [CrossRef]

- Yastrebov, V.A.; Fischlschweiger, M.; Cailletaud, G.; Antretter, T. The role of phase interface energy in martensitic transformations: A lattice Monte-Carlo simulation. Mech. Res. Commun. 2014, 56, 37–41. [Google Scholar] [CrossRef][Green Version]

- Mahtabi, M.; Shamsaei, N.; Mitchell, M. Fatigue of Nitinol: The State-of-the-Art and Ongoing Challenges. J. Mech. Behav. Biomed. Mater. 2015, 50, 228–254. [Google Scholar] [CrossRef]

- Basu, B.; Donzel, L.; Van Humbeeck, J.; Vleugels, J.; Schaller, R.; Van Der Biest, O. Thermal expansion and damping characteristics of Y-TZP. Scr. Mater. 1999, 40, 759–765. [Google Scholar] [CrossRef]

- Van Humbeeck, J. Damping capacity of thermoelastic martensite in shape memory alloys. J. Alloys Compd. 2003, 355, 58–64. [Google Scholar] [CrossRef]

- Shaw, G.A.; Stone, D.S.; Johnson, A.D.; Ellis, A.B.; Crone, W.C. Shape memory effect in nanoindentation of nickel–titanium thin films. Appl. Phys. Lett. 2003, 83, 257–259. [Google Scholar] [CrossRef]

- Bhattacharya, K.; Contia, S.; Zanzotto, G.; Zimmer, J. Crystal symmetry and reversibility of martensitic transformation. Nature 2004, 428, 55–59. [Google Scholar] [CrossRef]

- Waitz, T.; Antretter, T.; Fischer, F.D.; Simha, N.K.; Karnthaler, H.P. Size effects on the martensitic phase transformation of NiTi nanograins. J. Mech. Phys. Solids 2007, 55, 419–444. [Google Scholar] [CrossRef]

- Fischlschweiger, M.; Oberaigner, E.A. Kinetics and rates of martensitic phase transformation based on statistical physics. Comput. Mater. Sci. 2012, 52, 189–192. [Google Scholar] [CrossRef]

- Wei, Z.G.; Sandstrom, R.; Miyazaki, S. Shape-memory materials and hybrid composites for smart systems: Part I Shape-memory materials. J. Mater. Sci. 1998, 33, 3743–3762. [Google Scholar] [CrossRef]

- Levitas, V.I.; Preston, D.L. Three-dimensional Landau theory for multivariant stress-induced martensitic phase transformations. I. Austenite ↔ martensite. Phys. Rev. B 2002, 66, 134206. [Google Scholar] [CrossRef]

- Neuking, K.; Abu-Zarifa, A.; Youcheu-Kemtchou, S.; Eggeler, G. Polymer/NiTi-composites: Fundamental Aspects, Processing and Properties. Adv. Eng. Mater. 2005, 7, 1014–1023. [Google Scholar] [CrossRef]

- Idesman, A.V.; Cho, J.-Y.; Levitas, V.I. Finite element modeling of dynamics of martensitic phase transitions. Appl. Phys. Lett. 2008, 93, 043102. [Google Scholar] [CrossRef]

- Hartl, D.J.; Lagoudas, D.C. Thermomechanical Characterization of Shape Memory Alloy Materials; Springer: Berlin, Germany, 2008. [Google Scholar]

- Duerig, T.W. Some unsolved aspects in Nitinol. Mater. Sci. Eng. A 2006, 438, 69–74. [Google Scholar] [CrossRef]

- Roy, D.; Buravalla, V.; Mangalgiri, P.D.; Allegavi, S.; Ramamurty, U. Mechanical characterization of NiTi SMA wires using a dynamic mechanical analyzer. Mater. Sci. Eng. A 2008, 494, 429–435. [Google Scholar] [CrossRef]

- Wei, Z.G.; Sandstrom, R.; Miyazaki, S. Shape memory materials and hybrid composites for smart systems: Part II Shape-memory hybrid composites. J. Mater. Sci. 1998, 33, 3763–3783. [Google Scholar] [CrossRef]

- Piedboeuf, M.C.; Gauvin, R.; Thomas, M. Damping behaviour of shape memory alloys: Strain amplitude, frequency and temperature effects. J. Sound Vib. 1998, 214, 885–901. [Google Scholar] [CrossRef]

- Young, S.; Jin, D.-H.; Chung, D.-T.; Kim, J.-I.; Kim, J.-I.; Nam, T.-H. Dynamic impact behavior of Ni-rich and Ti-rich shape memory alloys. Mater. Res. Bull. 2013, 48, 5121–5124. [Google Scholar] [CrossRef]

- Sugimoto, K.; Nakaniwa, M. Change in Young’s modulus associated with martensitic transformation in shape memory alloys. Mater. Sci. Forum 2000, 327, 363–366. [Google Scholar] [CrossRef]

- Wang, J.; Sehitoglu, H. Martensite Modulus Dilemma in Monoclinic NiTi-Theory and Experiments. Int. J. Plast. 2014, 61, 17–31. [Google Scholar] [CrossRef]

- Iijima, M.; Muguruma, T.; Brantley, W.A.; Mizoguchi, I. Comparisons of nanoindentation, 3-point bending, and tension tests for orthodontic wires. Am. J. Orthod. Dentofac. Orthop. 2011, 140, 65–71. [Google Scholar] [CrossRef] [PubMed]

- Shabalovskaya, S.; Anderegg, J.; Van Humbeeck, J. Critical overview of Nitinol surfaces and their modifications for medical applications. Acta Biomater. 2008, 4, 447–467. [Google Scholar] [CrossRef] [PubMed]

- Sittner, P.; Landa, M.; Lukas, P.; Novak, V. R-Phase transformation phenomena in thermomechanically loaded NiTi polycrystals. Mech. Mater. 2006, 38, 475–492. [Google Scholar] [CrossRef]

- Sadjadpour, A.; Rittel, D.; Ravichandran, G.; Bhattacharya, K. A model coupling plasticity and phase transformation with application to dynamic shear deformation of iron. Mech. Mater. 2015, 80, 255–263. [Google Scholar] [CrossRef]

- Daly, S.; Ravichandran, G.; Bhattacharya, K. Stress-induced martensitic phase transformation in thin sheets of Nitinol. Acta Mater. 2007, 55, 3593–3600. [Google Scholar] [CrossRef]

- Van Humbeeck, J. Shape memory alloys: A material and a technology. Adv. Eng. Mater. 2001, 3, 837–850. [Google Scholar] [CrossRef]

- Shaw, J.A.; Kyriakides, S. Thermomechanical aspects of NiTi. J. Mech. Phys. Solids 1995, 43, 1243–1281. [Google Scholar] [CrossRef]

- Çakmak, U.D.; Major, Z. Experimental Thermomechanical Analysis of Elastomers under Uni-and Biaxial Tensile Stress State. Exp. Mech. 2014, 54, 653–663. [Google Scholar] [CrossRef]

- Nurveren, K.; Akdoğan, A.; Huang, W.M. Evolution of transformation characteristics with heating/cooling rate in NiTi shape memory alloys. J. Mater. Process. Technol. 2008, 196, 129–134. [Google Scholar] [CrossRef]

- Fischlschweiger, M.; Cailletaud, G.; Antretter, T. A mean-field model for transformation induced plasticity including backstress effects for non-proportional loadings. Int. J. Plast. 2012, 37, 53–71. [Google Scholar] [CrossRef]

- Miyazaki, S.; Imai, T.; Igo, Y.; Otsuka, K. Effect of cyclic deformation on the pseudoelasticity characteristics of Ti-Ni alloys. Metall. Trans. A 1986, 17, 115–120. [Google Scholar] [CrossRef]

- Schmoller, K.M.; Bausch, A.R. Similar nonlinear mechanical responses in hard and soft materials. Nat. Mater. 2013, 12, 278–281. [Google Scholar] [CrossRef] [PubMed]

- De Silva, C.W. Vibration: Fundamentals and Practice; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

| Alloy | Ni | Ti | Diameter | Surface Finish | Young’s Modulus E at 22 °C |

|---|---|---|---|---|---|

| % | % | µm | GPa | ||

| M1 | 55.60 | 44.40 | 1000 | Oxide | 13 |

| M2 | 55.34 | 44.66 | 320 | 30 | |

| M3 | 55.77 | 44.23 | 323 | 33 | |

| M4 | 54.80 | 45.20 | 305 | 24 | |

| M5 | 55.34 | 44.66 | 760 | Oxide free | 15 |

| Alloy | T-Rate (K/min) Heating/Cooling | AS (K) | AF (K) | RS (K) | RF (K) | MS (K) | MF (K) |

|---|---|---|---|---|---|---|---|

| M1 | 10 | 327.86 | 339.24 | 329.84 | 309.89 | 272.86 | 215.08 |

| M2 | 10 | 324.30 | 341.10 | 327.73 | 301.16 | 298.53 | 245.48 |

| M3 | 10 | 290.99 | 326.26 | 323.91 | 283.45 | - | - |

| M4 | 10 | 355.61 | 362.82 | 336.65 | 332.19 | 319.28 | 309.92 |

| M5–10 | 10 | 317.19 | 328.46 | 313.30 | 307.58 | 266.61 | 258.49 |

| M5–1 | 1.0 | 316.24 | 323.15 | 313.71 | 309.84 | 267.82 | 264.33 |

| M5–0.1 | 0.1 | 316.12 | 323.05 | 314.43 | 309.54 | 268.89 | 265.93 |

| Alloy | EPT (MPa) | EA (MPa) | EM (MPa) | T01 (K) | T02 (K) | h1 | h2 |

|---|---|---|---|---|---|---|---|

| M1 | 9025 | 11492 | 10994 | 302.93 | 330.83 | 0.21 | 0.32 |

| M2 | 27922 | 33941 | 34996 | 258.66 | 323.22 | 7.01 | 0.90 |

| M3 | 25152 | 29070 | 39038 | 282.05 | 319.44 | 0.24 | 0.25 |

| M4 | 12500 | 13098 | 25850 | 333.82 | 291.28 | 0.24 | 0.11 |

| M5 | 12020 | 17810 | 19657 | 266.55 | 315.75 | 0.06 | 0.87 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Çakmak, U.D.; Major, Z.; Fischlschweiger, M. Mechanical Consequences of Dynamically Loaded NiTi Wires under Typical Actuator Conditions in Rehabilitation and Neuroscience. J. Funct. Biomater. 2021, 12, 4. https://doi.org/10.3390/jfb12010004

Çakmak UD, Major Z, Fischlschweiger M. Mechanical Consequences of Dynamically Loaded NiTi Wires under Typical Actuator Conditions in Rehabilitation and Neuroscience. Journal of Functional Biomaterials. 2021; 12(1):4. https://doi.org/10.3390/jfb12010004

Chicago/Turabian StyleÇakmak, Umut D., Zoltán Major, and Michael Fischlschweiger. 2021. "Mechanical Consequences of Dynamically Loaded NiTi Wires under Typical Actuator Conditions in Rehabilitation and Neuroscience" Journal of Functional Biomaterials 12, no. 1: 4. https://doi.org/10.3390/jfb12010004

APA StyleÇakmak, U. D., Major, Z., & Fischlschweiger, M. (2021). Mechanical Consequences of Dynamically Loaded NiTi Wires under Typical Actuator Conditions in Rehabilitation and Neuroscience. Journal of Functional Biomaterials, 12(1), 4. https://doi.org/10.3390/jfb12010004