Data Management in Smart Manufacturing Supply Chains: A Systematic Review of Practices and Applications (2020–2025)

Abstract

1. Introduction

- •

- Procurement records purchase orders, supplier certifications, and contract performance metrics.

- •

- Production lines generate high-frequency IoT sensor feeds, equipment health logs, and machine-vision images.

- •

- •

- Examine how current research links data management practices with smart manufacturing supply chain processes, identifying the depth and nature of these interconnections.

- Assess the extent to which existing studies integrate technical, organizational, and governance dimensions when addressing data management in supply chain contexts.

- Identify research gaps and unaddressed challenges that hinder the development of a coherent and unified approach to data-driven decision-making across the smart manufacturing supply chain.

- •

- RQ1: How is data collected, integrated, and utilized across different functions within smart manufacturing supply chains between 2020 and 2025?

- •

- RQ2: What technologies, tools, and frameworks support data management and integration in these contexts?

- •

- RQ3: What technical, organizational, and strategic challenges limit effective cross-functional data use?

- •

- RQ4: What future research directions could help improve interoperability, governance, and decision-making across the full value chain?

2. Background and Foundations

2.1. Smart Manufacturing as a Data-Driven Paradigm?

2.2. The Industrial Shift Toward Data-Centric Operations

2.3. What Is Data Management in Supply Chain?

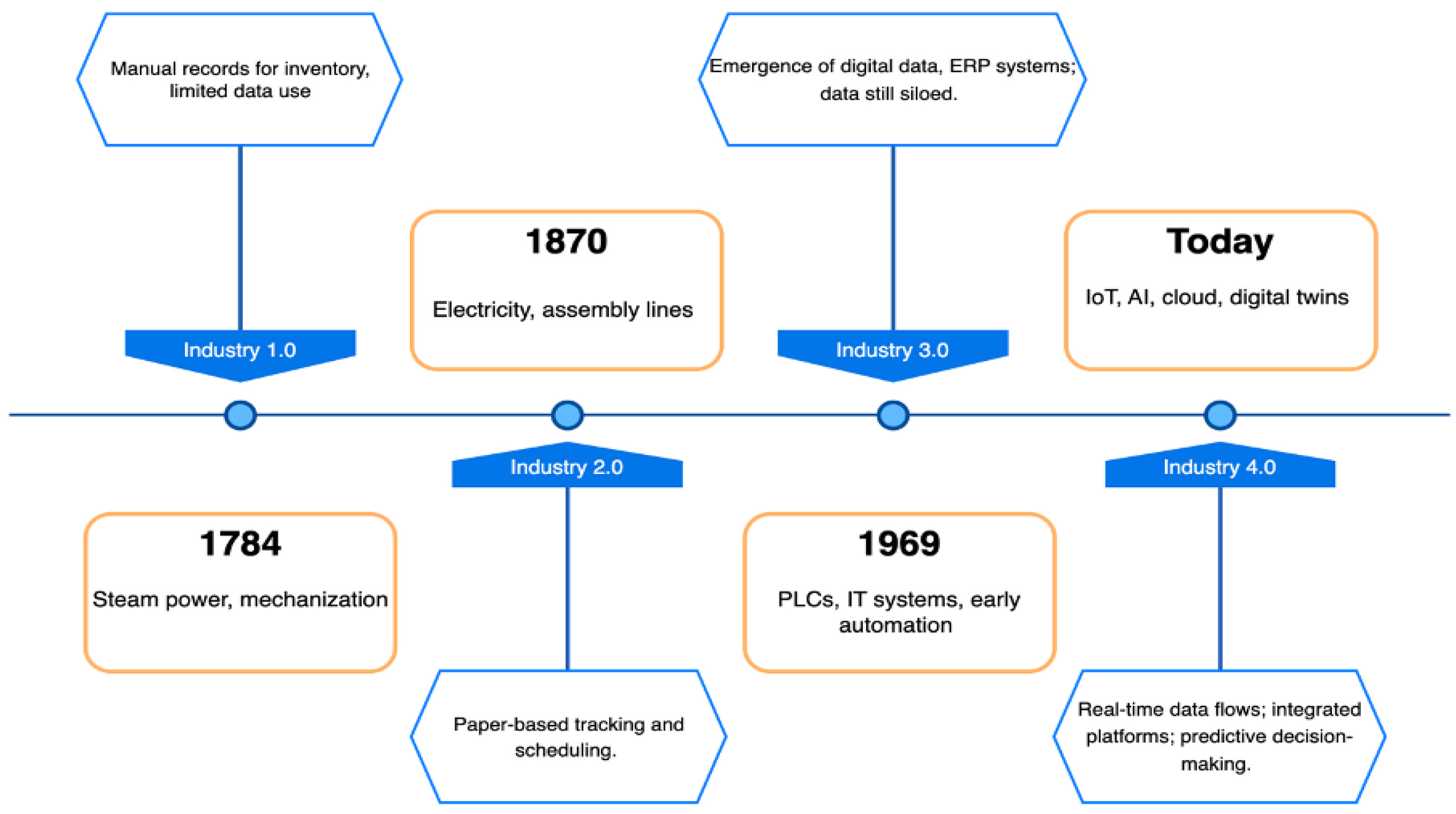

2.4. Historical Evolution of Data Management in Industrial Revolutions

2.5. Data Use in Supply Chain Management Functions

2.5.1. Procurement

2.5.2. Planning

2.5.3. Production

2.5.4. Inventory and Warehousing

2.5.5. Transportation and Distribution

2.5.6. Customer Service and Returns

2.6. Reference Models and Standards in Data Management of Smart Manufacturing

- •

- RAMI 4.0 (Reference Architecture Model for Industry 4.0): combines factory hierarchy levels, product lifecycles, and IT architecture layers to guide the integration and interoperability of systems [53].

- •

- IBM Industry Data Models: provide sector-specific semantic models and templates to accelerate data integration and analytics deployment [54].

- •

2.7. Cross-Cutting Challenges in Supply Chain Data Management

2.8. Motivation Behind the Work

3. Problem Statement and Research Methodology

3.1. Methodological Approach

3.2. Search Process

- •

- Data management and governance (e.g., data storage, sharing, acquisition, analysis, quality),

- •

- Supply chain functions (e.g., supply chain, logistics, production, planning, processes).

3.3. Inclusion and Exclusion Criteria

3.4. Data Extraction and Synthesis

- •

- Supply chain domain focus (production, logistics, quality),

- •

- Data management technologies mentioned (e.g., platforms, tools, systems),

- •

- Models or frameworks discussed,

- •

- Reported outcomes and limitations.

- •

- Common technologies and frameworks used,

- •

- Integration and interoperability challenges,

- •

- Gaps between academic theory and real-world practice.

3.5. Article Selection Process

4. Descriptive and Bibliometric Analysis of the Reviewed Studies

4.1. Analysis Process Overview

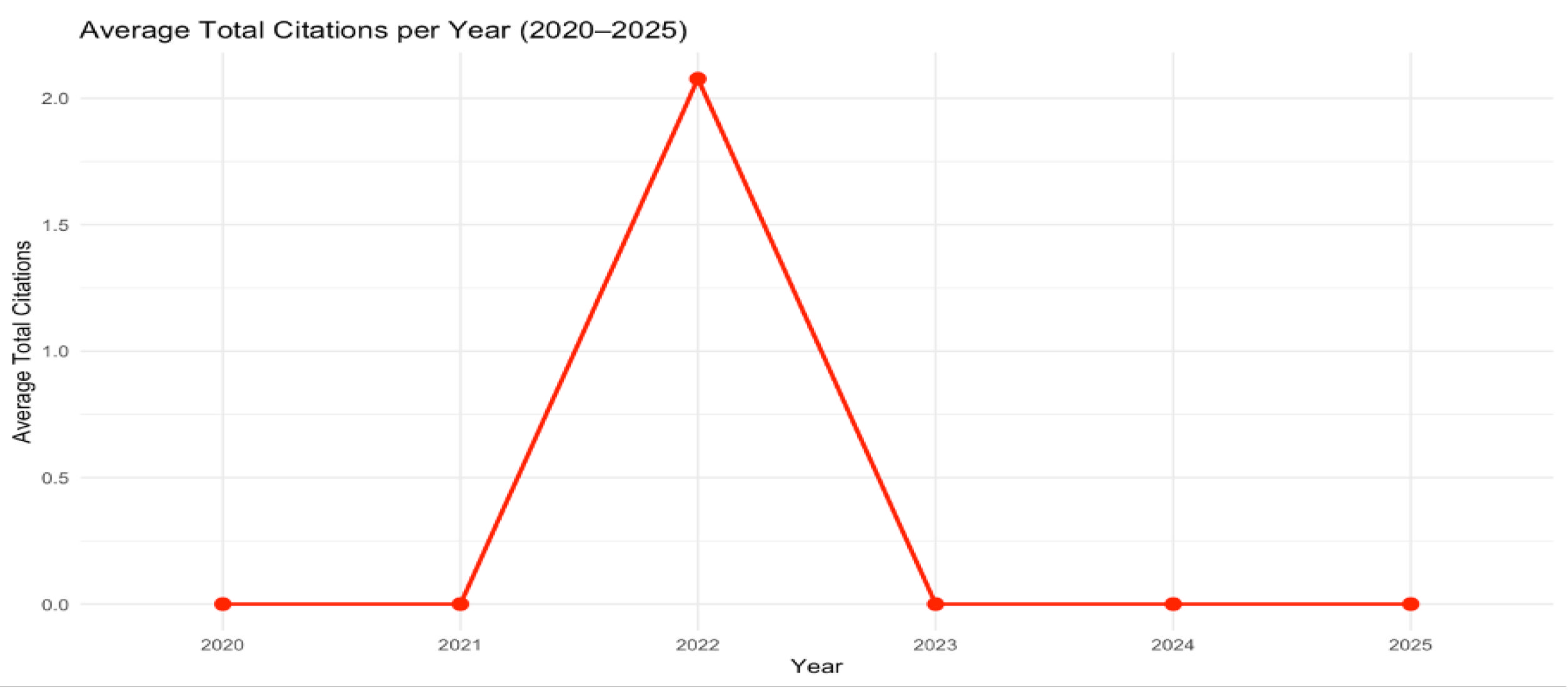

4.2. Publication Frequency

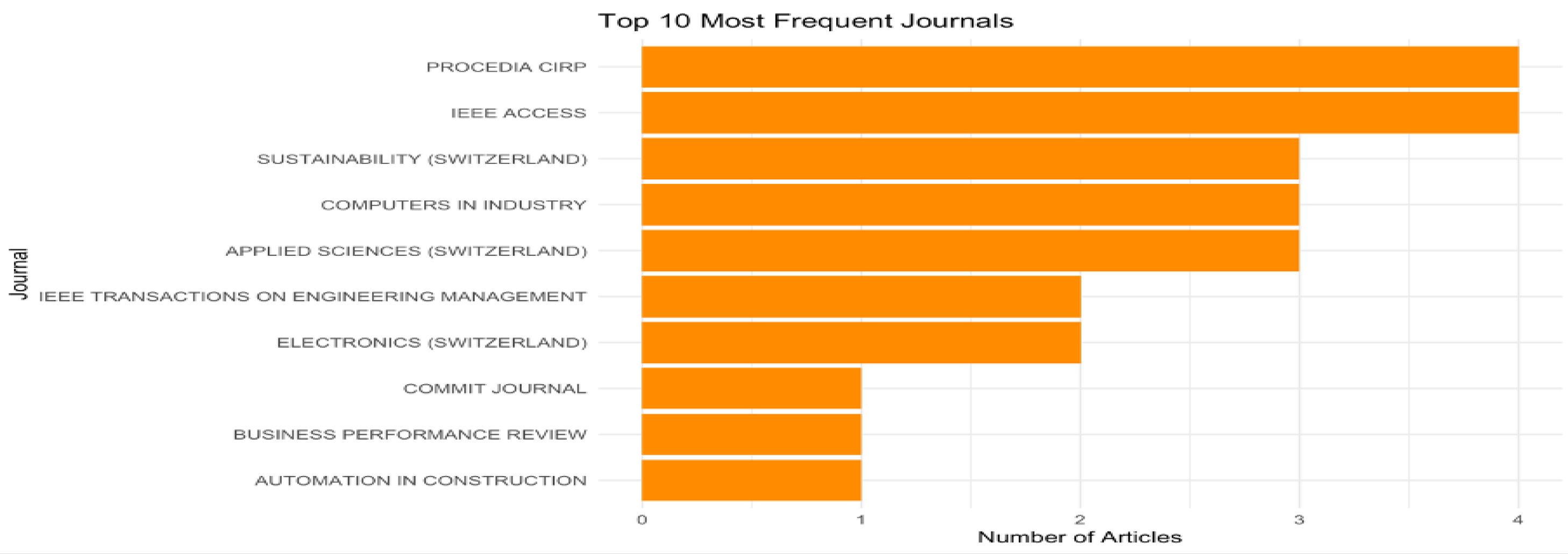

4.3. Publication Analysis

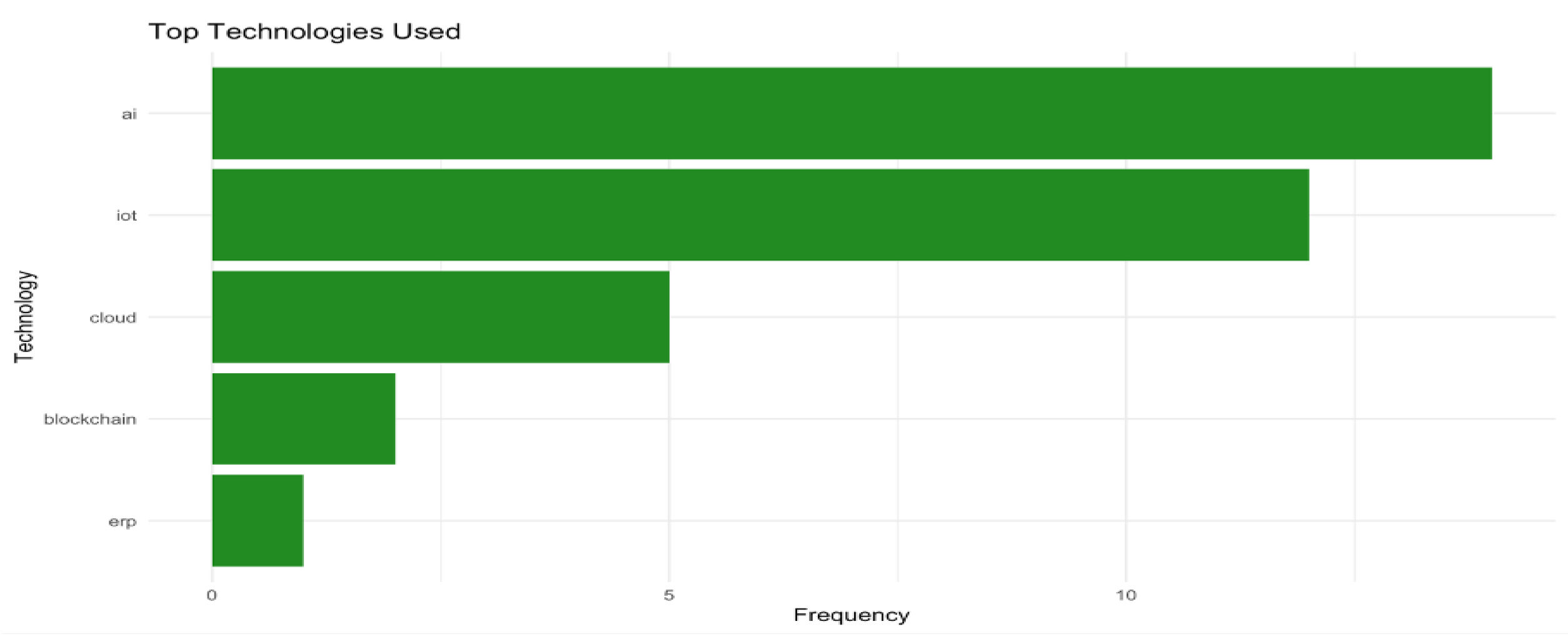

4.4. Technologies Used Analysis

4.5. Keyword Analysis

4.6. Supply Chain Phases Analysis

4.7. Summary of Findings

4.7.1. Classification of the 55 Articles

- •

- Reviews supply a panoramic understanding of the field, mapping core concepts such as data quality, governance, and dataspaces, but they mostly remain descriptive.

- •

- Framework/Model papers dominate (≈53%), reflecting the field’s emphasis on conceptual architecture and methodological proposals—IoT acquisition layers, hybrid edge-cloud pipelines, semantic knowledge graphs, and governance patterns.

- •

- Key Studies provide concrete industrial validations (≈31%), demonstrating the feasibility of predictive maintenance, blockchain traceability, and other advanced solutions, but they remain context-specific and rarely test long-term scalability.

Reviews (9 Articles)

- •

- Fragmented scope, often centered on a single technology or sector, with no truly end-to-end view of supply chain data management.

- •

- Heterogeneous methodologies with inconsistently reported search strategies and inclusion criteria, limiting reproducibility.

- •

- Limited quantitative synthesis, as most papers remain descriptive and rarely conduct bibliometric mapping or meta-analysis.

- •

- Recency and coverage biases, with several reviews relying on outdated or narrow datasets.

- •

- Insufficient practical guidance, as conceptual insights seldom translate into actionable or prescriptive frameworks.

Frameworks/Models (29 Articles)

- •

- Narrow scope, with a predominant focus on production phases rather than procurement, logistics, or distribution;

- •

- Interoperability assumptions, presuming standardized ontologies or protocols not yet widely adopted;

- •

- Scalability challenges, as few frameworks test performance under real-time, high-volume industrial conditions; and

- •

- Weak governance alignment, since many technical models overlook economic, organizational, or business-process integration.

Key Studies (17 Articles)

4.7.2. Overall Synthesis and Research Directions

- •

- From Concept to Practice: A large proportion (≈53%) of publications remain conceptual. The smaller set of empirical validations underscores the need for more longitudinal and multi-site evaluations.

- •

- Technology Imbalance: AI and IoT dominate, while blockchain, ERP, and standardized knowledge-graph approaches are emerging but under-explored.

- •

- Supply Chain Coverage: Manufacturing operations are well represented; upstream procurement and downstream distribution remain marginal.

- •

- Cross-Phase Integration—Developing architectures that span procurement, production, and distribution.

- •

- Governance and Standards—Embedding robust data-governance models and aligning with international standards (RAMI 4.0, IEC 62890 [106]).

- •

- Benchmarking and Replication—Publishing open datasets and reproducible benchmarks to enable comparative evaluation of frameworks.

- Key Findings, Research Gaps and Proposed Directions:

5. Proposed Framework for Unified Data Management in the SCM

5.1. Integrated Framework Overview

- •

- Holistic coverage–extending beyond manufacturing to encompass procurement, planning, warehousing, transportation, and after-sales.

- •

- Balanced technology adoption–integrating not only AI and IoT, but also blockchain, ERP, WMS, and TMS.

- •

- Empirical grounding–addressing the gap between conceptual models and practice by embedding value-driven outcomes, such as cost savings, service levels, and sustainability.

- •

- Cross-phase integration–ensuring data flows consistently across the supply chain instead of remaining fragmented.

5.2. Procurement Phase

5.3. Planning Phase

5.4. Production/Manufacturing Phase

5.5. Warehousing and Inventory Management Phase

5.6. Distribution and Transportation Phase

5.7. Customer Service and After-Sales Phase

5.8. Discussion: Positioning the Framework Within Existing Enterprise Architectures

5.9. Implications for Research and Practice

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, I.; Mangalaraj, G. Big Data Analytics in Supply Chain Management: A Systematic Literature Review and Research Directions. Big Data Cogn. Comput. 2022, 6, 17. [Google Scholar] [CrossRef]

- Cuñat Negueroles, S.; Reinosa Simón, R.; Julián, M.; Belsa, A.; Lacalle, I.; San Julián, R.; Palau, C.E. A Blockchain-Based Digital Twin for IoT Deployments in Logistics and Transportation. Future Gener. Comput. Syst. 2024, 158, 73–88. [Google Scholar] [CrossRef]

- Riahi, Y.; Saikouk, T.; Gunasekaran, A.; Badraoui, I. Artificial Intelligence Applications in Supply Chain: A Descriptive Bibliometric Analysis and Future Research Directions. Expert Syst. Appl. 2021, 173, 114702. [Google Scholar] [CrossRef]

- Atzeni, G.; Vignali, G.; Tebaldi, L.; Bottani, E. A Bibliometric Analysis on Collaborative Robots in Logistics 4.0 Environments. Procedia Comput. Sci. 2021, 180, 686–695. [Google Scholar] [CrossRef]

- Waduge, S.; Sugathadasa, R.; Piyatilake, A.; Nanayakkara, S. A Process Analysis Framework to Adopt Intelligent Robotic Process Automation (IRPA) in Supply Chains. Sustainability 2024, 16, 9753. [Google Scholar] [CrossRef]

- Zaidi, S.A.H.; Khan, S.A.; Chaabane, A. Unlocking the Potential of Digital Twins in Supply Chains: A Systematic Review. Supply Chain. Anal. 2024, 7, 100075. [Google Scholar] [CrossRef]

- Culot, G.; Podrecca, M.; Nassimbeni, G. Artificial Intelligence in Supply Chain Management: A Systematic Literature Review of Empirical Studies and Research Directions. Comput. Ind. 2024, 162, 104132. [Google Scholar] [CrossRef]

- Jahin, M.A.; Shovon, M.S.H.; Shin, J.; Ridoy, I.A.; Mridha, M.F. Big Data—Supply Chain Management Framework for Forecasting: Data Preprocessing and Machine Learning Techniques. arXiv 2025, arXiv:2307.12971. [Google Scholar]

- Willoughby, C.; Frey, J.G. Data Management Matters. Digit. Discov. 2022, 1, 183–194. [Google Scholar] [CrossRef]

- Li, X.; Cheng, Y.; Møller, C. Data Governance: A Critical Foundation for Data Driven Decision-Making in Operations and Supply Chains. arXiv 2024, arXiv:2409.15137. [Google Scholar] [CrossRef]

- Oger, R.; Lauras, M.; Montreuil, B.; Benaben, F. A Decision Support System for Strategic Supply Chain Capacity Planning under Uncertainty: Conceptual Framework and Experiment. Enterp. Inf. Syst. 2022, 16, 1793390. [Google Scholar] [CrossRef]

- Novoszel, L.; Claus, I. A Methodological Framework Addressing Challenges and Opportunities in Supply Chain AI. IFAC-PapersOnLine 2024, 58, 349–354. [Google Scholar] [CrossRef]

- Bližnák, K.; Munk, M.; Pilková, A. A Systematic Review of Recent Literature on Data Governance (2017–2023). IEEE Access 2024, 12, 149875–149888. [Google Scholar] [CrossRef]

- Henderson, D.; Earley, S.; Data Administration Management Association (Eds.) DAMA-DMBOK: Data Management Body of Knowledge, 2nd ed.; Technics Publications: Basking Ridge, NJ, USA, 2017; ISBN 978-1-63462-247-9. [Google Scholar]

- Schmuck, M. Master Data Management as Part of Data Governance: A Maturity Model to Improve Efficiency and Trust in Master Data and Thus Business Performance. Bus. Perform. Rev. 2024, 2, 20–34. [Google Scholar] [CrossRef]

- Lujic, I.; De Maio, V.; Brandic, I. Resilient Edge Data Management Framework. IEEE Trans. Serv. Comput. 2020, 13, 663–674. [Google Scholar] [CrossRef]

- Jackson, I.; Ivanov, D.; Dolgui, A.; Namdar, J. Generative Artificial Intelligence in Supply Chain and Operations Management: A Capability-Based Framework for Analysis and Implementation. Int. J. Prod. Res. 2024, 62, 6120–6145. [Google Scholar] [CrossRef]

- Pan, Y.; Kang, S.; Kong, L.; Wu, J.; Yang, Y.; Zuo, H. Remaining Useful Life Prediction Methods of Equipment Components Based on Deep Learning for Sustainable Manufacturing: A Literature Review. Artif. Intell. Eng. Des. Anal. Manuf. 2025, 39, e4. [Google Scholar] [CrossRef]

- Bahi, A.; Gharib, J.; Gahi, Y. Integrating Generative AI for Advancing Agile Software Development and Mitigating Project Management Challenges. Int. J. Adv. Comput. Sci. Appl. 2024, 15, 54–61. [Google Scholar] [CrossRef]

- Zorrilla, M.; Yebenes, J. A Reference Framework for the Implementation of Data Governance Systems for Industry 4.0. Comput. Stand. Interfaces 2022, 81, 103595. [Google Scholar] [CrossRef]

- Vial, G. Data Governance and Digital Innovation: A Translational Account of Practitioner Issues for IS Research. Inf. Organ. 2023, 33, 100450. [Google Scholar] [CrossRef]

- Al Nuaimi, D.; Awofeso, N. The value of applying big data analytics in health supply chain management. F1000Research 2025, 13, 1237. [Google Scholar] [CrossRef]

- Bena, Y.A.; Ibrahim, R.; Mahmood, J.; Al-Dhaqm, A.; Alshammari, A.; Nasser, M.; Nura Yusuf, M.; Ayemowa, M.O. Big Data Governance Challenges Arising from Data Generated by Intelligent Systems Technologies: A Systematic Literature Review. IEEE Access 2025, 13, 12859–12888. [Google Scholar] [CrossRef]

- Alhassan, I.; Sammon, D.; Daly, M. Data governance activities: An analysis of the literature. J. Decis. Syst. 2016, 25, 64–75. [Google Scholar] [CrossRef]

- Hussain, S.M.; Balakrishna, A.; Naidu, K.T.N.; Pareek, P.; Malviya, N.; Reis, M.J.C.S. Enhancing Supply Chain Efficiency in India: A Sustainable Framework to Minimize Wastage Through Authentication and Contracts. Sustainability 2025, 17, 808. [Google Scholar] [CrossRef]

- Turi, A. Mitigating Data Inaccuracy and Supply Chain Challenges in Western Romania’s Automotive Industry. Acta Logist. 2024, 11, 473–483. [Google Scholar] [CrossRef]

- Reinpold, L.M.; Wagner, L.P.; Gehlhoff, F.; Ramonat, M.; Kilthau, M.; Gill, M.S.; Reif, J.T.; Henkel, V.; Scholz, L.; Fay, A. Systematic Comparison of Software Agents and Digital Twins: Differences, Similarities, and Synergies in Industrial Production. J. Intell. Manuf. 2025, 36, 765–800. [Google Scholar] [CrossRef]

- Jamarani, A.; Haddadi, S.; Sarvizadeh, R.; Haghi Kashani, M.; Akbari, M.; Moradi, S. Big Data and Predictive Analytics: A Systematic Review of Applications. Artif. Intell. Rev. 2024, 57, 176. [Google Scholar] [CrossRef]

- Melo, P.F.S.; Godoy, E.P.; Ferrari, P.; Sisinni, E. Open Source Control Device for Industry 4.0 Based on RAMI 4.0. Electronics 2021, 10, 869. [Google Scholar] [CrossRef]

- Rolf, B.; Jackson, I.; Müller, M.; Lang, S.; Reggelin, T.; Ivanov, D. A Review on Reinforcement Learning Algorithms and Applications in Supply Chain Management. Int. J. Prod. Res. 2023, 61, 7151–7179. [Google Scholar] [CrossRef]

- Werbińska-Wojciechowska, S.; Giel, R.; Winiarska, K. Digital Twin Approach for Operation and Maintenance of Transportation System—Systematic Review. Sensors 2024, 24, 6069. [Google Scholar] [CrossRef]

- Abaku, E.A.; Edunjobi, T.E.; Odimarha, A.C. Theoretical Approaches to AI in Supply Chain Optimization: Pathways to Efficiency and Resilience. Int. J. Sci. Technol. Res. Arch. 2024, 6, 092–107. [Google Scholar] [CrossRef]

- Huda, M.; Rahayu, A.; Furqon, C.; Sultan, M.A.; Hartati, N.; Sugiana, N.S.S. Improving Performance with Big Data: Smart Supply Chain and Market Orientation in SMEs. Int. J. Adv. Comput. Sci. Appl. 2025, 16, 80. [Google Scholar] [CrossRef]

- Sony, M. Pros and Cons of Implementing Industry 4.0 for the Organizations: A Review and Synthesis of Evidence. Prod. Manuf. Res. 2020, 8, 244–272. [Google Scholar] [CrossRef]

- Alsolbi, I.; Shavaki, F.H.; Agarwal, R.; Bharathy, G.K.; Prakash, S.; Prasad, M. Big Data Optimisation and Management in Supply Chain Management: A Systematic Literature Review. Artif. Intell. Rev. 2023, 56, 253–284. [Google Scholar] [CrossRef]

- Fu, X.; Song, H.; Li, S.; Lu, Y. Digital Twin Technology in Modern Machining: A Comprehensive Review of Research on Machining Errors. J. Manuf. Syst. 2025, 79, 134–161. [Google Scholar] [CrossRef]

- Zimmermann, R.; Brandtner, P. From Data to Decisions: Optimizing Supply Chain Management with Machine Learning-Infused Dashboards. Procedia Comput. Sci. 2024, 237, 955–964. [Google Scholar] [CrossRef]

- Huang, J.; Li, S.M. Data-Driven Analysis of Supply Chain Integration’s Impact on Procurement Performance in International EPC Projects. Sustainability 2024, 16, 10729. [Google Scholar] [CrossRef]

- Cañas, H.; Mula, J.; Campuzano-Bolarín, F.; Poler, R. A Conceptual Framework for Smart Production Planning and Control in Industry 4.0. Comput. Ind. Eng. 2022, 173, 108659. [Google Scholar] [CrossRef]

- Oñate, W.; Sanz, R. Integration of Fog Computing in a Distributed Manufacturing Execution System Under the RAMI 4.0 Framework. Appl. Sci. 2024, 14, 10539. [Google Scholar] [CrossRef]

- Perano, M.; Cammarano, A.; Varriale, V.; Del Regno, C.; Michelino, F.; Caputo, M. Embracing Supply Chain Digitalization and Unphysicalization to Enhance Supply Chain Performance: A Conceptual Framework. Int. J. Phys. Distrib. Logist. Manag. 2023, 53, 628–659. [Google Scholar] [CrossRef]

- Iftikhar, A.; Ali, I.; Arslan, A.; Tarba, S. Digital Innovation, Data Analytics, and Supply Chain Resiliency: A Bibliometric-Based Systematic Literature Review. Ann. Oper. Res. 2024, 333, 825–848. [Google Scholar] [CrossRef]

- Douimia, S.; Bekrar, A.; Ait El Cadi, A.; El Hillali, Y.; Fillon, D. Machine Learning and Deep Learning Applications in the Automotive Manufacturing Industry: A Systematic Literature Review and Industry Insights. Robot. Comput. Integr. Manuf. 2025, 96, 103034. [Google Scholar] [CrossRef]

- Grace Tetteh, M.; Gupta, S.; Kumar, M.; Trollman, H.; Salonitis, K.; Jagtap, S. Pharma 4.0: A Deep Dive Top Management Commitment to Successful Lean 4.0 Implementation in Ghanaian Pharma Manufacturing Sector. Heliyon 2024, 10, e36677. [Google Scholar] [CrossRef]

- Kachiche, S.; Gahi, Y.; Gharib, J. An Efficient Framework for the Implementation of Sustainable Industry 4.0. In Innovations in Smart Cities Applications Volume 6; Ben Ahmed, M., Boudhir, A.A., Santos, D., Dionisio, R., Benaya, N., Eds.; Lecture Notes in Networks and Systems; Springer International Publishing: Cham, Switzerland, 2023; Volume 629, pp. 804–815. ISBN 978-3-031-26851-9. [Google Scholar]

- Herrmann, J.-P.; Tackenberg, S.; Padoano, E.; Gamber, T. A Literature Review and Cluster Analysis of the Aachen Production Planning and Control Model under Industry 4.0. Procedia Comput. Sci. 2021, 180, 208–218. [Google Scholar] [CrossRef]

- Rahmani, M.; Romsdal, A.; Sgarbossa, F.; Strandhagen, J.O.; Holm, M. Towards Smart Production Planning and Control; a Conceptual Framework Linking Planning Environment Characteristics with the Need for Smart Production Planning and Control. Annu. Rev. Control. 2022, 53, 370–381. [Google Scholar] [CrossRef]

- Shin, M. Development of Collaboration Model for Data Space-Based Open Collaboration Platform in Continuous Process Industries. Sustainability 2024, 17, 126. [Google Scholar] [CrossRef]

- Unterberger, P.; Müller, J.M. Clustering and Classification of Manufacturing Enterprises Regarding Their Industry 4.0 Reshoring Incentives. Procedia Comput. Sci. 2021, 180, 696–705. [Google Scholar] [CrossRef]

- Merwe, E.; Pisa, N.; Gideon, E.; Chakamera, C. Effects of Material Master Data Management on Supply Chain Performance at FLSmidth: The Moderating Role of PiLog External Service Provider. Acta Logist. 2024, 11, 569–578. [Google Scholar] [CrossRef]

- Spanaki, K.; Dennehy, D.; Papadopoulos, T.; Dubey, R. Data-Driven Digital Transformation in Operations and Supply Chain Management. Int. J. Prod. Econ. 2025, 284, 109599. [Google Scholar] [CrossRef]

- Pellen, C.; Munung, N.S.; Armond, A.C.; Kulp, D.; Mansmann, U.; Siebert, M.; Naudet, F. Data Management and Sharing. J. Clin. Epidemiol. 2025, 180, 111680. [Google Scholar] [CrossRef]

- Helmann, A.; Deschamps, F.; Loures, E.D.F.R. Reference Architectures for Industry 4.0: Literature Review. In Advances in Transdisciplinary Engineering; Pokojski, J., Gil, M., Newnes, L., Stjepandić, J., Wognum, N., Eds.; IOS Press: Amsterdam, The Netherlands, 2020; ISBN 978-1-64368-110-8. [Google Scholar]

- Atakok, G.; Cun, M. Management of the Engineering Data for Manufacturing. J. Eng. Res. 2022, 10, 258–269. [Google Scholar] [CrossRef]

- Binder, C.; Leiter, W.; Joebstl, O.; Mair, L.; Neureiter, C.; Luder, A. Utilizing an Enterprise Architecture Framework for Model-Based Industrial Systems Engineering. In Proceedings of the 2021 IEEE 19th International Conference on Industrial Informatics (INDIN), Palma de Mallorca, Spain, 21 July 2021; pp. 1–6. [Google Scholar]

- Techanamurthy, U.; Iqbal, M.S.; Abdul Rahim, Z. Industry 4.0 readiness and strategic plan failures in SMEs: A comprehensive analysis. PLoS ONE 2025, 20, e0324052. [Google Scholar] [CrossRef]

- Horstkemper, D.; Mülhausen, A.; Hellingrath, B. Structured Approach for Automated Enterprise Architecture Model Generation. IFAC-PapersOnLine 2023, 56, 3648–3653. [Google Scholar] [CrossRef]

- Baptista, L.F.; Barata, J. Piloting Industry 4.0 in SMEs with RAMI 4.0: An Enterprise Architecture Approach. Procedia Comput. Sci. 2021, 192, 2826–2835. [Google Scholar] [CrossRef]

- Jayadi, E.L. The Digitalization of the Humanitarian Supply Chain Performance Management Literature and Practice. J. Humanit. Logist. Supply Chain. Manag. 2025, 15, 175–193. [Google Scholar] [CrossRef]

- Aldossari, S.; Mokhtar, U.A.; Abdul Ghani, A.T. Factor Influencing the Adoption of Big Data Analytics: A Systematic Literature and Experts Review. Sage Open 2023, 13, 21582440231217902. [Google Scholar] [CrossRef]

- Leite, D.; Andrade, E.; Rativa, D.; Maciel, A.M.A. Fault Detection and Diagnosis in Industry 4.0: A Review on Challenges and Opportunities. Sensors 2024, 25, 60. [Google Scholar] [CrossRef] [PubMed]

- Tang, H.; Zhu, J.; Li, N.; Wu, W. Impact of Enterprise Supply Chain Digitalization on Cost of Debt: A Four-Flows Perspective Analysis Using Explainable Machine Learning Methodology. Sustainability 2024, 16, 8702. [Google Scholar] [CrossRef]

- Ma, S.; Ding, W.; Liu, Y.; Zhang, Y.; Ren, S.; Kong, X.; Leng, J. Industry 4.0 and Cleaner Production: A Comprehensive Review of Sustainable and Intelligent Manufacturing for Energy-Intensive Manufacturing Industries. J. Clean. Prod. 2024, 467, 142879. [Google Scholar] [CrossRef]

- Farshadfar, Z.; Mucha, T.; Tanskanen, K. Leveraging Machine Learning for Advancing Circular Supply Chains: A Systematic Literature Review. Logistics 2024, 8, 108. [Google Scholar] [CrossRef]

- Khant, L.P.; Widjaja, D.D.; Kim, D.; Rachmawati, T.S.N.; Kim, S. Optimizing Rebar Process and Supply Chain Management for Minimized Cutting Waste: A Building Information Modeling-Based Data-Driven Approach. Buildings 2025, 15, 844. [Google Scholar] [CrossRef]

- Hariharasudan, A.; Kot, S.; Sangeetha, J. THE DECADES OF RESEARCH ON SCM AND ITS ADVANCEMENTS: COMPREHENSIVE FRAMEWORK. Acta Logist. 2021, 8, 455–477. [Google Scholar] [CrossRef]

- Urgese, G.; Azzoni, P.; Van Deventer, J.; Delsing, J.; Macii, A.; Macii, E. A SOA-Based Engineering Process Model for the Life Cycle Management of System-of-Systems in Industry 4.0. Appl. Sci. 2022, 12, 7730. [Google Scholar] [CrossRef]

- Miksa, T.; Oblasser, S.; Rauber, A. Automating Research Data Management Using Machine-Actionable Data Management Plans. ACM Trans. Manag. Inf. Syst. 2022, 13, 1–22. [Google Scholar] [CrossRef]

- Ghorbani, B.; Zendehboudi, S.; Saady, N.M.C. Advancing Hybrid Cryogenic Natural Gas Systems: A Comprehensive Review of Processes and Performance Optimization. Energies 2025, 18, 1443. [Google Scholar] [CrossRef]

- Krumay, B.; Rueckel, D. Data Governance and Digitalization—A Case Study in a Manufacturing Company. In Proceedings of the Pacific Asia Conference on Information Systems (PACIS 2020), Dubai, United Arab Emirates, 20–24 June 2020. [Google Scholar]

- Su, J.; Yao, S.; Liu, H. Data Governance Facilitate Digital Transformation of Oil and Gas Industry. Front. Earth Sci. 2022, 10, 861091. [Google Scholar] [CrossRef]

- Geasela, Y.M.; Legowo, N. Designing Information System Architecture Based on Education 4.0 Case Study: Senior High School Institutions of Indonesia. J. Comput. Sci. 2022, 18, 622–637. [Google Scholar] [CrossRef]

- Bernardoa, B.M.V.; Mamede, H.S.; Barroso, J.M.P.; dos Santos, V.M.P.D. Data governance & quality management—Innovation and breakthroughs across different fields. J. Innov. Knowl. 2024, 9, 100475. [Google Scholar]

- Haug, A. Understanding the Differences across Data Quality Classifications: A Literature Review and Guidelines for Future Research. Ind. Manag. Data Syst. 2021, 121, 2651–2671. [Google Scholar] [CrossRef]

- Omri, N.; Al Masry, Z.; Mairot, N.; Giampiccolo, S.; Zerhouni, N. Industrial Data Management Strategy towards an SME-Oriented PHM. J. Manuf. Syst. 2020, 56, 23–36. [Google Scholar] [CrossRef]

- Prado, R.; Prado, E.P.V.; Grotta, A.; Barata, A.M. Benefits of the Enterprise Data Governance in Industry: A Qualitative Research. In Proceedings of the 23rd International Conference on Enterprise Information Systems (ICEIS 2021), Virtual, 26–28 April 2021; SCITEPRESS: Setúbal, Portugal, 2021; Volume 2, pp. 699–706. [Google Scholar] [CrossRef]

- Kim, S.-Y.; Hillemacher, S.; Kocher, M.; Rumpe, B.; Geisler, S. The Dataset Finder: A Tool Utilizing Data Management Plans as a Key to Data Discoverability. Data Sci. J. 2024, 23, 58. [Google Scholar] [CrossRef]

- Alsamhi, S.H.; Hawbani, A.; Kumar, S.; Timilsina, M.; Al-Qatf, M.; Haque, R.; Nashwan, F.M.A.; Zhao, L.; Curry, E. Empowering Dataspace 4.0: Unveiling Promise of Decentralized Data-Sharing. IEEE Access 2024, 12, 112637–112658. [Google Scholar] [CrossRef]

- Naghib, A.; Jafari Navimipour, N.; Hosseinzadeh, M.; Sharifi, A. A Comprehensive and Systematic Literature Review on the Big Data Management Techniques in the Internet of Things. Wirel. Netw. 2023, 29, 1085–1144. [Google Scholar] [CrossRef]

- Chen, K.-S.; Lin, S.-C.; Lai, K.-K.; Wang, W.-P. Decision-Making Model of Production Data Management for Multi-Quality Characteristic Products in Consideration of Industry 4.0. Appl. Sci. 2023, 13, 7883. [Google Scholar] [CrossRef]

- Liang, R.; Huang, C.; Zhang, C.; Li, B.; Saydam, S.; Canbulat, I. Exploring the Fusion Potentials of Data Visualization and Data Analytics in the Process of Mining Digitalization. IEEE Access 2023, 11, 40608–40628. [Google Scholar] [CrossRef]

- Asante, M.; Epiphaniou, G.; Maple, C.; Al-Khateeb, H.; Bottarelli, M.; Ghafoor, K.Z. Distributed Ledger Technologies in Supply Chain Security Management: A Comprehensive Survey. IEEE Trans. Eng. Manag. 2023, 70, 713–739. [Google Scholar] [CrossRef]

- Udokwu, C.; Brandtner, P.; Darbanian, F.; Falatouri, T. Proposals for Addressing Research Gaps at the Intersection of Data Analytics and Supply Chain Management. J. Adv. Inf. Technol. 2022, 13, 338–346. [Google Scholar] [CrossRef]

- Saridaki, M.; Haugbølle, K. Recognising diversity of data management approaches towards lifecycle costing through personas. J. Inf. Technol. Constr. 2022, 27, 1042–1059. [Google Scholar] [CrossRef]

- da Silva, A.L.T.; Assuad, C.S.A.; Ringen, G. A Data Management Framework for Life Cycle Simulation in Extruded Aluminium Products Production. Procedia CIRP 2024, 130, 637–641. [Google Scholar] [CrossRef]

- Wang, S.; Yang, J.; Yang, B.; Li, D.; Kang, L. An Intelligent Quality Control Method for Manufacturing Processes Based on a Human–Cyber–Physical Knowledge Graph. Engineering 2024, 41, 242–260. [Google Scholar] [CrossRef]

- Meyers, B.; Vangheluwe, H.; Lietaert, P.; Vanderhulst, G.; Van Noten, J.; Schaffers, M.; Maes, D.; Gadeyne, K. Towards a Knowledge Graph Framework for Ad Hoc Analysis in Manufacturing. J. Intell. Manuf. 2024, 35, 3731–3752. [Google Scholar] [CrossRef]

- Melikov, A.; Gasimov, V.; Ahmadov, S. Data Management as a Critical Component of Protecting Corporate Devices. J. Appl. Data Sci. 2024, 5, 1246–1257. [Google Scholar] [CrossRef]

- Nadal, S.; Jovanovic, P.; Bilalli, B.; Romero, O. Operationalizing and Automating Data Governance. J. Big Data 2022, 9, 117. [Google Scholar] [CrossRef]

- Bouaicha, S.; Ghemmaz, W.; Smaali, S. DaVe: Data Value Evaluation Framework for Seamless Data Integration. IEEE Access 2024, 12, 174749–174769. [Google Scholar] [CrossRef]

- Fan, B.; Sun, L.; Tan, D.; Pan, M. Optimal Selection Technology of Business Data Resources for Multi-Value Chain Data Space—Optimizing Future Data Management Methods. Electronics 2024, 13, 4690. [Google Scholar] [CrossRef]

- Li, Y.; Qu, W.; Zhang, Z. Intelligent Algorithm Operation and Data Management of Electromechanical Engineering Power Communication Network Based on the Internet of Things. Scalable Comput. 2024, 25, 3330–3341. [Google Scholar] [CrossRef]

- Chit, T.W.; Toro, C.; Lim, H.C.; Muthu, R. Scalable Remote Cloud Data Center for Vessel Equipment Predictive Maintenance Service-as-a-Product (SaaP). Procedia Comput. Sci. 2023, 225, 2826–2834. [Google Scholar] [CrossRef]

- Arena, S.; Manca, G.; Murru, S.; Orrù, P.F.; Perna, R.; Reforgiato Recupero, D. Data Science Application for Failure Data Management and Failure Prediction in the Oil and Gas Industry: A Case Study. Appl. Sci. 2022, 12, 617. [Google Scholar] [CrossRef]

- Hu, G.; Liu, Y.; Liu, K.; Yang, X. Research on Data-Driven Dynamic Decision-Making Mechanism of Mega Infrastructure Project Construction. Sustainability 2023, 15, 9219. [Google Scholar] [CrossRef]

- Mirabel, M.E.; Yuliana, O.Y.; Yahya, B.N. Conceptual Framework for Efficient Inbound Supply Chain Analytics. In Proceedings of the 2022 6th International Conference on Business and Information Management, ICBIM 2022, Guangzhou, China, 26–28 August 2022; pp. 196–201. [Google Scholar] [CrossRef]

- Yi-Fan, L. An Analysis Method of Ship Traffic Section Flow Based on Big Data. J. Phys. Conf. Ser. 2021, 1848, 012007. [Google Scholar] [CrossRef]

- Nikolakopoulos, A.; Julian Segui, M.; Pellicer, A.B.; Kefalogiannis, M.; Gizelis, C.-A.; Marinakis, A.; Nestorakis, K.; Varvarigou, T. BigDaM: Efficient Big Data Management and Interoperability Middleware for Seaports as Critical Infrastructures. Computers 2023, 12, 218. [Google Scholar] [CrossRef]

- Nam, S.; Lee, J.; Kim, K.; Jo, M.; Park, S. Data Utilization-Based Adaptive Data Management Method for Distributed Storage System in WAN Environment. Comput. Syst. Sci. Eng. 2023, 46, 3457–3469. [Google Scholar] [CrossRef]

- Rousopoulou, V.; Vafeiadis, T.; Nizamis, A.; Iakovidis, I.; Samaras, L.; Kirtsoglou, A.; Georgiadis, K.; Ioannidis, D.; Tzovaras, D. Cognitive Analytics Platform with AI Solutions for Anomaly Detection. Comput. Ind. 2022, 134, 103555. [Google Scholar] [CrossRef]

- Gharib, J.; Gahi, Y. Quantum Computing and AI Applications in Industry 5.0 Use Cases. In Quantum Computing and Artificial Intelligence: The Industry Use Cases; Raj, P., Sundaravadivazhagan, B., Ouaissa, M., Kavitha, V., Kumari, S.K., Eds.; Wiley: Hoboken, NJ, USA, 2025. [Google Scholar] [CrossRef]

- Yang, Q.; Cai, Y.; Shen, L.; Chen, X.; Lan, L.; Jiang, X. Research on Data Management of Power Grid Enterprises Based on Data Middle Platform. IOP Conf. Ser. Earth Environ. Sci. 2021, 714, 042012. [Google Scholar] [CrossRef]

- Wiemer, H.; Dementyev, A.; Ihlenfeldt, S. A Holistic Quality Assurance Approach for Machine Learning Applications in Cyber--physical Production Systems. Appl. Sci. 2021, 11, 9590. [Google Scholar] [CrossRef]

- Rinos, K.; Kostis, N.; Varitis, E.; Vekis, V. Implementation of Model-Based Definition and Product Data Management for the Optimization of Industrial Collaboration and Productivity. Procedia CIRP 2021, 100, 355–360. [Google Scholar] [CrossRef]

- Ostadabbas, H.; Merz, H.; Weippert, H. Integration of Urban Spatial Data Management and Visualization with Enterprise Applications Using Open-Source Software. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci.-ISPRS Arch. 2021, 43, 307–312. [Google Scholar] [CrossRef]

- IEC 62890:2016; Life-Cycle Management for Systems and Products Used in Industrial-Process Measurement, Control and Auto-Mation. IEC: Geneva, Switzerland, 2016.

- Lindström, V.; Persson, F.; Viswanathan, A.P.C.; Rajendran, M. Data Quality Issues in Production Planning and Control—Linkages to Smart PPC. Comput. Ind. 2023, 147, 103871. [Google Scholar] [CrossRef]

- Breunig, M.; Kuper, P.; Reitze, F.; Landgraf, S.; Al-Doori, M.; Stefanakis, E.; Abdulmuttalib, H.; Kugler, Z. IMPROVING DATA QUALITY AND MANAGEMENT FOR REMOTE SENSING ANALYSIS: USE-CASES AND EMERGING RESEARCH QUESTIONS. ISPRS Ann. Photogramm. Remote Sens. Spat. Inf. Sci. 2023, 10, 41–49. [Google Scholar] [CrossRef]

- Omri, N.; Al Masry, Z.; Mairot, N.; Giampiccolo, S.; Zerhouni, N. Towards an Adapted PHM Approach: Data Quality Requirements Methodology for Fault Detection Applications. Comput. Ind. 2021, 127, 103414. [Google Scholar] [CrossRef]

- Mulinka, P.; Kalalas, C.; Dzaferagic, M.; MacAluso, I.; Rojas, D.G.; Nardelli, P.J.; Marchetti, N. Information Processing and Data Visualization in Networked Industrial Systems. In Proceedings of the IEEE International Symposium on Personal, Indoor and Mobile Radio Communications, PIMRC 2021, Helsinki, Finland, 13–16 September 2021. [Google Scholar] [CrossRef]

- Epiphaniou, G.; Pillai, P.; Bottarelli, M.; Al-Khateeb, H.; Hammoudesh, M.; Maple, C. Electronic Regulation of Data Sharing and Processing Using Smart Ledger Technologies for Supply-Chain Security. IEEE Trans. Eng. Manag. 2020, 67, 1059–1073. [Google Scholar] [CrossRef]

- Röttcher, N.C.; Akkoc, G.D.; Finger, S.; Fritsch, B.; Möller, J.; Mayrhofer, K.J.J.; Dworschak, D. Accelerating Materials Research with a Comprehensive Data Management Tool: A Case Study on an Electrochemical Laboratory. J. Mater. Chem. A 2024, 12, 3933–3942. [Google Scholar] [CrossRef]

- Garcia, R.C.; Koch, D.; Steinmeier, S. Leveraging Digital Solutions for Enhanced Sustainability Management in Production Systems: A Case Study in Baden-Württemberg. Procedia CIRP 2024, 122, 1089–1094. [Google Scholar] [CrossRef]

- Zeng, X.; Yi, J. Analysis of the Impact of Big Data and Artificial Intelligence Technology on Supply Chain Management. Symmetry 2023, 15, 1801. [Google Scholar] [CrossRef]

- Vipond, N.; Kumar, A.; James, J.; Paige, F.; Sarlo, R.; Xie, Z. Real-Time Processing and Visualization for Smart Infrastructure Data. Autom. Constr. 2023, 154, 104998. [Google Scholar] [CrossRef]

- Silva, N.; Barros, J.; Santos, M.Y.; Costa, C.; Cortez, P.; Carvalho, M.S.; Gonçalves, J.N.C. Advancing Logistics 4.0 with the Implementation of a Big Data Warehouse: A Demonstration Case for the Automotive Industry. Electronics 2021, 10, 2221. [Google Scholar] [CrossRef]

- Sventeková, E.; Prievozník, P.; Sibila, M.; Boroš, M. Road Junction Throughput Testing in Transport Logistics—Slovak Case Study. Sustainability 2024, 16, 6249. [Google Scholar] [CrossRef]

- Bozic, D.; Zivicnjak, M.; Stankovic, R.; Ignjatic, A. Impact of the Product Master Data Quality on the Logistics Process Performance. Logistics 2024, 8, 43. [Google Scholar] [CrossRef]

- Rahmawati, R.; Ruldeviyani, Y.; Abdullah, P.P.; Hudoarma, F.M. Strategies to Improve Data Quality Management Using Total Data Quality Management (TDQM) and Data Management Body of Knowledge (DMBOK): A Case Study of M-Passport Application. CommIT J. 2023, 17, 27–42. [Google Scholar] [CrossRef]

- Rantala, S.; Swallow, B.; Lähteenmäki-Uutela, A.; Paloniemi, R. Forest Data Governance as a Reflection of Forest Governance: Institutional Change and Endurance in Finland and Canada. Environ. Sci. Policy 2022, 136, 751–760. [Google Scholar] [CrossRef]

- Balest, J.; Pezzutto, S.; Giacovelli, G.; Wilczynski, E. Engaging Stakeholders for Designing a FAIR Energy Data Management Tool: The Horizon 2020 EnerMaps Project. Sustainability 2022, 14, 11392. [Google Scholar] [CrossRef]

- Hasan, M.R.; Legner, C. End-to-End Data Quality: Insights from Two Case Studies. In Proceedings of the 11th International Conference on Data Science, Technology and Applications (Data), Lisbon, Portugal, 11–13 July 2022; SCITEPRESS: Setúbal, Portugal, 2022; pp. 392–399. [Google Scholar] [CrossRef]

- Shkarupylo, V.; Alsayaydeh, J.A.J.; Yusof, M.F.B.; Oliinyk, A.; Artemchuk, V.; Herawan, S.G. Exploring the Potential Network Vulnerabilities in the Smart Manufacturing Process of Industry 5.0 via the Use of Machine Learning Methods. IEEE Access 2024, 12, 152262–152276. [Google Scholar] [CrossRef]

- Komenda, T.; Brandstötter, M.; Gharagyozyan, T.; Pichler, A.; Liemberger, W. Failure Prediction in Robotic Spot-Welding Applications—Challenges in Data Management. Procedia CIRP 2022, 112, 454–458. [Google Scholar] [CrossRef]

- Zheng, L. Risk Management of New Cosmetic Product Development Based on Data Management of Visualization in Scientific Computing. Sci. Program. 2022, 2022, 5665208. [Google Scholar] [CrossRef]

- Steinwender, A.; Gallina, V.; Litvyak, O.; Lampoltshammer, T.J.; Bachlechner, D.; Schlund, S. From Analogue to Digital Product Passports in the Furniture Industry. IFAC PapersOnLine 2024, 58, 229–234. [Google Scholar] [CrossRef]

- Jarosz, K.; Opiola, L.; Dutka, L.; Slota, R.G.; Kitowski, J. Increasing Data Availability and Fault Tolerance for Decentralized Collaborative Data-Sharing Systems. In Proceedings of the 17th Conference on Computer Science and Intelligence Systems, FedCSIS 2022, Sofia, Bulgaria, 4–7 September 2022; pp. 563–566. [Google Scholar] [CrossRef]

- Park, J.S.; Lee, S.J.; Jimenez, J.; Kim, S.K.; Kim, J.W. Indoor Positioning-Based Mobile Resource Movement Data Management System for Smart Factory Operations Management. Int. J. Distrib. Sens. Netw. 2020, 16, 1550147720909760. [Google Scholar] [CrossRef]

- Ozkan-Ozen, Y.D.; Garza-Reyes, J.A.; Kazancoglu, Y. Integrating Lean Six Sigma with Life Cycle and Value Stream Level of RAMI 4.0. Qual. Manag. J. 2024, 31, 225–241. [Google Scholar] [CrossRef]

- Kornyshova, E.; Barrios, J. Industry 4.0 Impact Propagation on Enterprise Architecture Models. Procedia Comput. Sci. 2020, 176, 2497–2506. [Google Scholar] [CrossRef]

| Category | Number of Articles | Main Objective |

|---|---|---|

| Review | 9 | Provide state-of-the-art surveys of data management in smart manufacturing |

| Framework/Model | 29 | Propose conceptual/technical frameworks or architectures for data management |

| Key Studies | 17 | Present empirical evidence, case studies, or experiments on specific solutions |

| Findings | Identified Gaps/Limitations | Proposed Directions/Solutions |

|---|---|---|

| Strong growth in publications (2020–2025) and concentration in reputable journals | Limited dataset (55 articles) and possible exclusion of non-indexed or non-English studies | Extend corpus to include gray literature and regional databases; encourage multilingual reviews to capture diverse industrial contexts. |

| Dominance of AI (14 articles) and IoT (12 articles) | Under-representation of other technologies such as blockchain and ERP | Promote integrative frameworks that combine AI/IoT with ERP, blockchain, and digital twins for full supply chain visibility. |

| Keyword clusters show focus on data management, Industry 4.0, and security | Weak integration across clusters; few holistic approaches linking governance, security, and analytics | Develop cross-domain ontologies and governance models that unify technical, organizational, and security perspectives. |

| Supply chain phase analysis shows focus on manufacturing (23 articles) | Procurement, transportation, and downstream logistics largely absent | Expand research toward upstream (procurement) and downstream (distribution, after-sales) integration within smart supply chains. |

| Majority of papers propose frameworks/models (32 of 55) | Conceptual bias: limited large-scale or multi-site empirical validation; few longitudinal performance benchmarks | Encourage empirical validation through industry–academia collaboration, multi-site pilots, and long-term benchmarking studies. |

| Key empirical studies show tangible benefits (predictive maintenance, energy optimization, etc.) | Context-specific pilots with scarce evidence of cross-industry transferability or long-term data-governance sustainability | Establish standardized evaluation metrics, open datasets, and governance continuity plans for generalizable insights. |

| Early adoption of governance models and dataspaces | Lack of proven economic/business alignment and clear ROI metrics | Embed business-case modeling, KPI alignment, and ROI tracking mechanisms within governance frameworks. |

| High citation activity concentrated in recent years | Citation impact partly inflated by recency bias; long-term influence yet to be established | Foster cumulative research programs, replication studies, and open-access dissemination to validate long-term impact. |

| Dimension | TOGAF | RAMI 4.0 | IBM Industry 4.0 | Proposed Framework |

|---|---|---|---|---|

| Primary Focus | Enterprise IT architecture | Manufacturing integration and lifecycle | Technology enablers (AI, IoT, blockchain) | End-to-end data value chain across supply chain |

| Coverage of Supply Chain Phases | Low–generic, not SC-specific | Medium–strong in production, weak upstream/downstream | Medium–partial coverage (mostly production and logistics) | High–procurement → production → logistics → after-sales |

| Data Governance Integration | Limited, high-level | Weak, implied but not explicit | Minimal, tech-driven | Strong–governance embedded per SC phase |

| Interoperability Focus | Conceptual (requires customization) | Strong (standards, semantics) | Medium (tool-based) | Strong–cross-platform semantic and technical interoperability |

| Technology Orientation | Neutral | Neutral | High (AI, edge, blockchain) | Balanced (governance + integration + analytics) |

| Scalability/Modularity | High (architecture method) | High in manufacturing layers | High for tech services | High across SC stages with modular pipelines |

| Main Gap | Not domain-specific | Only production-oriented | Technology-centric | —(addresses gaps in other models) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Smina, N.; Gahi, Y.; Gharib, J. Data Management in Smart Manufacturing Supply Chains: A Systematic Review of Practices and Applications (2020–2025). Information 2026, 17, 19. https://doi.org/10.3390/info17010019

Smina N, Gahi Y, Gharib J. Data Management in Smart Manufacturing Supply Chains: A Systematic Review of Practices and Applications (2020–2025). Information. 2026; 17(1):19. https://doi.org/10.3390/info17010019

Chicago/Turabian StyleSmina, Nouhaila, Youssef Gahi, and Jihane Gharib. 2026. "Data Management in Smart Manufacturing Supply Chains: A Systematic Review of Practices and Applications (2020–2025)" Information 17, no. 1: 19. https://doi.org/10.3390/info17010019

APA StyleSmina, N., Gahi, Y., & Gharib, J. (2026). Data Management in Smart Manufacturing Supply Chains: A Systematic Review of Practices and Applications (2020–2025). Information, 17(1), 19. https://doi.org/10.3390/info17010019