Intelligent Supply Chain Management: A Systematic Literature Review on Artificial Intelligence Contributions

Abstract

1. Introduction

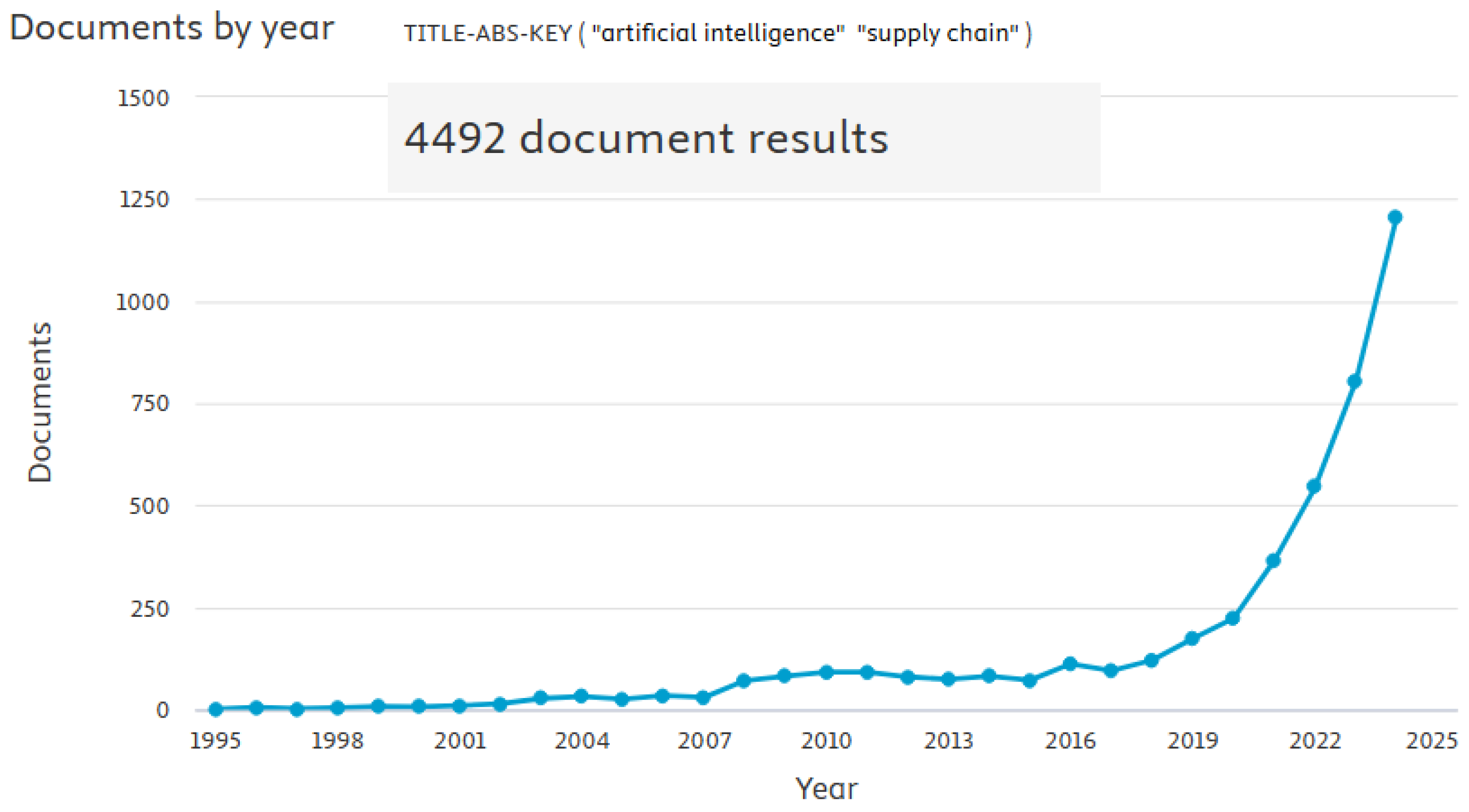

1.1. Research Territory

1.2. Previous Research

1.3. Research Objectives

- Examine the role of AI in enhancing supply chain resilience: Investigate how AI technologies contribute to improving the adaptability and recovery of supply chains in response to disruptions, including the optimization of risk management strategies and operational efficiency.

- Identify key AI-driven solutions for supply chain optimization: Analyze the specific AI techniques, such as machine learning, predictive analytics, and real-time data processing, that are currently being used to optimize critical functions in supply chain management, such as demand forecasting, inventory control, and logistics planning.

- Assess the impact of AI on sustainability in supply chains: Explore how the integration of AI in supply chains contributes to achieving sustainability goals, including economic, environmental, and social dimensions, with a particular focus on the fashion, manufacturing, and retail sectors.

- Investigate the challenges and barriers to AI implementation in supply chains: Identify the key challenges, such as scalability, ethical concerns, and integration with existing systems, that organizations face when adopting AI solutions in supply chain management.

- Outline future research directions: Identify and structure key gaps in the existing literature to propose future avenues for investigation.

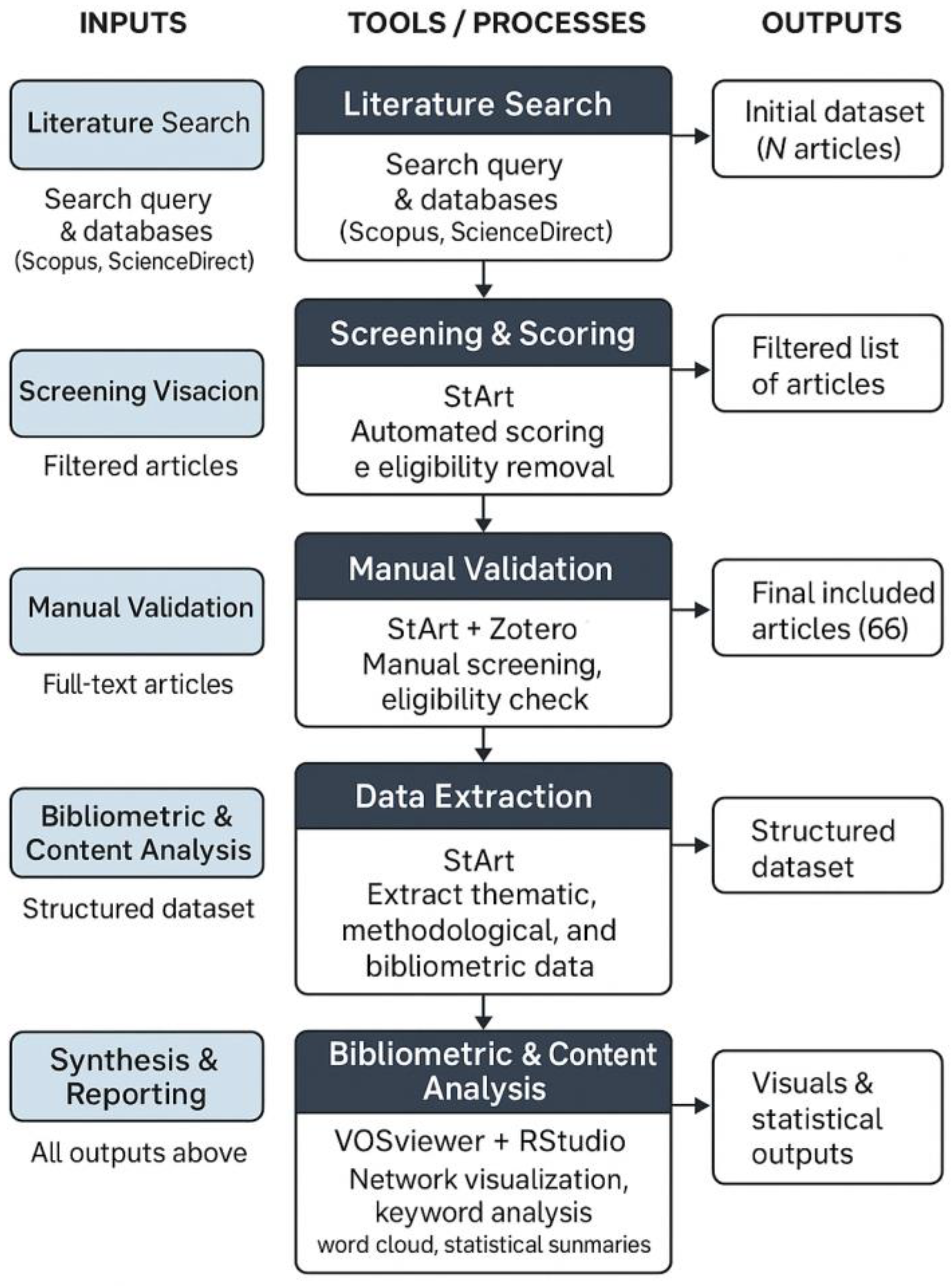

- Section 2 outlines the materials and methods used in this study, including the systematic review protocol based on the PRISMA framework, the use of tools such as StArt 2.3.4.2, Zotero 7.9.11, RStudio 4.4.2, and VOSviewer 1.6.20, the search strategy, inclusion and exclusion criteria, and the bibliometric approach adopted.

- Section 3 presents the results of the systematic literature review, offering a state-of-the-art analysis through a detailed synthesis of 66 selected articles. It includes a bibliometric overview and a classification of AI applications across various supply chain management functions and phases.

- Section 4 provides a comprehensive discussion of the main thematic findings—namely resilience, process optimization, sustainability, and implementation barriers—while also examining the role of emerging AI techniques, identifying research gaps, proposing future research directions, and discussing the theoretical and managerial implications.

- Section 5 outlines the limitations of the study, particularly regarding the scope of the databases, the dynamic evolution of the field, and the subjective nature of article selection and categorization.

- Section 6 presents the conclusion, summarizing the review and reinforcing the contribution of AI to intelligent supply chain management.

2. Materials and Methods

2.1. PRISMA Framework and StArt 2.3.4.2

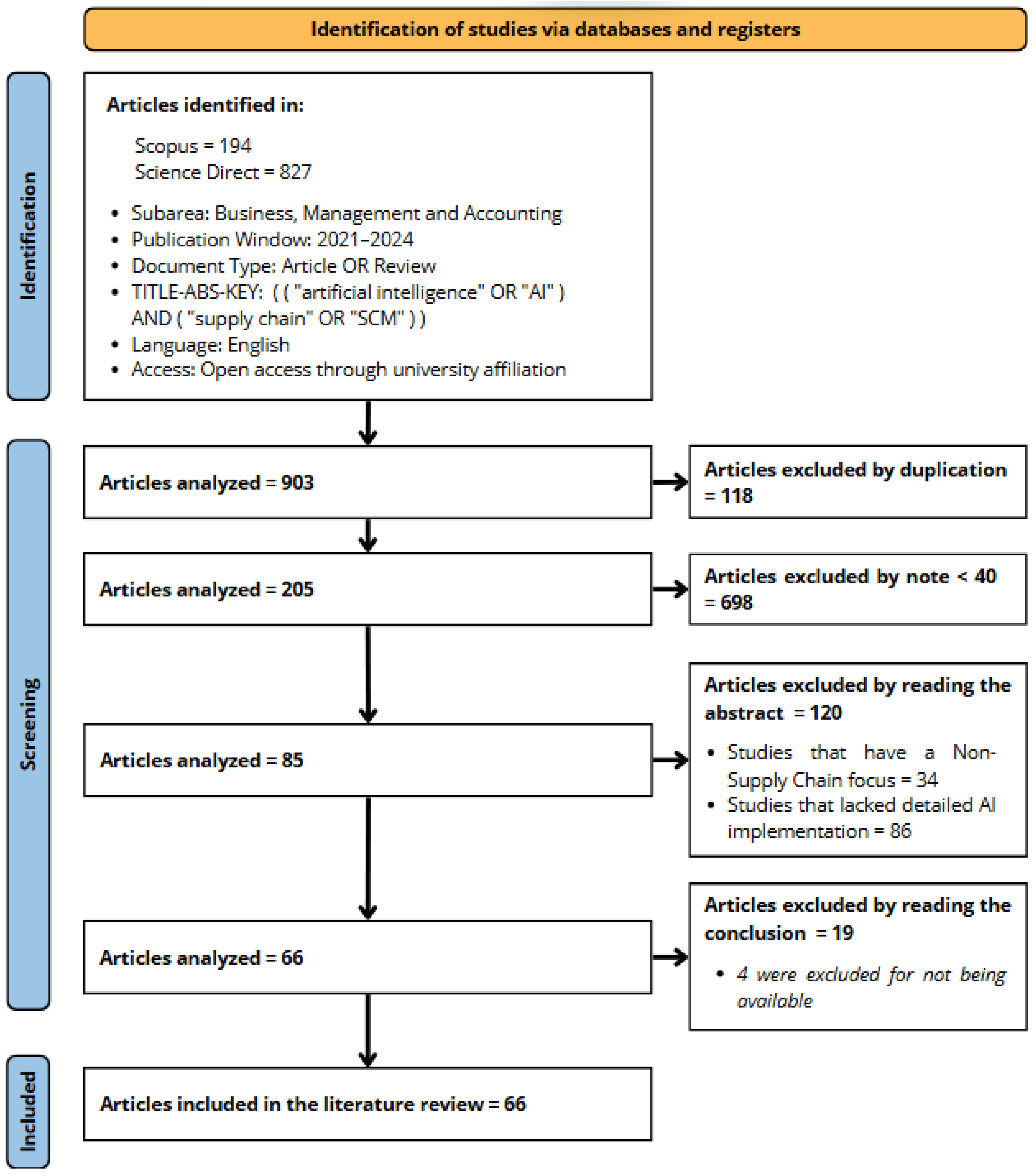

2.2. Search Strategy

- Keywords: ((“artificial intelligence” OR “AI”) AND (“supply chain” OR “SCM”)).

- Publication period: Studies published between 2021 and 2024.

- Subject area: Restricted to the Business, Management, and Accounting (BUSI) subject area.

- Document type: Limited to articles (ar) and reports (re).

- Language: Only English-language studies were included.

- Open Access: Open access articles available through the University of Aveiro library’s affiliation.

2.3. Eligibility Criteria and Data Extraction

2.4. Definitions of Key AI Technologies

- Machine Learning (ML): A subset of AI that enables systems to learn patterns from data and improve performance without being explicitly programmed. Common ML techniques include decision trees, support vector machines, and ensemble learning.

- Deep Learning (DL): A specialized form of machine learning that uses multilayered neural networks to process complex patterns in large datasets. It is particularly effective in image recognition, natural language processing, and time-series forecasting.

- Reinforcement Learning (RL): A learning paradigm where agents learn optimal actions through trial-and-error interactions with their environment, guided by reward signals. RL is widely used in dynamic and real-time optimization tasks.

- Generative AI (GAI): Refers to AI systems capable of generating new content—such as text, images, or simulations—by learning from existing data. Examples include language models like ChatGPT and generative adversarial networks (GANs).

- Explainable AI (XAI): A class of AI methods that aim to make model decisions transparent and interpretable to human users, addressing concerns related to algorithmic opacity and accountability.

- Neurosymbolic AI: An emerging hybrid approach that integrates neural networks with symbolic reasoning to combine learning capabilities with logical inference and explainability.

- Graph Neural Networks (GNNs): A type of neural network designed to operate on graph-structured data, enabling the modeling of relationships and dependencies, such as those found in complex supply networks.

- Federated Learning: A decentralized machine learning technique where models are trained across multiple devices or organizations without centralizing data, thereby enhancing privacy and data security.

- Digital Twins: Virtual replicas of physical supply chain systems that integrate real-time data and AI to simulate, predict, and optimize operations under various conditions.

3. Results—State of the Art

- AI Technique: Identifies the specific artificial intelligence methods used in each study (e.g., machine learning, deep learning, reinforcement learning, generative AI, explainable AI, neurosymbolic AI).

- SCM Application: Describes the functional objective within the supply chain, such as demand forecasting, risk management, logistics planning, inventory optimization, or sustainability enhancement.

- SCM Phase: Indicates the specific phase(s) of the supply chain addressed by the AI application, using the extended SCOR model (Plan, Source, Make, Deliver, Return, and Enable).

- Reported Benefits: Summarizes the main operational, strategic, or environmental advantages observed in each study.

- Limitations: Highlights key constraints, including methodological weaknesses, narrow contexts, or absence of real-world validation.

- Potential Biases: Notes possible distortions, such as survey self-reporting, limited geographic scope, or reliance on simulated data.

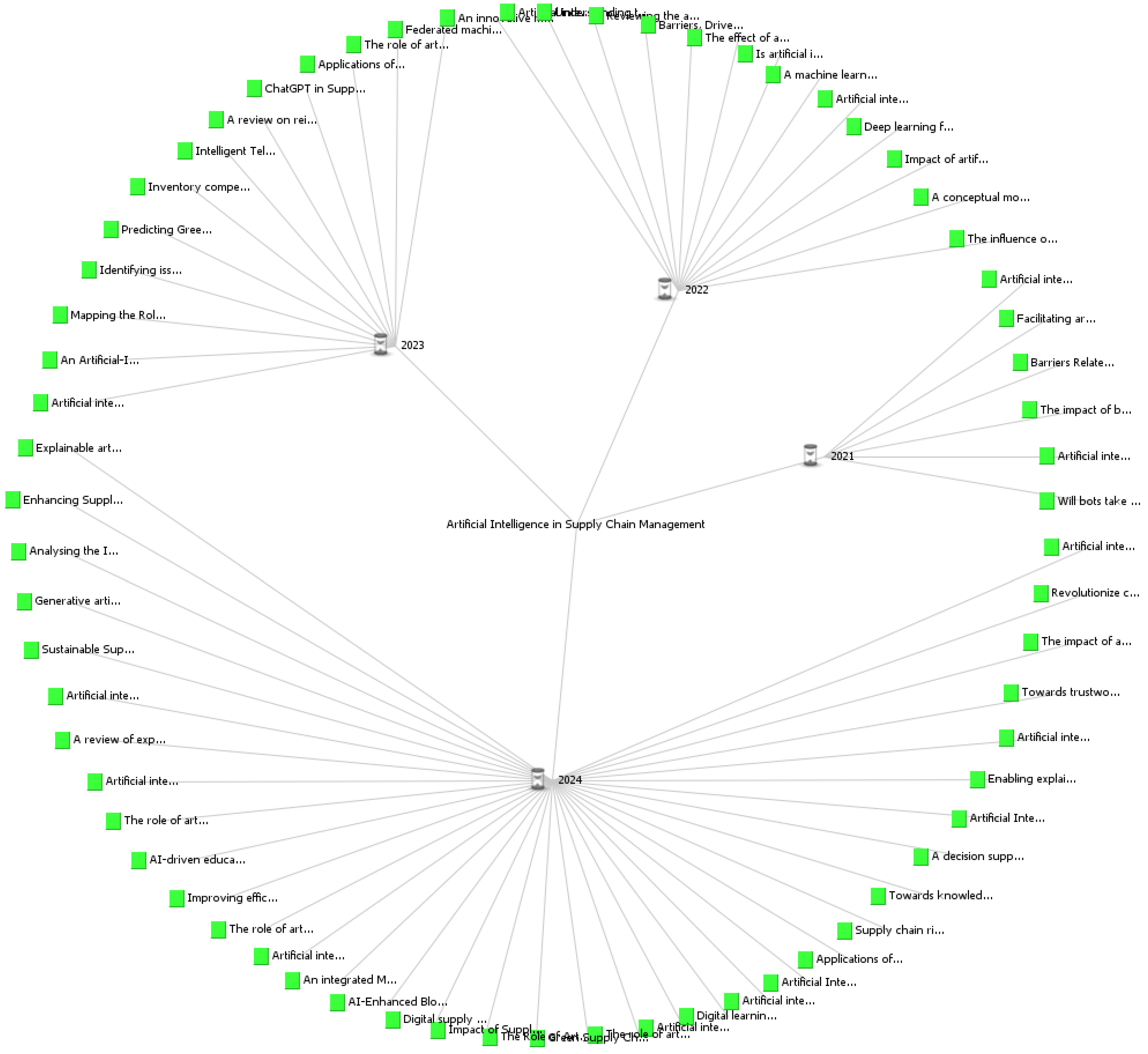

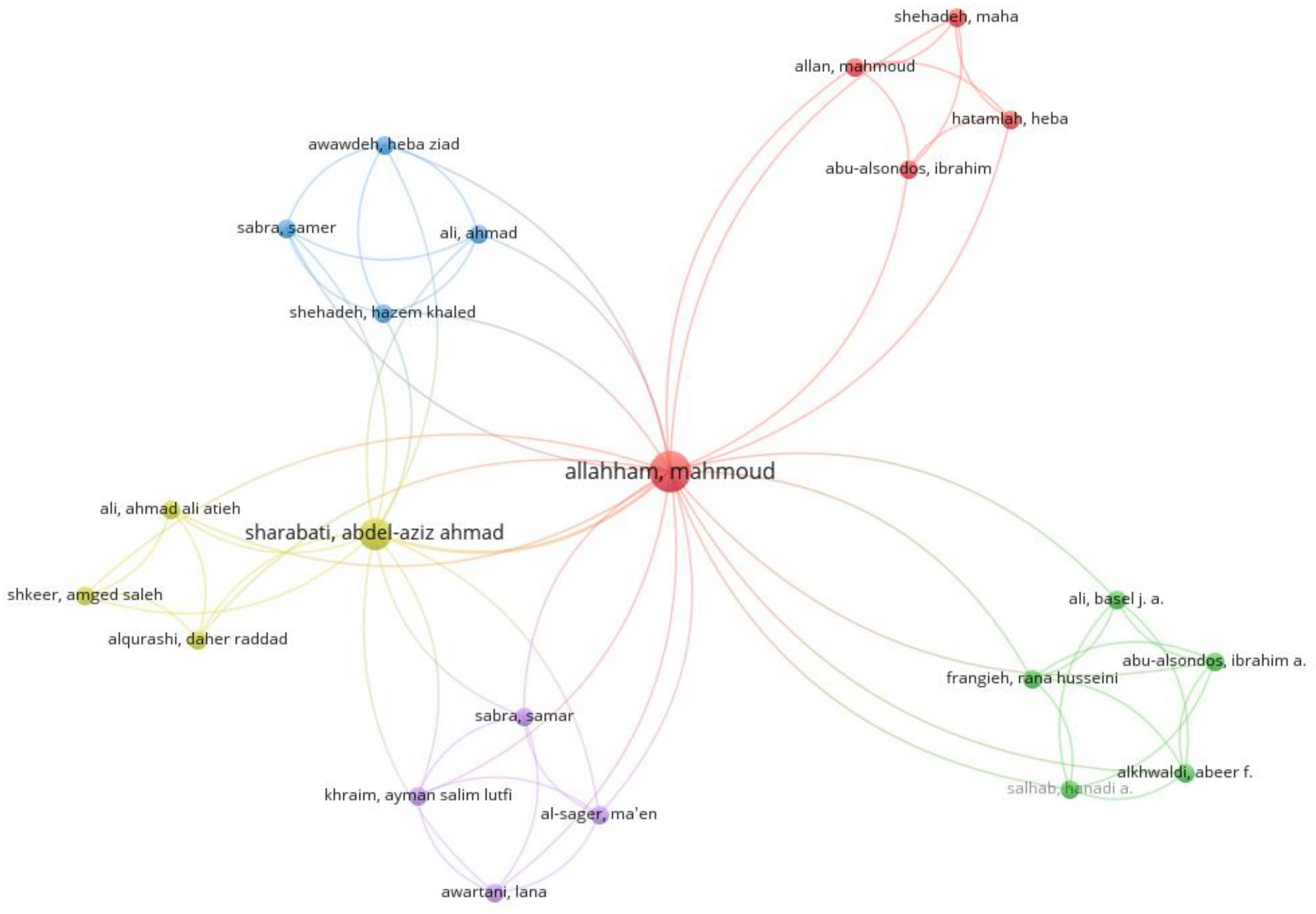

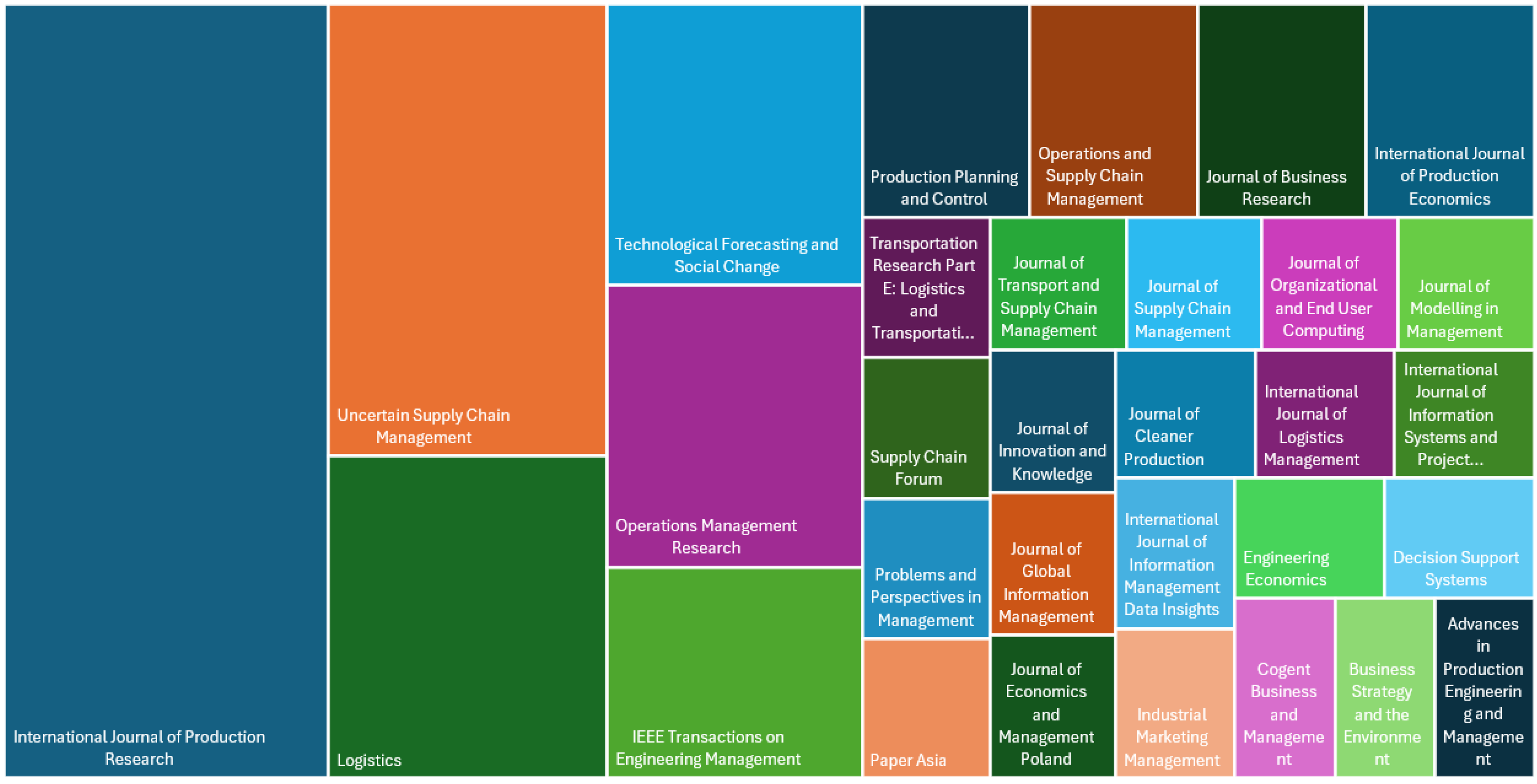

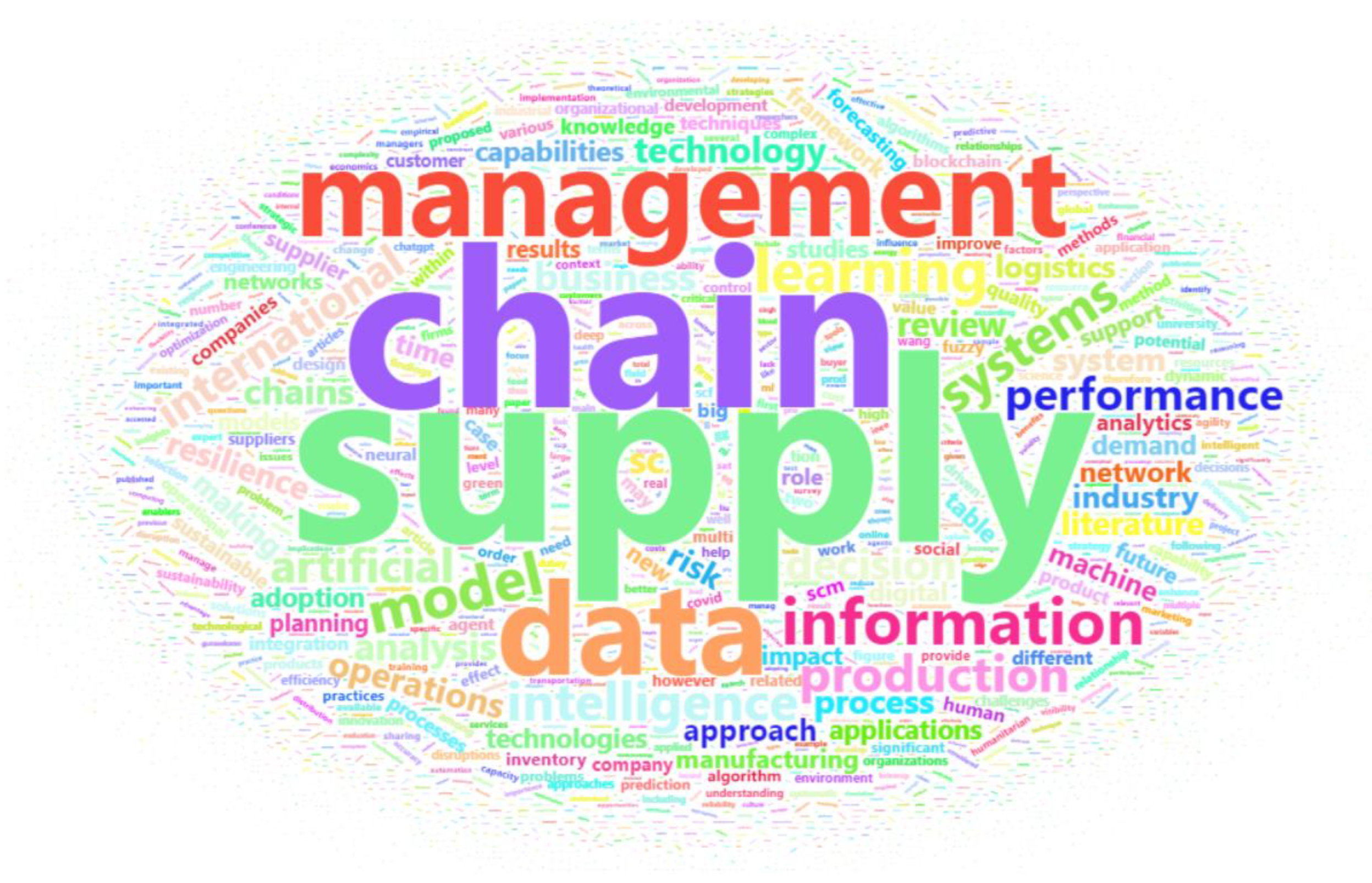

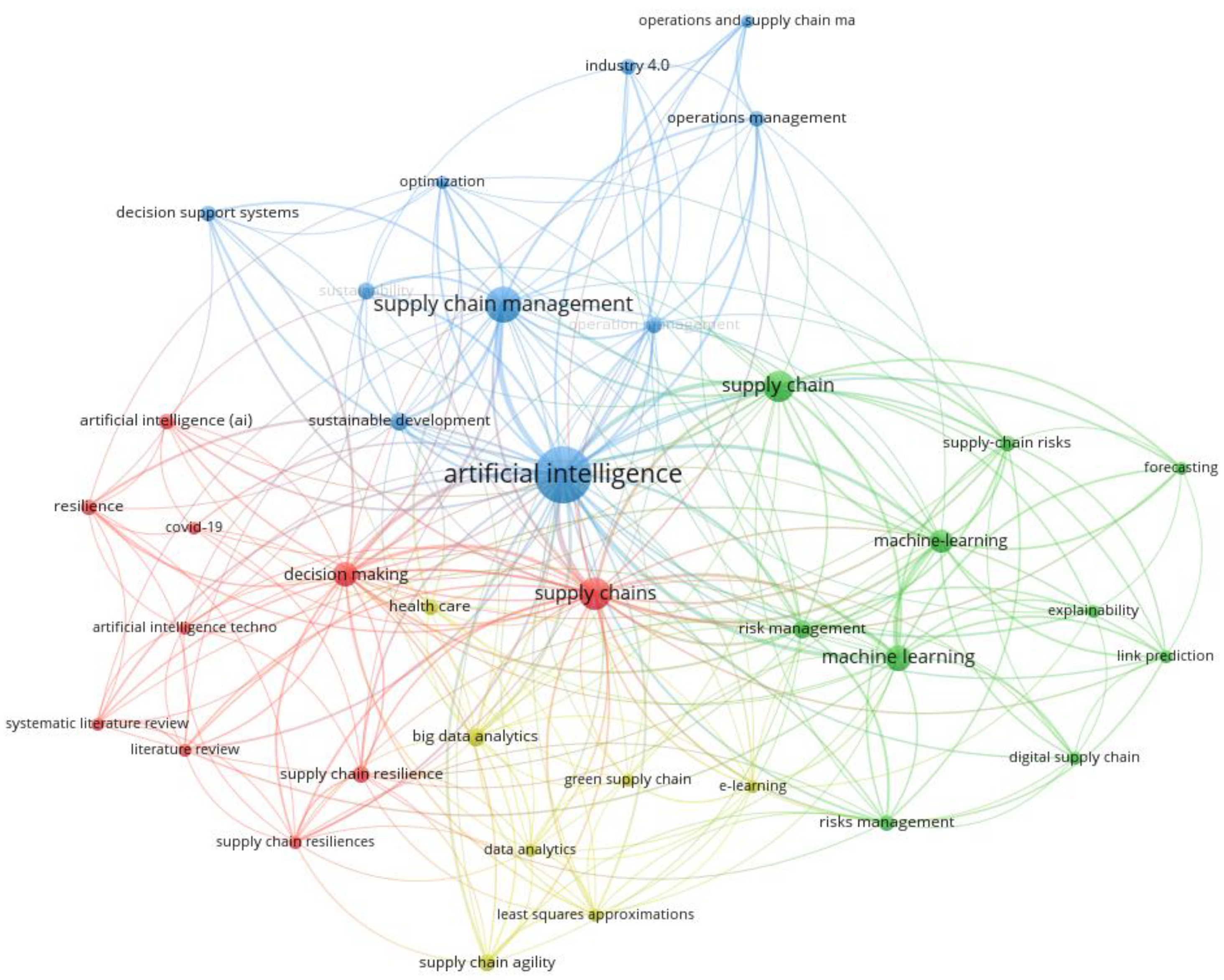

3.1. Bibliometric Analysis

- The blue cluster centers around “supply chain management”, “decision support systems”, and “optimization”, indicating a stream of research concerned with operational performance and planning.

- The green cluster highlights “machine learning”, “forecasting”, and “risk management”, pointing to predictive analytics and data-driven risk mitigation approaches.

- The red cluster links “resilience”, “COVID-19”, and “decision making”, suggesting a focus on adaptive strategies under uncertainty and disruption.

- The yellow cluster includes terms such as “big data analytics”, “green supply chain”, and “sustainability”, showing intersections between digital transformation and environmental objectives.

- Section 3.2—Enhancing Supply Chain Resilience examines how AI technologies contribute to risk mitigation, agility, and recovery capabilities across supply chains. This theme is strongly aligned with a co-occurrence cluster centered on keywords such as “machine learning”, “forecasting”, and “risk management”, reflecting the field’s focus on predictive analytics and resilience-building.

- Section 3.3—Optimizing Supply Chain Processes explores the role of AI in improving forecasting accuracy, inventory control, logistics planning, and automation. This section connects directly to the cluster dominated by terms like “supply chain management”, “decision support systems”, and “optimization”, highlighting the operational and strategic performance dimensions emphasized in the literature.

- Section 3.4—Applications in Sustainability addresses the intersection between AI and environmental, social, and governance (ESG) objectives, and is mapped to a distinct cluster featuring “big data analytics”, “green supply chain”, and “sustainability”, underscoring the growing importance of AI in supporting eco-efficiency and ethical practices.

- Section 3.5—Challenges and Barriers identifies critical obstacles to AI adoption, which, although thematically transversal, are also reflected in overlapping clusters that address explainability, data integration, and implementation constraints—issues that pervade multiple research streams.

- Section 3.7—Geographical and Industry-Specific Differences in AI Adoption synthesizes how regional and sectoral factors influence AI implementation, providing insights into the contextual diversity of adoption patterns.

- Section 3.8—Emerging Techniques and Future Directions outlines novel AI approaches and articulates future research needs, integrating both thematic gaps and evolving technological trajectories identified through the literature.

3.2. Enhancing Supply Chain Resilience

3.3. Optimizing Supply Chain Processes

3.4. Applications in Sustainability

3.5. Challenges and Barriers

3.6. Managing Supply Chain Dynamics and Disruptions

3.7. Geographical and Industry-Specific Differences in AI Adoption

- Southeast Asia: Vietnamese SMEs adopting AI for agility and circular economy integration [26].

3.8. Emerging Techniques and Future Directions

4. Discussion

5. Limitations

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Section and Topic | Item # | Checklist Item | Location Where Item is Reported |

|---|---|---|---|

| TITLE | |||

| Title | 1 | Identify the report as a systematic review. | Title |

| ABSTRACT | |||

| Abstract | 2 | See the PRISMA 2020 for Abstracts checklist. | Abstract |

| INTRODUCTION | |||

| Rationale | 3 | Describe the rationale for the review in the context of existing knowledge. | Section 1.1 |

| Objectives | 4 | Provide an explicit statement of the objective(s) or question(s) the review addresses. | Section 1.3 |

| METHODS | |||

| Eligibility criteria | 5 | Specify the inclusion and exclusion criteria for the review and how studies were grouped for the syntheses. | Section 2.3 |

| Information sources | 6 | Specify all databases, registers, websites, organizations, reference lists and other sources searched or consulted to identify studies. Specify the date when each source was last searched or consulted. | Section 2.2 |

| Search strategy | 7 | Present the full search strategies for all databases, registers and websites, including any filters and limits used. | Section 2.2 |

| Selection process | 8 | Specify the methods used to decide whether a study met the inclusion criteria of the review, including how many reviewers screened each record and each report retrieved, whether they worked independently, and if applicable, details of automation tools used in the process. | Section 2.3 |

| Data collection process | 9 | Specify the methods used to collect data from reports, including how many reviewers collected data from each report, whether they worked independently, any processes for obtaining or confirming data from study investigators, and if applicable, details of automation tools used in the process. | Section 2.3 |

| Data items | 10a | List and define all outcomes for which data were sought. Specify whether all results that were compatible with each outcome domain in each study were sought (e.g., for all measures, time points, analyses), and if not, the methods used to decide which results to collect. | Section 3.1 |

| 10b | List and define all other variables for which data were sought (e.g., participant and intervention characteristics, funding sources). Describe any assumptions made about any missing or unclear information. | Section 3.1 | |

| Study risk of bias assessment | 11 | Specify the methods used to assess risk of bias in the included studies, including details of the tool(s) used, how many reviewers assessed each study and whether they worked independently, and if applicable, details of automation tools used in the process. | Section 2.3 |

| Effect measures | 12 | Specify for each outcome the effect measure(s) (e.g., risk ratio, mean difference) used in the synthesis or presentation of results. | Section 3 |

| Synthesis methods | 13a | Describe the processes used to decide which studies were eligible for each synthesis (e.g., tabulating the study intervention characteristics and comparing against the planned groups for each synthesis (item #5)). | Section 2.3 |

| 13b | Describe any methods required to prepare the data for presentation or synthesis, such as handling of missing summary statistics, or data conversions. | Section 2.3 | |

| 13c | Describe any methods used to tabulate or visually display results of individual studies and syntheses. | Tables and Figures throughout the article | |

| 13d | Describe any methods used to synthesize results and provide a rationale for the choice(s). If meta-analysis was performed, describe the model(s), method(s) to identify the presence and extent of statistical heterogeneity, and software package(s) used. | Section 3 | |

| 13e | Describe any methods used to explore possible causes of heterogeneity among study results (e.g., subgroup analysis, meta-regression). | Section 3 | |

| 13f | Describe any sensitivity analyses conducted to assess robustness of the synthesized results. | Section 3 | |

| Reporting bias assessment | 14 | Describe any methods used to assess risk of bias due to missing results in a synthesis (arising from reporting biases). | Section 2.3 |

| Certainty assessment | 15 | Describe any methods used to assess certainty (or confidence) in the body of evidence for an outcome. | Section 4 |

| RESULTS | |||

| Study selection | 16a | Describe the results of the search and selection process, from the number of records identified in the search to the number of studies included in the review, ideally using a flow diagram. | PRISMA Flowchart (Figure 3) |

| 16b | Cite studies that might appear to meet the inclusion criteria, but which were excluded, and explain why they were excluded. | Section 2.3 | |

| Study characteristics | 17 | Cite each included study and present its characteristics. | Section 3.1 |

| Risk of bias in studies | 18 | Present assessments of risk of bias for each included study. | Section 2.3 |

| Results of individual studies | 19 | For all outcomes, present, for each study: (a) summary statistics for each group (where appropriate) and (b) an effect estimate and its precision (e.g., confidence/credible interval), ideally using structured tables or plots. | Section 3 |

| Results of syntheses | 20a | For each synthesis, briefly summarize the characteristics and risk of bias among contributing studies. | Section 3 |

| 20b | Present results of all statistical syntheses conducted. If meta-analysis was performed, present for each the summary estimate and its precision (e.g., confidence/credible interval) and measures of statistical heterogeneity. If comparing groups, describe the direction of the effect. | Section 3 | |

| 20c | Present results of all investigations of possible causes of heterogeneity among study results. | Section 3 | |

| 20d | Present results of all sensitivity analyses conducted to assess the robustness of the synthesized results. | Section 3 | |

| Reporting biases | 21 | Present assessments of risk of bias due to missing results (arising from reporting biases) for each synthesis assessed. | Section 2.3 |

| Certainty of evidence | 22 | Present assessments of certainty (or confidence) in the body of evidence for each outcome assessed. | Section 4 |

| DISCUSSION | |||

| Discussion | 23a | Provide a general interpretation of the results in the context of other evidence. | Section 4 |

| 23b | Discuss any limitations of the evidence included in the review. | Section 4 | |

| 23c | Discuss any limitations of the review processes used. | Section 4 | |

| 23d | Discuss implications of the results for practice, policy, and future research. | Section 4 | |

| OTHER INFORMATION | |||

| Registration and protocol | 24a | Provide registration information for the review, including register name and registration number, or state that the review was not registered. | Section 2 |

| 24b | Indicate where the review protocol can be accessed, or state that a protocol was not prepared. | Section 2 | |

| 24c | Describe and explain any amendments to information provided at registration or in the protocol. | Section 2 | |

| Support | 25 | Describe sources of financial or non-financial support for the review, and the role of the funders or sponsors in the review. | “Acknowledgments” section |

| Competing interests | 26 | Declare any competing interests of review authors. | “Conflicts of Interest” section |

| Availability of data, code and other materials | 27 | Report which of the following are publicly available and where they can be found: template data collection forms; data extracted from included studies; data used for all analyses; analytic code; any other materials used in the review. | “Data Availability Statement” section |

References

- Pap, J.; Hegedűs, C.; Palkovics, E.; Miskolczi, M.; Katalin, T. Enhancing supply chain safety and security: A novel AI-assisted supplier selection method. Decis. Mak. Appl. Manag. Eng. 2024, 8, 22–41. [Google Scholar] [CrossRef]

- Espina-Romero, L.; Gutiérrez Hurtado, H.; Ríos Parra, D.; Vilchez Pirela, R.A.; Talavera-Aguirre, R.; Ochoa-Díaz, A. Challenges and opportunities in the implementation of AI in manufacturing: A bibliometric analysis. Sci 2024, 6, 60. [Google Scholar] [CrossRef]

- Riad, M.; Naimi, M.; Okar, C. Enhancing supply chain resilience through artificial intelligence: Developing a comprehensive conceptual framework for AI implementation and supply chain optimization. Logistics 2024, 8, 111. [Google Scholar] [CrossRef]

- Nozari, H.; Abdi, H.; Szmelter-Jarosz, A.; Motevalli, S.H. Design of dual-channel supply chain network based on the Internet of Things under uncertainty. Math. Comput. Appl. 2024, 29, 118. [Google Scholar] [CrossRef]

- Aburayya, A. Analysing the influence of augmented reality on organization performance via supply and logistics value chain functions: A hybrid ANN-PLS model assessment in the Gulf Cooperation Council region. Logistics 2024, 8, 110. [Google Scholar] [CrossRef]

- Hajipour Machiani, N.; Taleizadeh, A.A.; Toloo, M.; Abedsoltan, H. Designing a new sustainable healthcare network considering the COVID-19 pandemic: Artificial intelligence-based solutions. Expert Syst. Appl. 2025, 260, 125357. [Google Scholar] [CrossRef]

- Zaid, M.; Farooqi, R.; Azmi, S.N. Driving sustainable supply chain performance through digital transformation: The role of information exchange and responsiveness. Cogent Bus. Manag. 2024, 12, 2443047. [Google Scholar] [CrossRef]

- Alon, I.; Haidar, H.; Haidar, A.; Guimón, J. The future of artificial intelligence: Insights from recent Delphi studies. Futures 2025, 165, 103514. [Google Scholar] [CrossRef]

- Haque, A.; Akther, N.; Khan, I.; Agarwal, K.; Uddin, N. Artificial intelligence in retail marketing: Research agenda based on bibliometric reflection and content analysis (2000–2023). Informatics 2024, 11, 74. [Google Scholar] [CrossRef]

- Toorajipour, R.; Sohrabpour, V.; Nazarpour, A.; Oghazi, P.; Fischl, M. Artificial intelligence in supply chain management: A systematic literature review. J. Bus. Res. 2021, 122, 502–517. [Google Scholar] [CrossRef]

- Smyth, C.; Dennehy, D.; Wamba, S.F.; Scott, M.; Harfouche, A. Artificial intelligence and prescriptive analytics for supply chain resilience: A systematic literature review and research agenda. Int. J. Prod. Res. 2024, 62, 8537–8561. [Google Scholar] [CrossRef]

- Rolf, B.; Jackson, I.; Müller, M.; Lang, S.; Reggelin, T.; Ivanov, D. A review on reinforcement learning algorithms and applications in supply chain management. Int. J. Prod. Res. 2023, 61, 7151–7179. [Google Scholar] [CrossRef]

- Jahin, M.A.; Naife, S.A.; Saha, A.K.; Mridha, M.F. AI in supply chain risk assessment: A systematic literature review and bibliometric analysis. arXiv 2025, arXiv:2401.10895v5. [Google Scholar]

- Hao, X.; Demir, E. Artificial intelligence in supply chain decision-making: An environmental, social, and governance triggering and technological inhibiting protocol. J. Model. Manag. 2024, 19, 605–629. [Google Scholar] [CrossRef]

- Liberati, A.; Altman, D.G.; Tetzlaff, J.; Mulrow, C.; Gøtzsche, P.C.; Ioannidis, J.P.A.; Clarke, M.; Devereaux, P.J.; Kleijnen, J.; Moher, D. The PRISMA statement for reporting systematic reviews and meta-analyses of studies that evaluate healthcare interventions: Explanation and elaboration. BMJ 2009, 339, b2700. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Carreira, R.J.; Ferreira, J.V.; Ramos, A.L. The consumer’s role in the transition to the circular economy: A state of the art based on a SLR with bibliometric analysis. Sustainability 2023, 15, 15040. [Google Scholar] [CrossRef]

- Ali, A.A.A.; Sharabati, A.-A.A.; Alqurashi, D.R.; Shkeer, A.S.; Allahham, M. The impact of artificial intelligence and supply chain collaboration on supply chain resilience: Mediating the effects of information sharing. Uncertain Supply Chain Manag. 2024, 12, 1801–1812. [Google Scholar] [CrossRef]

- Kosasih, E.E.; Brintrup, A. Towards trustworthy AI for link prediction in supply chain knowledge graph: A neurosymbolic reasoning approach. Int. J. Prod. Res. 2025, 63, 2268–2290. [Google Scholar] [CrossRef]

- Hirsch, K.; Niemann, W.; Swart, B. Artificial intelligence and information systems capabilities for supply chain resilience: A study in the South African fast-moving consumer goods industry. J. Transp. Supply Chain. Manag. 2024, 18, 1025. [Google Scholar] [CrossRef]

- Gupta, S.; Modgil, S.; Meissonier, R.; Dwivedi, Y.K. Artificial intelligence and information system resilience to cope with supply chain disruption. IEEE Trans. Eng. Manag. 2024, 71, 10496–10506. [Google Scholar] [CrossRef]

- Barhmi, A.; Slamti, F.; Laghzaoui, S.; Rouijel, M.R. Digital learning, big data analytics and mechanisms for stabilizing and improving supply chain performance. Int. J. Inf. Syst. Proj. Manag. 2024, 12, 30–47. [Google Scholar] [CrossRef]

- Dubey, R.; Bryde, D.J.; Dwivedi, Y.K.; Graham, G.; Foropon, C. Impact of artificial intelligence-driven big data analytics culture on agility and resilience in humanitarian supply chain: A practice-based view. Int. J. Prod. Econ. 2022, 250, 108618. [Google Scholar] [CrossRef]

- Isaid, E.N.; Abdullah, R.; Shahron, S.A. Impact of supply chain agility and collaboration on supply chain performance: The moderating role of artificial intelligence. PaperASIA 2024, 40, 264–273. [Google Scholar] [CrossRef]

- Wong, L.-W.; Tan, G.W.-H.; Ooi, K.-B.; Lin, B.; Dwivedi, Y.K. Artificial intelligence-driven risk management for enhancing supply chain agility: A deep-learning-based dual-stage PLS-SEM-ANN analysis. Int. J. Prod. Res. 2022, 62, 5535–5555. [Google Scholar] [CrossRef]

- Dey, P.K.; Chowdhury, S.; Abadie, A.; Vann Yaroson, E.; Sarkar, S. Artificial intelligence-driven supply chain resilience in Vietnamese manufacturing small- and medium-sized enterprises. Int. J. Prod. Res. 2023, 62, 5417–5456. [Google Scholar] [CrossRef]

- Modgil, S.; Singh, R.K.; Hannibal, C. Artificial intelligence for supply chain resilience: Learning from COVID-19. Int. J. Logist. Manag. 2022, 33, 1246–1268. [Google Scholar] [CrossRef]

- Dubey, R.; Bryde, D.J.; Blome, C.; Roubaud, D.; Giannakis, M. Facilitating artificial intelligence powered supply chain analytics through alliance management during the pandemic crises in the B2B context. Ind. Mark. Manag. 2021, 96, 135–146. [Google Scholar] [CrossRef]

- Naz, F.; Kumar, A.; Majumdar, A.; Agrawal, R. Is artificial intelligence an enabler of supply chain resiliency post COVID-19? An exploratory state-of-the-art review for future research. Oper. Manag. Res. 2021, 15, 378–398. [Google Scholar] [CrossRef]

- Sadeghi, K.R.; Ojha, D.; Kaur, P.; Mahto, R.V.; Dhir, A. Explainable artificial intelligence and agile decision-making in supply chain cyber resilience. Decis. Support Syst. 2024, 180, 114194. [Google Scholar] [CrossRef]

- Wang, W.; Chen, Y.; Wang, Y.; Deveci, M.; Cheng, S.; Brito-Parada, P.R. A decision support framework for humanitarian supply chain management—Analysing enablers of AI-HI integration using a complex spherical fuzzy DEMATEL-MARCOS method. Technol. Forecast. Soc. Chang. 2024, 206, 123556. [Google Scholar] [CrossRef]

- Kosasih, E.E.; Margaroli, F.; Gelli, S.; Aziz, A.; Wildgoose, N.; Brintrup, A. Towards knowledge graph reasoning for supply chain risk management using graph neural networks. Int. J. Prod. Res. 2022, 62, 5596–5612. [Google Scholar] [CrossRef]

- Pereira, E.T.; Shafique, M.N. The role of artificial intelligence in supply chain agility: A perspective of humanitarian supply chain. Eng. Econ. 2024, 35, 77–89. [Google Scholar] [CrossRef]

- Ghouri, A.M.; Khan, H.R.; Mani, V.; ul Haq, M.A.; Lopes de Sousa Jabbour, A.B. An artificial-intelligence-based omni-channel blood supply chain: A pathway for sustainable development. J. Bus. Res. 2023, 164, 113980. [Google Scholar] [CrossRef]

- Zheng, G.; Kong, L.; Brintrup, A. Federated machine learning for privacy preserving, collective supply chain risk prediction. Int. J. Prod. Res. 2023, 61, 8115–8132. [Google Scholar] [CrossRef]

- Shamout, M.; Ben-Abdallah, R.; Alshurideh, M.; Alzoubi, H.; Kurdi, B.A.; Hamadneh, S. A conceptual model for the adoption of autonomous robots in supply chain and logistics industry. Uncertain Supply Chain Manag. 2022, 10, 577–592. [Google Scholar] [CrossRef]

- Damoah, I.S.; Ayakwah, A.; Tingbani, I. Artificial intelligence (AI)-enhanced medical drones in the healthcare supply chain (HSC) for sustainability development: A case study. J. Clean. Prod. 2021, 328, 129598. [Google Scholar] [CrossRef]

- Kosasih, E.E.; Brintrup, A. A machine learning approach for predicting hidden links in supply chain with graph neural networks. Int. J. Prod. Res. 2021, 60, 5380–5393. [Google Scholar] [CrossRef]

- Allahham, M.; Sharabati, A.-A.A.; Al-Sager, M.; Sabra, S.; Awartani, L.; Khraim, A.S.L. Supply chain risks in the age of big data and artificial intelligence: The role of risk alert tools and managerial apprehensions. Uncertain Supply Chain. Manag. 2024, 12, 399–406. [Google Scholar] [CrossRef]

- Brintrup, A.; Kosasih, E.; Schaffer, P.; Zheng, G.; Demirel, G.; MacCarthy, B.L. Digital supply chain surveillance using artificial intelligence: Definitions, opportunities and risks. Int. J. Prod. Res. 2023, 62, 4674–4695. [Google Scholar] [CrossRef]

- Jackson, I.; Namdar, J.; Saénz, M.J.; Elmquist, R.A., III; Dávila Novoa, L.R. Revolutionize cold chain: An AI/ML driven approach to overcome capacity shortages. Int. J. Prod. Res. 2025, 63, 2190–2212. [Google Scholar] [CrossRef]

- Nguyen, T.T.H. Applications of artificial intelligence for demand forecasting. Oper. Supply Chain. Manag. Int. J. 2023, 16, 424–434. [Google Scholar] [CrossRef]

- Jackson, I.; Ivanov, D.; Dolgui, A.; Namdar, J. Generative artificial intelligence in supply chain and operations management: A capability-based framework for analysis and implementation. Int. J. Prod. Res. 2024, 62, 6120–6145. [Google Scholar] [CrossRef]

- Lin, H.; Lin, J.; Wang, F. An innovative machine learning model for supply chain management. J. Innov. Knowl. 2022, 7, 100276. [Google Scholar] [CrossRef]

- Cannas, V.G.; Ciano, M.P.; Saltalamacchia, M.; Secchi, R. Artificial intelligence in supply chain and operations management: A multiple case study research. Int. J. Prod. Res. 2023, 62, 3333–3360. [Google Scholar] [CrossRef]

- Abdelhamid, M.M.; Sliman, L.; Ben Djemaa, R. AI-enhanced blockchain for scalable IoT-based supply chain. Logistics 2024, 8, 109. [Google Scholar] [CrossRef]

- Dalal, S.; Lilhore, U.K.; Simaiya, S.; Radulescu, M.; Belascu, L. Improving efficiency and sustainability via supply chain optimization through CNNs and BiLSTM. Technol. Forecast. Soc. Chang. 2024, 209, 123841. [Google Scholar] [CrossRef]

- Hejazi, M.; Alrusaini, O.; Beyari, H. The effect of artificial intelligence and payment flexibility on operational performance: The enabling role of supply chain risk management. Uncertain Supply Chain Manag. 2022, 10, 1117–1130. [Google Scholar] [CrossRef]

- Xu, L.; Mak, S.; Brintrup, A. Will bots take over the supply chain? Revisiting agent-based supply chain automation. Int. J. Prod. Econ. 2021, 241, 108279. [Google Scholar] [CrossRef]

- Alnadi, M.; Altahat, S. Artificial intelligence applications for enhancing organizational excellence: Modifying role of supply chain agility. Probl. Perspect. Manag. 2024, 22, 339–351. [Google Scholar] [CrossRef]

- Sharabati, A.-A.A.; Awawdeh, H.Z.; Sabra, S.; Shehadeh, H.K.; Allahham, M.; Ali, A. The role of artificial intelligence on digital supply chain in industrial companies: Mediating effect of operational efficiency. Uncertain Supply Chain Manag. 2024, 12, 1867–1878. [Google Scholar] [CrossRef]

- Frederico, G.F. ChatGPT in supply chains: Initial evidence of applications and potential research agenda. Logistics 2023, 7, 26. [Google Scholar] [CrossRef]

- Helo, P.; Hao, Y. Artificial intelligence in operations management and supply chain management: An exploratory case study. Prod. Plan. Control 2021, 33, 1573–1590. [Google Scholar] [CrossRef]

- Olan, F.; Arakpogun, E.O.; Jayawickrama, U.; Suklan, J.; Liu, S. Sustainable supply chain finance and supply networks: The role of artificial intelligence. IEEE Trans. Eng. Manag. 2024, 71, 13296–13311. [Google Scholar] [CrossRef]

- Zhao, G.; Shi, H.B.; Wang, J.F. The influence of artificial intelligence technology judicial decision reasoning on contract performance in manufacturing supply chain: A simulation analysis using evolutionary game approach. Adv. Prod. Eng. Manag. 2022, 17, 108–120. [Google Scholar] [CrossRef]

- Salhab, H.A.; Allahham, M.; Abu-AlSondos, I.A.; Frangieh, R.H.; Alkhwaldi, A.F.; Ali, B.J.A. Inventory competition, artificial intelligence, and quality improvement decisions in supply chains with digital marketing. Uncertain Supply Chain Manag. 2023, 11, 1915–1924. [Google Scholar] [CrossRef]

- Olan, F.; Spanaki, K.; Ahmed, W.; Zhao, G. Enabling explainable artificial intelligence capabilities in supply chain decision support making. Prod. Plan. Control 2025, 36, 808–819. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Govindan, K.; Ghosh Dastidar, S.; Sharma, P. Applications of artificial intelligence in closed-loop supply chains: Systematic literature review and future research agenda. Transp. Res. Part E Logist. Transp. Rev. 2024, 184, 103455. [Google Scholar] [CrossRef]

- Virmani, N.; Singh, R.K.; Agarwal, V.; Aktas, E. Artificial intelligence applications for responsive healthcare supply chains: A decision-making framework. IEEE Trans. Eng. Manag. 2024, 71, 8591–8605. [Google Scholar] [CrossRef]

- Nozari, H. Green supply chain management based on artificial intelligence of everything. J. Econ. Manag. 2024, 46, 171–188. [Google Scholar] [CrossRef]

- Li, T.; Donta, P.K. Predicting green supply chain impact with SNN-stacking model in digital transformation context. J. Organ. End User Comput. 2023, 35, 1–19. [Google Scholar] [CrossRef]

- Dohale, V.; Kamble, S.; Ambilkar, P.; Gold, S.; Belhadi, A. An integrated MCDM-ML approach for predicting the carbon neutrality index in manufacturing supply chains. Technol. Forecast. Soc. Chang. 2024, 201, 123243. [Google Scholar] [CrossRef]

- Naz, F.; Agrawal, R.; Kumar, A.; Gunasekaran, A.; Majumdar, A.; Luthra, S. Reviewing the applications of artificial intelligence in sustainable supply chains: Exploring research propositions for future directions. Bus. Strategy Environ. 2022, 31, 2400–2423. [Google Scholar] [CrossRef]

- Benzidia, S.; Makaoui, N.; Bentahar, O. The impact of big data analytics and artificial intelligence on green supply chain process integration and hospital environmental performance. Technol. Forecast. Soc. Chang. 2021, 165, 120557. [Google Scholar] [CrossRef]

- Jamwal, A.; Agrawal, R.; Sharma, M. Deep learning for manufacturing sustainability: Models, applications in Industry 4.0 and implications. Int. J. Inf. Manag. Data Insights 2022, 2, 100107. [Google Scholar] [CrossRef]

- Hatamlah, H.; Allan, M.; Abu-AlSondos, I.; Shehadeh, M.; Allahham, M. The role of artificial intelligence in supply chain analytics during the pandemic. Uncertain Supply Chain. Manag. 2023, 11, 1175–1186. [Google Scholar] [CrossRef]

- Rana, J.; Daultani, Y. Mapping the role and impact of artificial intelligence and machine learning applications in supply chain digital transformation: A bibliometric analysis. Oper. Manag. Res. 2022, 16, 1641–1666. [Google Scholar] [CrossRef]

- Ronchini, A.; Guida, M.; Moretto, A.; Caniato, F. The role of artificial intelligence in the supply chain finance innovation process. Oper. Manag. Res. 2024, 17, 1213–1243. [Google Scholar] [CrossRef]

- Georgiev, S.; Polychronakis, Y.; Sapountzis, S.; Polychronakis, N. The role of artificial intelligence in project management: A supply chain perspective. Supply Chain Forum Int. J. 2024, 1–14. [Google Scholar] [CrossRef]

- Purnama, I.K.E.; Wibowo, A.; Suyanto, R.M.; Hartati, S.; Lestari, S.; Fitriani, Y.; Wahyudi, R.D.; Handayani, P.W. Intelligent teledermatology system: A case of implementing artificial intelligence-based services in healthcare supply chain. Oper. Supply Chain Manag. Int. J. 2023, 16, 140–151. [Google Scholar] [CrossRef]

- Singh, A.; Dwivedi, A.; Agrawal, D.; Singh, D. Identifying issues in adoption of AI practices in construction supply chains: Towards managing sustainability. Oper. Manag. Res. 2023, 16, 1667–1683. [Google Scholar] [CrossRef]

- Raman, R.; Sreenivasan, A.; Suresh, M.; Gunasekaran, A.; Nedungadi, P. AI-driven education: A comparative study on ChatGPT and Bard in supply chain management contexts. Cogent Bus. Manag. 2024, 11, 2412742. [Google Scholar] [CrossRef]

- Shrivastav, M. Barriers related to AI implementation in supply chain management. J. Glob. Inf. Manag. 2022, 30, 1–19. [Google Scholar] [CrossRef]

- Cadden, T.; Dennehy, D.; Mantymaki, M.; Treacy, R. Understanding the influential and mediating role of cultural enablers of AI integration to supply chain. Int. J. Prod. Res. 2021, 60, 4592–4620. [Google Scholar] [CrossRef]

- Hendriksen, C. Artificial intelligence for supply chain management: Disruptive innovation or innovative disruption? J. Supply Chain Manag. 2023, 59, 65–76. [Google Scholar] [CrossRef]

- Kosasih, E.E.; Papadakis, E.; Baryannis, G.; Brintrup, A. A review of explainable artificial intelligence in supply chain management using neurosymbolic approaches. Int. J. Prod. Res. 2023, 62, 1510–1540. [Google Scholar] [CrossRef]

- Hangl, J.; Behrens, V.J.; Krause, S. Barriers, drivers, and social considerations for AI adoption in supply chain management: A tertiary study. Logistics 2022, 6, 63. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q.P.; Osei-Kyei, R. Scientometric review of global research trends on green buildings in construction journals from 1992 to 2018. Energy Build. 2019, 190, 69–85. [Google Scholar] [CrossRef]

- Zhang, R.; Gomaa, S.M.M.H.; Hussein, M.; Zayed, T.; Meguid, M. Review of numerical approaches used in soil–pipe interaction analysis of water mains. Transp. Geotech. 2023, 42, 101008. [Google Scholar] [CrossRef]

- Priore, P.; Ponte, B.; Rosillo, R.; de la Fuente, D. Applying machine learning to the dynamic selection of replenishment policies in fast-changing supply chain environments. Int. J. Prod. Res. 2019, 57, 6455–6469. [Google Scholar] [CrossRef]

- Badakhshan, E.; Ball, P. Applying digital twins for inventory and cash management in supply chains under physical and financial disruptions. Int. J. Prod. Res. 2022, 60, 7059–7079. [Google Scholar] [CrossRef]

- Ivanov, D. Predicting the impacts of epidemic outbreaks on global supply chains: A simulation-based analysis on the coronavirus outbreak (COVID-19/SARS-CoV-2) case. Transp. Res. Part E Logist. Transp. Rev. 2020, 136, 101922. [Google Scholar] [CrossRef] [PubMed]

- Yashan, N.; Samanta, K.; Sahu, S.R.; Sundari, V.M.; Dande, M.P. Blockchain and AI integration: Transforming transparency in supply chain management. Eur. Econ. Lett. 2024, 14, 1238–1247. [Google Scholar] [CrossRef]

| Inclusion Criteria (I) | Exclusion Criteria (E) | Potential Research Questions for Future Studies |

|---|---|---|

| Studies that explicitly explored AI technologies in SCM, including machine learning, deep learning, neural networks, etc. | Studies with a non-supply chain focus | How can machine learning models be adapted to handle real-time disruptions across multiple supply chain phases? |

| Studies that investigated AI implementation across different supply chain phases (Plan, Source, Make, Deliver, Return, Enable) | Studies lacking detailed analysis of AI implementation | What AI techniques are most effective in integrating circular economy principles in the ‘Return’ phase of supply chains? |

| Studies that provided insights into resilience, optimization, or sustainability through AI | Studies focusing solely on conceptual frameworks without empirical validation | How can digital twins and reinforcement learning be combined to enhance operational resilience in dynamic supply networks? |

| Studies presenting real-world applications or case-based validation of AI in SCM | Studies using purely simulated data with no discussion of real-world feasibility | What are the barriers and enablers to implementing explainable AI frameworks in sustainable supply chain decision-making? |

| (A) | |||||||

| Nº | Reference | AI Technique | SCM Application | SCM Phase | Reported Benefits | Limitations | Potential Biases |

| [3] | Riad et al. (2024) | Multiple (ML, Predictive Analytics, NLP, RPA, etc.) | Resilience: forecasting, risk mitigation, optimization | End-to-end (Plan, Source, Make, Deliver, Monitor) | Improved forecasting, risk anticipation, automation, visibility | Single case study; context-specific; needs legacy integration | Conceptual assumptions; simulation-based; digital readiness |

| [11] | Smyth et al. (2024) | ML, RL, NLP, ANN, Hybrid Models | Resilience via prescriptive analytics | Planning, Risk, Visibility, Inventory | Enhanced visibility, optimization, decision automation | Conceptual synthesis; fragmented validation | Past literature focus; no unified empirical framework |

| [18] | Ali et al. (2024) | AI (ML, Predictive Analytics, BDA, Automation) | SC resilience through collaboration and AI integration | Resilience, Planning, Coordination | Enhanced collaboration, agility, real-time decisions | Jordanian sector; survey-based; perception-driven | Regional focus; lacks deployment data |

| [19] | Kosasih & Brintrup (2024) | Neurosymbolic AI (GNN + Knowledge Graph Reasoning) | Supply chain link prediction for risk mapping | Risk Management/Network Visibility | High accuracy, explainability, scalable reasoning | Requires structured ontologies; complex implementation | Manual ontology design; limited adaptability to dynamic data |

| [20] | Hirsch et al. (2024) | AI + Info Systems | Resilience: planning, monitoring, automation | Planning, Sourcing, Risk Management | Faster decisions, improved integration, operational efficiency | FMCG sector focus; 12 interviews only | Perception-based; developing economies’ challenges |

| [21] | Gupta et al. (2024) | AI-enabled RIS (ML, NLP, Digital Twins, Blockchain) | Risk mitigation, disruption mgmt, scenario simulation | Risk Management, Planning, Crisis Response | Faster recovery, predictive capabilities, trust restoration | Qualitative; India-based manufacturing | Context-specific; expert-driven |

| [22] | Barhmi et al. (2024) | SCDA with AI (dashboards, decision tools) | Flexibility, resilience, responsiveness | Operational and Risk/Performance Mgmt | Enhanced flexibility, resilience, responsiveness, decision-making | Cross-sectional; Morocco focus; no longitudinal data | Regional; survey-based; excludes financial metrics |

| [23] | Dubey et al. (2022) | AI-BDAC (ML, NLP, cognitive computing) | Agility and resilience in humanitarian SCs | Risk, Agility, Crisis Response | Improved agility, disaster response, data-driven decisions | Humanitarian NGOs; survey-based; no tracking | Self-report; geopolitical specificity |

| [24] | Isaid et al. (2024) | AI (ML, planning, automation) | Agility, collaboration, performance (healthcare) | Planning, Resilience, Performance Mgmt | Strengthened agility and collaboration; responsiveness | Qatar healthcare; survey; no system deployment | Self-report; social desirability bias |

| [25] | Wong et al. (2024) | ANN and PLS-SEM | Risk and agility for SMEs | Risk Mgmt/Agility Enhancement | Faster decisions, predictive risk response, visibility | Malaysian SMEs; survey; no real-world testing | Self-report; geographic limitation |

| [26] | Dey et al. (2024) | AI Decision Support (conceptual + SEM) | Resilience via circular economy and agility (SMEs) | Strategic and Operational Resilience | Agility, risk mitigation, CE adoption | Vietnam SMEs; cross-sectional; no longitudinal validation | Managerial perception; lack of diversification |

| [27] | Modgil et al. (2022) | AI (ML, BDA, NLP, agent-based) | Resilience post-COVID (forecasting, delivery) | End-to-end SCM (Plan, Source, Deliver) | Transparency, agile procurement, disruption mitigation | India-centric; interviews; qualitative coding | Perception-based; lacks real-time validation |

| [28] | Dubey et al. (2021) | AI-SCAC (Cognitive Tech) | Performance via alliance mgmt in crises | Strategic and Operational Planning | SC agility, better decisions, performance under uncertainty | Indian auto industry; survey; no longitudinal analysis | Industry-specific; self-report bias |

| [29] | Naz et al. (2021) | Multiple (ML, DL, Fuzzy Logic, STM, etc.) | Risk mgmt and resilience post-COVID | Risk, Strategic Resilience, Recovery | Preparedness, forecasting, resilience modeling | Review-based; no empirical deployment | Keyword bias; COVID-19 focus |

| [30] | Sadeghi et al. (2024) | XAI (LIME, LRP, DeepLIFT) | Cyber resilience and agile decision-making | Risk/Cyber Resilience/Decision Support | Transparency, fast decisions, enhanced cyber response | Experimental; US sample; simulation-based | Survey design; no operational deployment |

| [31] | Wang et al. (2024) | Hybrid AI–Human Integration (CSF-DEMATEL-MARCOS) | Enabler assessment in humanitarian SCM | Preparedness, Response, Recovery | Better decision support, coordination, efficiency | Expert judgment; no operational validation | Cognitive bias; regional variation |

| [32] | Kosasih et al. (2024) | Neurosymbolic AI (Graph Neural Networks + Knowledge Graphs) | Risk management via link prediction and hidden relationship discovery | Risk Monitoring/Visibility | Enhanced visibility, hidden risk detection, explainability | Needs structured data; manual ontology | Dataset-dependent; limited dynamic adaptability |

| [33] | Pereira & Shafique (2024) | AI-BDAC | Agility and collaboration in humanitarian SCM | Disaster Relief/Agility | Improved agility, coordination, responsiveness | NGOs in Pakistan; survey-based | Perception-based; lacks generalizability |

| [34] | Ghouri et al. (2023) | ML (LSTM, RF, CART, k-NN, Transfer Learning) | Omnichannel blood SC optimization | Humanitarian Logistics/Emergency Response | Forecast accuracy, better inventory and response | Four hospitals in Pakistan; time-intensive retraining | Context-specific; operational constraints |

| [35] | Zheng et al. (2023) | Federated Machine Learning | Risk prediction (delivery delays) | Risk Management/Resilience | Enhanced prediction with data privacy | Complex coordination; data quality dependency | May underperform with imbalanced data |

| [36] | Shamout et al. (2022) | Autonomous Robots | Adoption of autonomous robots | Strategic and Logistics Operations | Resource allocation, cost-efficiency, operational autonomy | MENA-focused; survey-based; no longitudinal data | Self-reporting bias; regional context |

| [37] | Damoah et al. (2021) | AI-Enhanced Medical Drones | Delivery of medical supplies to remote areas | Logistics and Last-Mile (Healthcare SCM) | Reduced mortality, faster response, emissions reduction | Ghana-focused; qualitative; no control group | Context-specific; lacks quantitative data |

| [38] | Kosasih & Brintrup (2022) | Graph Neural Networks (GNN) | Prediction of hidden supply chain links | Network Design/Visibility | Better visibility, hidden risk detection | Automotive data only; limited GNN explainability | Data incompleteness; narrow sector focus |

| [39] | Allahham et al. (2024) | AI and Big Data Analytics | Risk alert tools for SCM | Risk Monitoring/Resilience | Enhanced responsiveness, predictive risk management | US-focused; managerial only | Self-reporting bias; excludes lower-level views |

| [40] | Brintrup et al. (2024) | NLP, GNNs, Neurosymbolic AI, BERT | Digital SC surveillance (risk, ESG, finance) | Cross-phase (Visibility, Risk, Finance) | Real-time risk detection, ESG monitoring, supplier mapping | UK-based; no longitudinal deployment | Black-box concerns; privacy; explainability issues |

| (B) | |||||||

| Nº | Reference | AI Technique | SCM Application | SCM Phase | Reported Benefits | Limitations | Potential Biases |

| [5] | Aburayya (2024) | AR + ANN + PLS-SEM | Warehousing, logistics, HR | Cross-functional | Efficiency, better training, reduced errors | Furniture sector; self-reported data | Regional focus; subjective perception |

| [10] | Toorajipour et al. (2021) | Multiple (ANN, Fuzzy Logic, GA, SVM, etc.) | Broad SCM: marketing, logistics, production | Forecasting, Scheduling, Risk, Sustainability | Performance improvements; roadmap | Literature review only (64 articles); 2008–2018 | Selection bias; limited generalizability |

| [12] | Rolf et al. (2023) | Reinforcement Learning (Q-learning, DQN, etc.) | Inventory, transportation, supplier selection | Inventory, Sourcing, Risk, Pricing | Adaptive decision-making; real-time learning | Simulation-based; lacks empirical studies | Artificial data; underrepresentation of real-world cases |

| [41] | Jackson et al. (2024) | ML (Facebook Prophet) + SARIMA | Cold chain: demand forecasting and capacity planning | Planning and Operations | Optimized planning, risk reduction, tailored forecasts | Single-site case; models not always superior | Site-specific focus; overfitting risks |

| [42] | Nguyen (2023) | Multiple (ANN, SVM, LSTM, BiLSTM, GAN, CNN) | Demand Forecasting (energy, water, fashion) | Planning and Demand Management | Forecast accuracy; operational cost reduction | Review-based; lacks empirical validation | Database selection bias; limited KPI assessment |

| [43] | Jackson et al. (2024) | Generative AI (GANs, Transformers) | Forecasting, inventory, sourcing, logistics, etc. | End-to-end SCM | Learning, adaptability, scenario simulation, agility | Conceptual; no empirical testing | Exploratory; functional focus; interpretation bias |

| [44] | Lin et al. (2022) | CGAN and BP Neural Networks | Partner selection, inventory, transportation optimization | Strategic Sourcing and Operational Logistics | Improved prediction, clustering, SCM integration | Simulated data; no real-world validation | Limited generalizability beyond tested datasets |

| [45] | Cannas et al. (2024) | Multiple (ML, ANN, Visual Inspection, Cobot-AI, NLP) | Planning, scheduling, maintenance, inventory, customer service | Planning, Make, Deliver | Cost/time reduction, quality, safety, sustainability | Six Italian firms; qualitative only | Country/sector-specific; expert interpretation |

| [46] | Abdelhamid et al. (2024) | AI + Blockchain (BDI Agents, Swarm Intelligence) | Data storage/processing in IoT-based SCM | Monitoring, Traceability, Infrastructure | Scalability, traceability, latency reduction | Simulation-based; no real-world pilot | Simulation limits; lacks real-time complexity validation |

| [47] | Dalal et al. (2024) | Hybrid CNN + BiLSTM (Bayesian Optimization) | Forecasting, inventory, transport planning | Planning, Procurement, Distribution | High prediction accuracy, reduced carbon footprint | Cosmetic sector data; simulation only | Domain-specific; overfitting risk |

| [48] | Hejazi et al. (2022) | AI-based product rec. and social media analysis | Operational performance via demand stimulation and risk mgmt. | Demand and Risk Mgmt/Customer Interface | Better performance, engagement, disruption resilience | Five e-commerce firms; weak factor loadings | Regional specificity; survey bias |

| [49] | Xu et al. (2021) | Agent-Based and Multi-Agent Systems | Automation (procurement, coordination, negotiation) | Cross-phase | Distributed decisions, scalability, flexibility | Review-based; lacks empirical validation | Literature bias; underrepresents ML-driven systems |

| [50] | Alnadi & Altahat (2024) | Expert Systems and Neural Networks | AI-driven ops and decision support in e-commerce | Strategic and Operational (SCM agility mediation) | Improved performance, precision, agility-supported excellence | Jordan-focused; self-reported; cross-sectional | Social desirability bias; regional scope |

| [51] | Sharabati et al. (2024) | AI (ML, robotics, automation) + DOI and TOE frameworks | Digital transformation and operational efficiency | Strategic and Operational Transformation | Enhanced scalability, responsiveness, conceptual integration | Jordanian industry; survey-based; lacks real-time deployment | Theoretical dependency; perception-based |

| [52] | Frederico (2023) | Generative AI (ChatGPT) | Communication, optimization, data analysis, reporting | Cross-phase | Process efficiency, improved communication, waste reduction | Industry blogs only; no empirical validation | Secondary source bias; early-stage insights |

| [53] | Helo & Hao (2022) | Multiple (Rule-based, GA, Deep Learning, etc.) | Sales configuration, production planning, maintenance | Planning, Make, Deliver, Service | Faster quotations, optimized production, predictive maintenance | Four cases; qualitative; early-stage implementations | Interviewee bias; no longitudinal outcomes |

| [54] | Olan et al. (2024) | XAI (SHAP, CBR, Genetic Algorithms, MAS) | Decision support in uncertain scenarios | Strategic and Tactical Decision-Making | Transparency, trust, better scenario planning | Simulation-based; no real-world deployment | Dataset-dependent; oversimplification risk |

| [55] | Zhao et al. (2022) | Evolutionary Game Theory + AI | Contract performance and compliance modeling | Governance/Legal Oversight | Better understanding of AI’s influence on compliance | Conceptual only; China-specific | Assumption bias; lacks real-world validation |

| [56] | Salhab et al. (2023) | AI-Powered Decision Support | Quality improvement under digital marketing influence | Strategic and Operational Quality Management | Enhanced quality, improved decision-making | US-focused; survey-based; cross-sectional | Response bias; limited generalizability |

| (C) | |||||||

| Nº | Reference | AI Technique | SCM Application | SCM Phase | Reported Benefits | Limitations | Potential Biases |

| [14] | Hao & Demir (2024) | Multiple (ML, DL, GA, ANN, MAS, IDSS, NLP) | ESG: AI adoption triggers/inhibitors | Strategic/ESG Integration | Emissions reduction, risk management, quality improvement | Literature-based; no empirical deployment | Database and coding bias; English-only focus |

| [57] | Olan et al. (2024) | AI-Enabled Systems (ANNs, Fuzzy Logic, AI-driven SCF) | Sustainable supply chain finance (SCF) | Finance, Network Integration | Improved financing, resource allocation, sustainability | Survey-based; no system validation | Self-reported; regional skew |

| [58] | Bhattacharya et al. (2024) | Multiple (GA, ANN, RL, CNN, etc.) | Reverse logistics, remanufacturing, CLSC design | Reverse Logistics/Circular Ops | Cost reduction, sustainability, CLSC optimization | Conceptual; no empirical validation | Literature selection bias |

| [59] | Virmani et al. (2024) | Fuzzy–Delphi, F-DEMATEL, Graph Theory | Enabler prioritization in healthcare SCM | Strategic Adoption and Responsiveness | Traceability, readiness, strategic alignment | India-focused; qualitative; no empirical implementation | Expert subjectivity; limited generalizability |

| [60] | Nozari (2024) | AIoE (AI, IoE, IoT, Big Data, ML, etc.) | Smart green supply chain | End-to-end (Green Procurement, Production, Recycling) | Energy efficiency, green sourcing, sustainability | Conceptual only; expert validation | Overgeneralization; early-stage |

| [61] | Li & Donta (2023) | XGBoost + SNN-Stacking | Demand forecasting in green supply chains | Strategic Planning/Sustainability | High accuracy, reduced environmental risk, better resource use | China-based; domain-specific; no external validation | Regional focus; model complexity |

| [62] | Dohale et al. (2024) | Bayesian Network and VAHP (MCDM) | Carbon Neutrality Index prediction (clothing industry) | Sustainability/Strategic Ops | Identifies key determinants, prioritizes actions | India-focused; perception-based | Regional bias; expert subjectivity |

| [63] | Naz et al. (2022) | GA, Fuzzy Logic, ML, ANN, NLP, Metaheuristics | Sustainable SC development (reverse logistics, transport) | Cross-phase (Sustainability, Planning) | Carbon reduction, optimized operations, sustainability | Theoretical only; no empirical data | Scopus-based selection bias |

| [64] | Benzidia et al. (2021) | BDA-AI (Big Data + AI tools) | Green SC process integration (hospital logistics) | Integration and Collaboration | Emission reduction, supplier alignment, decision efficiency | French hospitals; perception-based | Regional; no multi-stakeholder validation |

| [65] | Jamwal et al. (2022) | Deep Learning (CNN, RNN, LSTM, AE, RBM) | Sustainability in manufacturing (predictive maintenance) | Operational and Strategic Sustainability | Less downtime, higher quality, predictive capacity | Conceptual; no empirical validation | Literature bias; limited generalization |

| (D) | |||||||

| Nº | Reference | AI Technique | SCM Application | SCM Phase | Reported Benefits | Limitations | Potential Biases |

| [66] | Hatamlah et al. (2023) | AI Supply Chain Analytics | Alliance mgmt during pandemic | Strategic and Operational Planning | Better decisions, agility, alliance coordination | Indian auto industry; survey; no longitudinal validation | Regional; self-report bias |

| [67] | Rana & Daultani (2023) | Multiple (ML, ANN, CNN, RL, Hybrid Models) | Broad AI/ML applications overview | Cross-phase | Trends, research gaps, leading techniques | Bibliometric; no empirical validation | Publication and keyword bias |

| [68] | Ronchini et al. (2024) | Multiple (ML, NLP, RPA, Chatbots) | SC Finance innovation | Implementation Processes | Faster processes, cost savings, risk reduction | Ten SCF providers; qualitative only | Provider sampling bias |

| [69] | Georgiev et al. (2024) | Multiple (ML, DL, NLP, RPA, GenAI) | Project management in SCM | Strategic and Operational PM | Planning, automation, risk analysis | Survey-based; cross-industry; limited generalisability | Respondent bias; no longitudinal data |

| [70] | Purnama et al. (2023) | Deep Learning + Case-Based Reasoning | Decision support in teledermatology services | Service Supply Chain/Healthcare Logistics | Diagnostic accuracy, service reach, patient access | Design-focused; lacks empirical performance metrics | Healthcare-specific; no clinical validation |

| [71] | Singh et al. (2023) | AI, ML, DL, Robotics, Fuzzy DEMATEL | Critical issues in AI adoption (construction SCM) | Strategic Adoption and Digital Transformation | Roadmap for adoption, barrier prioritization | India-focused; qualitative | Expert subjectivity; no empirical implementation |

| [72] | Raman et al. (2024) | Generative AI (ChatGPT and Bard—LLMs) | SC education and certification (CSCP simulation) | Training and Knowledge Management | Personalized feedback, improved educational outcomes | Simulation only; scored by experts | AI version variability; subjective scoring |

| [73] | Shrivastav (2022) | Cross-cutting AI (ML, DL, IoT-AI, Recommender Systems) | Barriers to AI adoption across SCM | Strategic and Operational Transformation | Framework of 10 AI barriers; guidance for alignment | Conceptual; US-focused; no empirical testing | Expert-based; limited generalization |

| [74] | Cadden et al. (2022) | AI + Business Analytics (ML, RPA, CRM-AI) | Cultural, technical, business enablers of AI/BA adoption | Strategic Integration and Performance Improvement | Highlights cultural enablers; improved alignment and performance | UK manufacturing; survey-based; cross-sectional | Buyer-side focus; absence of multi-tier view |

| [75] | Hendriksen (2023) | Generative AI (GPT-4) + AII Framework | Theoretical/strategic integration and disruption assessment | Strategy, Risk, Coordination | Conceptualization of AI’s role; AII framework | Theoretical; lacks empirical validation | Subjective projections; metaphor-based modeling |

| [76] | Kosasih et al. (2024) | Neurosymbolic AI (ANFIS, GNN + Knowledge Graphs, etc.) | Explainability in SCM decision support | Cross-phase (Planning, Sourcing, Risk, Monitoring) | Enhanced transparency, human–AI trust, regulatory potential | Focused on ANFIS; limited real-world deployment | Overrepresentation of neuro-fuzzy; few sector validations |

| [77] | Hangl et al. (2022) | Cross-cutting (meta-SLR on AI: ML, DL, NLP, etc.) | Barriers, drivers, human/social factors in AI adoption | Cross-phase (Strategic, Operational, Sustainability) | Synthesis of 44 SLRs; roadmap for AI readiness | No empirical data; secondary/tertiary focus | Dependent on quality of prior SLRs |

| Research Direction | Description |

|---|---|

| Life-Cycle Sustainability Assessment (LCSA) | Explore the use of AI, particularly machine learning and generative models, to automate and enhance life-cycle assessments (LCAs), allowing for continuous evaluation of environmental, social, and economic impacts across supply chain stages. |

| AI and Circular Economy | Investigate the integration of AI with circular economy principles, including intelligent disassembly planning, remanufacturing optimization, and reverse logistics through reinforcement learning and digital twins. |

| Green Supplier Selection | Develop explainable AI models for sustainable supplier evaluation based on ESG performance, compliance, and environmental risk profiling to enable more informed and ethical sourcing decisions. |

| Energy and Emission Optimization | Leverage AI-driven digital twins and optimization algorithms to simulate energy use and emissions in logistics and operations, supporting the planning of low-carbon supply chain scenarios. |

| AI for ESG Reporting and Traceability | Examine how AI can support automated and accurate sustainability reporting, ensuring traceability of environmental performance indicators and alignment with regulatory requirements. |

| Ethical and Governance Frameworks | Propose governance models that guide the ethical implementation of AI for sustainability, addressing transparency, accountability, fairness, and long-term environmental justice in supply chain practices. |

| Research Area | Description | Recommended Methodological Approaches |

|---|---|---|

| Hybrid AI Models | Development of AI frameworks that integrate machine learning, graph neural networks (GNNs), and neurosymbolic AI to ensure transparency, reasoning capability, and interpretability in decision-making. | Design science research; development and testing of prototype systems; experimental validation using real-world datasets. |

| Explainable AI (XAI) | Integration of interpretable AI methods (e.g., Integrated Gradients, symbolic reasoning) to enhance trust, accountability, and regulatory compliance. | Multi-case study research; human-in-the-loop evaluations; usability and trustworthiness assessments; structured surveys of end-users. |

| Reinforcement Learning (RL) | Application of RL in real-time supply chain optimization and autonomous decision-making under uncertainty. | Simulation-based research; reinforcement learning model deployment in pilot environments; performance benchmarking under dynamic conditions. |

| Generative AI (GAI) | Exploration of GAI for predictive analytics, scenario modeling, simulation, and autonomous communication within supply chains. | Scenario-driven simulation studies; participatory action research; design and validation of proof-of-concept applications. |

| AI–Human Intelligence Collaboration (AI-HI) | Development of hybrid frameworks that combine AI and human expertise for complex decision-making in uncertain environments (e.g., humanitarian logistics). | Mixed-methods research; controlled experiments comparing AI-only versus hybrid AI–human systems; focus groups with practitioners. |

| AI-Enabled Digital Twins | Simulation and optimization of supply chain operations using digital twins enhanced with real-time AI-based learning. | Advanced simulation modeling; iterative development of digital twin prototypes; longitudinal industrial case studies. |

| Knowledge Graph Reasoning | Use of GNNs and symbolic reasoning to infer hidden links, supplier dependencies, and potential risks in complex networks. | Ontology and knowledge graph construction; experimental validation of GNN reasoning capabilities; explainability and robustness testing. |

| AI for Governance and Compliance | Development of AI models for supporting contract enforcement, ethical compliance, and legal reasoning in SCM. | Legal-technical case studies; design science methodologies; expert workshops with compliance and legal specialists; regulatory sandbox testing. |

| AI and Emerging Technologies | Convergence of AI with blockchain, IoT, and big data analytics to improve visibility, traceability, and cybersecurity. | Pilot deployment studies; system architecture evaluations; cross-industry comparative case analyses; cybersecurity stress testing. |

| Green and Sustainable SCM with AI | Design of AI-based frameworks that promote environmentally sustainable practices (e.g., carbon tracking, eco-routing). | Field experiments in sustainable supply chain contexts; environmental performance monitoring; longitudinal assessments of carbon reduction initiatives. |

| Ethical and Responsible AI Adoption | Creation of governance models that ensure fair, explainable, and human-centered AI deployment in supply chains. | Delphi panels with multidisciplinary experts; policy analysis; structured interviews with stakeholders; comparative assessments of governance frameworks. |

| Data Privacy and Federated Learning | Research on decentralized AI models that ensure data confidentiality while enabling collaboration across supply networks. | Simulation of federated environments; empirical validation of privacy-preserving algorithms; inter-organizational pilot implementations. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teixeira, A.R.; Ferreira, J.V.; Ramos, A.L. Intelligent Supply Chain Management: A Systematic Literature Review on Artificial Intelligence Contributions. Information 2025, 16, 399. https://doi.org/10.3390/info16050399

Teixeira AR, Ferreira JV, Ramos AL. Intelligent Supply Chain Management: A Systematic Literature Review on Artificial Intelligence Contributions. Information. 2025; 16(5):399. https://doi.org/10.3390/info16050399

Chicago/Turabian StyleTeixeira, António R., José Vasconcelos Ferreira, and Ana Luísa Ramos. 2025. "Intelligent Supply Chain Management: A Systematic Literature Review on Artificial Intelligence Contributions" Information 16, no. 5: 399. https://doi.org/10.3390/info16050399

APA StyleTeixeira, A. R., Ferreira, J. V., & Ramos, A. L. (2025). Intelligent Supply Chain Management: A Systematic Literature Review on Artificial Intelligence Contributions. Information, 16(5), 399. https://doi.org/10.3390/info16050399