Abstract

The emergence of the fourth industrial revolution (Industry 4.0, hereinafter I 4.0) has led to an entirely fresh approach to production, helping to enhance the key industrial processes and therefore increase the growth of labor productivity and competitiveness. Simultaneously, I 4.0 compels changes in the organization of work and influences the lives of employees. The paper intends to construct a model for predicting the allocation of human resources in the sectors of the national economy of the Czech Republic in connection with I 4.0. The model used in this research visualizes the shift of labor in the economic sectors of the Czech Republic from the year 2013 to the following years in the near future. The main contribution of this article is to show the growth of employment in the high-tech services sector, which will have an ascending trend.

1. Introduction

The essence of the fourth industrial revolution is considered and known as Industry 4.0 (hereinafter I 4.0), and the manufacturing sector has been making use of it recently by utilizing cyberphysical systems (CPSs) in an effort to seize high levels of automation [1]. The cyberphysical system (CPS) is the understructure for smart factories, and it provides the means to interconnect sensors, machines and IT systems within the value chain throughout the boundaries of the enterprise [2]. Internet of things (IoT), Internet of services (IoS) and artificial intelligence (AI) are considered other critical components of I 4.0 next to cyber physical systems (CPSs) [3].

A significant number of studies have been conducted in regard to Industry 4.0 and also about readiness and maturity models. The available studies are typically from a technological point of view. On the other hand, the perspective and predictions of the allocation of human resource management in the context of I 4.0 is remarkable, which calls for more attention and inspires conducting research in this specific area.

According to the chairman and founder of the World Economic Forum, Klaus Schwab (2018), there are four main impacts that can be described in the context of I 4.0 [4]. Those four main impacts are as follows:

- Customer expectations;

- Product improvement;

- Innovation in cooperation;

- Organizational forms.

The focus of everything is customers and the subsequent care for them, which requires constant improvement. In regard to products, they can be increasingly enriched with digital capabilities, which consequently results in an increase in their value. New technologies increase their resilience, new innovative data, their overall value and the way they are maintained. As far as customers are concerned, it is a service-based world. Having said that, data through analytical services require special forms of collaboration, one that takes into account speed and innovation [5].

According to a comparison of the World Economic Forum in the survey of potential yield from I 4.0, the Czech Republic ranked sixth overall, which can be considered a noteworthy and significant success. This classifies the Czech Republic as one of the 25 leading countries in the field of robotics. In this evaluation, 100 countries and economies were participating. The evaluation demonstrates the current preparedness of the country as well as how the trend is evolving with time [6].

The Czech Republic has achieved its place in this assessment most specifically due to the high share of the developed automotive industry. The fact that Czech companies are constantly keeping up with the modern trends and are eager to be involved in them ensures their competitiveness. For these reasons mentioned before, I 4.0 represents a substantial potential for the Czech Republic.

According to a study [7], which observed estimates of the impact of I 4.0 on the manufacturing industry in Germany, the employment rate in this sector will increase quite significantly in the next decade. The fastest growth (up to 0.9% per year) is logically expected to be for the field of engineering, which is basically a producer of the new generation of production equipment for the entire production sector. This will result in a significantly increased demand for new professions throughout the high-tech sector. These professions will use mechanical engineering and combine it with knowledge of electronics, cybernetics and computer science.

The high-technology sector is frequently brought up as a typical characteristic of economic development in a particular territorial unit. Oftentimes, businesses in these industries utilize advanced technologies to produce on a large scale, while the development of their products is associated with high research and development (R&D) costs and subsequent innovations. The high-technology sector consists of a few industries within selected industries in the manufacturing industry (high-technology industry) as well as selected service industries (high-technology services) [8].

A four-way exports classification has been developed by the OECD: high, medium-high, medium-low and low-technology. The classification is done based on the significance of research and development expenditures relative to the gross output and value added of different types of industries, which produce goods to export.

Some examples of high-technology industries are aircraft, computers and pharmaceuticals; medium-high-technology, including instances such as motor vehicles, electrical equipment and the majority of chemicals; medium-low-technology, including examples like rubber, plastics, basic metals and ship construction; and finally, low-technology industries, including food processing, textiles, clothing and footwear [9,10].

In high-tech sectors, the majority of the human capital is both highly skilled and well educated. A large number of employees that are members of these sectors are scientists, engineers and technicians. From the HR point of view, a major restructuring of work will be happening. Trends of the onset of I 4.0 are already coming out with increasing intensity; that is, ICT technologies and digitization are not only penetrating into all economic activities but also into the everyday life of society.

In this context, both the scope and structure of employment are currently changing and will also continue to change significantly in the future. This means that new professions are constantly being born, and this will continue happening; some professions will face changes in the requirements in terms of the knowledge and skills necessary for their performance, and other professions will disappear completely.

The aim of this paper is to develop a suitable model for predicting the allocation of human resources in different sectors of the national economy of the Czech Republic in connection with I 4.0.

2. Theoretical Background

2.1. Sectors of the National Economy

The Materials A sector is considered to be a part of the national economy into which the national economy is divided in some similar regard. Furthermore, these sectors are divided into a few different categories: public, private, mixed or primary, secondary, tertiary and quaternary sectors [11].

Traditionally the economy is divided into three main sectors:

- The agricultural sector (A), which includes domestic agriculture, fisheries and forestry;

- The industrial sector (I), which includes the mining and processing industries, the production and distribution of electricity, gas and water, in addition to construction;

- The services sector (S), which includes trade, finance and insurance, transport, storage and communications, education, health, veterinary and social work, and other services.

The importance of the industrial sector is significant to every country’s economy and it is considered as the driver of growth and employment [12].

2.1.1. Primary Sector

The primary sector is a field that is in charge of obtaining products or raw materials in a natural way. The primary sector is also known as primary production, which includes all branches of human activity that are responsible for the conversion of natural resources into basic products.

There is a gradual slowdown in the primary sector in developed economies, and these economies are characterized by it. The particular reason for this circumstance is the fact that developed countries simply prefer to buy raw materials and to buy or use cheaper labor abroad [13].

2.1.2. Secondary Sector

The secondary sector is in charge of the processing of products from the primary sector. It is also known as the processing or manufacturing sector, which includes all sectors of human activity that are responsible for the conversion of raw materials into products or goods. In a developed economy, this sector is rather inactive. Again, the cheap labor found abroad is preferred to be used, where part of the processing of products is being moved or by significant modernization, which gradually reduces staff costs [13].

2.1.3. Tertiary Sector

The tertiary sector includes all types of services. Services related to economic activities such as banking, financial management and insurance are also sometimes mentioned when speaking of the tertiary sector.

Developed countries in which the population is rich have the strongest sector where most people work. This sector generates about 60% of GDP in these countries. The services sector practically includes all organizations (except agriculture, raw materials processing and manufacturing companies), which subject their business to at least one service sector [14].

In the last 20–30 years, a dynamic development has been observed in the tertiary sector. The noteworthy change for the two other sectors is that they have begun to become separated, namely the quaternary sector and the fifth sector. They are listed in this article for the purpose of completeness.

2.1.4. Quaternary Sector

In fact, the quaternary sector used to belong to the tertiary sector. However, in the modern conception of economics, it is considered to be completely independent [14]. Furthermore, since the quaternary sector is based on high education and requires highly qualified staff, it is referred to as the knowledge sector.

The quaternary sector is first and foremost growing in the most developed countries and it is considered to be a driving force for innovation in other sectors, especially in industry and services. This sector originates new industries, produces novel services, products and methods of work. Therefore, the quaternary sector is of high significance for the development of the economy and society as a whole.

2.1.5. The Fifth Sector

The fifth sector is often referred to as the development services sector; that is, services that significantly affect economic growth with an emphasis on their own development. This includes services that preserve and cultivate human potential, especially in science and research.

2.2. Labor Market in the Czech Republic

This section maps the labor sectors in the economy and explains the progress of the labor market since 2013, which is the year when I 4.0 started to appear in the Czech Republic. Subsequently, the structure of employees is observed and demonstrated in terms of economic activity. Finally, the shares of employment in certain economic sectors of industry and services are shown graphically.

Structure of Employment in Industry Sectors and According to the Classification of Occupations in the Czech Republic

In 2018 [15], the employment in the primary sector (I) escalated by 20 thousand to 1,483,000 people (Table 1). The primary sector accounted for 2.8% of total employment as in the prior year.

Table 1.

Structure of employment in the period 2017–2018 by sector.

Regarding the secondary sector (II—industry incl. Construction), on the contrary, a slight decrease in employment was tracked down to 1984, 900. The share of this sector in the total employment minimized in a year from 38.1% to 37.5%.

Predominantly, the reduction of employment in the secondary sector was due to a decrease in the number of workers in construction, where after a short-term increase in 2017, the employment rate experienced a downturn by 7900 workers down to 384,000, meaning the share of the people employed in construction decreased by 0.2% to 7.3% of the total employment.

The employment in the Czech Republic decreased mostly in a period of 18 years, starting from the year 2000 to 2018, in the primary and secondary sectors, specifically in the agriculture, forestry and fishery sectors. The number of employees in these sectors decreased by almost 104,000, and so in 2018, the total number of employees working in these sectors narrowed down to less than 130,000. The massive drop in the number of employees also affected the textile, clothing and leather industry. In addition to those, the mining industry was significantly affected such that its employee count halved between the years 2000 and 2014. While this industry had 70,000 employees in the year 2000, only less than 36,000 remained employed in 2014.

The growth of employment in industry decelerated remarkably such that the number of employees increased by only 6000 up to a total of 1,601,000. The share of industry in the total employment dropped by 0.3% to 30.2%. All sections contributed slightly to the increase in industry, but the most noticeable sector was the manufacturing sector with an increase of 3600 to 1,458,400 persons.

The overall rise in employment affected the development of employment in the tertiary sector of services (III) positively, where employment expanded by 72,800 to 3,160,300 persons. Within this sector, however, employment developed differently in comparison with the year 2017. Substantially, the number of employees grew in the section of information and communication activities (by 20,400), in the section of wholesale and retail trade, repair of motor vehicles (by 15,600) and in the section of accommodation and food service activities (by 14,700). A smaller number of employments was recorded only in the section of health and social work (by 5100) and slightly also in the section transport and storage.

The share of the tertiary sector in the total employment got to 59.7% when it rose by 0.6% compared to the year 2017. This trend carries on, though the official data available from public sources for the year 2019 has not been published yet.

Due to the I 4, human resources are transferring from Sectors I and II to Sector III, and with the arrival of I 4.0 elements, the number of employees in the high-tech sector that utilizes these elements is on the rise.

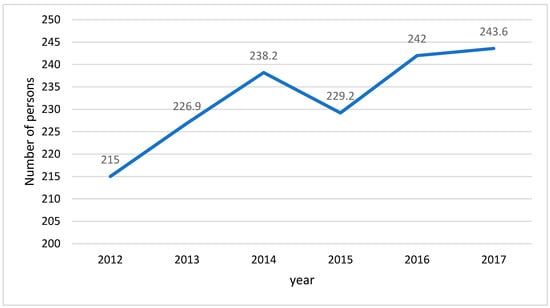

As shown in Figure 1, it is comprehensible that in the year 2012, the values are the lowest as the high-tech sector started to develop only in 2013 [16]. And that is when the elements of the industrial revolution began to be introduced into business processes and new jobs came into existence.

Figure 1.

Total employment in the high-tech sector in the Czech Republic (in thousands).

2.3. Digital Transformation

Digitalization, digital transformation and evolving technologies activate the fourth industrial revolution or Industry 4.0 that is characterized by the widespread networking of products, devices, machinery, vehicles, workplaces, ICT systems, enterprises and human resources [17].

In business, digital transformation is considered an organizational change taking place by the use of digital technologies as well as business models for the purpose of improving economic indicators and to acknowledge and respond to the changing consumer behavior and the competition between different sectors [18].

All industrial companies are at different levels of digitalization and adoption of new digital trends in recent years. Some of these industrial companies are more innovative than other companies, which mostly depends on the complexity of the company’s structure; the smaller companies are more flexible to adopt new trends [3]. Small and medium enterprises (SMEs) can easily implement digital transformation much faster, and the particular reason behind that is the fact that they are able to develop and implement new IT structures and solutions from scratch much faster due to their size [12].

From the perspective of human resource management, digital transformation suggests the attraction of employees that have both digital and analytical skills that could possibly replace the existing workforce. In marketing, for example, traditional brand and product marketers are swapped by online and mobile marketing experts, and at the same time, data analysts have the possibility to take over the role of marketing researchers. One key challenge for current employees is to compete for talent with these skills with new digital candidates [19].

The information and communication technologies have developed into an essential element of enterprise functioning and its large-scale and intensive use, together with new approaches of accessing and using the internet efficiently, define what is called the digital economy [18].

Since the creation of information and communication technologies (ICT), the economies of countries everywhere in the world have increased intensely as companies are able to compete on a global scale to seize opportunities [12].

Thanks to information and communication technology, ideal sectoral outputs are guaranteed with a decrease in the human interface of a production line, which is called “smart production” [3].

The development of Industry 4.0 often triggers the fear of employment issues and disparity. However, some studies show that Industry 4.0 has the potential to produce innovative ways to address global challenges, but the limits and risks of Industry 4.0 to sustainable development have to be better understood [20].

Digital processes and the use of robot technologies excessively will lead to a decrease in the number of employees in mostly low-ordered jobs [21], but on the other hand, new job titles may rise with a focus on digital transformation by an increase in the level of digitalization and availability of data coming from industry process; for example, “Innovation Director” or “Digitization Director.”

The future of digitalization could be shaped by these roles at the decision-making level of the industry [3]. It is necessary to understand the opportunities being created through technological developments in order to completely embrace the digital transformation journey [22].

One major concern when creating intelligent production plants that are known as smart factories is related to the use of digital transformation and intelligent robotics. Industry 4.0 is considered a combination of technological changes as well as some changes in the business models, strategic thinking and also some changes in value and supply chains [23].

3. Methodology and Objectives

The main objective of this paper is to develop a suitable model for predicting the allocation of human resources in different sectors of the national economy of the Czech Republic in connection with I 4.0. The model visualizes the movement of labor in the economic sectors of the Czech Republic from 2013 to the near future.

This model also demonstrates how much the field of robotics expands and grows from the year 2013 to the foreseeable future. This model has its limitations as well. The fact that this development has been monitored only in the Czech Republic can be considered its largest limitation. All the data used were collected from the publicly available sources of CZSO.

The following reservoirs are used in the model (main variables in the model):

- Population—this reservoir visualizes the total population in the Czech Republic set in default values.

- Economically active people—They represent a part of the population or the number of people who are able to work in a group from 15 to 64 years.

- Robotics—Introduction of a given number of automation machines into the industry.

Storage facilities in the form of industries (services, industry and agriculture) and high-tech sectors are also shown in the model.

The subsequent flows and quantities are used in the model:

Increase (% population growth in the Czech Republic since 2013), mortality (% population mortality in the Czech Republic since 2013), workers (number of economically active inhabitants), increase in robotics (increasing automation and modernization in sectors) and increase in employees (distribution of able-bodied into individual sectors).

The STELLA program was used in order to create this model. The model itself was visually very extensive, so it is not mentioned in the article.

The outputs are presented in the form of graphs, which clearly visualize the prediction of HR allocation in national economic sectors and the growing number of employees in high-tech sectors of industry and services. The definition and boundaries of the high-tech sector are based on the definition used by CZSO [8], which also follows the Eurostat methodology [24].

Most of these data are obtained by the Czech Statistical Office through a combination of exhaustive and sample survey methods. The survey is carried out by the Czech Statistical Office once a year in accordance with approved regulations (293/2019 Sb. Decree on the Program of Statistical Surveys for 2020, 2019), using electronic or paper forms. The structured data are subsequently published in cooperation with the Ministry of Industry and Trade of the Czech Republic [25,26] (The Ministry of Industry and Trade of the Czech Republic, 2018b, 2018a).

4. Results

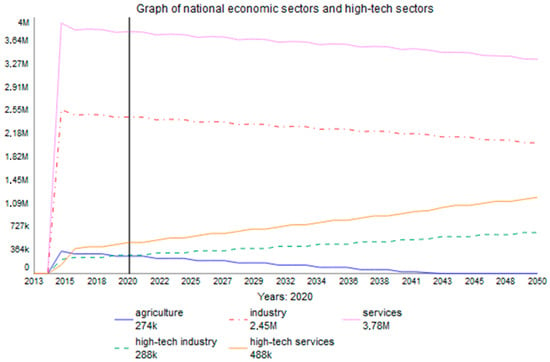

The following graphs (Figure 2 and Figure 3) depict a forecast of how the number of workers in economic sectors is going to change over time, without the commencement of high-tech industries and the subsequent comparison of the number of workers with the onset of high-tech industries.

Figure 2.

National economic sectors and high-tech sectors (year 2020).

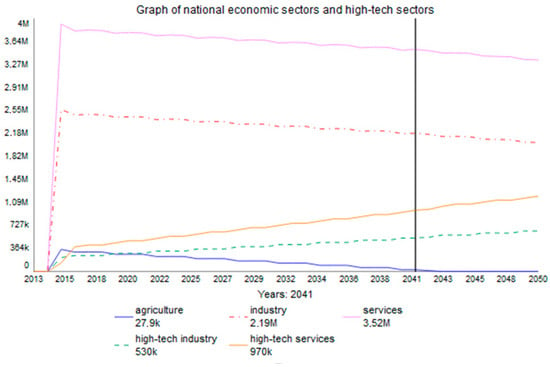

Figure 3.

National economic sectors and high-tech sectors (year 2041—prediction).

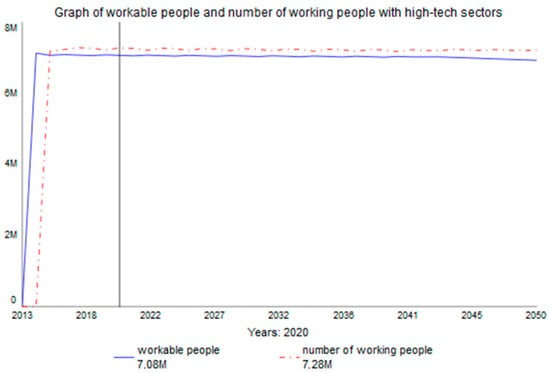

The graphs show how the expected situation is going to be, and so they predict that the number of employees in the national economy will be decreasing.

However, the agriculture sector will experience the most significant downfall. In other national economic sectors, or in other words services and industry, the number of workers will keep descending in about the same way. Although it is shown that the number of workers in high-tech sectors is increasing noticeably, this will compensate for the loss of jobs in other sectors.

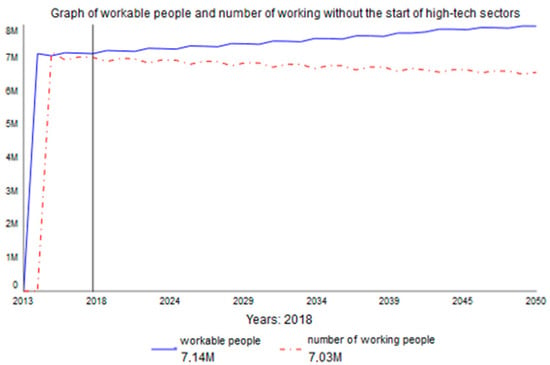

The following figure (Figure 4) shows the economically active people, the number of employees since the year 2013 onwards, and the subsequent prediction without considering the emergence of high-tech sectors.

Figure 4.

Economically active people and the number of working without the start of high-tech sectors (year 2018).

Figure 5 shows economically active people and the number of employees from the year 2013 with subsequent prediction until 2050 after setting up high-tech sectors.

Figure 5.

Economically active people and number of working people with high-tech sectors (year 2020).

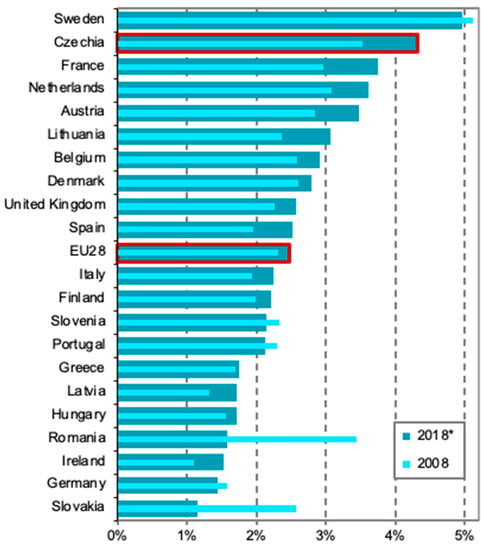

The next figure (Figure 6) shows how much European countries invested in ICT in the years 2008 and 2018 in terms of percentage of their GDP.

Figure 6.

ICT investment (% of GDP, *or the nearest available year).

As we can see, the Czech Republic is among the leading countries in the amount of investment in ICT with respect to the GDP and proportionally has more investment than the European Union (EU28) [27]. Another interesting thing that we can notice here is the fact that the Czech Republic has increased its investment in ICT from 2008 to 2018.

5. Discussion and Conclusions

According to Eurostat (2018), the industrial sector in the EU-28 employed 35 million individuals, which corresponds to 15.4% of total employment in the year 2017 [24]. Out of this number, 2.4 million individuals were employed in the high-tech industry, which is 1.1% of the total employment, and the high-tech services sector accounted for three times that number, which is 3.0% of the total employment. The Czech Republic most specifically is on an average level in terms of employment in the high-tech sector. Its total employment in this area is 4.6% (services 3.0% and high-tech industry 1.6%). Developed countries such as Ireland (5.4), Finland (4.7%), Estonia (4.5%) and Sweden (4.4%) showed a large difference in comparison with other countries in terms of services [28]. The smallest values were observed in Greece (2.0%) and Lithuania (2.1%), and solely, Turkey recorded a value of less than 1%. Speaking of the largest total employment in high-tech sectors, Ireland was recorded with an overall employment rate of 8.5%. Slovakia, on the other hand, appears to have a significantly lower number, with a rate of 3.1% of total employment in high-tech sectors.

Since the creation of Information and communication technologies (ICT), the economies of countries everywhere in the world have increased intensely as companies are able to compete on a global scale to seize opportunities [12]. Thanks to information and communication technology, ideal sectoral outputs are guaranteed with a decrease in the human interface of a production line, which is called “smart production” [29]. From a HR point of view, a major restructuring of work will be happening [30]. Trends of the onset of I 4.0 are already coming out with increasing intensity. ICT technologies and digitization are not only penetrating into all economic activities but also into the everyday life of society. In this context, both the scope and structure of employment are currently changing and will also continue to change significantly in the future. New professions are continuously being born, and this will continue happening; some professions will face changes in the requirements in terms of the knowledge and skills necessary for their performance, and other professions will disappear completely. Expenditures of the European countries in technologies (for example, investment in ICT, Figure 6) have an increasing trend, and this is a valid argument that recommendations are needed to be developed on the choice of an effective strategy of the human resources management with the implementation of Industry 4.0 technologies.

The concept of future development may not be possible to be accurately predicted or generalized. Nevertheless, it is necessary to keep in mind that a given problem must always be placed in a specific context and then solved in regard to other factors. The basis of successful adaptation to changes in the context of I 4.0 is a proactive approach. In brief, the main aim of this contribution is to shed light on the development of employment in the high-tech services sector and to demonstrate that it will have an increasing tendency.

Author Contributions

Conceptualization, H.M.; formal analysis, H.M.; resources, M.Z.N.; software, H.M.; supervision, H.M.; writing—original draft, M.Z.N.; writing—review & editing, M.Z.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The paper was written with the support of the specific project 2106/2020 grant “Determinants of Cognitive Processes Impacting the Work Performance” granted by the University of Hradec Králové, Czech Republic, and thanks to help from students František Hašek and Anna Borkovcová. The paper was processed with support from the institutional support fund for the long-term conceptual development of science and research at the Faculty of Informatics and Statistics of Prague University of Economics and Business (IP 400040).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ziaei Nafchi, M.; Mohelská, H. Effects of Industry 4.0 on the Labor Markets of Iran and Japan. Economies 2018, 6, 39. [Google Scholar] [CrossRef]

- Kopp, J.; Basl, J. Study of the Readiness of Czech Companies to the Industry 4.0. J. Syst. Integr. 2017, 8, 1804–2724. [Google Scholar] [CrossRef]

- Maskuriy, R.; Selamat, A.; Maresova, P.; Krejcar, O.; David, O.O. Industry 4.0 for the construction industry: Review of management perspective. Economies 2019, 7, 68. [Google Scholar] [CrossRef]

- Schwab, K. The Fourth Industrial Revolution; Crown Business: New York, NY, USA, 2017. [Google Scholar]

- Benhamou, S. The World of Work in 2030: Four Scenarios. In NEUFEIND, Max, Jacqueline O’REILLY a Florian RANFT, Work in the Digital Age: Challenges of the Fourth Industrial Revolution; Rowman & Littlefield International: London, UK, 2018; pp. 259–270. ISBN 978-1-78660-907-6. Available online: https://policynetwork.org/wp-content/uploads/2018/06/Work-in-the-Digital-Age.pdf (accessed on 6 July 2018).

- Weltwirtschaftsforum, A.T.; Kearney Incorporated. Readiness for the Future of Production Report 2018. Available online: https://www.weforum.org/reports/readiness-for-the-future-of-production-report-2018 (accessed on 17 August 2020).

- BSG. Industry 4.0: The Future of Productivity and Growth in Manufacturing Industries. 2015. Available online: https://www.bcg.com/publications/2015/engineered_products_project_business_industry_4_future_productivity_growth_manufacturing_industries.aspx (accessed on 17 April 2020).

- Czech Statistical Office. High-Tech Sector. 2019. Available online: https://www.czso.cz/csu/czso/high_tech_sektor?fbclid=IwAR04i98Wa6Zli8mGUOPFqLa9v4YrGjgi7bxsuA15hu9uG4u3nppRQ8L_BI (accessed on 5 April 2020).

- OECD. High, Medium and Low Technology Exports. Available online: https://stats.oecd.org/oecdstat_metadata/ShowMetadata.ashx?Dataset=CSP6&Coords=%5BSUB%5D.%5BHTEXPORT%5D&Lang=en (accessed on 7 March 2021).

- Mohelská, H.; Sokolová, M.; Cierniak-Emerych, A.; Dziuba, S.T. Employment in high-technology industries in the european union and job satisfaction—Case study Czech Republic and Poland. Econ. Res.-Ekon. Istraživanja 2020, 33, 639–651. [Google Scholar] [CrossRef]

- Synek, M.; Kislingerová, E. Podniková ekonomika; C.H. Beck: Munich, Germany, 2017. [Google Scholar]

- Bahrin, M.A.K.; Othman, M.F.; Azli, N.H.N.; Talib, M.F. Industry 4.0: A review on industrial automation and robotic. J. Teknologi 2016, 78, 137–143. [Google Scholar] [CrossRef]

- Stejskal, J.; Kuvíková, H.; Mikušová Meričková, B.; Linhartová, V. Teorie a Praxe Veřejných Služeb; Wolters Kluwer: Alphen aan den Rijn, The Netherlands, 2017. [Google Scholar]

- Kraftová, I. Finanční Analýza Municipální Firmy; C.H. Beck: Munich, Germany, 2002. [Google Scholar]

- Mpsv, Č.R. Analýza Vývoje Zaměstnanosti a Nezaměstnanosti v Roce 2018. Ministerstvo Práce a Sociálních Věcí ČR, 2019/84292-414/1. 2019. Available online: https://www.mpsv.cz/documents/20142/848077/anal2018.pdf/760053b9-9f64-b616-5453-2447ee935b7e (accessed on 11 January 2020).

- Czech Statistical Office. Employment, Unemployment. 2020. Available online: https://www.czso.cz/csu/czso/zamestnanost_nezamestnanost_prace (accessed on 17 April 2020).

- Gajšek, B.; Vujica Herzog, N. Smart Glasses in Sustainable Manual Order Picking Systems. In Sustainable Logistics and Production in Industry 4.0. EcoProduction (Environmental Issues in Logistics and Manufacturing); Grzybowska, K., Awasthi, A., Sawhney, R., Eds.; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Boneva, M. Challenges related to the digital transformation of business companies. In Proceedings of the 6th International Conference Innovation Management, Entrepreneurship and Sustainability (IMES 2018), Prague, Czech Republic, 31 May–1 June 2018; pp. 101–114. [Google Scholar]

- Verhoef, P.C.; Broekhuizen, T.; Bart, Y.; Bhattacharya, A.; Qi Dong, J.; Fabian, N.; Haenlein, M. Digital transformation: A multidisciplinary reflection and research agenda. J. Bus. Res. 2021, 122, 889–901. [Google Scholar] [CrossRef]

- Kumar, A.; Nayyar, A. si3-Industry: A Sustainable, Intelligent, Innovative, Internet-of-Things Industry. In A Roadmap to Industry 4.0: Smart Production, Sharp Business and Sustainable Development; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar] [CrossRef]

- Hausberg, J.P.; Liere-Netheler, K.; Packmohr, S.; Pakura, S.; Vogelsang, K. Research streams on digital transformation from a holistic business perspective: A systematic literature review and citation network analysis. J. Bus Econ. 2019, 89, 931–963. [Google Scholar] [CrossRef]

- Kumar, A.; Gupta, D. Challenges Within the Industry 4.0 Setup. In A Roadmap to Industry 4.0: Smart Production, Sharp Business and Sustainable Development; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Grabowska, S.; Gajdzik, B.; Saniuk, S. The Role and Impact of Industry 4.0 on Business Models. In Sustainable Logistics and Production in Industry 4.0. EcoProduction (Environmental Issues in Logistics and Manufacturing); Grzybowska, K., Awasthi, A., Sawhney, R., Eds.; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Eurostat. Available online: https://ec.europa.eu/eurostat (accessed on 11 January 2018).

- The Ministry of Industry and Trade of the Czech Republic. Panorama of the Manufacturing Industry of the Czech Republic. 2018. Available online: https://www.mpo.cz/assets/en/industry/manufacturing-industry/panorama-of-the-manufacturing-industry/2019/10/panorama_aj_web.pdf (accessed on 6 July 2020).

- The Ministry of Industry and Trade of the Czech Republic. Panorama zpracovatelského průmyslu ČR 2018 (1. vyd., Roč. 22); The Ministry of Industry and Trade of the Czech Republic: Praha, Czech Republic, 2018. [Google Scholar]

- Czech Statistical Office. Digital Economy in Figures. 2020. Available online: https://www.czso.cz/documents/10180/122362640/06300620_c.pdf/bcd3a63b-1507-4a55-a218-b58680df4adb?version=1.1 (accessed on 11 January 2020).

- Czech Statistical Office. Employment. 2019. Available online: https://www.czso.cz/csu/czso/13-1132-06-za_rok_2005-3_2__zamestnanost (accessed on 5 April 2020).

- Maskuriy, R.; Selamat, A.; Ali, K.N.; Maresova, P.; Krejcar, O. Industry 4.0 for the Construction Industry—How Ready Is the Industry? Appl. Sci. 2019, 9, 2819. [Google Scholar] [CrossRef]

- Bučková, V. Industry 4.0: A Human Resource Management Perspective. Bachelor’s Thesis, Faculty of Informatics and Management, University of Hradec Králové, Hradec Králové, Czech Republic, 2019. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).