Precision of a Streamlined Life Cycle Assessment Approach Used in Eco-Rating of Mobile Phones

Abstract

1. Introduction

1.1. Review of Prior Knowledge Observations

1.2. Open Eco Rating LCA

1.3. Objectives

1.4. Hypotheses

2. Materials and Methods—Full LCAs Used and OLCA

2.1. Functional Units

2.2. System Boundaries

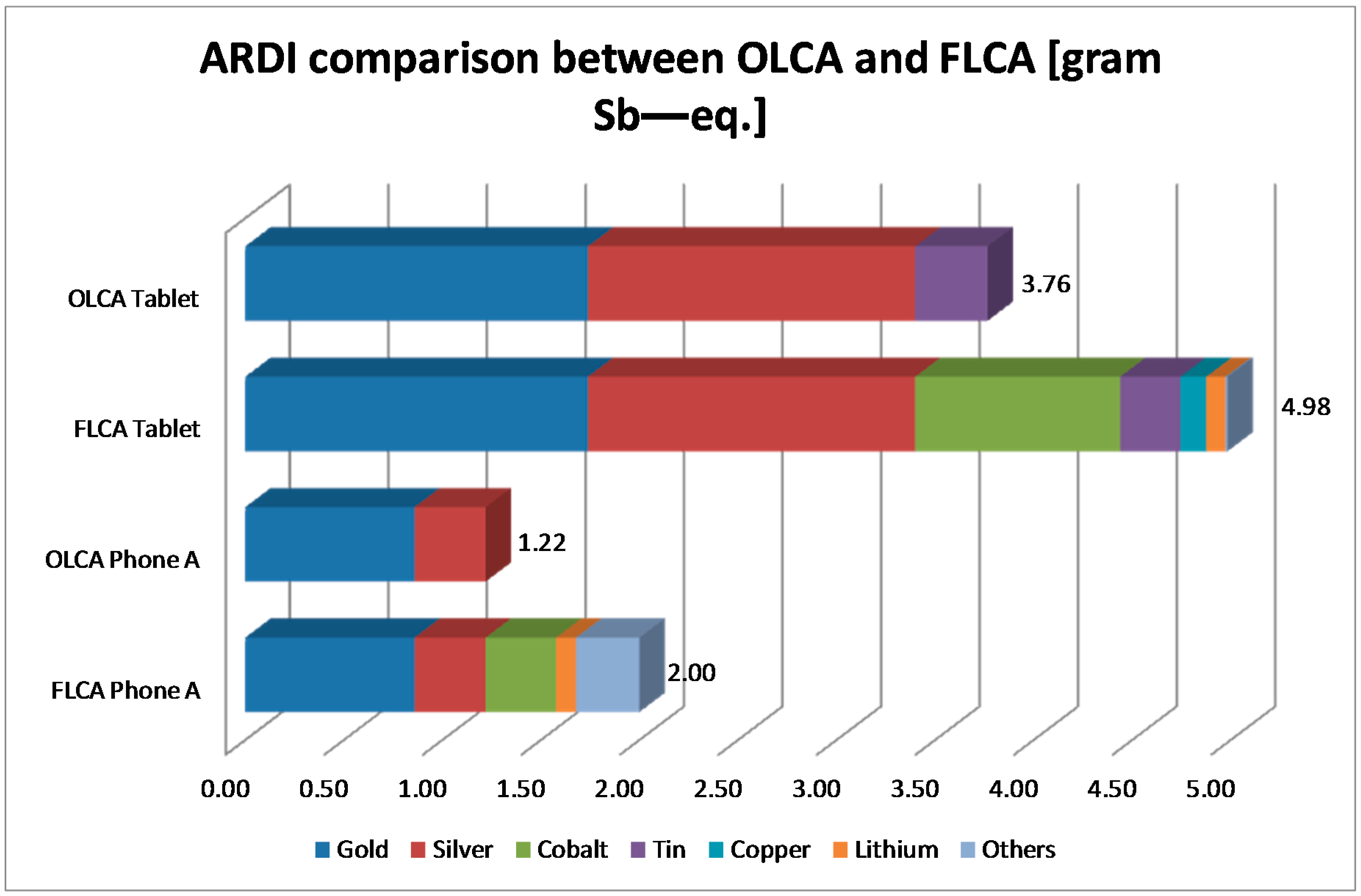

2.3. ARDI Scores for Tablet and OLCA

- = mass of metal j used by tablet based on LCIA method i, [kg j].

- = average mass of metal j used by tablet based on several LCIA methods i, [kg j].

- n = 1,2.

- i = life cycle impact assessment impact category indicator for ARD (ReCiPe (H) midpoint; Centrum voor Milieuwetenschappen Leiden (CML) CML 2013 baseline; Environmental Priority Strategies (EPS2000) depletion of metal reserves) [36].

- j = metal type, (e.g., gold, silver).

- = Total score for i for metal j, [kg Fe—eq.; kg Sb—eq.; Environmental Load Unit (ELU)].

- = Characterisation factor for metal j in i, [kg Fe—eq./kg j; kg Sb—eq./kg j; ELU/kg j].

2.4. ARDI Scores for Phone A with FLCA and OLCA

- = Share of total score for i for metal j, [kg Sb—eq.].

- ARDILCD = life cycle impact assessment impact category for ARD in ILCD.

2.5. Product Metrics and Carbon Intensities Used to Compare FLCA and OLCA

2.6. Carbon Footprint Modeling in OLCA

2.6.1. Integrated Circuit and other PCBA Parts Production

- -

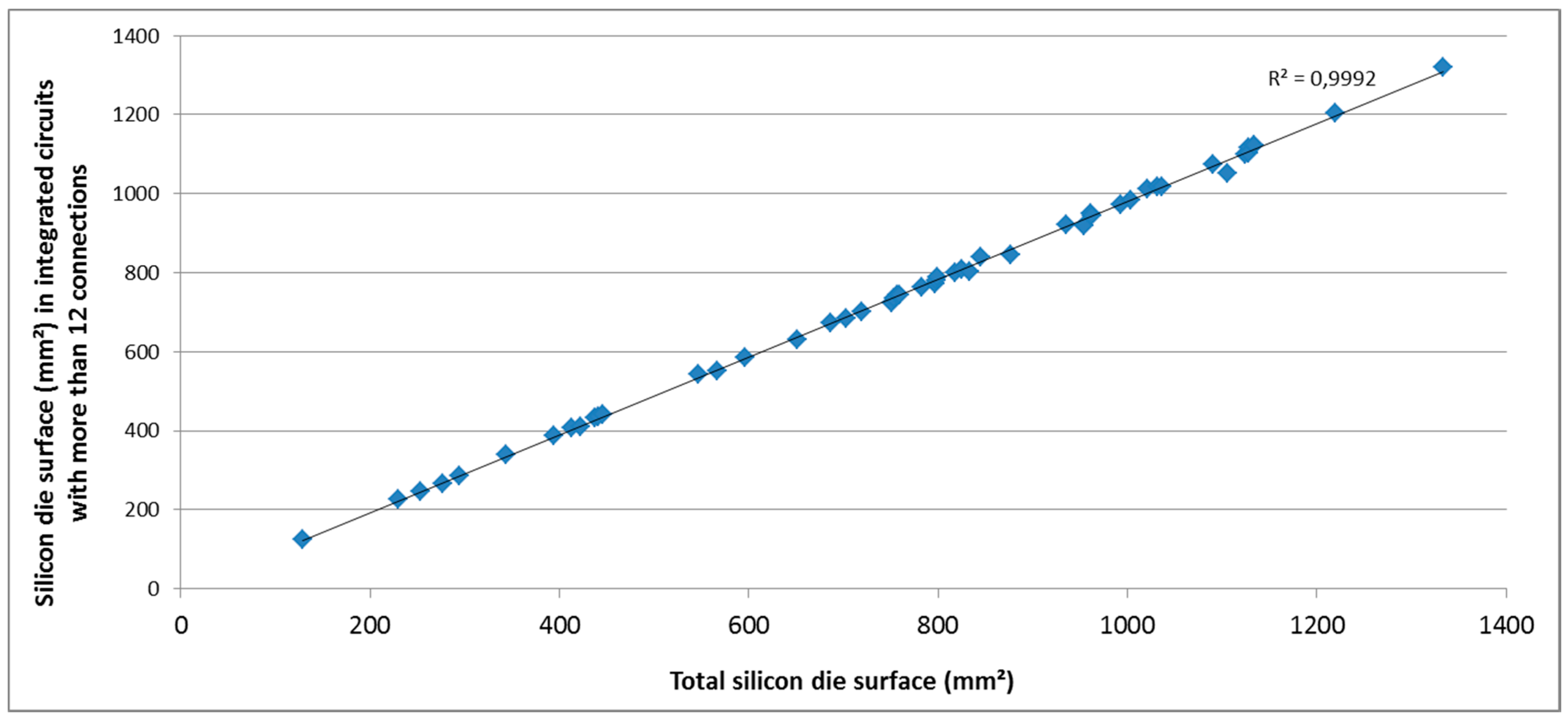

- Total surface of silicon dies (Siarea) in ICs. Stacked dies (e.g., in NAND memory) and wafer level chip scale package—WL-CSP also known as flip chips—were also taken into account,

- -

- Total mass of IC and total IC packaging surface. The different types of packaging—e.g., ball grid array, dual/quad flat no-lead, small outline package—were also considered thanks to specific models available in the databases of the LCA tool Environmental Impact Made Easy (EIME©) [35]. Previous use of EIME has been reported by Ma et al. [41] and Andrae and Vaija [4].

- -

- Total mass of transistors, diodes, and surface mounted Light Emitting Diodes (LEDs). The different types of packaging—e.g., small outline transistor, small outline diode—were also considered based on specific models available in EIME©.

- -

- Total mass of passive components, such as resistors, capacitors, inductors, Surface Acoustic Wave (SAW) filters and crystals. The different types of technology (e.g., multilayer ceramic chip capacitors or tantalum capacitors) were also considered based on specific models available in EIME©.

- -

- Total mass of electro-mechanical components—e.g., microphone, headset jack, Subscriber Identification Module (SIM) card socket, antennas. For these items materials declarations sheets (MDS) were used in order to create cradle-to-gate LCA models combining materials (e.g., polyamide, liquid crystal polymer, stainless steel) and manufacturing processes such as injection molding, deep drawing and extrusion.

- -

- Total mass of soldering paste. All the soldering dots (for wave soldering) and pads (for reflow soldering) were counted and sorted according to their size—e.g., 0201, 0402, 0603 for Surface Mount Devices (SMD) soldering pads. Documentation from PCBA parts manufacturers was used to assess the quantity of solder paste per pad. The total mass of soldering paste was then assessed by multiplying the number of dots/pads by the quantity of solder paste per dot/pad. Both wave and reflow solder paste were considered as tin-silver-copper (SAC) type.

- -

- Total surface of surface treatment on printed circuit boards, such as electroless nickel immersion gold (ENIG).

2.6.2. Camera Production

- -

- rear or front camera type,

- -

- resolution from 1.2 to 16 Megapixels,

- -

- directly soldered on the motherboard or featuring a flexible PCB fastened on the motherboard with a “board-to-board” connector,

- -

- without flash, with LED flash or with Xenon flash,

- -

- with fixed focus or with autofocus,

- -

- without zoom, with digital zoom or with optical zoom.

- -

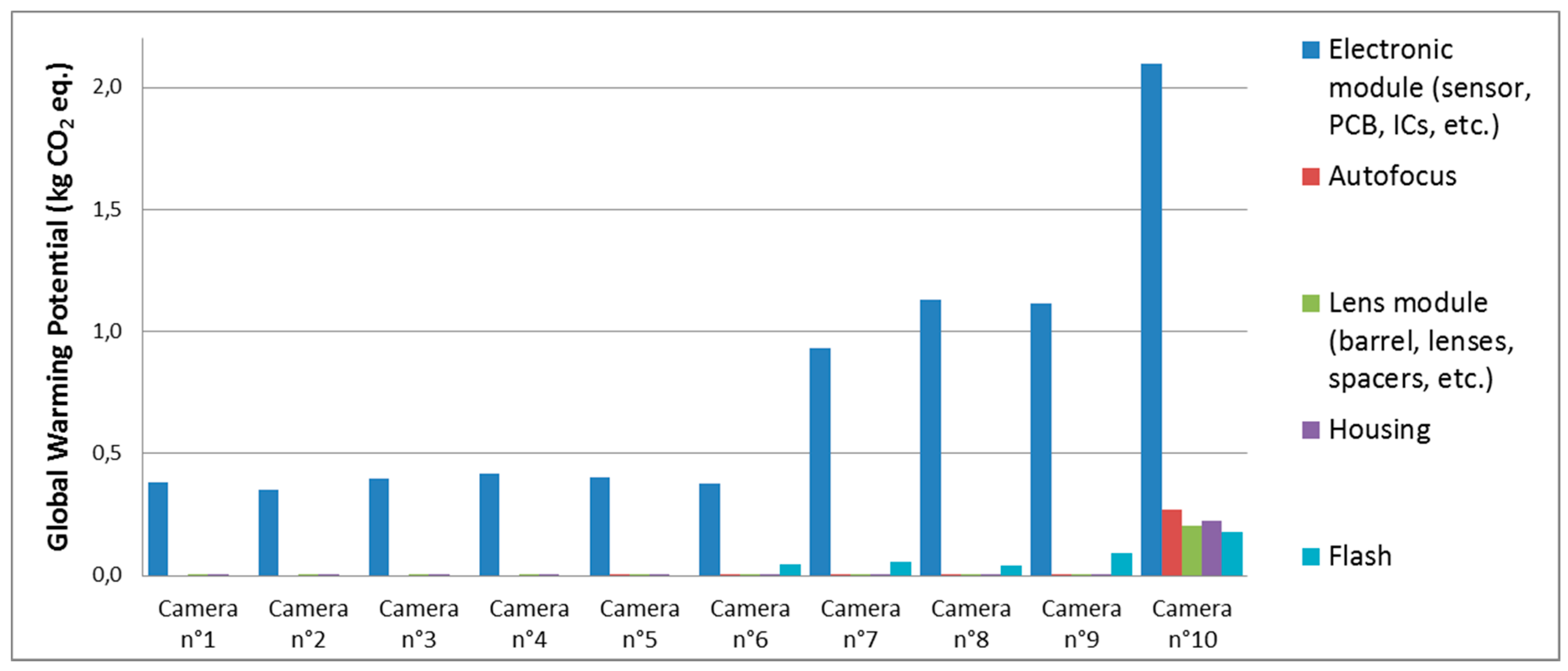

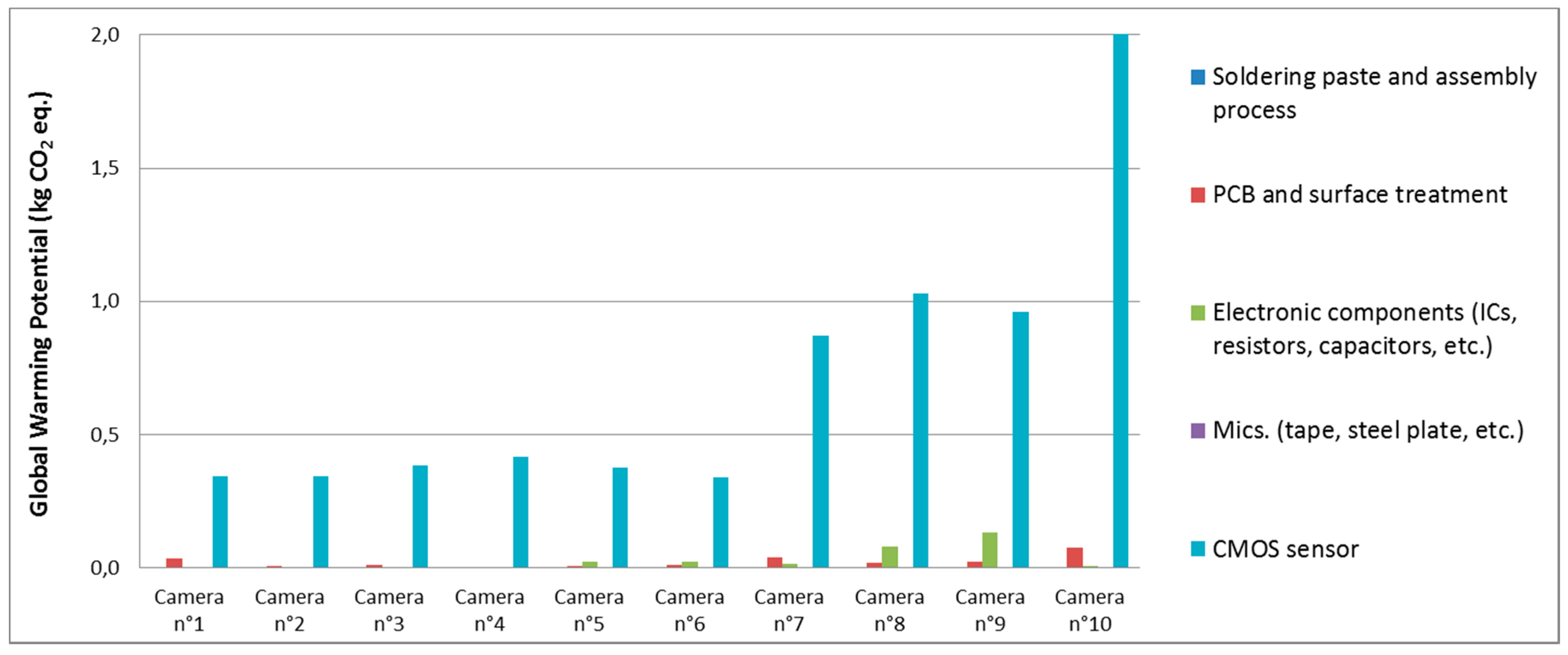

- Soldering paste and assembly process,

- -

- PCB and surface treatment (solder mask deposition and ENIG finish for example),

- -

- Electronic parts (including ICs such as OIS Driver, Microelectromechanical systems (MEMS) OIS Gyroscope, Autofocus VCM Driver or Serial Flash Memory),

- -

- Miscellaneous (including a large variety of small mechanical parts such as tape or steel/plastic reinforcement plates),

- -

- CMOS sensor.

- -

- For front cameras (models n°1 and n°2) and simple rear cameras (models n°3—°6 and all featuring a resolution ≤5 Megapixels) a single model was created based on the GWPI scores (average value ~400 g CO2—eq.) of camera models n°1—°6. Indeed, for these camera models the CMOS sensor sizes are of the same order of magnitude (about 24.5 mm2 +/− 10%),

- -

- For camera models with a compact digital camera design—e.g., featuring a large optical zoom—a single model was created (~3000 g CO2—eq.),

- -

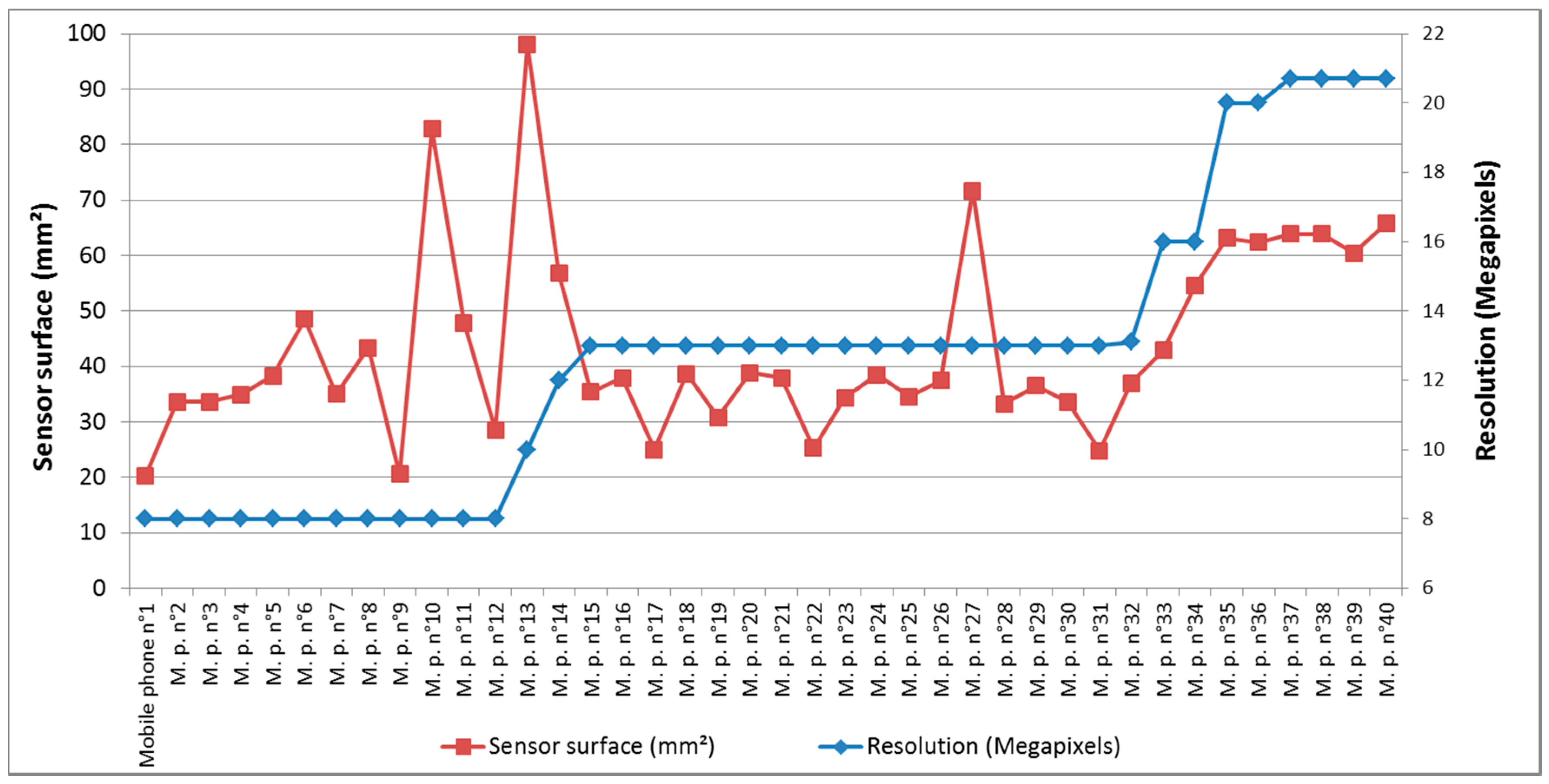

- For the remaining camera models (n°7—°9)—i.e., those with a resolution >5 Megapixels and not designed as the one for compact digital cameras—a complementary assessment of 40 mobile phones was carried out. It demonstrated that, unlike cameras with resolution ≤5 Megapixels, the size of the CMOS sensors of these more complex cameras varied a lot (see Figure 5).

3. Results

4. Discussion

- (i)

- same calculation rules are used,

- (ii)

- same LCA tool is used,

- (iii)

- same LCI databases are used,

- (iv)

- and a third party review is conducted.

5. Conclusions

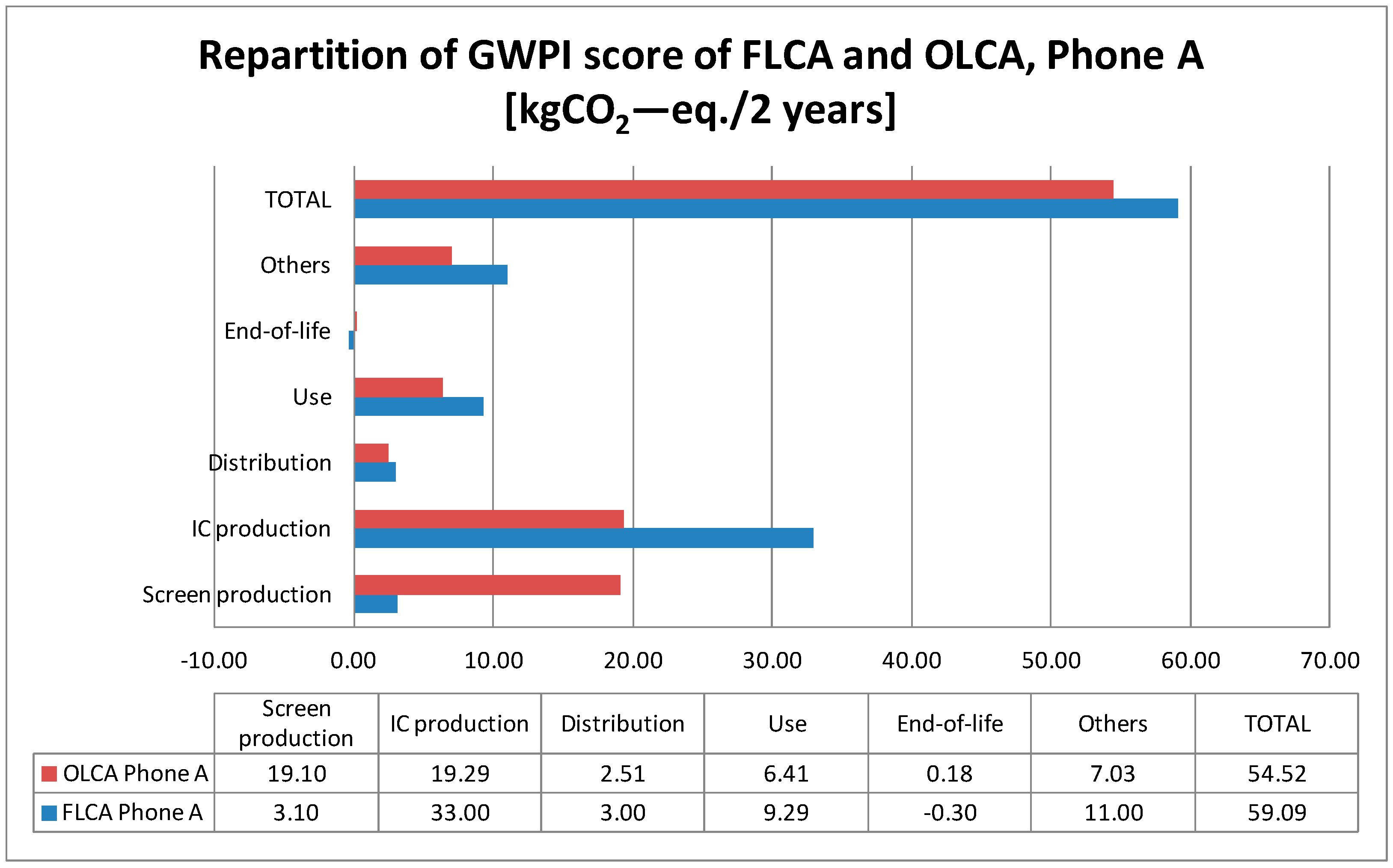

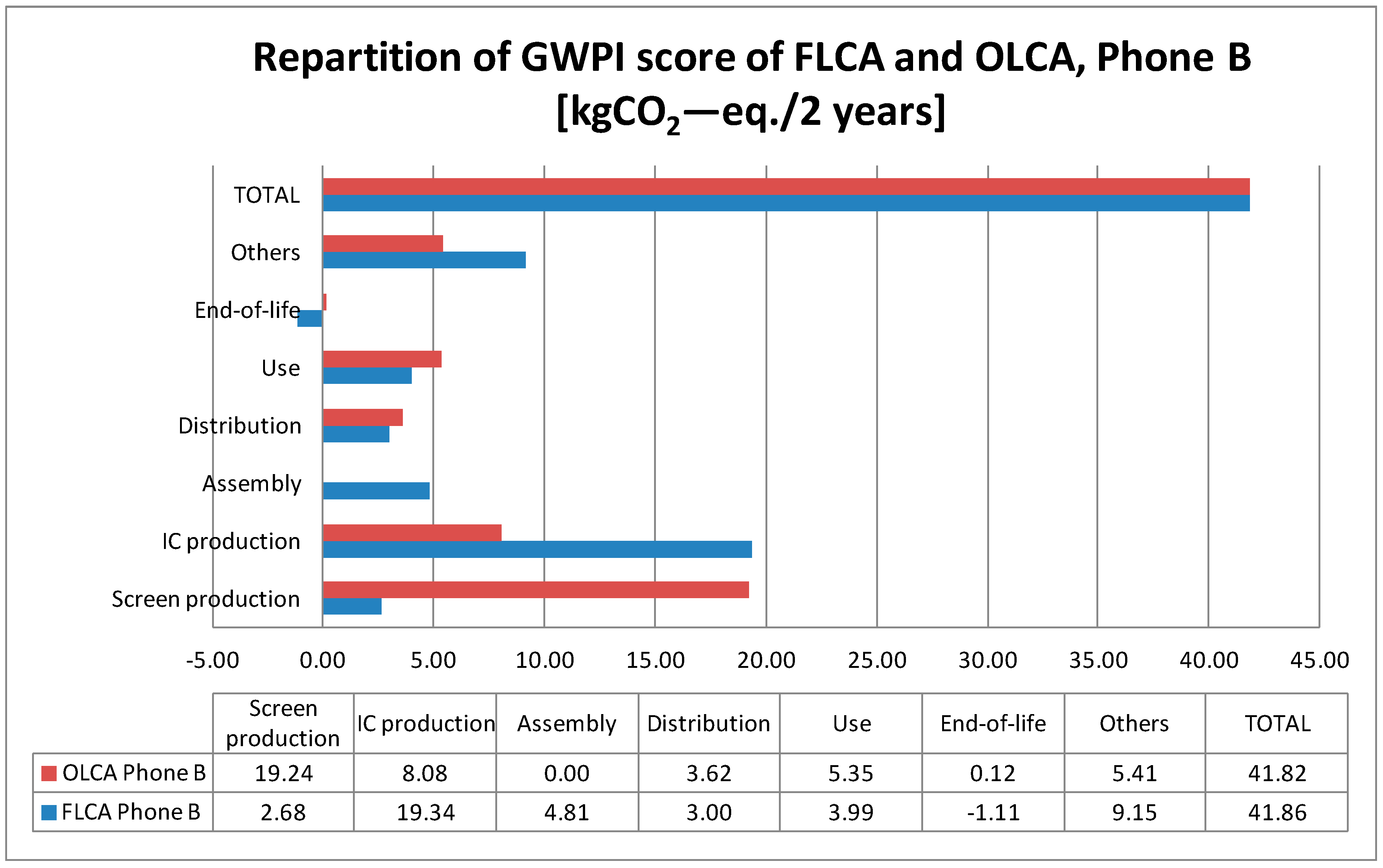

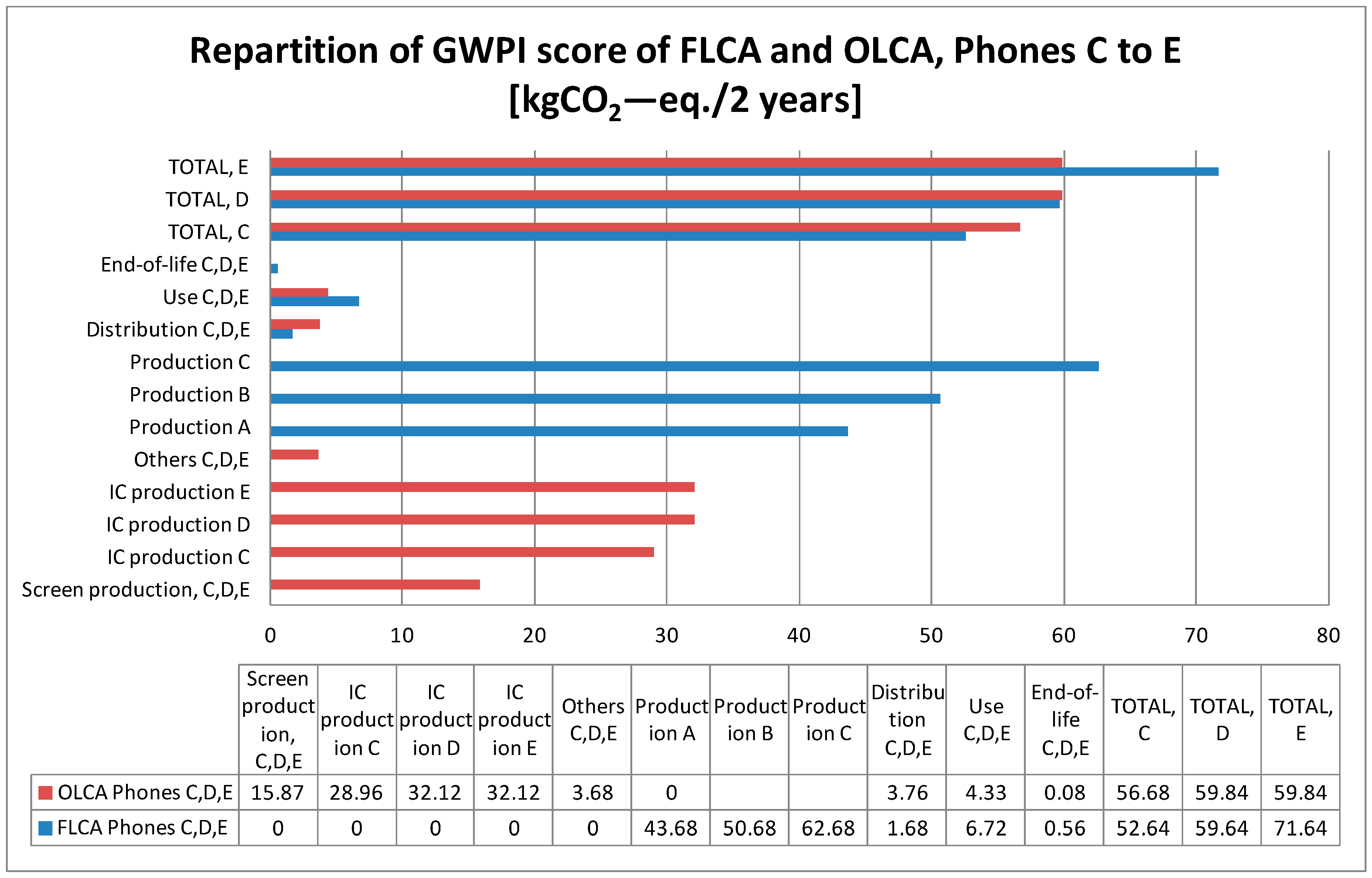

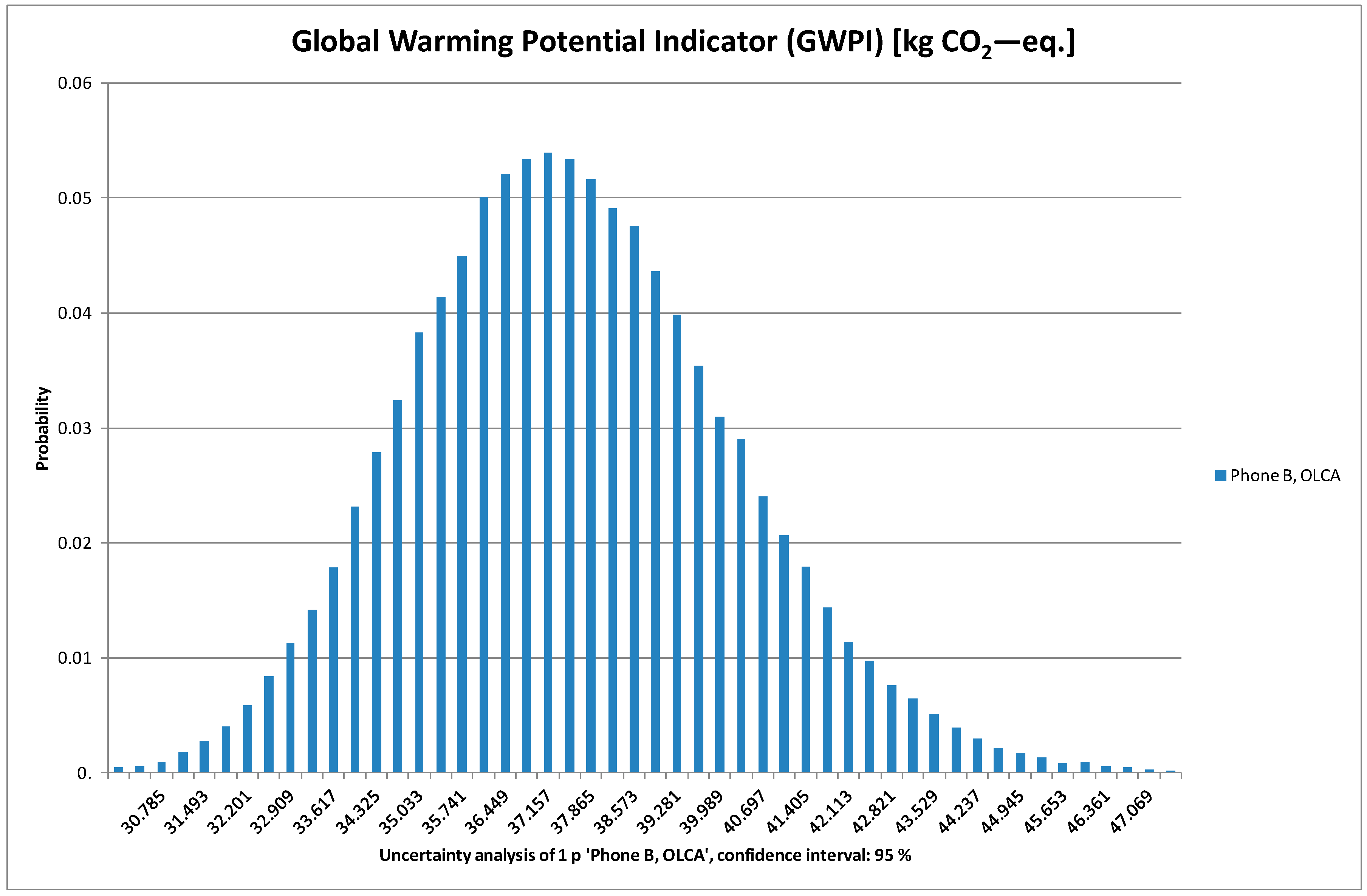

- (H1) The FLCA scores are <50% higher than OLCA scores for Phones A—E for GWPI at ≈20%, so H1 is falsified;

- (H2) The FLCA score is >50% higher than the OLCA score for Phone A for ARDI at ≈70%, so H2 is not falsified;

- (H3) The ARDI score based on metal content of the tablet is <50% higher than OLCA ARDI at ≈30%, so H3 is falsified;

- Differences in silicon die manufacturing intensity, screen production intensity and missing assembly emissions in OLCA mainly explain the GWPI differences;

- Cobalt missing from OLCA for the most part explains the ARDI differences.

6. Looking Ahead

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Andrae, A.S.G.; Edler, T. On electricity usage of communication technology: Trends to 2030. Challenges 2015, 6, 117–157. Available online: www.mdpi.com/2078-1547/6/1/117 (accessed on 17 May 2017). [CrossRef]

- Andrae, A.S.G.; Corcoran, P. Emerging Trends in Electricity Consumption for Consumer ICT. Available online: https://aran.library.nuigalway.ie/bitstream/handle/10379/3563/CA_MainArticle14_all-v02.pdf?sequence=4&isAllowed=y (accessed on 15 June 2017).

- Andrae, A.S.G.; Xia, M.; Zhang, J.; Tang, X. Practical Eco-Design and Eco-Innovation of Consumer Electronics—The Case of Mobile Phones. Challenges 2016, 7, 3. Available online: https://www.mdpi.com/2078-1547/7/1/3 (accessed on 17 May 2017). [CrossRef]

- Andrae, A.S.G.; Vaija, M.S. To Which Degree does Sector Specific Standardization Make Life Cycle Assessments Comparable?—The Case of Global Warming Potential of Smartphones. Challenges 2014, 5, 409–429. Available online: https://www.mdpi.com/2078-1547/5/2/409/htm (accessed on 17 May 2017). [CrossRef]

- Hagelüken, M.; Schischke, K.; Müller, J.; Griese, H.J. Welcome to the Jungle—Survival of the Fittest Environmental Screening Indicators? In Proceedings of the Electronics Goes Green 2004+, Berlin, Germany, 6–8 September 2004; Available online: http://www.ecodesignarc.info/servlet/is/652/Welcome%20to%20the%20Jungle%20-%20Survival%20of%20the%20Fittest%20Environmental.pdf?command=downloadContent&filename=Welcome%20to%20the%20Jungle%20-%20Survival%20of%20the%20Fittest%20Environmental.pdf (accessed on 29 May 2017).

- Pamminger, R.; Krautzer, F.; Wimmer, W.; Schischke, K. “LCA to Go”—Environmental Assessment of Machine Tools According to Requirements of Small and Medium-Sized Enterprises (SMEs)—Development of the Methodological Concept. In Re-Engineering Manufacturing for Sustainability, 1st ed.; Nee, A.Y.C., Song, B., Ong, S.K., Eds.; Springer: Singapore, 2013; Volume 1, pp. 481–486. [Google Scholar] [CrossRef]

- Schischke, K.; Nissen, N.F.; Lang, K.D. Translating product specifications into environmental evidence—Carbon Footprint Models explained on the example of a netbook, a consumer laptop and an ultrabook. In Proceedings of the Going Green CARE INNOVATION 2014, Vienna, Austria, 17–20 November 2014; Available online: http://publica.fraunhofer.de/eprints/urn_nbn_de_0011-n-3159403.pdf (accessed on 29 May 2017).

- Schischke, K.; Proske, M.; Schulz, G.; Husemann, J.; Trenner, T.; Sonnenberg, T.; Huck, W.; Kelm, K.; Tempel, N.; Wunderlich, P.; et al. Methodology Guidance—Energy Profiles and Carbon Footprint Data for Passive Components and Connectors, version 1.2; Fraunhofer IZM: Berlin, Germany, 2015; Available online: http://publica.fraunhofer.de/eprints/urn_nbn_de_0011-n-3349766.pdf (accessed on 29 May 2017).

- Schischke, K.; Nissen, N.F.; Lang, K.D. Experiences of Small Electronics Companies to Underpin Circular Economy Approaches by Means of Simplified Life Cycle Indicator. In Proceedings of the World Resources Forum, Davos, Switzerland, 12–14 October 2015; Available online: http://www.wrforum.org/wp-content/uploads/2015/10/SS1-Schischke.pdf (accessed on 29 May 2017).

- Del Borghi, A. LCA and communication: environmental product declaration. Int. J. Life Cycle Assess. 2013, 18, 293–295. Available online: https://link.springer.com/content/pdf/10.1007%2Fs11367-012-0513-9.pdf (accessed on 28 May 2017). [CrossRef]

- European Commission. Environmental Footprint Guidance document—Guidance for the development of Product Environmental Footprint Category Rules (PEFCRs), Version 6.0, November 2016. Available online: http://ec.europa.eu/environment/eussd/smgp/pdf/Guidance_products.pdf (accessed on 20 April 2017).

- Ojala, E.; Uusitalo, V.; Virkki-Hatakka, T.; Niskanen, A.; Soukka, R. Assessing product environmental performance with PEF methodology: Reliability, comparability, and cost concerns. Int. J. Life Cycle Assess. 2016, 21, 1092–1105. [Google Scholar] [CrossRef]

- Ercan, M.; Malmodin, J.; Bergmark, P.; Kimfalk, E.; Nilsson, E. Life Cycle Assessment of a Smartphone. 2016. Available online: http://www.atlantis-press.com/php/download_paper.php?id=25860375 (accessed on 20 April 2017).

- Proske, M.; Clemm, C.; Richter, N. Life Cycle Assessment of the Fairphone 2. 2016. Available online: https://www.fairphone.com/wp-content/uploads/2016/11/Fairphone_2_LCA_Final_20161122.pdf (accessed on 20 April 2017).

- Apple iPhone7 Environmental Report. 2016. Available online: http://images.apple.com/environment/pdf/products/iphone/iPhone_7_PER_sept2016.pdf (accessed on 20 April 2017).

- Andrae, A.S.G.; Andersen, O. Life cycle assessments of consumer electronics—Are they consistent? Int. J. Life Cycle Assess. 2010, 15, 827–836. [Google Scholar] [CrossRef]

- Andrae, A.S.G.; Vaija, M.S. Life Cycle Assessments of an Optical Network Terminal and a Tablet: Experiences of the Product Environmental Footprint Methodology. In Advances in Environmental Research, 1st ed.; Daniels, J.A., Ed.; Nova Science Publishers: Hauppauge, NY, USA, 2017; Volume 55, pp. 31–46. [Google Scholar]

- Nissen, N.F.; Griese, H.; Middendorf, A.; Müller, J.; Pötter, H.; Reichl, H. Comparison of simplified environmental assessments versus full life cycle assessment (LCA) for the electronics designer. In Life Cycle Networks, 1st ed.; Krause, F.L., Seliger, G., Eds.; Springer Science + Business Media: Dordrecht, The Netherlands, 1997; Volume 55, pp. 301–312. [Google Scholar]

- Bribián, I.Z.; Usón, A.A.; Scarpellini, S. Life cycle assessment in buildings: State-of-the-art and simplified LCA methodology as a complement for building certification. Build. Environ. 2009, 44, 2510–2520. [Google Scholar] [CrossRef]

- Padey, P.; Girard, R.; Le Boulch, D.; Blanc, I. From LCAs to simplified models: A generic methodology applied to wind power electricity. Environ. Sci. Technol. 2013, 47, 1231–1238. [Google Scholar] [CrossRef] [PubMed]

- Bala, A.; Raugei, M.; Benveniste, G.; Gazulla, C.; Fullana-i-Palmer, P. Simplified tools for global warming potential evaluation: When ‘good enough’is best. Int. J. Life Cycle Assess. 2010, 15, 489–498. [Google Scholar] [CrossRef]

- Arzoumanidis, I.; Salomone, R.; Petti, L.; Mondello, G.; Raggi, A. Is there a simplified LCA tool suitable for the agri-food industry? An assessment of selected tools. J. Clean. Product. 2017, 149, 406–425. [Google Scholar] [CrossRef]

- Teehan, P.; Kandlikar, M. Comparing embodied greenhouse gas emissions of modern computing and electronics products. Env. Sci. Technol. 2013, 47, 3997–4003. [Google Scholar] [CrossRef] [PubMed]

- Moberg, Å.; Borggren, C.; Ambell, C.; Finnveden, G.; Guldbrandsson, F.; Bondesson, A.; Malmodin, J.; Bergmark, P. Simplifying a life cycle assessment of a mobile phone. Int. J. Life Cycle Assess. 2014, 19, 979–993. [Google Scholar] [CrossRef]

- Corcoran, P.M.; Andrae, A.S.G.; Vaija, S.M.; Garcia, C.; Dechenaux, E. Effect of Modeling Approach on Climate Change Focused Life Cycle Assessments for a Contemporary Smartphone Device 2014. Available online: http://aran.library.nuigalway.ie/xmlui/handle/10379/4522 (accessed on 20 April 2017).

- Andrae, A.S.G. A review of methodological approaches for life cycle assessment (LCA) of consumer electronics. IEEE Consum. Electron. Mag. 2016, 5, 51–60. [Google Scholar] [CrossRef]

- International Telecommunication Union. L.Sup32: Supplement for Eco-Specifications and Rating Criteria for Mobile Phones Eco-Rating Programmes 2016. Available online: http://www.itu.int/rec/T-REC-L.Sup32-201610-I (accessed on 20 April 2017).

- Open Eco Rating. Available online: http://openecorating.com/ (accessed on 17 May 2017).

- Base IMPACTS®. Available online: http://www.base-impacts.ademe.fr/ (accessed on 2 August 2017).

- European Commission-Joint Research Centre. Recommendations Based on Existing Environmental Impact Assessment Models and Factors for Life Cycle Assessment in European Context. 2011. Available online: eplca.jrc.ec.europa.eu/uploads/ILCD-Recommendation-of-methods-for-LCIA-def.pdf (accessed on 20 April 2017).

- Ramos, S.; Larrinaga, L.; Albinarrate, U.; Jungbluth, N.; Ingolfsdottir, G.M.; Yngvadottir, E.; Landquist, B.; Woodhouse, A.; Olafsdottir, G.; Esturo, A.; et al. SENSE tool: Easy-to-use web-based tool to calculate food product environmental impact. Int. J. Life Cycle Assess. 2016, 21, 710–721. Available online: https://link.springer.com/content/pdf/10.1007%2Fs11367-015-0980-x.pdf (accessed on 20 April 2017). [CrossRef]

- Subramanian, V.; Ingwersen, W.; Hensler, C.; Collie, H. Comparing product category rules from different programs: Learned outcomes towards global alignment. Int. J. Life Cycle Assess. 2012, 17, 892–903. [Google Scholar] [CrossRef]

- Minkov, N.; Schneider, L.; Lehmann, A.; Finkbeiner, M. Type III environmental declaration programmes and harmonization of product category rules: Status quo and practical challenges. J. Clean. Product. 2015, 94, 235–246. [Google Scholar] [CrossRef]

- European Telecommunication Standards Institute. 2014. Available online: http://www.etsi.org/deliver/etsi_es/203100_203199/203199/01.02.01_60/es_203199v010201p.pdf (accessed on 20 April 2017).

- CODDE. EIME Base. Available online: https://codde.fr/en/our-software/eime-en/eime-base (accessed on 5 June 2017).

- Son, K.B.; Lee, D.S.; Lim, S.R. Effect of technology convergence for tablet PC on potential environmental impacts from heavy metals. Int. J. Sustain. Dev. World Ecol. 2016, 23, 154–162. [Google Scholar] [CrossRef]

- Van Oers, L.; Guinée, J. The Abiotic Depletion Potential: Background, Updates, and Future. Resources 2016, 5, 16. Available online: www.mdpi.com/2079-9276/5/1/16 (accessed on 28 May 2017). [CrossRef]

- Centrum voor Milieuwetenschappen. CML-IA Characterisation Factors. 2016. Available online: https://www.universiteitleiden.nl/en/research/research-output/science/cml-ia-characterisation-factors (accessed on 20 April 2017).

- GSM Arena. Available online: http://www.gsmarena.com/sony_xperia_z5-7534.php (accessed on 20 April 2017).

- GSM Arena. Available online: http://www.gsmarena.com/apple_iphone_7-8064.php (accessed on 20 April 2017).

- Ma, J.; Yin, F.; Liu, Z.; Zhou, X. The eco-design and green manufacturing of a refrigerator. Proc. Environ. Sci. 2012, 16, 522–529. [Google Scholar] [CrossRef]

- PEP Ecopassport Program. Available online: http://www.pep-ecopassport.org/fileadmin/webmaster-fichiers/version_anglaise/PEP-PCR-ed_2.1-EN-2012_12_11.pdf (accessed on 5 June 2017).

- Stratgraphics. Centurion—Version 16.1.05. Available online: http://www.statgraphics.com/centurion-xvii (accessed on 5 June 2017).

- Treeze. Life Cycle Inventories of Electricity Mixes and Grid—Version 1.3. Available online: http://esu-services.ch/fileadmin/download/publicLCI/itten-2012-electricity-mix.pdf (accessed on 5 June 2017).

- IC Insights. Global Wafer Capacity. Available online: http://www.icinsights.com/services/global-wafer-capacity/ (accessed on 5 June 2017).

- SystemPlus. Available online: http://www.systemplus.fr/available-reports/ (accessed on 5 June 2017).

- Andrae, A.S.G. Life Cycle Assessment of a Virtual Reality Device. Challenges 2017, 8, 15. [Google Scholar] [CrossRef]

- Manfredi, S.; Allacker, K.; Pelletier, N.; Schau, E.; Chomkhamsri, K.; Pant, R.; Pennington, D. Comparing the European Commission product environmental footprint method with other environmental accounting methods. Int. J. Life Cycle Assess. 2015, 20, 389–404. [Google Scholar] [CrossRef]

- Alcaraz Ochoa, M.D.L. Development of metrics for streamlined life cycle assessments: A case study on tablets, 2016. Available online: https://dspace.mit.edu/handle/1721.1/107098 (accessed on 20 April 2017).

| Feature | FLCA of Phone A [13] | FLCA of Phone B [14] | FLCAs of Phones C–E [15] | OLCA for All Phones |

|---|---|---|---|---|

| Life Cycle Assessment (LCA) conceptual model | Attributional LCA (ALCA) | ALCA | ALCA | ALCA |

| Standard followed | ISO 14040 and ISO 14044, ETSI 203 199 [34] | None | ISO 14040 and ISO 14044 | None (OLCA itself is however based on FLCAs following ISO 14040 and 14044 standards) |

| Number of midpoint indicators included | 12 {GWP100, ODP, HumToxCan, HumTox, PM, POCP, AP, EP fresh, EP terr, EcoTox, Water, ADP} | 5 {GWP100 ADP elements, ADP fossil, HumTox, EcoTox} | 1 {GWP100} | 2 {GWP100 and ADP} |

| Reference for midpoint indicators | International Life Data System 2011 Midpoint + version 1.08 [30] | CML 2001 | Intergovernmental Panel on Climate Change (IPCC) | International Life Data System 2011 Midpoint + version 1.08 [30] |

| Functional unit | “life time usage (3 years) of the smartphone device and its accessories for a representative usage scenario” | “an intensive smartphone use over three years” | “a three-year period for power use by first owners” | “life time usage (2 years) of the smartphone device and its accessories for a representative usage scenario” |

| Temporal scope | 1 to 3 years | 3 years | 3 years | 2 years |

| Geographical scope, intended market for use | Global | Europe | Global | Global |

| Life cycle scope | Cradle-to-grave | Cradle-to-grave | Cradle-to-grave | Cradle-to-grave |

| Metal recycling credited | Yes | Yes | No | No |

| Secondary data sources | GaBi, ecoinvent | GaBi, ecoinvent | Not transparent | Environmental Impact Made Easy (EIME©) [35]. |

| Main Unit Process | FLCA of Phone A | FLCA of Phone B | FLCAs of Phone C–E | OLCA for All Phones |

|---|---|---|---|---|

| Gold production | Yes (ʹ) | Yes (ʹ) | Not transparent (N.T.) | Yes (ʹ) |

| Screen production | ʹ | ʹ | N.T. | ʹ |

| IC production | ʹ | ʹ | N.T. | ʹ |

| Flexible Printed Circuit Board (PCB) production | ʹ | ʹ | N.T. | ʹ |

| Rigid PCB production | ʹ | ʹ | N.T | ʹ |

| Production of other electronic parts on the PCB Assemblies (PCBAs) | ʹ | ʹ | N.T | ʹ |

| Camera production | ʹ | ʹ | N.T. | ʹ |

| Plastics production | ʹ | ʹ | N.T. | ʹ |

| Aluminum production | ʹ | ʹ | ʹ | ʹ |

| Steel production | ʹ | ʹ | N.T. | ʹ |

| Battery production | ʹ | ʹ | N.T | ʹ |

| Charger production | ʹ | ʹ | N.T. | ʹ |

| Other Parts production | ʹ | ʹ | N.T. | ʹ |

| Manual production | ʹ | ʹ | N.T. | ʹ |

| Packaging production | ʹ | ʹ | N.T. | ʹ |

| Assembly | ʹ | ʹ | N.T. | ʹ |

| Distribution | ʹ | ʹ | ʹ | ʹ |

| Use | ʹ | ʹ | ʹ | ʹ |

| End-of-life | ʹ | ʹ | ʹ | ʹ |

| Support activities | ʹ | No | N.T. | No |

| Metal in Tablet | ARDCML2013,total,j [kg Sb—eq.] | Mass,CML2013,j [kg] | ARDReCiPe,total,j [kg Fe—eq.] | Mass,ReCiPe,j [kg] | ARDEPS2000,total,j [ELU] | Mass,EPS2000,j [kg] | Average Mass, , (kg) | ARDILCD,factor,j [kg Sb—eq./kg] [38] | ARDILCD,total,j Result [kg Sb—eq.] |

|---|---|---|---|---|---|---|---|---|---|

| Cr | 1.00 × 10−7 | 2.26 × 10−4 | 9.00 × 10−3 | 3.61 × 10−4 | 5.00 × 10−2 | 5.89 × 10−4 | 3.92 × 10−4 | 2.53 × 10−5 | 9.92 × 10−9 |

| Au | 2.00 × 10−3 | 3.85 × 10−5 | 3.6 | 5.15 × 10−5 | 65 | 5.46 × 10−5 | 4.82 × 10−5 | 36 | 1.74 × 10−3 |

| Co | 7.00 × 10−7 | 4.46 × 10−2 | 5.00 × 10−2 | 4.95 × 10−2 | 7 | 2.73 × 10−2 | 4.05 × 10−2 | 2.56 × 10−2 | 1.04 × 10−3 |

| Cu | 1.00 × 10−4 | 7.30 × 10−2 | 1.53 | 3.58 × 10−2 | 10 | 4.81 × 10−2 | 5.23 × 10−2 | 2.50 × 10−3 | 1.31 × 10−4 |

| Fe | 2.00 × 10−10 | 3.82 × 10−3 | 5.00 × 10−3 | 5.00 × 10−3 | 5.00 × 10−3 | 5.20 × 10−3 | 4.67 × 10−3 | 1.67 × 10−6 | 7.78 × 10−9 |

| Mo | 2.00 × 10−7 | 1.12 × 10−5 | 5.00 × 10−3 | 2.40 × 10−5 | 4.00 × 10−2 | 1.89 × 10−5 | 1.80 × 10−5 | 7.11 × 10−2 | 1.28 × 10−6 |

| Ni | 6.00 × 10−8 | 9.45 × 10−4 | 8.00 × 10−3 | 6.40 × 10−4 | 1.00 × 10−1 | 6.25 × 10−4 | 7.37 × 10−4 | 4.18 × 10−3 | 3.08 × 10−6 |

| Sn | 5.00 × 10−5 | 3.09 × 10−3 | 3.00 | 2.36 × 10−3 | 3 | 2.52 × 10−3 | 2.66 × 10−3 | 1.15 × 10−1 | 3.06 × 10−4 |

| V | 3.00 × 10−12 | 3.90 × 10−6 | 3.00 × 10−4 | 5.36 × 10−6 | 4.63 × 10−6 | 4.93 × 10−3 | 2.28 × 10−8 | ||

| Zn | 1.00 × 10−6 | 1.86 × 10−3 | 4.00 × 10−3 | 1.78 × 10−3 | 8.00 × 10−2 | 1.40 × 10−3 | 1.68 × 10−3 | 3.65 × 10−3 | 6.13 × 10−6 |

| Li | 1.00 × 10−7 | 8.70 × 10−3 | 6.00 × 10−4 | 6.00 × 10−3 | 7.35 × 10−3 | 1.33 × 10−2 | 9.77 × 10−5 | ||

| Mn | 1.00 × 10−9 | 3.94 × 10−4 | 4.00 × 10−2 | 5.22 × 10−4 | 5.00 × 10−3 | 8.87 × 10−4 | 6.01 × 10−4 | 2.35 × 10−5 | 1.41 × 10−8 |

| Ti | 1.00 × 10−10 | 3.58 × 10−3 | 6.00 × 10−3 | 6.30 × 10−3 | 4.94 × 10−3 | 1.52 × 10−3 | 7.51 × 10−6 | ||

| Ag | 2.00 × 10−4 | 1.69 × 10−4 | 7.00 × 10−2 | 2.45 × 10−4 | 9.5 | 1.76 × 10−4 | 1.97 × 10−4 | 8.42 | 1.66 × 10−3 |

| Al | 1.00 × 10−10 | 9.17 × 10−2 | 2.00 × 10−3 | 2.22 × 10−2 | 9.00 × 10−3 | 2.05 × 10−2 | 4.48 × 10−2 | 2.53 × 10−5 | 1.13 × 10−6 |

| Ba | 1.00 × 10−10 | 1.66 × 10−5 | 7.00 × 10−5 | 1.57 × 10−5 | 1.61 × 10−5 | 3.37 × 10−3 | 5.44 × 10−8 | ||

| Pb | 5.00 × 10−7 | 7.89 × 10−5 | 8.00 × 10−3 | 4.57 × 10−5 | 6.23 × 10−5 | 1.50 × 10−2 | 9.34 × 10−7 | ||

| TOTAL | 4.98 × 10−3 |

| Metric Essential in OLCA Identified in FLCA Reports and on GSM Arena Web Site | Phone A [13] | Phone B [14] | Phones C–E [15] | Tablet [36] |

|---|---|---|---|---|

| Length [cm], L | 14.6 [39] | Not transparent (N.T.) | 13.83 [40] | Not applicable (N.A.) |

| Width [cm], W | 7.2 [39] | N.T. | 6.71 [40] | N.A. |

| Screen-to-body ratio [%], STB | 69.6 [39] | N.T. | 65.6 [40] | N.A. |

| Screen area, ScreenA [cm2], L × W × STB | 73.2, UF = 1.01 | 73.7 (p. 17 in [14]), UF = 1.01 | 60.8 | N.A. |

| Printed Circuit Board (PCB) area, PCBA [cm2] | N.T. | 125.3 (Table 3-6 in [14]), UF = 1.1 | N.T. | N.A. |

| Silicon die area, Siarea [cm2] | 9.5 (p. 125 in [13]), UF = 1.1 | 3.94 (p. 27 in [14]), UF = 1.1 | N.T. | N.A. |

| Not AND (NAND) flash memory capacity, SiNAND [GB] | Not used | Not used | 32, 128 and 256 [15] | N.A. |

| Camera resolution, Cam,res [MP] | 23 [39] | 8 (p. 21 in [14]) | 12 | N.A. |

| Camera sensor size, Cam,sensize [inch, "], a fraction of an inch of the sensor size is used | 1/2.3" [39] | N.T. | 1/3" [40] | N.A. |

| Plastics mass, massPla [g] | N.T. | 20 (p. 64 in [14]), UF = 1.1 | 7 [15] | N.A. |

| Aluminium mass, massAlu [g] | N.T. | N.T. | 24 [15] | N.A. |

| Steel mass, massSteel [g] | N.T. | 2.99 (Tables 4–9 in [14]), UF = 1.1 | 23 [15] | N.A. |

| Battery mass, massBat [g] | N.T | 38 (Tables 3-1 [14]), UF = 1.05 | 26 [15] | N.A. |

| Charger mass, massCha [g] | N.T. | 0 (p. 13 [14]) | N.T. | N.A. |

| Others mass, massOth [g] | N.T. | 112 (Tables 3-1 and 3-14 in [14]), UF = 1.1 | 6 [15] | N.A. |

| Total mass, massTot = massCha + massPla + massAlu + massSteel massOth + massBat + massMan + massPack + [g] | N.T. | 344 (Table 3-14 in [14]), UF = 1.1 | 308 [15] | N.A. |

| Manual mass, massMan [g] | N.T. | N.T. | N.T. | N.A. |

| Packaging materials mass, massPack [g] | N.T | 171 (Table 3-10 in [14]), UF = 1.05 | 170 [15] | N.A. |

| Location of manufacturing site | Asia | Asia | N.T. | N.A. |

| Location of distribution market | Global | Europe | Global | N.A. |

| Main mode of transport | Air | Air | N.T. | N.A. |

| Battery capacity, Batt,Cap [mAh] | 2900 [39], UF = 1.05 | 2420 (Table 3-11 in [14]), UF = 1.05 | 1960 [40] | N.A. |

| Battery voltage, Batt,Vol [V] | N.T. | 3.8 (Table 3-11 in [14]), UF = 1.01 | N.T | N.A. |

| Charging frequency, ChaFre | 2 (=every other day Table III in [13]). 1 (=daily) is used in comparison with OLCA | 1 (Table 3-11 (=daily) in [14]) | N.T. | N.A. |

| Lifetime [years], LT | 3 (Table III in [13]). 2 is used in the comparison with OLCA | 3 (Table 3-11 in [14]), 2 is used in the comparison with OLCA | 3 [15]. 2 is used in the comparison with OLCA | N.A. |

| Abiotic Resource Depletion, International Life Data System 2011 Midpoint+ version 1.08 (ARDILCD,total [g Sb—eq.]) | 2.0 (Figure 4 in [13]) | 0.61 (Tables 4-3 to 4-8 in [14]). Note that a different ARDI is used in [14]. | N.T. | 4.98 see Table 2. (derived from Figure 3a–c in [36]) |

| Unit Process | Phone A [13] | Phone B [14] | Phones C–E [15] | OLCA |

|---|---|---|---|---|

| Screen production, I,ScreenA | 47.9 g/cm2 (Figure 3 {3500/73.2} in [13]) | 39 g/cm2 (Table 4-3, p. 58, {2680/73} in [14]) | N.T. | See more details in Supplementary Materials file Section 1 |

| Gold production, I,Au | Not transparent (N.T.) | N.T. | N.T. | See more details in Supplementary Materials file Section 3 |

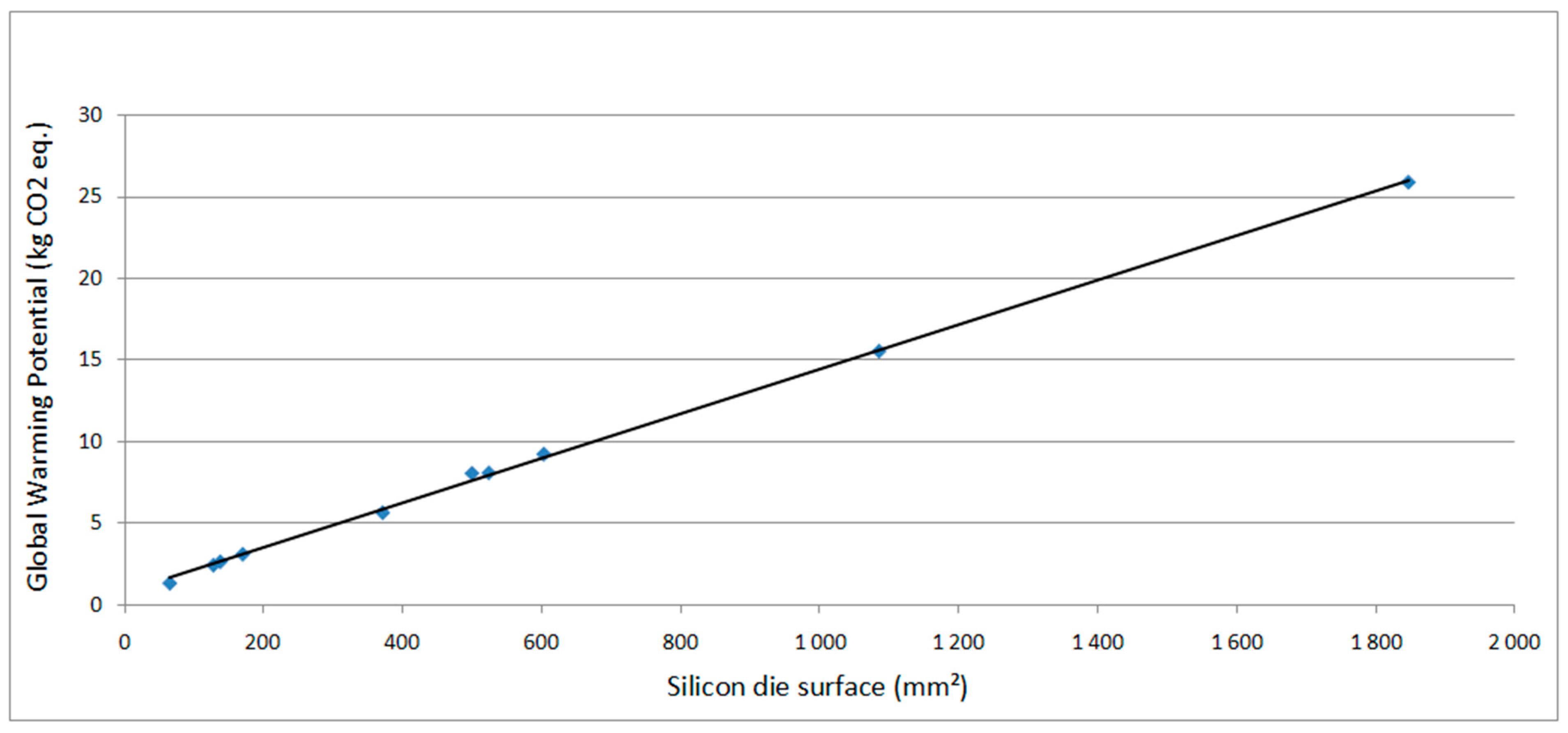

| Integrated Circuit (IC) production, I,Siarea | 3.5 kg/cm2 “known good die” (page 127 in [13]) | 5.4 kg/cm2 “die node 32 nm” (Table 3-8 in [14]) | N.T. | I,Siarea (kg CO2—eq.) = (0.0202 × Siarea cm2) × 100) + 0.142, [UF {0.0202} = 1.1, UF {0.142} = 1.1] in Section 2.6.1 |

| Flexible Printed Circuit Board (PCB) production, I,PCB,f,area | N.T. | N.T. | N.T. | See more details in Supplementary Materials file Section 3 |

| Rigid PCB production, I,PCB,r,area | N.T. | 25 g/cm2 (3.13 kg, {Table 4-4}/125.3 cm2 {Table 3-6} in [14]) | N.T. | See more details in Supplementary Materials file Section 3 |

| Production of other electronic parts than ICs located on the PCB Assemblies (PCBAs), I,PCBA,oth | N.T. | N.T. | N.T. | Included in the IC production, See more details Section 2.6.1 |

| Camera production, I,Cam | N.T. | 1709 g/g. (1.93 kg {Table 4-3} divided by, 1129 mg {p. 21} [14]) or 507 g/g. (1.93 kg {Table 4-3} divided by 3.8 g {Table 3-1} in [14]) Optical zoom and sensor size N.T. | N.T. | See more details in Section 2.6.2 |

| Plastics production, I,Plast | N.T. | N.T. | N.T. | See more details in Supplementary Materials file Section 5 |

| Aluminum production, I,Alu | N.T. | N.T. | N.T. | See more details in Supplementary Materials file Section 5 |

| Steel production, I,Steel | N.T. | N.T. | N.T. | See more details in Supplementary Materials file Section 5 |

| Battery production, I,Batt | N.T | 51 g/g (Tables 4-3 and 3-1 in [14]) | N.T. | See more details in Supplementary Materials file Section 5 |

| Charger production, I,Cha | N.T. | N.A. | N.T. | I,Cha (kg CO2—eq.) = ((0.647 × 0.78) + (0.647 × 0.12 × ((massCha in grams − 35.6)/22.5)), [UF {0.647} = 1.1, UF {0.78} = 1.1, UF {0.12} = 1.1, UF {35.6} = 1.1, UF {22.5} = 1.1]. See more details in Supplementary Materials file Section 6 |

| Other Parts production, I,Oth | N.T. | N.T. | N.T. | See more details in Supplementary Materials file Section 7 |

| Manual production, I,Man | N.T. | N.T. | N.T. | See more details in Supplementary Materials file Section 7 |

| Packaging production, I,Pack | N.T. | 1.17 g/g. ([200 g {Table 4-5}/170 g {Table 3-10} in [14]) | N.T. | 49.8 + 0.737 × (massMan + massPack), [UF {49.8} = 1.1, UF {0.737} = 1.1]. See more details in Supplementary Materials file Section 7 |

| Assembly, I,F.A. | N.T. | 4810 g/phone (Table 4-3 in [14]) | N.T. | See more details in Section 2.6.2 |

| Distribution, I,Dist | N.T. | N.T. | N.T. | See more details in Supplementary Materials file Section 8 |

| Use, I,Use | ChaFre = 1 | ChaFre = 1 | N.T. | BattCap × BattVol/1000 × 1/0.65 × 365/ChaFre × LT × 0.515; [UF {0.65} = 1.1, UF {0.515} = 1.1]. See more details in Supplementary Materials file Section 9 |

| End-of-life, I,EoLT | N.T. | N.T. | N.T. | See more details in Supplementary Materials file Section 10 |

| Support activities, I,Supp | N.T. | N.T. | N.T. | Not included (N.I.) |

| Country, Region or Geographical Area | ≈Share (%) of IC Wafer Delivery | Wafer Model Selected in EIME© Databases |

|---|---|---|

| South Korea | 20.61 | RER |

| Chinese Taipei | 20.53 | 50% RER–50% CN |

| Japan | 18.88 | RER |

| North America | 14.32 | RER |

| Singapore & Malaysia | 9.51 | 50% RER–50% |

| China | 8.95 | CN |

| Europe | 7.19 | RER |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andrae, A.S.G.; Vaija, M.S. Precision of a Streamlined Life Cycle Assessment Approach Used in Eco-Rating of Mobile Phones. Challenges 2017, 8, 21. https://doi.org/10.3390/challe8020021

Andrae ASG, Vaija MS. Precision of a Streamlined Life Cycle Assessment Approach Used in Eco-Rating of Mobile Phones. Challenges. 2017; 8(2):21. https://doi.org/10.3390/challe8020021

Chicago/Turabian StyleAndrae, Anders S. G., and Mikko Samuli Vaija. 2017. "Precision of a Streamlined Life Cycle Assessment Approach Used in Eco-Rating of Mobile Phones" Challenges 8, no. 2: 21. https://doi.org/10.3390/challe8020021

APA StyleAndrae, A. S. G., & Vaija, M. S. (2017). Precision of a Streamlined Life Cycle Assessment Approach Used in Eco-Rating of Mobile Phones. Challenges, 8(2), 21. https://doi.org/10.3390/challe8020021