Long-Term Marine Environment Exposure Effect on Butt-Welded Shipbuilding Steel

Abstract

:1. Introduction

2. Materials and Methods

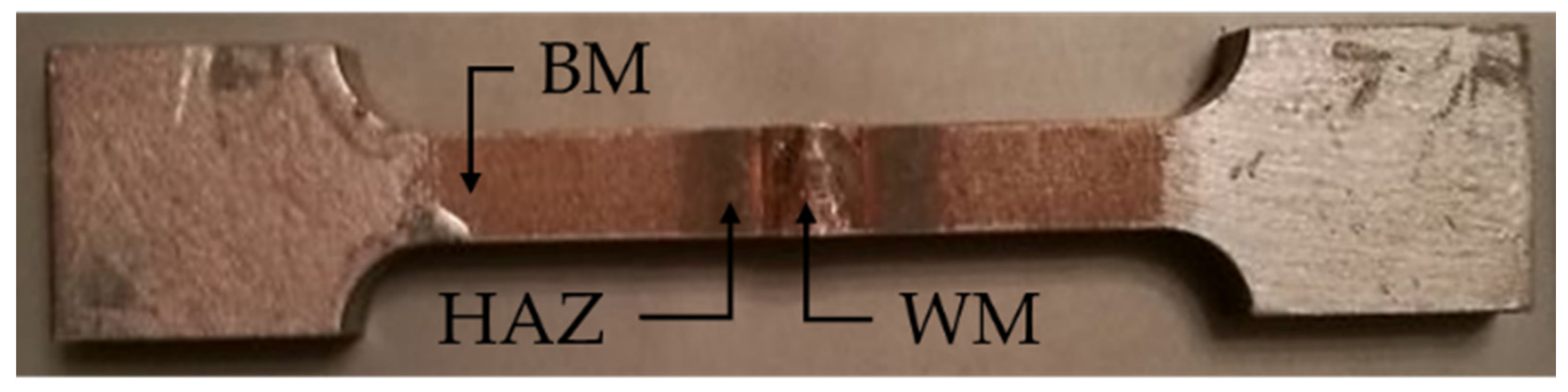

2.1. Material

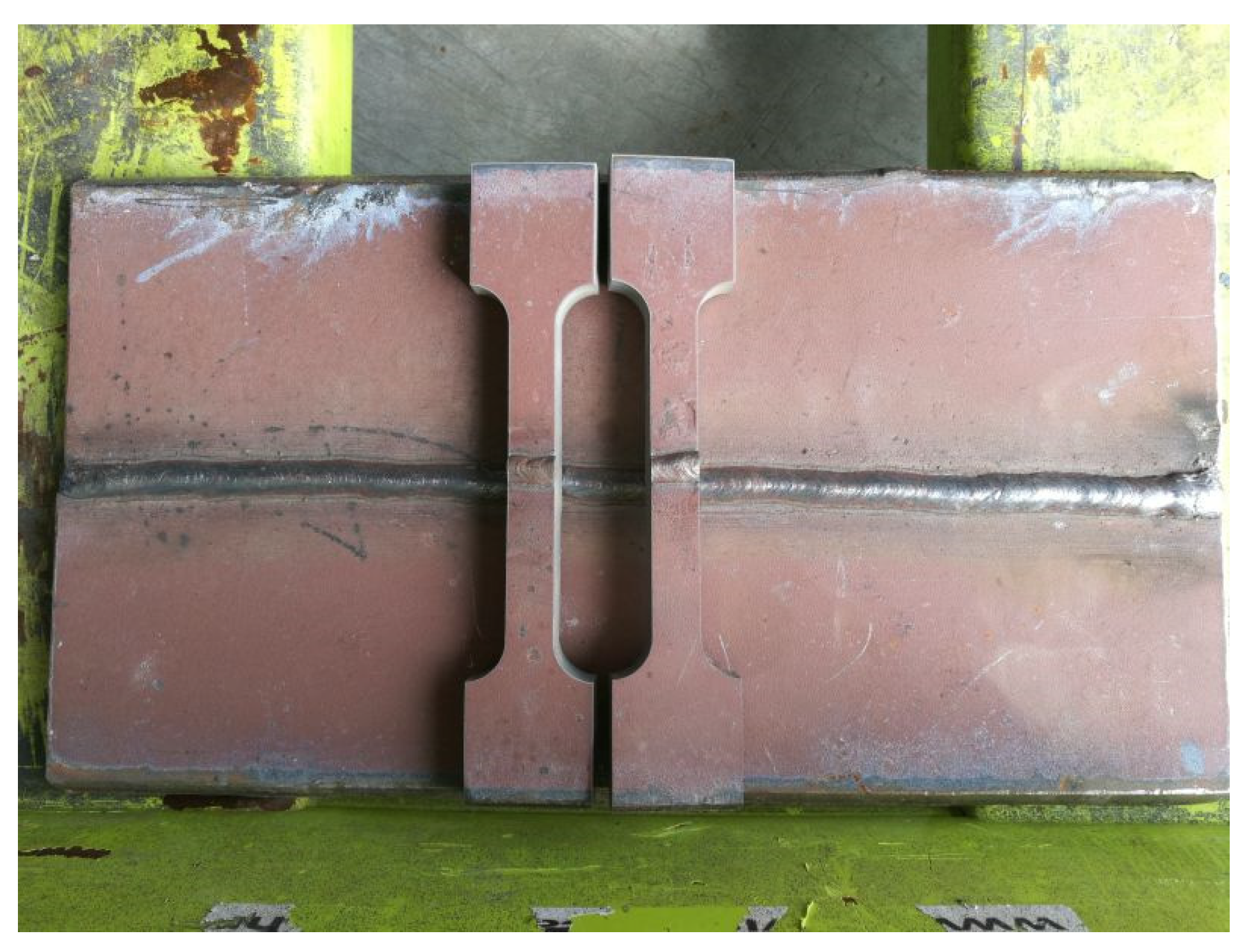

2.2. Specimen Preparation and Marine Environment Exposure

- Tap water in laboratory;

- Seawater, 10 m below sea surface, location: the northern Adriatic, in front of the city of Rijeka in Croatia;

- Sea splash, same geographical location, but with specimens at the sea surface exposed to daily change of tides and splashing of waves.

2.3. Testing Procedures

3. Results

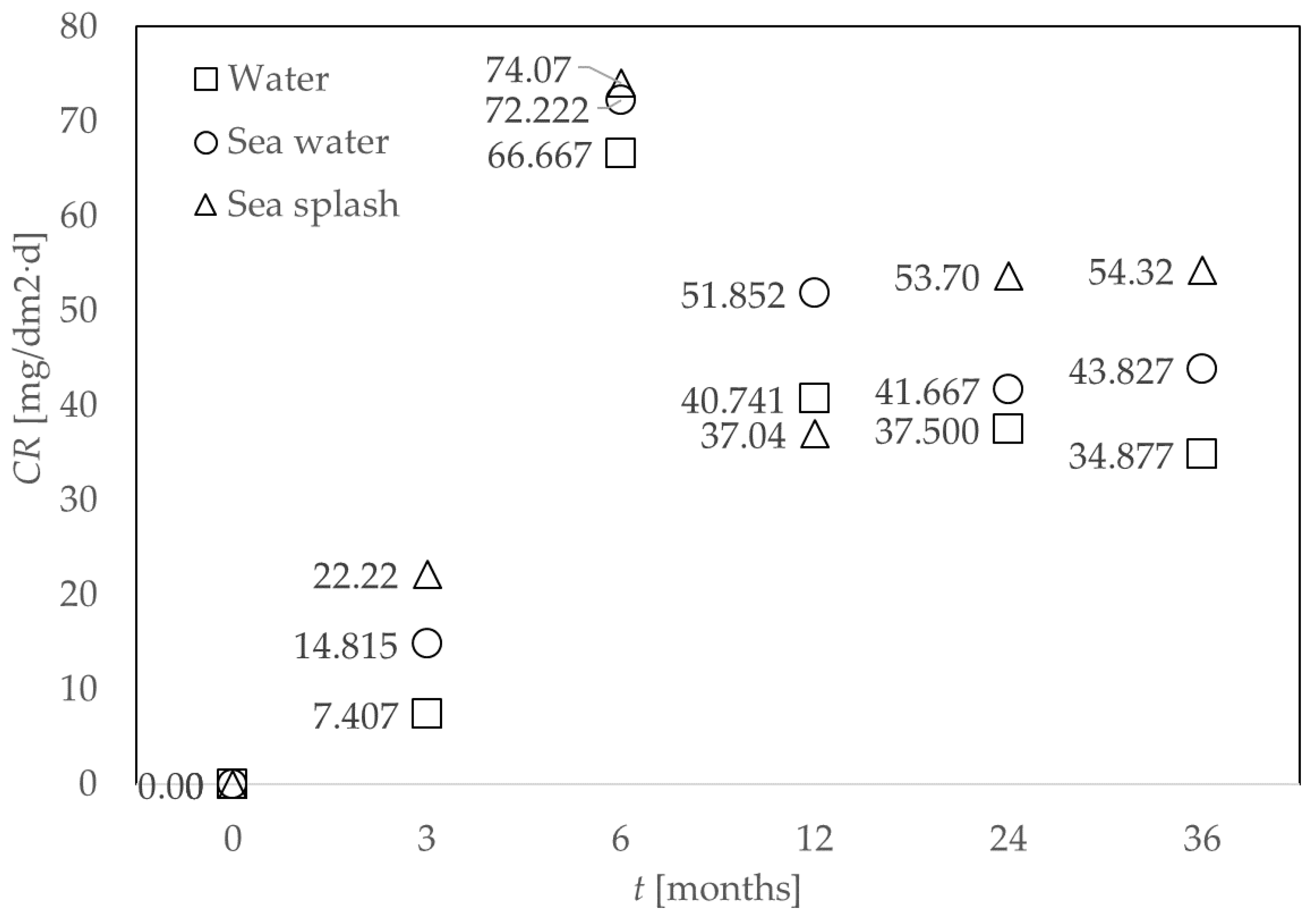

3.1. Mass Loss

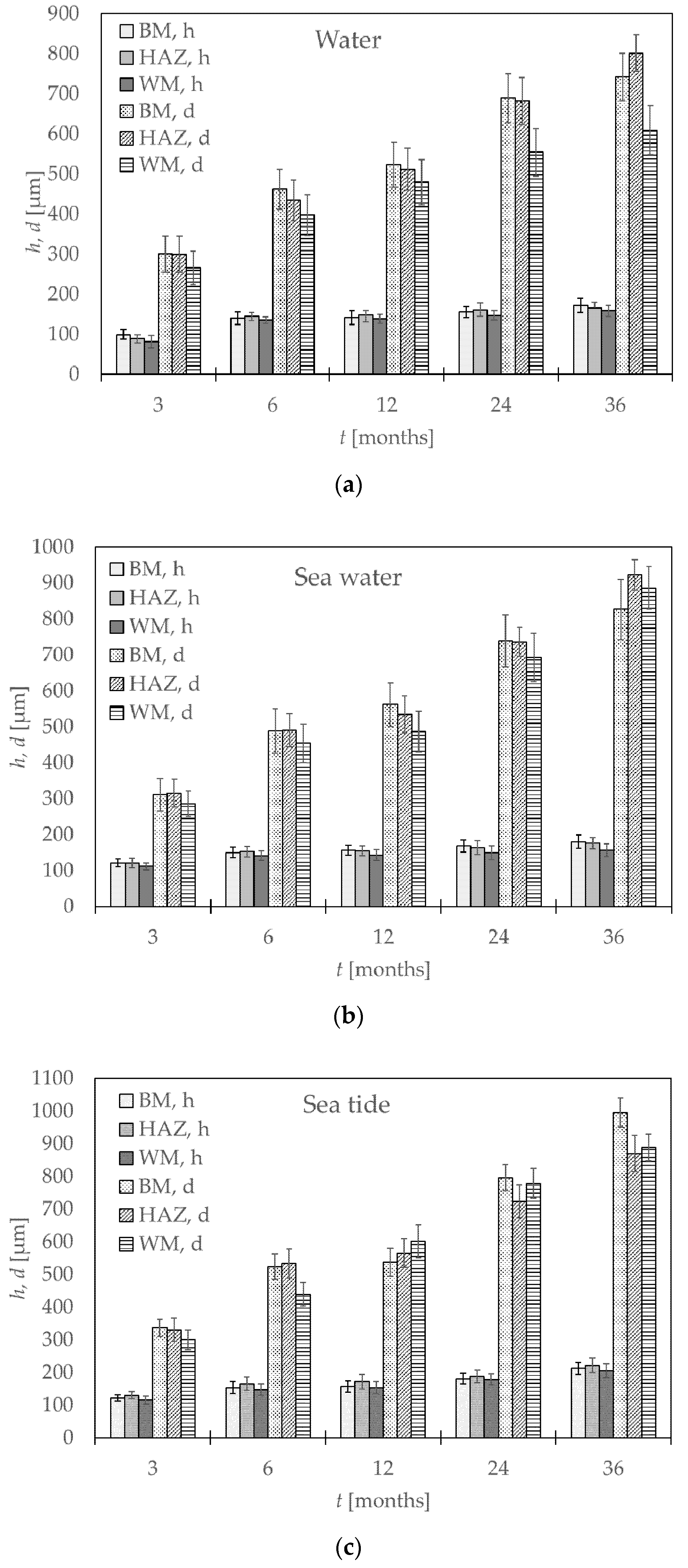

3.2. Pit Density and Dimensions

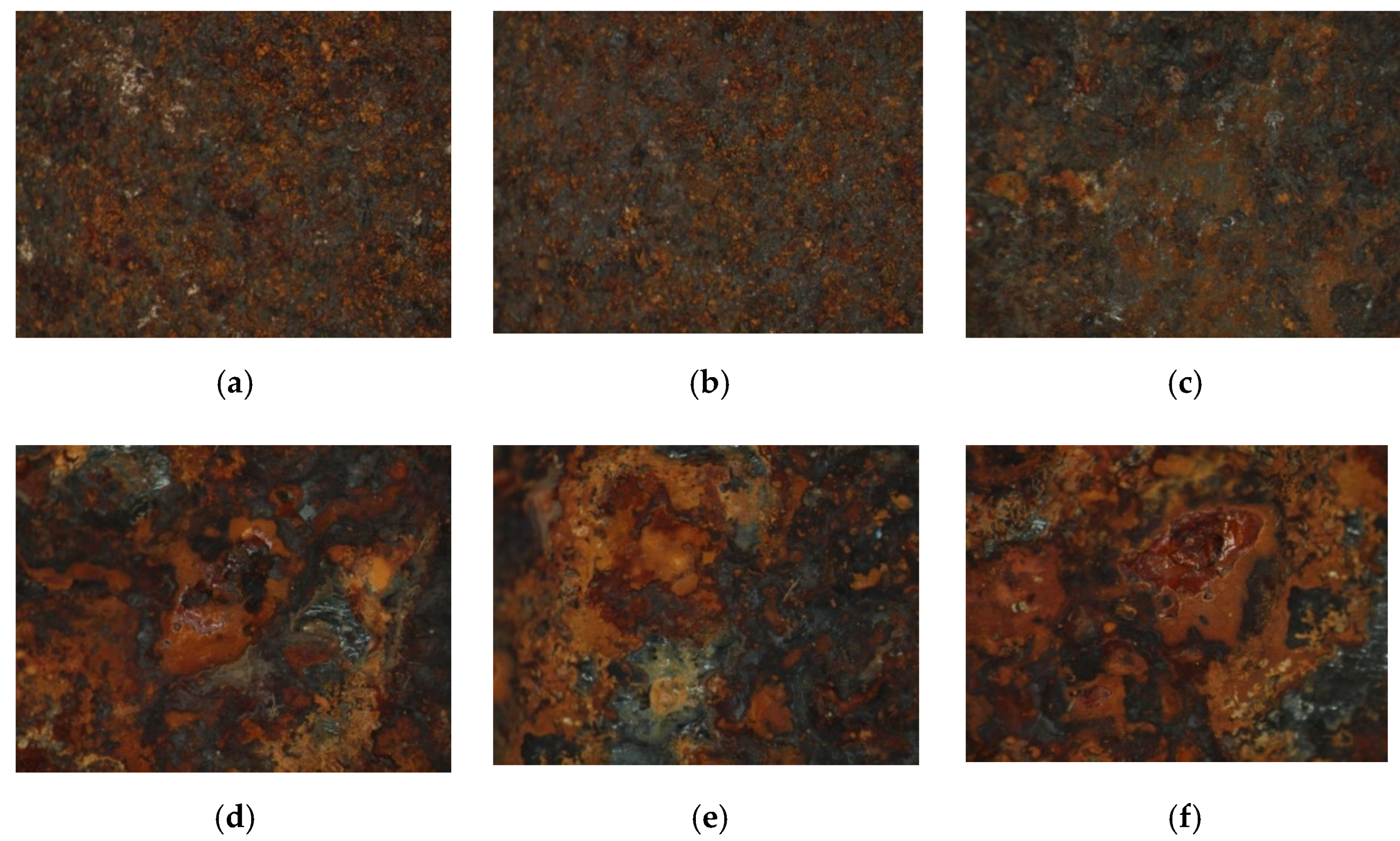

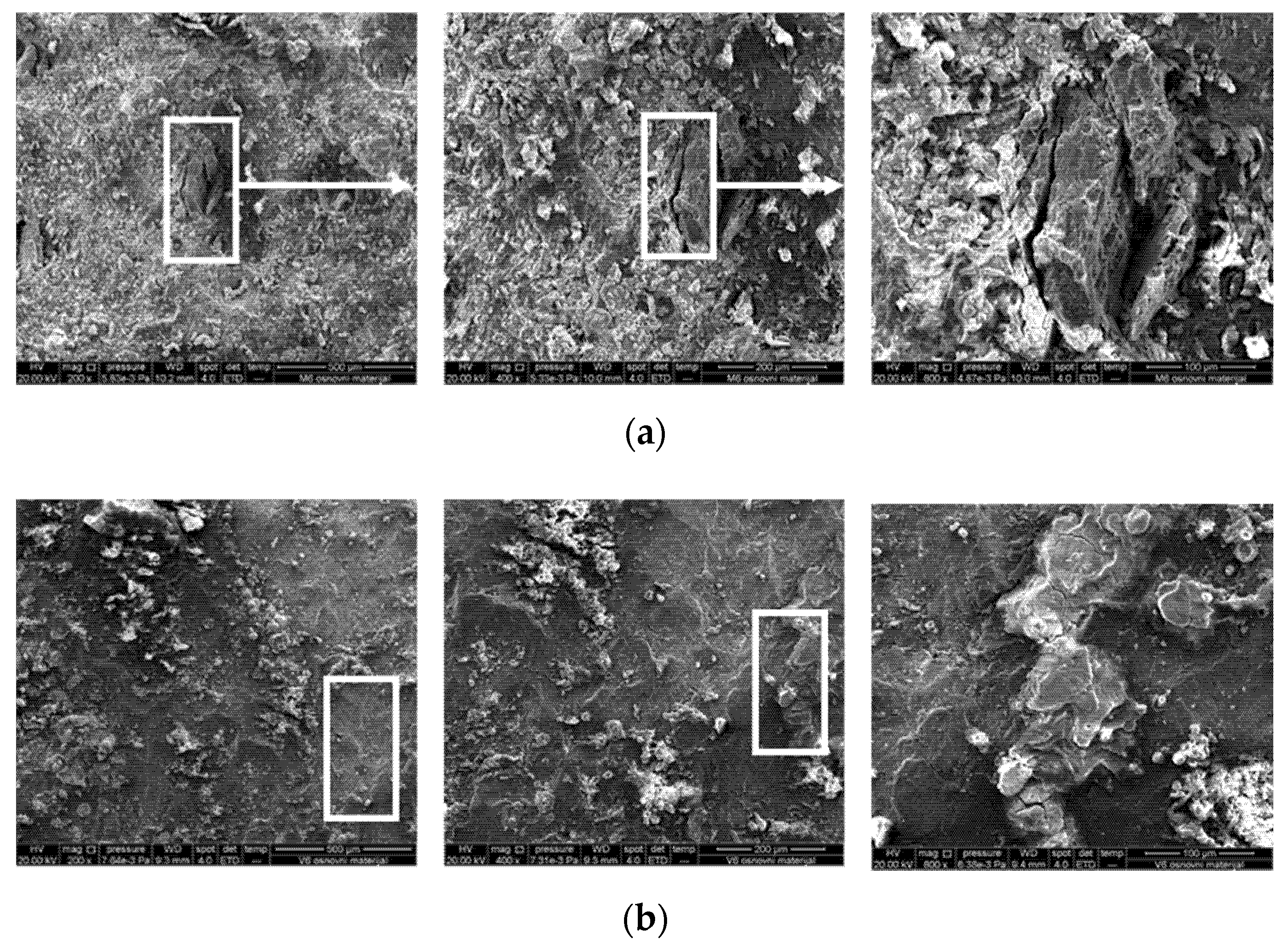

3.3. Corroded Surface Morphology

4. Discussion

5. Conclusions

- Material was exposed to a natural corrosive environment, which was not the case for most of the previous research studies based in laboratory experiments in simulated environments.

- Exposure to a corrosive environment was performed for prolonged periods, contrary to usual accelerated laboratory tests.

- Findings can be summarized as:

- Exposure between three and six months shows significant influence on mass loss of specimens.

- Sea splash generally has the most negative impact on the corrosion rate due to combined chemical and mechanical degradation of material.

- Pit density is the highest at the BM area of the specimen and lowest at the HAZ area of the specimen.

- The diameter of corrosion pits grows over the time of exposure as the pits coalesce and join.

- Sea splash impacts the shape of the pits, making them rounder and smoother compared to specimens exposed to the sea.

- Pit depths grow fastest during the first six months of exposure to a corrosive environment; after that, the rate of growth tends to slow down.

- Pit depths are generally greatest in the HAZ area of the specimen, followed by BM and WM.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Ivošević, Š.; Meštrović, R.; Kovač, N. Probabilistic estimates of corrosion rate of fuel tank structures of aging bulk carriers. Int. J. Nav. Archit. Ocean Eng. 2019, 11, 165–177. [Google Scholar] [CrossRef]

- Ivošević, Š.; Meštrović, R.; Kovač, N. A Probabilistic Method for Estimating the Percentage of Corrosion Depth on the Inner Bottom Plates of Aging Bulk Carriers. J. Mar. Sci. Eng. 2020, 8, 442. [Google Scholar] [CrossRef]

- Vizentin, G.; Vukelic, G.; Murawski, L.; Recho, N.; Orovic, J. Marine propulsion system failures—A review. J. Mar. Sci. Eng. 2020, 8, 662. [Google Scholar] [CrossRef]

- Vukelic, G.; Brnic, J. Predicted fracture behavior of shaft steels with improved corrosion resistance. Metals 2016, 6, 40. [Google Scholar] [CrossRef] [Green Version]

- Vukelic, G.; Brnic, J. Using experimental and numerical characterization in comparing marine exhaust system stainless steels. In Proceedings of the 6th. European Conference on Computational Mechanics (Solids, Structures and Coupled Problems) ECCM 6 and 7th. European Conference on Computational Fluid Dynamics ECFD 7; Owen, R., de Borst, R., Reese, J., Pearce, C., Eds.; CIMNE: Glasgow, UK, 2018; pp. 4423–4431. [Google Scholar]

- Kozak, J.; Tarełko, W. Case study of masts damage of the sail training vessel POGORIA. Eng. Fail. Anal. 2011, 18, 819–827. [Google Scholar] [CrossRef]

- Zunkel, A.; Tiebe, C.; Schlischka, J. “Stolt Rotterdam”–The sinking of an acid freighter. Eng. Fail. Anal. 2014, 43, 221–231. [Google Scholar] [CrossRef]

- Lo, M.; Karuppanan, S.; Ovinis, M. Failure Pressure Prediction of a Corroded Pipeline with Longitudinally Interacting Corrosion Defects Subjected to Combined Loadings Using FEM and ANN. J. Mar. Sci. Eng. 2021, 9, 281. [Google Scholar] [CrossRef]

- Salazar-Domínguez, C.M.; Hernández-Hernández, J.; Rosas-Huerta, E.D.; Iturbe-Rosas, G.E.; Herrera-May, A.L. Structural Analysis of a Barge Midship Section Considering the Still Water and Wave Load Effects. J. Mar. Sci. Eng. 2021, 9, 99. [Google Scholar] [CrossRef]

- Xu, S.; Wang, H.; Li, A.; Wang, Y.; Su, L. Effects of corrosion on surface characterization and mechanical properties of butt-welded joints. J. Constr. Steel Res. 2016, 126, 50–62. [Google Scholar] [CrossRef]

- Česen, A.; Kosec, T.; Legat, A. Characterization of steel corrosion in mortar by various electrochemical and physical techniques. Corros. Sci. 2013, 75, 47–57. [Google Scholar] [CrossRef] [Green Version]

- Reiser, D.B.; Alkire, R.C. The measurement of shape change during early stages of corrosion pit growth. Corros. Sci. 1984, 24, 579–585. [Google Scholar] [CrossRef]

- Holme, B.; Lunder, O. Characterisation of pitting corrosion by white light interferometry. Corros. Sci. 2007, 49, 391–401. [Google Scholar] [CrossRef]

- Ren, Z.; Ernst, F. Stress–Corrosion Cracking of AISI 316L Stainless Steel in Seawater Environments: Effect of Surface Machining. Metals 2020, 10, 1324. [Google Scholar] [CrossRef]

- He, J.; Xu, S.; Ti, W.; Han, Y.; Mei, J.; Wang, X. The Pitting Corrosion Behavior of the Austenitic Stainless Steel 308L-316L Welded Joint. Metals 2020, 10, 1258. [Google Scholar] [CrossRef]

- Melchers, R.E. Long-Term Durability of Marine Reinforced Concrete Structures. J. Mar. Sci. Eng. 2020, 8, 290. [Google Scholar] [CrossRef] [Green Version]

- Melchers, R.E. Experience-Based Physico-Chemical Models for Long-Term Reinforcement Corrosion. Corros. Mater. Degrad. 2021, 2, 6. [Google Scholar] [CrossRef]

- Kim, D.K.; Wong, E.W.C.; Cho, N.K. An advanced technique to predict time-dependent corrosion damage of onshore, offshore, nearshore and ship structures: Part I = generalisation. Int. J. Nav. Archit. Ocean Eng. 2020, 12, 657–666. [Google Scholar] [CrossRef]

- Kim, D.K.; Lim, H.L.; Cho, N.K. An advanced technique to predict time-dependent corrosion damage of onshore, offshore, nearshore and ship structures: Part II = Application to the ship’s ballast tank. Int. J. Nav. Archit. Ocean Eng. 2020, 12, 645–656. [Google Scholar] [CrossRef]

- Świerczyńska, A.; Fydrych, D.; Landowski, M.; Rogalski, G.; Łabanowski, J. Hydrogen embrittlement of X2CrNiMoCuN25-6-3 super duplex stainless steel welded joints under cathodic protection. Constr. Build. Mater. 2020, 238, 117697. [Google Scholar] [CrossRef]

- Świerczyńska, A.; Landowski, M. Plasticity of Bead-on-Plate Welds Made with the Use of Stored Flux-Cored Wires for Offshore Applications. Materials 2020, 13, 3888. [Google Scholar] [CrossRef] [PubMed]

- Paik, J.K.; Thayamballi, A.K.; Park, Y.I. Hwang, J.S. A time-dependent corrosion wastage model for seawater ballast tank structures of ships. Corros. Sci. 2004, 46, 471–486. [Google Scholar] [CrossRef]

- Guedes Soares, C.; Garbatov, Y.; Zayed, A.; Wang, G. Corrosion wastage model for ship crude oil tanks. Corros. Sci. 2008, 50, 3095–3106. [Google Scholar] [CrossRef]

- Soares, C.G.; Garbatov, Y.; Zayed, A.; Wang, G. Influence of environmental factors on corrosion of ship structures in marine atmosphere. Corros. Sci. 2009, 51, 2014–2026. [Google Scholar] [CrossRef]

- Paik, J.K.; Kim, D.K. Advanced method for the development of an empirical model to predict time-dependent corrosion wastage. Corros. Sci. 2012, 63, 51–58. [Google Scholar] [CrossRef]

- Mohd, M.H.; Kim, D.K.; Kim, D.W.; Paik, J.K. A time-variant corrosion wastage model for subsea gas pipelines. Ships Offshore Struct. 2014, 9, 161–176. [Google Scholar] [CrossRef]

- Saeed, A.; Khan, Z.A.; Nazir, M.H. Time dependent surface corrosion analysis and modelling of automotive steel under a simplistic model of variations in environmental parameters. Mater. Chem. Phys. 2016, 178, 65–73. [Google Scholar] [CrossRef]

- Pastorcic, D.; Vukelic, G.; Bozic, Z. Coil spring failure and fatigue analysis. Eng. Fail. Anal. 2019. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, W.; Gu, X. Modeling time-dependent circumferential non-uniform corrosion of steel bars in concrete considering corrosion-induced cracking effects. Eng. Struct. 2019, 201, 109766. [Google Scholar] [CrossRef]

- Yu, Y.; Gao, W.; Castel, A.; Chen, X.; Liu, A. An integrated framework for modelling time-dependent corrosion propagation in offshore concrete structures. Eng. Struct. 2021, 228, 111482. [Google Scholar] [CrossRef]

- Choi, Y.Y.; Lee, S.H.; Park, J.C.; Choi, D.J.; Yoon, Y.S. The impact of corrosion on marine vapour recovery systems by VOC generated from ships. Int. J. Nav. Archit. Ocean Eng. 2019, 11, 52–58. [Google Scholar] [CrossRef]

- Schoefs, F.; Boéro, J.; Capra, B. Long-Term Stochastic Modeling of Sheet Pile Corrosion in Coastal Environment from On-Site Measurements. J. Mar. Sci. Eng. 2020, 8, 70. [Google Scholar] [CrossRef] [Green Version]

- Duan, T.; Peng, W.; Ding, K.; Guo, W.; Hou, J.; Cheng, W.; Liu, S.; Xu, L. Long-term field exposure corrosion behavior investigation of 316L stainless steel in the deep sea environment. Ocean Eng. 2019, 189, 106405. [Google Scholar] [CrossRef]

- Martins, K.L.; Pinto, V.T.; Fragassa, C.; Real, M.V.; Rocha, L.A.O.; Isoldi, L.A.; dos Santos, E.D. A Simplified Numerical Method for the Design and Analysis of FPSO Platform Brackets Subjected to Operational Conditions. J. Mar. Sci. Eng. 2020, 8, 929. [Google Scholar] [CrossRef]

- Kim, J.D.; Myoung, G.H.; Suh, J. Butt weldability of shipbuilding steel AH36 using laser-arc hybrid welding. Trans. Korean Soc. Mech. Eng. A 2016, 40, 901–906. [Google Scholar] [CrossRef]

- Dueren, C.F. Prediction of the hardness in the HAZ of HSLA steels by means of the C-equivalent. In Proceedings of the Conference on Hardenability of Steels 1990, Derby, UK, 17 May 1990. [Google Scholar]

- Institute of Oceanography and Fisheries. Početna Procjena Stanja i Opterećenja Morskog Okoliša Hrvatskog Dijela Jadrana; Institute of Oceanography and Fisheries: Split, Croatia, 2012. [Google Scholar]

- Garbatov, Y.; Saad-Eldeen, S.; Guedes Soares, C.; Parunov, J.; Kodvanj, J. Tensile test analysis of corroded cleaned aged steel specimens. Corros. Eng. Sci. Technol. 2019, 54, 154–162. [Google Scholar] [CrossRef]

- American Society for Testing and Materials, ASTM G1-03 Standard Practice for Preparing, Cleaning and Evaluating Corrosion Test Specimens; West Conshohocken: Montgomery County, PA, USA, 2011.

- Florescu, S.N.; Gheonea, M.C.; Mihailescu, D.; Teodor, V. Influence of marine corrosion on the roughness of MAG welded joint surfaces. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd.: Bristol, UK, 2020; Volume 968, p. 012008. [Google Scholar]

- Muthanna, B.G.N.; Amara, M.; Meliani, M.H.; Mettai, B.; Božić, Ž.; Suleiman, R.; Sorour, A.A. Inspection of internal erosion-corrosion of elbow pipe in the desalination station. Eng. Fail. Anal. 2019. [Google Scholar] [CrossRef]

- Luo, L.; Huang, Y.; Weng, S.; Xuan, F.Z. Mechanism-related modelling of pit evaluation in the CrNiMoV steel in simulated environment of low pressure nuclear steam turbine. Mater. Des. 2016, 105, 240–250. [Google Scholar] [CrossRef]

- Li, S.X.; Akid, R. Corrosion fatigue life prediction of a steel shaft material in seawater. Eng. Fail. Anal. 2013, 34, 324–334. [Google Scholar] [CrossRef]

- Zerbst, U.; Madia, M.; Klinger, C.; Bettge, D.; Murakami, Y. Defects as a root cause of fatigue failure of metallic components. III: Cavities, dents, corrosion pits, scratches. Eng. Fail. Anal. 2019, 97, 759–776. [Google Scholar] [CrossRef]

- Rajput, A.; Park, J.H.; Hwan Noh, S.; Kee Paik, J. Fresh and sea water immersion corrosion testing on marine structural steel at low temperature. Ships Offshore Struct. 2020, 15, 661–669. [Google Scholar] [CrossRef]

- Rajput, A.; Paik, J.K. Effects of naturally-progressed corrosion on the chemical and mechanical properties of structural steels. Structures 2021, 29, 2120–2138. [Google Scholar] [CrossRef]

- Tavares, S.S.M.; Batista, R.T.; Landim, R.V.; Velasco, J.A.C.; Senna, L.F. Investigation of the effect of low temperature aging on the mechanical properties and susceptibility to sulfide stress corrosion cracking of 22%Cr duplex stainless steel. Eng. Fail. Anal. 2020, 113, 104553. [Google Scholar] [CrossRef]

- Kodvanj, J.; Garbatov, Y.; Guedes Soares, C.; Parunov, J. Numerical Analysis of Stress Concentration in Non-uniformly Corroded Small-Scale Specimens. J. Mar. Sci. Appl. 2020, 1–9. [Google Scholar] [CrossRef]

- Vukelic, G.; Vizentin, G.; Masar, A. Hydraulic torque wrench adapter failure analysis. Eng. Fail. Anal. 2019, 96, 530–537. [Google Scholar] [CrossRef]

- Poggi, L.; Gaggero, T.; Gaiotti, M.; Ravina, E.; Rizzo, C.M. Recent developments in remote inspections of ship structures. Int. J. Nav. Archit. Ocean Eng. 2020, 12, 881–891. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cr | Cu | Al | Ti | V | Mo | Ni | CEq |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.157 | 0.392 | 1.501 | 0.014 | 0.003 | 0.03 | 0.015 | 0.042 | 0.003 | 0.003 | 0.08 | 0.01 | 0.2763 |

| Environment: | Water | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Location: | BM | HAZ | WM | ||||||||||||

| Exposure Time (months): | 3 | 6 | 12 | 24 | 36 | 3 | 6 | 12 | 24 | 36 | 3 | 6 | 12 | 24 | 36 |

| Pit density (10 mm−2): | 3 ± 1 | 4 ± 1 | 5 ± 1 | 4 ± 1 | 5 ± 1 | 2 ± 1 | 3 ± 1 | 5 ± 2 | 4 ± 1 | 5 ± 1 | 2 ± 1 | 2 ± 1 | 3 ± 1 | 3 ± 1 | 4 ± 1 |

| Environment: | Seawater | ||||||||||||||

| Location: | BM | HAZ | WM | ||||||||||||

| Exposure Time (months): | 3 | 6 | 12 | 24 | 36 | 3 | 6 | 12 | 24 | 36 | 3 | 6 | 12 | 24 | 36 |

| Pit Density (10 mm−2): | 6 ± 1 | 9 ± 3 | 6 ± 2 | 5 ± 2 | 5 ± 1 | 2 ± 1 | 3 ± 1 | 3 ± 1 | 2 ± 1 | 2 ± 2 | 4 ± 1 | 7 ± 2 | 6 ± 2 | 6 ± 1 | 5 ± 1 |

| Environment: | Sea splash | ||||||||||||||

| Location: | BM | HAZ | WM | ||||||||||||

| Exposure Time (months): | 3 | 6 | 12 | 24 | 36 | 3 | 6 | 12 | 24 | 36 | 3 | 6 | 12 | 24 | 36 |

| Pit Density (10 mm−2): | 4 ± 1 | 6 ± 2 | 6 ± 2 | 5 ± 1 | 5 ± 1 | 3 ± 2 | 5 ± 2 | 5 ± 2 | 4 ± 1 | 5 ± 1 | 2 ± 1 | 4 ± 1 | 3 ± 1 | 3 ± 1 | 2 ± 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vukelic, G.; Vizentin, G.; Brnic, J.; Brcic, M.; Sedmak, F. Long-Term Marine Environment Exposure Effect on Butt-Welded Shipbuilding Steel. J. Mar. Sci. Eng. 2021, 9, 491. https://doi.org/10.3390/jmse9050491

Vukelic G, Vizentin G, Brnic J, Brcic M, Sedmak F. Long-Term Marine Environment Exposure Effect on Butt-Welded Shipbuilding Steel. Journal of Marine Science and Engineering. 2021; 9(5):491. https://doi.org/10.3390/jmse9050491

Chicago/Turabian StyleVukelic, Goran, Goran Vizentin, Josip Brnic, Marino Brcic, and Florian Sedmak. 2021. "Long-Term Marine Environment Exposure Effect on Butt-Welded Shipbuilding Steel" Journal of Marine Science and Engineering 9, no. 5: 491. https://doi.org/10.3390/jmse9050491

APA StyleVukelic, G., Vizentin, G., Brnic, J., Brcic, M., & Sedmak, F. (2021). Long-Term Marine Environment Exposure Effect on Butt-Welded Shipbuilding Steel. Journal of Marine Science and Engineering, 9(5), 491. https://doi.org/10.3390/jmse9050491

.JPG)