Operational Analysis of Container Ships by Using Maritime Big Data

Abstract

1. Introduction

2. Related Work

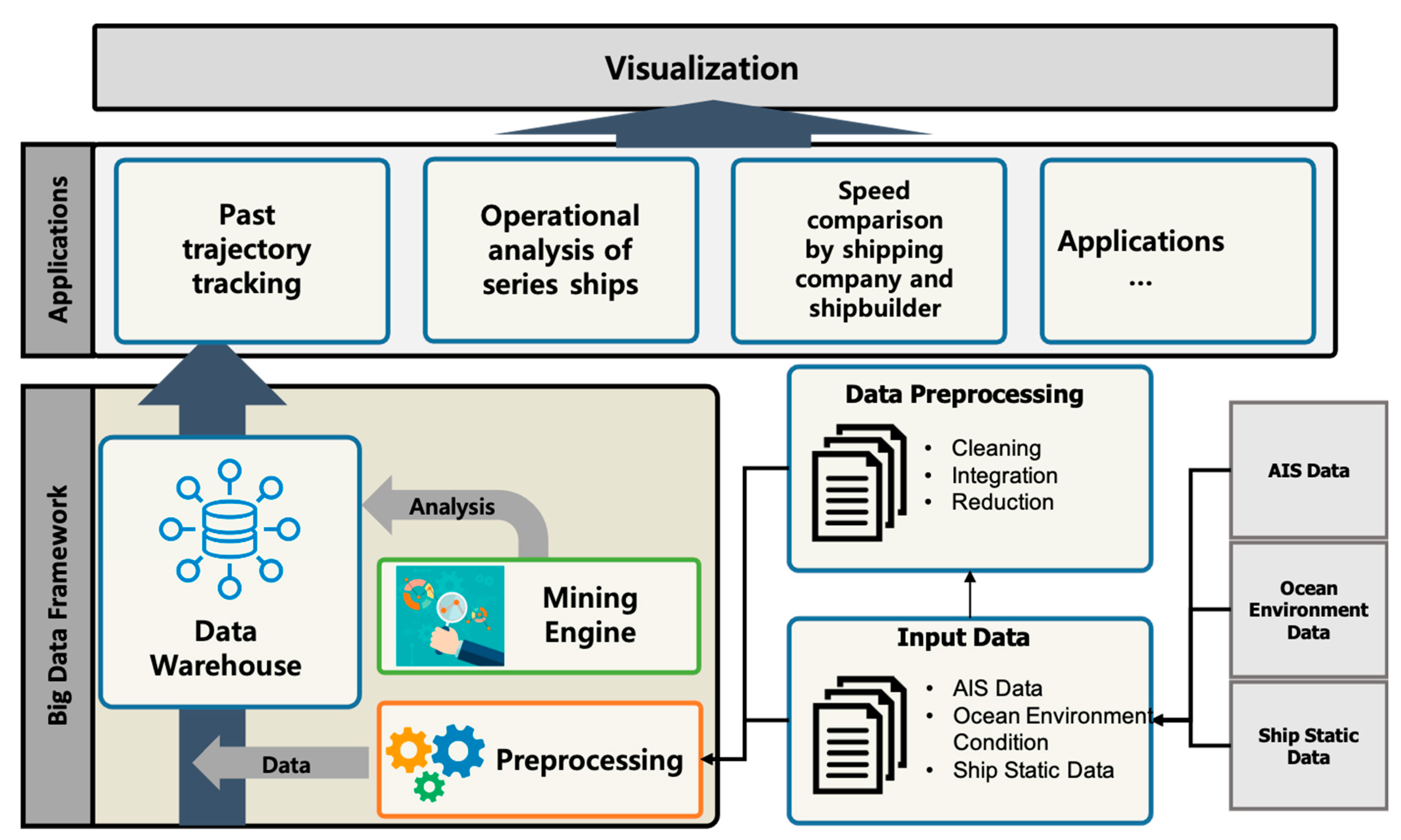

3. Maritime Big Data and the Big Data Handling Framework for Operational Analysis

3.1. Input Data

3.1.1. AIS Data

3.1.2. Ocean Environment Data

3.2. Combining the Maritime Big Data and the Data Handling Framework

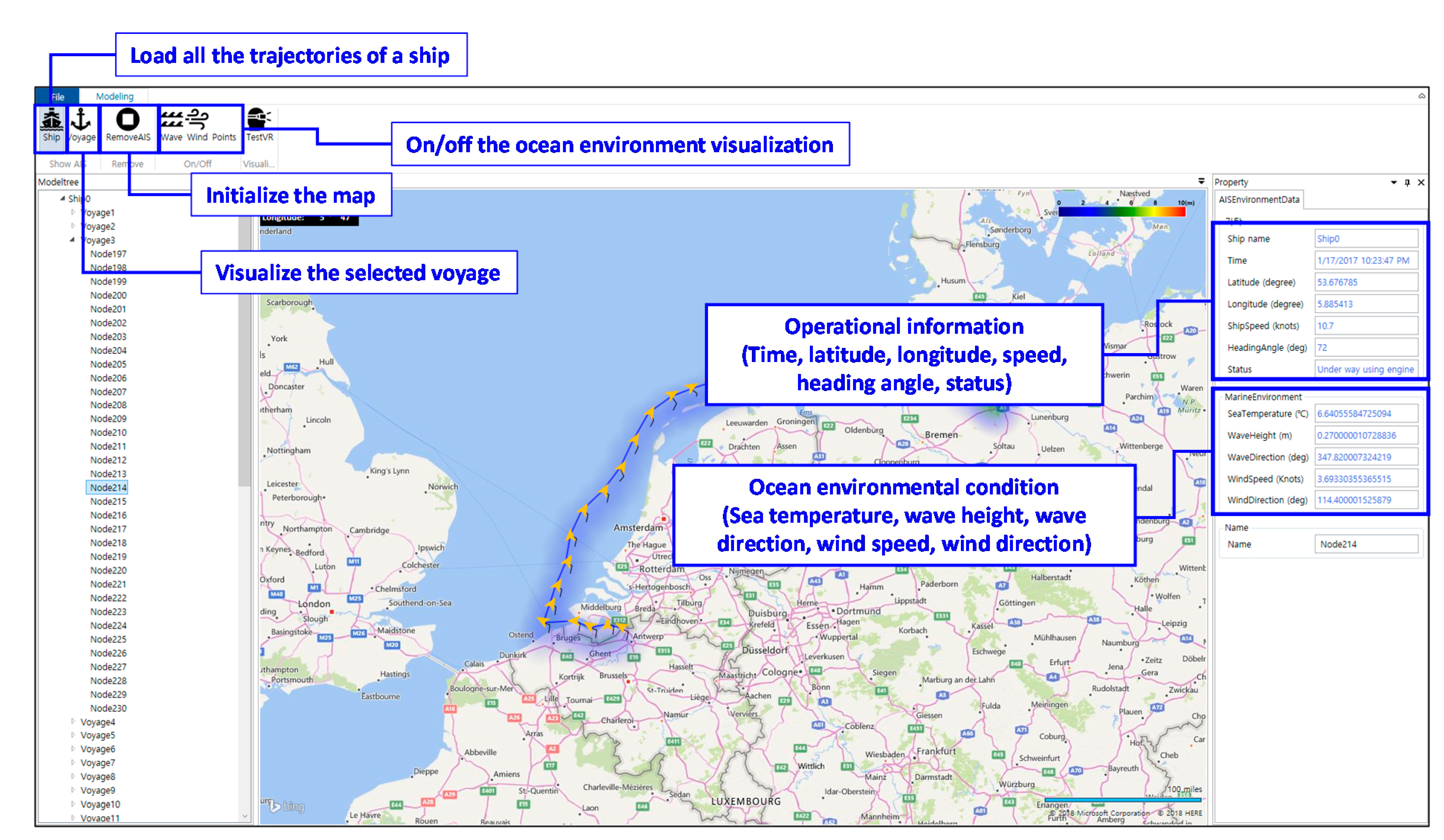

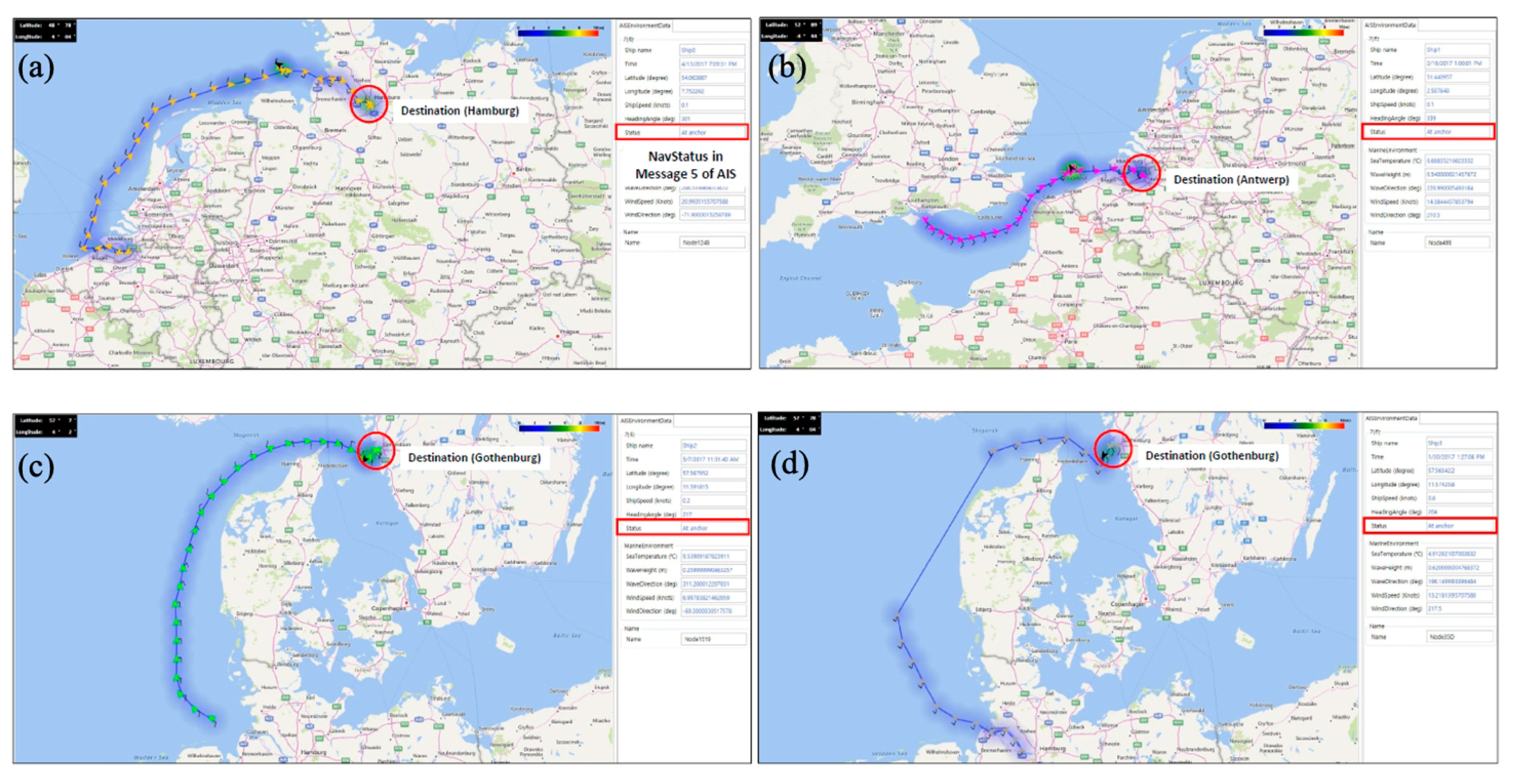

3.3. Visualization Program for Maritime Data Analysis

4. Operational Analysis of Container Ships

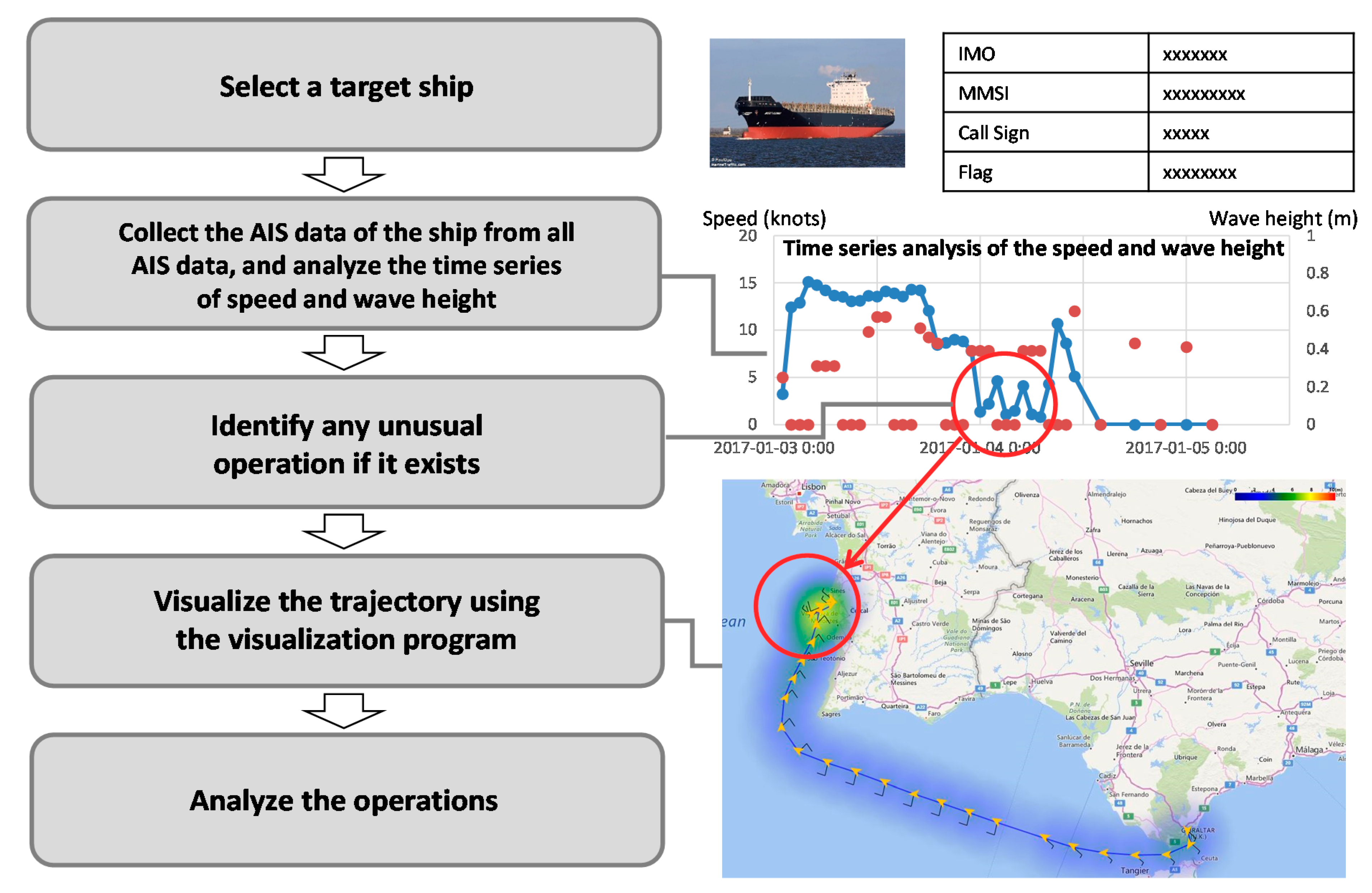

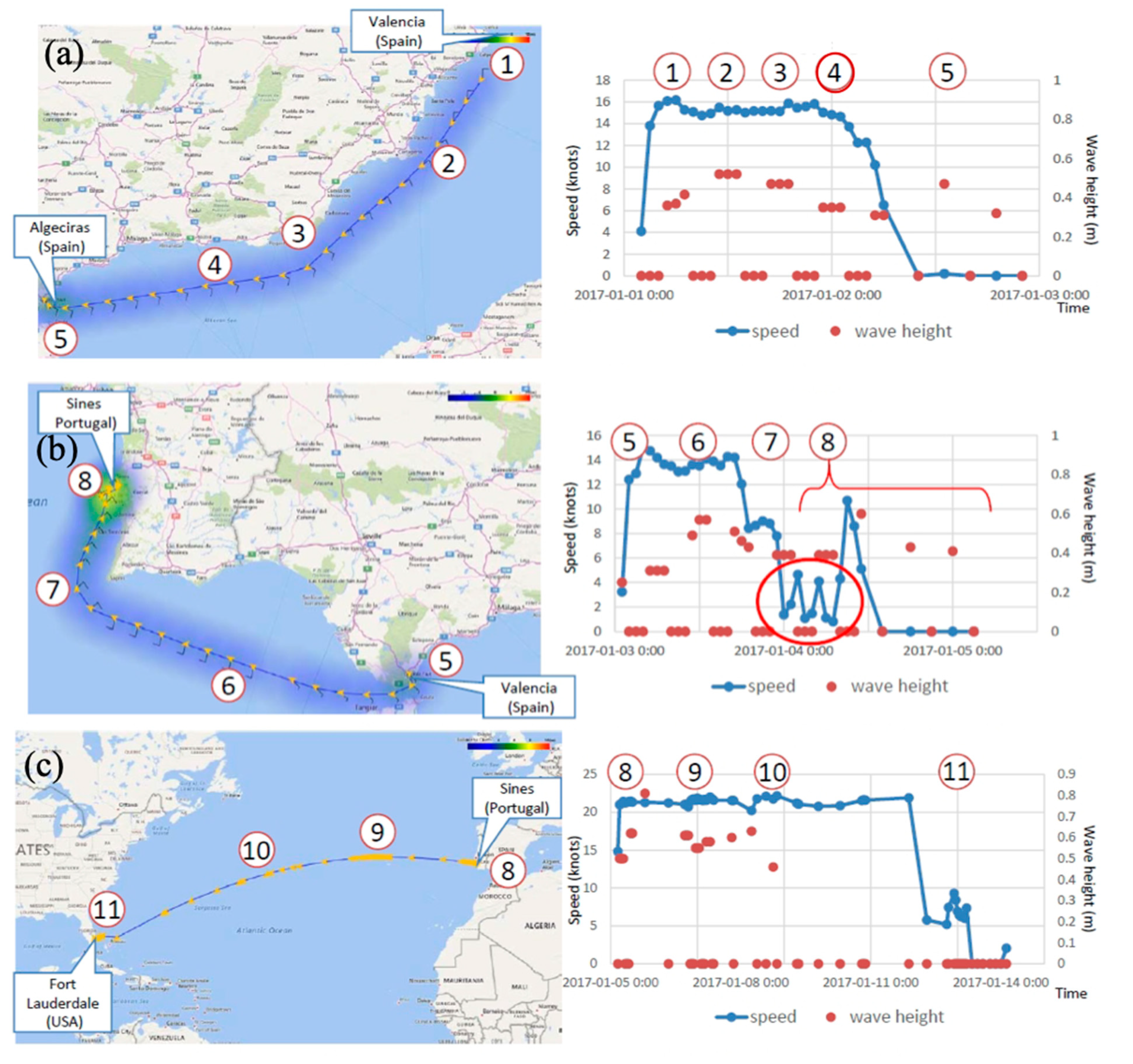

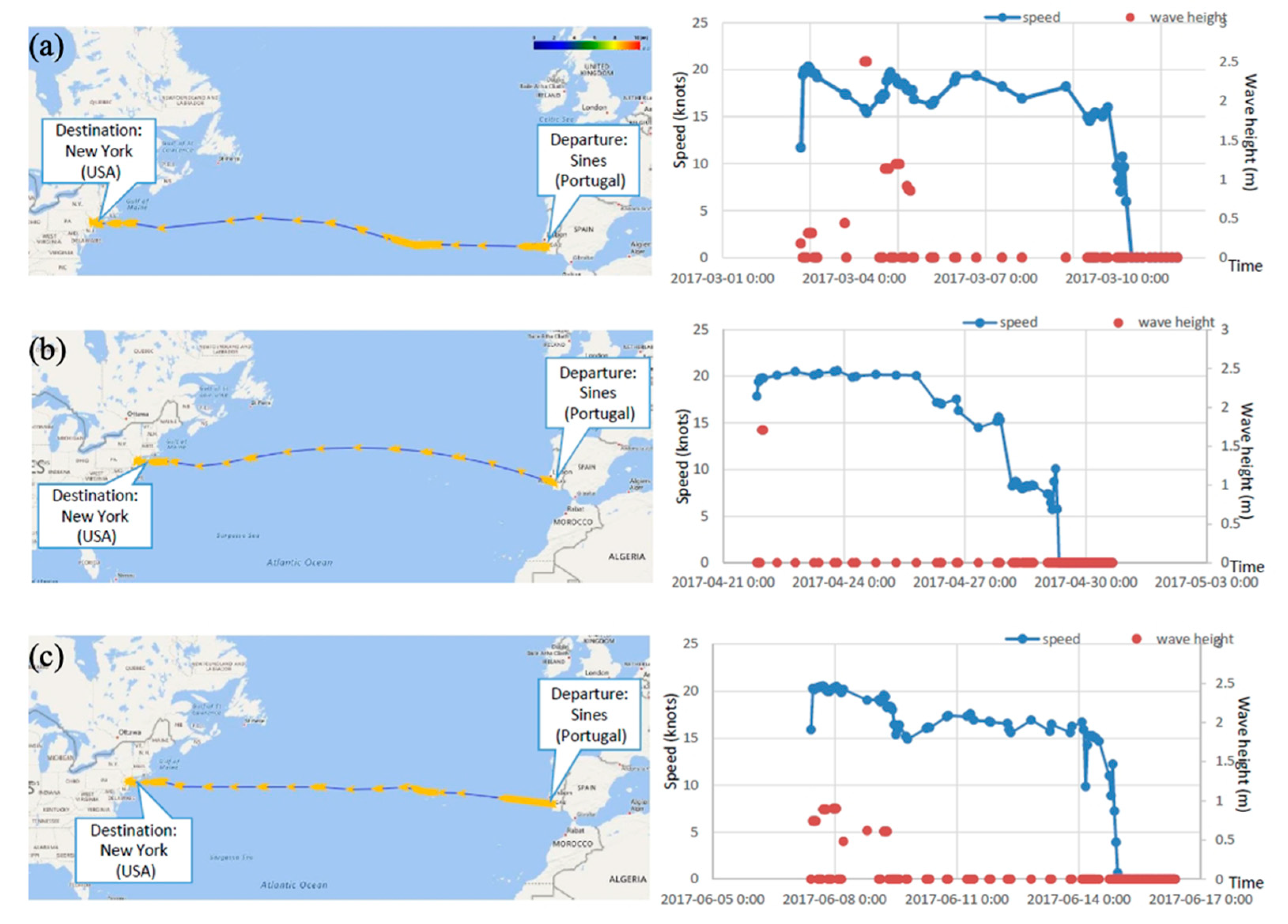

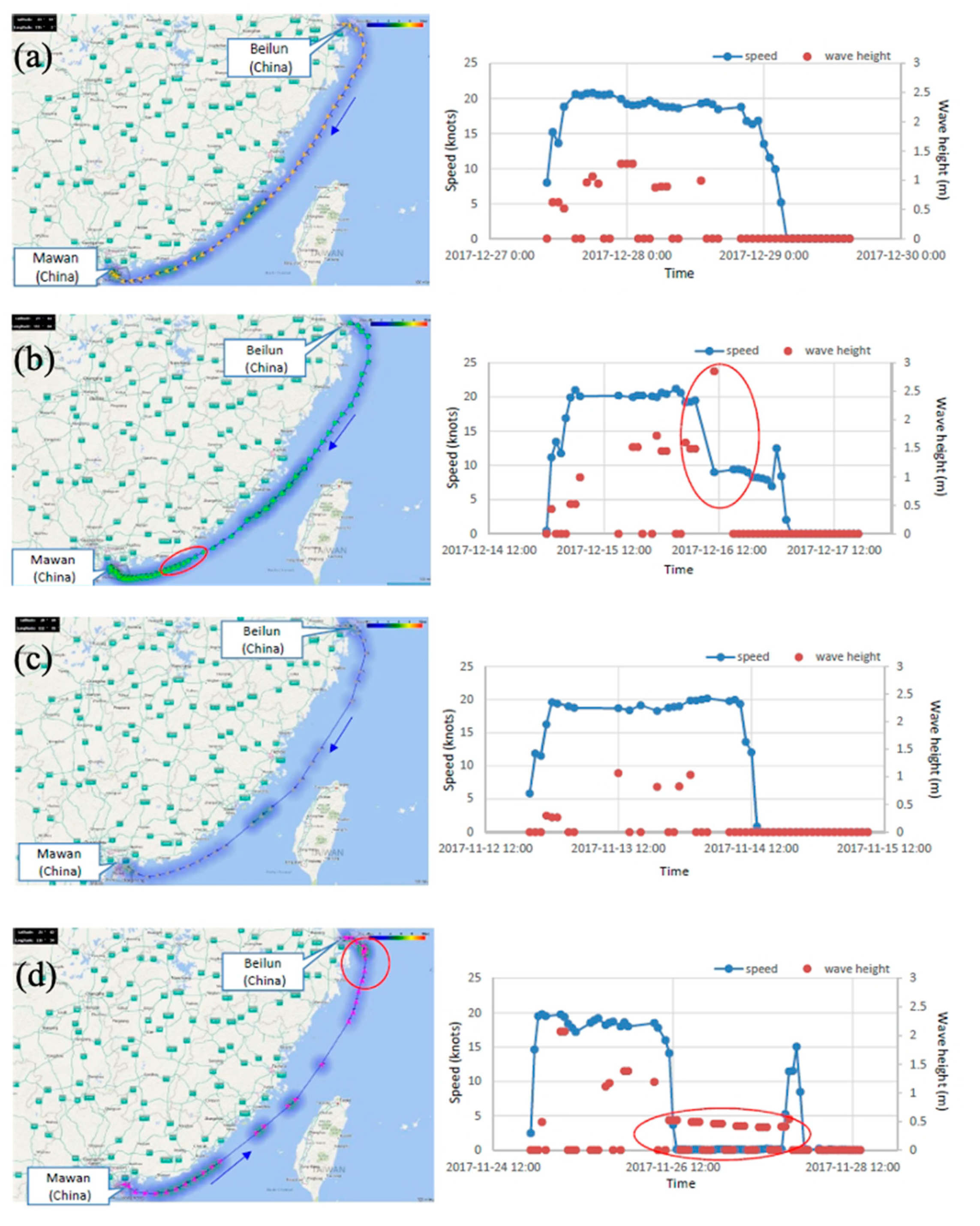

4.1. Trajectory Tracking and Analysis

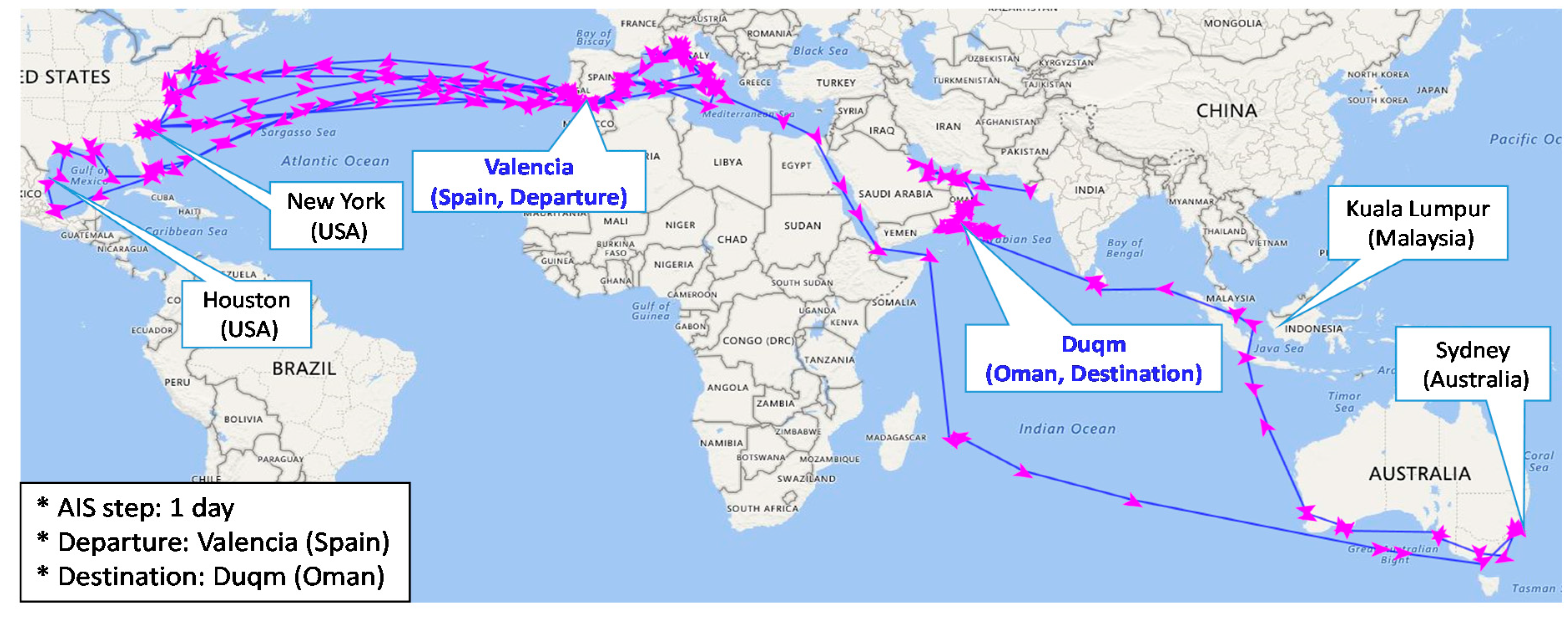

4.1.1. Past Trajectory Tracking of a Container Ship

4.1.2. Speed Comparison of a Container Ship for the Same Route

4.1.3. Operation Comparison among Series Container Ships for the Same Route

4.1.4. Mooring or Anchoring Time Analysis around Ports

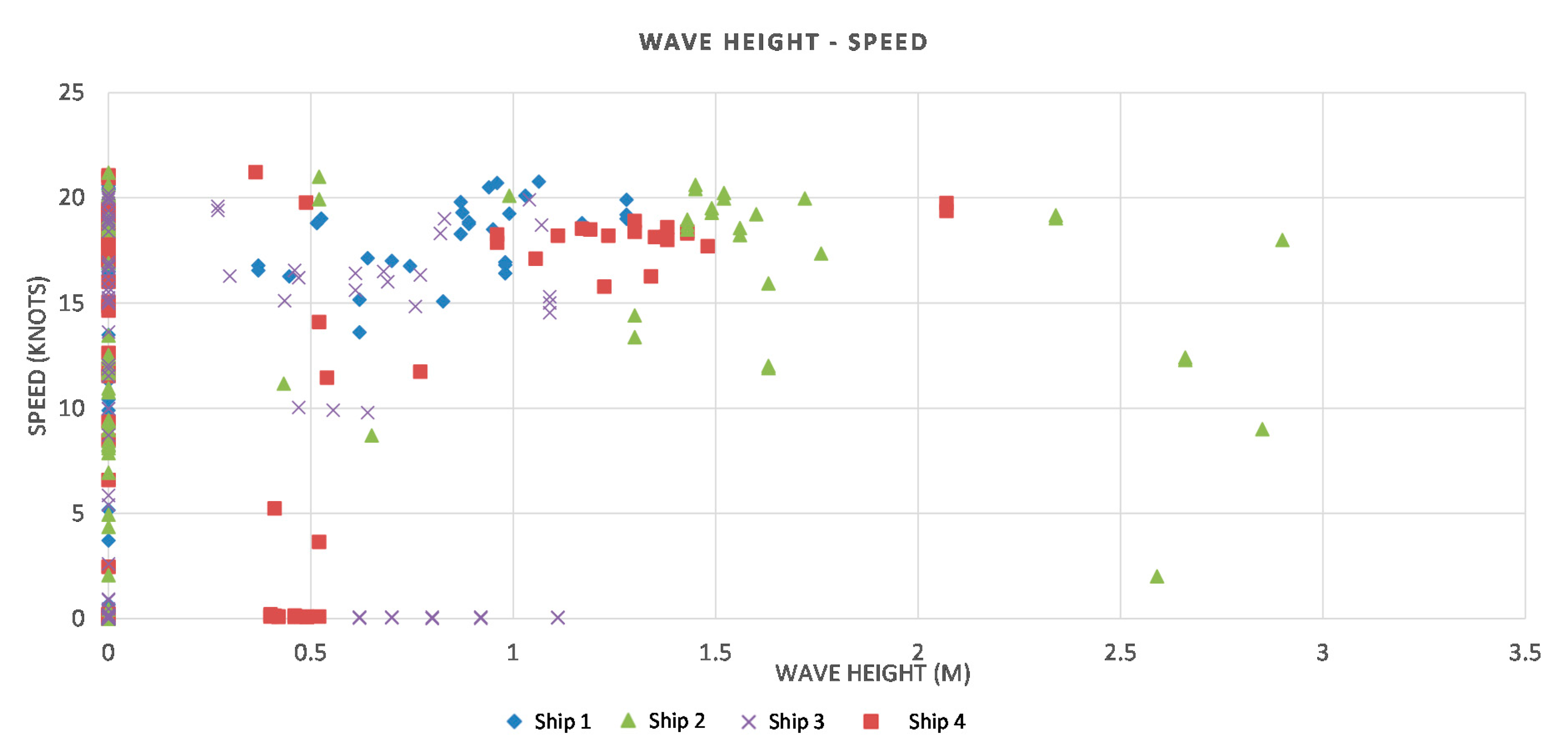

4.2. Speed Pattern Analysis of Container Ships by Shipping Companies and Shipbuilders

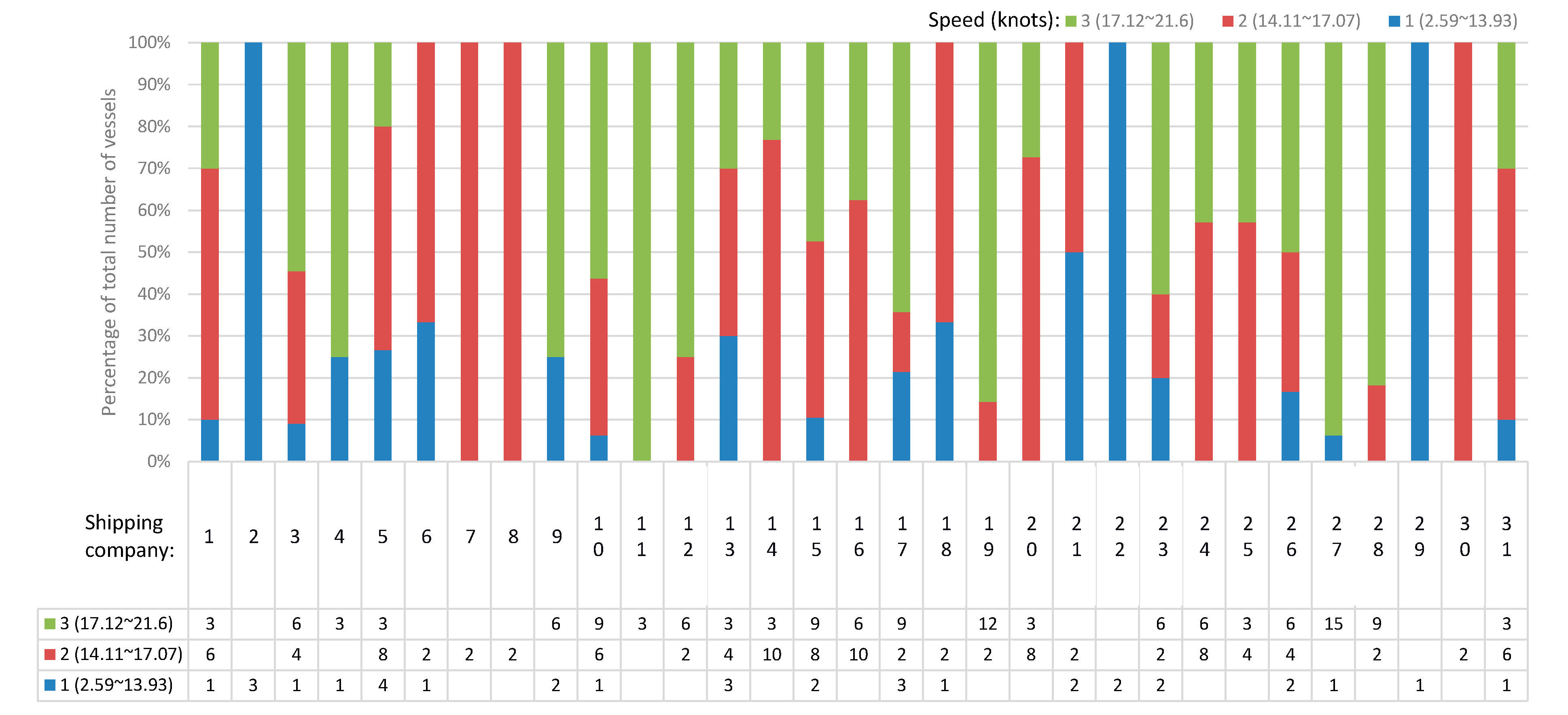

4.2.1. Speed Pattern Analysis by Shipping Companies

- 1.

- Speed pattern analysis of the 8600 TEU container ships operated by different shipping companiesThe analysis result of the speed pattern by shipping companies for the 8600 TEU container ships that sailed in 4 m and above wave conditions is shown in Figure 12. As the number of cluster K was given as three, the result shows that the speed groups are 2.59–13.93 knots; 14.11–17.07 knots; and 17.12–21.6 knots. Thirty-one shipping companies were found from the result. This means that the 8600 TEU class container ships owned by 31 companies were operated in 4 m and above wave conditions in 2017. The largest number of ships owned by a single shipping company that sailed in these wave conditions was 19 and were owned by shipping company 15. Most of them had medium to high speeds. The ships that are owned by shipping companies 19, 27, and 28 were operated at very high speed under harsh environmental conditions. The ships that are owned by shipping companies 1, 5, 14, 20, and 31 were operated in the middle-speed range. Some shipping companies with patterns operating at low speeds in a range between 2.59 and 13.93 knots under harsh environmental conditions were found.

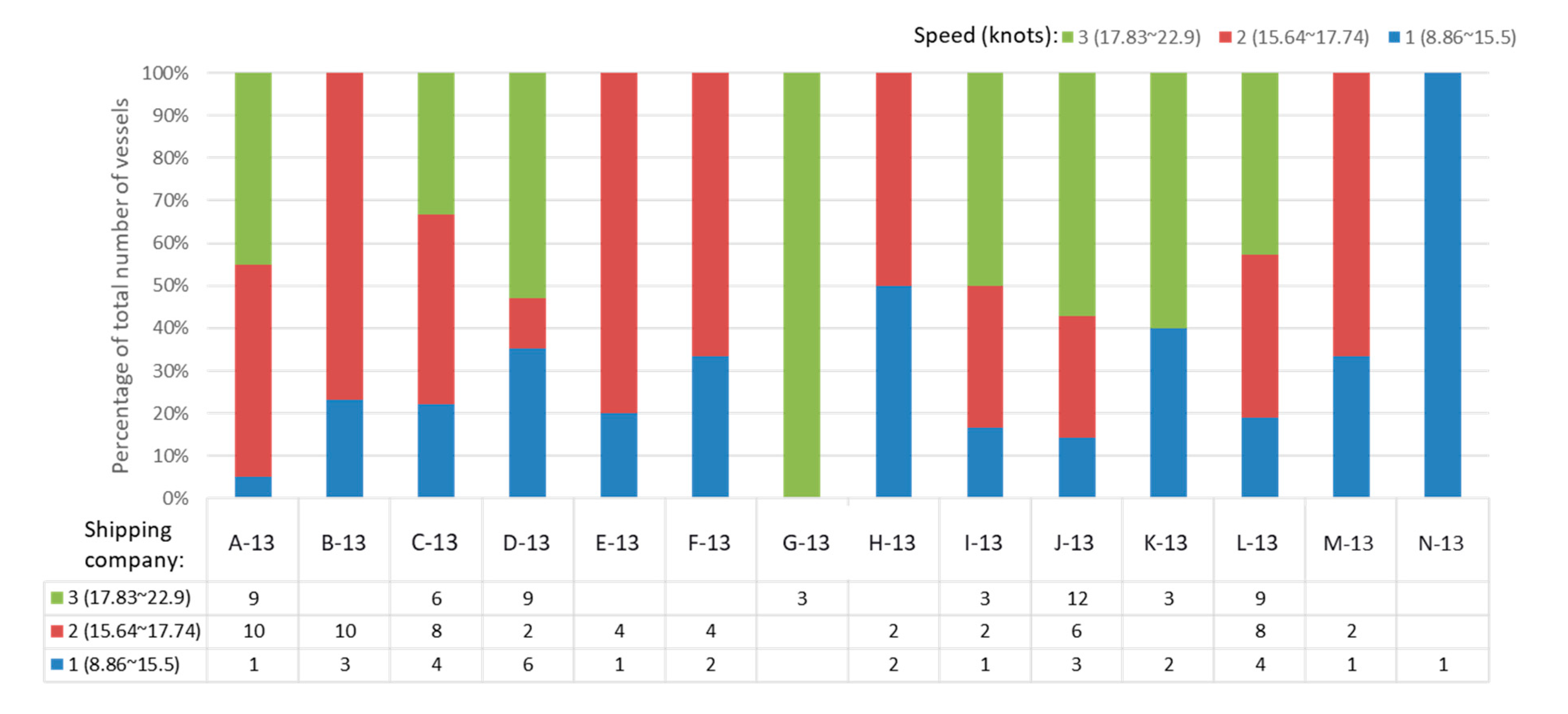

- 2.

- Speed pattern analysis of the 13,000 TEU container ships by different shipping companiesThe speed pattern clustering result is shown in Figure 13. Fourteen shipping companies that satisfied the clustering constraints were found. The number of clustering groups here is also three, but the speed values are higher than those for the 8600 TEU container ships. This means that the 13,000 TEU container ships were operated at a higher speed than the 8600 TEU container ships. The ships owned by shipping company D-13 operated at low and high speeds, and the ships owned by company G-13 operated only at high speeds. The ships owned by company B-13 operated at middle speed, and many ships of company J-13 operated at high speeds.

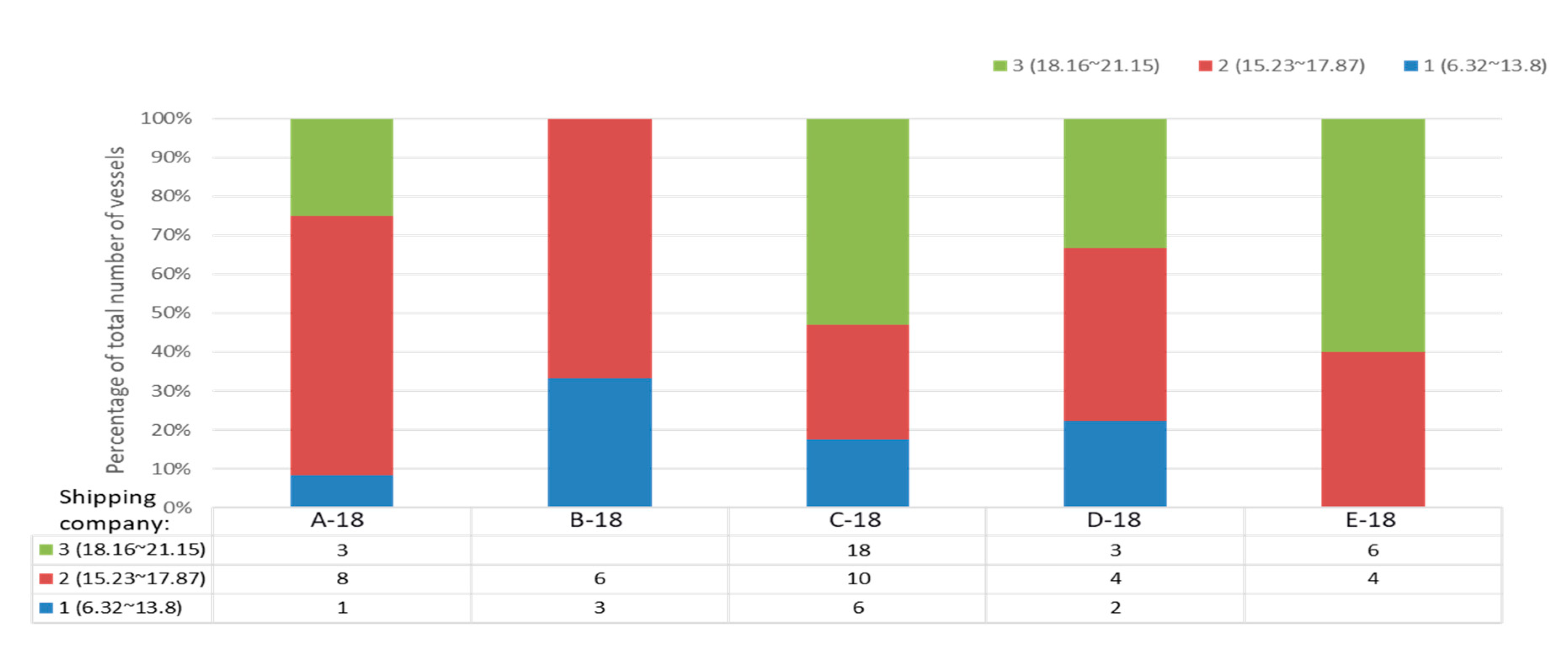

- 3.

- Speed pattern analysis of the 18,000 TEU container ships by shipping companiesThe analysis of the speed pattern for 18,000 TEU container ships is shown in Figure 14. It was found that shipping company C-18 owned the most ships among all. Among the ships owned by company C-18, most of them operated at high speeds and middle speeds. The ships owned by company B-18 operated at relatively middle and low speeds, and the ships owned by company E-18 operated at middle and high speeds under the harsh environmental conditions.

4.2.2. Speed Pattern Analysis by Shipbuilders

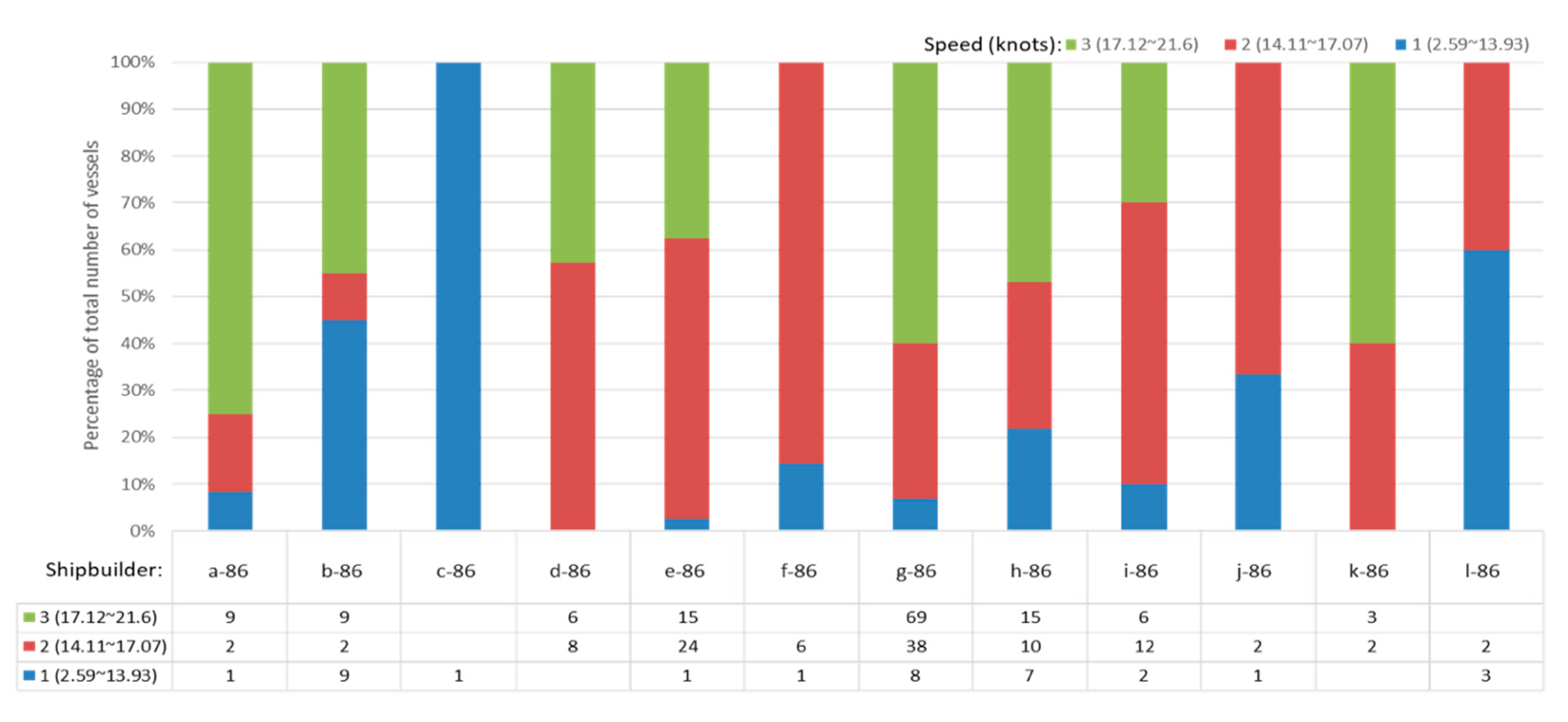

- 1.

- Speed pattern analysis of the 8600 TEU container ships by shipbuildersFrom the analysis result in Figure 15, it is observed that shipbuilder g-86 has built the largest number of 8600 TEU class ships, and most of them were operated in a high-speed range from 17.12 to 21.6 knots under the given harsh environmental conditions. The ship’s speed may be affected by the shipping companies’ operational policy, route, weather conditions, and scheduled time, but it can be said that ships from certain shipbuilders can deliver high performance.

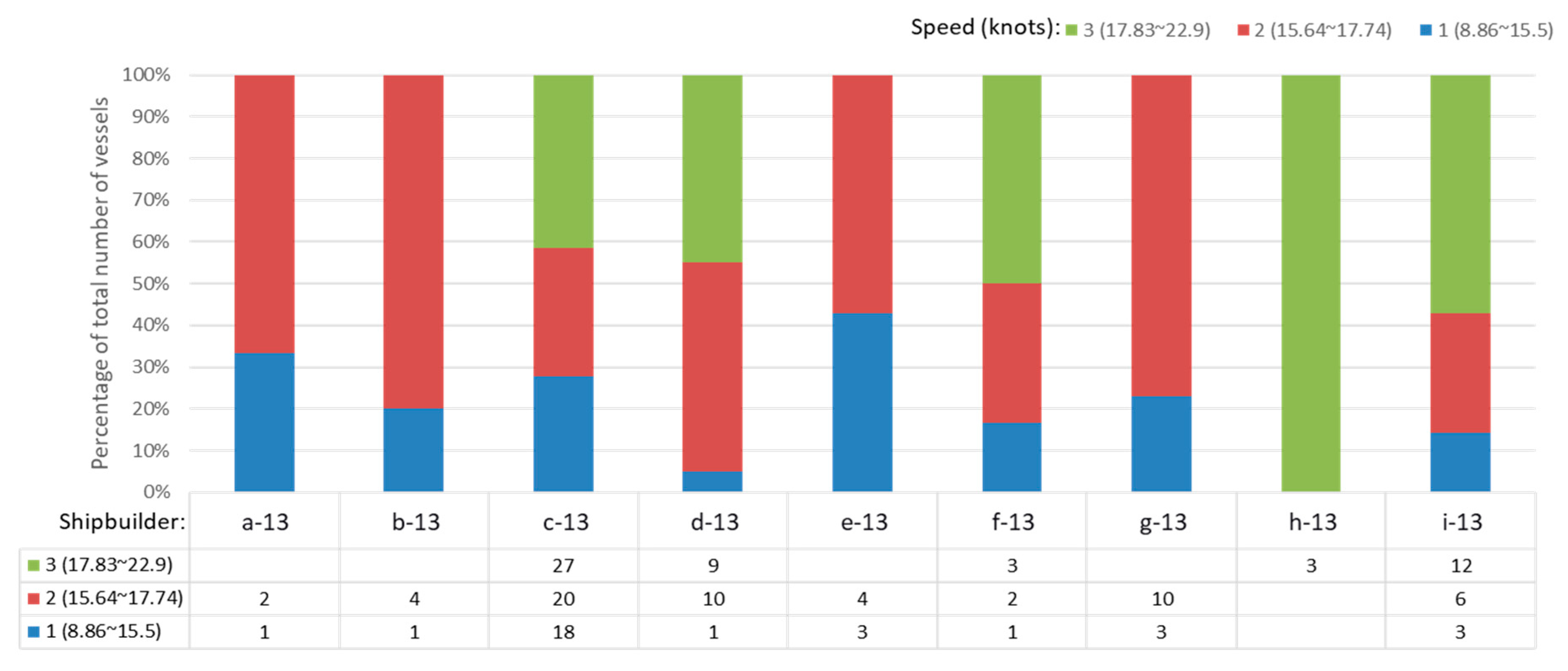

- 2.

- Speed pattern analysis of the 13,000 TEU container ships by shipbuildersIn the case of the 13,000 TEU class container ships (see Figure 16), shipbuilder c-13 built the largest number of ships, and the ships were quite evenly distributed among the three speed clusters. It was also identified that the ships from shipbuilder I can deliver high performance, and the ships from shipbuilder g-13 deliver middle range performance. However, in this case, the other conditions that were discussed in the 8600 TEU analysis result should be considered.

- 3.

- Speed pattern analysis of the 18,000 TEU container ships by the shipbuildersIn the case of the 18,000 TEU class container ships (see Figure 17), we find that shipbuilder a-18 built the largest number of ships. The distributed speed of these ships ranged from the middle to high. The ships from shipbuilder d-18 also have the same speed range, but the ships from the shipbuilders b-18 and c-18 have relatively low-speed range.

5. Conclusions and Future Work

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Algorithm A1. Speed pattern analysis of container ships by shipping companies and shipbuilders using the K-means clustering. |

| Data: AIS data of container ships, ocean environment data, and ship static data Result: Clustering of the speeds by shipping companies or shipbuilders Initialize: Select the target ships; Select the target period; Select the target ocean environmental condition; Clustering: Select the number of clusters K; Calculate the average speed of each ship for the period; Initial speed of clusters ← Randomly select K distinct data by the average speed of a ship; while Clusters change do foreach Average speed of each ship do Measure the difference between the initial speed of clusters and the given data; Assign the given data to the nearest cluster; Calculate the mean speed of each cluster; Initial speed of clusters ← mean speed of clusters; end end Map the clustered speed data to the shipping companies or shipbuilders in the ship static data; |

References

- Bell, M.G.H.; Meng, Q. Special issue in transportation research part B—Shipping, port and maritime logistics. Transp. Res. Part B Methodol. 2016, 93, 697–699. [Google Scholar] [CrossRef]

- Vejvar, M.; Lai, K.H.; Lo, C.K.Y. A citation network analysis of sustainability development in liner shipping management: A review of the literature and policy implications. Marit. Policy Manag. 2020, 47, 1–26. [Google Scholar] [CrossRef]

- Le, L.T.; Lee, G.; Kim, H.; Woo, S.H. Voyage-based statistical fuel consumption models of ocean-going container ships in korea. Marit. Policy Manag. 2020, 47, 304–331. [Google Scholar] [CrossRef]

- Kim, S.H.; Roh, M.I.; Oh, M.J.; Park, S.W.; Kim, I.I. Estimation of ship operational efficiency from AIS data using big data technology. Int. J. Nav. Archit. Ocean Eng. 2020, 12, 440–454. [Google Scholar] [CrossRef]

- Yuen, K.F.; Wang, X.; Ma, F.; Lee, G.; Li, X. Critical success factors of supply chain integration in container shipping: An application of resource-based view theory. Marit. Policy Manag. 2019, 46, 653–668. [Google Scholar] [CrossRef]

- International Maritime Organization. SOLAS Chapter V Safety of Navigation; International Maritime Organization: London, UK, 2002. [Google Scholar]

- International Maritime Organization. Guidelines for the Installation of a Shipborne Automatic Identification System (AIS); International Maritime Organization: London, UK, 2003. [Google Scholar]

- Yang, D.; Wu, L.; Wang, S.; Jia, H.; Li, K.X. How big data enriches maritime research—A critical review of Automatic Identification System (AIS) data applications. Transp. Rev. 2019, 39, 755–773. [Google Scholar] [CrossRef]

- Jia, H.; Lampe, O.D.; Solteszova, V.; Strandenes, S.P. An automatic algorithm for generating seaborne transport pattern maps based on AIS. Marit. Econ. Logist. 2017, 19, 619–630. [Google Scholar] [CrossRef]

- Jia, H.; Prakash, V.; Smith, T. Estimating vessel payloads in bulk shipping using AIS data. Int. J. Shipp. Transp. Logist. 2019, 11, 25–40. [Google Scholar] [CrossRef]

- Perera, L.P.; Carvalho, J.P.; Guedes Soares, C. Fuzzy logic based decision making system for collision avoidance of ocean navigation under critical collision conditions. J. Mar. Sci. Technol. 2011, 16, 84–99. [Google Scholar] [CrossRef]

- Wen, Y.; Huang, Y.; Zhou, C.; Yang, J.; Xiao, C.; Wu, X. Modelling of marine traffic flow complexity. Ocean Eng. 2015, 104, 500–510. [Google Scholar] [CrossRef]

- Sang, L.; Wall, A.; Mao, Z.; Yan, X.; Wang, J. A novel method for restoring the trajectory of the inland waterway ship by using AIS data. Ocean Eng. 2015, 110, 183–194. [Google Scholar] [CrossRef]

- Dobrkovic, A.; Iacob, M.-E.; van Hillegersberg, J. Using machine learning for unsupervised maritime waypoint discovery from streaming AIS data. In Proceedings of the 15th International Conference on Knowledge Technologies and Data-Driven Business—i-KNOW ′15, Graz, Austria, 21–23 October 2015; Association for Computing Machinery: New York, NY, USA, 2015; pp. 1–8. [Google Scholar]

- Dobrkovic, A.; Iacob, M.E.; Van Hillegersberg, J. Maritime pattern extraction from AIS data using a genetic algorithm. In Proceedings of the 2016 IEEE International Conference on Data Science and Advanced Analytics (DSAA), Montreal, QC, Canada, 17–19 October 2016; pp. 642–651. [Google Scholar]

- Xiao, F.; Ligteringen, H.; van Gulijk, C.; Ale, B. Comparison study on AIS data of ship traffic behavior. Ocean Eng. 2015, 95, 84–93. [Google Scholar] [CrossRef]

- Wu, X.; Mehta, A.L.; Zaloom, V.A.; Craig, B.N. Analysis of waterway transportation in Southeast Texas waterway based on AIS data. Ocean Eng. 2016, 121, 196–209. [Google Scholar] [CrossRef]

- Zhang, W.; Goerlandt, F.; Montewka, J.; Kujala, P. A method for detecting possible near-miss ship collision from AIS data. Ocean Eng. 2016, 107, 60–69. [Google Scholar] [CrossRef]

- Yu, J.; Tang, G.; Song, X.; Yu, X.; Qi, Y.; Li, D.; Zhang, Y. Ship arrival prediction and its value on daily container terminal operation. Ocean Eng. 2018, 157, 73–86. [Google Scholar] [CrossRef]

- Wu, X.; Rahman, A.; Zaloom, V.A. Study of travel behavior of vessels in narrow waterways using AIS data—A case study in sabine-neches waterways. Ocean Eng. 2018, 147, 399–413. [Google Scholar] [CrossRef]

- Svanberg, M.; Santén, V.; Hörteborn, A.; Holm, H.; Finnsgård, C. AIS in maritime research. Mar. Policy 2019, 106, 10352. [Google Scholar] [CrossRef]

- Liu, C.; Liu, J.; Zhou, X.; Zhao, Z.; Wan, C.; Liu, Z. AIS data-driven approach to estimate navigable capacity of busy waterways focusing on ships entering and leaving port. Ocean. Eng. 2020, 218, 108215. [Google Scholar] [CrossRef]

- Yan, Z.; Xiao, Y.; Cheng, L.; He, R.; Ruan, X.; Zhou, X.; Li, M.; Bin, R. Exploring AIS data for intelligent maritime routes extraction. Appl. Ocean Res. 2020, 101, 102271. [Google Scholar] [CrossRef]

- Wu, X.; Roy, U.; Hamidi, M.; Craig, B.N. Estimate travel time of ships in narrow channel based on AIS data. Ocean. Eng. 2020, 202, 106790. [Google Scholar] [CrossRef]

- Yan, Z.; Xiao, Y.; Cheng, L.; Chen, S.; Zhou, X.; Ruan, X.; Li, M.; He, R.; Ran, B. Analysis of global marine oil trade based on automatic identification system (AIS) data. J. Transp. Geogr. 2020, 83, 102637. [Google Scholar] [CrossRef]

- Vettor, R.; Guedes Soares, C. Characterisation of the expected weather conditions in the main European coastal traffic routes. Ocean Eng. 2017, 140, 244–257. [Google Scholar] [CrossRef]

- Kepaptsoglou, K.; Fountas, G.; Karlaftis, M.G. Weather impact on containership routing in closed seas: A chance-constraint optimization approach. Transp. Res. Part C Emerg. Technol. 2015, 55, 139–155. [Google Scholar] [CrossRef]

- Tsou, M.-C. Online analysis process on automatic identification system data warehouse for application in vessel traffic service. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2016, 230, 199–215. [Google Scholar] [CrossRef]

- Mao, S.; Tu, E.; Zhang, G.; Rachmawati, L.; Rajabally, E.; Huang, G.-B. An Automatic Identification System (AIS) database for maritime trajectory prediction and data mining. In Proceedings of the ELM-2016, Adaptation, Learning and Optimization, Singapore, 13–15 December 2016; Springer: Cham, Switzerland, 2016; pp. 241–257. [Google Scholar]

- Apache Hadoop. Apache Hadoop. 2019. Available online: http://hadoop.apache.org/ (accessed on 25 April 2019).

- Apache Spark. Apache SparkTM—Unified Analytics Engine for Big Data. 2019. Available online: https://spark.apache.org/ (accessed on 25 April 2019).

- ECMWF. ECMWF|Advancing Global NWP through Co-Operation. Available online: http://www.ecmwf.int/ (accessed on 25 April 2019).

- National Oceanic and Atmospheric Administration (NOAA). U.S Department of Commerce. Available online: https://www.noaa.gov/ (accessed on 17 April 2021).

- Hortonworks. Data Management Platform, Solutions and Big Data Analysis|Hortonworks. 2018. Available online: https://hortonworks.com/ (accessed on 25 April 2019).

- Apache Zeppelin. 2019. Available online: http://zeppelin.apache.org/ (accessed on 25 April 2019).

- Microsoft. Custom Maps API for Business|Bing Maps for Enterprise. 2019. Available online: https://www.microsoft.com/en-us/maps/default (accessed on 25 April 2019).

- Psaraftis, H.N.; Kontovas, C.A. Speed models for energy-efficient maritime transportation: A taxonomy and survey. Transp. Res. Part C 2013, 26, 331–351. [Google Scholar] [CrossRef]

- Ilie, A.; Oprea, C.; Olteanu, S.; Dinu, O.; Ruscǎ, F. An heuristic model for port optimization. Procedia Manuf. 2019, 32, 975–982. [Google Scholar] [CrossRef]

- Shahpanah, A.; Poursafary, S.; Shariatmadari, S.; Gholamkhasi, A.; Zahraee, S.M. Optimization waiting time at berthing area of port container terminal with hybrid Genetic Algorithm (GA) and Artificial Neural Network (ANN). Adv. Mater. Res. 2014, 902, 431–436. [Google Scholar] [CrossRef]

- Sheikholeslami, A.; Ilati, G.; Yeganeh, Y.E. Practical solutions for reducing container ships’ waiting times at ports using simulation model. J. Mar. Sci. Appl. 2013, 12, 434–444. [Google Scholar] [CrossRef]

- Forgy, E.W. Cluster analysis of multivariate data: Efficiency versus interpretability of classifications. Biometrics 1965, 21, 768–769. [Google Scholar]

- MacQueen, J. Some methods for classification and analysis of multivariate observations. In Proceedings of the 5th Berkeley Symposium on Mathematical Statistics and Probability, Berkeley, CA, USA, 21 June–18 July 1965 and 27 December 1965 and 7 January 1966; University of California Press: Berkley, CA, USA, 1967; pp. 281–297. [Google Scholar]

- Schinas, O.; Stefanakos, C.N. Cost assessment of environmental regulation and options for marine operators. Transp. Res. Part C Emerg. Technol. 2012, 25, 81–99. [Google Scholar] [CrossRef]

- Adland, R.; Cariou, P.; Jia, H.; Wolff, F.C. The energy efficiency effects of periodic ship hull cleaning. J. Clean. Prod. 2018, 178, 1–13. [Google Scholar] [CrossRef]

- Oh, M.J.; Roh, M.I.; Park, S.W.; Chun, D.H.; Myung, S.H. Big data-based piping material analysis framework in offshore structure for contract design. Ocean Syst. Eng. 2019, 9, 79–95. [Google Scholar]

- Oh, M.J.; Roh, M.I.; Park, S.W.; Chun, D.H.; Lee, J.Y.; Son, M.J. Operational analysis of container ships using AIS data. In Proceedings of the ACDDE 2018, Okinawa, Japan, 1–3 November 2018; pp. 1–5. [Google Scholar]

- Oh, M.J.; Roh, M.I.; Park, S.W.; Chun, D.H.; Son, M.J. Operational analysis of container ships using AIS data based on big data technology. In Proceedings of the Annual Autumn Conference, The Society of Naval Architects of Korea, Changwon, Korea, 8–9 November 2018; p. 218. [Google Scholar]

| Study | Input Data | Application | Algorithm | Big Data |

|---|---|---|---|---|

| Jia et al. [10] (2019) | AIS data | Bulk ship payloads estimation | Regression | No |

| Kim et al. [4] (2020) | AIS data and ocean environment data | Operational efficiency estimation | Own algorithm | Yes |

| Liu et al. [22] (2020) | AIS data | Navigable capacity of waterways estimation | K-means clustering | No |

| Yan et al. [23] (2020) | AIS data | Maritime routes extraction | Graph theory | No |

| Wu et al. [24] (2020) | AIS data | Travel time estimation in narrow channel | Own algorithm | No |

| Yan et al. [25] (2020) | AIS data | Oil trade analysis | Own algorithm | No |

| This study | AIS data and ocean environment data | Operation analysis | Data mining, K-mean clustering | Yes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oh, M.-J.; Roh, M.-I.; Park, S.-W.; Chun, D.-H.; Son, M.-J.; Lee, J.-Y. Operational Analysis of Container Ships by Using Maritime Big Data. J. Mar. Sci. Eng. 2021, 9, 438. https://doi.org/10.3390/jmse9040438

Oh M-J, Roh M-I, Park S-W, Chun D-H, Son M-J, Lee J-Y. Operational Analysis of Container Ships by Using Maritime Big Data. Journal of Marine Science and Engineering. 2021; 9(4):438. https://doi.org/10.3390/jmse9040438

Chicago/Turabian StyleOh, Min-Jae, Myung-Il Roh, Sung-Woo Park, Do-Hyun Chun, Myeong-Jo Son, and Jeong-Youl Lee. 2021. "Operational Analysis of Container Ships by Using Maritime Big Data" Journal of Marine Science and Engineering 9, no. 4: 438. https://doi.org/10.3390/jmse9040438

APA StyleOh, M.-J., Roh, M.-I., Park, S.-W., Chun, D.-H., Son, M.-J., & Lee, J.-Y. (2021). Operational Analysis of Container Ships by Using Maritime Big Data. Journal of Marine Science and Engineering, 9(4), 438. https://doi.org/10.3390/jmse9040438