Parametric Hull Design with Rational Bézier Curves and Estimation of Performances

Abstract

1. Introduction

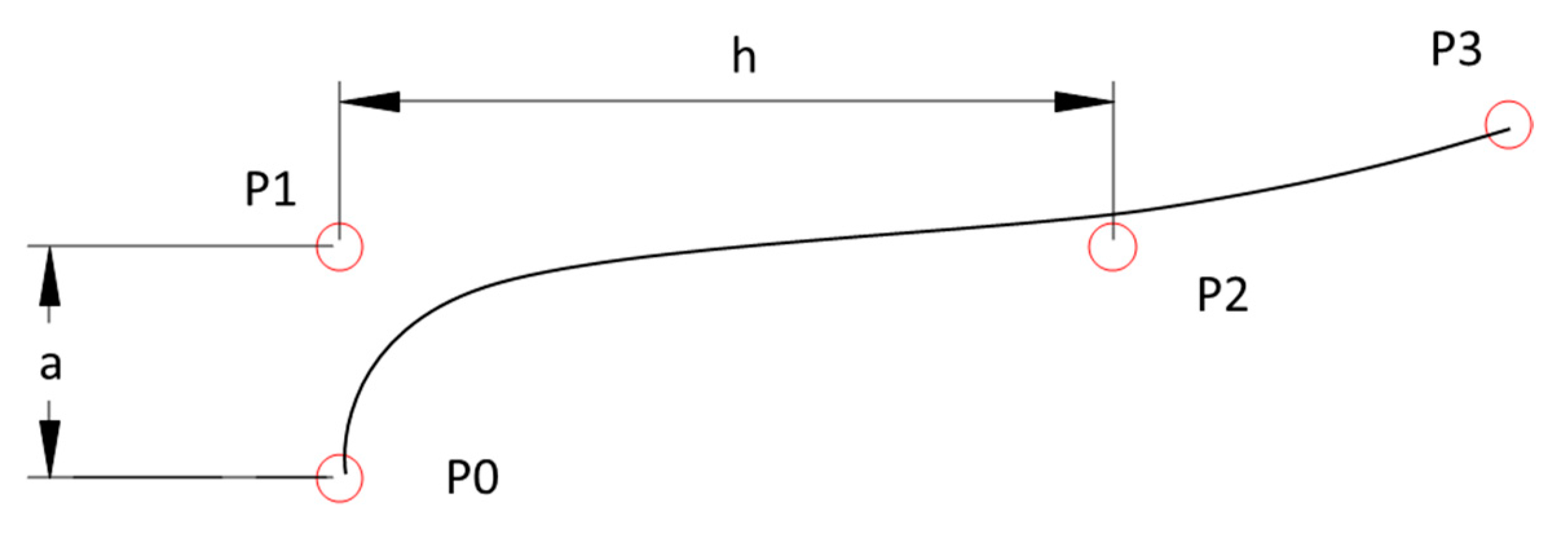

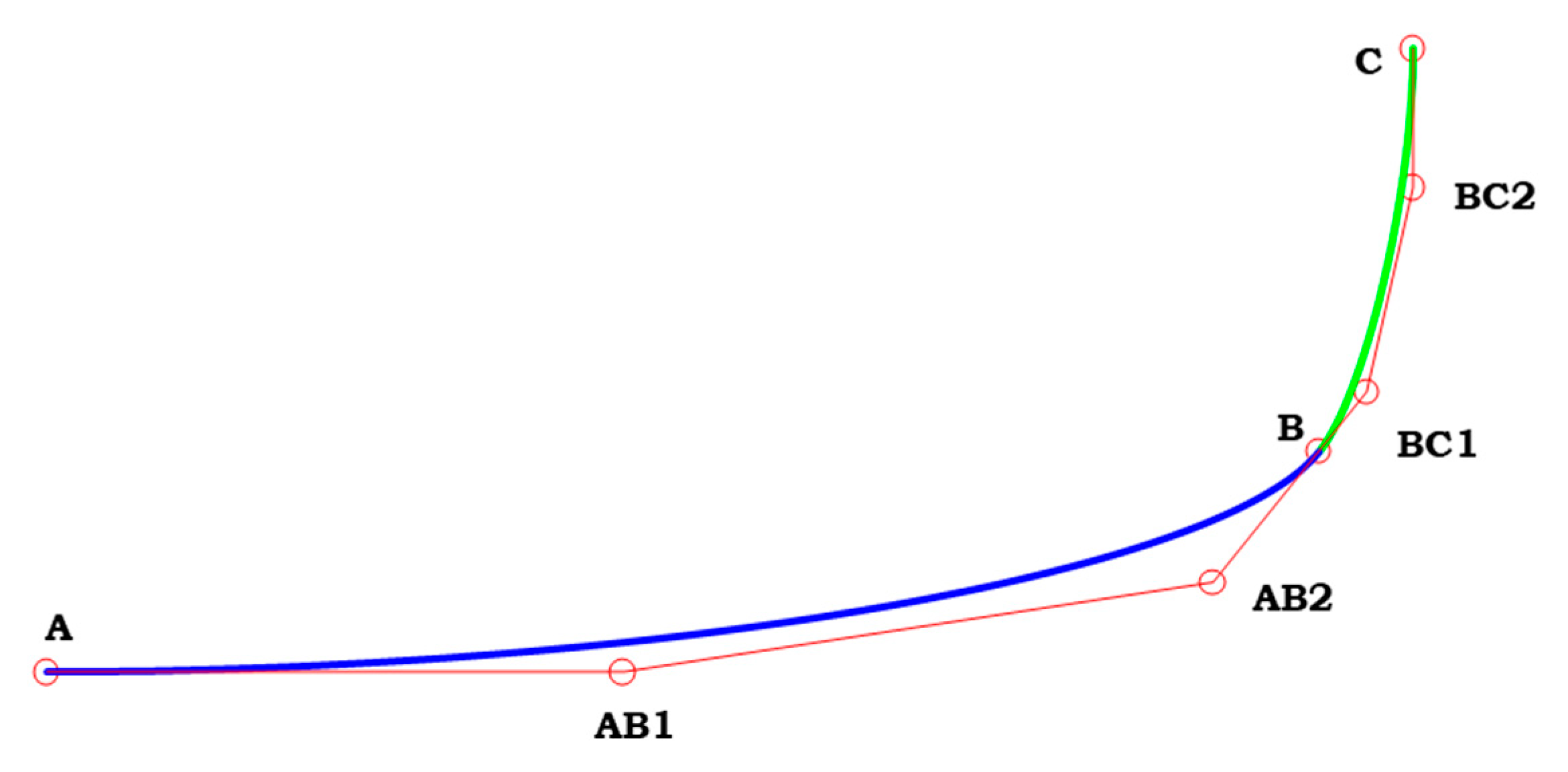

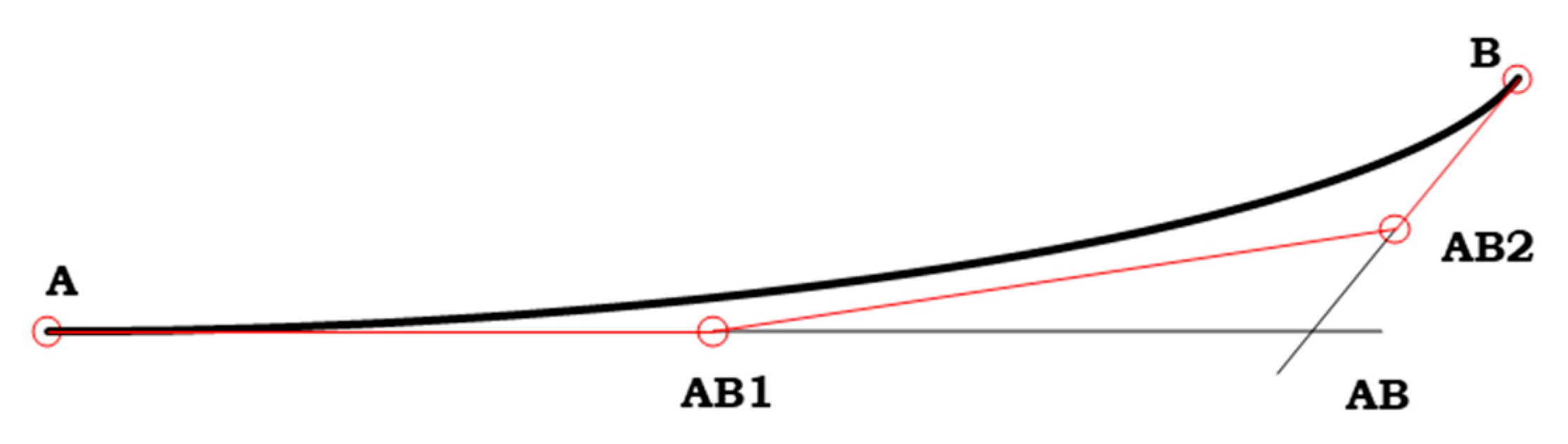

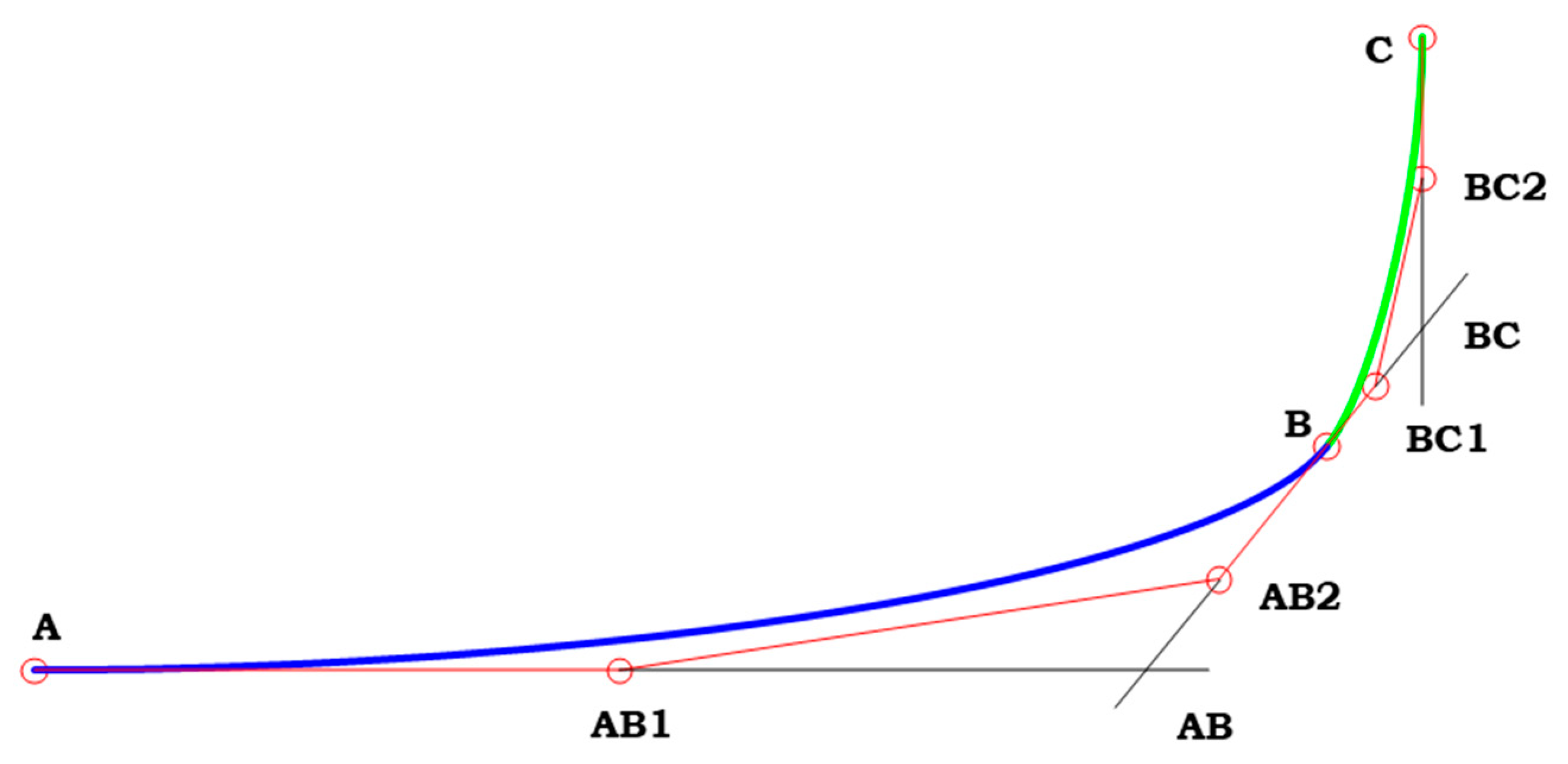

2. Rational Bézier Curves

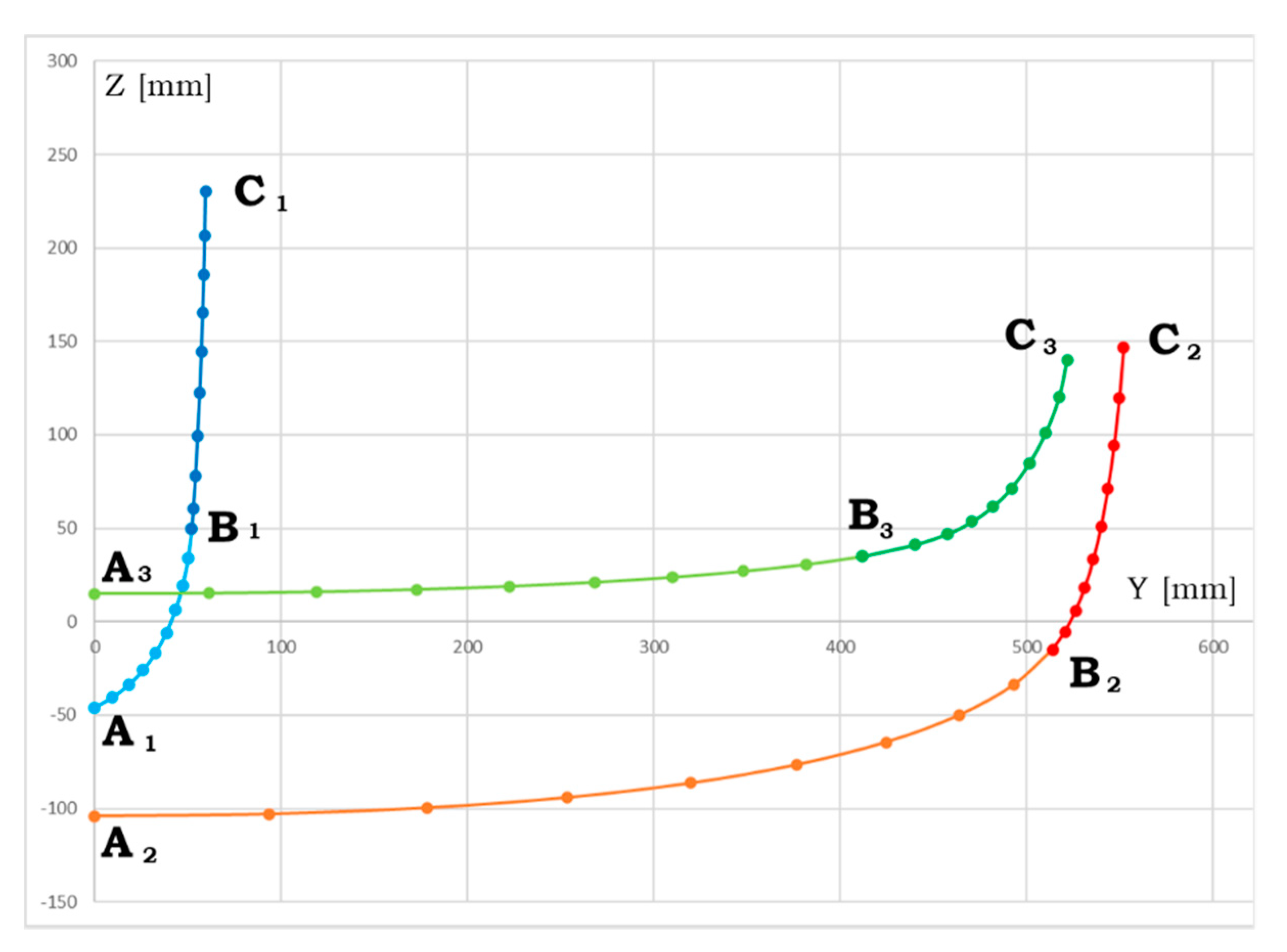

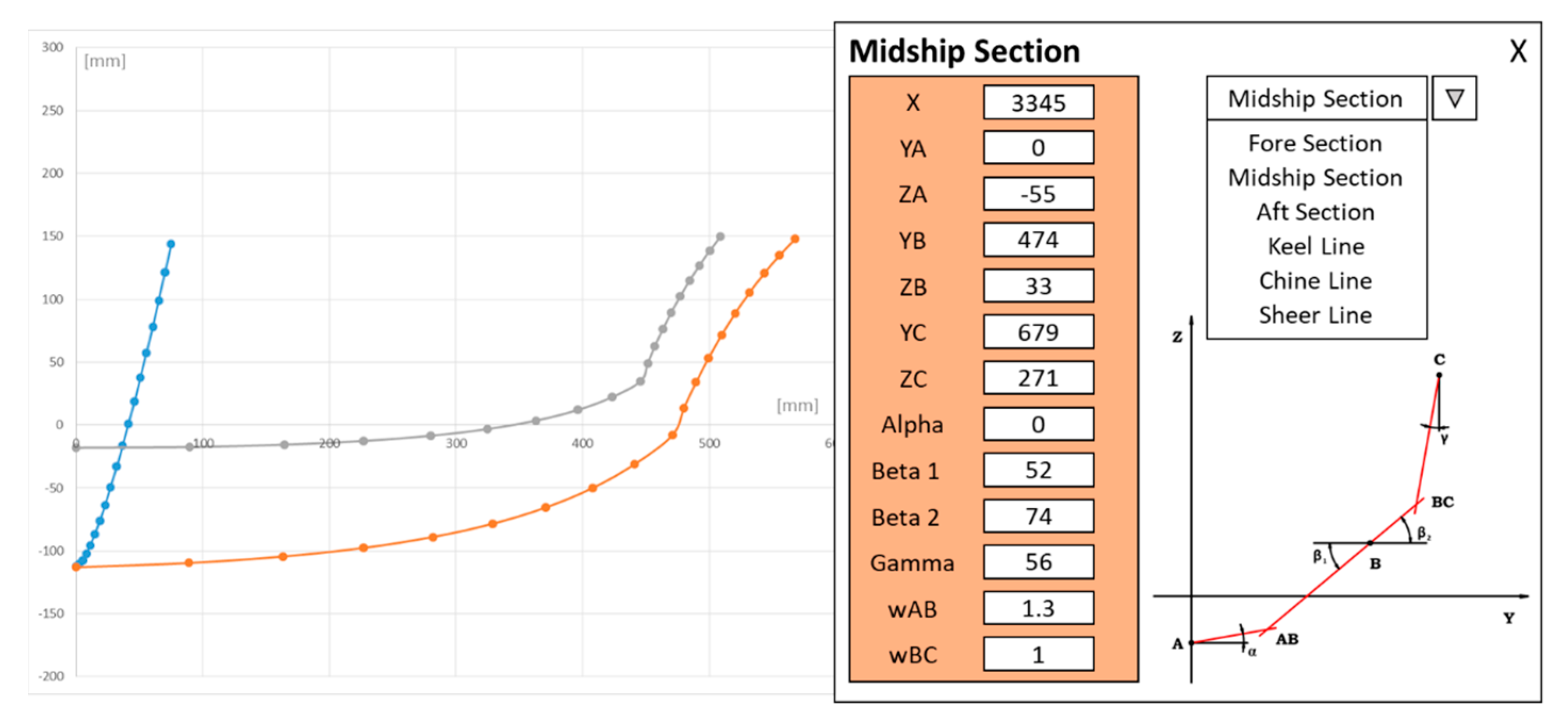

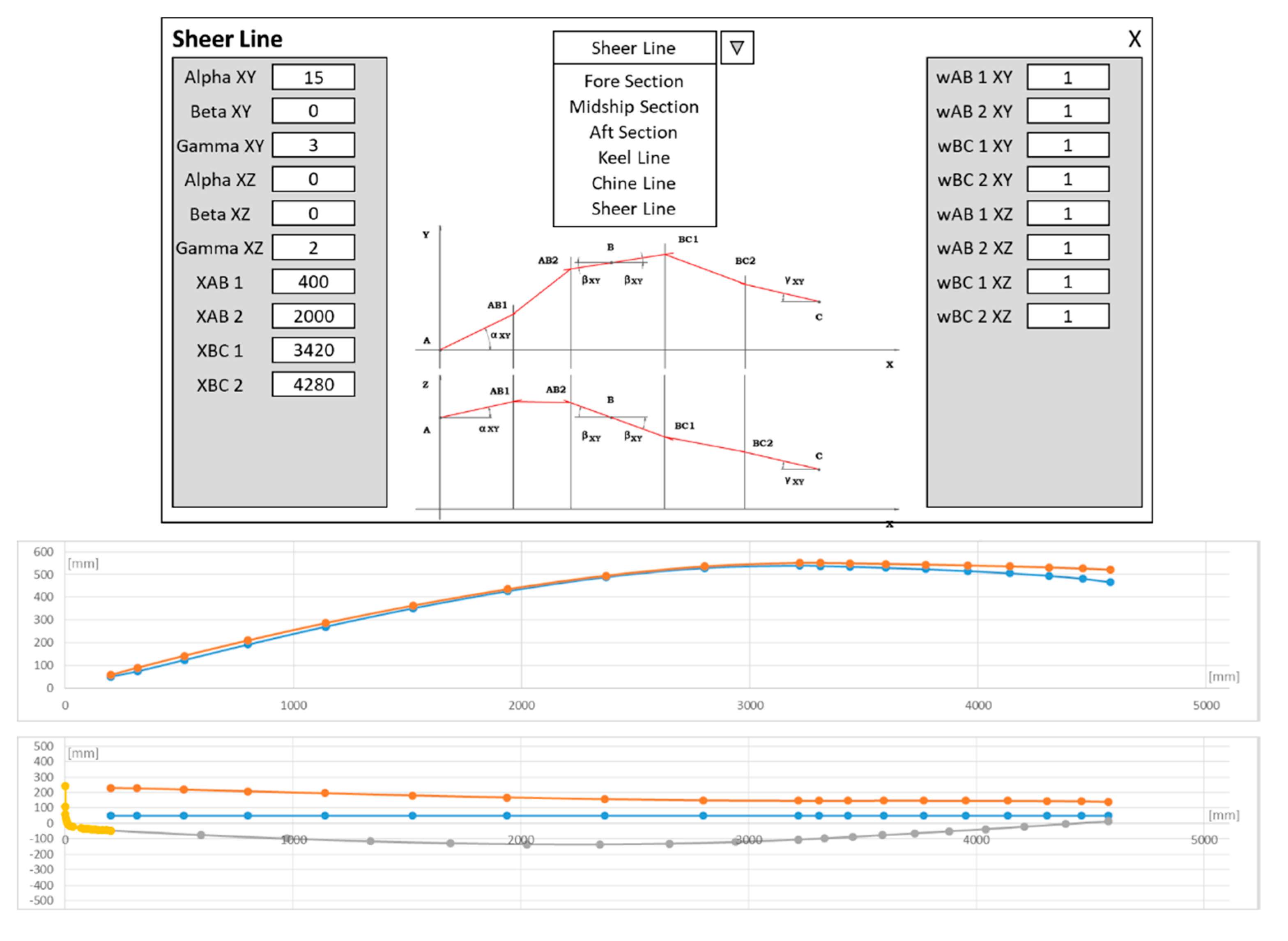

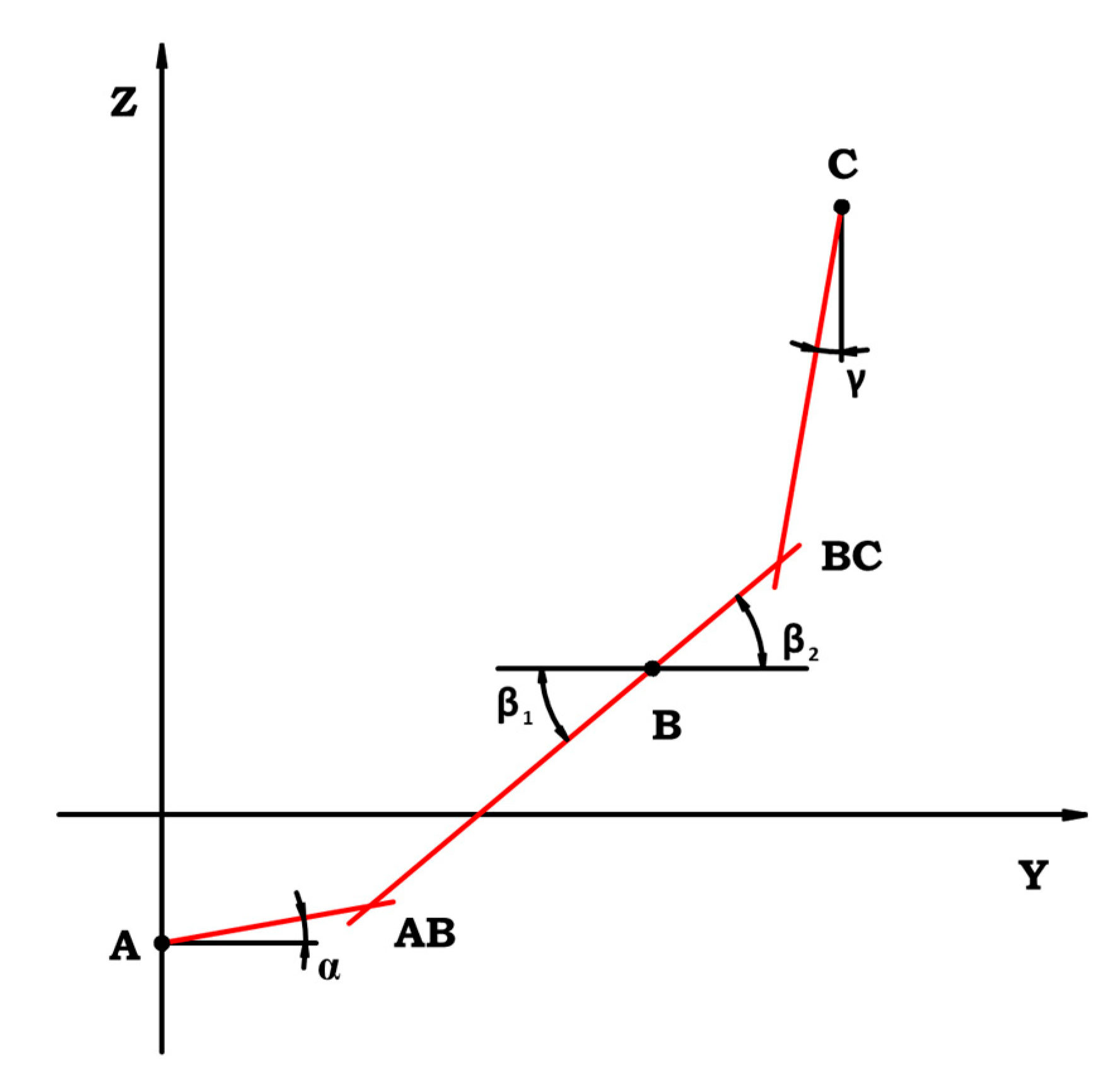

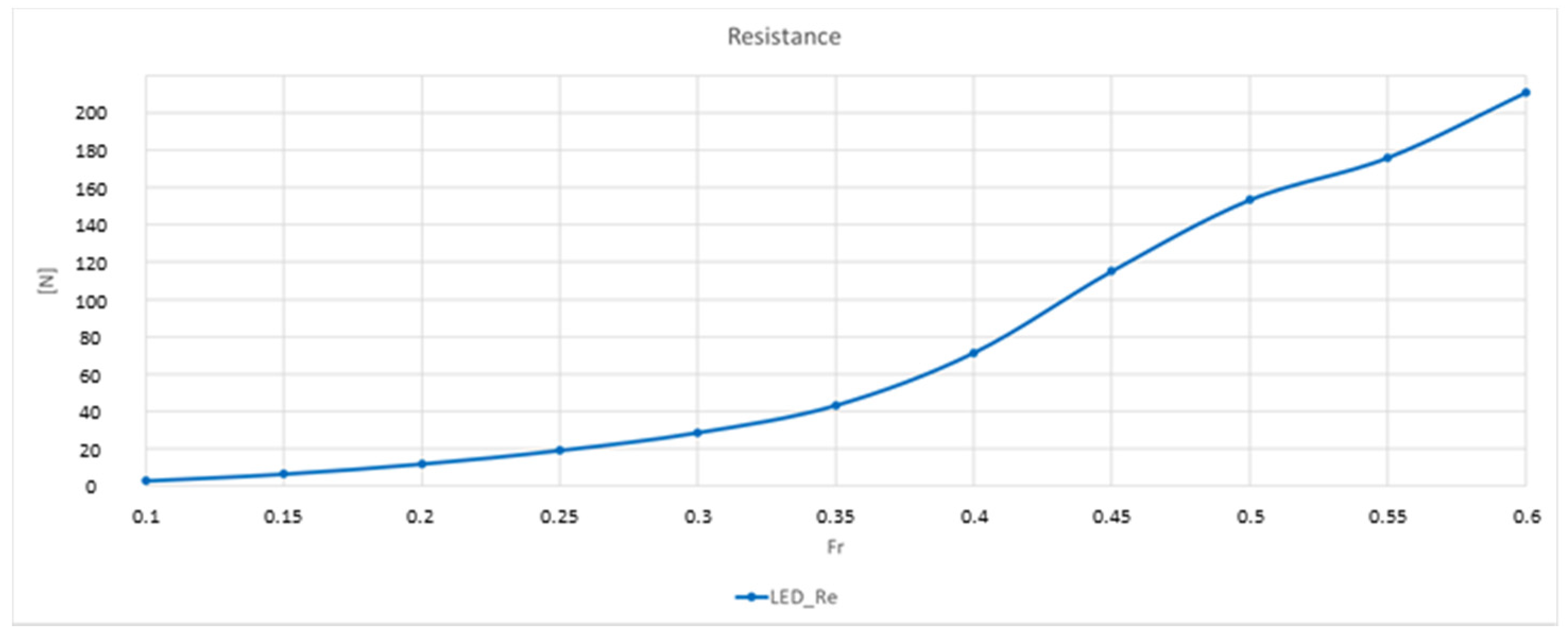

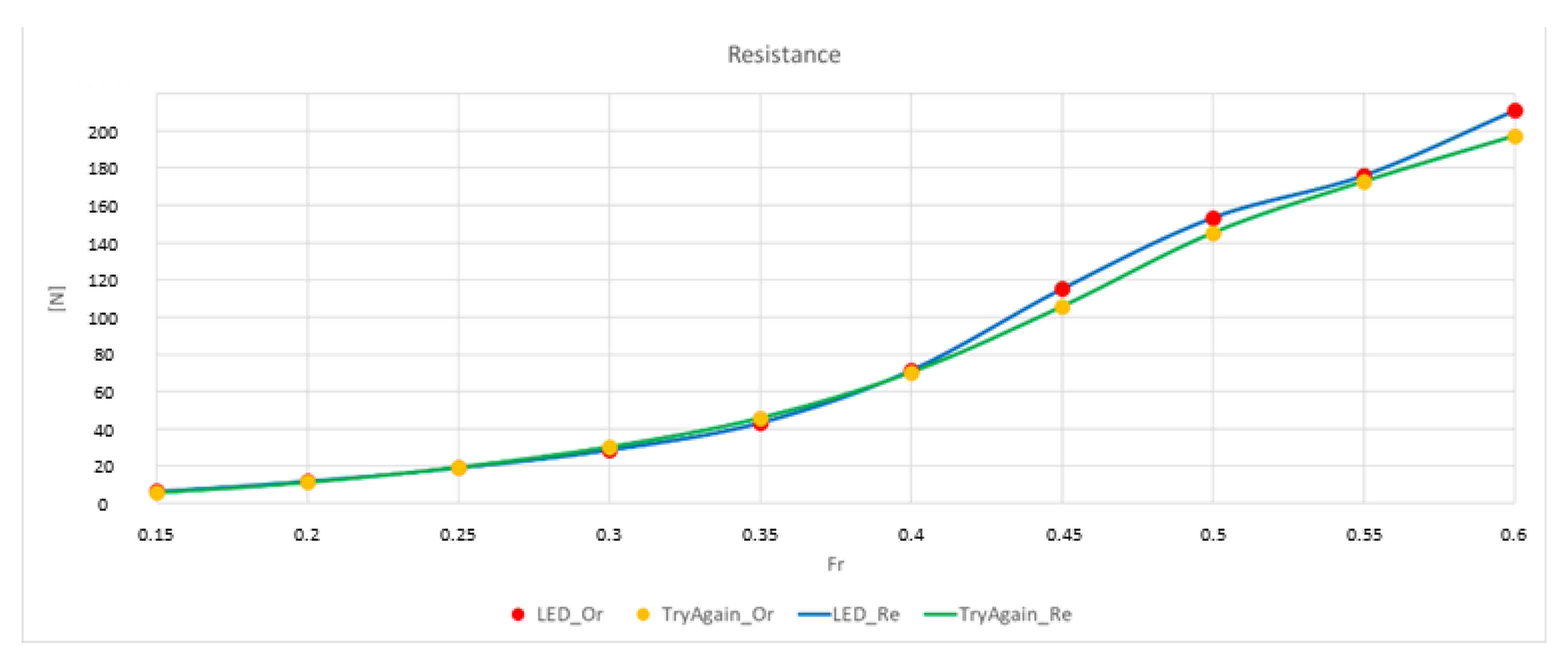

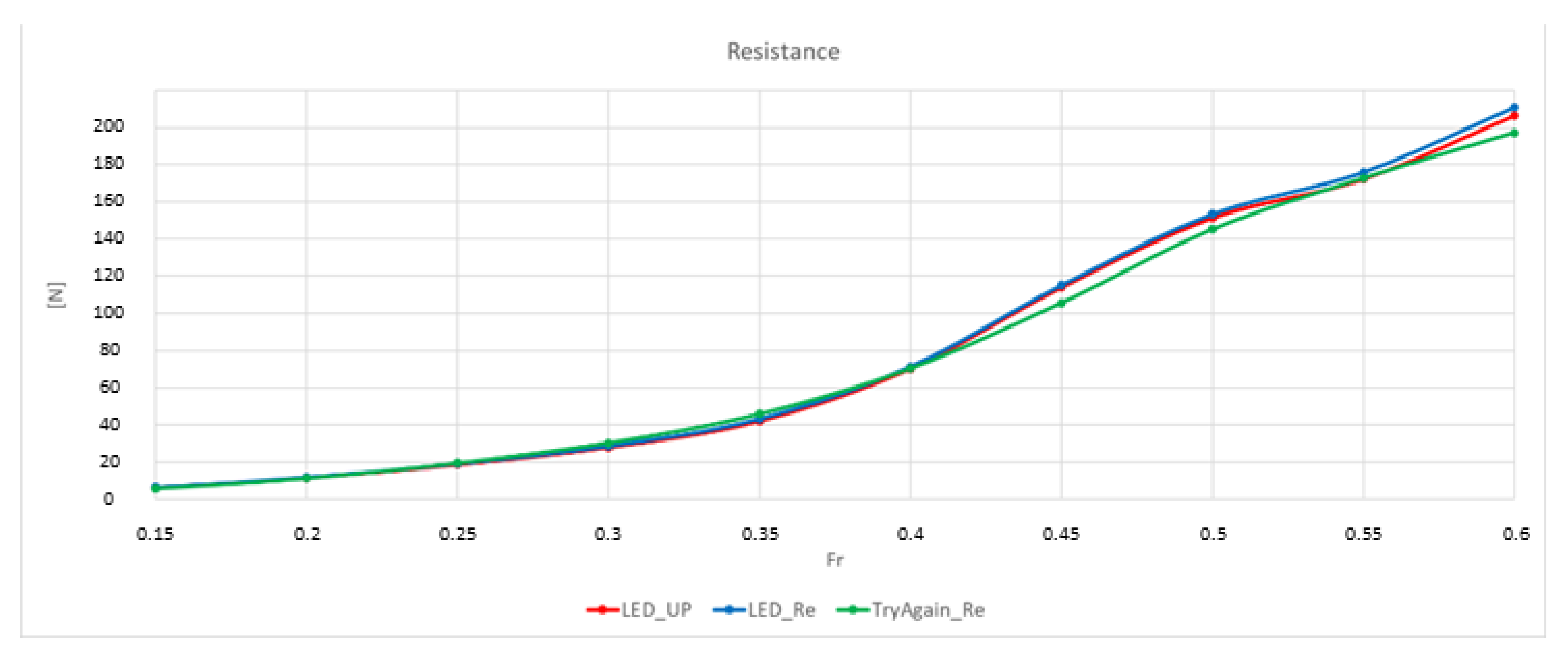

3. Estimation of Resistance for a Sailboat

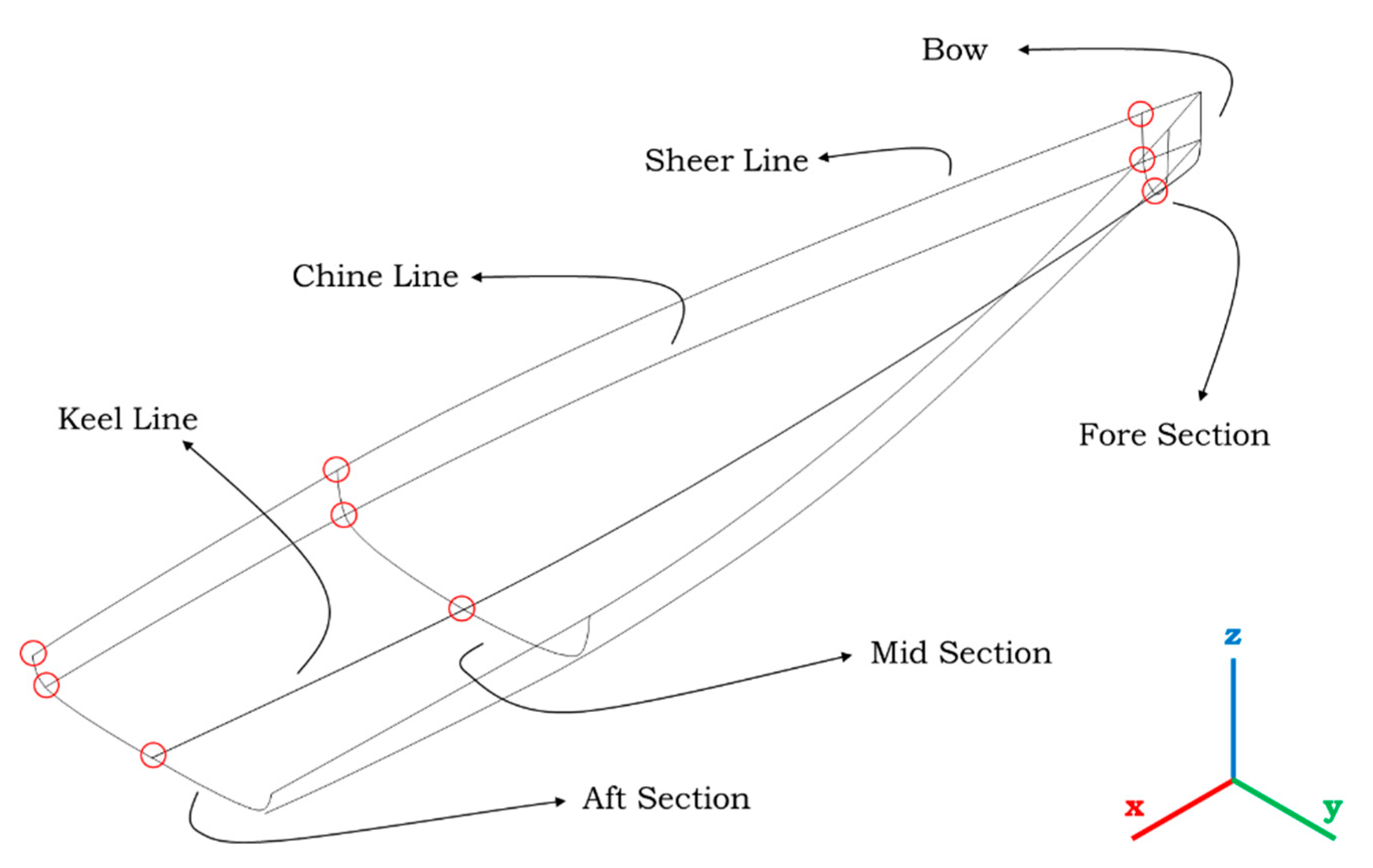

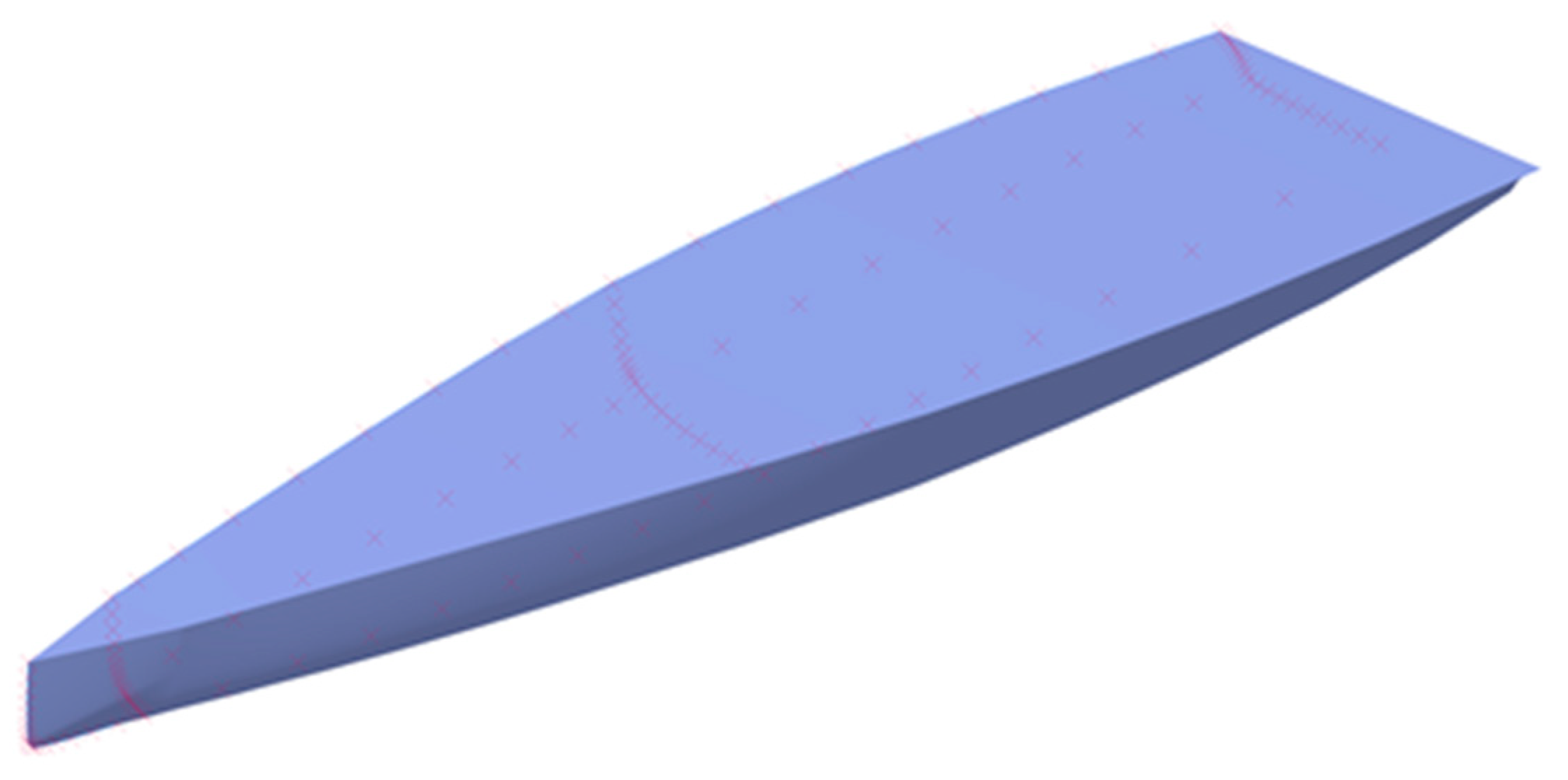

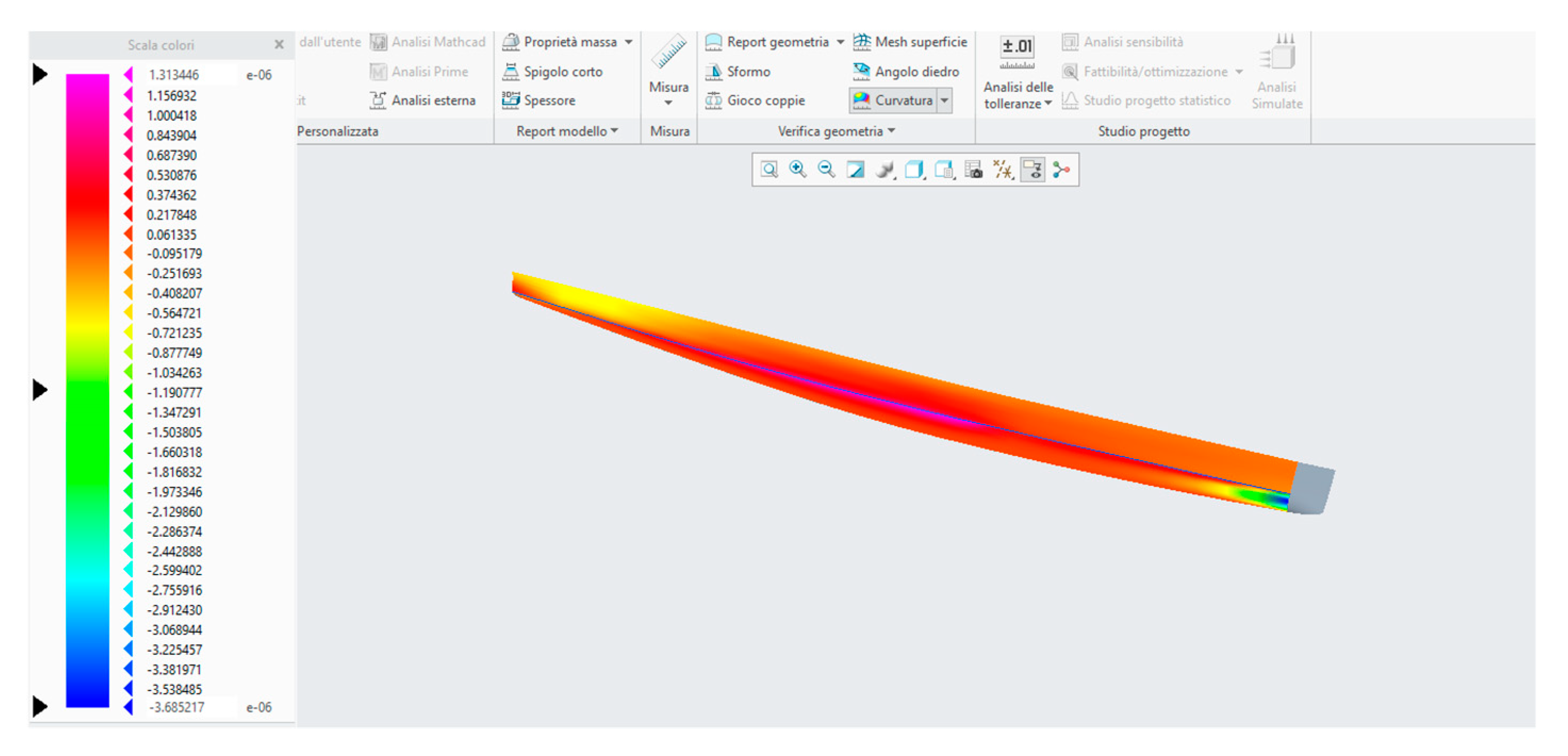

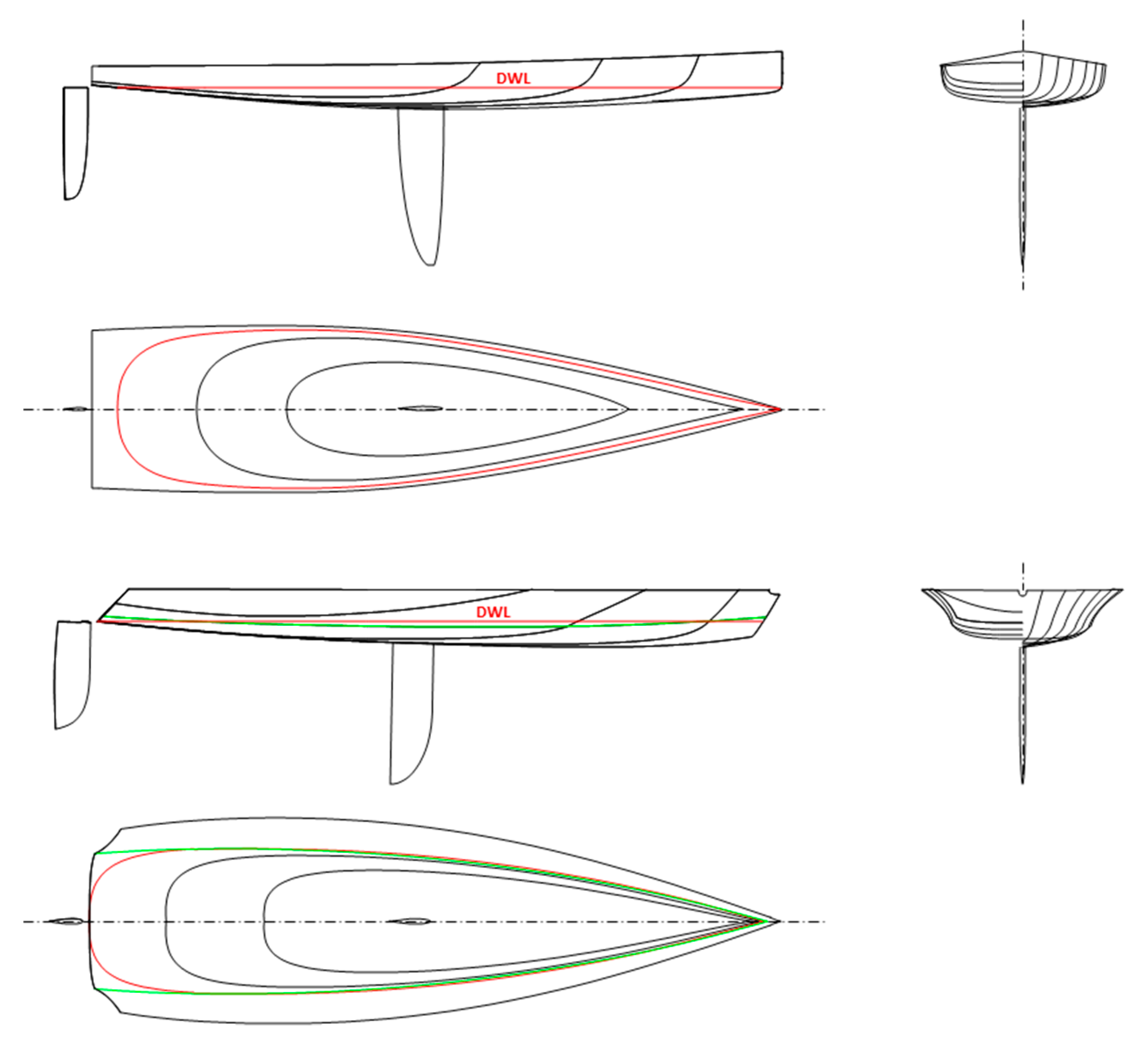

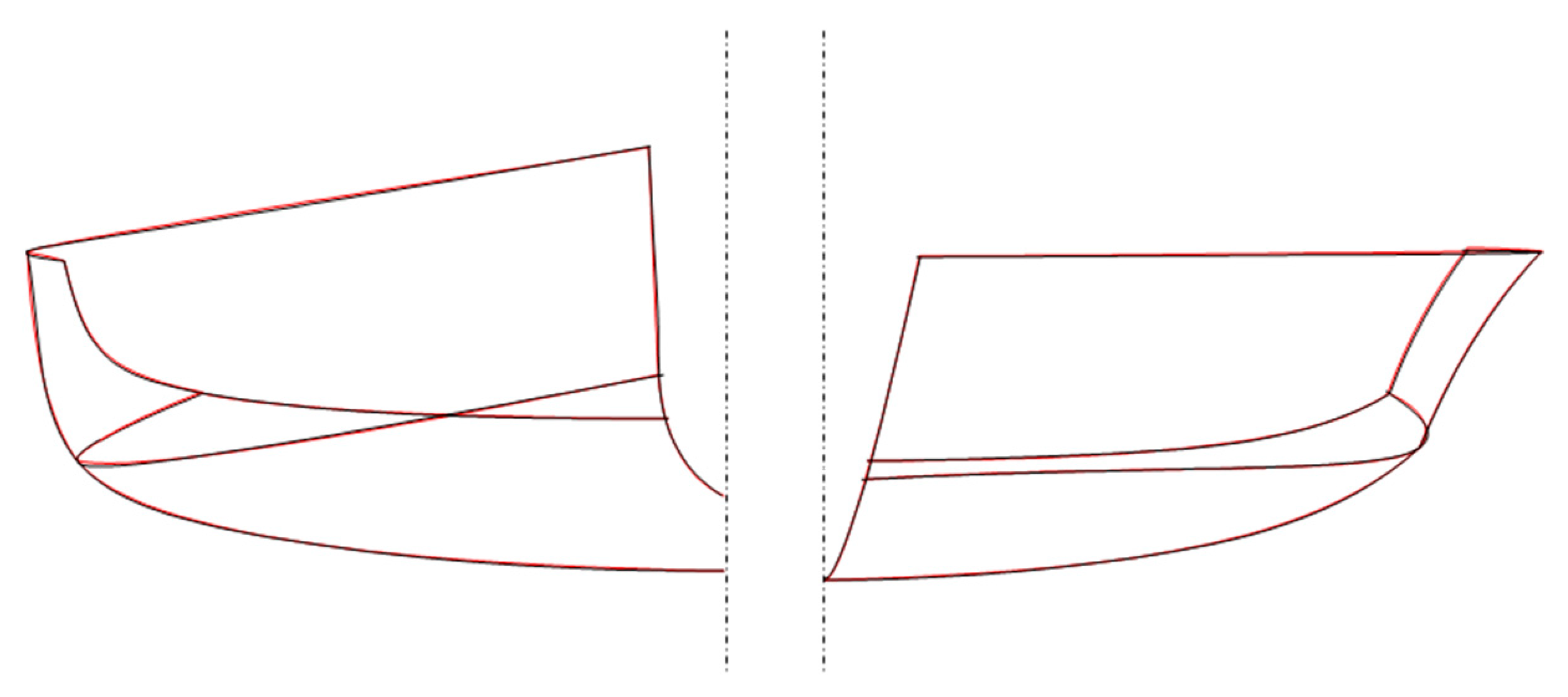

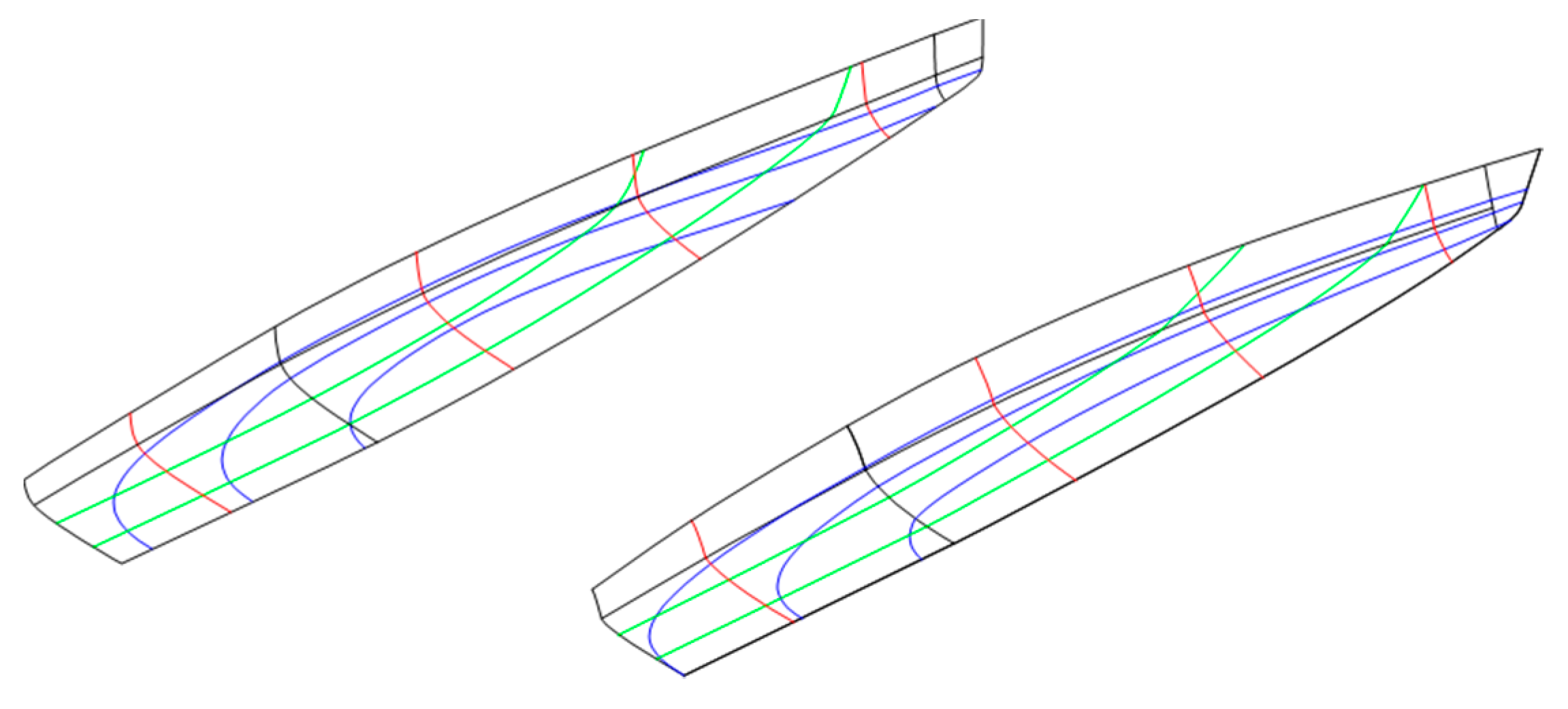

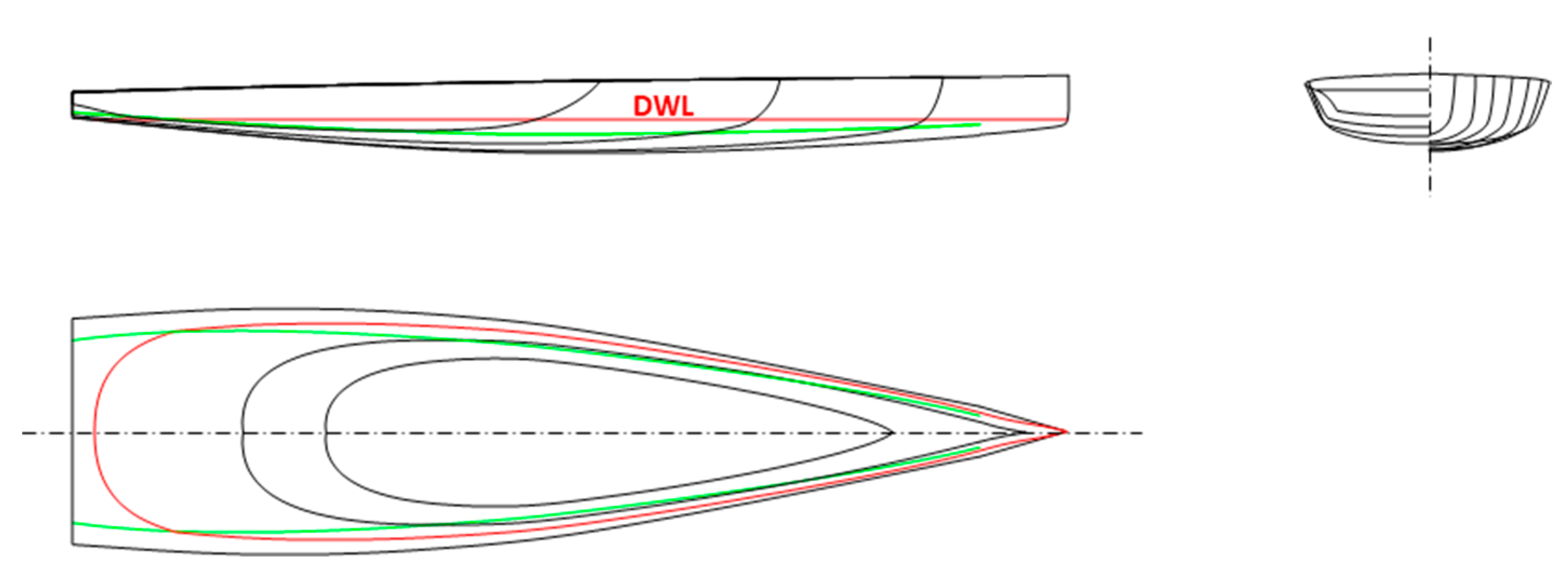

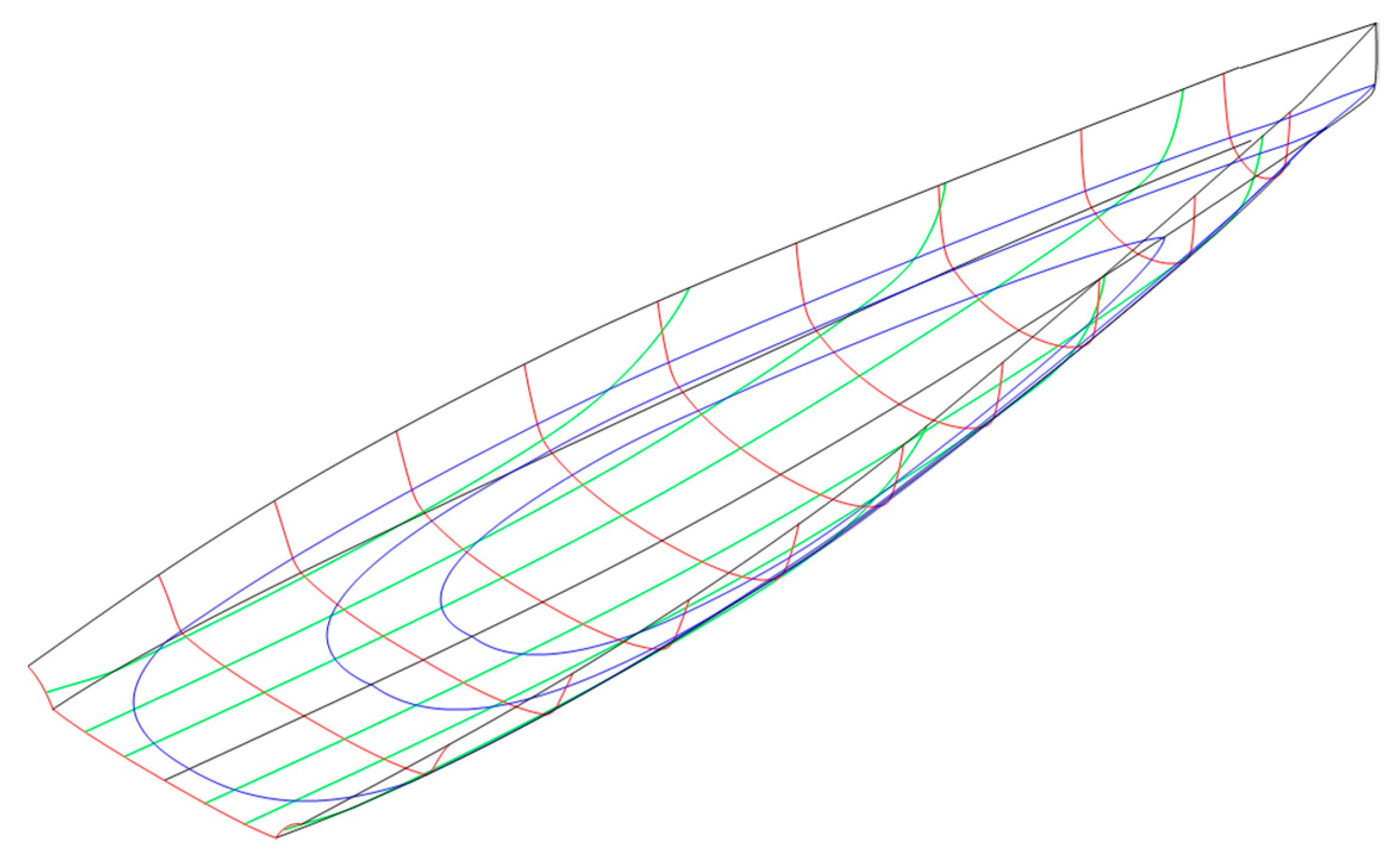

4. Design Approach

5. Design an Existing Sailboat

6. Design of a New Sailboat

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Rrh | Residuary Resistance | N |

| Displacement | m3 | |

| ρ | Density of Water | kg/m3 |

| g | Gravity Acceleration | m/s2 |

| LOA | Length Overall | m |

| SW | Wetted Surface | m2 |

| AX | Max Transversal Area | m2 |

| Lwl | Length of Water Line | m |

| Bwl | Beam of Water Line | m |

| Tc | Canoe Body Draft | m |

| LCBfpp | Center of Buoyancy | m |

| LCFfpp | Center of Flotation | m |

| Cp | Prismatic Coefficient (CP = ∇c/LWL Ax) | - |

| Aw | Water Plane Area | m2 |

| ai | Coefficients | - |

| Pi | Coordinate of control points | m |

| wi | Weight of control points | - |

| Bi,n | Bernstein polynomials | - |

| Re | Reynolds number | - |

References

- Nam, J.; Bang, N.S. A curve based hull form variation with geometric constraints of area and centroid. Ocean Eng. 2017. [Google Scholar] [CrossRef]

- Khan, S.; Gunpinar, E.; Sener, B. GenYacht: An interactive generative design system for computer-aided yacht hull design. Ocean Eng. 2019. [Google Scholar] [CrossRef]

- Cirello, A.; Cucinotta, F.; Ingrassia, T.; Nigrelli, V.; Sfavara, F. Fluid-structure interaction of downwind sails: A new computational method. J. Mar. Sci. Technol. 2019, 24, 86–97. [Google Scholar] [CrossRef]

- Mancuso, A. Parametric design of sailing hull shapes. Ocean Eng. 2006, 33, 234–246. [Google Scholar] [CrossRef]

- Larsson, L.; Eliasson, R.E.; Orych, M. Principles of Yacht Design; Adlard Coles Nautical: London, UK, 2014. [Google Scholar]

- Calkins, D.E.; Schachter, R.D.; Oliveira, L.T. An automated computational method for planning hull form definition in concept design. Ocean Eng. 2001, 28, 297–327. [Google Scholar] [CrossRef]

- Chrismianto, D.; Zakki, A.F.; Arswendo, B.; Kim, D.J. Development of Cubic Bezier Curve and Curve-Plane Intersection Method for Parametric Submarine Hull Form Design to Optimize Hull Resistance Using CFD. J. Mar. Sci. Technol. 2015, 14, 399–405. [Google Scholar] [CrossRef][Green Version]

- Khan, S.; Gunpinar, E.; Dogan, K.M. A novel design framework for generation and parametric modification of yacht hull surfaces. Ocean Eng. 2017. [Google Scholar] [CrossRef]

- Pérez-Arribas, F. Parametric generation of planing hulls. Ocean Eng. 2014, 81, 89–104. [Google Scholar] [CrossRef]

- Ingrassia, T.; Mancuso, A.; Nigrelli, V.; Tumino, D. A multi-technique simultaneous approach for the design of a sailing yacht. Int. J. Interact. Des. Manuf. 2017, 11, 19–30. [Google Scholar] [CrossRef]

- Keuning, J.A.; Sonnenberg, U.B. Approximation of the hydrodynamic forces on a sailing yacht based on the Delft Systematic Yacht Hull Series. In Proceedings of the 15th International Symposium on “Yacht Design and Yacht Construction”, Amsterdam, The Netherlands, 16 November 1998; ISBN 902700171-8. [Google Scholar]

- Keuning, J.A.; Katgert, M. A bare hull resistance prediction method derived from the results of the Delft systematic yacht hull series extended to higher speeds. In Proceedings of the International Conference on Innovation in High Performance Sailing Yachts, Lorient, France, 29–30 May 2008. [Google Scholar]

- Savitsky, D.; Brown, P.W. Procedures for Hydrodynamic Evaluation od Planing Hulls in Smooth and Rough Water. Mar. Technol. 1976, 13, 381–400. [Google Scholar]

- ITTC. Practical Guidelines for Ship CFD Applications. In Proceedings of the 26th International Towing Tank Conference, Rio de Janeiro, Brazil, 28 August–3 September 2011. [Google Scholar]

- ITTC. Uncertainty Analysis in CFD Verification and Validation Methodology and Procedures. In Proceedings of the Recommended Procedures and Guidelines of the International Towing Tank Conference; 2017. Available online: https://www.ittc.info/media/7691/75-04-01-011.pdf (accessed on 26 March 2021).

- Eca, L.; Hoekstra, M. A procedure for the estimation of the numerical uncertainty of CFD calculations based on grid refinement studies. J. Comput. Phys. 2014, 262. [Google Scholar] [CrossRef]

- Raymond, J.; Cudby, K. Using Parametric Modelling, CFD, and Historical Data, to Estimate Planing Hull Performance on a Laptop. In Proceedings of the 4th High Performance Yacht Design Conference, Auckland, New Zealand, 12–14 March 2012. [Google Scholar]

- Viola, I.M.; Enlander, J.; Adamson, H. Trim effect on the resistance of sailing planing hulls. Ocean Eng. 2014, 88, 187–193. [Google Scholar] [CrossRef]

- Sederberg, T.W. Computer Aided Geometric Design. Computer Aided Geometric Design Course Notes; BYU Scholars Archive, 2012; Available online: https://scholarsarchive.byu.edu/cgi/viewcontent.cgi?article=1000&context=facpub (accessed on 26 March 2021).

- ANSI Standard. Initial Graphics Exchange Specification IGES 5.3; U.S. Product Data Association: Charleston, SC, USA, 1996. [Google Scholar]

| Entity | Symbol | Unit | LED | TryAgain | ||

|---|---|---|---|---|---|---|

| Original | Rebuilt | Original | Rebuilt | |||

| Displacement | ∇ | m3 | 0.257 | 0.258 | 0.262 | 0.263 |

| Length Overall | LOA | m | 4.60 | 4.60 | 4.60 | 4.60 |

| Length Water Line | LWL | m | 4.46 | 4.46 | 4.49 | 4.49 |

| Max Beam Water Line | BWL | m | 1.05 | 1.05 | 0.95 | 0.95 |

| Wetted Surface | SW | m2 | 3.49 | 3.48 | 3.46 | 3.50 |

| Water Plane Area | AW | m2 | 3.21 | 3.20 | 3.10 | 3.14 |

| Max Transversal Area | AX | m2 | 0.107 | 0.107 | 0.094 | 0.093 |

| Long. Centre of Buoyancy | LCB | m | 2.48 | 2.52 | 2.25 | 2.26 |

| Long. Centre of Flotation | LCF | m | 2.69 | 2.70 | 2.60 | 2.60 |

| Max Draught | Tc | m | 0.14 | 0.14 | 0.17 | 0.17 |

| Prismatic Coefficient | Cp | 0.539 | 0.540 | 0.621 | 0.629 | |

| Midship Section Coefficient | Cm | 0.728 | 0.728 | 0.582 | 0.576 | |

| Coeff. | LED | TryAgain | Diff. (%) |

|---|---|---|---|

| VC | 0.258 | 0.263 | +1.90 |

| LCB | 2.47 | 2.26 | −9.29 |

| SW | 3.48 | 3.50 | +0.57 |

| LWL | 4.46 | 4.49 | +0.67 |

| BWL | 1.05 | 0.95 | −10.53 |

| AW | 3.20 | 3.14 | −1.91 |

| LCF | 2.70 | 2.60 | −3.85 |

| TC | 0.14 | 0.17 | +17.65 |

| AX | 0.107 | 0.093 | −15.05 |

| CP | 0.540 | 0.629 | +14.15 |

| CM | 0.728 | 0.576 | −26.39 |

| Coeff. | LED | TryAgain | LED_UP_06 |

|---|---|---|---|

| VC | 0.258 | 0.263 | 0.259 |

| LCB | 2.47 | 2.26 | 2.48 |

| SW | 3.48 | 3.50 | 3.39 |

| LWL | 4.46 | 4.49 | 4.48 |

| BWL | 1.05 | 0.95 | 0.995 |

| AW | 3.20 | 3.14 | 3.08 |

| LCF | 2.70 | 2.60 | 2.71 |

| TC | 0.14 | 0.17 | 0.16 |

| AX | 0.107 | 0.093 | 0.107 |

| CP | 0.540 | 0.629 | 0.540 |

| CM | 0.728 | 0.576 | 0.689 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ingrassia, T.; Mancuso, A.; Nigrelli, V.; Saporito, A.; Tumino, D. Parametric Hull Design with Rational Bézier Curves and Estimation of Performances. J. Mar. Sci. Eng. 2021, 9, 360. https://doi.org/10.3390/jmse9040360

Ingrassia T, Mancuso A, Nigrelli V, Saporito A, Tumino D. Parametric Hull Design with Rational Bézier Curves and Estimation of Performances. Journal of Marine Science and Engineering. 2021; 9(4):360. https://doi.org/10.3390/jmse9040360

Chicago/Turabian StyleIngrassia, Tommaso, Antonio Mancuso, Vincenzo Nigrelli, Antonio Saporito, and Davide Tumino. 2021. "Parametric Hull Design with Rational Bézier Curves and Estimation of Performances" Journal of Marine Science and Engineering 9, no. 4: 360. https://doi.org/10.3390/jmse9040360

APA StyleIngrassia, T., Mancuso, A., Nigrelli, V., Saporito, A., & Tumino, D. (2021). Parametric Hull Design with Rational Bézier Curves and Estimation of Performances. Journal of Marine Science and Engineering, 9(4), 360. https://doi.org/10.3390/jmse9040360