Influence of Impeller Gap Drainage Width on the Performance of Low Specific Speed Centrifugal Pump

Abstract

1. Introduction

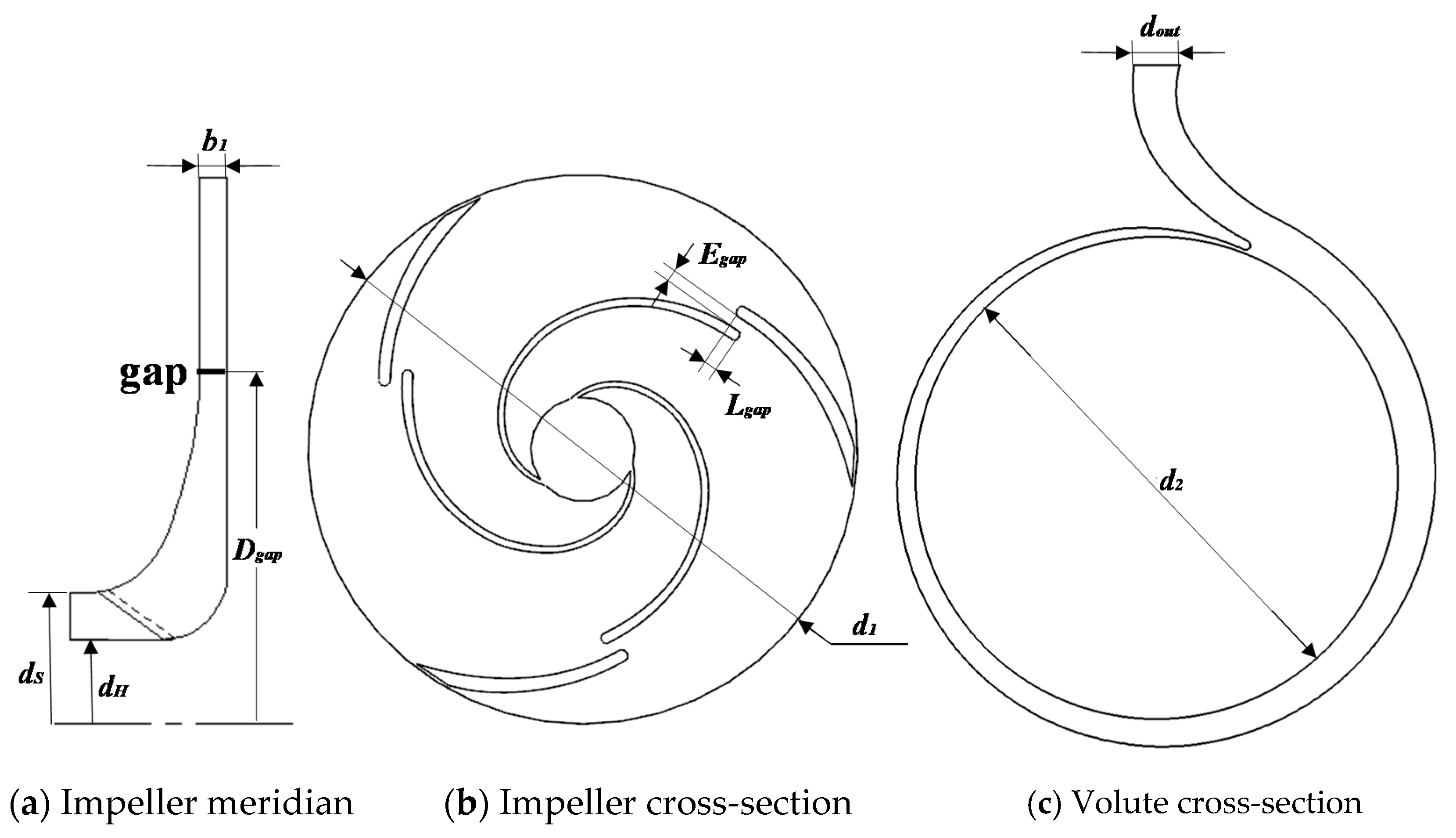

2. Geometry and Parameters

3. Numerical Methods and Settings

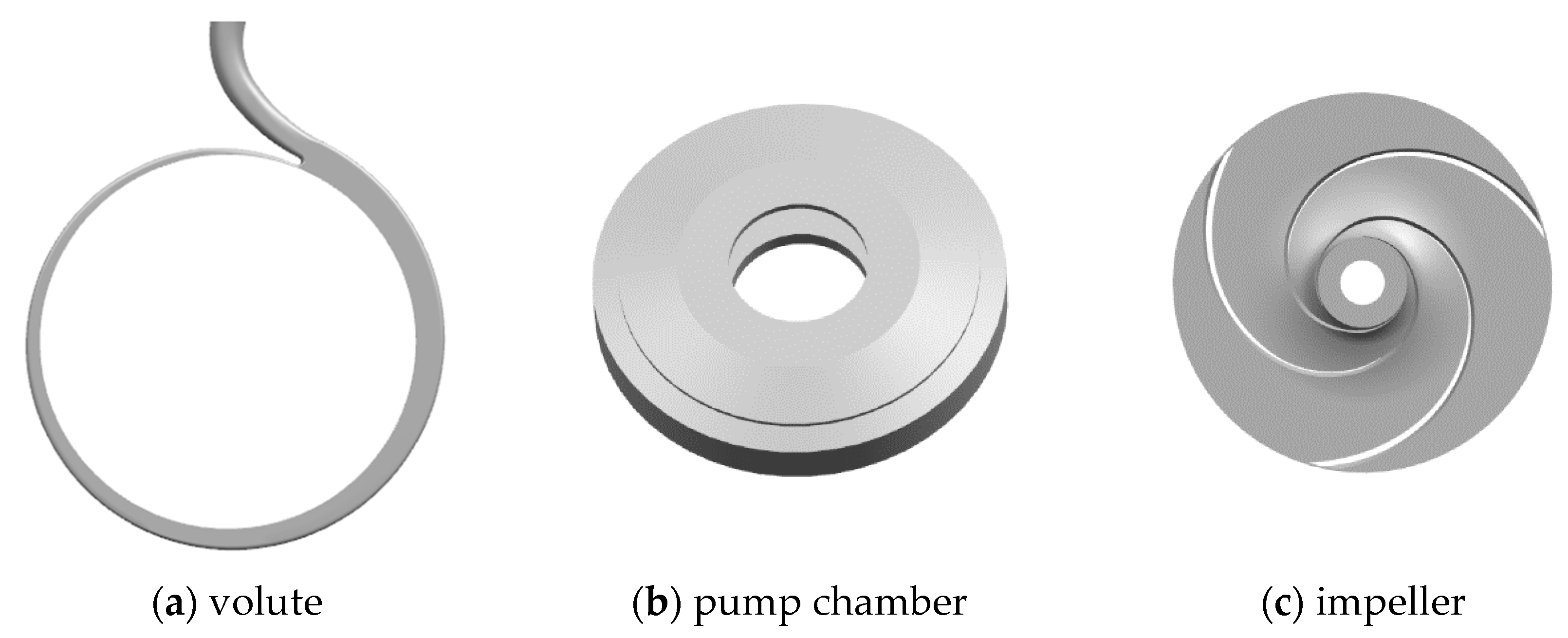

3.1. Computational Model

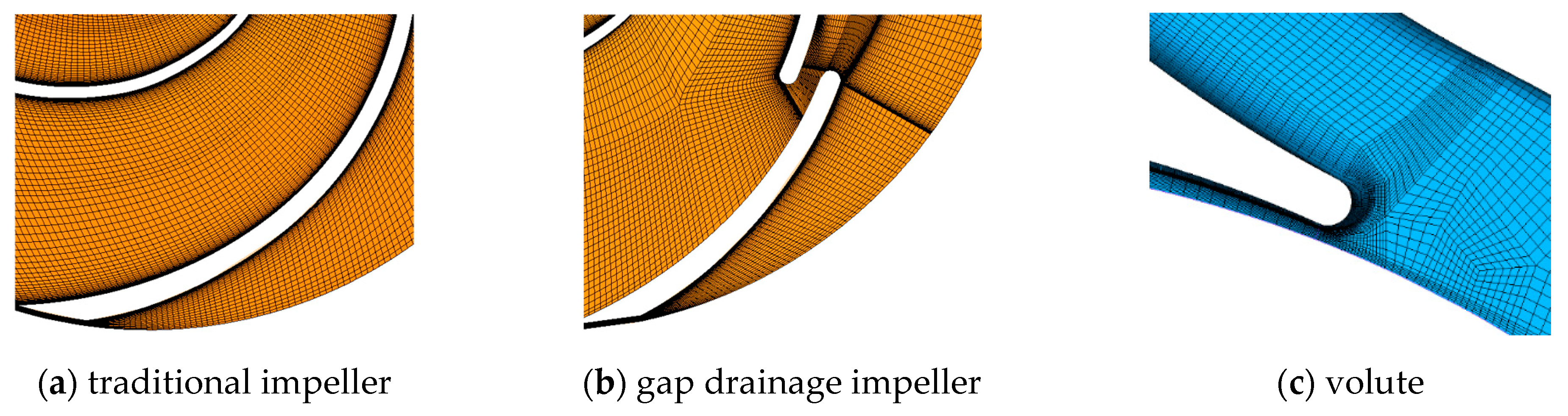

3.2. Grid

3.3. Grid Independency Analysis

3.4. Boundary Conditions

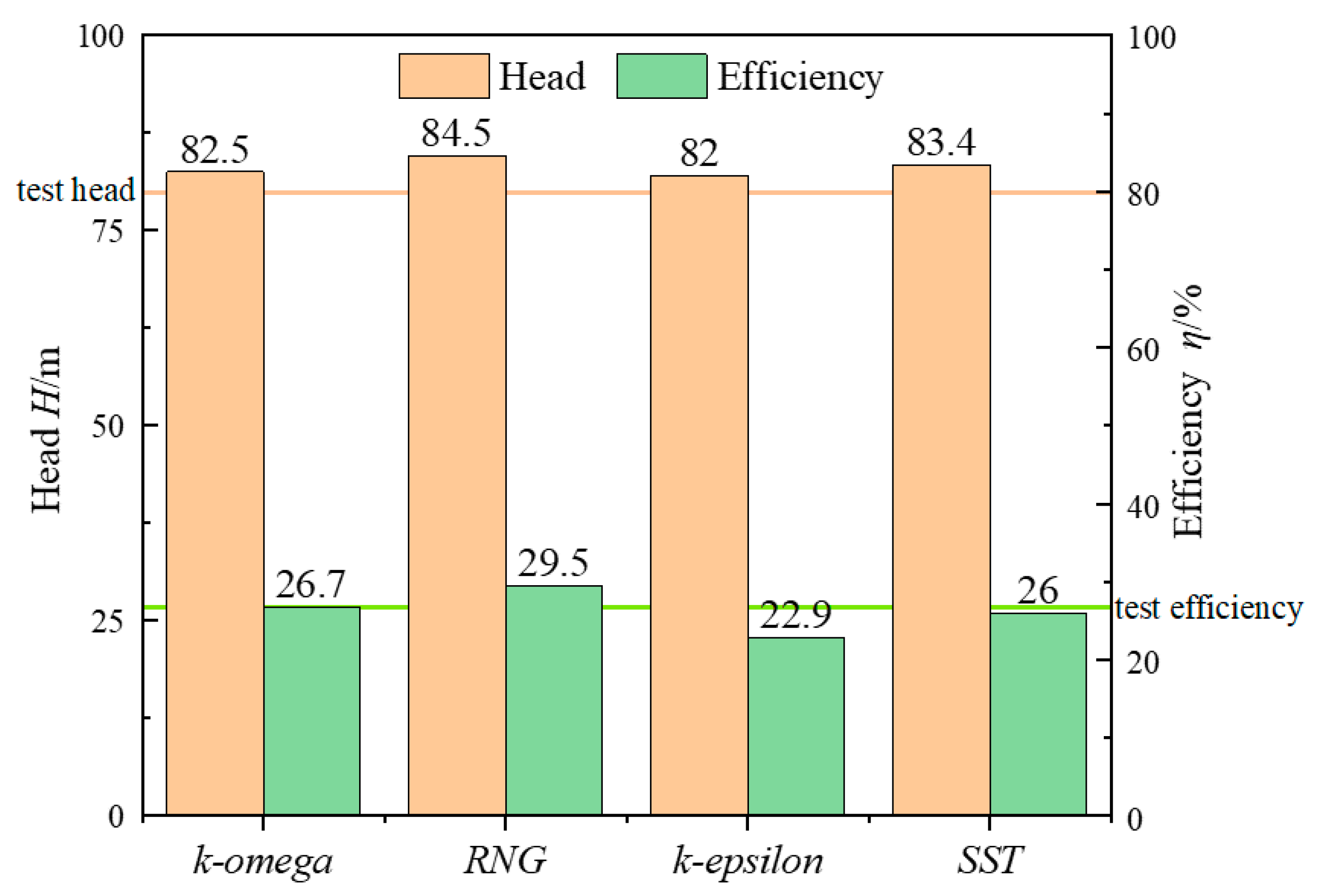

4. Pump Performance Validation

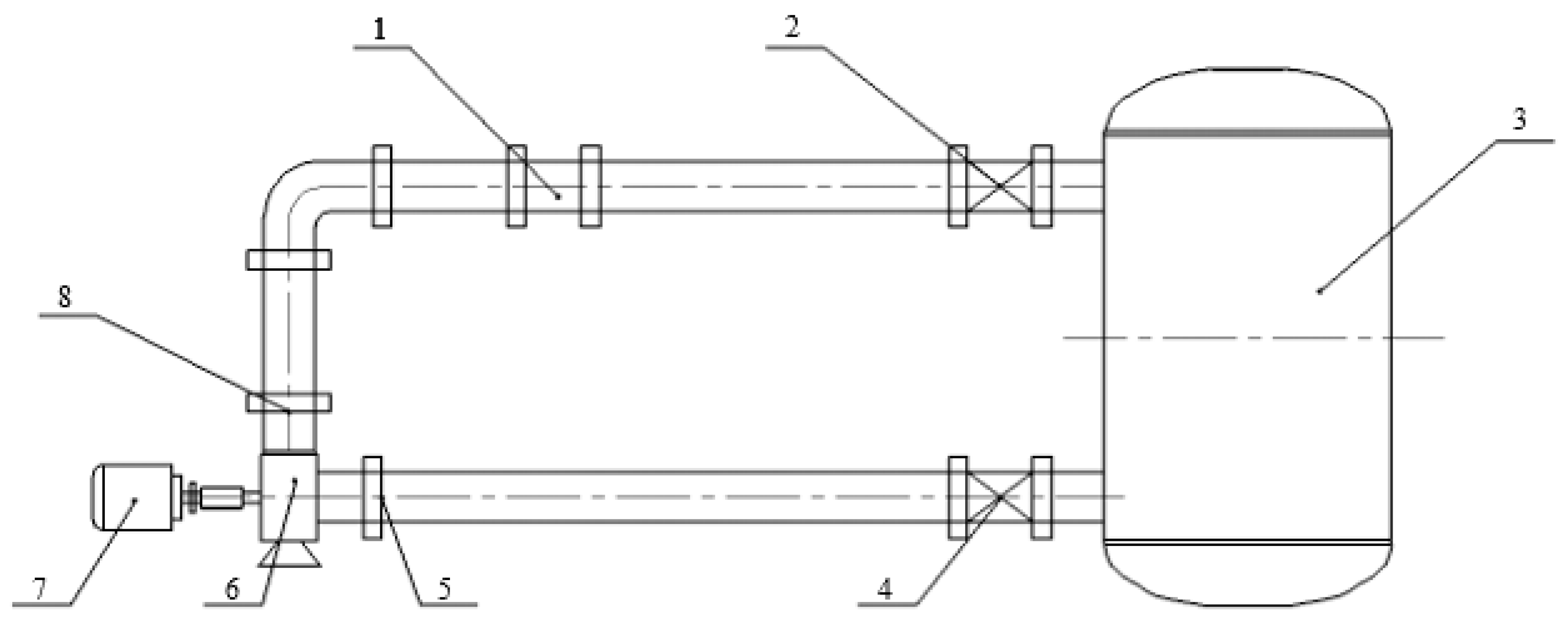

4.1. Testbed and Methods

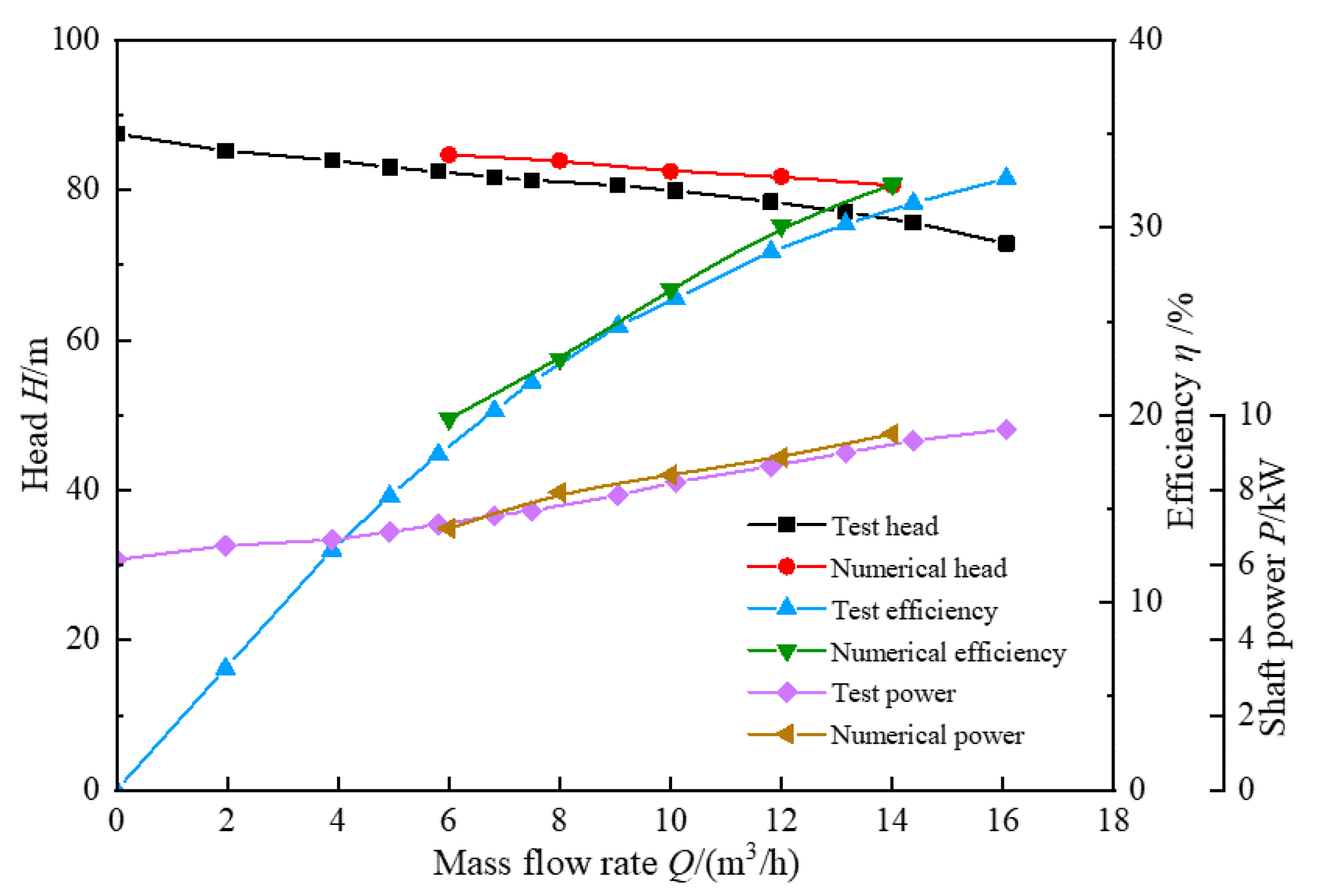

4.2. Model Validation

5. Results and Discussion

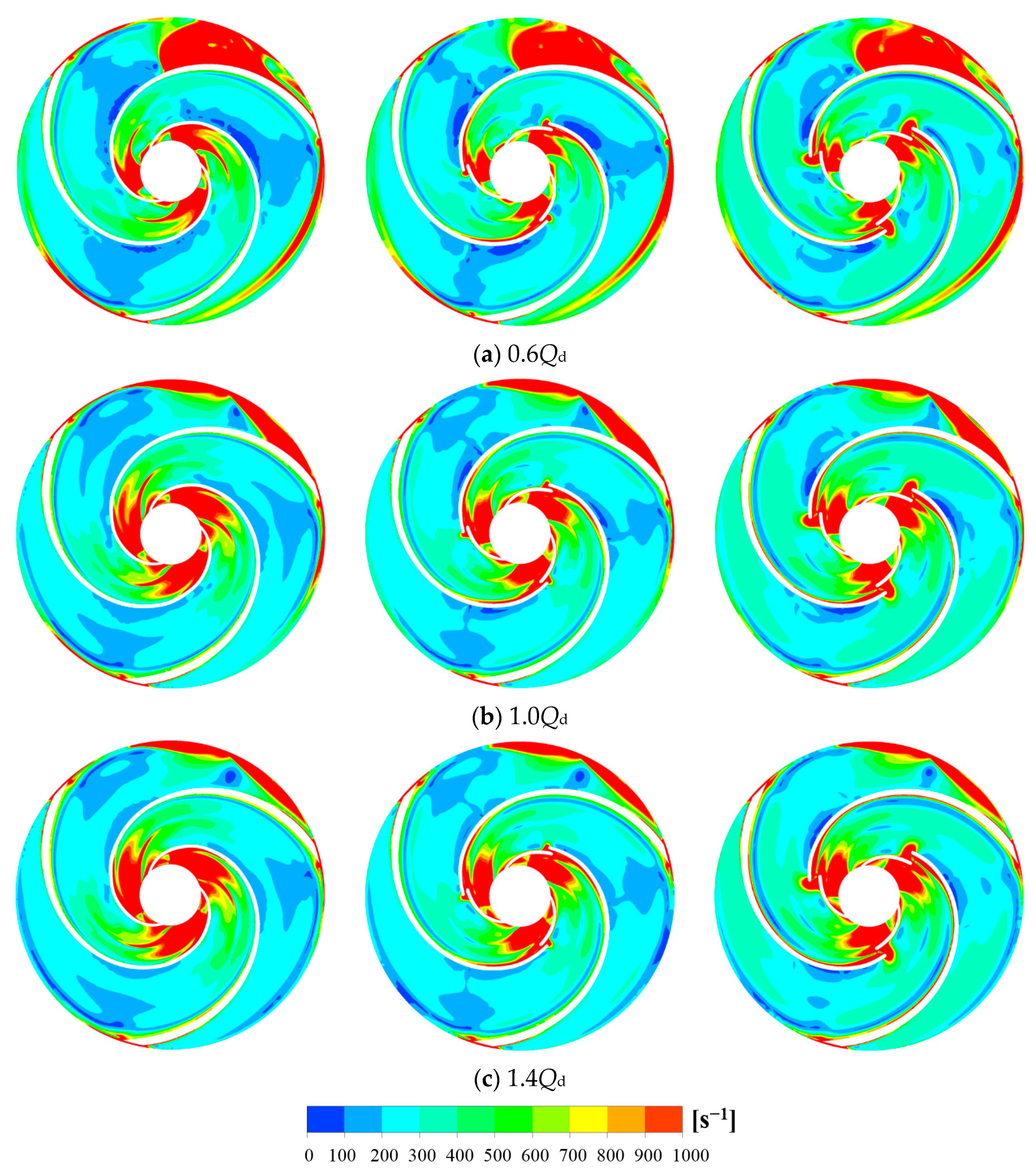

5.1. The Effect of Gap Width on Pump Performance

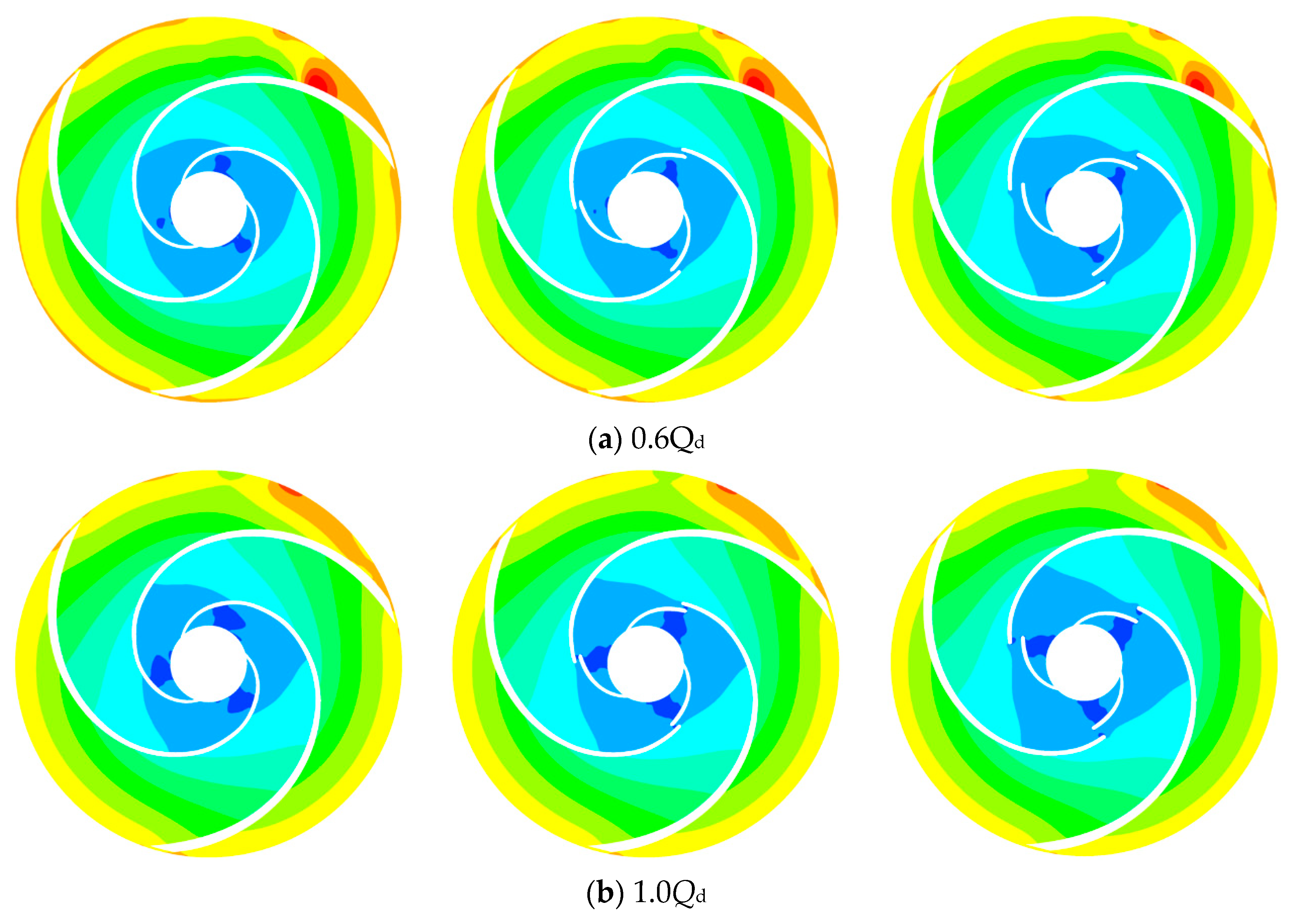

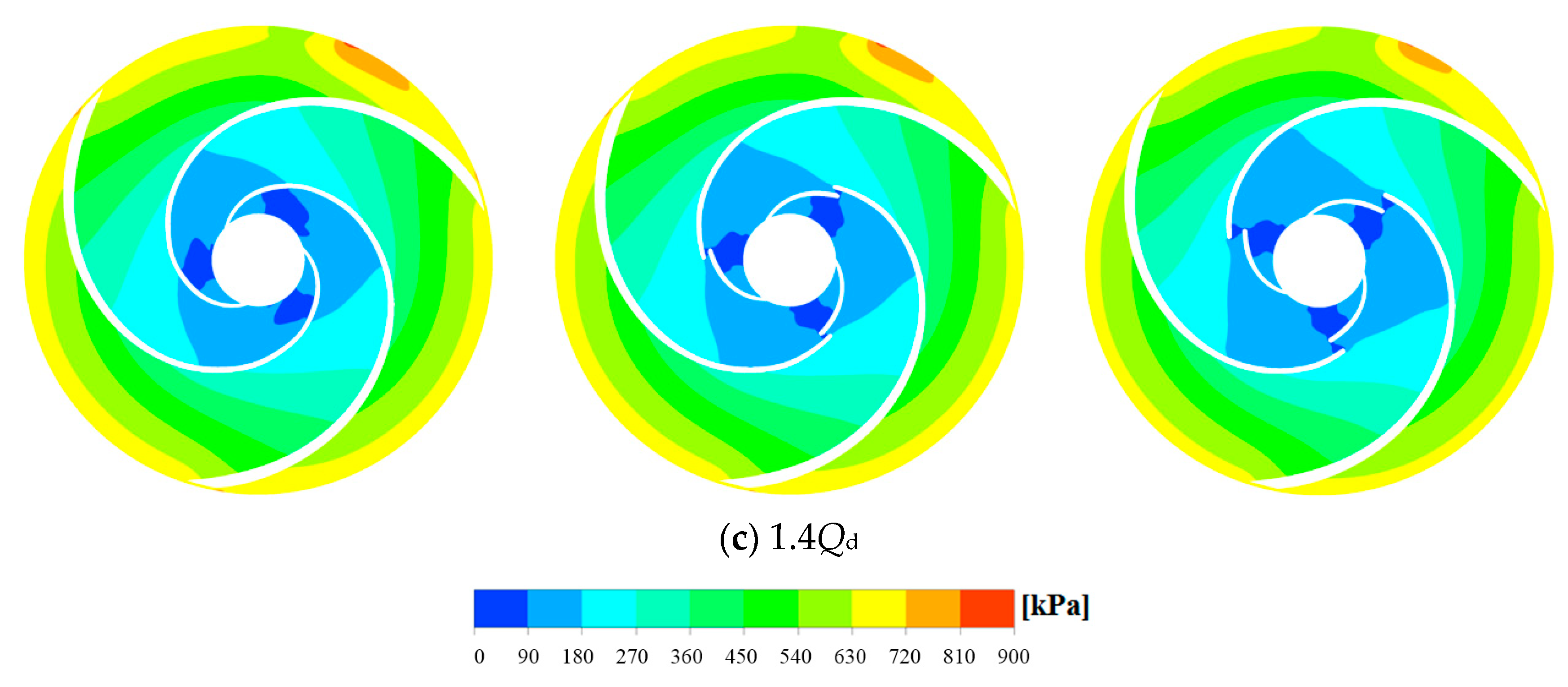

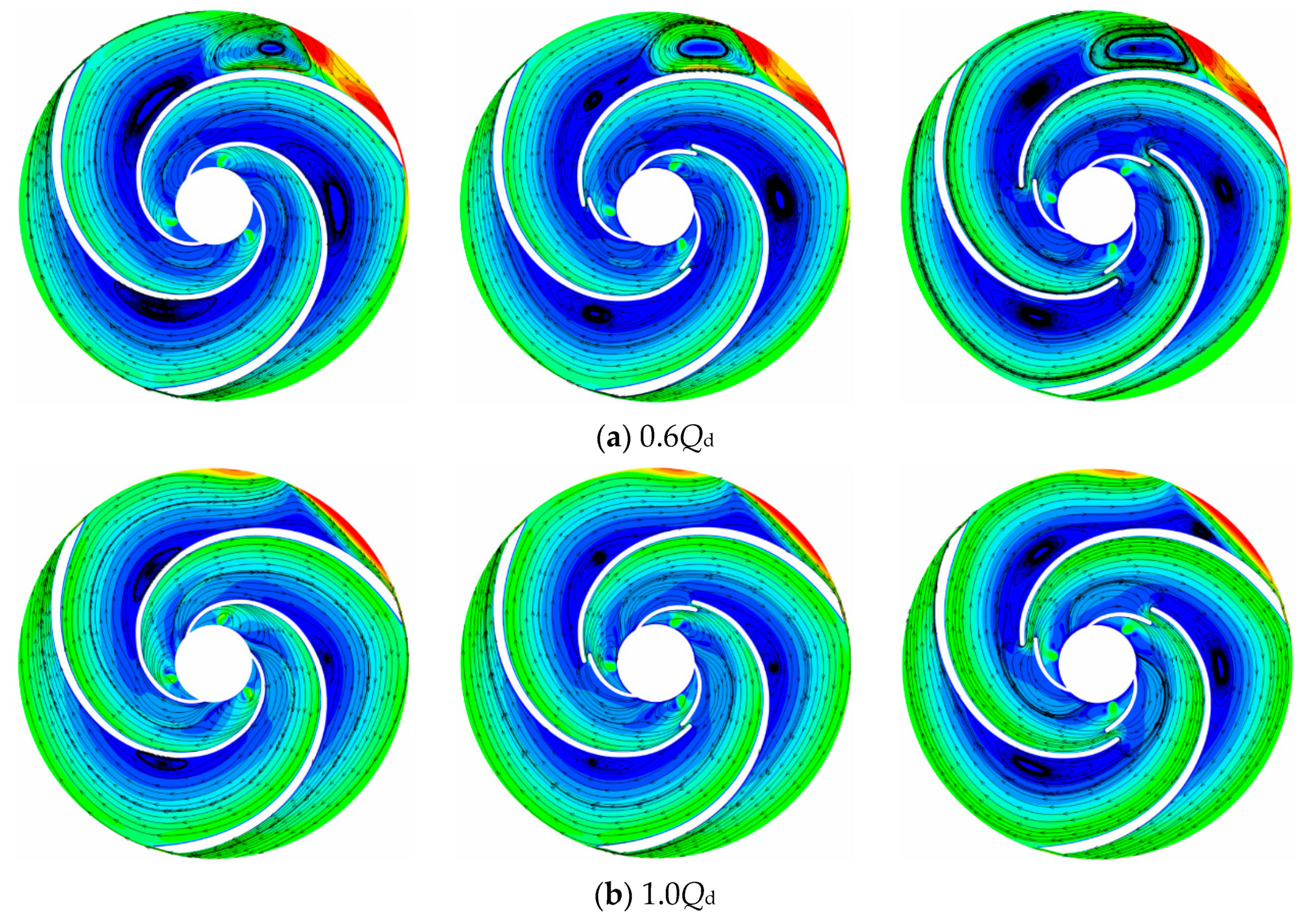

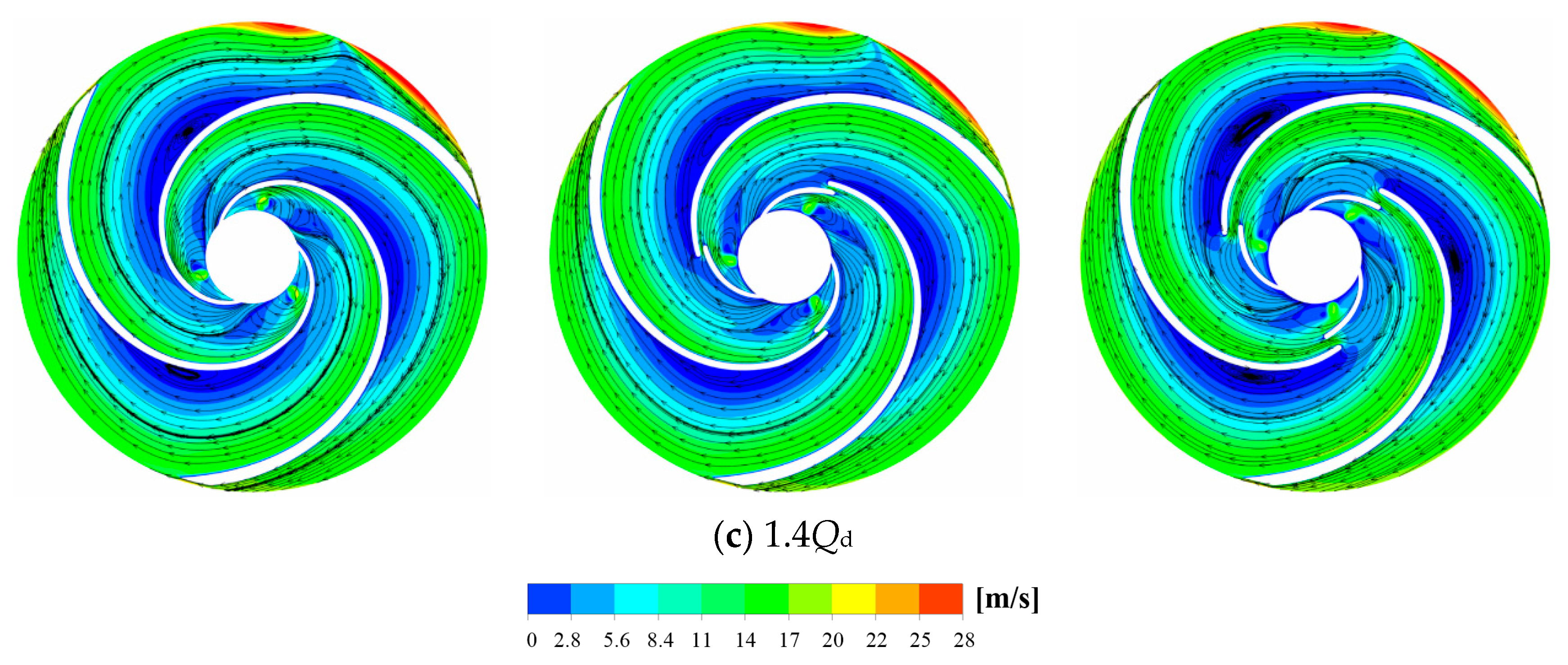

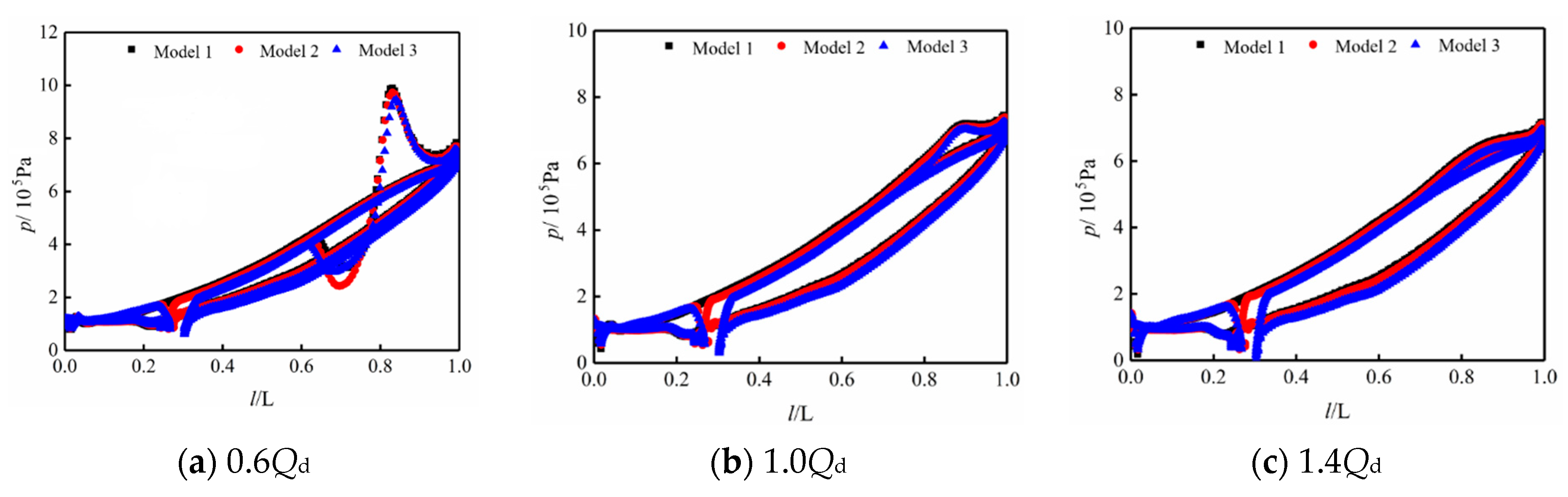

5.2. The Effect of Gap Width on Flow Field

6. Conclusions

- (1)

- The head, efficiency, and shaft power based on the numerical prediction were slightly higher than the experimental values and the numerical results had the largest predicted deviation under 1.4 times the rated operating conditions. However, the difference between the predicted results and the experimental values of the head and efficiency was less than 3% under rated flow conditions. Additionally, under full flow conditions, the agreement between the numerical results and the experimental results was relatively high and the two had basically the same trend of change. Therefore, the numerical calculation method used in this article had high accuracy in predicting the performance of low specific speed centrifugal pumps.

- (2)

- Gap drainage could reduce the head of the low specific speed centrifugal pump, but it could improve hydraulic efficiency. The performance of the three models verified the conclusion that the gap width had a greater influence on the gap drainage effect. The optimal gap for this study is 1.5 mm. A small gap width in the low specific speed centrifugal pump could greatly improve its hydraulic efficiency with small head drop.

- (3)

- The gap drainage impeller could reduce the occurrence of turbulent vortex in the impeller flow passage and energy loss. Thereby, its hydraulic performance was improved. The gap drainage structure could make the high-pressure liquid on the pressure surface of the blade flow to the suction surface through the gap, which increased the liquid pressure on the suction surface and inhibited the development of the low-pressure area at the impeller inlet. When the gap width was too large, the high-pressure leakage flow rate was too large, which could cause that the impeller outlet pressure and head were decreased.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Q | volumetric flow rate |

| H | head |

| n | rotating speed |

| ns | specific speed |

| N | impeller blade number |

| φ | blades wrap angle |

| dH | impeller hub diameter |

| dS | impeller shroud diameter |

| d1 | impeller diameter |

| b1 | impeller outlet width |

| d2 | volute inlet diameter |

| b2 | volute inlet width |

| dout | volute outlet diameter |

| Dgap | gap diameter |

| Lgap | blade lap length |

| Egap | gap width |

| p1 | pump inlet pressure |

| p2 | pump outlet pressure |

| V1 | pump inlet velocity |

| V2 | pump outlet velocity |

| Z1 | pump inlet height |

| Z2 | pump outlet height |

| P1 | numerical hydraulic power |

| P2 | numerical shaft power |

| P3 | motor input power |

| η1 | numerical hydraulic efficiency |

| η2 | experimental hydraulic efficiency |

| ρ | medium density |

| g | acceleration of gravity |

| U | motor voltage |

| I | motor current |

References

- Jafarzadeh, B.; Hajari, A.; Alishahi, M.; Akbari, M. The flow simulation of a low-specific-speed high-speed centrifugal pump. Appl. Math. Model. 2011, 35, 242–249. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, W.; Hang, J.; Shi, W.; Yan, H.; Zhu, Y. Numerical investigation of a high-speed electrical submersible pump with different end clearances. Water 2020, 12, 1116. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, L.; Shi, W.; He, Z.; Xiao, Y. Interstage difference of pressure pulsation in a three-stage electrical submersible pump. J. Pet. Sci. Eng. 2020, 196, 107653. [Google Scholar] [CrossRef]

- Choi, Y.D.; Kurokawa, J.; Matsui, J. Performance and internal flow characteristics of a very low specific speed centrifugal pump. AMSE J. Fluids Eng. 2006, 128, 341–349. [Google Scholar] [CrossRef]

- Veselov, V. Effect of the outlet angle β2 on the characteristics of low specific-speed centrifugal pumps. Hydrotech. Constr. 1982, 16, 267–273. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, H.; Lu, W.; Chen, T. Influence of diameter of rear sealing ring on axial force characteristics of centrifugal pump. J. Drain. Irrig. Mach. Eng. 2020, 38, 115–120. [Google Scholar]

- Detert, O.; van Der, S.; Kruyt, N.; van Der, Z. Prediction of the effect of impeller trimming on the hydraulic performance of low specific-speed centrifugal pumps. AMSE J. Fluids Eng. 2018, 140, 081202. [Google Scholar] [CrossRef]

- Zhou, L.; Shi, W.; Li, W.; Agarwal, R. Numerical and experimental study of axial force and hydraulic performance in a deep-well centrifugal pump with different impeller rear shroud radius. AMSE J. Fluids Eng. 2013, 135, 104501–104508. [Google Scholar] [CrossRef]

- Kagawa, S.; Kurokawa, J.; Matsui, J.; Choi, Y. Performance of very low specific speed centrifugal pumps with circular casing. J. Fluid Sci. Technol. 2007, 2, 130–138. [Google Scholar] [CrossRef]

- Friedrichs, J.; Kosyna, G. Rotating cavitation in a centrifugal pump impeller of low specific speed. AMSE J. Fluids Eng. 2002, 124, 356–362. [Google Scholar] [CrossRef]

- Kelder, J.; Dijkers, R.; Van Esch, B.; Kruyt, B. Experimental and theoretical study of the flow in the volute of a low specific-speed pump. Fluid Dyn. Res. 2001, 28, 267. [Google Scholar] [CrossRef]

- Šavar, M.; Kozmar, H.; Sutlović, I. Improving centrifugal pump efficiency by impeller trimming. Desalination 2009, 249, 654–659. [Google Scholar] [CrossRef]

- Alemi, H.; Nourbakhsh, S.; Raisee, M.; Najafi, A. Effects of volute curvature on performance of a low specific-speed centrifugal pump at design and off-design conditions. ASME J. Turbomach. 2015, 137, 041009. [Google Scholar] [CrossRef]

- Visser, F.; Brouwers, J.; Jonker, J. Fluid flow in a rotating low-specific-speed centrifugal impeller passage. Fluid Dyn. Res. 1999, 24, 275. [Google Scholar] [CrossRef]

- Pang, Q.; Jiang, X.; Zhu, J.; Wu, G.; Wang, X.; Wang, L. Influences of radial clearance between impeller and diffuser on flow field in side chambers of multistage centrifugal pump. J. Drain. Irrig. Mach. Eng. 2019, 37, 580–586. [Google Scholar]

- Nie, C.; Xu, G.; Cheng, X.; Chen, J. Micro air injection and its unsteady response in a low-speed axial compressor. Turbo Expo Power Land Sea Air 2002, 3610, 343–352. [Google Scholar]

- Culley, D.E.; Bright, M.M.; Prahst, P.S.; Strazisar, A. Active flow separation control of a stator vane using embedded injection in a multistage compressor experiment. ASME J. Turbomach. 2004, 126, 24–34. [Google Scholar] [CrossRef]

- Gupta, A.; Alsultan, A.; Amano, R.; Kumar, S.; Welsh, A. Design and analysis of wind turbine blades: Winglet, tubercle, and slotted. Turbo Expo: Power for Land, Sea, and Air. Am. Soc. Mech. Eng. 2013, 55294, 1–10. [Google Scholar]

- Zhu, B.; Chen, H. Cavitating suppression of low specific speed centrifugal pump with gap drainage blades. J. Hydrodyn. 2012, 24, 729–736. [Google Scholar] [CrossRef]

- Wang, H.; Long, B.; Wang, C.; Han, C.; Li, L. Effects of the impeller blade with a slot structure on the centrifugal pump performance. Energies 2020, 13, 1628. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, L.; Hang, J.; Du, D.; Shi, W.; He, Z. Energy characteristics and optimal design of diffuser meridian in an electrical submersible pump. Renew. Energy 2020, 167, 718–727. [Google Scholar] [CrossRef]

- Zhou, L.; Han, C.; Bai, L.; Li, W.; El-Emam, M.; Shi, W. CFD-DEM bidirectional coupling simulation and experimental investigation of particle ejections and energy conversion in a spouted bed. Energy 2020, 211, 118672. [Google Scholar] [CrossRef]

- Zhou, L.; Deshpande, K.; Zhang, X.; Agarwal, R. Process simulation of chemical looping combustion using ASPEN plus for a mixture of biomass and coal with various oxygen carriers. Energy 2020, 195, 116955. [Google Scholar] [CrossRef]

- Peng, G.; Huang, X.; Zhou, L.; Zhou, G.; Zhou, H. Solid-liquid two-phase flow and wear analysis in a large-scale centrifugal slurry pump. Eng. Fail. Anal. 2020, 114, 104602. [Google Scholar] [CrossRef]

- Li, W.; Li, E.; Ji, L.; Zhou, L.; Shi, W.; Zhu, Y. Mechanism and propagation characteristics of rotating stall in a mixed-flow pump. Renew. Energy 2020, 153, 74–92. [Google Scholar] [CrossRef]

- Zhou, L.; Bai, L.; Li, W.; Shi, W.; Wang, C. PIV validation of different turbulence models used for numerical simulation of a centrifugal pump diffuser. Eng. Comput. 2018, 35, 2–17. [Google Scholar] [CrossRef]

- Yan, H.; Su, X.; Zhang, H.; Hang, J.; Zhou, L.; Liu, Z.; Wang, Z. Design approach and hydrodynamic characteristics of a novel bionic airfoil. Ocean Eng. 2020, 216, 108076. [Google Scholar] [CrossRef]

- Shi, W.; Hou, Y.; Zhou, L.; Li, Y.; Xue, S. Numerical simulation and test of performance of deep-well centrifugal pumps with different stages. J. Drain. Irrig. Mach. Eng. 2019, 37, 562–567. [Google Scholar]

- Bai, L.; Zhou, L.; Jiang, X.; Pang, Q.; Ye, D. Vibration in a multistage centrifugal pump under varied conditions. Shock Vib. 2019, 2057031, 1–9. [Google Scholar] [CrossRef]

| Impeller Parameters | Volute Parameters | ||

|---|---|---|---|

| Number of blades | N = 3 | Inlet diameter | d2 = 131.5 mm |

| Blades wrap angle | φ = 190° | Inlet width | b2 = 21 mm |

| Hub diameter | dH = 30.7 mm | Outlet diameter | dout = 25 mm |

| Suction diameter | dS = 50 mm | Parameters | Gap |

| Impeller diameter | d1 = 259 mm | Gap diameter | Dgap = 90 mm |

| Outlet width | b1 = 6.5 mm | Blade lap length | Lgap = 5 mm |

| Model 1 | Model 2 | Model 3 | |

| Gap width | Egap1 = 0 mm | Egap2 = 1.5 mm | Egap3 = 6 mm |

| Number of Grids | Head/m | Efficiency/% |

|---|---|---|

| 2,169,713 | 83.51 | 25.57 |

| 3,251,493 | 83.34 | 25.98 |

| 4,365,848 | 82.53 | 26.73 |

| 5,246,214 | 82.49 | 26.92 |

| 5,941,363 | 82.51 | 26.74 |

| Flow Conditions | Gap Width (mm) | H/m | η/% |

|---|---|---|---|

| 0.6Qd | 0 | 84.7 | 19.8 |

| 1.5 | 84.49 | 20.81 | |

| 6 | 81.24 | 19.84 | |

| 1.0Qd | 0 | 82.5 | 26.7 |

| 1.5 | 82.39 | 28.62 | |

| 6 | 80.03 | 27 | |

| 1.4Qd | 0 | 80.6 | 32.3 |

| 1.5 | 80.54 | 34.32 | |

| 6 | 77.51 | 33.06 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, Y.; Yang, Y.; Zhou, L.; Jiang, L.; Shi, W.; Huang, G. Influence of Impeller Gap Drainage Width on the Performance of Low Specific Speed Centrifugal Pump. J. Mar. Sci. Eng. 2021, 9, 106. https://doi.org/10.3390/jmse9020106

Wei Y, Yang Y, Zhou L, Jiang L, Shi W, Huang G. Influence of Impeller Gap Drainage Width on the Performance of Low Specific Speed Centrifugal Pump. Journal of Marine Science and Engineering. 2021; 9(2):106. https://doi.org/10.3390/jmse9020106

Chicago/Turabian StyleWei, Yangyang, Yang Yang, Ling Zhou, Lei Jiang, Weidong Shi, and Gaoyang Huang. 2021. "Influence of Impeller Gap Drainage Width on the Performance of Low Specific Speed Centrifugal Pump" Journal of Marine Science and Engineering 9, no. 2: 106. https://doi.org/10.3390/jmse9020106

APA StyleWei, Y., Yang, Y., Zhou, L., Jiang, L., Shi, W., & Huang, G. (2021). Influence of Impeller Gap Drainage Width on the Performance of Low Specific Speed Centrifugal Pump. Journal of Marine Science and Engineering, 9(2), 106. https://doi.org/10.3390/jmse9020106