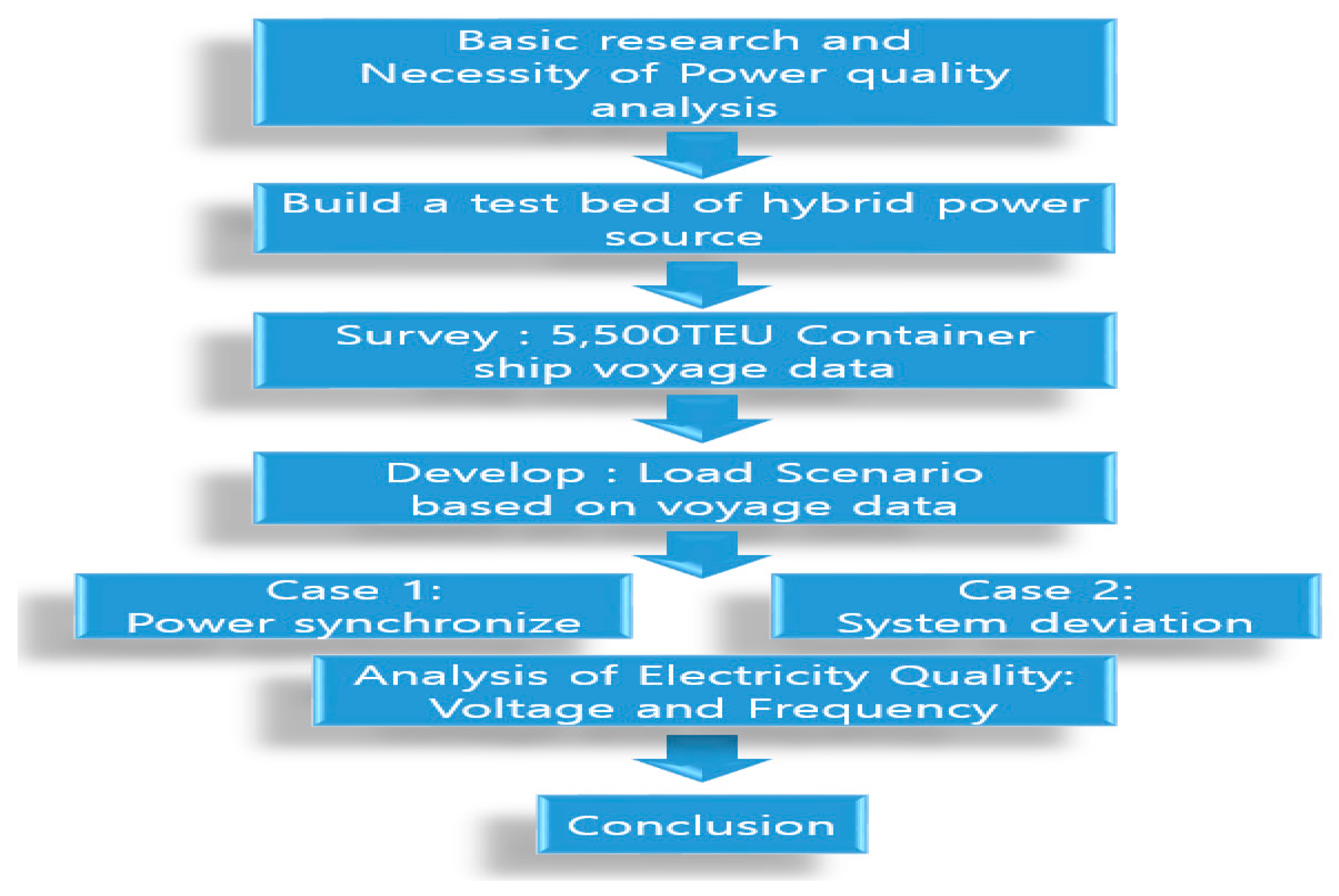

Figure 1.

Flowchart for research procedure.

Figure 1.

Flowchart for research procedure.

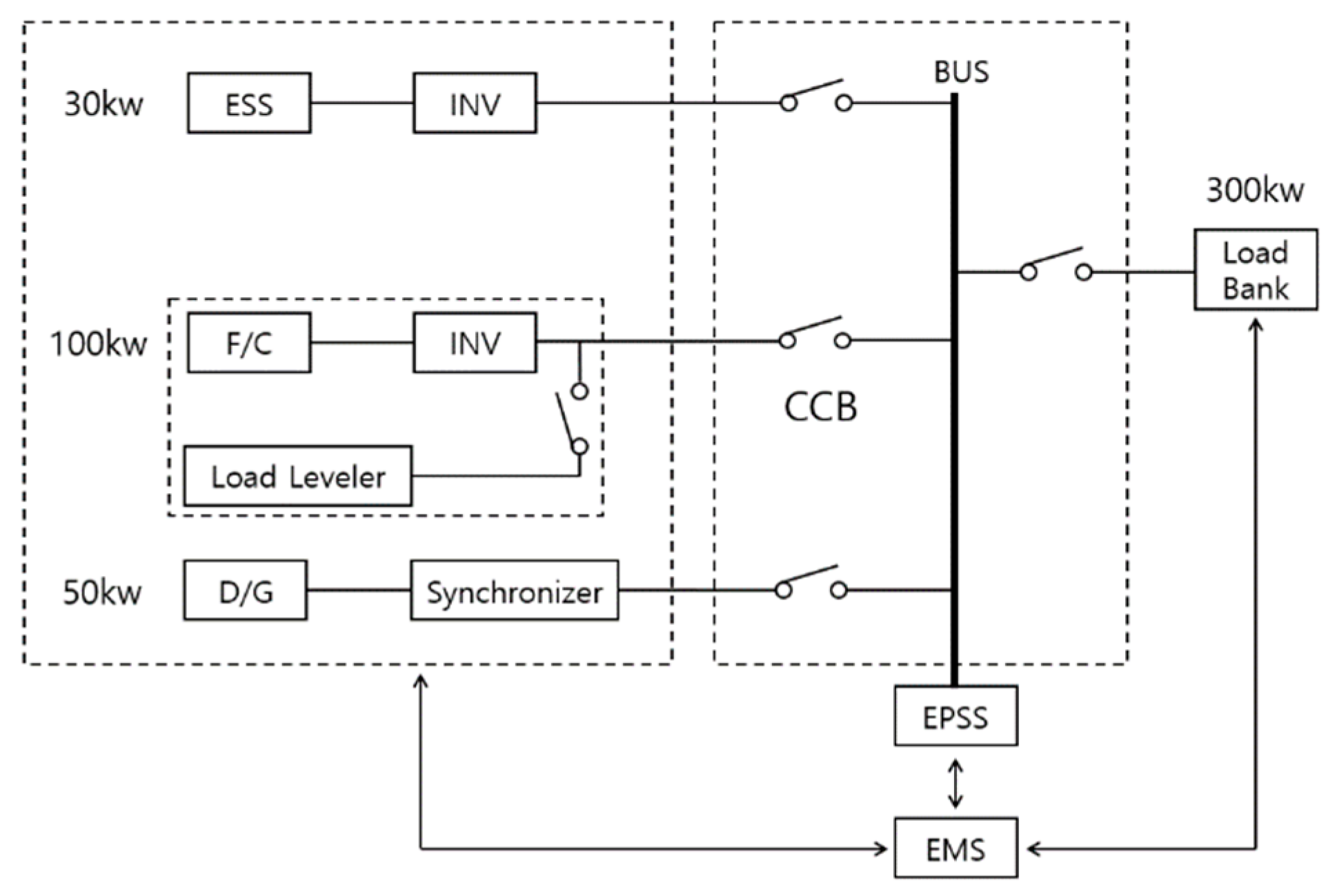

Figure 2.

Basic outline of hybrid power systems for the test bed.

Figure 2.

Basic outline of hybrid power systems for the test bed.

Figure 3.

Actual placement of the test bed.

Figure 3.

Actual placement of the test bed.

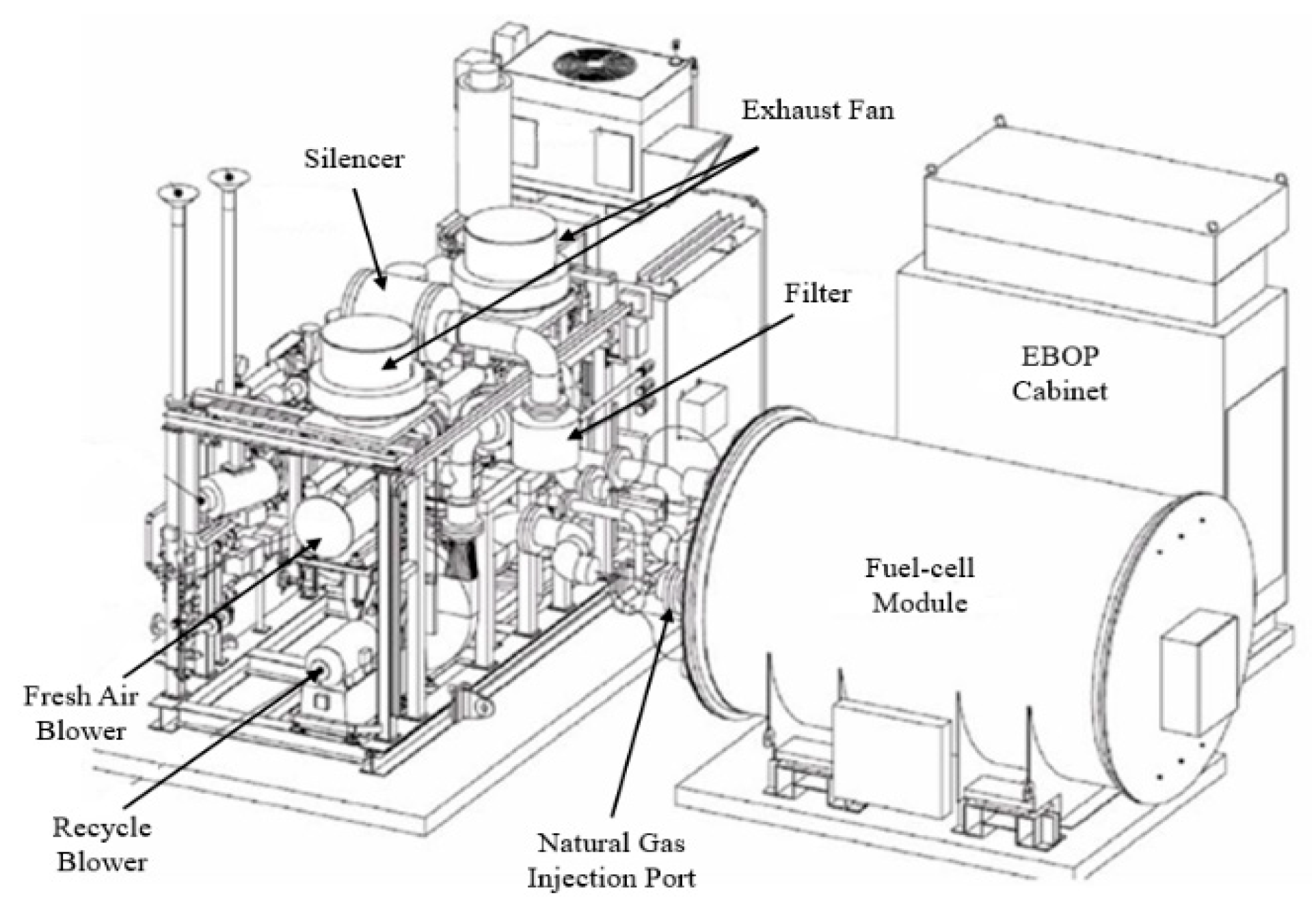

Figure 4.

Overall configuration for fuel cell system.

Figure 4.

Overall configuration for fuel cell system.

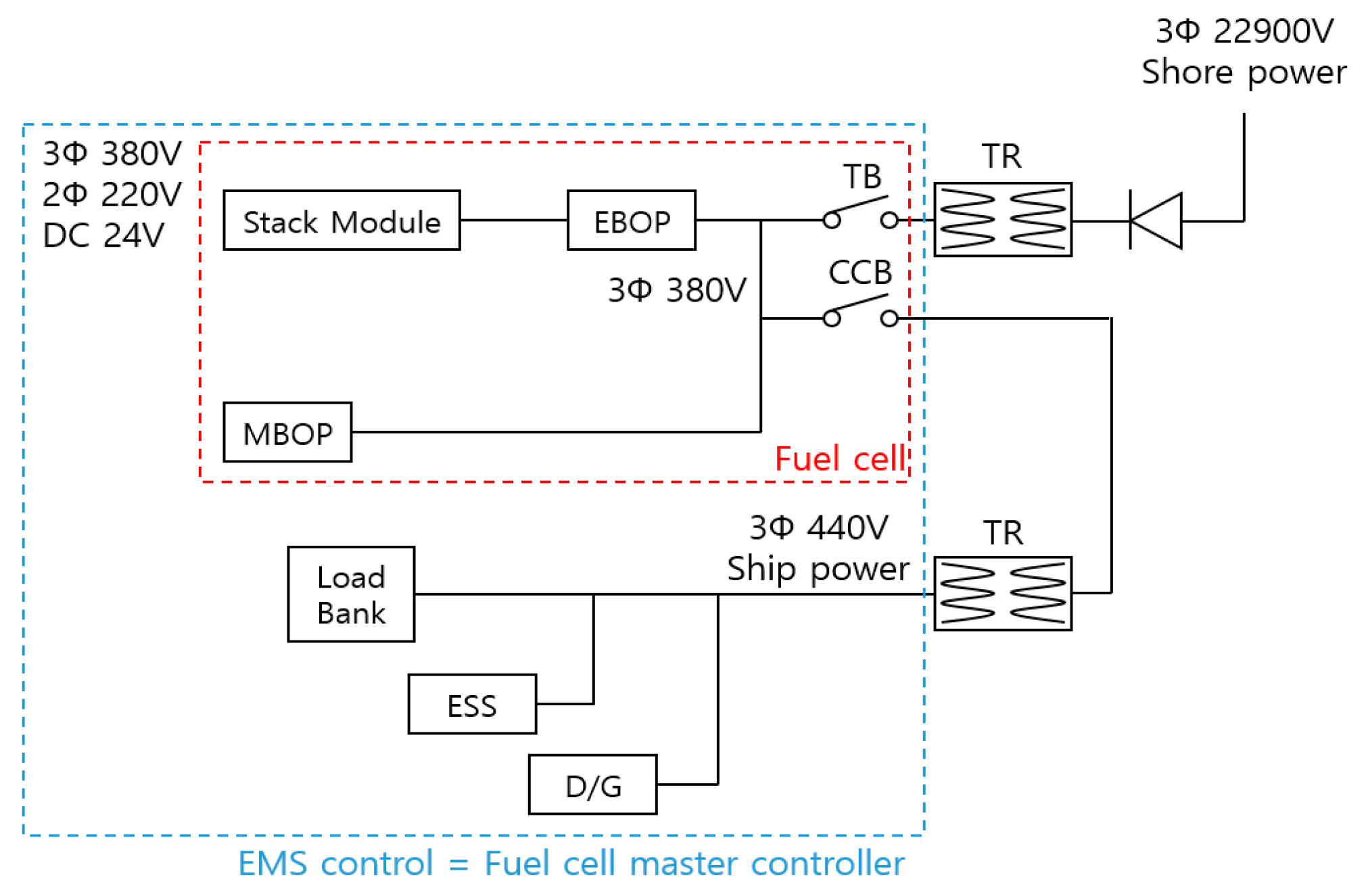

Figure 5.

Concept of the fuel cell power generation.

Figure 5.

Concept of the fuel cell power generation.

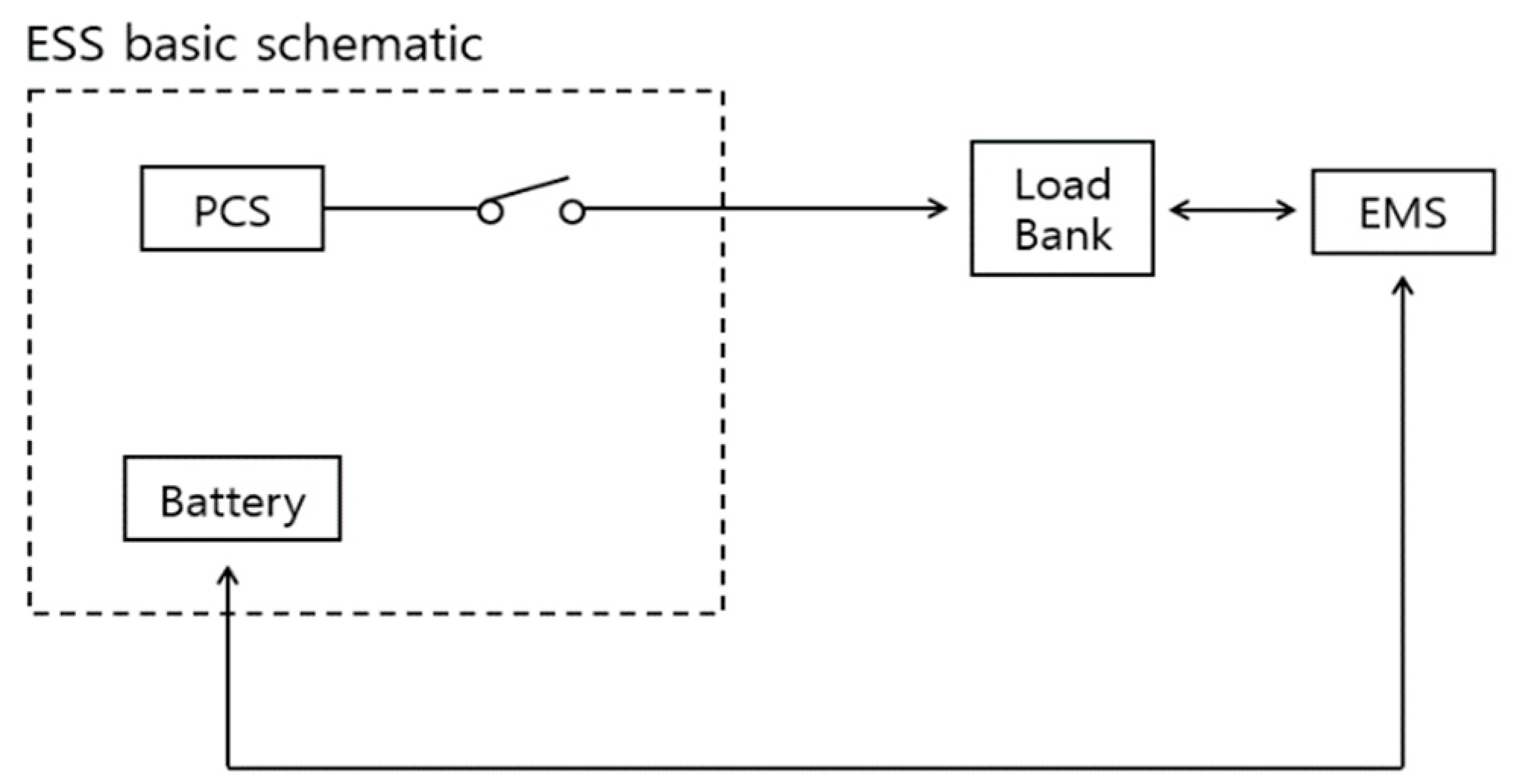

Figure 6.

Configuration diagram energy storage system (ESS).

Figure 6.

Configuration diagram energy storage system (ESS).

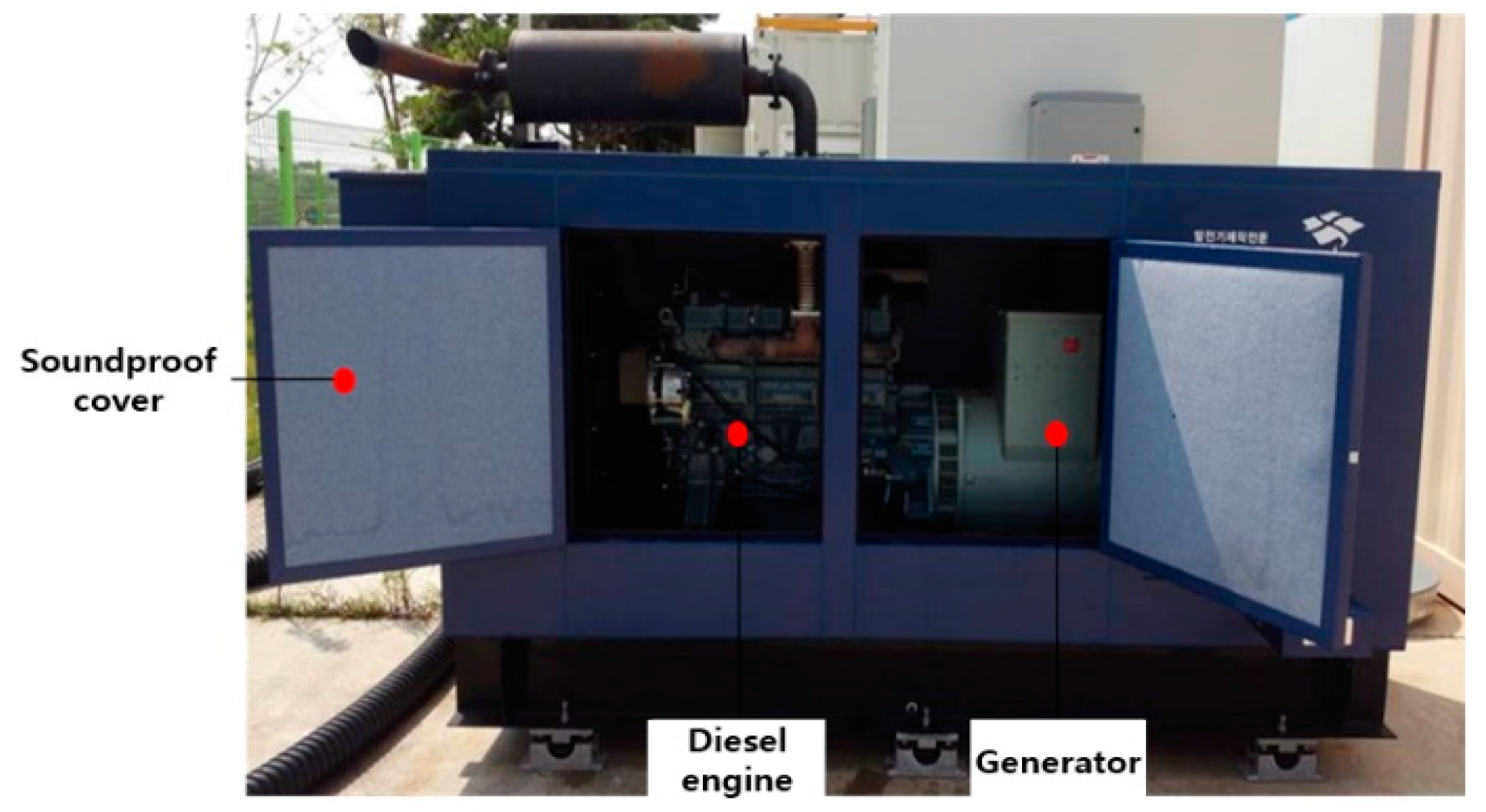

Figure 7.

Appearance of diesel generator.

Figure 7.

Appearance of diesel generator.

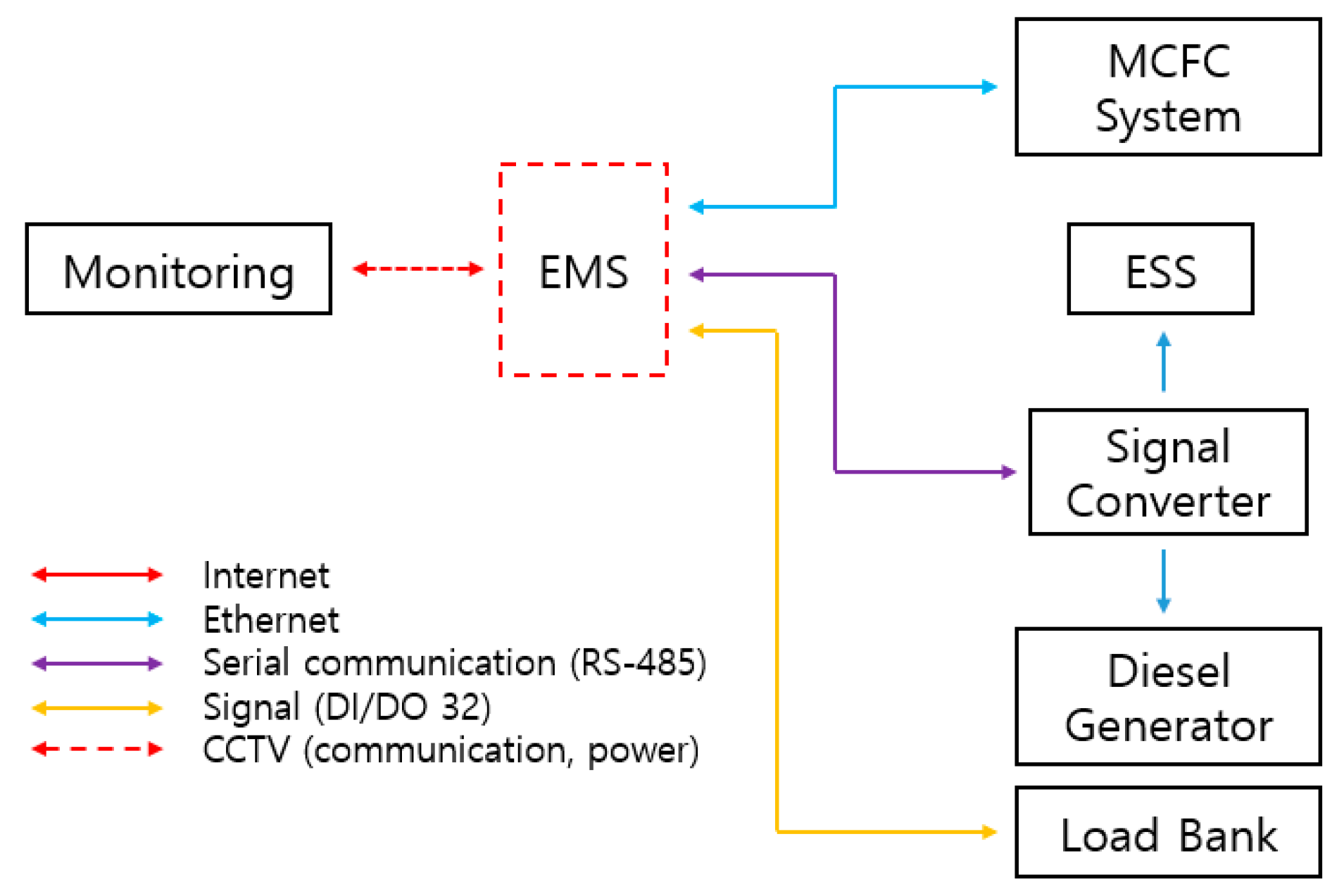

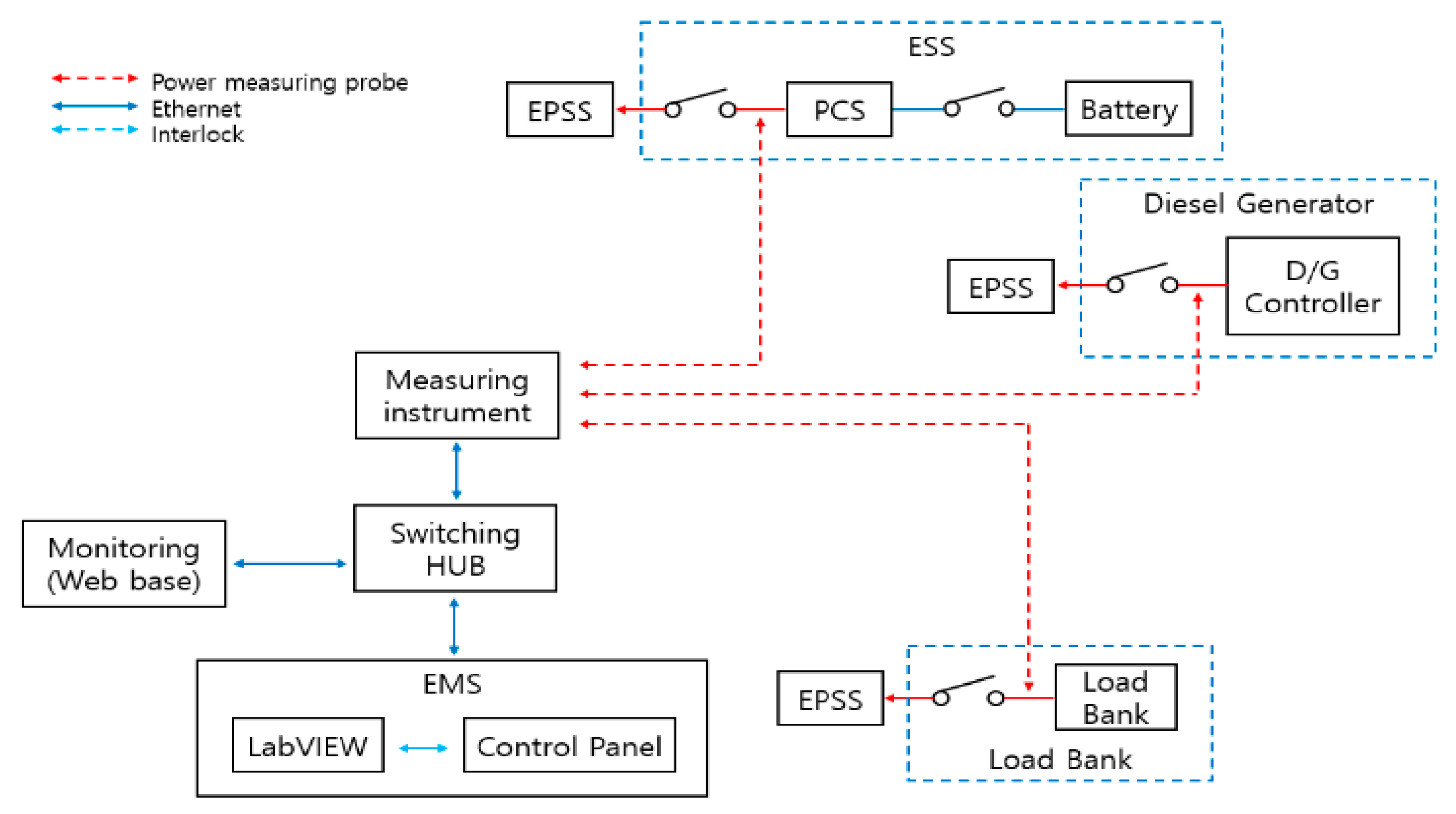

Figure 8.

Integrated power control system configuration.

Figure 8.

Integrated power control system configuration.

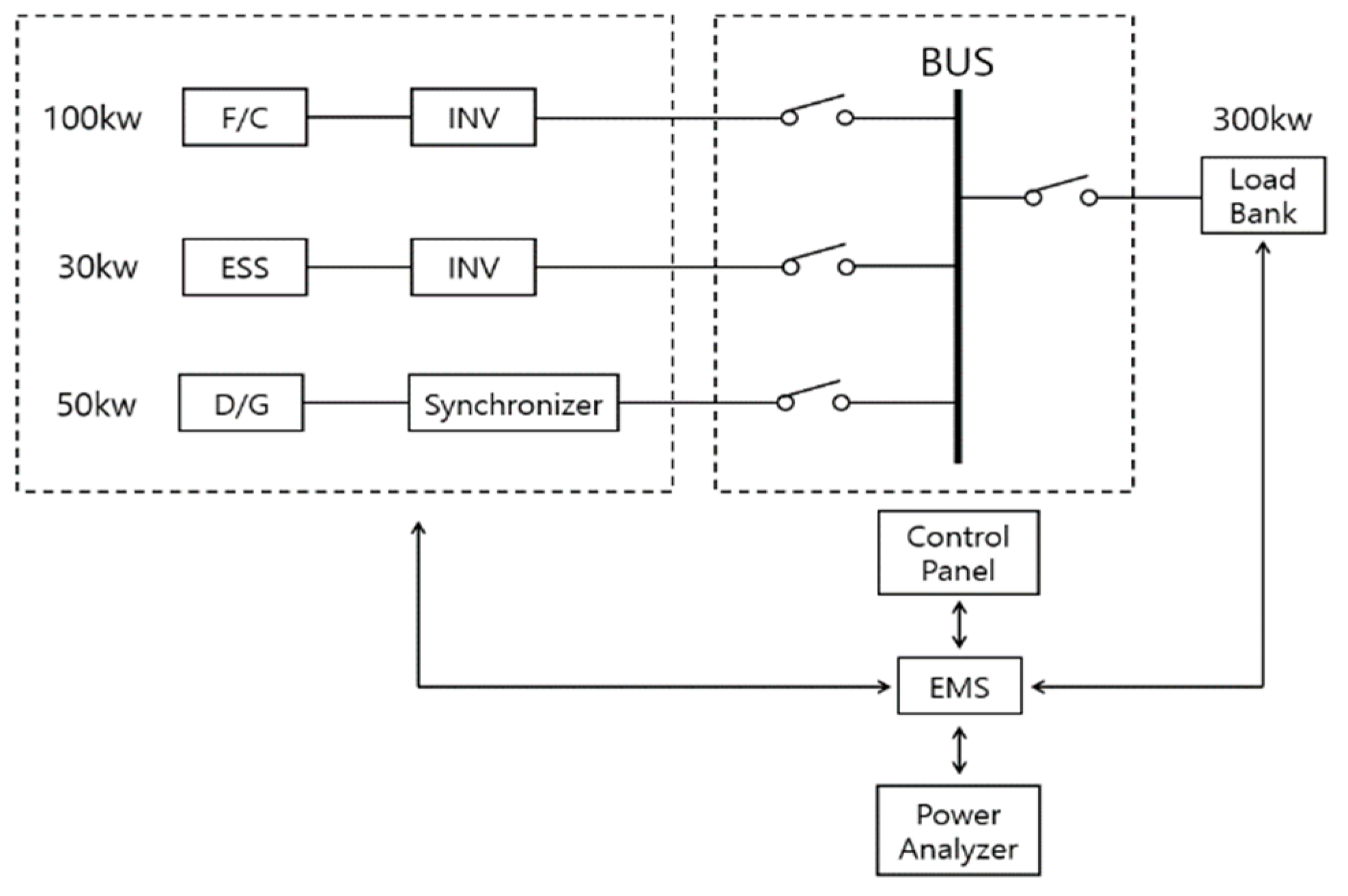

Figure 9.

Overall system configuration for power quality analysis.

Figure 9.

Overall system configuration for power quality analysis.

Figure 10.

Monitoring system configuration for power quality analysis.

Figure 10.

Monitoring system configuration for power quality analysis.

Figure 11.

Installed voltage measuring equipment.

Figure 11.

Installed voltage measuring equipment.

Figure 12.

Installed current measuring equipment.

Figure 12.

Installed current measuring equipment.

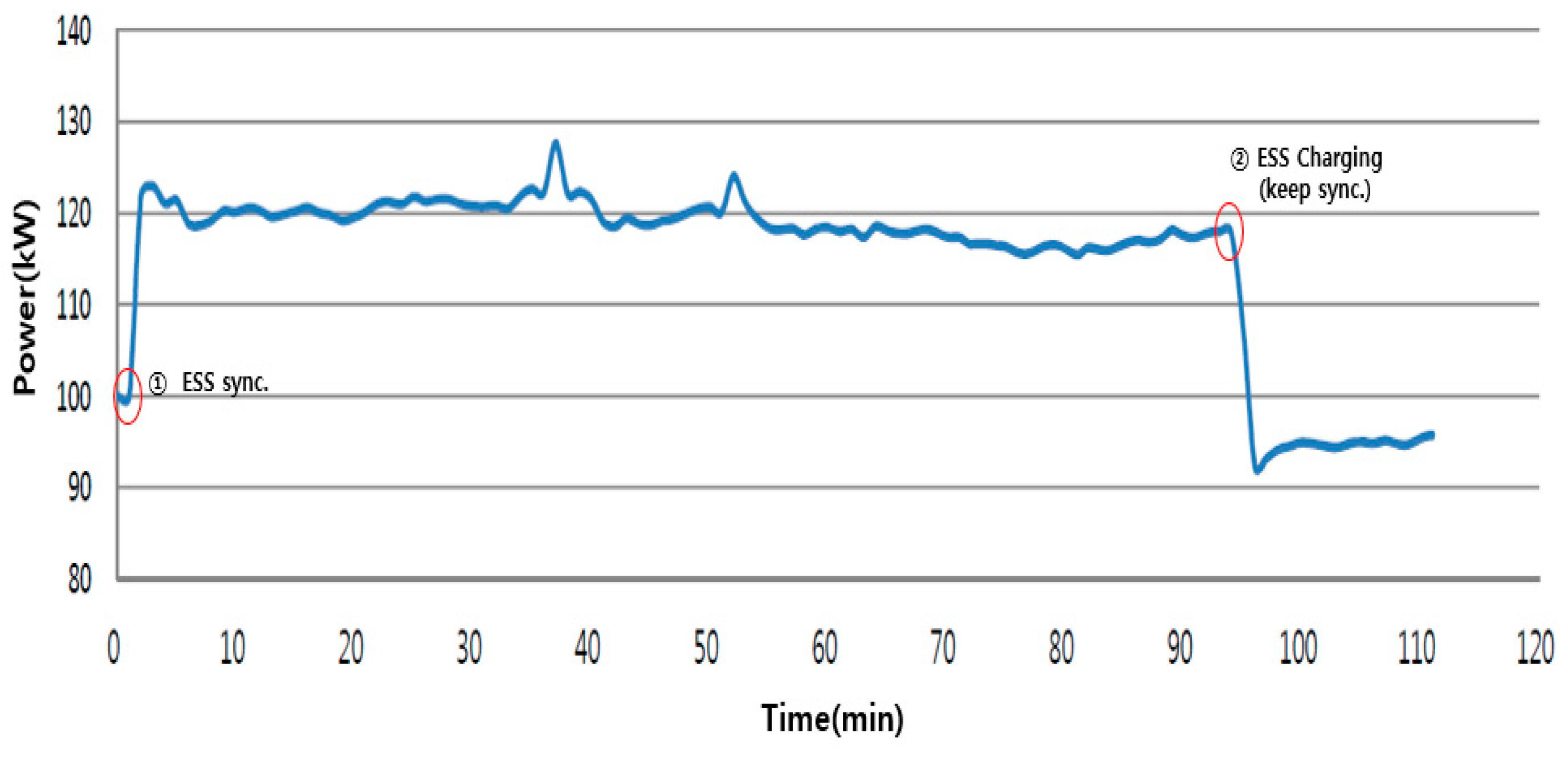

Figure 13.

Synchronization and system deviation for load pattern of normal seagoing case 1.

Figure 13.

Synchronization and system deviation for load pattern of normal seagoing case 1.

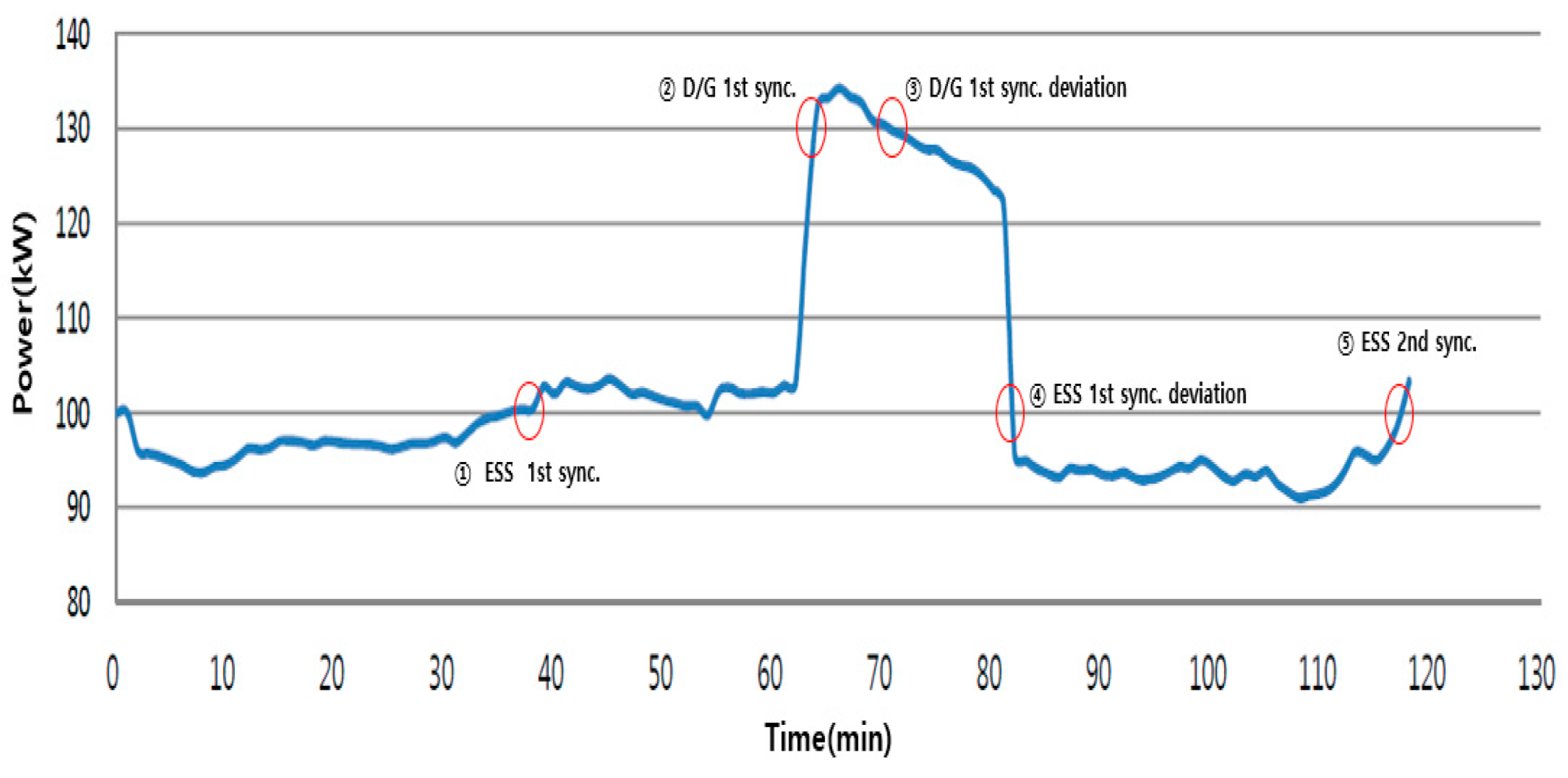

Figure 14.

Synchronization and system deviation for load pattern of normal seagoing case 2.

Figure 14.

Synchronization and system deviation for load pattern of normal seagoing case 2.

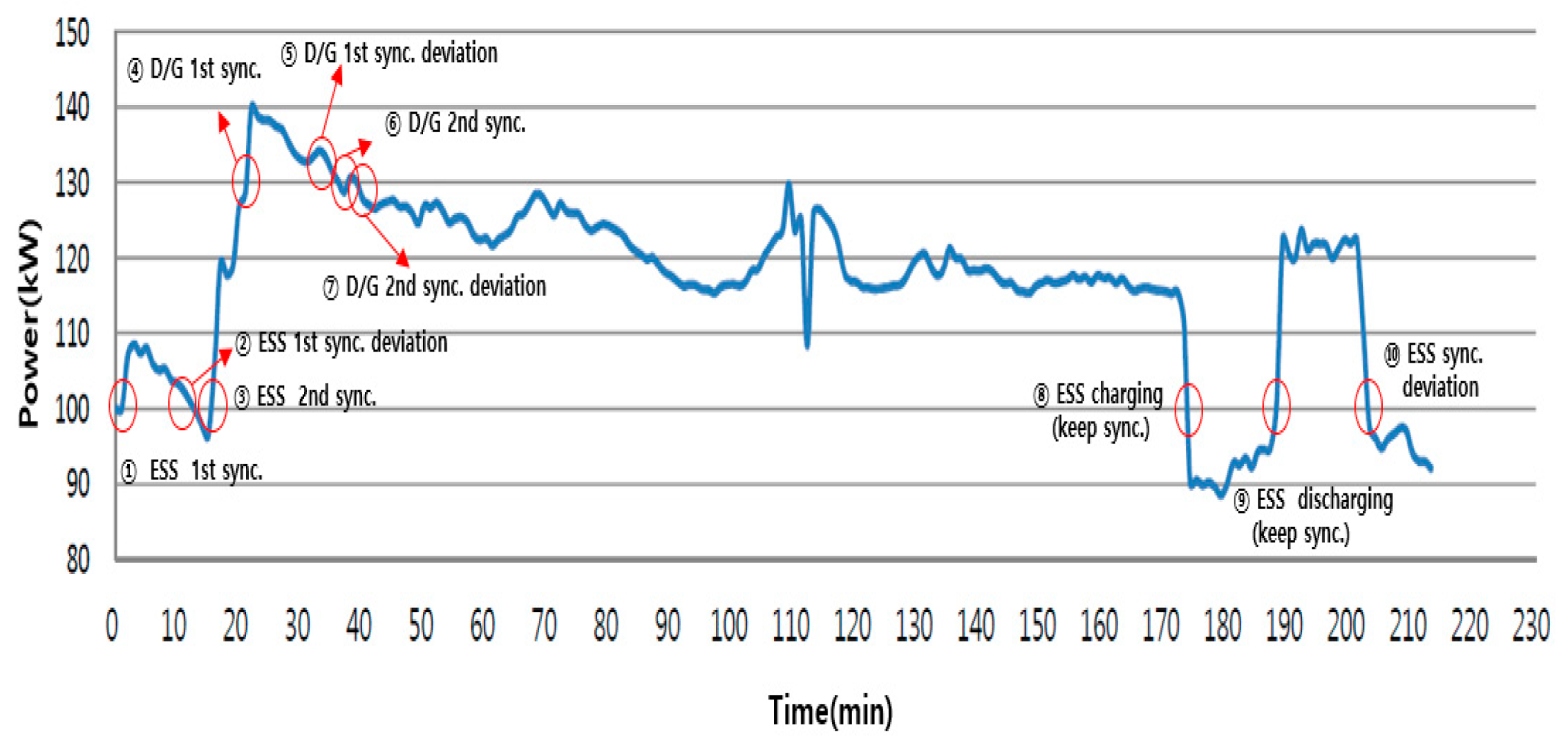

Figure 15.

Synchronization and system deviation for load pattern of normal seagoing case 3.

Figure 15.

Synchronization and system deviation for load pattern of normal seagoing case 3.

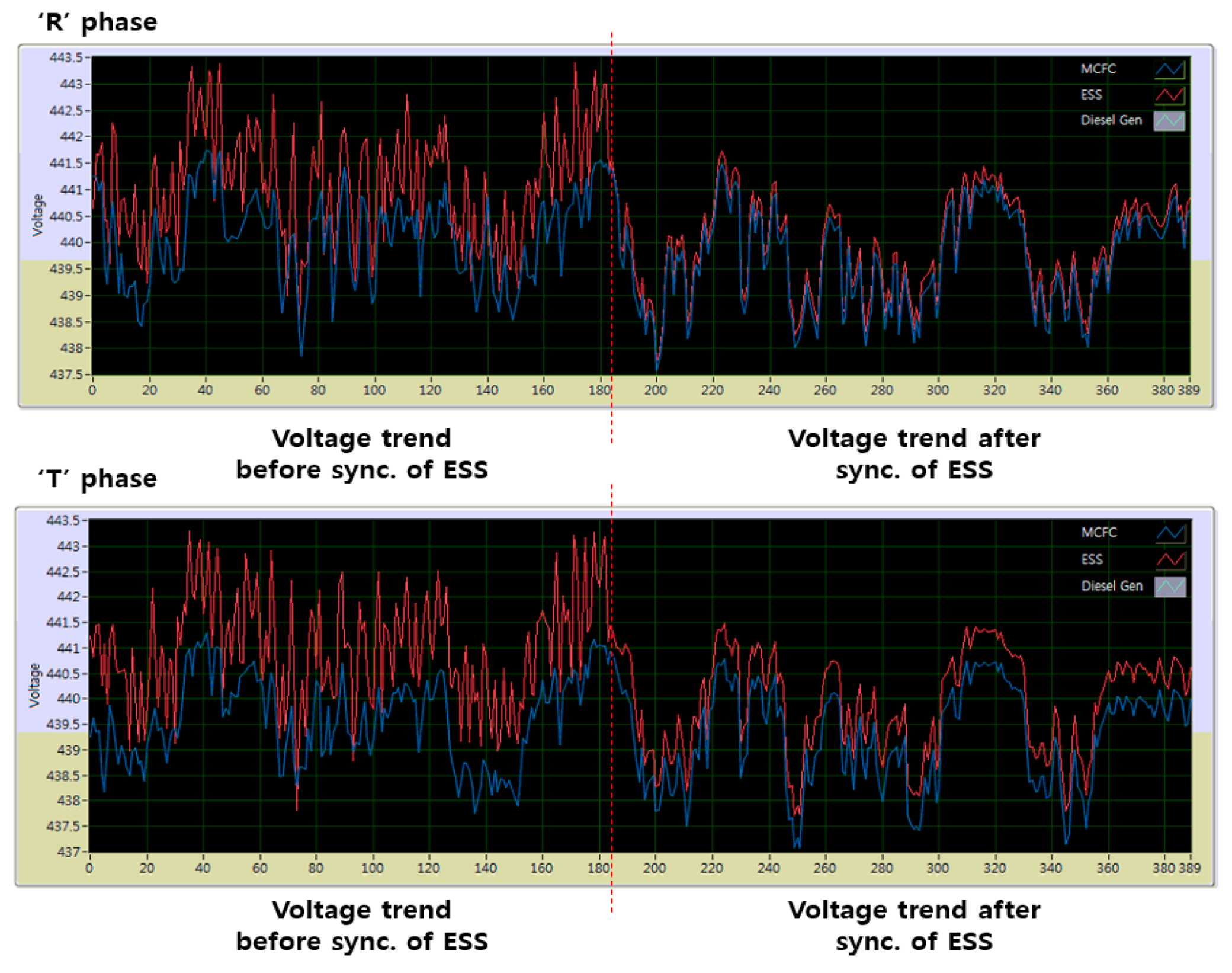

Figure 16.

Voltage change during ESS synchronization.

Figure 16.

Voltage change during ESS synchronization.

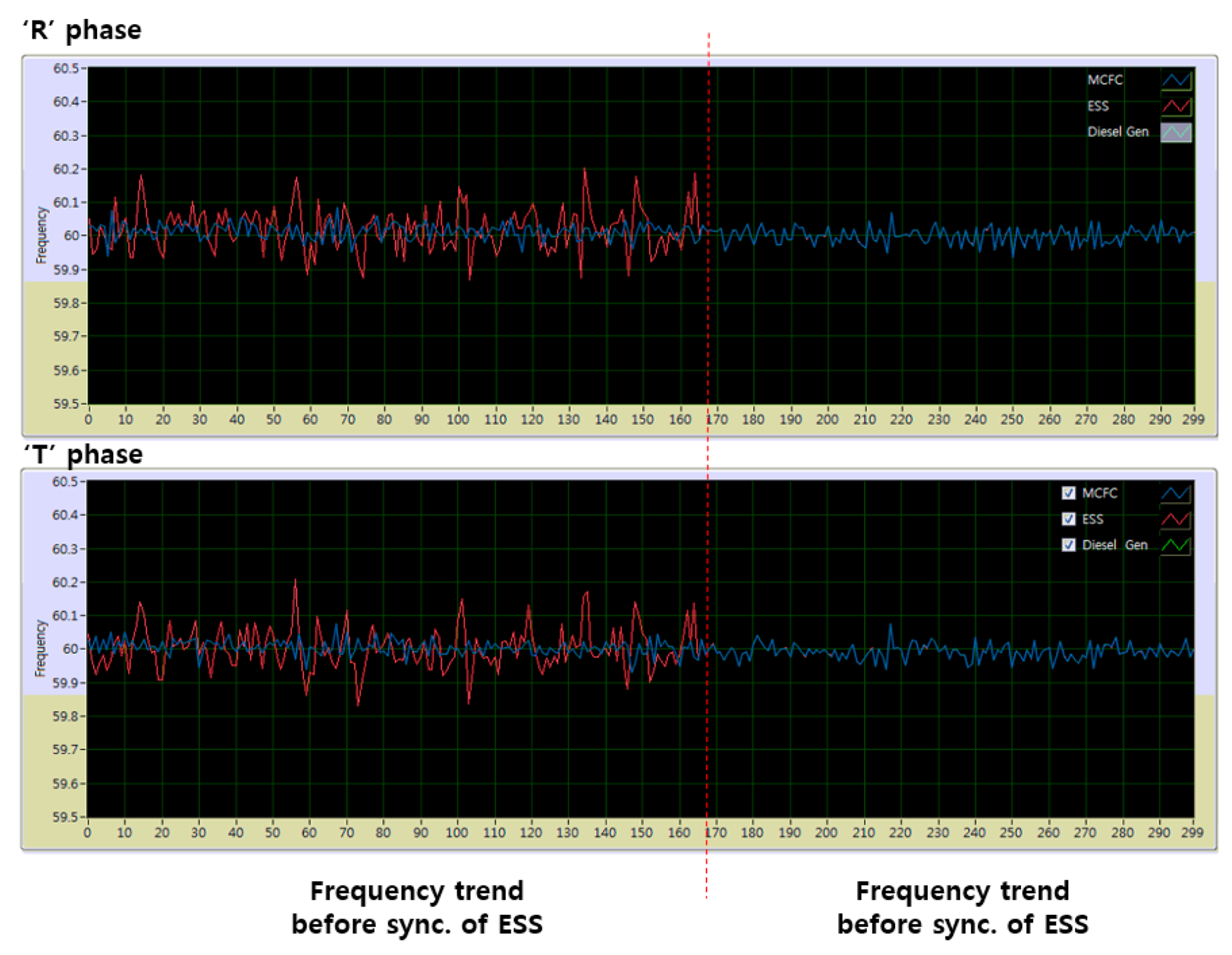

Figure 17.

Frequency change during ESS synchronization.

Figure 17.

Frequency change during ESS synchronization.

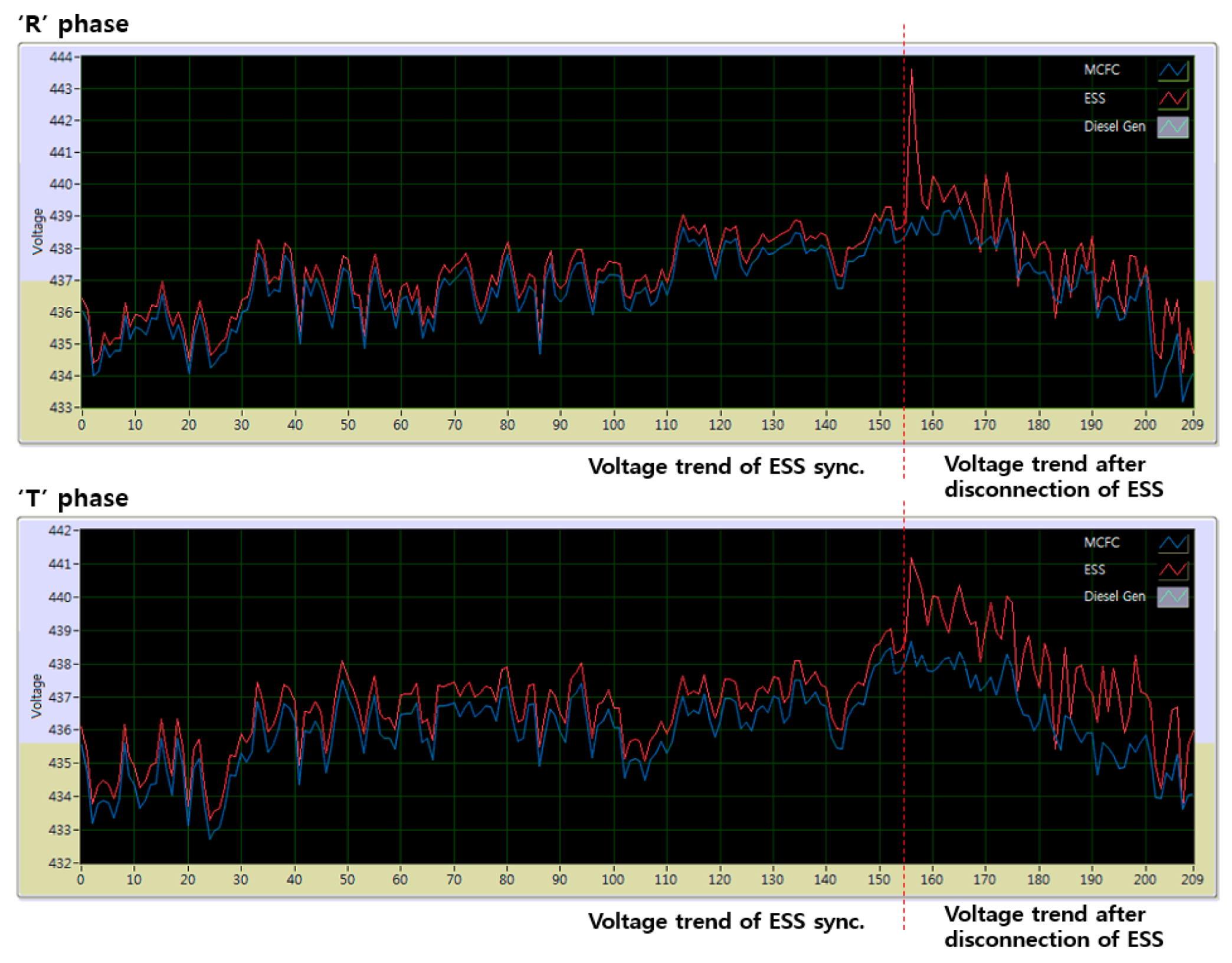

Figure 18.

Voltage change when the ESS system was disconnected.

Figure 18.

Voltage change when the ESS system was disconnected.

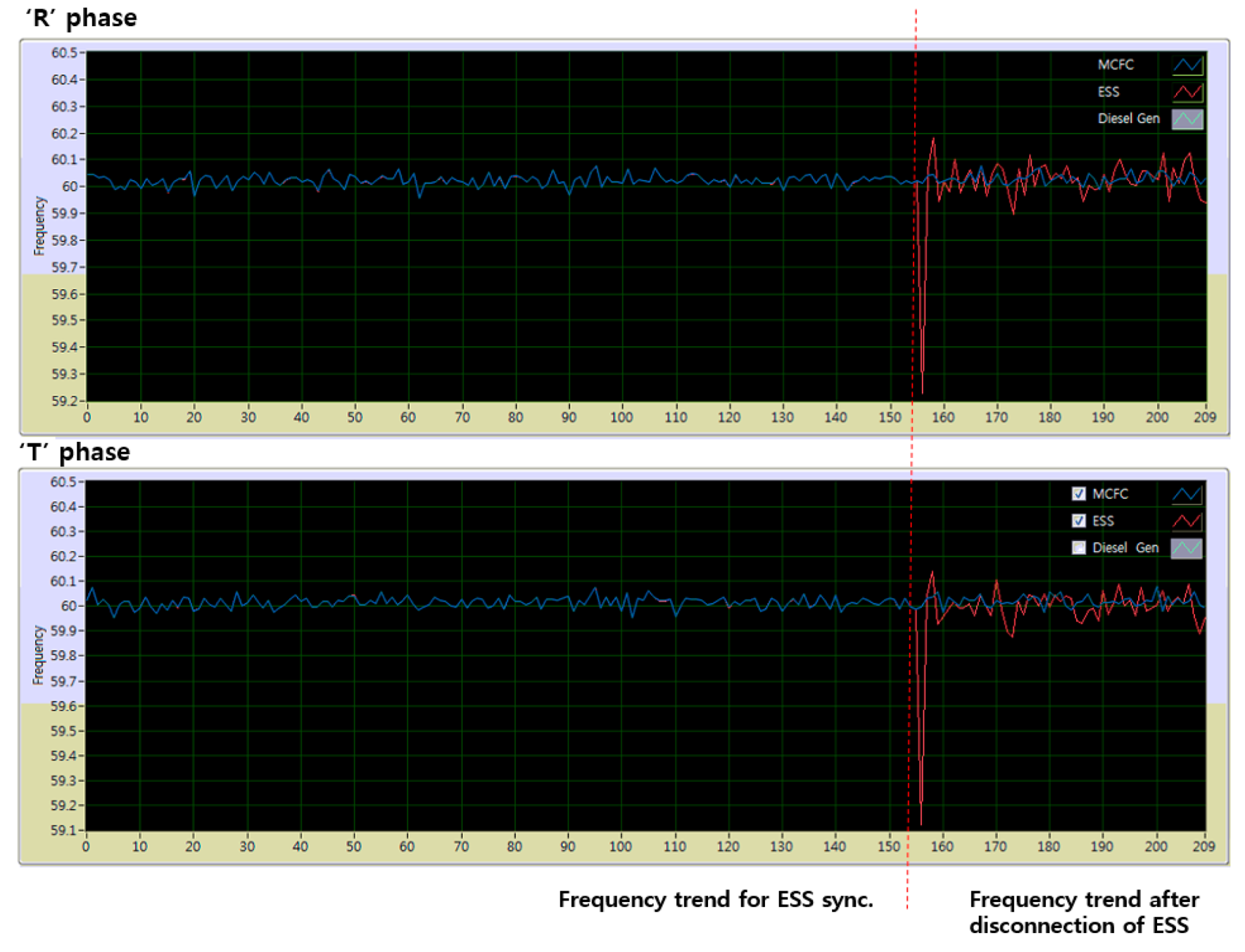

Figure 19.

Frequency change in ESS system deviation.

Figure 19.

Frequency change in ESS system deviation.

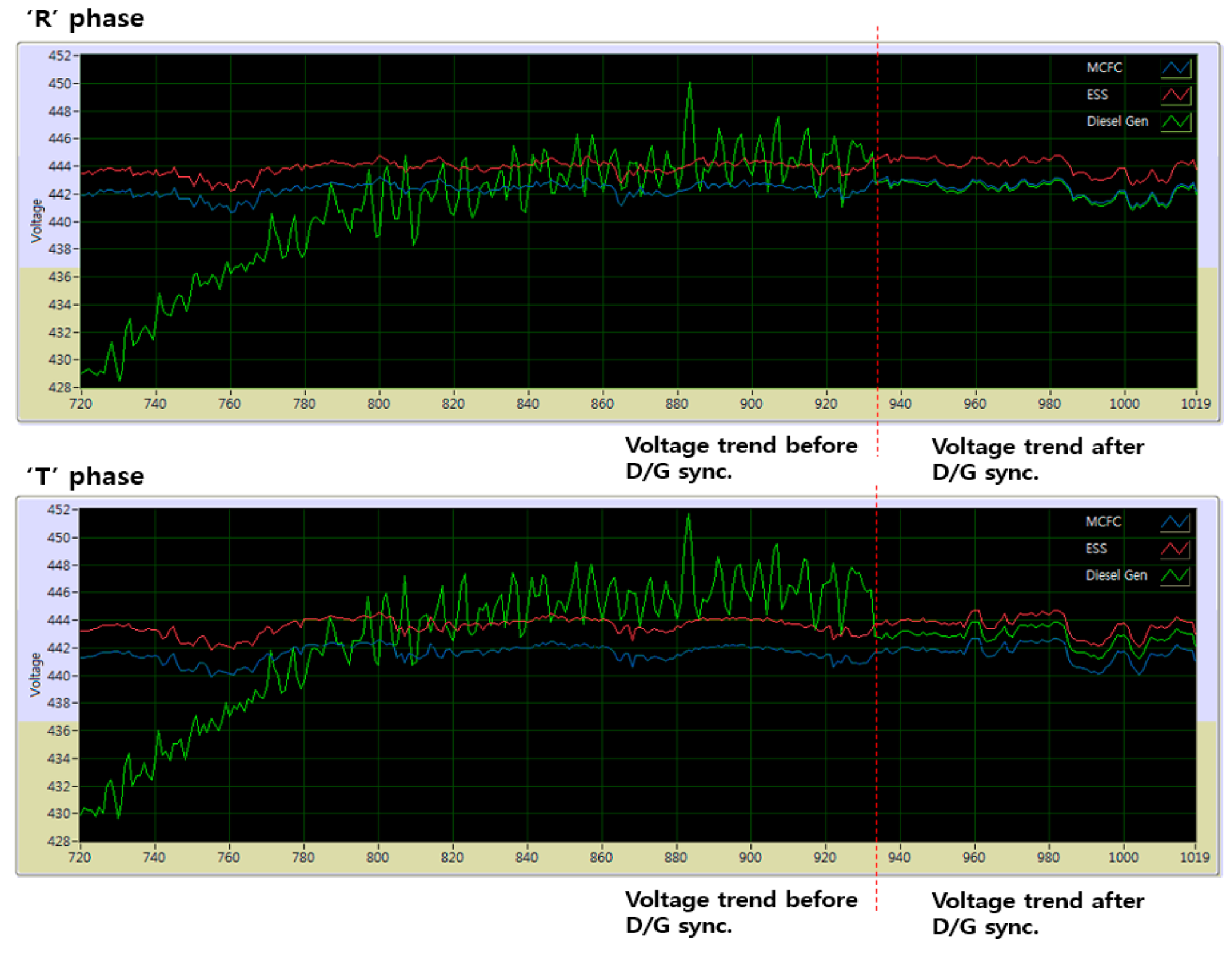

Figure 20.

Voltage change when synchronizing diesel generators.

Figure 20.

Voltage change when synchronizing diesel generators.

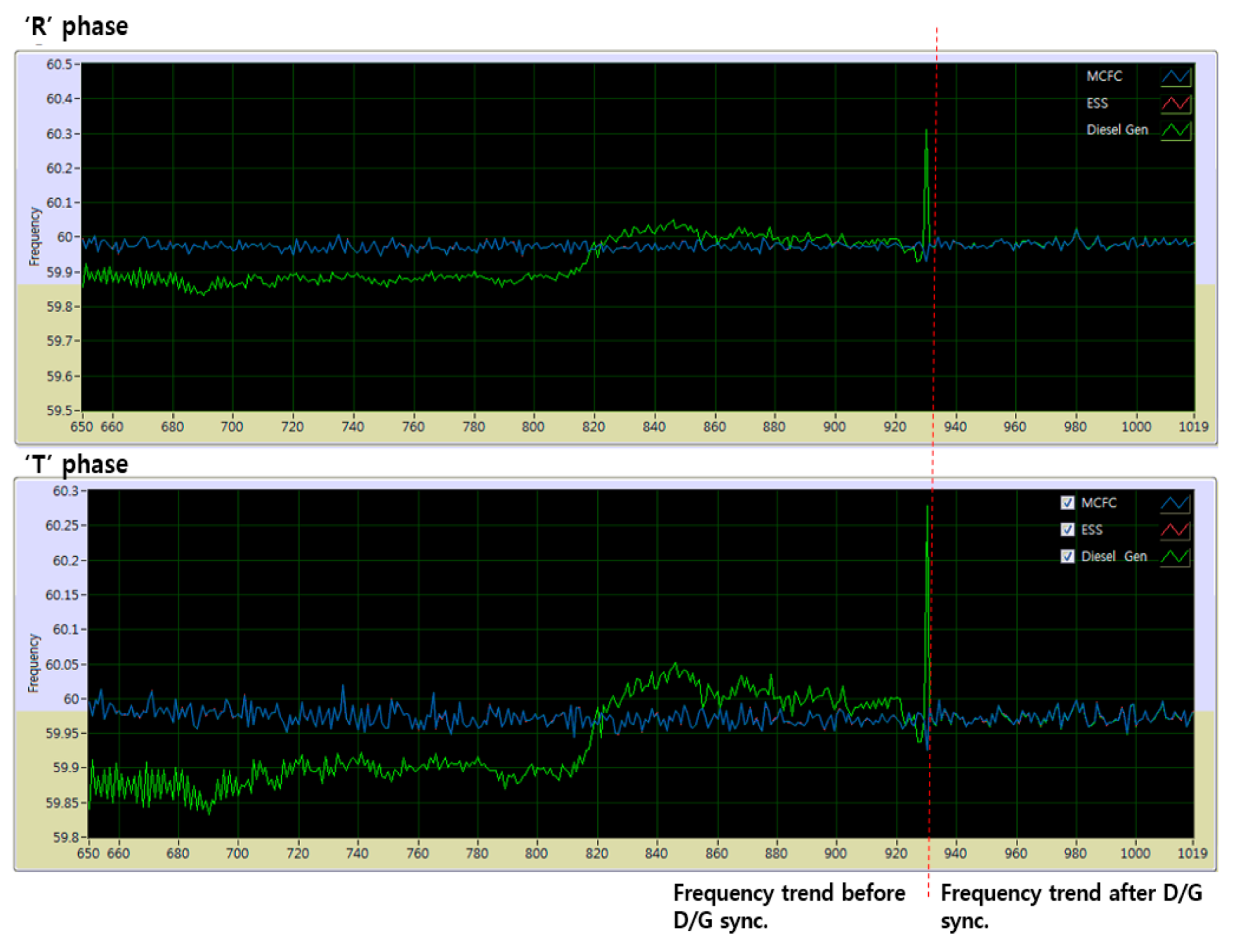

Figure 21.

Frequency change when synchronizing diesel generators.

Figure 21.

Frequency change when synchronizing diesel generators.

Figure 22.

Voltage change when diesel generators are broken away.

Figure 22.

Voltage change when diesel generators are broken away.

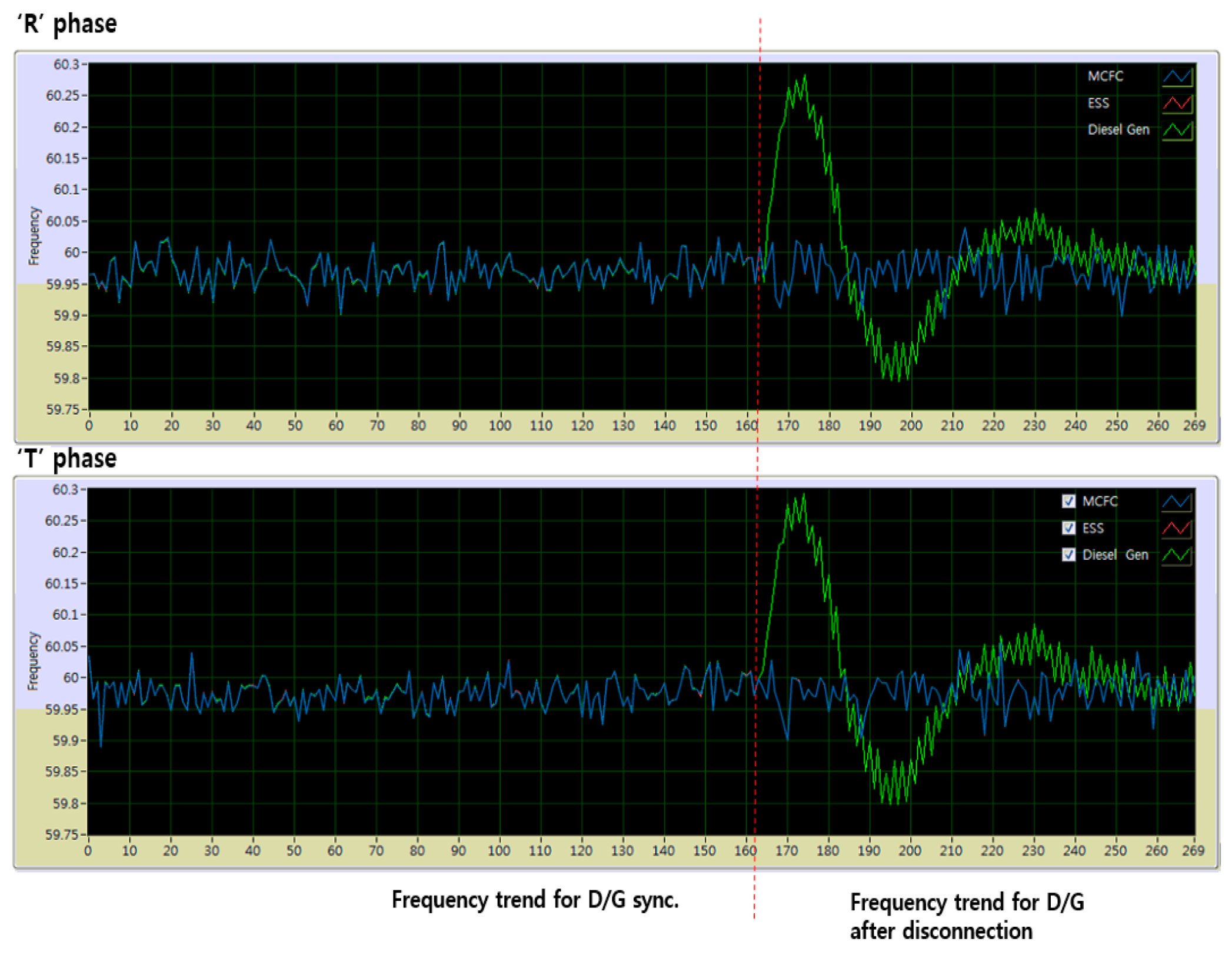

Figure 23.

Frequency change when leaving diesel generator system.

Figure 23.

Frequency change when leaving diesel generator system.

Table 1.

Specification of the fuel cell system.

Table 1.

Specification of the fuel cell system.

| Specification for ‘DFC300MA’. |

|---|

| Power Output | - |

| -Rated output | 250 kW |

| -Voltage | 380 - 480 VAC |

| Frequency | 50 ~ 60 Hz |

| -Power Quality | Per IEEE 519 |

| Emissions | - |

| -NOx | <0.02 lb/MWh |

| -SOx | <0.001 lb/MWh |

| -CO | <0.05 lb/MWh |

Table 2.

Specification of ESS.

Table 2.

Specification of ESS.

| ESS Specification |

|---|

| Input Voltage | 440VAC 3phase 3wire(60 Hz) |

| Output Voltage | 440VAC 3phase 3wire(60 Hz) |

| Load Capacity | 30 kW |

| Battery Ampere-hour | 400 Ah |

| Inverter Type | Bi-directional grid connected type |

Table 3.

Major specification of diesel generator engine.

Table 3.

Major specification of diesel generator engine.

| Item | Specification |

|---|

| Standby Power Rating | >95 PS |

| Engine Type | 4 stroke, water cooled |

| Revolution | 1800 RPM |

| Number of Cylinders | 6 |

| Fuel | Diesel |

Table 4.

Major specification of diesel generator.

Table 4.

Major specification of diesel generator.

| Item | Specification |

|---|

| Type | Salient Pole Generator |

| Standby Power Rating | 50 kW / 62.5 kVA |

| Prime Power Rating | 45 kW / 56 kVA |

| Voltage | 440 / 254 V |

| Current | 82 A |

| Phase and Wire | 3phase 4wire |

| Frequency | 60 Hz |

| Number of Pole | 4 P |

| Revolution | 1800 RPM |

| Excitation System | Blushless Self-Exciter |

Table 5.

Specification of the load bank.

Table 5.

Specification of the load bank.

| Rated Power | 300 Kw |

| Rated Voltage | 3∅ 440 V, 60 Hz |

| Current and resistance value for each capacity |

| Unit Capacity (kW) | Quantity | Total Capacity (kW) | Unit Current (A) | Unit Resistance | Cabinet |

| 0.1 | 1 | 0.1 | 0.13 | 1936Ω*3∅ | 1 box |

| 0.2 | 1 | 0.2 | 0.26 | 968Ω*3∅ |

| 0.4 | 1 | 0.4 | 0.52 | 484Ω*3∅ |

| 0.8 | 1 | 0.8 | 1.04 | 242Ω*3∅ |

| 1 | 1 | 1 | 1.31 | 193.6Ω*3∅ |

| 2 | 1 | 2 | 2.62 | 96.8Ω*3∅ |

| 4 | 1 | 4 | 5.24 | 48.4Ω*3∅ |

| 8 | 1 | 8 | 10.49 | 24.2Ω*3∅ |

| 16 | 1 | 16 | 20.99 | 12.1Ω*3∅ |

| 32 | 1 | 32 | 41.98 | 6.05Ω*3∅ |

| 60 | 4 | 240 | 78.78 | 3.22Ω*3∅ |

| Total | 15 | 304.5 | 399.7 | - | |

Table 6.

Synchronization condition in normal seagoing case 1.

Table 6.

Synchronization condition in normal seagoing case 1.

| Status | Power Sources |

|---|

| ① ESS sync. | MCFC + ESS |

| ② ESS Charging (keep sync.) | MCFC + ESS |

Table 7.

Synchronization condition in normal seagoing case 2.

Table 7.

Synchronization condition in normal seagoing case 2.

| Status | Power Sources |

|---|

| ① ESS 1st sync. | MCFC + ESS |

| ② D/G 1st sync. | MCFC + ESS+ D/G |

| ③ D/G 1st sync. deviation | MCFC + ESS |

| ④ ESS 1st sync. deviation | MCFC |

| ⑤ ESS 2nd sync. | MCFC + ESS |

Table 8.

Synchronization condition in normal seagoing case 3.

Table 8.

Synchronization condition in normal seagoing case 3.

| Status | Power Sources |

|---|

| ① ESS 1st sync. | MCFC + ESS |

| ③ ESS 1st sync. deviation | MCFC |

| ④ ESS 2nd sync. | MCFC + ESS |

| ⑤ D/G 1st sync. | MCFC + ESS + D/G |

| ⑥ D/G 1st sync. deviation | MCFC +ESS |

| ⑦ D/G 2nd sync. | MCFC + ESS + D/G |

| ⑧ D/G 2nd sync. Deviation | MCFC + ESS |

| ⑨ ESS Charging (keep sync.) | MCFC + ESS |

| ⑩ ESS Discharging (keep sync.) | MCFC + ESS |

| ⑪ ESS sync. Deviation | MCFC |

Table 9.

Rules for the classification of electrical installation and control systems of the Korean Register of Shipping.

Table 9.

Rules for the classification of electrical installation and control systems of the Korean Register of Shipping.

| Item | Regulation | Stabilization Time |

|---|

| Steady State | Transient State |

|---|

| Frequency | ±5% | ±10% (5s) | <15s |

| Voltage | +6%, −10% | ±20% (1.5s) | - |

Table 10.

Power data analysis before and after ESS synchronization.

Table 10.

Power data analysis before and after ESS synchronization.

| Item | Voltage Fluctuation | Frequency Fluctuation |

|---|

| MCFC | ESS | D/G | MCFC | ESS | D/G |

|---|

| Condition of Synchronization | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft |

| Maximum | 440.8 | 440.8 | 443.7 | 444.0 | - | - | 60.1 | 60.1 | 60.2 | 60.2 | - | - |

| Minimum | 438.4 | 438.3 | 440.1 | 438.5 | - | - | 60.0 | 59.9 | 59.8 | 59.9 | - | - |

| Average | 439.6 | 439.7 | 441.8 | 440.2 | - | - | 60.0 | 60.0 | 60.0 | 60.0 | - | - |

| Maximum rate of change (%) | 1.00 | 1.00 | 1.01 | 1.01 | - | - | 1.00 | 1.00 | 1.00 | 1.00 | - | - |

| Minimum rate of change (%) | 1.00 | 1.00 | 1.00 | 1.00 | - | - | 1.00 | 1.00 | 1.00 | 1.00 | - | - |

| Regulation (%) | ±1.00 | ±1.00 | ±1.00 | ±1.00 | - | - | ±1.00 | ±1.00 | ±1.00 | ±1.00 | - | - |

Table 11.

Power data analysis before and after ESS synchronization.

Table 11.

Power data analysis before and after ESS synchronization.

| Item | Voltage Fluctuation | Frequency Fluctuation |

|---|

| MCFC | ESS | D/G | MCFC | ESS | D/G |

|---|

| Condition of Synchronization | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft |

| Maximum | 439.6 | 439.5 | 445.0 | 440.7 | - | - | 60.1 | 60.1 | 60.1 | 60.4 | - | - |

| Minimum | 437.2 | 437.5 | 440.8 | 437.8 | - | - | 60.0 | 60.0 | 0.0 | 60.0 | - | - |

| Average | 438.6 | 438.5 | 442.5 | 438.8 | - | - | 60.0 | 60.0 | 8.1 | 60.0 | - | - |

| Maximum rate of change (%) | 1.00 | 1.00 | 1.01 | 1.00 | - | - | 1.00 | 1.00 | 1.00 | 1.01 | - | - |

| Minimum rate of change (%) | 0.99 | 1.09 | 1.00 | 1.09 | - | - | 1.00 | 1.00 | 0.00 | 1.00 | - | - |

| Regulation (%) | ±1.00 | ±1.00 | ±1.01 | ±1.00 | - | - | ±1.00 | ±1.00 | ±0.13 | ±1.00 | - | - |

Table 12.

Power data analysis before and after diesel generator synchronization.

Table 12.

Power data analysis before and after diesel generator synchronization.

| Item | Voltage Fluctuation | Frequency Fluctuation |

|---|

| MCFC | ESS | D/G | MCFC | ESS | D/G |

|---|

| Condition of Synchronization | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft |

| Maximum | 441.1 | 440.7 | 442.8 | 442.4 | 445.1 | 444.6 | 60.1 | 60.1 | 60.1 | 60.1 | 60.0 | 60.2 |

| Minimum | 438.0 | 437.9 | 439.6 | 439.6 | 426.9 | 438.2 | 60.0 | 60.0 | 60.0 | 60.0 | 59.8 | 59.9 |

| Average | 440.0 | 439.6 | 441.6 | 441.3 | 434.8 | 440.5 | 60.0 | 60.0 | 60.0 | 60.0 | 59.9 | 60.0 |

| Maximum rate of change (%) | 1.00 | 1.00 | 1.01 | 1.01 | 1.01 | 1.01 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| Minimum rate of change (%) | 1.00 | 1.00 | 1.00 | 1.00 | 0.97 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| Regulation (%) | ±1.00 | ±1.00 | ±1.00 | ±1.00 | ±0.99 | ±1.00 | ±1.00 | ±1.00 | ±1.00 | ±1.00 | ±1.00 | ±1.00 |

Table 13.

Power data analysis before and after departing from the diesel generator system.

Table 13.

Power data analysis before and after departing from the diesel generator system.

| Item | Voltage Fluctuation | Frequency Fluctuation |

|---|

| MCFC | ESS | D/G | MCFC | ESS | D/G |

|---|

| Condition of Synchronization | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft |

| Maximum | 438.5 | 439.2 | 440.2 | 440.9 | 438.5 | 444.4 | 60.1 | 60.1 | 60.1 | 60.1 | 60.1 | 60.4 |

| Minimum | 434.5 | 436.2 | 436.2 | 437.9 | 434.5 | 436.0 | 60.0 | 59.9 | 60.0 | 59.9 | 60.0 | 59.9 |

| Average | 437.2 | 437.6 | 438.9 | 439.3 | 437.2 | 439.6 | 60.0 | 60.0 | 60.0 | 60.0 | 60.0 | 60.0 |

| Maximum rate of change (%) | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.01 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.01 |

| Minimum rate of change (%) | 0.99 | 0.99 | 0.99 | 1.00 | 0.99 | 0.99 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| Regulation (%) | ±0.99 | ±0.99 | ±1.00 | ±1.00 | ±0.99 | ±1.00 | ±1.00 | ±1.00 | ±1.00 | ±1.00 | ±1.00 | ±1.00 |

Table 14.

Power data analysis before and after ESS system outage.

Table 14.

Power data analysis before and after ESS system outage.

| Item | Voltage Fluctuation | Frequency Fluctuation |

|---|

| MCFC | ESS | D/G | MCFC | ESS | D/G |

|---|

| Condition of Synchronization | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft |

| Maximum | 441.2 | 440.7 | 443.3 | 441.5 | - | - | 60.1 | 60.1 | 60.3 | 60.1 | - | - |

| Minimum | 438.1 | 437.2 | 438.4 | 438.8 | - | - | 60.0 | 60.0 | 60.0 | 59.9 | - | - |

| Average | 439.9 | 439.2 | 440.3 | 440.4 | - | - | 60.0 | 60.0 | 60.0 | 60.0 | - | - |

| Maximum rate of change (%) | 1.00 | 1.00 | 1.01 | 1.00 | - | - | 1.00 | 1.00 | 1.00 | 1.00 | - | - |

| Minimum rate of change (%) | 1.00 | 0.99 | 1.00 | 1.00 | - | - | 1.00 | 1.00 | 1.00 | 1.00 | - | - |

| Regulation (%) | ±1.00 | ±1.00 | ±1.00 | ±1.00 | - | - | ±1.00 | ±1.00 | ±1.00 | ±1.00 | - | - |

Table 15.

Power data analysis before and after ESS synchronization.

Table 15.

Power data analysis before and after ESS synchronization.

| Item | Voltage Fluctuation | Frequency Fluctuation |

|---|

| MCFC | ESS | D/G | MCFC | ESS | D/G |

|---|

| Condition of Synchronization | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft |

| Maximum | 442.9 | 442.6 | 445.2 | 442.9 | - | - | 60.1 | 60.1 | 60.2 | 60.1 | - | - |

| Minimum | 440.4 | 440.3 | 440.6 | 440.5 | - | - | 60.0 | 60.0 | 59.9 | 60.0 | - | - |

| Average | 441.7 | 441.5 | 442.7 | 441.8 | - | - | 60.0 | 60.0 | 60.0 | 60.0 | - | - |

| Maximum rate of change (%) | 1.01 | 1.01 | 1.01 | 1.01 | - | - | 1.00 | 1.00 | 1.00 | 1.00 | - | - |

| Minimum rate of change (%) | 1.00 | 1.00 | 1.00 | 1.00 | - | - | 1.00 | 1.00 | 1.00 | 1.00 | - | - |

| Regulation (%) | ±1.00 | ±1.00 | ±1.01 | ±1.00 | - | - | ±1.00 | ±1.00 | ±1.00 | ±1.00 | - | - |

Table 16.

Power data analysis before and after ESS system outage.

Table 16.

Power data analysis before and after ESS system outage.

| Item | Voltage Fluctuation | Frequency Fluctuation |

|---|

| MCFC | ESS | D/G | MCFC | ESS | D/G |

|---|

| Condition of Synchronization | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft |

| Maximum | 441.3 | 441.4 | 441.6 | 443.5 | - | - | 60.0 | 60.0 | 60.0 | 61.3 | - | - |

| Minimum | 439.0 | 438.7 | 439.4 | 438.2 | - | - | 60.0 | 60.0 | 60.0 | 59.8 | - | - |

| Average | 440.4 | 440.3 | 440.8 | 440.8 | - | - | 60.0 | 60.0 | 60.0 | 60.0 | - | - |

| Maximum rate of change (%) | 1.00 | 1.00 | 1.00 | 1.01 | - | - | 1.00 | 1.00 | 1.00 | 1.02 | - | - |

| -Minimum rate of change (%) | 1.00 | 1.00 | 1.00 | 1.00 | - | - | 1.00 | 1.00 | 1.00 | 1.00 | - | - |

| Regulation (%) | ±1.00 | ±1.00 | ±1.00 | ±1.00 | - | - | ±1.00 | ±1.00 | ±1.00 | ±1.00 | - | - |

Table 17.

Power data analysis before and after diesel generator synchronization.

Table 17.

Power data analysis before and after diesel generator synchronization.

| Item | Voltage Fluctuation | Frequency Fluctuation |

|---|

| MCFC | ESS | D/G | MCFC | ESS | D/G |

|---|

| Condition of Synchronization | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft |

| Maximum | 437.3 | 437.7 | 438.9 | 439.3 | 444.6 | 443.5 | 60.1 | 60.1 | 60.1 | 60.1 | 60.2 | 60.5 |

| Minimum | 432.8 | 433.2 | 434.4 | 434.8 | 426.4 | 433.0 | 59.9 | 59.9 | 59.9 | 59.9 | 59.7 | 59.9 |

| Average | 435.5 | 435.7 | 437.1 | 437.3 | 434.8 | 436.7 | 60.0 | 60.0 | 60.0 | 60.0 | 59.9 | 60.0 |

| Maximum rate of change (%) | 0.99 | 0.99 | 1.00 | 1.00 | 1.01 | 1.01 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.01 |

| Minimum rate of change (%) | 0.98 | 0.98 | 0.99 | 0.99 | 0.97 | 0.98 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| Regulation (%) | ±0.99 | ±0.99 | ±0.99 | ±0.99 | ±0.99 | ±0.99 | ±1.00 | ±1.00 | ±1.00 | ±1.00 | ±1.00 | ±1.00 |

Table 18.

Power data analysis before and after diesel generators outage.

Table 18.

Power data analysis before and after diesel generators outage.

| Item | Voltage Fluctuation | Frequency Fluctuation |

|---|

| MCFC | ESS | D/G | MCFC | ESS | D/G |

|---|

| Condition of Synchronization | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft | Bef | Aft |

| Maximum | 439.1 | 439.7 | 440.7 | 441.2 | 439.0 | 444.8 | 60.1 | 60.1 | 60.1 | 60.1 | 60.1 | 60.3 |

| Minimum | 435.3 | 436.1 | 436.9 | 437.7 | 435.2 | 436.1 | 60.0 | 59.9 | 60.0 | 59.9 | 60.0 | 59.9 |

| Average | 437.4 | 437.7 | 439.0 | 439.3 | 437.3 | 439.3 | 60.0 | 60.0 | 60.0 | 60.0 | 60.0 | 60.0 |

| Maximum rate of change (%) | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.01 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.01 |

| Minimum rate of change (%) | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 0.99 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| Regulation (%) | ±0.99 | ±0.99 | ±1.00 | ±1.00 | ±0.99 | ±1.00 | ±1.00 | ±1.00 | ±1.00 | ±1.00 | ±1.00 | ±1.00 |