Experimental and Numerical Research on the Influence of Stern Flap Mounting Angle on Double-Stepped Planing Hull Hydrodynamic Performance

Abstract

:1. Introduction

2. Towing Test

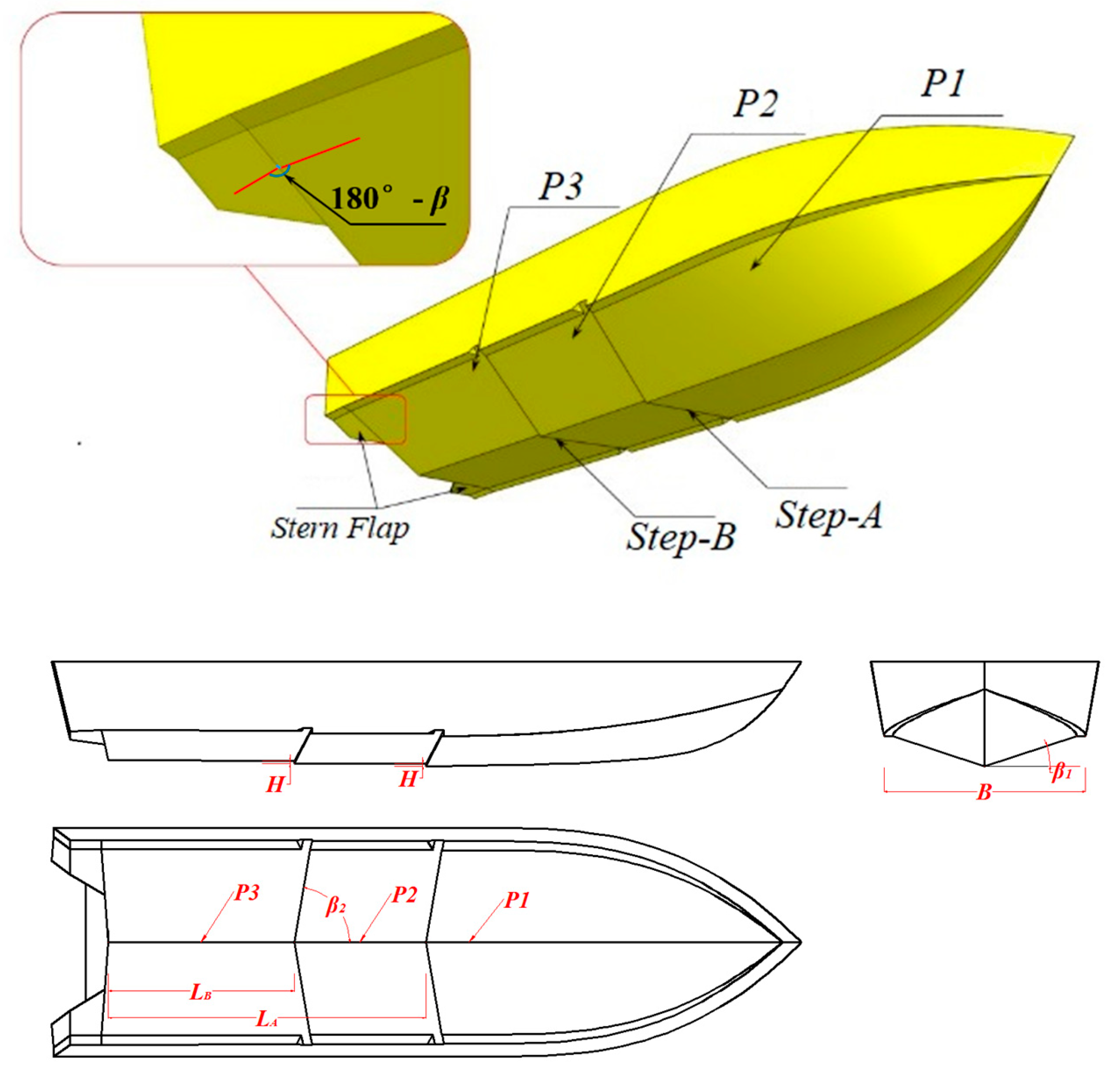

2.1. Geometrical Description of the Hull Model

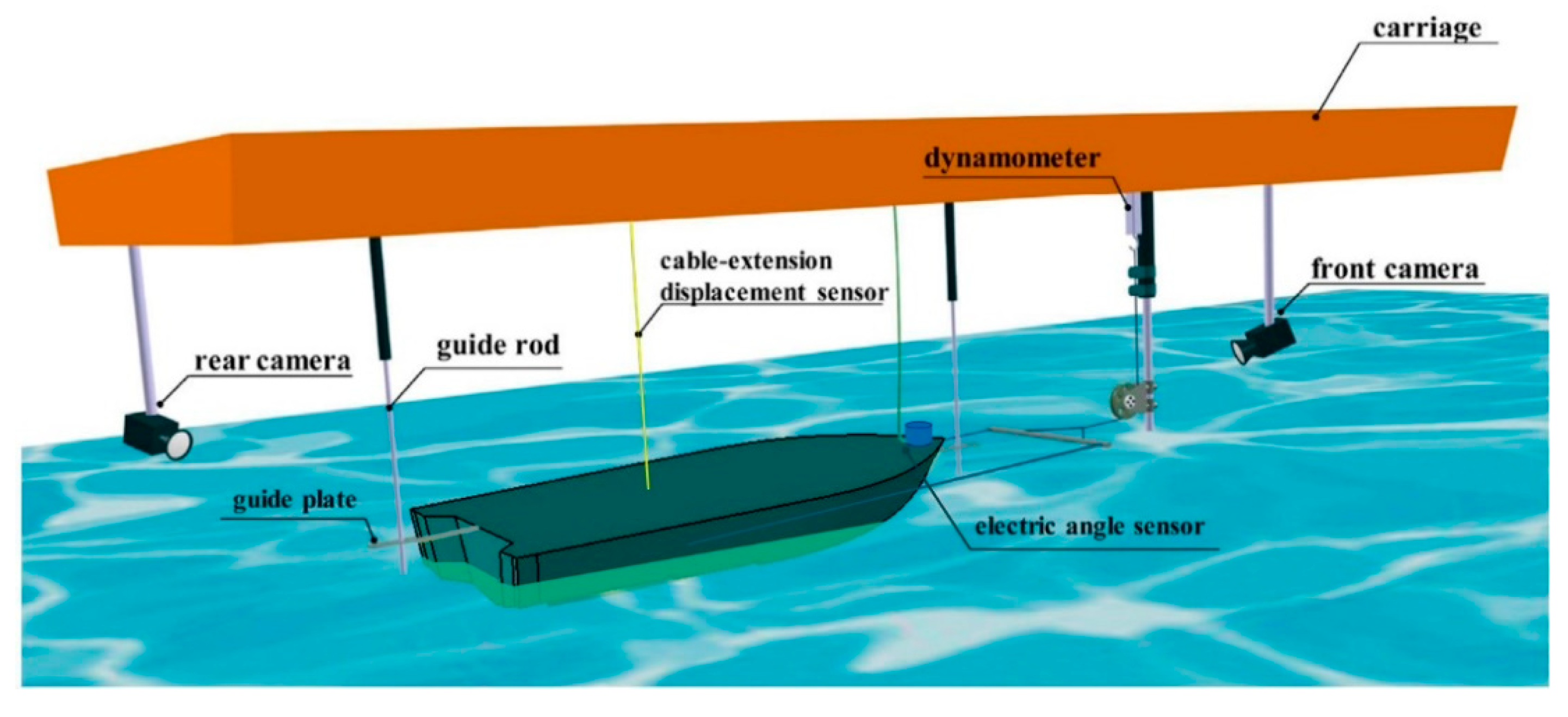

2.2. Experimental Setup

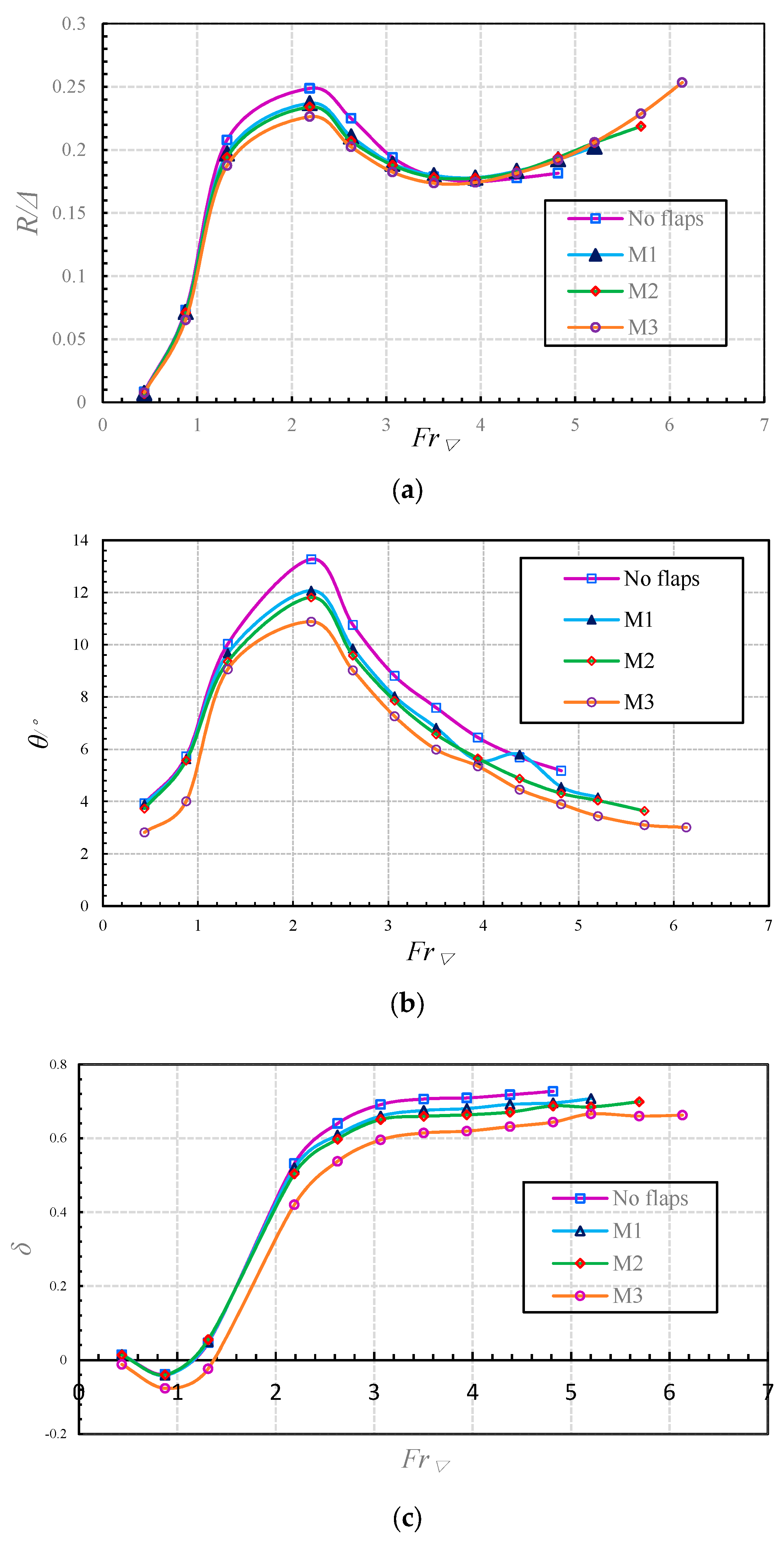

2.3. Experimental Results and Analysis

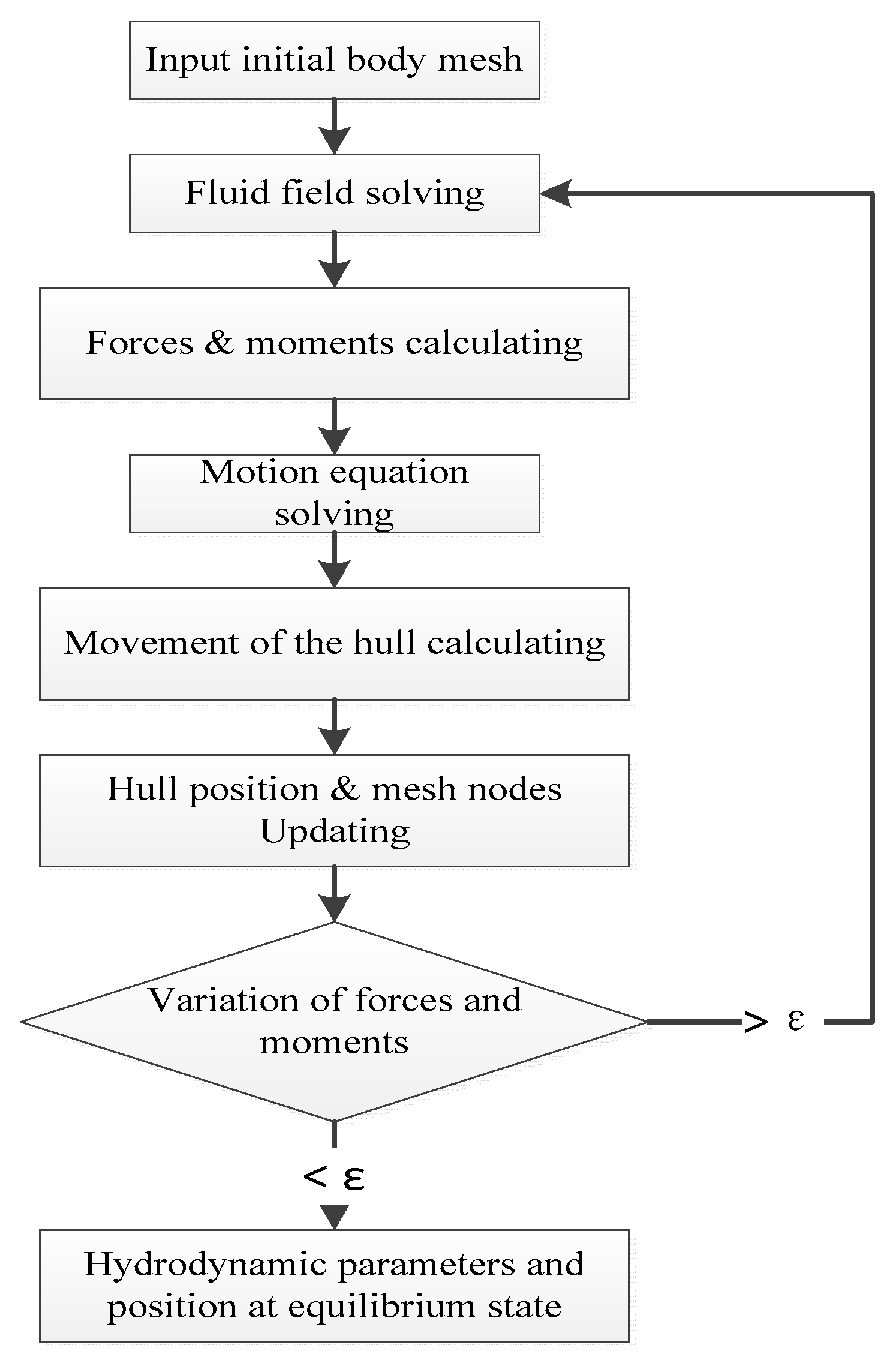

3. Numerical Simulation Setup

3.1. Mathematical and Numerical Models

3.2. Boundary Conditions

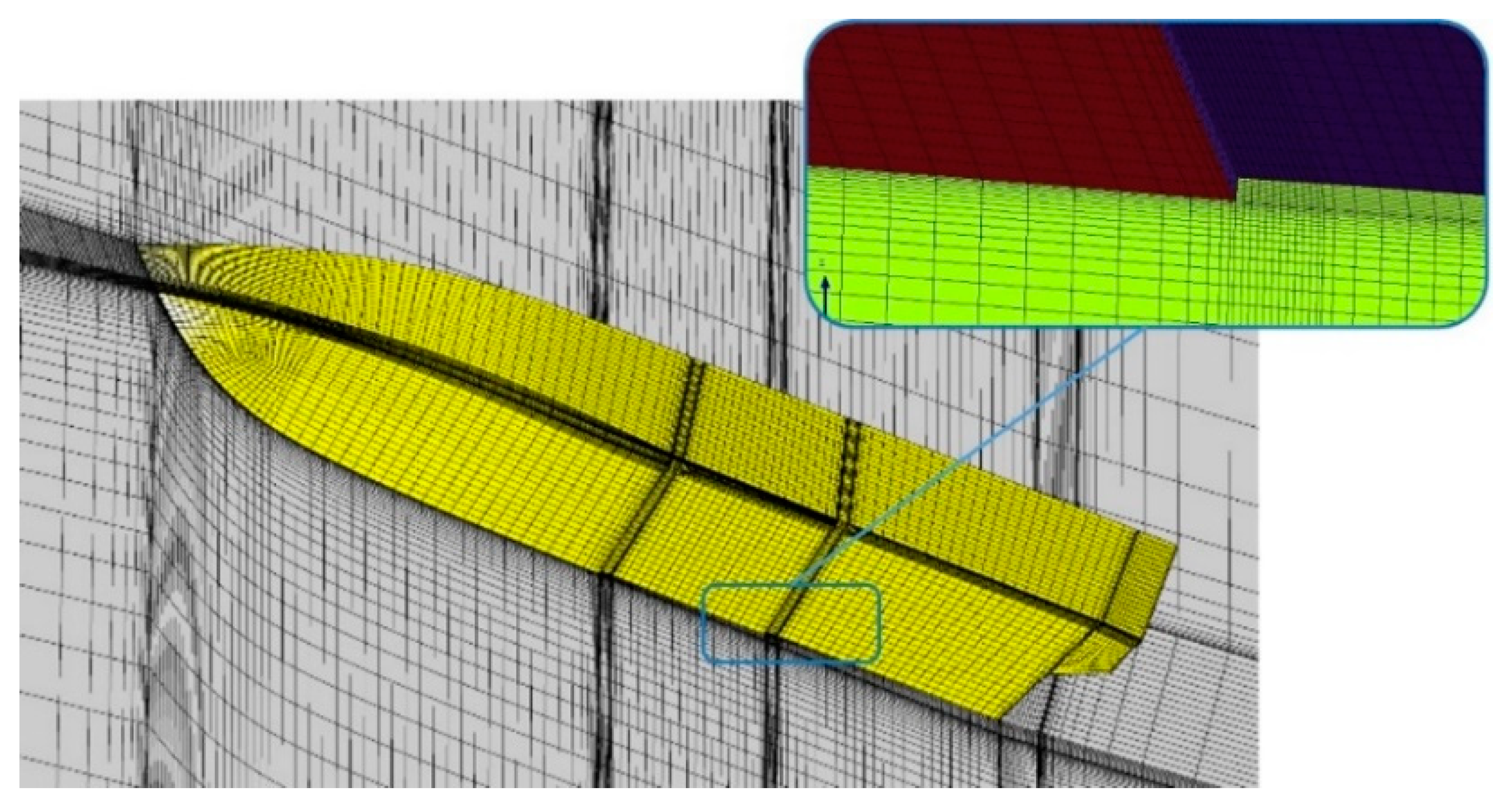

3.3. Mesh Generation and Dependency Analysis

4. Results and Discussion

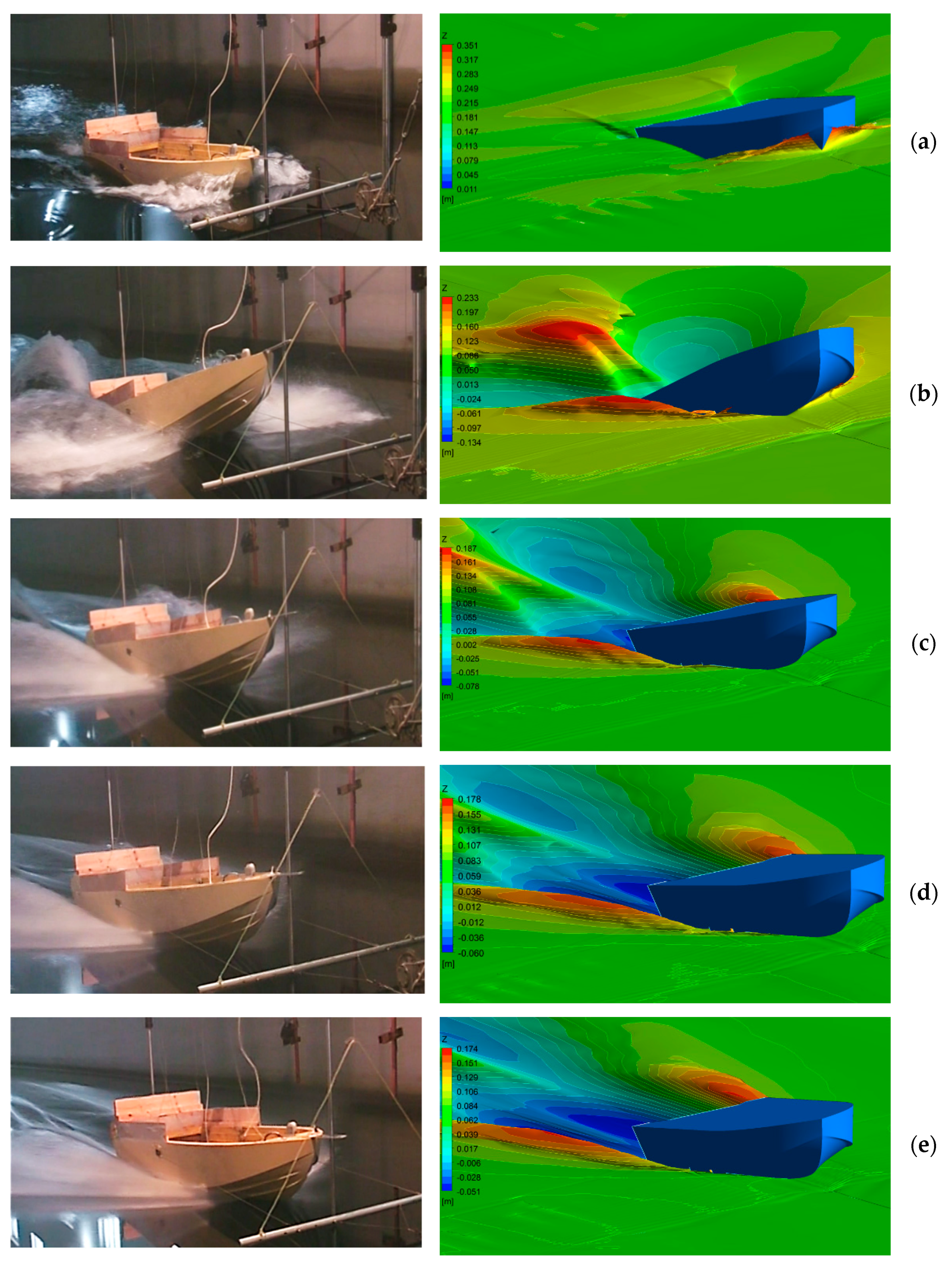

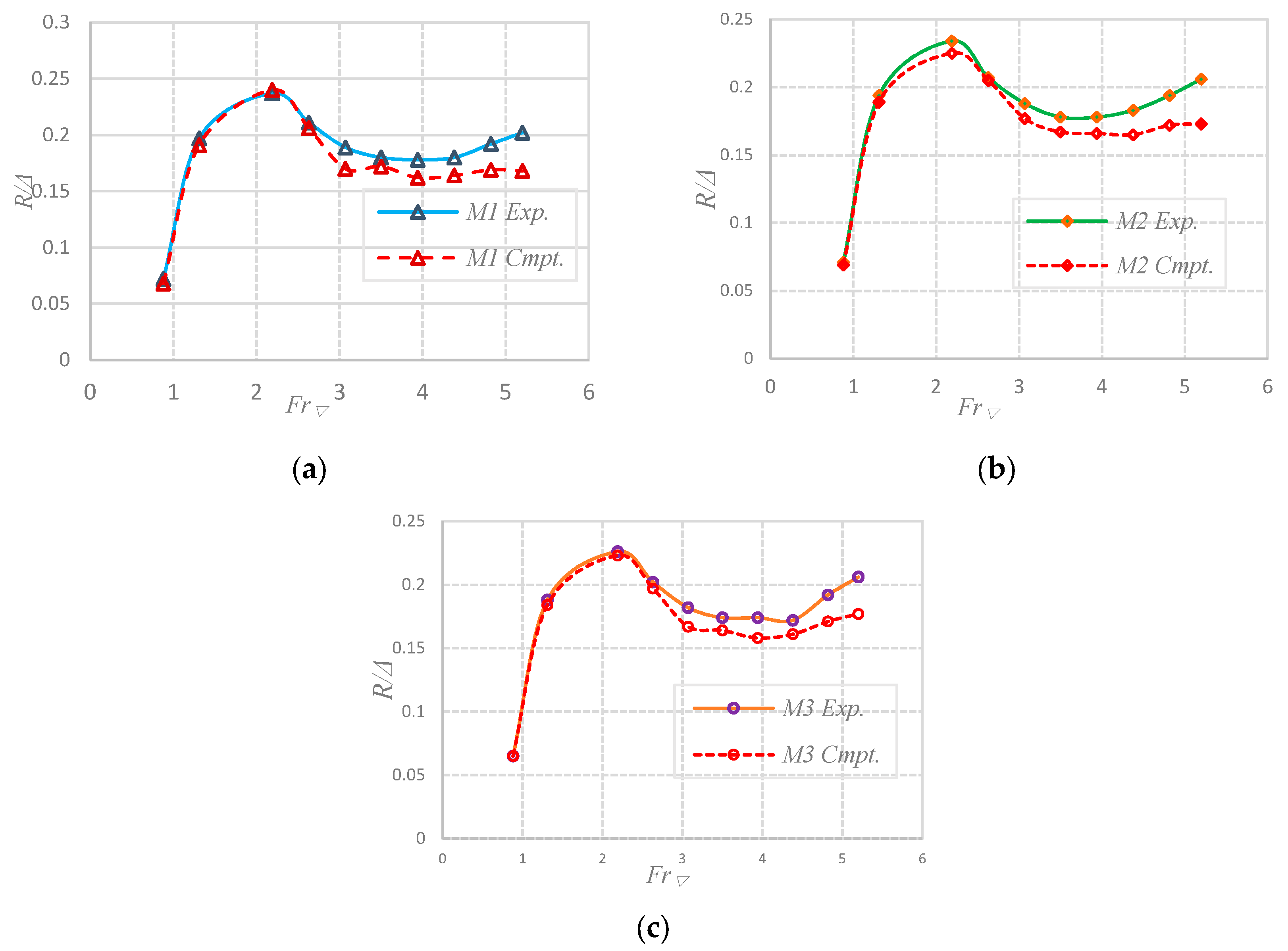

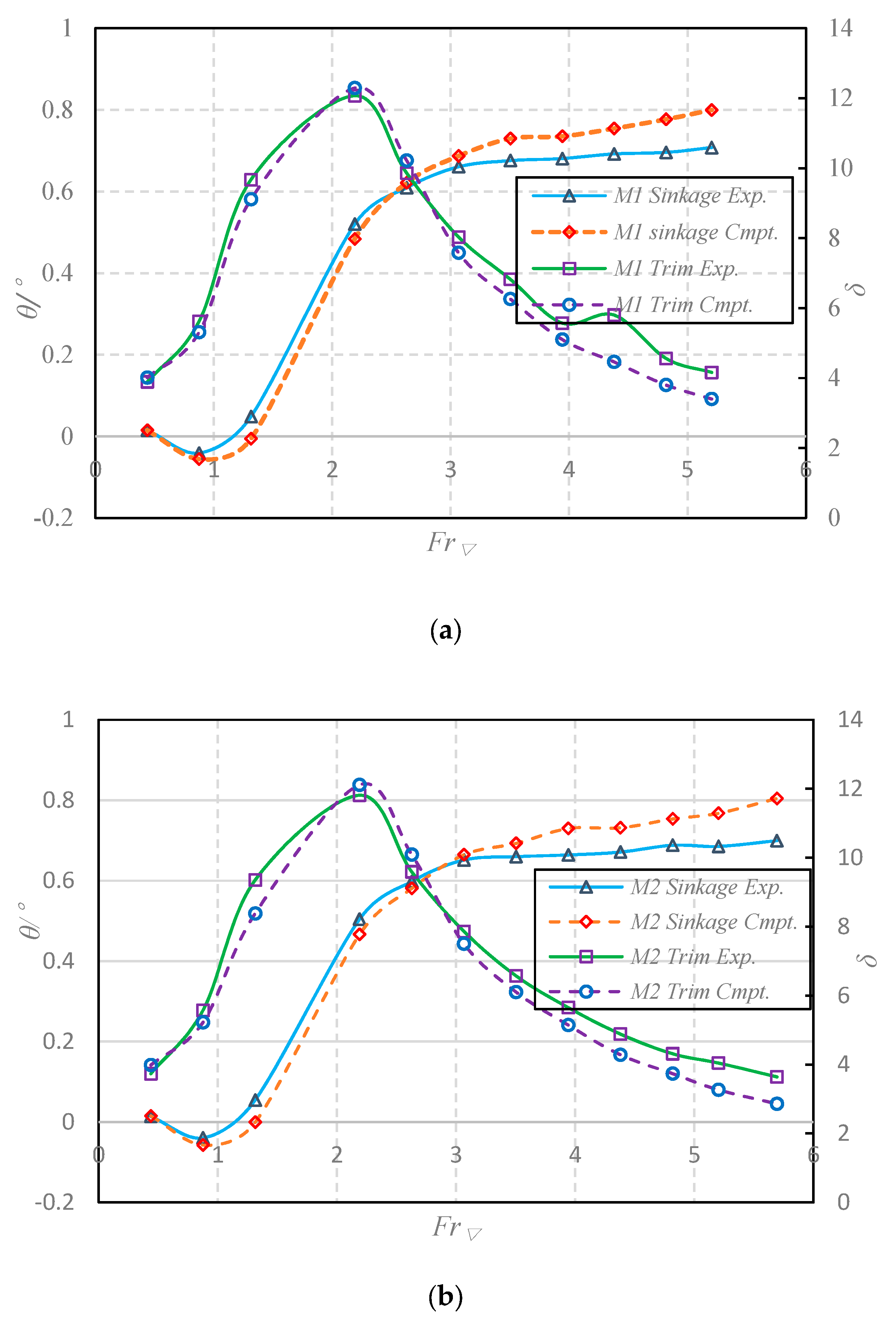

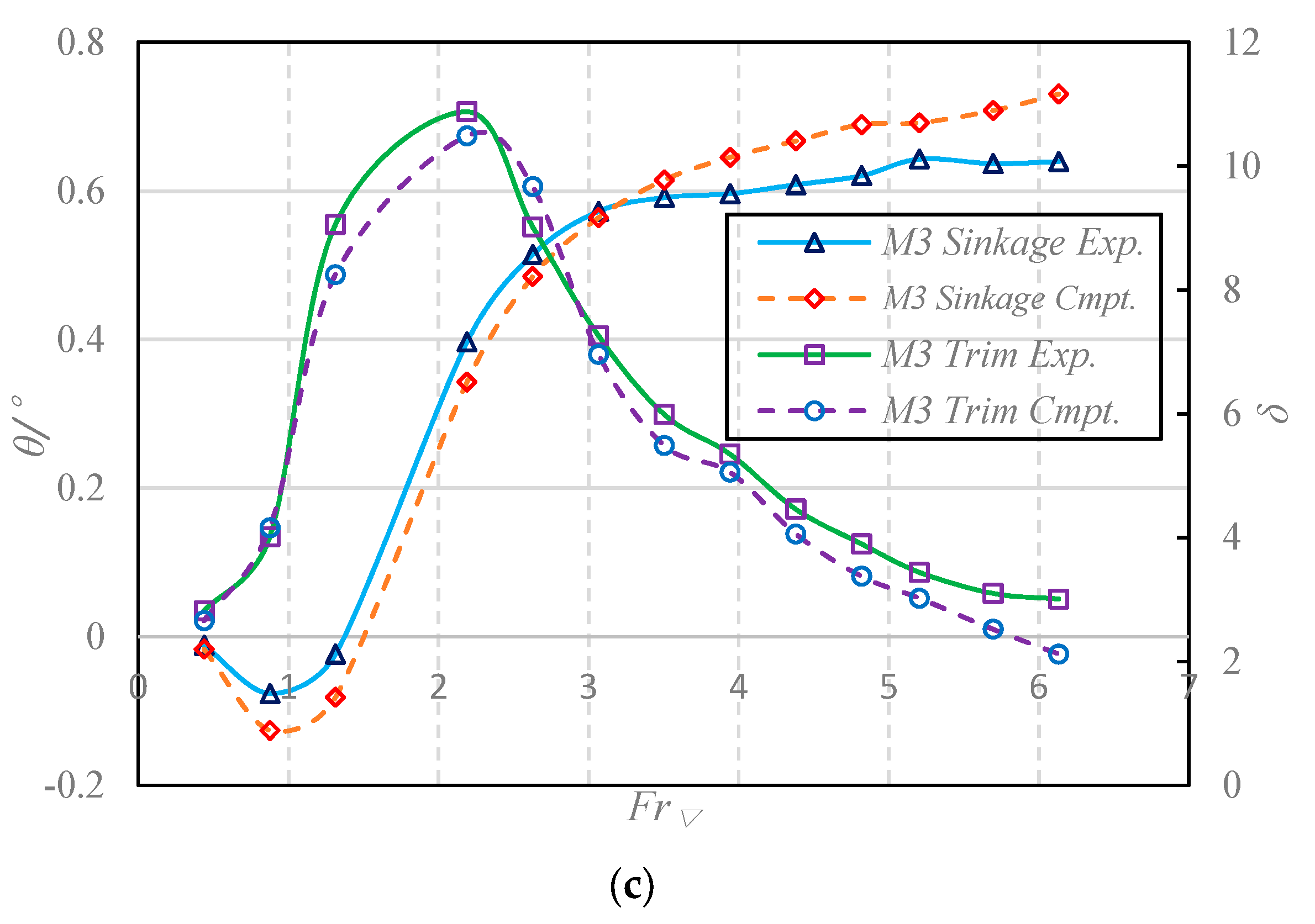

4.1. Validation of the Numerical Method

4.2. Cavity and Wetted Surface Analysis

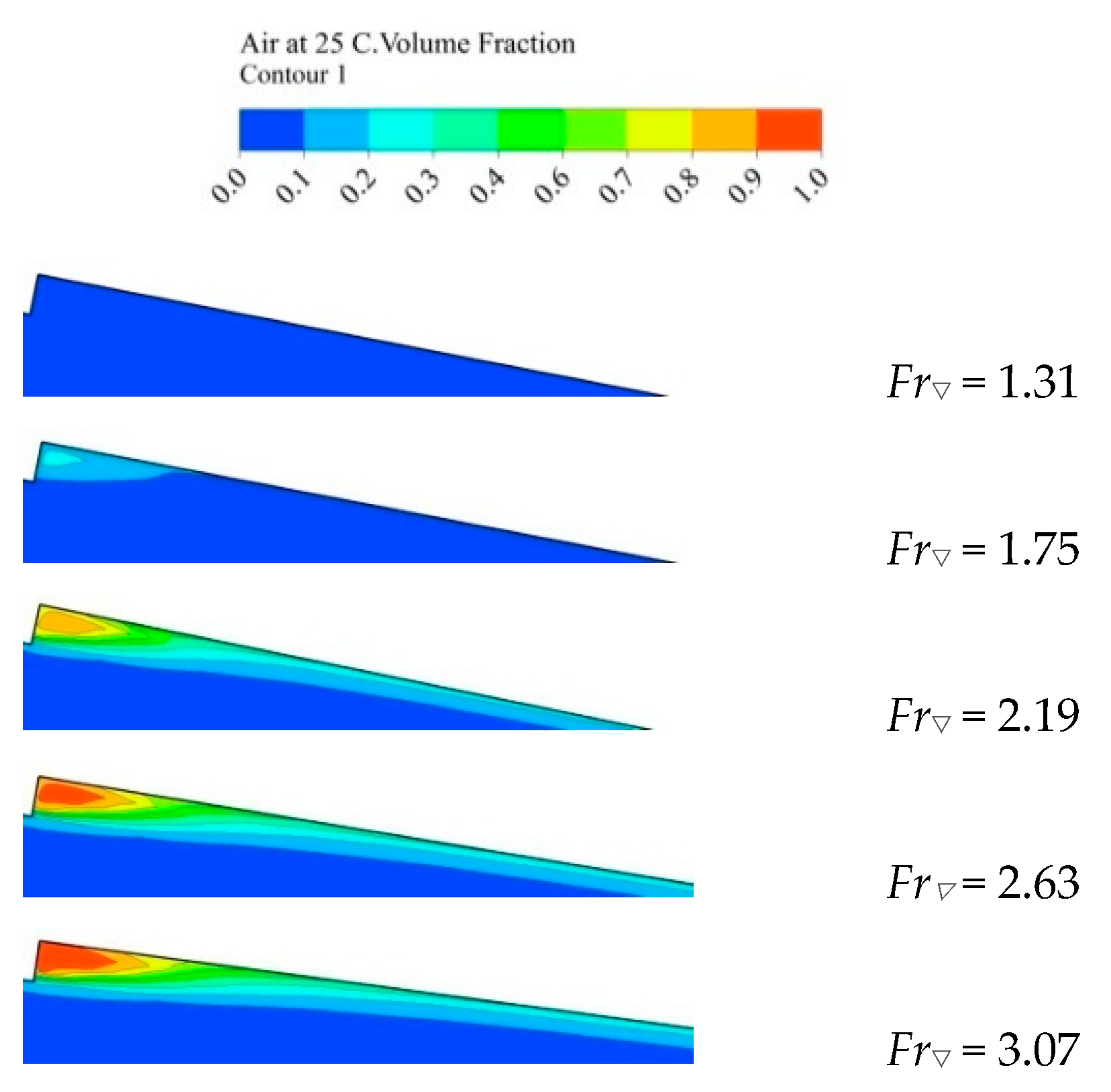

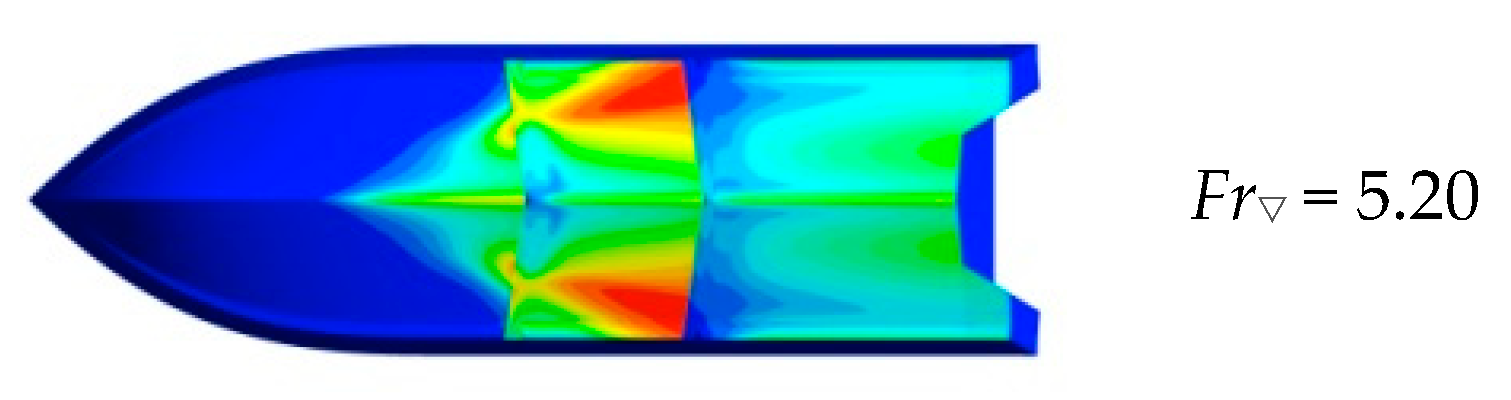

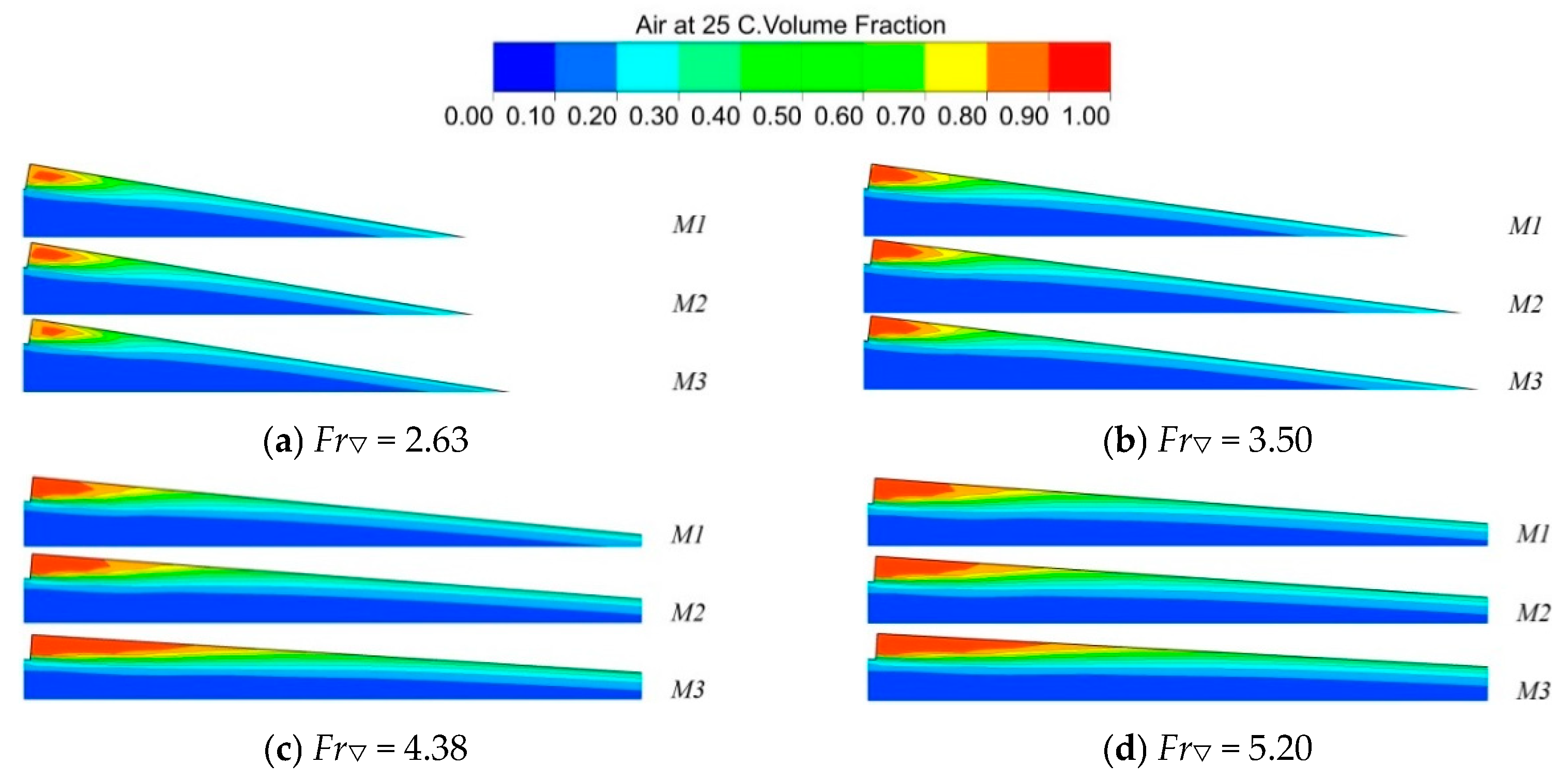

4.2.1. Cavity Behind the Step

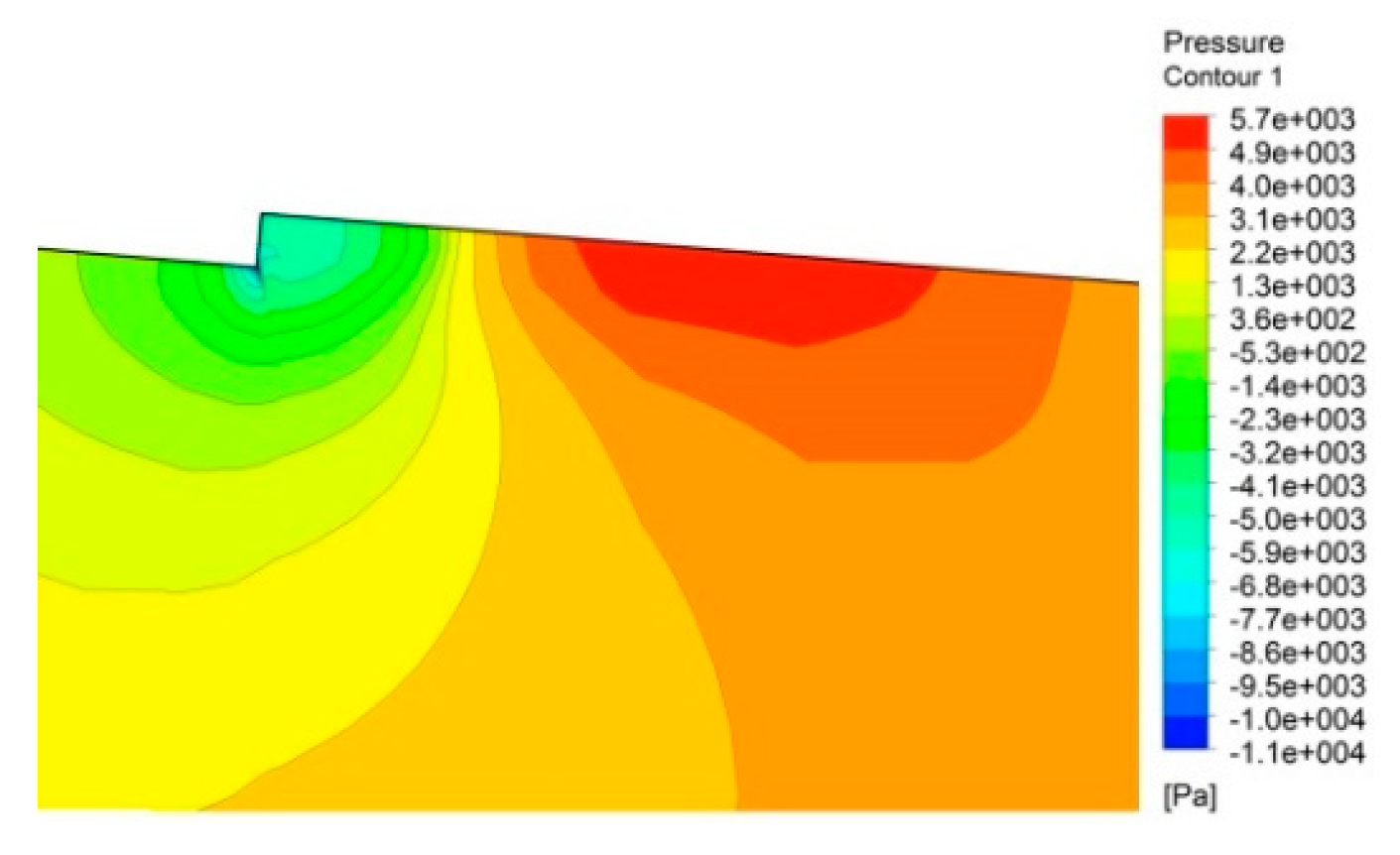

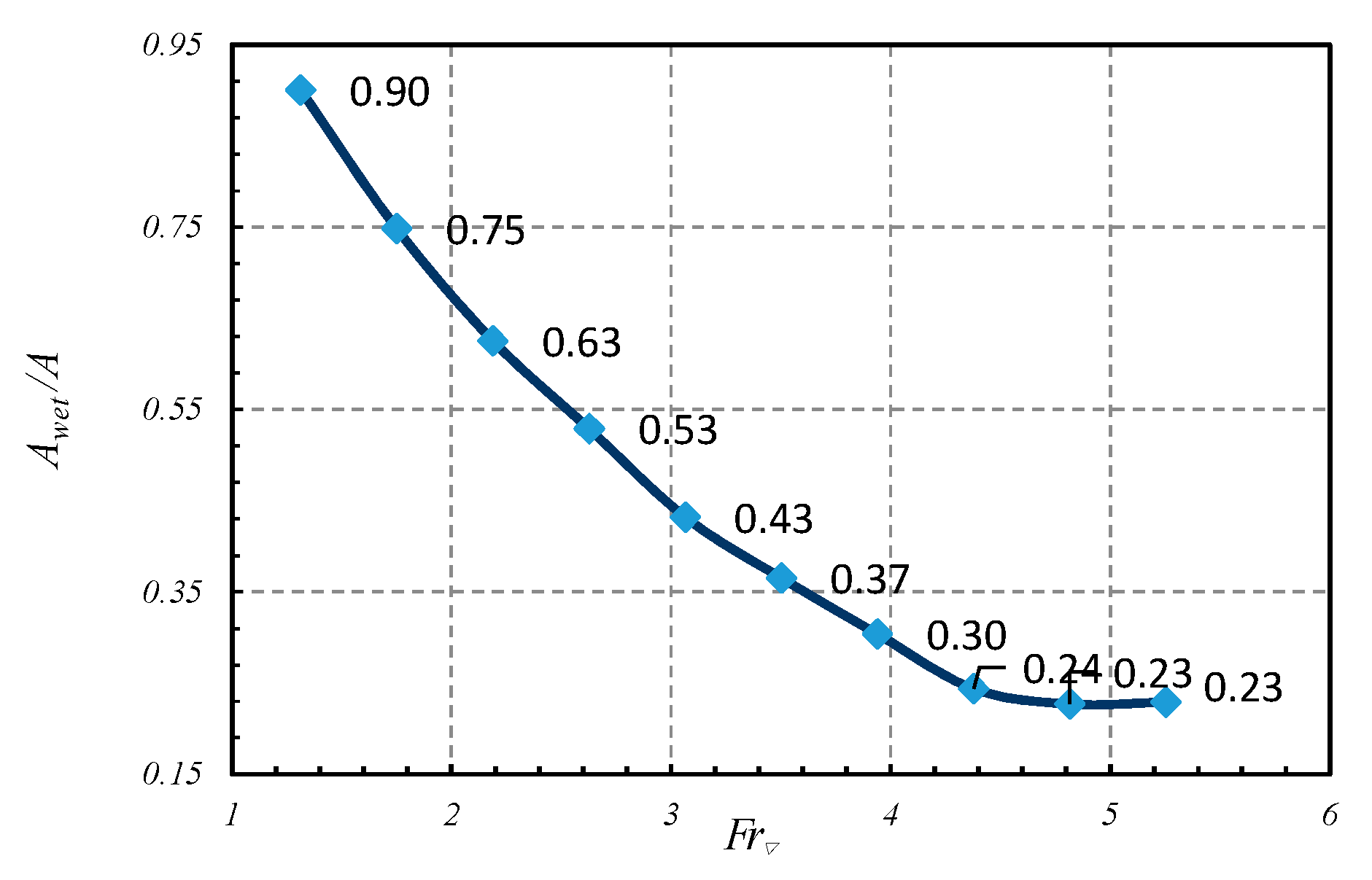

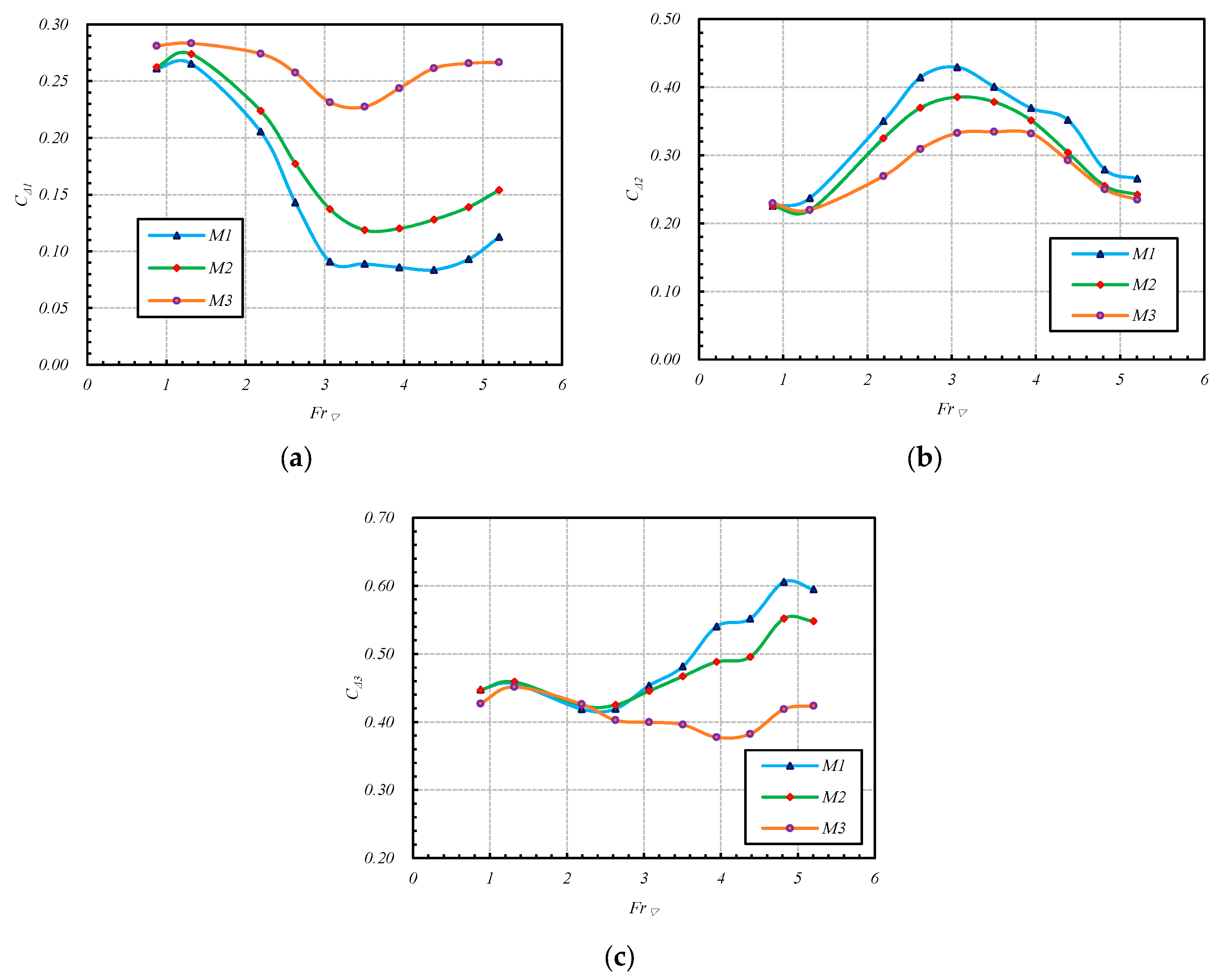

4.2.2. Influence of Steps on the Wetted Surface

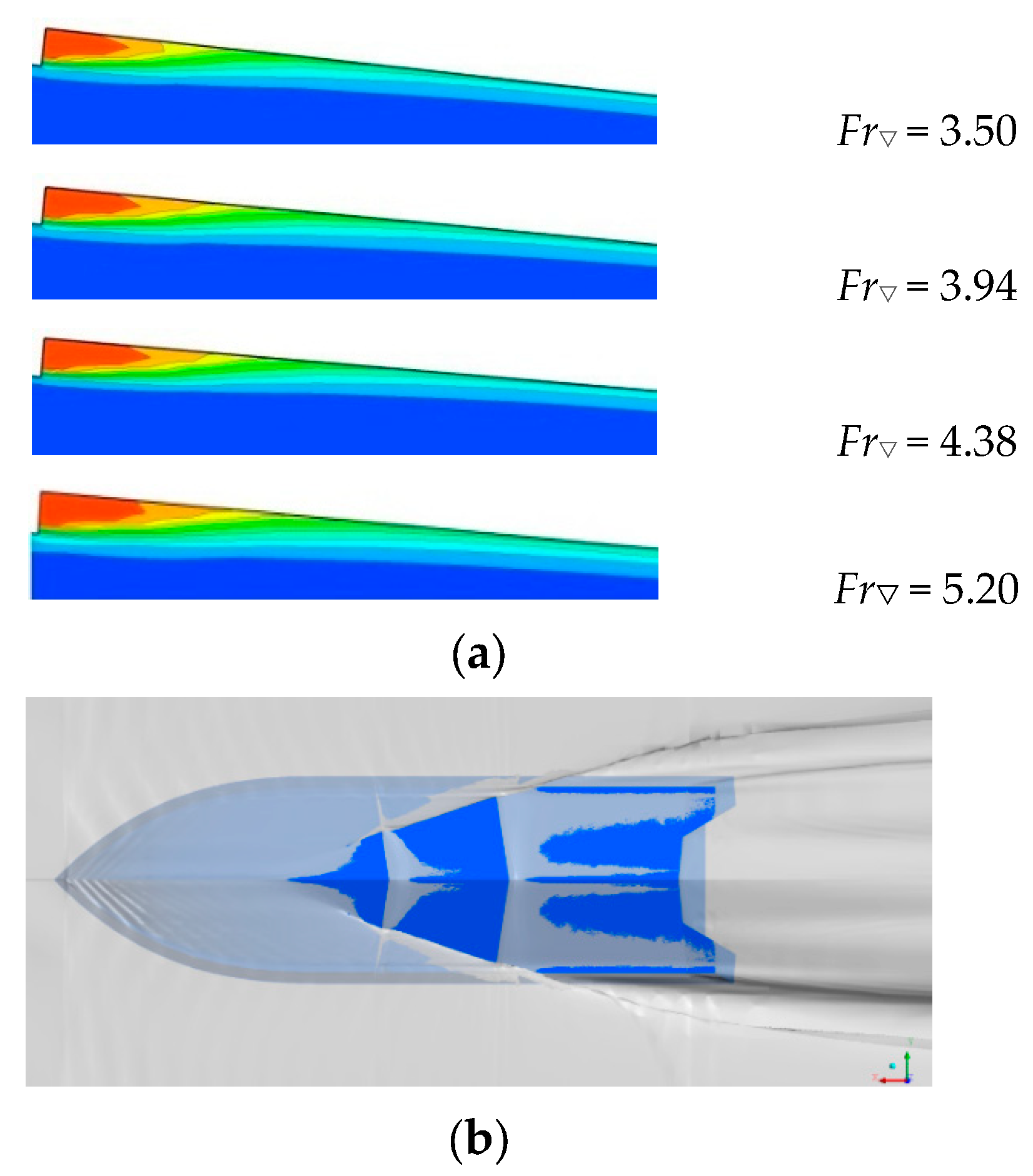

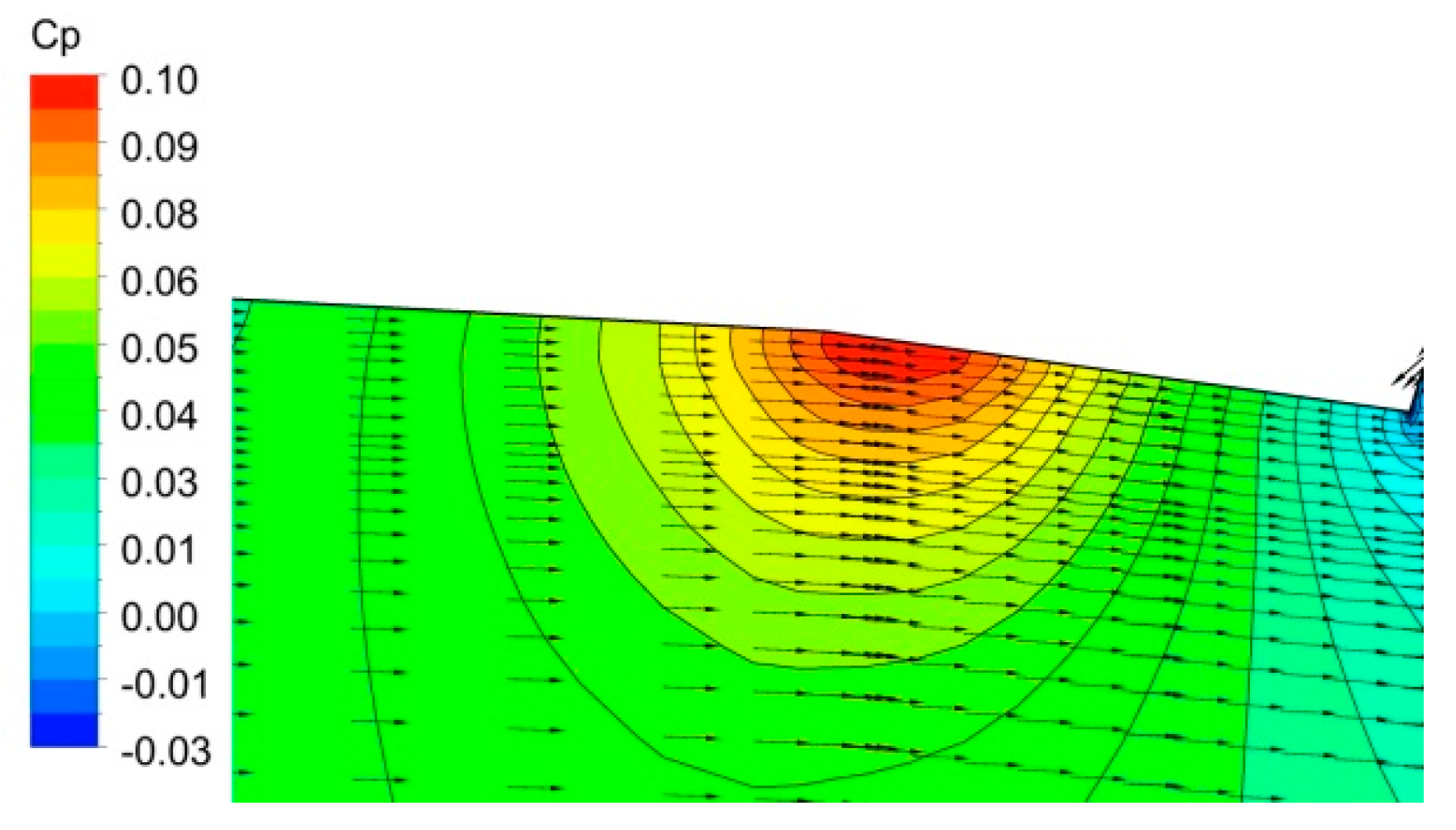

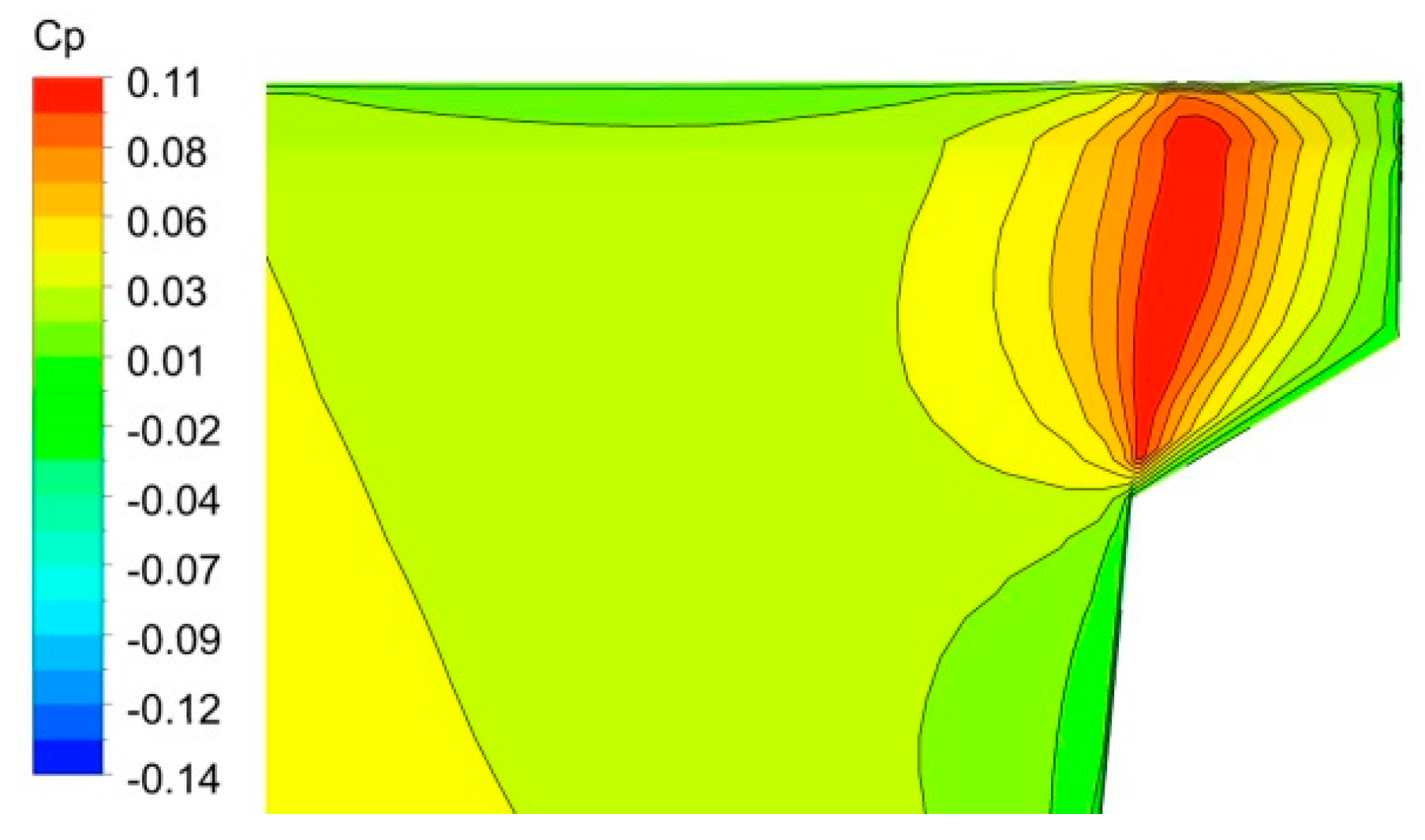

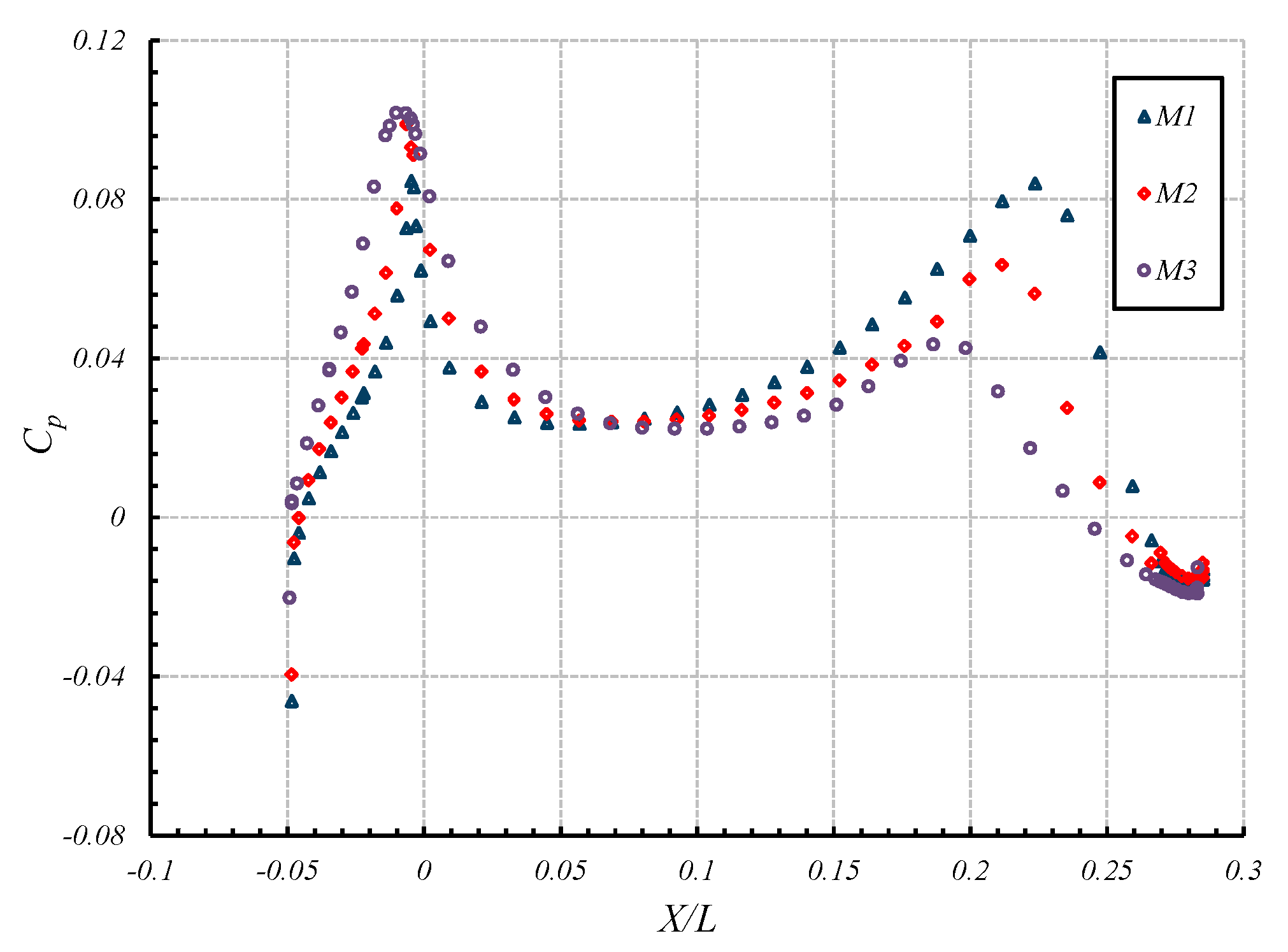

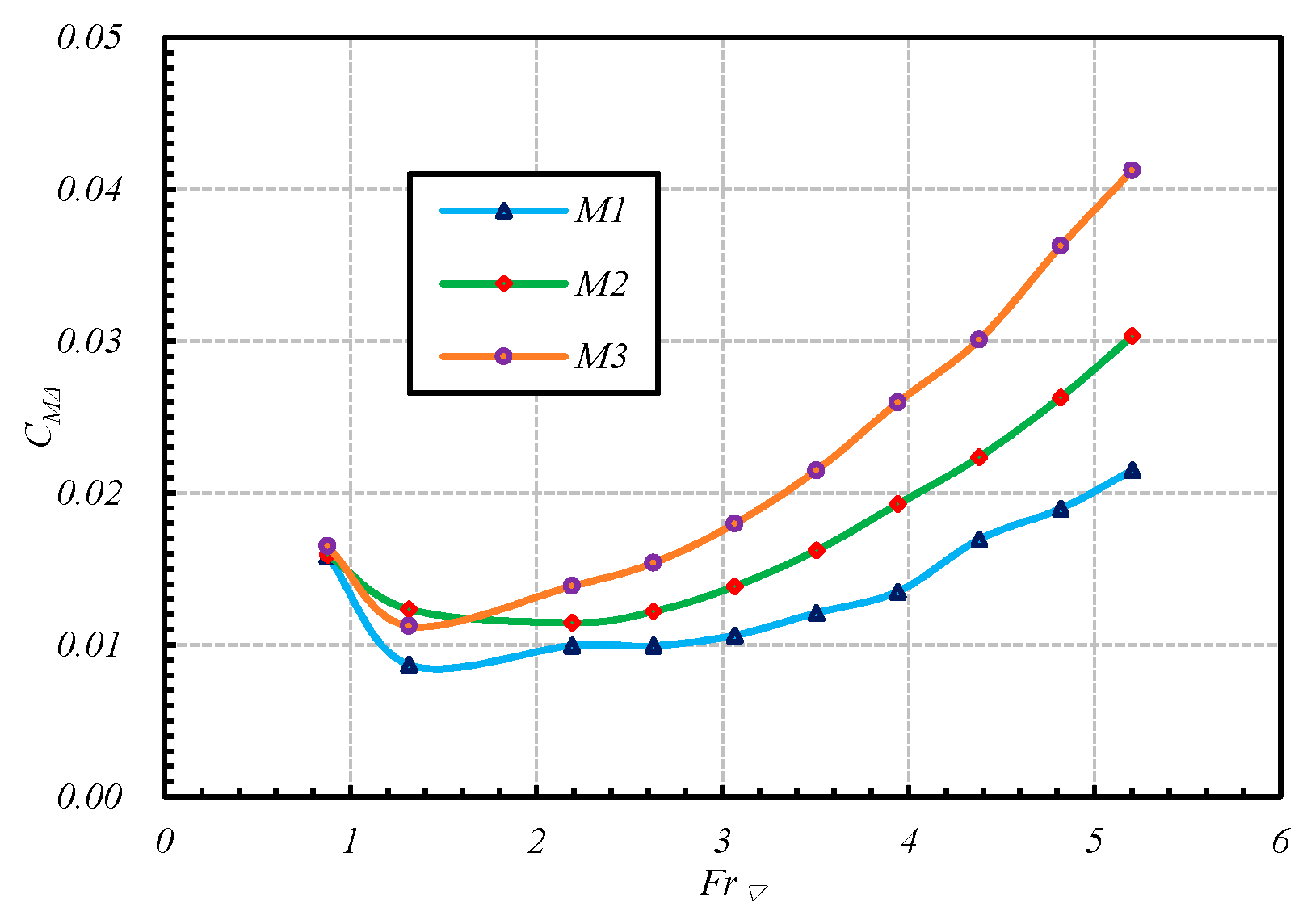

4.3. Hydrodynamic Characteristics of the Stern Flap

4.4. Influence of the Mounting Angle on the Stepped Planing Hull

5. Conclusions

- (1)

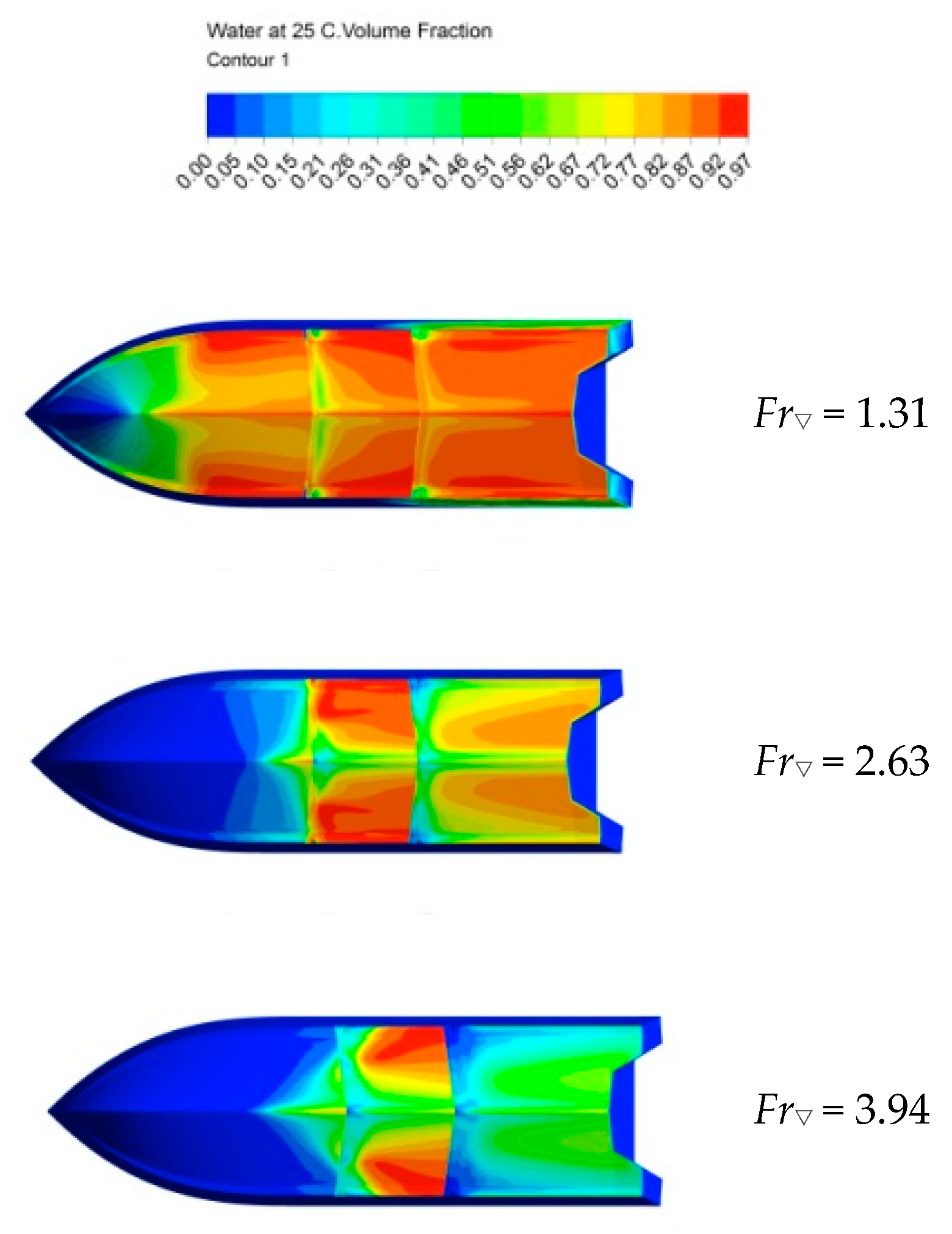

- The low-pressure region caused by the step saltation is the immediate induction of the cavity. With a speed increase, the cavity expands toward the rear, increasing the cavity coverage area. Conversely, the wetted surface area decreases. As for the distribution, the wetted surface is mainly concentrated in the post-median part of a planing surface. After the Froude number exceeds 4.38, the ratio of the wetted area and bottom area Awet/A remains at a fairly stable value of 0.23. The decrease of the wetted surface indicates the steps’ friction resistance reducing mechanism.

- (2)

- The stern flap is an effective resistance and motion regulating device. Enlarging the stern flap mounting angle within the variation range improves the resistance performance obviously. Moreover, it has a significant porpoising inhibition effect, with a slight cost of resistance during the high speed segment. The maximal porpoising critical speed extends with the increase in the mounting angle.

- (3)

- The connection position of the stern flap and hull is a high-pressure concentration area. With the increase of the mounting angle, the pressure value and the trim moment of the stern flap also increase. Correspondingly, the hull motion regulating ability is also improved.

- (4)

- Increasing the stern flap mounting angle reduces the trim, and intensifies the cavity expansion speed. The wetted surface area shrinks; the friction resistance is reduced. Therefore, the total resistance amplification is slight. In the meantime, the load among the planing surfaces distributes more uniformly with the increasing flap angle, which is also beneficial for inhibiting porpoising.

Author Contributions

Funding

Conflicts of Interest

Appendix A

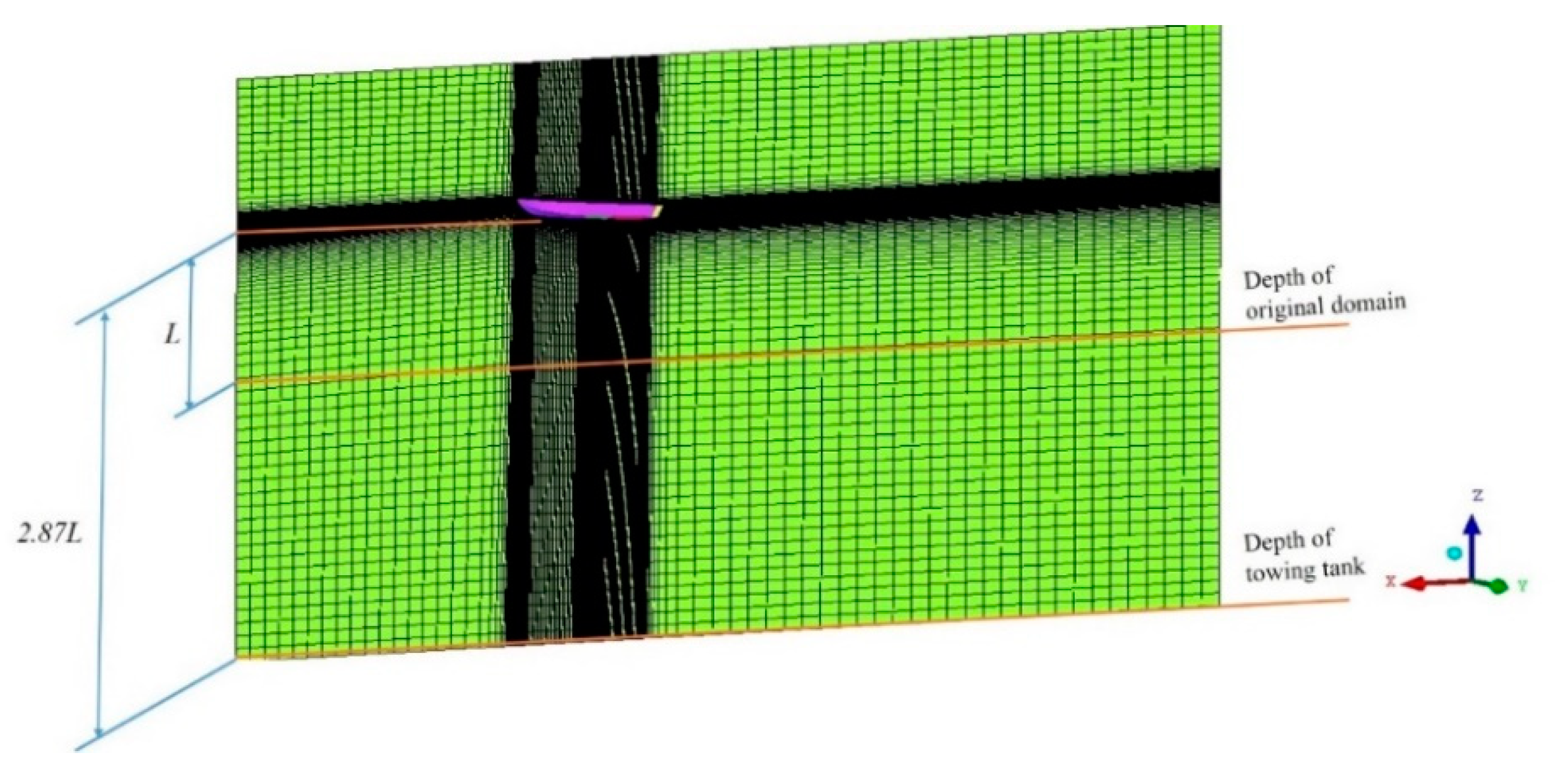

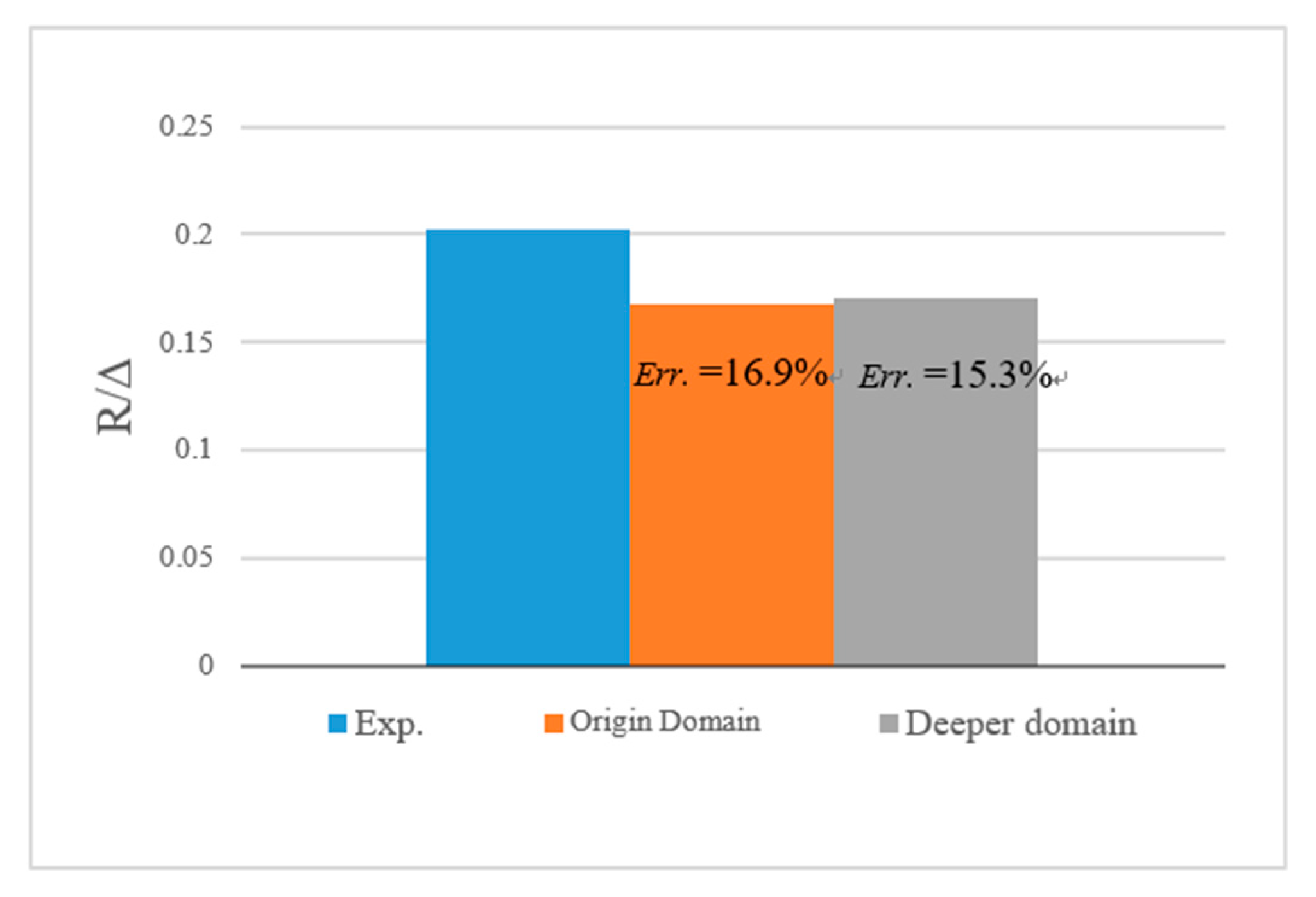

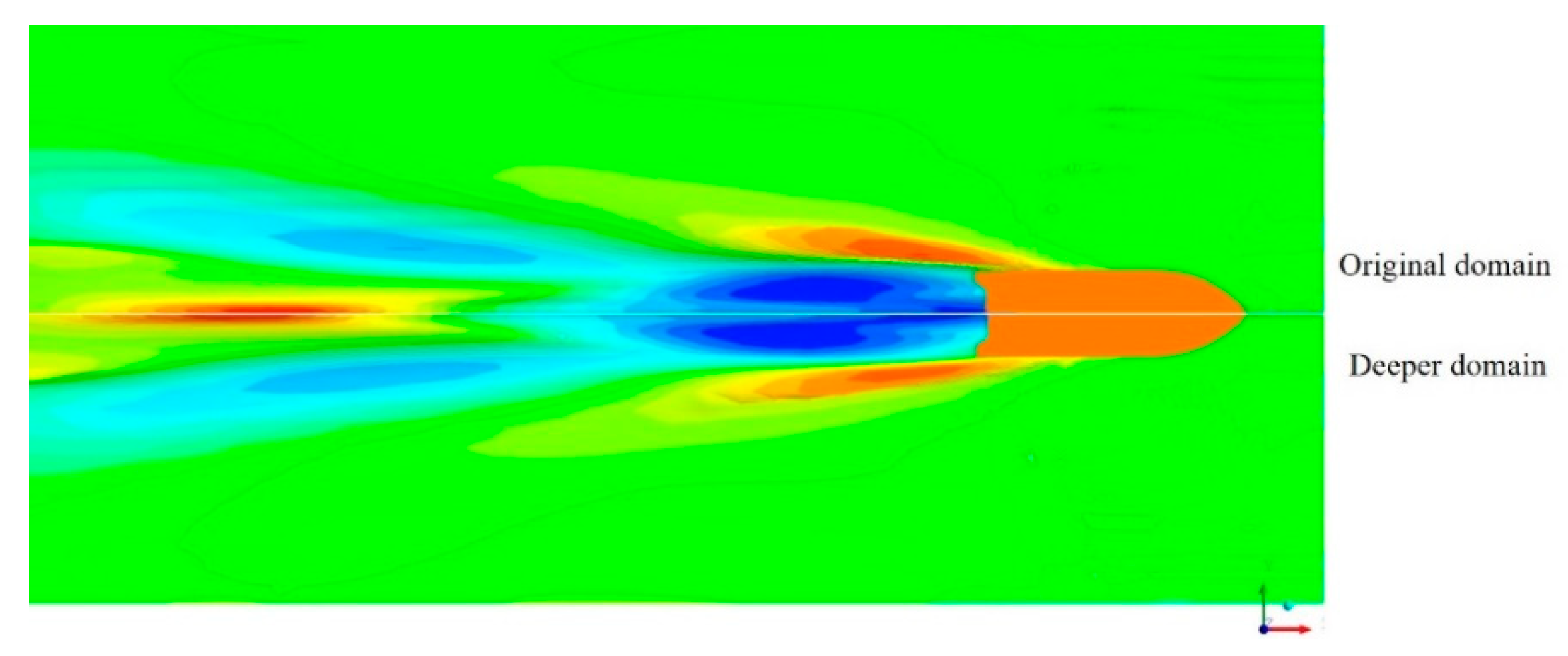

Appendix A.1. Width and Length Study of the Domain

Appendix A.2. Depth Study of the Domain

Appendix A.3. Conclusions

References

- Zheng, Y.; Dong, W.C.; Yao, C.B. Experimental study on resistance reduction of displacement type Deep-V hull model using stern flap. J. Shanghai Jiaotong Univ. 2011, 45, 475–479. [Google Scholar]

- Maki, A.; Arai, J.; Tsutsumoto, T.; Suzuki, K.; Miyauchi, Y. Fundamental research on resistance reduction of surface combatants due to stern flaps. J. Mar. Sci. Technol. 2016, 21, 344–358. [Google Scholar] [CrossRef]

- Savitsky, D. Hydrodynamic design of planing hulls. Mar. Technol. 1964, 1, 71–95. [Google Scholar]

- Villa, D.; Brizzolara, S. A systematic CFD analysis of flaps/interceptors hydrodynamic performance. In Proceedings of the 10th International Conference on Fast Sea Transportation FAST, Athens, Greece, 5–8 October 2009; pp. 1032–1038. [Google Scholar]

- Karimi, M.H.; Mohammad, S.S.; Majid, A. A study on vertical motions of high-speed planing boats with automatically controlled stern interceptors in calm water and head waves. Sh. Offshore Struct. 2015, 10, 335–348. [Google Scholar] [CrossRef]

- Celano, T. The prediction of porpoising inception for modern planing craft. Trans. Soc. Nav. Archit. Mar. Eng. 1998, 106, 269–292. [Google Scholar]

- Lee, E.; Pavkov, M.; McCue, W.L. The systematic variation of step configuration and displacement for a double-step planing craft. J. Sh. Prod. Des. 2014, 30, 89–97. [Google Scholar] [CrossRef]

- Garland, W.; Maki, K.J. A numerical study of a two-dimensional stepped planing surface. J. Sh. Prod. Des. 2012, 28, 60–72. [Google Scholar] [CrossRef]

- Morabito, M.G.; Pavkov, M.E. Experiments with stepped planing hulls for special operations craft. Trans. Roy. Inst. Nav. Archit Part B Int. J. Small Cr. Technol. 2014, 156, 87–97. [Google Scholar] [CrossRef]

- DeMarco, A.; Mancini, S.; Miranda, S.; Scognamiglio, R.; Vitiello, L. Experimental and numerical hydrodynamic analysis of a stepped planing hull. J. Appl. Ocean Res. 2017, 64, 135–154. [Google Scholar] [CrossRef]

- Garland, W.R. Stepped planing hull investigation. Trans. Soc. Nav. Archit. Mar. Eng. 2012, 119, 448–458. [Google Scholar]

- Lotf, P.; Ashrafzaadeh, M.; Kowsari, E.R. Numerical investigation of a stepped planing hull in calm water. Ocean Eng. 2015, 94, 103–110. [Google Scholar] [CrossRef]

- Makasyeyev, M.V. Numerical modeling of cavity flow on bottom of a stepped planing hull. In Proceedings of the 7th International Symposium on Cavitation, Ann Arbor, MI, USA, 17–22 August 2009. CAV2009-116. [Google Scholar]

- Morabito, M.G. Empirical equations for planing hull bottom pressure. J. Sh. Res. 2014, 58, 185–200. [Google Scholar] [CrossRef]

- Ghadimi, P.; Tavakoli, S.; Dashtimanesh, A.; Zamanian, R. Steady performance prediction of a heeled planing boat in calm water using asymmetric 2D+t model. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2016, 231, 234–257. [Google Scholar] [CrossRef]

- Dashtimanesh, A.; Esfandiari, A.; Mancini, S. Performance Prediction of Two-Stepped Planing Hulls Using Morphing Mesh Approach. J. Ship. Prod. Des. 2018, 34, 236–248. [Google Scholar] [CrossRef]

- Veysi, S.J.; Bakhtiari, M.; Ghassemi, H.; Ghiasi, M. Toward numerical modeling of the stepped and non-stepped planing hull. J. Braz. Soc. Mech. Sci. Eng. 2015, 37, 1635–1645. [Google Scholar] [CrossRef]

- Ghadimi, P.; Panahi, S.; Tavakoli, S.J. Hydrodynamic study of a double-stepped planing craft through numerical simulations. Braz. Soc. Mech. Sci. Eng. 2019, 41, 2. [Google Scholar] [CrossRef]

- Xin, T. Analysis on Hydrodynamic Performance of Double-stepped Planing Craft and its Appendages. Master’s Thesis, Harbin Engineering University, Harbin, China, 2014. [Google Scholar]

- ITTC. Recommended Procedures and Guidelines: General Guidelines for Uncertainty Analysis in Resistance, 7.5-02-02-02. In Proceedings of the International Towing Tank Conference, Copenhagen, Denmark, 1–5 September 2014. [Google Scholar]

- ITTC. Recommended Procedures and Guidelines: Testing and Extrapolation Methods Resistance Resistance Test, 7.5-02-02-01. In Proceedings of the International Towing Tank Conference, Wuxi, China, 18–22 September 2017. [Google Scholar]

- Celik, I.B.; Ghia, U.; Roache, P.J.; Freitas, C.J. Procedure for estimation and reporting of uncertainty due to discretization in CFD applications. ASME J. Fluids Eng. 2008, 130, 078001. [Google Scholar] [CrossRef]

| Main Feature | Symbol | Value |

|---|---|---|

| Length overall (mm) | L | 2370 |

| Beam between chine line (mm) | B | 646 |

| Longitudinal step-A (from rear) (mm) | LA | 1000 |

| Longitudinal step-B (from rear) (mm) | LB | 600 |

| Longitudinal center of gravity (from rear) (mm) | X g | 700 |

| Height of steps (mm) | H | 8 |

| Deadrise angle/(°) | β1 | 18 |

| Angle between steps & middle line plane/(°) | β2 | 80 |

| Mounting angles of stern flap/(°) | β | 2, 3, 4.5 |

| Average width projection of stern flap (mm) | Bf | 138 |

| Length of stern flap (mm) | Lf | 100 |

| M1 | M2 | M3 | |||

|---|---|---|---|---|---|

| 0.44 | 0.0073 | 0.0069 | −5.5% | 0.0076 | 4.1% |

| 0.88 | 0.0715 | 0.0709 | −0.8% | 0.0652 | −8.9% |

| 1.31 | 0.1971 | 0.1940 | −1.6% | 0.1875 | −4.9% |

| 2.19 | 0.2370 | 0.2340 | −1.3% | 0.2263 | −4.5% |

| 2.63 | 0.2106 | 0.2070 | −1.7% | 0.2024 | −3.9% |

| 3.07 | 0.1891 | 0.1879 | −0.6% | 0.1824 | −3.5% |

| 3.50 | 0.1799 | 0.1781 | −1.0% | 0.1736 | −3.5% |

| 3.94 | 0.1780 | 0.1777 | −0.2% | 0.1741 | −2.2% |

| 4.38 | 0.1803 | 0.1827 | 1.3% | 0.1816 | 0.7% |

| 4.82 | 0.1924 | 0.1941 | 0.9% | 0.1921 | −0.2% |

| 5.20 | 0.2025 | 0.2057 | 1.6% | 0.2060 | 1.7% |

| 5.69 | -- | 0.2187 | -- | 0.2286 | -- |

| 6.13 | -- | -- | -- | 0.2534 | -- |

| M1 | M2 | M3 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Cmpt. | Exp. | Err. | Cmpt. | Exp. | Err. | Cmpt. | Exp. | Err. | |

| 0.88 | 0.068 | 0.072 | 5.62% | 0.069 | 0.071 | 2.69% | 0.065 | 0.065 | 0.36% |

| 1.31 | 0.191 | 0.197 | 3.24% | 0.189 | 0.194 | 2.77% | 0.184 | 0.188 | 1.85% |

| 2.19 | 0.240 | 0.237 | −1.22% | 0.225 | 0.234 | 3.96% | 0.223 | 0.226 | 1.38% |

| 2.63 | 0.206 | 0.211 | 2.20% | 0.205 | 0.207 | 1.00% | 0.197 | 0.202 | 2.55% |

| 3.07 | 0.170 | 0.189 | 9.87% | 0.177 | 0.188 | 5.76% | 0.167 | 0.182 | 8.20% |

| 3.50 | 0.172 | 0.180 | 4.23% | 0.167 | 0.178 | 6.53% | 0.164 | 0.174 | 5.65% |

| 3.94 | 0.162 | 0.178 | 8.80% | 0.166 | 0.178 | 6.68% | 0.158 | 0.174 | 9.22% |

| 4.38 | 0.164 | 0.180 | 9.02% | 0.165 | 0.183 | 9.70% | 0.161 | 0.172 | 11.44% |

| 4.82 | 0.169 | 0.192 | 12.40% | 0.172 | 0.194 | 11.63% | 0.171 | 0.192 | 10.82% |

| 5.20 | 0.168 | 0.203 | 16.97% | 0.173 | 0.206 | 15.89% | 0.177 | 0.206 | 14.16% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, J.; Lu, S.; Jiang, Y.; Sun, H.; Li, Z. Experimental and Numerical Research on the Influence of Stern Flap Mounting Angle on Double-Stepped Planing Hull Hydrodynamic Performance. J. Mar. Sci. Eng. 2019, 7, 346. https://doi.org/10.3390/jmse7100346

Zou J, Lu S, Jiang Y, Sun H, Li Z. Experimental and Numerical Research on the Influence of Stern Flap Mounting Angle on Double-Stepped Planing Hull Hydrodynamic Performance. Journal of Marine Science and Engineering. 2019; 7(10):346. https://doi.org/10.3390/jmse7100346

Chicago/Turabian StyleZou, Jin, Shijie Lu, Yi Jiang, Hanbing Sun, and Zhuangzhuang Li. 2019. "Experimental and Numerical Research on the Influence of Stern Flap Mounting Angle on Double-Stepped Planing Hull Hydrodynamic Performance" Journal of Marine Science and Engineering 7, no. 10: 346. https://doi.org/10.3390/jmse7100346

APA StyleZou, J., Lu, S., Jiang, Y., Sun, H., & Li, Z. (2019). Experimental and Numerical Research on the Influence of Stern Flap Mounting Angle on Double-Stepped Planing Hull Hydrodynamic Performance. Journal of Marine Science and Engineering, 7(10), 346. https://doi.org/10.3390/jmse7100346