2.2.2. Analysis of Wheel–Seabed Interaction Forces

The motion characteristics of wheeled ROVs in the soft seabed sand environment are significantly different from those on hard and flat ground. The deformable nature of sandy soil leads to complex nonlinear characteristics in the wheel–ground interaction, which are mainly manifested in the increase in the longitudinal slip ratio and lateral slip displacement—directly affecting the trajectory tracking accuracy of the robot. The wheel subsidence caused by soil plastic deformation significantly changes the mechanical characteristics of wheel–ground contact, increases motion resistance, and intensifies energy consumption. This dynamically changing wheel–ground interaction mechanism introduces additional motion uncertainties, posing challenges to operational efficiency and system stability. To address the special working conditions of soft seabed terrain, it is necessary to establish a wheel–ground interaction model incorporating multiple parameters such as subsidence depth and slip ratio.

Figure 5 illustrates the mechanical interaction model of the driving wheel on deformable ground.

When a wheeled robot operates in a loose sandy environment, the wheel dynamics are influenced by multiple factors, and the mechanism through which these factors act is centrally reflected in the wheel-terrain interaction. From a mechanical perspective, the primary forces acting on the wheels include: tangential motion resistance, normal load, motor driving torque, and the shear and normal stresses exerted by the soil. Key parameters characterizing the wheel’s motion state include: slip ratio

s, sideslip angle

β, angular velocity

ω, and the wheel–seabed contact angle

θk [

18]. Among them, the sideslip angle

β represents the angle between the actual travel direction of the wheel and the longitudinal axis of the vehicle body, indicating the degree of lateral deviation of the wheel. The wheel–seabed contact angle

θk comprises three key components: the entry angle

θe, defined as the angle between the wheel’s vertical center plane and the radial direction at the initial contact point; the departure angle

θl, representing the angle between the vertical center plane and the radial direction at the final contact point; and the maximum stress angle

θm, corresponding to the direction of maximum radial stress. As a core motion parameter, the slip ratio s quantitatively characterizes the difference between the actual moving velocity

vs of the wheel and its theoretical rolling velocity. Its mathematical expression is given by [

19]

The longitudinal shear displacement between the wheel and the soil can be obtained by integration.

In the environment of soft seabed sand, pore water pressure significantly offsets the normal load of the soil and reduces its shear strength. Based on Terzaghi’s principle of effective stress, the calculation formulas for the longitudinal shear force and vertical stress at any point in the contact area between the wheel and the ground can be derived.

In the formula, c is the soil cohesion parameter (Pa), φ is the soil internal friction angle (°), ks is the soil shear deformation parameter (m), kc is the cohesion deformation modulus (m), kφ is the friction deformation modulus (m), and n is the sinkage index. uw is the pore water pressure. In this study, a simplified calculation model is adopted: uw = γw⋅z, where γw is the seawater density and z is the sinkage. Among them, z = r (1 − cosθk).

In the wheel–ground contact mechanics analysis, the maximum vertical stress

σm in the contact area occurs at the contact center. Its stress distribution can be characteristically decomposed into two key regions: the stress σ

1 in the front contact region and the stress

σ2 in the rear contact region, which are asymmetrically distributed on both sides of

σm. This dichotomous characterization reveals the basic mechanical characteristics of tire–ground interaction.

When a wheeled ROV passes through a loose soil environment, the tangential shear strength of the soil directly determines the maximum traction the wheels can generate. Therefore, the soil’s shear characteristics are a decisive factor affecting vehicle trafficability. Based on the classical Janosi–Hanamoto soil model, the relationship between soil shear stress and shear displacement assumes the following nonlinear form [

20]:

In the deep-sea environment, the partial subsidence of the ROV will cause the height of the center of buoyancy to rise. At this time, the effective buoyancy Fb′ is less than the theoretical buoyancy Fb, and the buoyancy reduction effect can be quantified by the following formula, Fb′ = Fb⋅(1 − α⋅z), where α is the buoyancy reduction coefficient and z is the subsidence-related parameter.

The normal load, traction force, and rotational torque are given as

Under the working condition where the robot as a whole bears a vertical normal load of 600 N and the ground slope ranges from 0° to 10°, the wheel pressures of each driving wheel show a dynamic distribution of 100–200 N. Based on the established wheel–ground contact mechanics model, when the slip ratio variation range of the wheels is set to 0–0.5, curves of wheel–ground interaction with respect to the slip ratio as shown in

Figure 6 are obtained through numerical simulation.

In

Figure 6a, the Sinkage Curve shows that the sinkage increases with the rise in the slip ratio under a fixed wheel pressure. In

Figure 6b, the Traction Curve indicates that the traction force increases as the slip ratio goes up, but tends to stabilize after reaching a critical value, and increasing the wheel pressure can raise the critical slip ratio. These results provide important mechanical basis for slope motion control. When the wheeled ROV moves on a slope, the vehicle as a whole is subjected to a vertically downward normal load

W(N) (the resultant of gravity, vertical thrust, and buoyancy) and water resistance

Fwater(N) acting opposite to the direction of linear velocity. Each wheel experiences the slope support force

Ni(N), traction

FDPi(N), seabed resistance

Fri(N), and lateral force

Fyi(N). The forces on the ROV on the sloped seabed are shown in

Figure 7.

To enhance the trafficability of mobile robots in soft ground and slope environments, this study proposes a driving torque optimal distribution method based on the difference in wheel normal loads. When the robot operates on a slope with different postures, the normal loads on each wheel exhibit a non-uniform distribution characteristic. Based on this mechanical property, a load distribution calculation model considering the slope inclination angle and wheel position is established. By accurately calculating the normal load of each wheel, a reasonable distribution of driving torque is achieved, thereby maximizing the traction output. When the robot is on a slope at different angles, the normal load of each wheel varies, and its calculation formula is

Substituting

Gx =

Gsinφ,

Gy =

Gsinγcosφ, and

Gz =

Gcosγcosφ into Equation (23), we can obtain

The lateral force of a wheel is related to both the wheel slip angle and the wheel normal load, and their relationship curves are illustrated in

Figure 8.

It can be seen from

Figure 8 that the variation law of the wheel lateral force exhibits a typical dual-parameter coupling characteristic. Under the condition of constant normal load, when the slip angle is within a reasonable range, there is an approximately linear increasing relationship between the lateral force and the slip angle; if the slip angle is kept constant, a phenomenon that the lateral force increases monotonically with the increase in the normal load can be observed. This mechanical characteristic is consistent with the experimental results on deep-sea soft sand. Based on the analysis of this mechanical characteristic, to simplify the complexity of controller design, this paper adopts a linearization method to establish a wheel cornering force calculation model under slope conditions [

21]. This model simplifies the complex ground mechanical relationship into a linear functional relationship between the slip angle and the normal load, as follows:

In the formula,

ci is the cornering stiffness of the i-th wheel (KN/rad),

cβ is the relative cornering stiffness (KN/(kN/(rad·kN))), and the parameter values are selected from the test values obtained in the deep-sea sandy soil environment in reference [

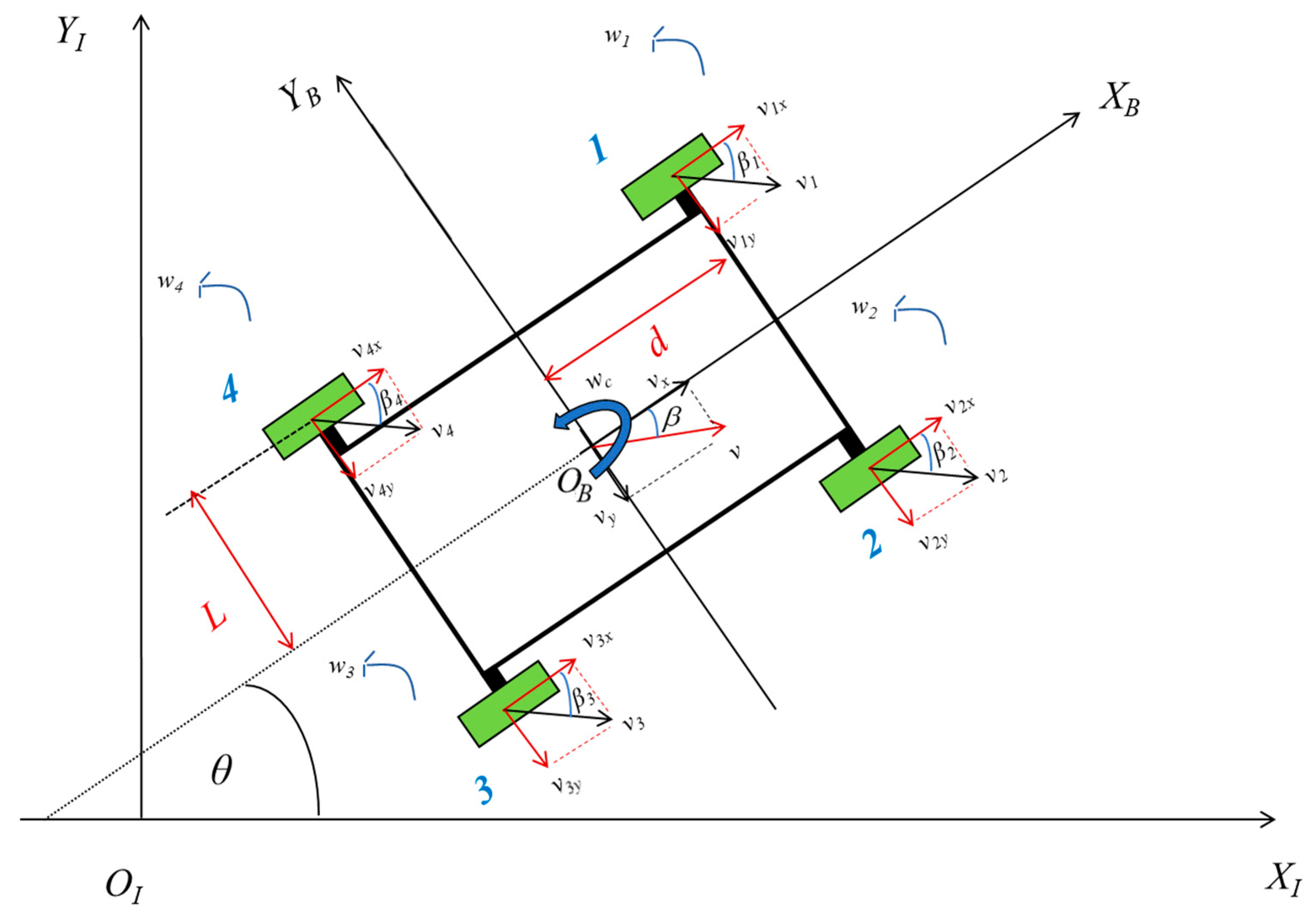

21]. To establish a complete dynamic closed-loop system, it is essential to supplement the coupling relationship between wheel rotation and vehicle body movement. To clarify the physical meaning and ensure coordinate system consistency, the velocity components in the body-fixed coordinate system {O

B X

B Y

B Z

B} are explicitly defined as follows: X′ Longitudinal velocity component along the X

B-axis at the robot’s center of mass; Y′: Lateral velocity component along the Y

B-axis at the robot’s center of mass. On this basis, the three-degree-of-freedom dynamic equilibrium equations for the ROV operating on a loose sloped seabed are formulated.

Among them,

Jw represents the moment of inertia of the wheel, and

.

Tf,i is the rolling resistance moment of the wheel, which satisfies

Tf,i = rFf,i. Here,

Ff,i is the rolling friction force, and its expression is

Ffi = μWi,

μ is the ground friction coefficient, and

Ti is the input torque of the motor.

Iz represents the moment of inertia of the robot. The simplified hydrodynamic drag formula is as follows:

where

Cd is the drag coefficient;

A is the projected area of the robot perpendicular to the direction of motion; and

vw is the speed of the robot relative to the water flow. The seabed soil parameters are provided in

Table 3.

Slip and sideslip phenomena occurring during wheeled ROV operation significantly impact wheel velocity. Thus, it is difficult to maintain precise motion control with position tracking alone. Therefore, a complete dynamic model based on the inertial coordinate frame is required. This model should describe both the overall motion of the vehicle and the dynamic behavior of the wheels. By introducing the effects of longitudinal slippage and sideslip into the model, precise control of wheel velocity

can be achieved, enhancing the system’s trajectory tracking performance under non-ideal seabed conditions. An integrated dynamic analysis yields the following system model:

where

denotes the inertial force matrix,

the Coriolis and centrifugal force matrix,

denotes the water resistance term,

the gravity term,

the friction force term,

the unknown disturbance term,

the system constraint,

the constraint force,

the input transfer matrix, and

the motor driving torque.

Differentiating

yields:

Substituting Equations (6), (11), and (17) into Equation (16) yields Equation (18):

Given

, an explicit mathematical relationship between the wheel angular velocity and the body dynamics of the vehicle can be established. By left-multiplying both sides of the equation by the transpose matrix

, the system dynamics equations can be transformed into the body-fixed coordinate frame of the vehicle, yielding a complete dynamic model that includes wheel–seabed interaction forces:

After organizing and combining terms,

Let , , , , , , .

The dynamic equations for operation on a sloped seabed are expressed as

Similarly, substituting and multiplying both sides by

results in

where

,

,

,

,

,

,

.