Universal Screening Criteria for VIV of Free Spans, V*

Abstract

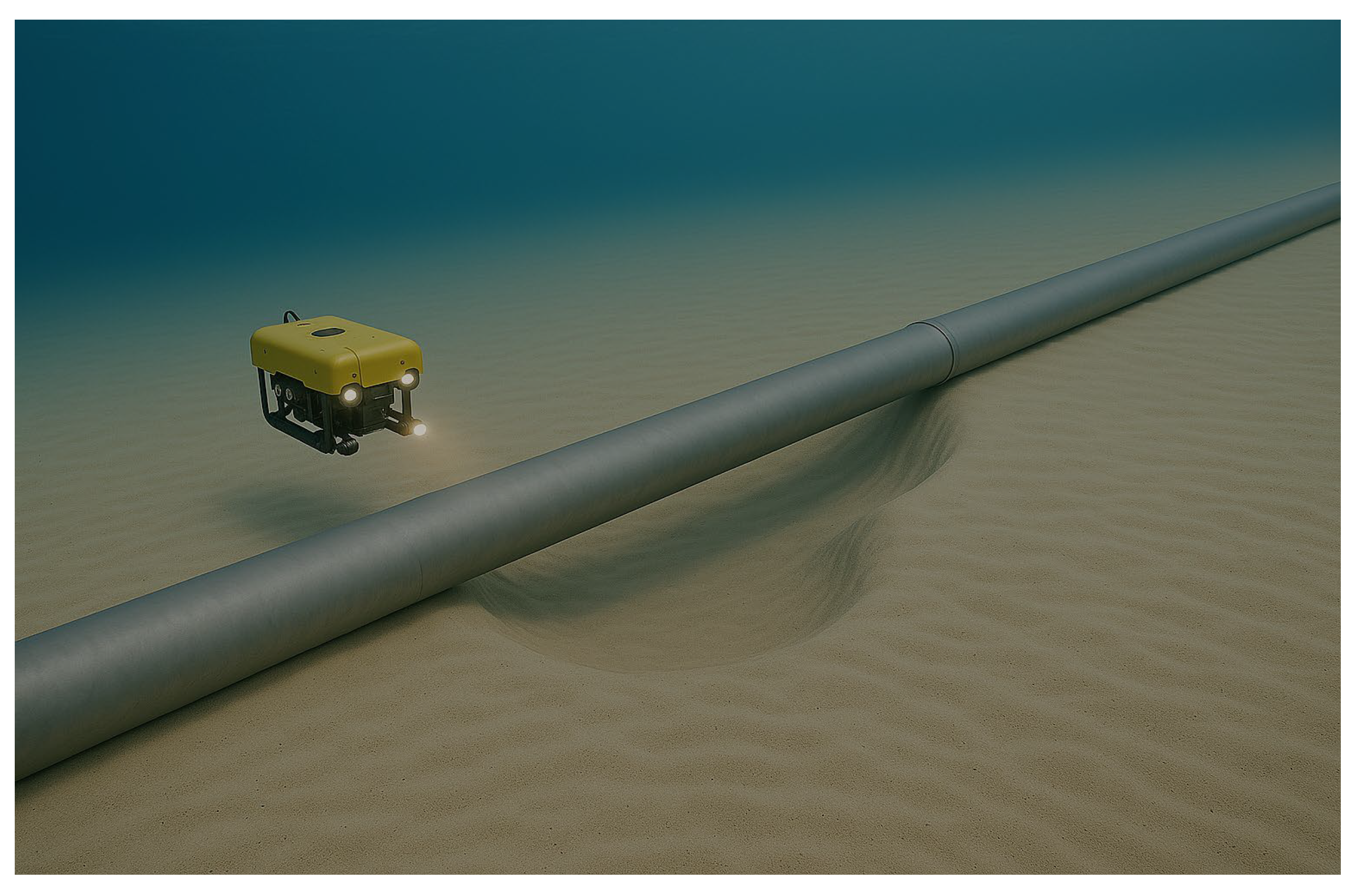

1. Introduction

The Onset of VIV

2. Non-Dimensional Analysis

2.1. Identification of Relevant Variables and Dimensions

- Characteristic outside diameter D [L];

- Current velocity, V [LT−1];

- Fluid density ρf [ML−3];

- Mass density of structure (cable or pipe) ρS [ML−3];

- Characteristic free-span length, L [L];

- Cable or pipe bending stiffness, EI [MLT−2]. L2 = [ML3T−2];

- Cable or pipe as-laid effective tension, Teff [MLT−2].

- D, V and ρf.

2.2. Simplified Governing Equations

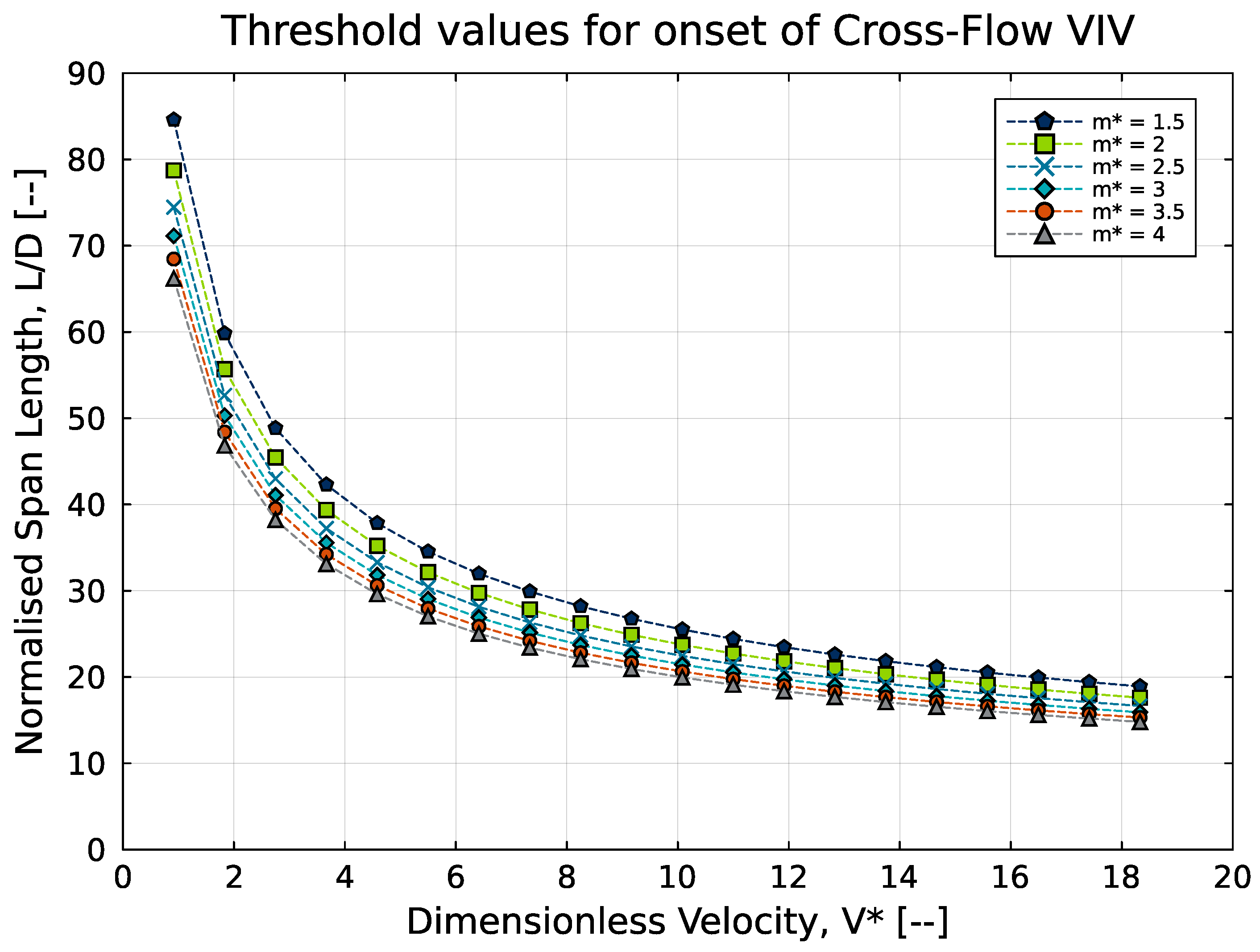

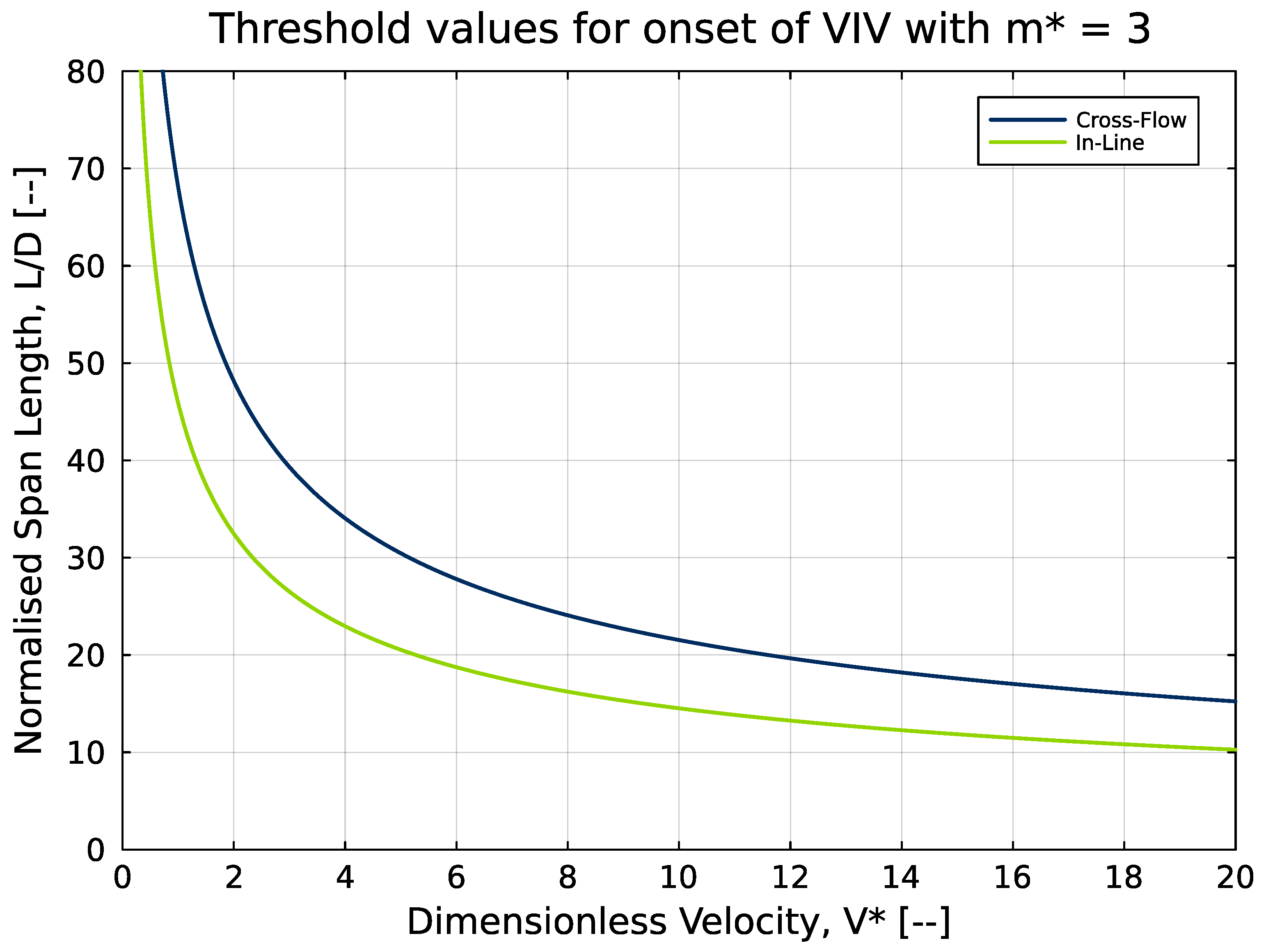

3. Simplified Response Curve

- Clamped–clamped end condition (per DNV [3] single span recommendation);

- Ca = 1.0;

- Safety factor on onset value for in-line VIV, γonIL = 1.1 (cross-flow onset safety factor not applied in determining cross-flow VIV onset condition in [3]);

- Safety factor on in-line and cross-flow natural frequencies, γ fIL = 1, γ fCF = 1;

- Lowest natural frequencies in in-line and cross-flow directions for a given span are termed fIL,1 and fCF,1 and computed per Section 2.2 in [3];

- VR onset for cross-flow VIV is effectively 2.0 (Section 2.3.3 [3]);

- No multi-spans, interactions between spans or significant sagging are considered, except when a multi-span can be assumed as one span, which, under some circumstances, can be a very conservative assumption;

- This covers screening for fatigue (FLS), not local buckling of ultimate stress (ULS).

4. Case Studies

4.1. Power-Cable Free-Span Screening—Critical Minimum Velocity

- Free-span length, L = 5 m;

- Diameter, D = 0.176 m;

- Bending Stiffness, EI = 12 kNm2;

- Mass/Length = 77.3 kg/m.

- L/D = 28.4;

- m* = 3.1 (from Equation (1));

- VIL* = 2.57, VCF* = 5.65 (from Equations (11) and (12));

- Onset velocities VIL = 0.284 m/s, VCF = 0.625 m/s (from Equation (4)).

- There is no difference in calculated onset velocities when compared to the methodology set out in DNV-GL-RP-F105 [3].

- If assuming m* = 3 (using Equation (13) and (14)), then VIL = 0.289 m/s, and VCF = 0.635 m/s.

- o

- The m* = 3 assumption is shown to only change the onset velocities by <2% in this example.

- If L = 6 m (+20%), then onset velocities are VIL~0.20 m/s and VCF~0.43 m/s.

- o

- A 20% increase in span length reduced the onset velocities by ~30%, noting that the relationship between these parameters has been established as non-linear.

4.2. Pipeline Free-Span Screening—Critical Minimum Span Length

- Diameter, D = 0.483 m (~19 inch);

- Maximum V: 1.7 m/s;

- Bending Stiffness, EI: 4.68 × 107 Nm2;

- Mass/Length = 518 kg/m.

- m* = 2.76 (from Equation (1));

- V* = 1.86 × 10−3 (from Equation (4));

- (L/D)IL = 34.4, (L/D)CF = 51.1 (from Equations (11) and (12));

- Critical minimum span lengths: LIL = 16.6 m, LCF = 24.7 m.

- There is no difference in calculated critical minimum span lengths when compared to the methodology set out in DNV-GL-RP-F105 [3].

- If assuming m* = 3 (using Equations (13) and (14)), then LIL = 16.3 m, and LCF = 24.2 m.

- o

- The m* = 3 assumption is shown to only change the onset velocities by ~2% in this example.

- If V = 2 m/s (+20%), then LIL = 15.3 m, and LCF = 22.7 m.

- o

- A 20% increase in maximum velocity reduced the span lengths by ~10%, noting the non-linear relationship of these parameters.

5. Discussion

- Multi-spans could be, for screening purposes, considered as one combined span length. Importantly, this approach does not account for the influence on VIV from interacting multi-spans. It is recommended that, if multi-spans are being considered, the reader seek further guidance on calculating these interactions per DNV [3].

- The free-span length of a curved pipeline can be estimated by using the arc length of the pipeline.

- Dynamic seabed conditions may be screened by assuming, if possible, that the end-of-life condition applies. For example, if scour of the seabed is anticipated, then the free-span length can be assumed as the largest length possible under those conditions.

6. Conclusions

- The non-dimensionalisation of a free span under VIV revealed three dominant physical mechanisms: mass ratio, aspect ratio and bending stiffness curvature loading.

- A universal curve was established to conservatively assess the onset of VIV, where conservativism over-predicts VIV onset velocities or under-predicts threshold span lengths.

- Even though mass ratio is generally considered important in VIV predictions, the range of mass ratios considered in this investigation of VIV on free spans does not show a significant influence of mass ratio on the critical free-span length for a given non-dimensional flow velocity. Thus, a mass ratio of 3 is a reasonable approximation for screening free-span VIV on offshore cables and pipes.

- The methodology provided in this paper provides reduced complexity screening criteria for the determination of onset VIV and critical minimum span lengths. These screening criteria may be practically implemented during preliminary design or throughout the operational phases to determine the location and extent to which VIV high-fidelity fatigue assessments are required to be performed. In effect, this screening methodology will act as a precursor to select the instances where detailed analysis tools such as SHEAR7 and FATFREE can be implemented.

- This methodology may produce very conservative estimates if high as-laid tension is present in the system. However, it is important to note that the purpose of the method is for screening only.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CF | Cross-Flow |

| IL | In-line |

| LGS | Longitudinal Grooved Suppression |

| VIV | Vortex-Induced Vibration |

References

- Martins, R.R.; Cardoso, C.O.; Matt, C.G.C.; Nunes, L.A.N.; Góes, R.C.O.; Rosa, A.S.; Silveira, E.S.S. Improving the Free Span Analysis of Subsea Rigid Pipelines for Life Extension Through Integration and Automation and Efficiency. In Proceedings of the Offshore Technology Conference, OTC, Houston, TX, USA, 5–8 May 2025; p. D021S022R008. [Google Scholar]

- Zhu, J.; Ren, B.; Dong, P.; Chen, W. Vortex-Induced Vibrations of a Free Spanning Submarine Power Cable. Ocean. Eng. 2023, 272, 113792. [Google Scholar] [CrossRef]

- Free Spanning Pipelines. DNV-RP-F105. Edition 2017-06—Amended 2021-09. Recommended Practice. Available online: https://www.dnv.com/energy/standards-guidelines/dnv-rp-f105-free-spanning-pipelines/ (accessed on 10 June 2025).

- Available online: https://shear7.com/ (accessed on 10 June 2025).

- DNV. Available online: https://sesam.dnv.com/download/userdocumentation/fatfree-user-manual.pdf (accessed on 10 June 2025).

- Negri, M.; Mirauda, D.; Malavasi, S. An analysis method of the vortex-induced vibrations of a tethered sphere. Meccanica 2020, 55, 1949–1974. [Google Scholar] [CrossRef]

- Kelly, S.G. Fundamentals of Mechanical Vibrations; McGraw-Hill Series in Mechanical Engineering; McGraw-Hill: New York, NY, USA, 1993; ISBN 978-0-07-911533-1. [Google Scholar]

- Resvanis, T.L.; Vikas, J.; Vandiver, J.K.; Stergios, L. Reynolds Number Effects on the Vortex-Induced Vibration of Flexible Marine Risers. In Volume 5: Ocean Engineering; CFD and VIV (1 July 2012); American Society of Mechanical Engineers: New York, NY, USA, 2012; ISBN 978-0-7918-4492-2. [Google Scholar]

- Vandiver, J.K. Dimensionless Parameters Important to the Prediction of Vortex-Induced Vibration of Long, Flexible Cylinders in Ocean Currents. J. Fluids Struct. 1993, 7, 423–455. [Google Scholar] [CrossRef]

- Pantazopoulos, M.S. Vortex-Induced Vibration Parameters: Critical Review. In Proceedings of the 13th International Conference on OMAE 1994 Offshore Mechanics and Arctic Engineering, Houston, TX, USA, 27 February–3 March 1994; ISBN 0-7918-1264-2. [Google Scholar]

- Lienhard, J.H. Synopsis of Lift, Drag, and Vortex Frequency Data for Rigid Circular Cylinders; College of Engineering, Research Division (Report). Bulletin 300; Washington State University: Pullman, WA, USA, 1966. [Google Scholar]

- Rao, S.S. Mechanical Vibrations, 6th ed.; Pearson: Hoboken, NJ, USA; London, UK; Toronto, ON, Canada, 2017; ISBN 978-0-13-436130-7. [Google Scholar]

- NREL. Available online: https://www.nrel.gov/docs/fy21osti/76968.pdf (accessed on 10 June 2025).

- Jayasinghe, K.; Marcollo, H.; Potts, A.E.; Dillon-Gibbons, C.; Kurts, P.; Pezet, P. Mitigation of Pipeline Free Span Fatigue Due to Vortex Induced Vibration Using Longitudinally Grooved Suppression. In Volume 5: Pipelines, Risers, and Subsea Systems; American Society of Mechanical Engineers: Madrid, Spain, 2018. [Google Scholar]

- Vandiver, J.K.; Swithenbank, S.; Jaiswal, V.; Marcollo, H. The Effectiveness of Helical Strakes in the Suppression of High-Mode-Number VIV. In Proceedings of the Offshore Technology Conference, OTC, Houston, TX, USA, 1–4 May 2006. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marcollo, H.; Behan, M.; Dillon-Gibbons, C. Universal Screening Criteria for VIV of Free Spans, V*. J. Mar. Sci. Eng. 2025, 13, 1501. https://doi.org/10.3390/jmse13081501

Marcollo H, Behan M, Dillon-Gibbons C. Universal Screening Criteria for VIV of Free Spans, V*. Journal of Marine Science and Engineering. 2025; 13(8):1501. https://doi.org/10.3390/jmse13081501

Chicago/Turabian StyleMarcollo, Hayden, Matthew Behan, and Craig Dillon-Gibbons. 2025. "Universal Screening Criteria for VIV of Free Spans, V*" Journal of Marine Science and Engineering 13, no. 8: 1501. https://doi.org/10.3390/jmse13081501

APA StyleMarcollo, H., Behan, M., & Dillon-Gibbons, C. (2025). Universal Screening Criteria for VIV of Free Spans, V*. Journal of Marine Science and Engineering, 13(8), 1501. https://doi.org/10.3390/jmse13081501