1. Introduction

The maritime transport sector, which forms the foundation of global trade and commerce, actively seeks to enhance operational efficiency, reduce costs, and achieve environmental sustainability goals. The maritime transportation industry has increasingly adopted Articulated Tug Barge systems, primarily serving coastwise in the United States, while expanding their use worldwide [

1].

ATBs combine the financial advantages of tugboat and barge operations with ship-like performance features, providing speed and stability at sea, as well as in severe weather conditions. The core concept of an ATB involves a dedicated tugboat that is mechanically and rigidly connected to a barge, enabling the two units to function as a single integrated system. This connection is typically achieved through various systems, such as Intercon [

2], Articouple [

3], or Jak [

4]. These systems allow the tug to pitch independently of the barge while remaining rigidly connected in yaw and roll.

The articulation feature distinguishes ATBs from previous Integrated Tug Barge (ITB) concepts, using a more flexible, ship-like connection. This flexibility can create operational challenges when the tug operates independently or connects or disconnects at different draft levels. Nevertheless, the ATB design overcomes many limitations of conventional towed barges, offering significant cost advantages, including lower crew requirements and adaptable construction.

Fuel costs comprise a substantial portion of a vessel’s operating expenses, typically accounting for 50–60% of the total costs [

5]. As a result, any improvements in fuel and energy efficiency can provide substantial competitive advantages for shipping companies. Therefore, improving efficiency focuses on vessel design, equipment selection, maintenance practices, and operational procedures. Articulated Tug Barges, due to their design and operational mode, offer several opportunities for improving energy efficiency. These include optimised hull forms for both the tug and barge when operating as a combined unit, the potential for more efficient propulsion systems, and improved hydrodynamic performance compared to traditional towed barges, leading to a reduction in fuel consumption over conventional tug-and-barge setups.

The development of tug–barge transport began with sailing ships serving as towed barges and progressing to the sophisticated, purpose-built ATB units. The driving force behind the development of this type of transport was economic efficiency and operational reliability. Early enhancements to simple towing included notched barges and the Integrated Tug and Barge concept. Pioneering units such as the “CARPORT” demonstrated the potential of pushed barge configurations [

6,

7,

8]. However, the development of reliable articulated connection systems, along with a more favourable regulatory interpretation [

9], truly paved the way for modern ATBs. These systems enabled a dual-mode capability, where the tug, while designed to integrate with its barge, could also function as a conventional towing vessel if necessary, and other tugs could manage the barge. This offered operational flexibility compared to many earlier ITB designs.

The present study provides a comprehensive analysis of ATB technology, examining its development and operational benefits while exploring its crucial role in meeting the shipping industry’s growing demands for energy efficiency. It discusses numerous benefits of ATBs, particularly in terms of energy efficiency, operational performance, safety, and economic viability. Additionally, specific design elements, technological advancements, and operational approaches that increase ATB transport efficiency are analysed, focusing on hull design, propulsion, connection systems, and the impacts of modern technologies.

2. Articulated Tug-and-Barge Transport

Barges have been used for transporting cargoes since the beginning of maritime commerce. Tugs appeared later, illustrating the concept of using a steam engine to tow a ship [

10]. The new maritime technology introduced effective methods to connect tugs with barges, thereby enhancing their performance. These early concepts represented rigid connections, where the combined unit would behave more like a conventional ship [

7]. The primary goal was to improve speed, control, and sea-keeping ability by allowing the tug to push the barge rather than pull it.

The first efficient application of the ITB concept emerged with the development of the ITB “CARPORT”, featuring a purpose-built tug that fitted into a notched stern of a specially designed barge, with the two units held together by massive turnbuckles [

6,

8]. The “CARPORT” demonstrated the viability of the ITB concept, achieving higher speeds (around thirteen knots) and better manoeuvrability than traditional towed units. The availability of inexpensive surplus tonnage, including conventional tugs and barges, provided a more economical, albeit less efficient, means of transport for some time [

8]. However, the rigid connection systems were complex to engage and disengage, especially if there were differences in draft between the tug and barge. Furthermore, the tugs were more specialised for their integrated role and could not operate efficiently as independent units if separated from their dedicated barges [

8].

Companies like Ingram Ocean Systems built notable ITBs, such as the “Carole G. Ingram” and “Martha R. Ingram”, delivered in 1971, which were large-capacity units designed for open-ocean service [

8].

Despite the advances in ITB design, it remained inherently unstable due to the atypical shape of the tug required to mate with the barge [

11].

The transition from ITBs to ATBs began in the 1970s, as operators required improved operational flexibility and enhanced sea-keeping performance in challenging open-sea conditions. An ATB vessel achieves its defining characteristic through its articulated connection system, which enables the tug to move independently of the barge during pitching motions while maintaining a rigid connection in the yaw and roll axes. The articulated design enhances the combined unit’s heavy sea-keeping capabilities, reducing connection system stresses and delivering better crew comfort than ITBs or towed barges with rigid connections.

One of the first single-degree-of-freedom (pitching) connection systems applied to a large tug and barge was reported in [

6]. The transition from ITBs to ATBs began as operators required improved operational flexibility and enhanced sea-keeping performance in harsh open-sea conditions.

If the tug component of a dual-mode unit met all the requirements of a towing vessel, the combined unit could operate in accordance with the regulatory standards of a traditional tug and barge, even when pushing 100% of the time [

8,

12]. This enlightened policy recognised the inherent safety advantages of mechanically connected pushing systems and was crucial in encouraging further investment and development in ATB technology.

In this regard, the INTERCON system addressed issues related to differential loading and draft variations during connection, incorporating features such as Articouple’s unlimited-draft-connection capability but utilising a mechanical screw drive instead of hydraulics for ram extension [

3].

The designs have been refined to optimise hydrodynamic efficiency, leading to higher service speeds of approximately 10–13 knots and improved fuel economy compared to both towed barges and earlier ITB/ATB designs [

8,

12]. ATBs have found widespread use for transporting petroleum products, chemicals, and other bulk commodities.

As discussed in [

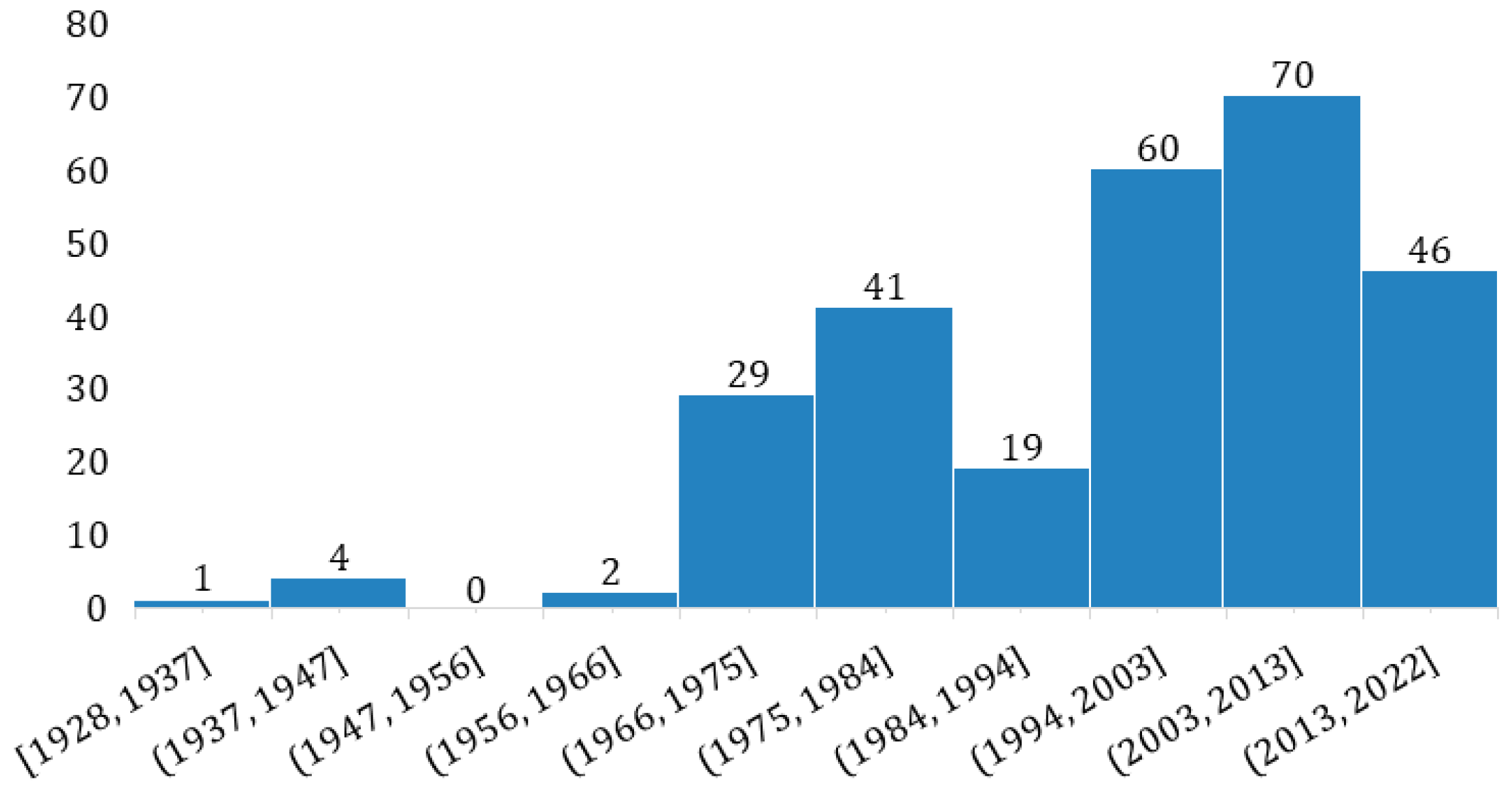

8], there was a surge in new-built ATBs in the middle of the 20th century, which later lost some of its momentum but then regained it at the end of the 20th and the beginning of the 21st century, as can be seen in

Figure 1.

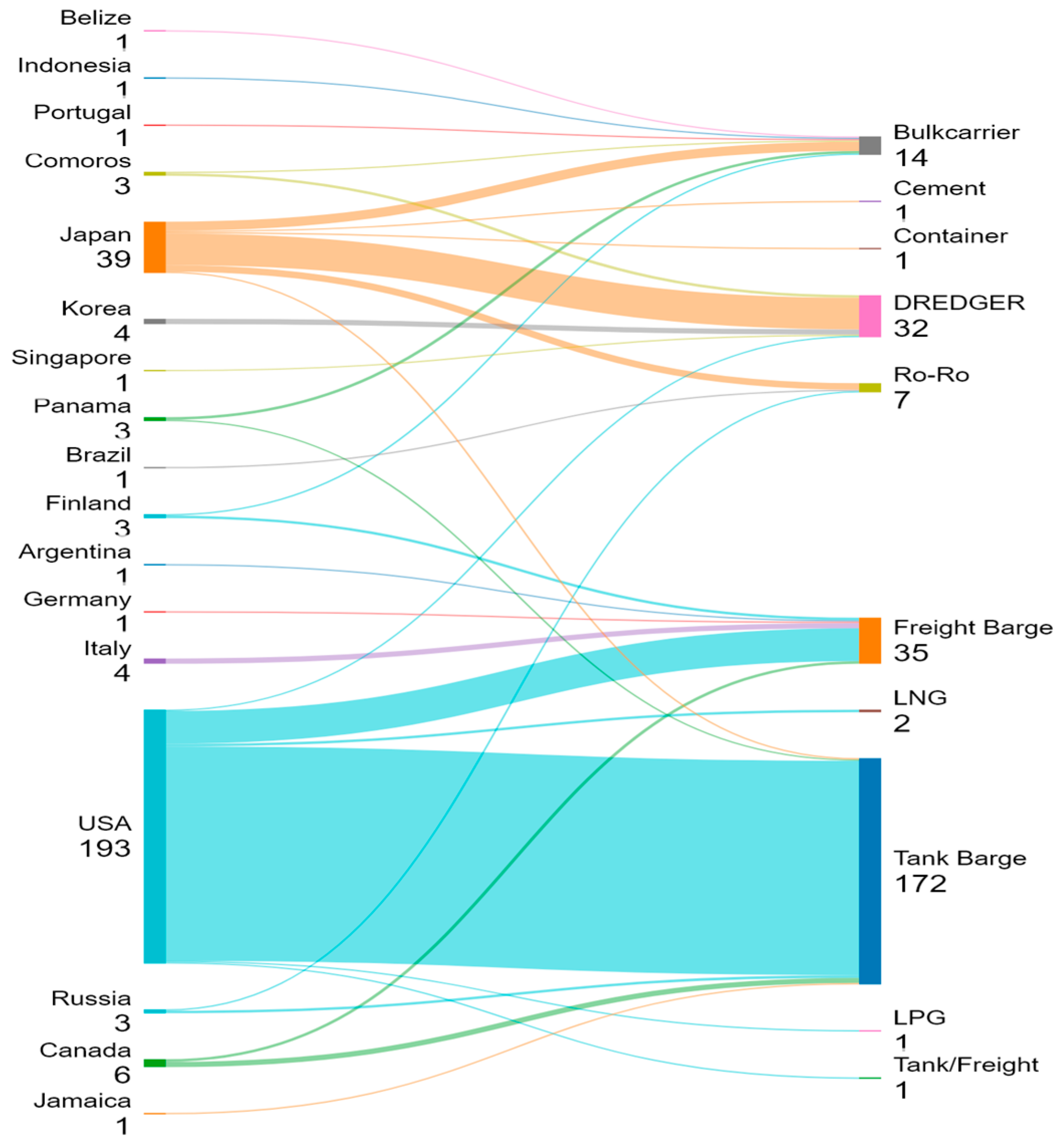

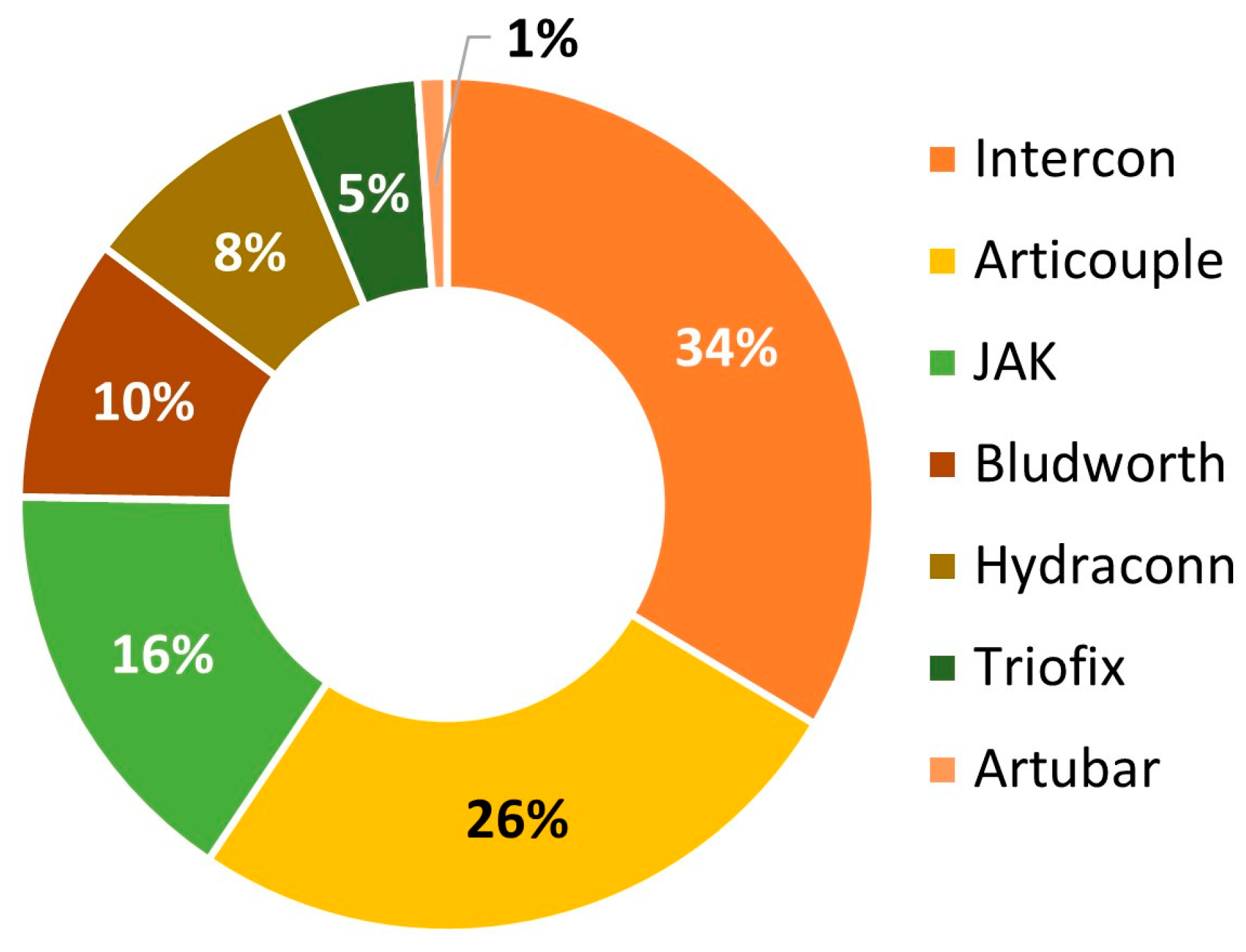

Several factors contributed to the development of the ATB fleet in different geographical areas (

Figure 2). In the United States, the popularity of coastwise trade routes for petroleum products facilitated the rapid adoption of the technology, leading to the development of several coupling systems.

With its unique geography, Japan was also highly conducive to the application of ATB vessels. Its substantial number of islands, long coastline, and rich maritime traditions imposed the development of short-sea shipping, for which the ATB concept was well-suited. These facts motivated the invention of several connection systems, with the Articouple being the most popular.

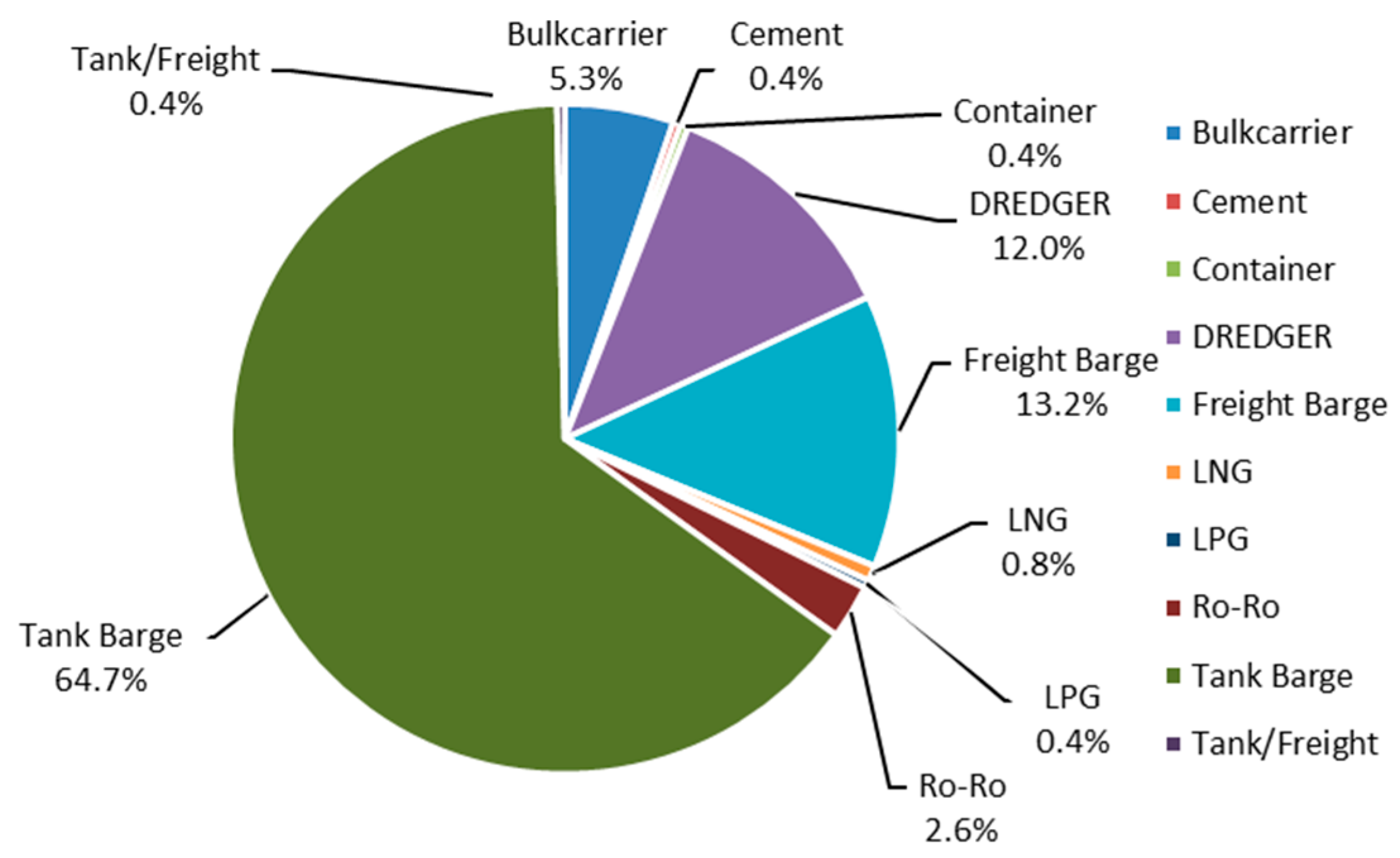

Similarly, the trend that the most common type of cargo transported by sea worldwide is oil and petroleum products also applies to the cargoes transported by ATB units, with tank barges accounting for more than half of the total number of vessels. The next large group of cargo carried by ATBs consists of bulk carriers’ barges with dredging equipment, carrying inert materials in bulk (

Figure 3).

A notable difference is that 90% of the vessels in the USA serve hydrocarbon trades, whereas the other large ATB fleet in Japan consists primarily of dredgers and bulk carriers (

Figure 4).

3. Analysis of the Current State of the Art

When searching for the term “articulated” in the title and refining the search with the term “tug,” the SCOPUS database identifies a total of ten sources, of which only seven are relevant to the topics. The analysis indicates that there are limited publications specifically addressing the characteristics of Articulated Tug–Barge (ATB) systems. However, up-to-date information about ATB transport can be found on various websites.

ATB transport is most utilised for short sea shipping, particularly in shallow waters. Consequently, the impact of water depth on the resistance and manoeuvrability of the tug, barge, and the overall system is a significant area of interest. Zhang et al. [

13] investigated the resistance performance of articulated pusher barge vessels in both deep and shallow waters with depth to draught h/T = 2.0, 1.5, and 1.2 by model tests. In deep water, the total resistance of the barge was greater than that of the articulated pusher barge system. For the barge in shallow water, the resistance increases approximately 0.4 to 0.7 times for a ratio h/T = 2.0 and ranges from 0.7 to 2.3 times at h/T = 1.2. For the pusher, the shallow water resistance increases by approximately 1.0 to 0.4 times at h/T = 2.7 and by 1.7 to 2.4 times at a ratio of 1.6. Concerning the articulated ATB system, the resistance in shallow water increases from a range of 0.2 to 0.3 times at h/T = 2.0 to a range of 1.0 to 3.5 times at h/T = 1.2.

Koh and Yasukawa [

14] studied the manoeuvrability of ATB under three different ratios h/T: deep water (h/T = 19), medium shallow (h/T = 3), and shallow (h/T = 1.5). The results indicated that the system is unstable in shallow water with a negative course stability index (C). In contrast, in medium and deep water, it exhibits small positive course stability indices (0.0299 and 0.0327, respectively), suggesting improved stability but remains relatively easy to deviate from the course under external forces.

A paper [

15] explores the suitability of the fixed trim methodology in comparison to the more realistic free trimming approach in the analysis of stability for tugboats and towboats. The information provided suggests that relying on a fixed trim assumption when conducting stability analysis for tugboats may not yield accurate results. Older tugs are being repowered, modernised, and frequently converted into contemporary ATB units. Since these tugs were not originally designed to meet current stability standards, ensuring compliance can often be a challenge. The requirements of CFR (Code of Federal Regulations) 46, Ch. I, Subchapter S, § 174.145—Intact stability requirements (

https://www.news.uscg.mil/, Accessed on 23 July 2025) permit both approaches.

The use of loading software on commercial ships is a well-established practice, and for certain types of ships, it is mandatory. Convenience and ensuring safe operation can also be realised with ATBs, as shown in [

16].

The most essential quality in shipping is safety for the crew, the environment, and the cargo carried. In the bi-national region of the USA and Canada, a total of 32,779 incidents between 2002 and 2019 were analysed. The findings revealed that tank barges and articulated tug–barge (ATB) units exhibited the lowest hazard probabilities across all types of hazards [

17]. It is of great importance to ensure effective maintenance and safety management of the barge. The lack of both was the reason for the explosion and subsequent fire that occurred on the bow of the barge, killing two crew members on 20 October 2017 [

18]. The explosion was traced back to a buildup of gases that accumulated in an empty compartment, which had leaked from a nearby crude oil cargo tank through a bulkhead. The investigation revealed that there were through-cracks and perforations caused by corrosion in the bulkhead separating the compartments.

The development of ATB transport has experienced peaks and troughs typical of the entire shipbuilding industry. According to a 2007 analysis [

19], ATB construction is on the rise, with 23 new ATBs ordered in the United States alone. It is anticipated that the ATB conversion and construction will continue.

Based on the collected and analysed data on existing ATBs in this study, 167 of them were built after 2000. There are two pronounced peaks in the number of ships built, namely in 2002 and 2009, along with a similarly large number of ships from 2015 to 2018.

In a recently published report, the Articulated Tug Barge market was valued at USD 2.5 billion in 2024 and is projected to grow to USD 4.0 billion by 2033, with a compound annual growth rate (CAGR) of 6.5% expected from 2026 to 2033 [

20].

This trend is supported by several examples from recent years. Since the early 20th century, ATB has been used as a crude oil shuttle [

21]. In 2021, two ATBs for fuel transport to remote regions of western Alaska entered service [

22]. In 2022, a project for two sea-going 700 TEU tug–barge sets for services along the Brazilian coast and on the Amazon River was launched [

23].

To support the goal of achieving carbon neutrality by 2050, research was conducted in Japan on a multiconnected pusher–barge system. This system aims to incorporate the flexibility and economies of scale found in inland convoys into seagoing operations [

24]. Experiments were conducted with one tug and one, two, and three connected barges. The motion and load responses of the P/B system were observed to be proportional to wave height within a specific range, with minimal impact from the connections between vessels. While increasing the number of barges did not significantly affect the motion amplitudes of individual ships, it resulted in increased loads on the foremost coupling device, which necessitates careful consideration for safe operations.

Research conducted in [

12] highlighted that optimising hull design is crucial for enhancing energy efficiency in vessels. The coefficient of viscous resistance is influenced by the hull shape, vessel speed, and water properties, and specific design choices can aid in minimising this resistance. The operational speed range of ATB systems, which is between 9 and 12 knots, is approximately half that of self-propelled ships. This results in lower hydrodynamic resistance and significant fuel economy advantages when transporting equivalent cargo volumes. Findings demonstrate that ATB configurations can reduce fuel consumption by 25% compared to conventional tug–barge operations [

12].

Additionally, optimising bow design presents a significant opportunity to improve operational efficiency. Shipping companies hold varying opinions on the preferred type of bow design: some favour ship-shaped forms for better efficiency, while others prefer spoon-shaped forms for better tracking capabilities. However, bulbous bow designs, when optimised through Computational Fluid Dynamics (CFD) methods, can reduce hull resistance by up to 15% [

12], regardless of load or speed conditions. The operational characteristics of ATBs make these efficiency improvements especially vital since these vessels experience varying load weights and speeds.

Hull coatings and anti-fouling technologies are essential for maintaining energy efficiency in marine operations. When marine growth accumulates on ship hulls, it increases friction resistance and negatively impacts overall hull performance. Research indicates that properly cleaning fouled hulls can improve effective power output by 18–59% [

12]. This highlights the importance of hull coating maintenance and the use of advanced technologies for ATB operations.

The optimisation of propulsion systems is crucial for achieving energy savings. ATBs primarily use diesel engines; however, diesel–electric drives have become increasingly popular because they are well-suited for vessels that operate under varying loads and speeds. These systems enhance efficiency by providing adjustable engine power. The operation of the propulsion engine reaches its peak efficiency at 85% of the Maximum Continuous Rating (MCR), allowing for engine shutdown during periods of low load.

Utilising digital technologies and automation, operational optimisation technologies, such as adaptive autopilot systems that provide a 1% improvement in efficiency and advanced fuel management systems that offer 5–15% fuel savings, represent actionable solutions to enhance the energy efficiency of ATBs.

4. Design Concepts

Articulated Tug Barge systems represent a significant evolution in maritime transport, particularly concerning coastwise trade and specialised cargo movements. They have established a distinct niche by providing a hybrid solution that combines the economic advantages of barge operations with performance characteristics more adequate to those of conventional ships.

In addition to the typical applications of ATBs, a few unique types of barges were launched in 2017 [

25]. In recent years, ATBs have contributed to efforts to reduce greenhouse gas emissions by responding to the growing demand for liquefied natural gas (LNG) bunkering [

26]. Additionally, in 2024, Edison Chouest Offshore introduced two ATB units dedicated to supporting a wind turbine installation vessel [

27].

Kaskin [

7] presented the development of Ocean-Going Tug–Barge (OGTBs) systems in a chronological framework (

Table 1).

The third generation of these systems can be further classified based on the type of linkage used, which can be divided into rigid, mechanically linked (or integrated) systems; semi-rigid, mechanically linked (or articulated) systems; flexibly linked systems; and loosely linked systems.

The tug–barge system offers numerous advantages that warrant exploration compared to conventional modes of transportation. At the same time, it adheres to the general rules for ship design, evaluating specific needs and encompassing factors that pertain to ship hull characteristics (

Table 2). Additionally,

Table 3 summarises the ATB disadvantages from [

12,

28,

29].

The methods for improving design can be divided into three main categories: mathematical programming techniques, stochastic processes, and statistical methods. Mathematical programming is employed to find optimal solutions by creating mathematical models and solving them using specialised algorithms. A stochastic process involves a collection of random variables indexed by a parameter, with each variable representing a different outcome or state of the design that evolves randomly. This approach is vital for modelling the design process, particularly in situations where randomness plays a significant role. Experimental design is a systematic approach that focuses on planning and executing computer experiments. It is crucial for ensuring that results are reliable and valid, especially when paired with statistical methods. This approach emphasises careful data collection to minimise bias and enhance the ability to draw meaningful conclusions. Furthermore, experimental design is essential for analysing the collected data and assessing the significance of the design solution. Some examples of exploring these techniques can be found in [

30,

31,

32].

The optimisation process identifies possible design options, although there is often a trade-off between different objectives, as not all designs work perfectly for each goal [

33]. Pareto optimality [

34] helps manage these trade-offs by identifying solutions where improving one objective does not negatively impact another. The design problem involves making decisions based on various goals, such as cargo capacity and speed, while adhering to specific ship limitations and safety requirements. Factors like ship stability, resistance, and energy efficiency also play a crucial role in determining the final design [

35].

The design is characterised as a multi-criteria decision support issue involving compromises with various goal constraints, considering the owner’s specifications regarding cargo capacity, speed, operational range, regulations, and available information on similar vessels to determine the primary ship dimensions and ship hull form descriptors [

36]. The design aims to meet system constraints related to ship cargo capacity and visibility, and ship operation [

37], equilibrium, initial stability, resistance and propulsion, [

38] ship–propeller–motor compatibility [

39] cargo capacity, freeboard, manoeuvrability [

40] seakeeping [

41], energy efficiency [

42], and ship strength [

43]. Safety limits are established by ports and canals where required, and the block coefficient falls within designated ranges [

44,

45].

The ship design is closely tied to the description of the ship and its voyage. The defined objective functions aim to minimise the required daily cost rate, reduce fuel consumption, and identify the optimal match between ship, propeller, motor, tugboat and barge.

The design process begins by defining the governing parameters for the ship model’s development, which includes implementing several mathematical modules, as well as determining design variables, objective functions, and constraints. The sister ship serves as the foundation for the original hull offset. The hydrostatic and sectional area curves are calculated using a Lackenby [

46] transformation, which modifies the original offset based on the design parameters.

Figure 5 shows an example of a tugboat hull offset that might serve as the basis for the Lackenby conversion.

4.1. Main Dimensions

The contemporary articulated tug–barge is a sophisticated and highly engineered system that maximises efficiency, safety, and weather reliability in challenging maritime environments.

For this study, a database was created to trace the development of the global ATB fleet over the years, gathering information from various internet sources [

2,

3,

4,

47,

48,

49,

50,

51]. Although manufacturers’ websites indicate that 559 units have been fabricated and installed on ships, this study uses data from 267 vessels that additional sources for statistical analysis have corroborated.

ATBs are constructed in a diverse range of sizes to cater to various cargo types and trade routes. The coastwise transportation of petroleum products and chemicals exemplifies this diversity among fleet operators, with articulated tug barges ranging from 100,000-barrel capacity to the larger 750-Series units, which can carry up to 327,000 barrels. Some modern ATBs are designed to transport over 350,000 barrels, rivalling the capacities of medium-range tankers.

The dimensions of these ATBs vary accordingly. For example, a typical barge may have an overall length of approximately 91.44 m, a beam of 24.38 m, and a depth of 5.48 m, paired with a similarly sized tug.

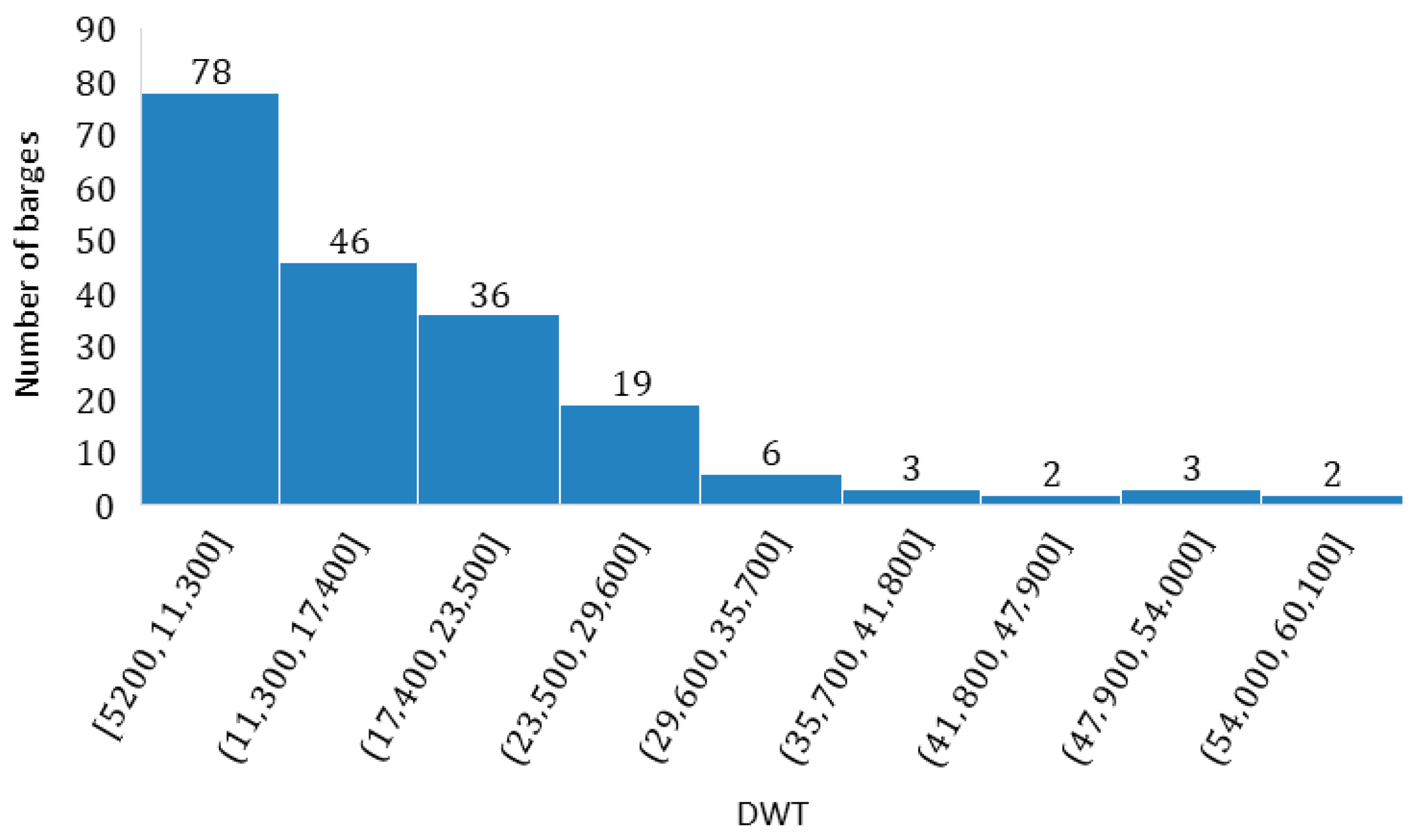

An ATB barge’s average deadweight tonnage (DWT) is approximately 10,000 tons. The highest registered DWT is 58,478 tons, associated with a 350,000-barrel crude oil ATB carrier (

Figure 6).

The trades involving ATBs typically operate at low speeds, ranging from 9 to 13 knots. As a result, the power demand on the tugs is moderate, with an average requirement of approximately 3000 kW.

The most powerful articulated tug barge is 12,000 HP. About 92% of barges are between 105 m and 203 m in length. The average beam of a barge is 23.7 m, and the maximum beam does not exceed 32 m due to the restrictions of the Panama Canal when they were designed.

Recently, the American Bureau of Shipping (ABS) has granted Approval in Principle (AP) [

52]. A new articulated tug barge, classed by ABS, will be utilised for liquefied natural gas (LNG) bunkering. The vessel will be designed to carry 4000 m

3 of LNG [

53].

A statistical analysis using a three-sigma limit has been applied to examine the main dimensional ratio of the collected data for tugboats and barges. According to the empirical rule, this method accounts for 99.7% of the data within three standard deviations of the mean. The three-sigma limits are used to establish the upper and lower control limits, which are recognised here as the minimum and maximum statistical values [

54].

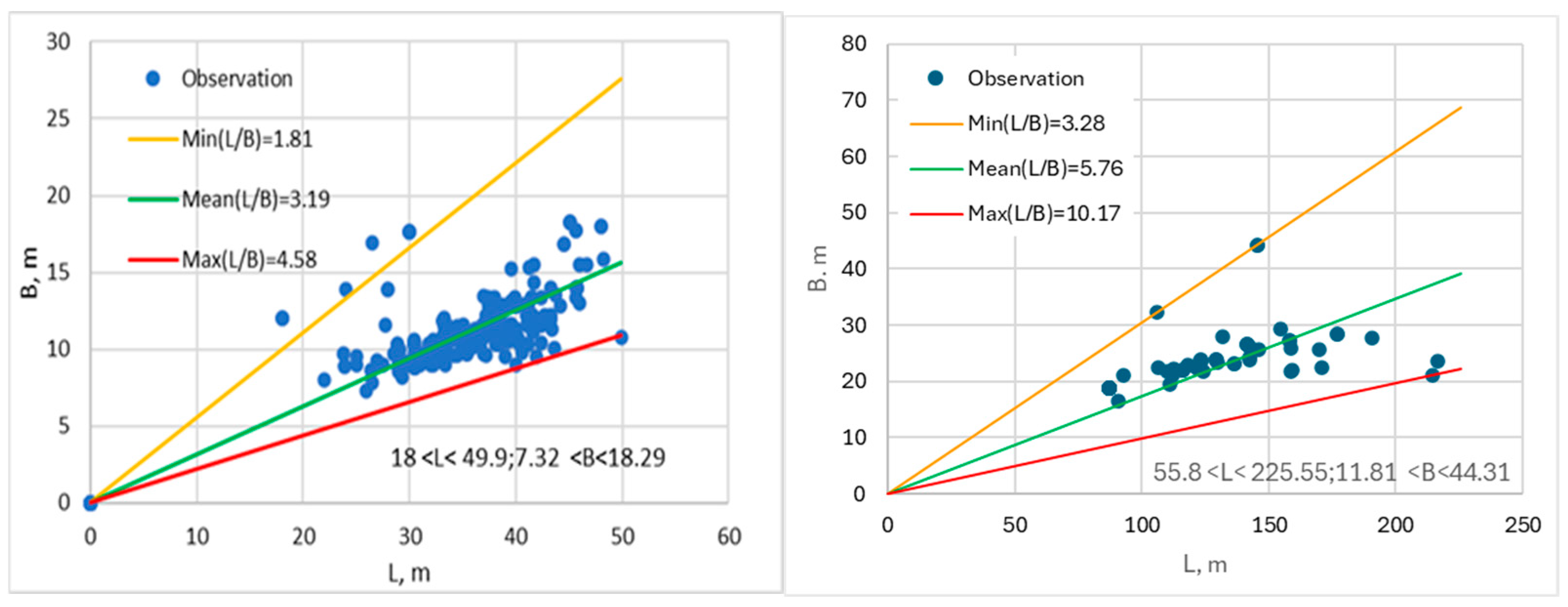

The length (L), breadth (B), and the ratio of length to breadth (L/B) are characteristics that impact the manoeuvrability, stability, and structural weight of vessels. Based on the collected data,

Figure 7 (left) presents the relationship between length and breadth. In this graph, blue dots denote tugboats, as indicated by the data. The straight lines represent the L/B ratio, with the estimated minimum, mean and maximum levels at 1.81, 3.19 and 4.58, respectively.

The length of the vessels ranges from 18 to 50 m, while the breadth varies from 7.32 to 18.29 m. The straight lines in

Figure 7, right, illustrate the L/B ratio for barges, with minimum, mean, and maximum values of 3.28, 5.76, and 10.17, respectively. The length is observed to fall within a range of 55.8 to 225.55 m, and the breadth ranges from 11.88 to 44.31 m. The corresponding regression equation for B as a function of L is also shown.

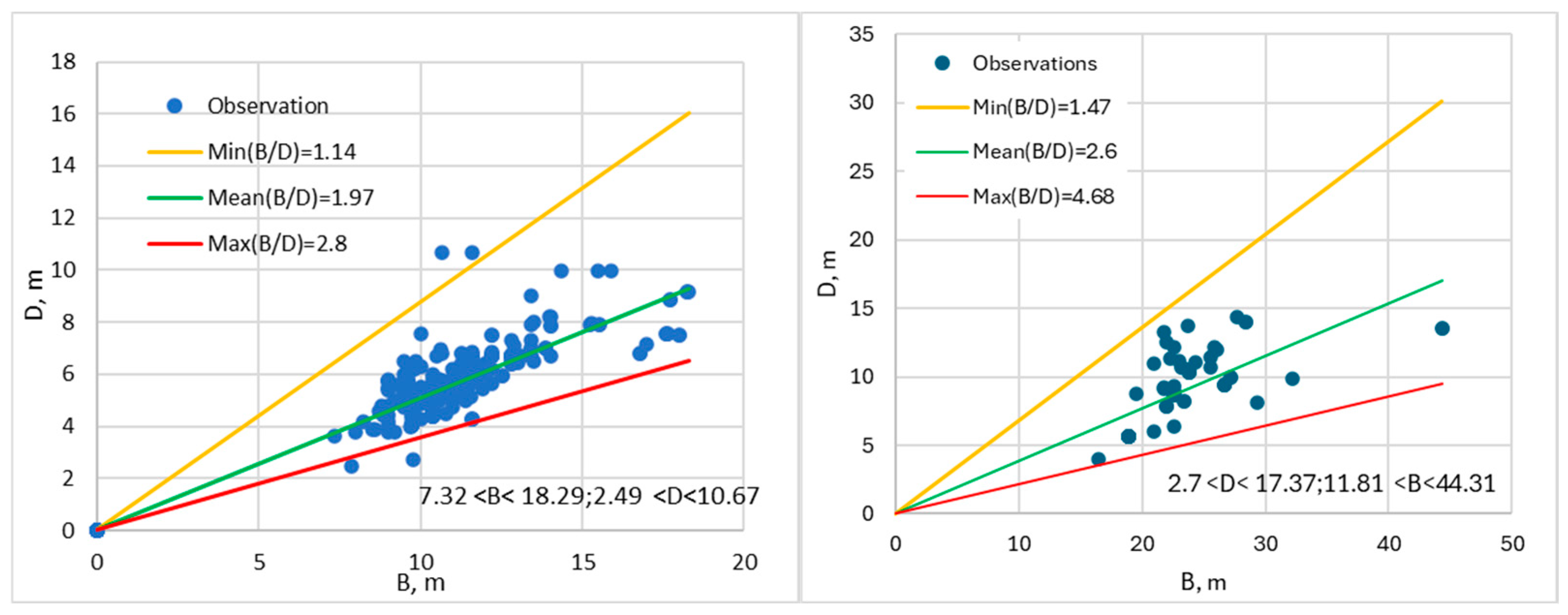

The parameters of breadth (B), depth (D), and the B/D ratio significantly influence the transverse stability of ships. Based on the analysed data,

Figure 8 left presents breadth on the horizontal axis and depth on the vertical axis. The depth values span from 2.49 to 10.67 m, with the B/D ratio having minimum, mean and maximum levels at 1.14, 1.97 and 2.8, respectively.

The right side of

Figure 8 illustrates the breadth (B), depth (D), and B/D ratio for the barges. The depth values range from 2.7 to 17.37 m, while the B/D values are calculated to have minimum, mean, and maximum levels of 1.47, 2.6, and 4.68, respectively.

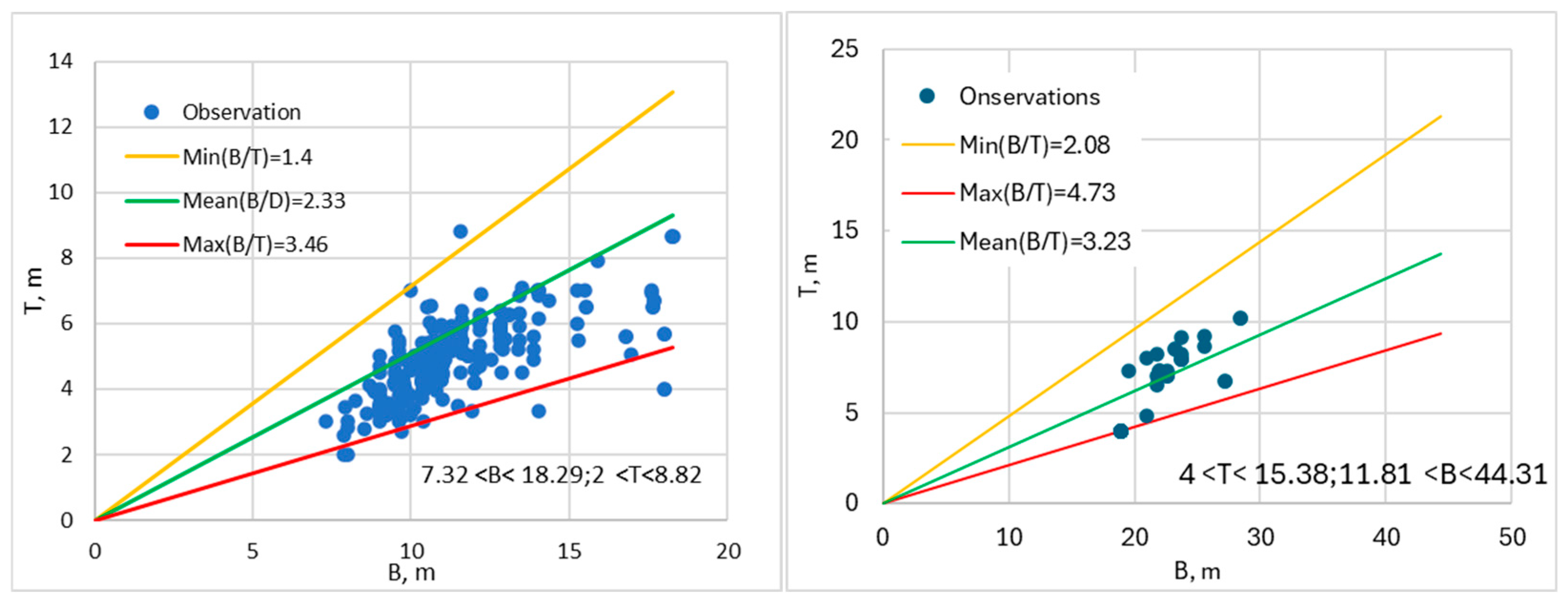

Figure 9 demonstrates the relationship between breadth and draught for both the tugboat (left) and the barge (right). The analysis includes breadth, draught, and geometric characteristics—the draught values of the tugboat range from 2.0 to 8.82 m. The B/T ratio has been estimated to have minimum, mean, and maximum values of 1.4, 2.33, and 3.46, respectively, as shown in

Figure 9 (left).

The breadth, draught and the geometric ratio B/T for the barge are estimated at the minimum, mean and maximum levels at 2.08, 3.23 and 4.73, respectively (see

Figure 9, right).

The difference between draught and depth defines the vessel’s freeboard, a parameter that fundamentally influences static stability.

Figure 10 (left) illustrates the values of D and T for the analysed tugboats. It also shows the estimated minimum, mean and maximum values of the D/T ratios, at 0.58, 0.84 and 0.99, respectively.

Figure 10 (right) shows the values of D and T for the analysed barges—the estimated minimum. The mean and maximum values of D/T ratios are 0.62, 0.75 and 0.92, respectively.

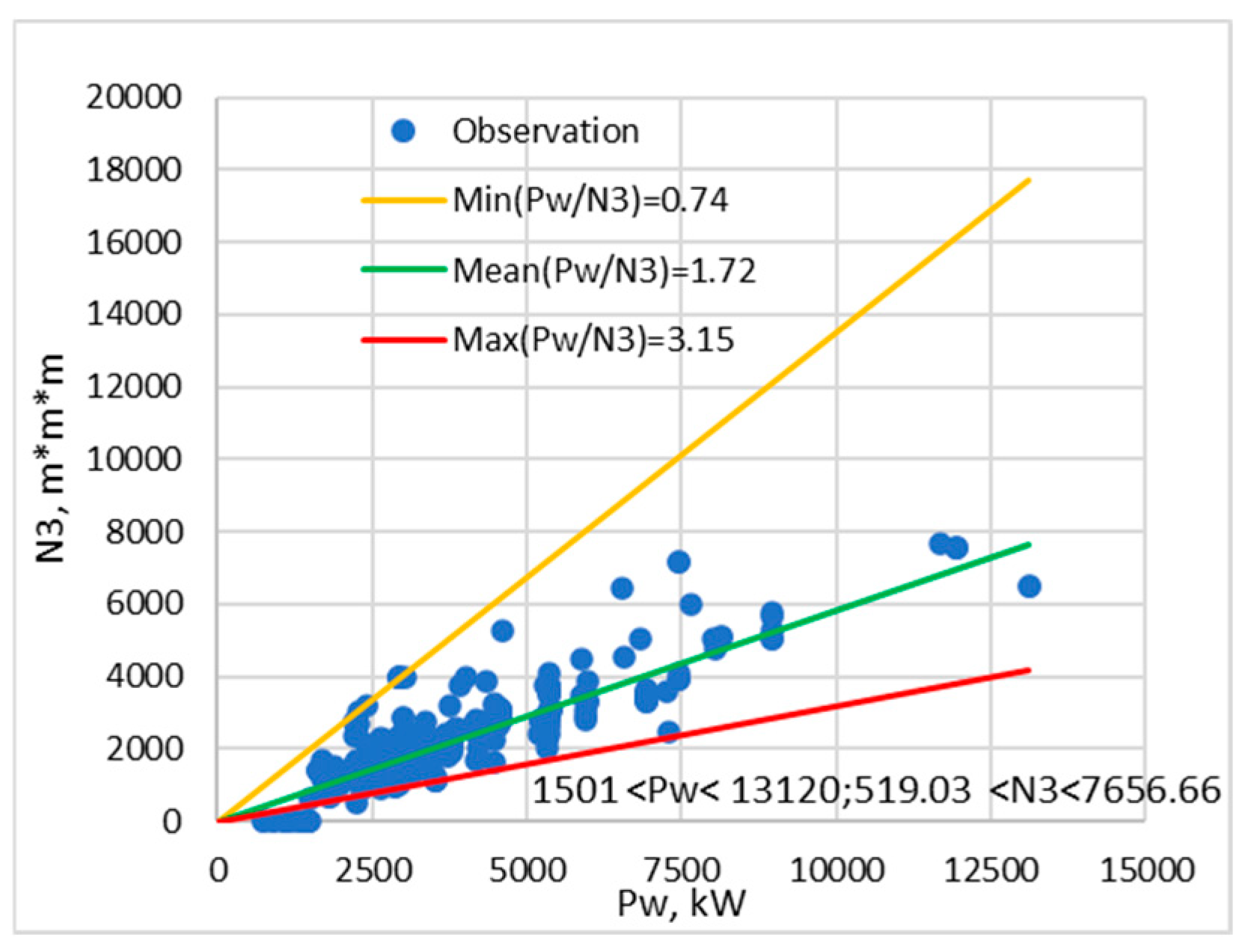

The installed power of tugboats is directly related to the size and weight of the propulsion system. The capacity of a tugboat to accommodate larger engines increases the internal space available, which is calculated by the cubic number formula: N3 = L B D.

The cubic number as a function of the installed power for all analysed tugboats is presented in

Figure 11. The minimum, mean, and maximum levels of the N

3/Power ratios have been calculated as 0.74, 1.72 and 3.15, respectively.

4.2. Design and Articulated Connection

The articulated connection serves as the technological core of the articulated tug–barge system. One widely adopted system is the Intercon system (see

Figure 12), developed by Intercontinental Engineering and Manufacturing Corp [

2], which utilises mechanical screw drives for connection, effectively addressing issues related to differential loading and the draft between the tug and the barge. Another notable system is the Articouple [

3], which often utilises hydraulic rams for extension and has gained international acceptance.

Additionally, the Bludworth flexible push system and the earlier Arturbar [

6] concept were essential players in the market. More recent innovations, such as the Jak [

4] system, continue to advance connection technology. All these systems provide a rigid transverse axis for the connection, enabling precise, ship-like steering and significantly improving seakeeping in challenging conditions.

Articulated tug–barge systems achieve service speeds of 9 to 12 knots. However, some specialised designs, such as Crowley’s 550 and 650 classes [

55], are rated for speeds up to 12 knots. ATBs are used for specific services, such as transporting light products or RoRo/container shipping, and may reach speeds of 13 to 15 knots.

Manoeuvrability is another key advantage of ATBs. The rigid connection between the tug and barge provides steering capabilities comparable to those of a conventional ship, surpassing those of traditional towed barges or older deep notch pushing arrangements. This enhanced manoeuvrability is particularly beneficial in congested waters or when navigating challenging port entrances and bar conditions. Additionally, the sea-keeping ability of ATBs allows them to operate safely and maintain schedules in weather conditions that would sideline towed barges.

The hull designs of the tug and the barge in an ATB system are carefully optimised for pushing mode operations and hydrodynamic efficiency. Barge hulls are designed for speed and seakeeping during movement rather than towing stability, featuring a stern notch precisely engineered to integrate with the tug. Barge bow designs vary, with ship-shaped bows typically favoured for efficiency, although spoon bows may offer better tracking characteristics. The incorporation of bulbous bows on ATB barges can further reduce wave-making resistance.

The stern of the barge features skegs for directional stability, which, although they add some drag, are essential for control. The hull of the tug, particularly its bow, is shaped for optimal water flow when engaged in the barge notch. Most tugs are designed with a twin-propeller configuration, which enhances manoeuvrability by allowing variation in rotational speed and thrust from each propeller. The hydrodynamic interaction between the tug and barge is complex, necessitating extensive computational fluid dynamics (CFD) analysis and model tank testing to refine designs for maximum efficiency and manoeuvrability [

12].

4.3. Propulsion System and Machinery

ATB tugs have high-horsepower propulsion systems to achieve their designed service speeds while pushing large, laden barges. Although diesel engines remain the traditional prime movers, diesel–electric propulsion systems are gaining increasing popularity [

12]. The diesel-electric drive system offers better fuel efficiency for ships operating at varying speeds and loads. This is achieved through engine power matching and cycling, which helps maintain operating engines at their most efficient RPM range.

The selection of propellers is crucial for determining the performance capabilities of ATB vessels. Main engines equipped with Controllable Pitch Propellers (CPPs) can achieve optimal revolutions per minute (RPMs) across a range of vessel speeds, potentially resulting in up to 15% fuel savings [

12]. However, the initial installation and maintenance costs are higher for these systems. Additionally, nozzles or ducted propellers enhance thrust at slower speeds while providing some protection to the propeller; however, this design can create extra drag when operating at higher service speeds.

ATB units are equipped with advanced cargo systems designed for the flexible handling of various liquid and bulk cargoes, including petroleum products and chemicals, while maintaining the integrity of the cargo. A significant operational feature of ATBs is their ability to achieve high cargo transfer rates. The smaller size of an ATB allows it to access harbours and terminals with restricted drafts or manoeuvrability and navigate rivers and inland waterways.

A key operational and economic aspect of ATBs is their smaller manning levels. ATBs operate with crews of only 7 to 12 personnel, compared to conventional tankers of similar cargo capacity, which might require crews of 25 or more. This reduced crew size drives economic benefits but has also raised regulatory discussions and safety considerations, particularly as ATBs’ sizes and cargo volumes have increased.

The effort to improve energy efficiency has led to interest in advanced hull coatings to reduce frictional resistance and waste heat recovery systems (WHRSs) that extract energy from exhaust gases to enhance thermal efficiency, and alternative fuels such as liquefied natural gas (LNG), methanol, ammonia, and hydrogen are actively considered for future maritime applications.

5. Economic Viability

The economic viability of ships, ATB, relies on several factors, such as capital expenditures (CAPEXs), operating expenditures (OPEXs), regulatory environments, and specific trade characteristics. Due to their favourable economic attributes, articulated tug–barge systems have established themselves as a competitive alternative in many markets.

A key consideration in the economic assessment is the initial investment cost. The use of a separate tug and barge unit, along with a specialised connection mechanism, has been regarded as a more cost-effective option compared to building a single, self-propelled ship of equivalent cargo capacity. This cost differential can be attributed to several factors, including the possibility of constructing the tug and barge components in different shipyards, which may offer specialised expertise or more competitive pricing for each element.

The specialised articulated connection system is a significant CAPEX component unique to ATBs. Additionally, as the ATB barge is classified as an uncrewed vessel, it benefits from relaxed safety requirements and firefighting system standards, which positively influence CAPEX. Another cost-saving aspect of the barge is its hull structure’s steel weight, which is designed according to less stringent class rules than standard structural rules for ships.

The separable nature of the tug and barge means they are minor units compared to a conventional ship, allowing them to be built in Tier II and Tier III shipyards. These facilities are more flexible than larger shipyards, resulting in lower costs for new builds and repairs.

Operating costs are another area where ATBs show significant advantages, particularly in high-wage maritime economies.

Manning costs are one of the most significant differentiators in operating expenses (OPEXs). Articulated tug barges operate with much smaller crews, ranging from 7 to 12 personnel, compared to conventional ships of similar cargo capacity, which may require 25 or more crew members. This reduction in crew size is made possible under specific regulatory frameworks. As a result, ATBs benefit from lower wage bills, reduced employee benefits, and lower provisioning costs. However, it is crucial to consider concerns raised by industry [

28] regarding the potential impacts on crew workload, fatigue, and the ability to manage emergencies or perform comprehensive onboard maintenance with smaller crews. These factors could lead to indirect costs and increased operational risks.

ATBs operate at slower service speeds and, as a result, consume less fuel daily for vessel displacement. Although daily fuel consumption may be lower, the longer voyage durations required for the same distance compared to faster vessels could offset some of these fuel savings. Therefore, a critical metric to consider is fuel consumption per ton-mile of cargo transported, which heavily depends on the specific trade route, operational profile, and the efficiencies achieved by the ATB and its conventional counterparts.

Comparing maintenance and repair (M&R) costs is a complex process. ATBs have three units: a powered tug, an unpowered barge, and a mechanical connection system. This separation allows for more flexible maintenance scheduling, potentially improving overall fleet utilisation if a tug can be temporarily paired with another barge. However, the connection system is a unique and critical component requiring specialised maintenance. Some studies suggest that ATBs may have more limited onboard workshop capabilities and rely more on shore-based maintenance crews [

28]. Like new builds, the OPEX for maintenance, repair, and overhaul (MRO) can benefit from separating an ATB into two smaller units, which opens more opportunities for repair yard utilisation and enhances the bargaining power of the shipowner [

56]. In contrast, conventional ships, despite having integrated systems, involve the maintenance of a single, more complex entity, necessitating a repair facility with a larger dry or floating dock.

Insurance premiums vary based on vessel type, age, trading area, and operational history of the shipowner [

56]. Port costs and dues can differ depending on the gross registered tonnage (GRT), vessel length, and specific port tariffs. ATB tugs are often designed to remain under specific gross tonnage (GRT) thresholds, which can lead to advantages in manning requirements or reduced port fees. Additionally, regulatory compliance costs may vary. ATBs might operate under regulatory frameworks identified as less troublesome or costly in specific domestic trade than those applicable to larger international trading ships. This difference can influence administrative overhead and compliance expenditures.

While CAPEX does not differ significantly from what is observed in various types of commercial ships, OPEX should account for the unique characteristics of ATB vessels. The estimation methods to be used will be based on the already established methods for ships, adjusted to the specific conditions of ATB. However, this adjustment was not included in the objectives and will be addressed in a future study.

6. Conclusions and Recommendations

The comprehensive analysis of ATB transport systems reveals numerous benefits when assessing contemporary energy efficiency standards in maritime shipping. This evaluation incorporates historical data, technical advancements, and economic information, along with operational records from various studies, to draw these conclusions.

Maritime transport efficiency has undergone a significant transformation due to the development of ATB technology. The transition from traditional towed barges to articulated systems was driven by operators’ ongoing pursuit of economic efficiency, operational reliability, and safety improvements. A key innovation of articulated connection systems is their ability to allow the tug to pitch independently while maintaining stability against yaw and roll. This advancement has revolutionised tug–barge operations, enabling performance levels comparable to those of conventional ships, but at reduced costs due to the separation of units.

Modern ATB systems showcase substantial enhancements in design and functional capabilities. The development of connection systems has addressed various operational challenges while offering advantages for different vessel sizes and applications. The optimised hull designs of both the tug and barge components, along with their connection mechanisms, have led to significant improvements in hydrodynamic efficiency.

The future research should focus on maximising hydrodynamic efficiency by optimising hull forms and connection systems, as well as developing cost-effective alternative fuel and propulsion solutions for ATB systems. It is crucial to address the technical and regulatory challenges associated with expanding ATB technology to larger vessels and diverse operational needs.

Future development should be concentrated on the following specific areas:

Bulbous bow design optimisation, where further research is needed to investigate bulbous bow designs across multiple load and speed conditions using computational fluid dynamics and machine learning methods to predict operational performance under varying scenarios.

Tug–barge interface hydrodynamics, including more detailed studies, are required to analyse the complex hydrodynamic interactions between the tug and barge. This research aims to reduce drag while maintaining essential steering functions.

Development and testing of hybrid propulsion systems, focusing on ATB operational profiles, utilising diesel-electric drives with battery storage and renewable energy inputs.

Integration of Energy-Saving Devices (ESDs), including adaptation and optimisation of ESDs, such as implementing pre-swirl stators and post-swirl fins, in conjunction with wake-equalising ducts.

Wind-assisted propulsion for ATBs, exploring how to incorporate wind-assisted propulsion systems, including rotor sails, into ATB ship designs while addressing associated operational challenges.

Development of alternative fuel systems, focusing on the handling and utilisation of LNG, ammonia, and hydrogen storage systems, considering the separate components of the tug and barge.

Applying digital optimisation tools, through the development of specialised software systems, is necessary to optimise voyage operations and enhance operational efficiency based on the characteristics of ATB.

Life-Cycle Assessment by evaluating ATBs against traditional ships across different shipping routes and cargo types to provide valuable insights for shipowners, operators, and policymakers.

The Articulated Tug-and-Barge transportation method is an essential and evolving system that enhances maritime shipping economics and efficiency. ATBs combine the economic advantages of tug–barge operations with the performance characteristics of ships, making them an attractive choice for coastal and short-sea shipping considering current economic and environmental demands.

The efficiency of ATB systems will improve further through the integration of advanced hull designs with optimised propulsion systems, energy-efficient power generation, and emerging energy-saving devices. The increasing demand for decarbonisation, alongside the growing availability of alternative fuels, positions ATBs to play a critical role in achieving maritime sustainability goals.

The maritime industry can effectively reduce fuel consumption and operational costs while minimising environmental impact through the expanded adoption of ATBs and continuous system development that meet operational demands for flexibility and reliability.

The contribution of the present study lies in its comprehensive analysis of ATBs and operational benefits, discussing the numerous advantages in terms of energy efficiency, transportation performance, safety, and economic viability. Additionally, the main governing parameters analysed here are to be incorporated as specific constraints for the new design of the tugboat–barge system, where the efficiency is identified, focusing on hull design, propulsion, connection systems, and the impacts of modern technologies. It focused on conceptual design aspects, including main dimensions, articulated connections, propulsion systems, and machinery, concluding with an assessment of economic viability. Special attention is given to defining the main dimensions, as a part of complex design process where the ratios of length to beam (L/B), beam to draft (B/D), beam to depth (B/T), draft to depth (T/D), and power to number of tugs cubed (Pw/N3) are established as design control parameters in the conceptual design. This highlights the novelty of the present study, which represents the novelty of the present work. The design of the tugboat barge system is not part of the present study, and it will be covered as future work.

This study aimed to provide valuable insights into advancements in ATB technology, with a focus on the current worldwide fleet. It also gathers important information from various sources that can be used for the conceptual design of tugboats and barges.

However, a limitation of this study is the scarcity of information available in the open literature. Additionally, because ATBs are designed for short sea shipping, which heavily depends on specific routes for transporting goods, some design solutions are tailored to these unique conditions. Unfortunately, these details are often omitted in existing literature, leading to a relatively high variability in the collected data.