Abstract

Excessive reliance on traditional energy sources such as coal, petroleum, and gas leads to a decrease in natural resources and contributes to global warming. Consequently, the adoption of renewable energy sources in power systems is experiencing swift expansion worldwide, especially in offshore areas. Floating solar photovoltaic (FPV) technology is gaining recognition as an innovative renewable energy option, presenting benefits like minimized land requirements, improved cooling effects, and possible collaborations with hydropower. This study aims to assess the levelized cost of electricity (LCOE) associated with floating solar initiatives in offshore and onshore environments. Furthermore, the LCOE is assessed for initiatives that utilize floating solar PV modules within aquaculture farms, as well as for the integration of various renewable energy sources, including wind, wave, and hydropower. The LCOE for FPV technology exhibits considerable variation, ranging from 28.47 EUR/MWh to 1737 EUR/MWh, depending on the technologies utilized within the farm as well as its geographical setting. The implementation of FPV technology in aquaculture farms revealed a notable increase in the LCOE, ranging from 138.74 EUR/MWh to 2306 EUR/MWh. Implementation involving additional renewable energy sources results in a reduction in the LCOE, ranging from 3.6 EUR/MWh to 315.33 EUR/MWh. The integration of floating photovoltaic (FPV) systems into green hydrogen production represents an emerging direction that is relatively little explored but has high potential in reducing costs. The conversion of this energy into hydrogen involves high final costs, with the LCOH ranging from 1.06 EUR/kg to over 26.79 EUR/kg depending on the complexity of the system.

1. Introduction

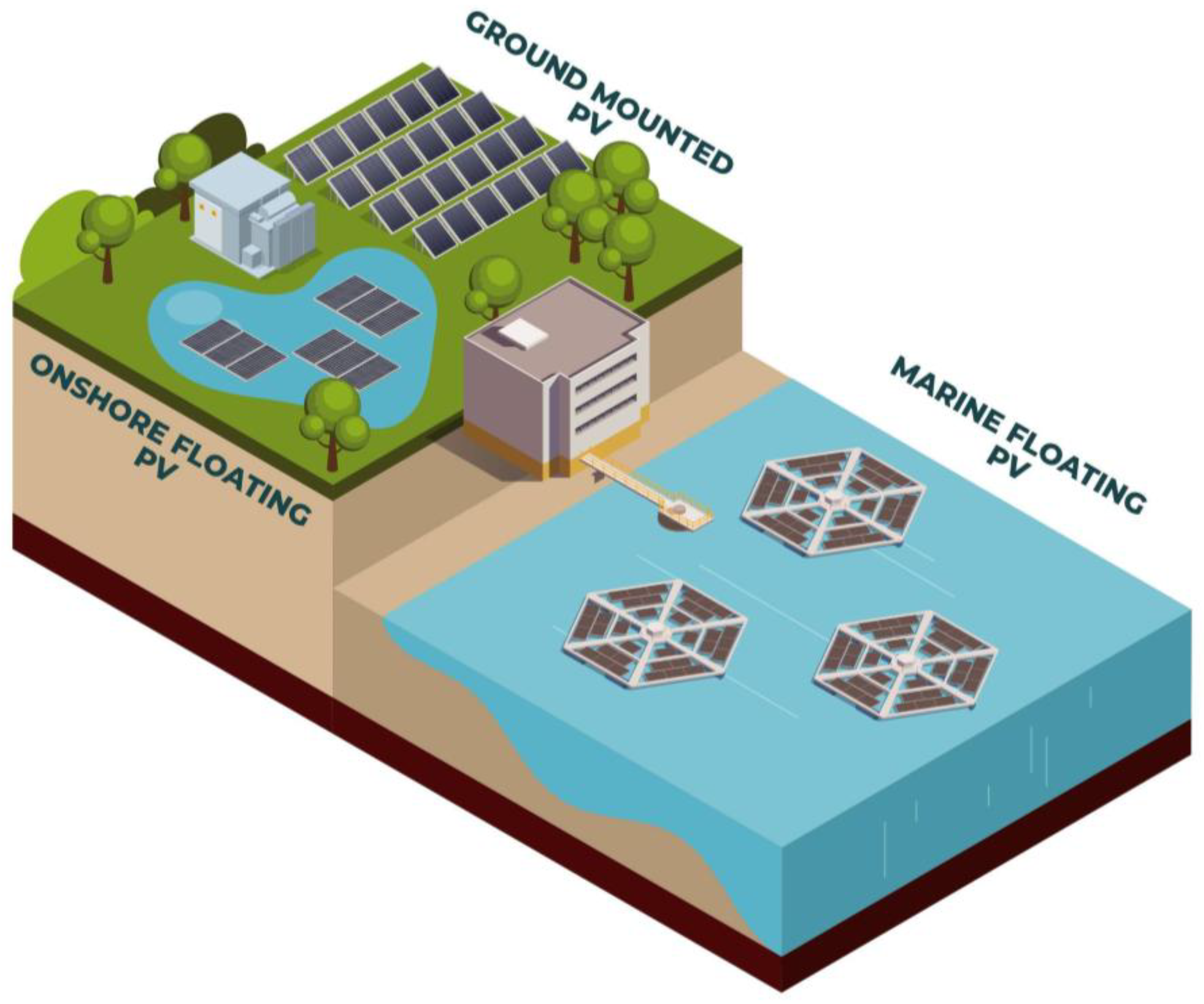

In the renewable energy sector, solar technology can be implemented in two main ways: ground-mounted solar and floating solar systems. While ground-mounted systems (GPV) are located on land surfaces, occupying extensive spaces and being limited by competition for available land, floating solar technology offers an innovative alternative, efficiently exploiting water surfaces and having a minimal impact on the terrestrial landscape [1,2,3,4].

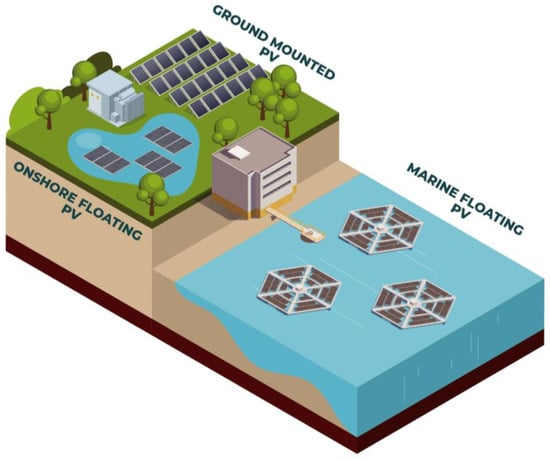

Floating solar photovoltaic systems (FPV) represent an ecological and versatile solution as they are located on water surfaces and have a high potential to exploit available water resources [5,6,7]. FPV technology can be categorized into two broad classes, onshore FPV and marine FPV, each of which is adapted to specific environmental conditions and water body characteristics [8,9].

Onshore FPV systems, also known as inland FPV systems, refer to solar systems set up on bodies of water found in land areas, which can vary from calm waters with little movement to larger inland waters that may have medium waves [10]. Marine FPV systems, on the other hand, are intended for deployment on brackish or salt water and include subcategories such as coastal FPV systems, designed for sheltered waters with waves of up to 2–3 m, and offshore FPV systems, intended for unprotected open waters where conditions are more intense and the waves frequently exceed 2–3 m [11,12]. Figure 1 depicts these two divisions as well as a GPV system.

Figure 1.

Different methods of solar PV module installation (the vectors were taken from [13]).

The distinction between onshore FPV and marine FPV systems emphasizes the flexibility of floating solar technology, allowing design and materials to be adapted to a variety of scenarios and aquatic environments while helping to diversify energy sources and reduce pressure on usable land for energy infrastructure.

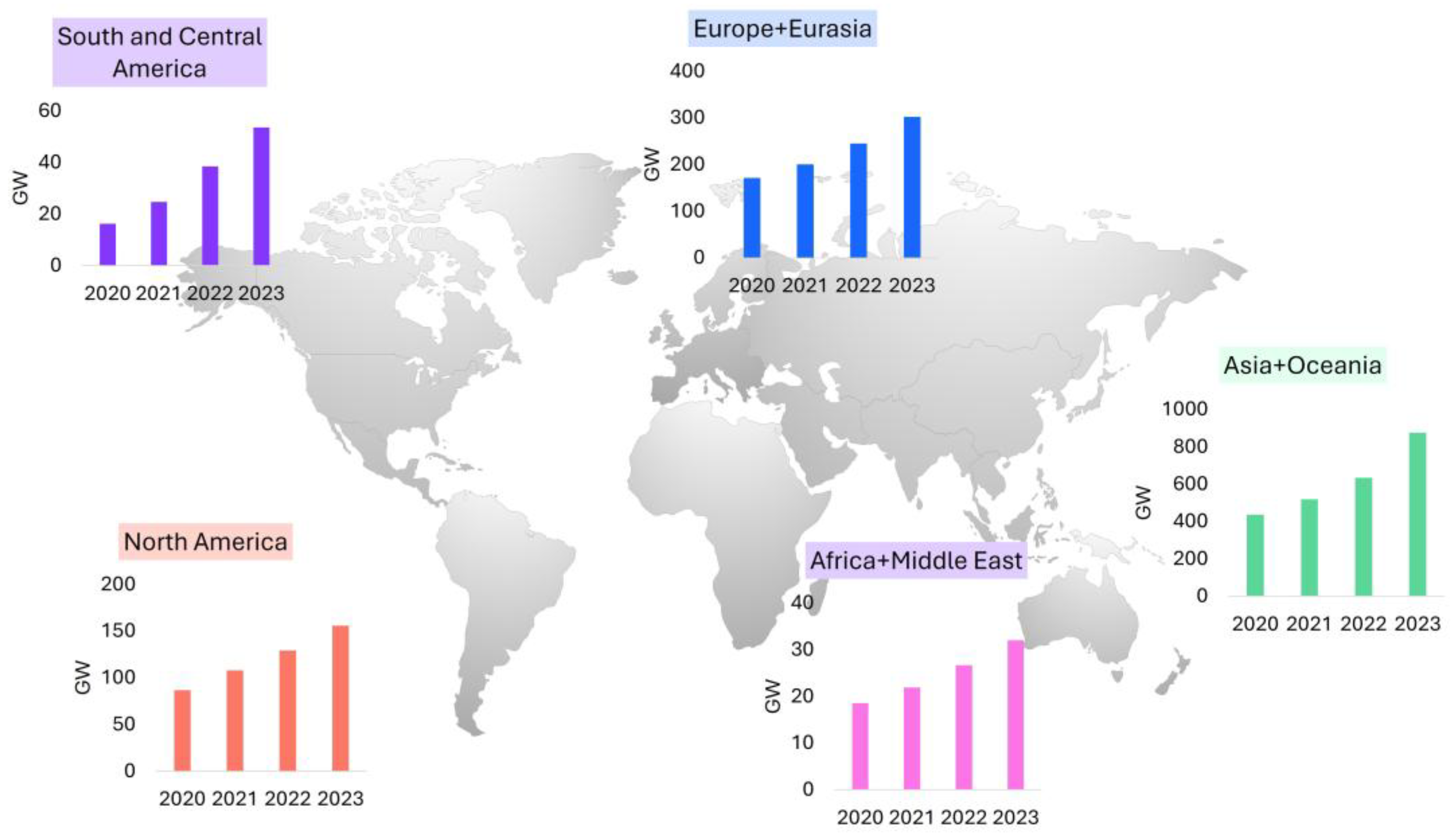

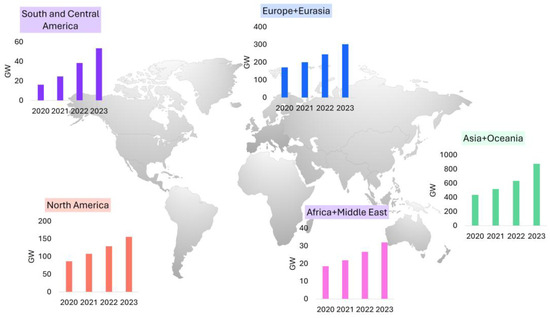

The global PV capacity added approximately 345 GW by the end of 2023, bringing the total installed capacity to approximately 1418 GW. This suggests a market increase of approximately 73% compared to 2022, when nearly 199 GW was installed. The results shown in Figure 2 were produced using statistical data obtained from IRENA, which only included data for the 2020–2023 period [14]. China is the current leader in the global PV market [15], with 610 GW installed, of which 217 GW was installed in 2023. This is due to its dominance in both production and installation. Nevertheless, the market for PV systems is becoming more competitive, which enables them to be deployed independently of subsidy programs. Consequently, an increasing number of countries are installing PV systems on a significant scale. By the end of 2023, experts estimated the FVP market to be 5.9 GW.

Figure 2.

Total installed capacity worldwide designed with information from IRENA [14].

Recently, many countries have adopted floating solar power projects, transforming lakes, reservoirs, and even coastal areas into sources of clean energy. Projects such as the 1 GW FPV facility in the Shandong province of China or the 192 MW FPV in the West Java province of Indonesia are not only impressive technological demonstrations but also concrete steps towards a greener and more efficient energy system. The increase in investment in this technology suggests that, in the future, floating solar power could become a key component of the global transition to sustainability.

1.1. State of the Art

Scientific studies on floating photovoltaic (FPV) systems have recently expanded dramatically due to their complexity and great promise in the worldwide transition to renewable energy sources. The evaluated papers cover a broad spectrum of six main categories: design and engineering, modeling and performance, environmental impact, economic consideration, site selection, and emerging technologies. Each category reflects a vital component of FPV development and application, offering different perspectives on technical, environmental, financial, and social issues.

The design and engineering literature underlines the need to optimize FPV system architecture to fit different hydrodynamic, climatic, and technical environments. We closely investigate the effects of floating forms on stability in nearshore and offshore environments as well as array geometry, module tilt angle, orientation to the sun, and module spacing to minimize shadow [16,17,18,19,20]. Technologies including tracking systems and the use of lightweight, durable materials (such as high-density polyethylene and advanced polymers) are often mentioned to improve resistance to UV rays, corrosion, and forces from waves or winds [21,22,23,24,25,26,27,28,29,30,31]. Particularly in offshore uses, advanced shore-tie and anchoring system structural designs are also being developed to accommodate negative weather and water level fluctuations. Research on hybrid solutions combining FPV with pumped hydropower, aquaculture, or water treatment plants is increasing in parallel since they provide advantages in terms of resource synergy, reduced land footprint, and enhanced efficiency of integrated systems [32,33,34,35,36,37,38,39].

Modeling and performance are still quite vital subjects of research. Using advanced methods such as PVsyst, the annual energy yield of FPV systems is researched while considering the cooling effect of water, heat loss coefficients, shading, material degradation, and system responsiveness under demand. Because of the lower module temperatures, the results show that, depending on the climate zone, FPV systems can offer greater efficiency than ground-mounted or roof-mounted systems [2,18,40,41,42,43,44]. Sophisticated numerical models have been developed to examine the mechanical behavior of platforms under the effect of waves, ice loads, or storms [41,42,43,45,46,47,48,49,50,51,52,53]. These models prevent damage and help to size buildings. The recent integration of artificial intelligence and neural networks has made it possible to forecast energy output in hybrid FPV–green hydrogen or FPV–storage systems. Such technology has made optimized maintenance and predictive control possible [54,55,56].

Research on environmental impact shows the related problems and the ecological benefits of FPV. Among the advantages noted are less water evaporation (especially in arid regions), less algae bloom due to the shade effect, and natural incorporation into the lake or dam scenery. However, many studies highlight potential downsides, such as changed water temperature stratification, less light penetration into the water column, silt accumulation, and possible contamination with materials resulting from module or fixing system breakdown [57,58,59,60,61,62,63,64,65,66]. Compared to terrestrial systems [67], a life cycle assessment (LCA) provides vital information on CO2 emissions throughout the FPV life cycle; in some cases, it also highlights efficient recycling methods for important components such as silicon and rare metals [57,68,69,70,71]. However, the absence of long-term research and standardized ecological evaluation techniques remain two significant obstacles to a thorough understanding of the effect on aquatic ecosystems.

Particularly in hybrid configurations that make use of technological synergies, research on FPV systems’ potential to lower the levelized cost of energy (LCOE) and levelized cost of hydrogen (LCOH) is now underway at the economic consideration level [35,57,69,72,73,74,75,76,77,78,79,80,81]. Many studies show that in places with high energy costs, limited acreage, and easily available water supplies, FPV systems are economically feasible. In addition to payback periods and return on investment, financing schemes such as feed-in tariffs, public subsidies, and power purchase agreements (PPAs) are examined. The research does, however, underline that without strong economic foundations and well-defined policy frameworks, technical results—while encouraging—are insufficient. Regulatory obstacles such as water rights, safety rules, or the absence of standardized administrative procedures may hinder large-scale adoption [82].

The site selection process is improved by using advanced tools like geospatial models (GIS), multi-criteria decision methods (MCDMs and fuzzy logic), and climate data to find the best places for FPV systems [73,77]. Among the considerations are solar radiation, water and air temperatures, water depth and quality, proximity to energy transit facilities, social acceptability, and local legislation. Careful site selection determines the technical, financial, and environmental viability of projects; new studies point to combining strategies including these elements.

Regarding developing technologies, FPV technology is under constant investigation alongside other innovative energy sources. Integration with wave mitigating systems (wave energy converters and floating dikes), energy storage devices (batteries and pumped hydro), or green hydrogen generation (by FPV-powered electrolyzers) generates opportunities for decentralized and resilient energy systems [76,83,84]. Given climate change, recent studies have looked at FPV technology’s resistance to storms, dust, cold, and salinity; the structural design has been changed to resist demanding surroundings [85,86]. Concurrently, efficient operations management increasingly depends on the use of IoT sensors and digital twin applications as automation tools.

Generally speaking, the scientific literature reveals a clear trend of interdependence among the social, environmental, financial, and technological aspects of FPV systems. Combining experimental approaches, numerical modeling, life cycle analysis, and socioeconomic assessments helps studies try to support decisions based on real data. Despite considerable advancements, substantial efforts remain necessary to bridge these gaps through additional research, pilot initiatives, and interdisciplinary collaboration. By grouping the main contributions of the investigated works into topic categories and subcategories, Table 1 logically summarizes the current situation.

Table 1.

Research in the field of FPV technology.

1.2. The Scope, Objectives, and Structure of the Review

Before estimating the costs of a solar farm, it is essential to understand the variables that are involved. Among the primary factors that influence price are the components of the farm itself. In addition to the technical components, the location is of crucial importance. Knowing the location of the farm’s implementation helps in determining its potential efficacy and the suitability of the site for installation. The availability of sunlight, the characteristics of the land, and the proximity to utility connections are all vital variables in this analysis. Furthermore, understanding the current market state is fundamental. Prices for materials, labor, and energy outputs fluctuate, so keeping up with market trends is necessary to make informed decisions.

To address these considerations in a systematic manner, the review is divided into six sections. To begin with, the current market conditions are examined to provide context and insights into the global potential of solar energy, which is presented in Section 2. This gives an overview of location-based performance. Following this, Section 3 presents the primary components of the solar farm. Section 4 delineates the expenses associated with the components enumerated in Section 2, which collectively constitute the capital expenditure (CAPEX), alongside the maintenance costs that comprise the operational expenditure (OPEX). It also includes the LCOE for various global locations pertaining to both onshore and marine FPV systems and a comparative analysis of the LCOE for hybrid FPV technology integration.

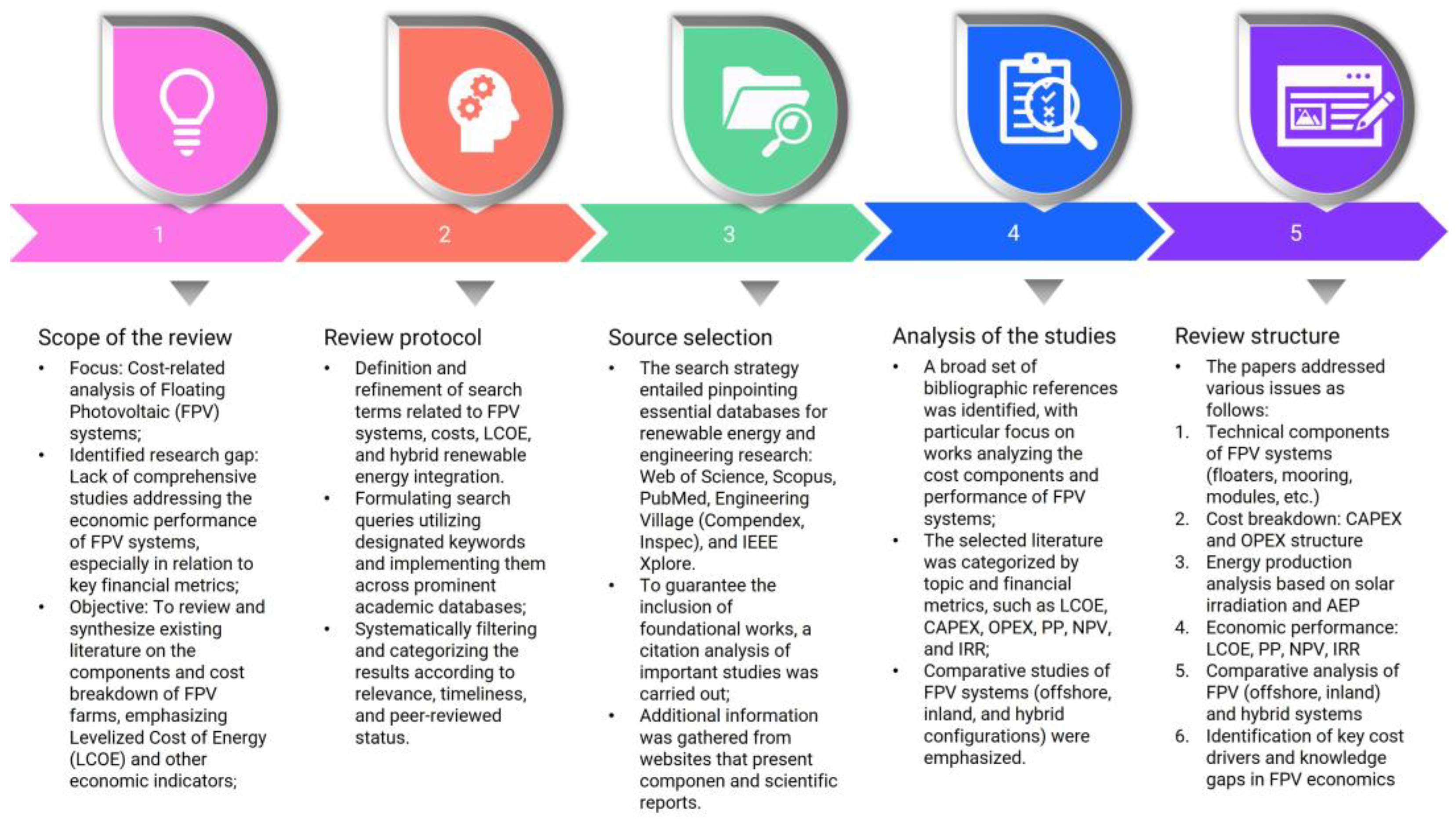

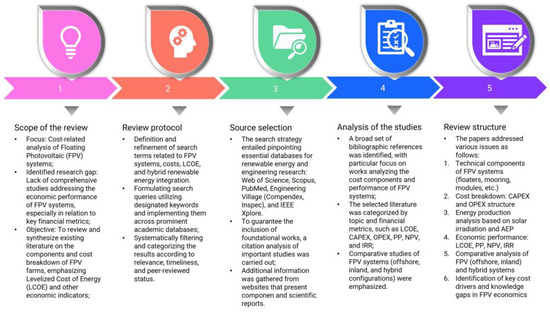

1.3. Search Strategy

The costs and components of FPV were reviewed. Methodical research revealed relevant academic papers. In this step, we learned about FPV architecture, nature, projects, how they integrate renewable energy, and whether other renewable energies can be used together. The search method ensures scientific integrity and relevant research.

For clarity, Figure 3 shows the review article preparation process.

Figure 3.

The structure of the search strategy.

To begin with, keywords such as “offshore floating solar”, “floating photovoltaics”, “FPV”, “cost for floating solar”, “hybrid energies cost”, and “floating solar LCOE”, were used in known databases. FPV systems, key components, cost impacts, and prices were identified. The final cost of various projects, whether standalone or integrated with other renewable energy sources, was estimated. FPV technology integration with other renewable energy sources and aquaculture farms was also considered due to the need to supply farms with energy, which is not always available from the energy grid. The search covered the peer-reviewed literature in many reliable databases such as Web of Science, Scopus, PubMed, Engineering Village (Compendex and Inspec), and IEEE Xplore, including offshore engineering, renewable energy, and marine sciences conference proceedings.

The past decade’s search results only included peer-reviewed English articles. These filters emphasize the current research and scientific rigor in language. Tailored searches yielded FPV technology data like current projects, comprehensive evaluations, and other relevant observations. This method increased tangible data keyword combinations, including project specifics and analytical research. We sought as much information on FPV system costs, functions, the impact of components over costs, and the influence of technological advances on costs.

The second step was to assess citations from relevant papers.

The third step was to evaluate FPV systems’ renewable energy use using the scientific literature and statistical analysis. Active farms, energy efficiency, technology advances, estimated costs for FPV and hybrid projects, and systems which are the most studied were covered.

Finally, scientific reports and component price websites were used to support FPV technology economic analysis.

2. Solar Energy Resources and Their Potential Applications

As mentioned in Section 1, to determine the LCOE, it is necessary to know the potential location for the FPV system to determine whether it could bring a significant contribution to the energy sector or not. Therefore, this section presents a global analysis of the potential of solar energy by referring to two main parameters: solar irradiation and AEP.

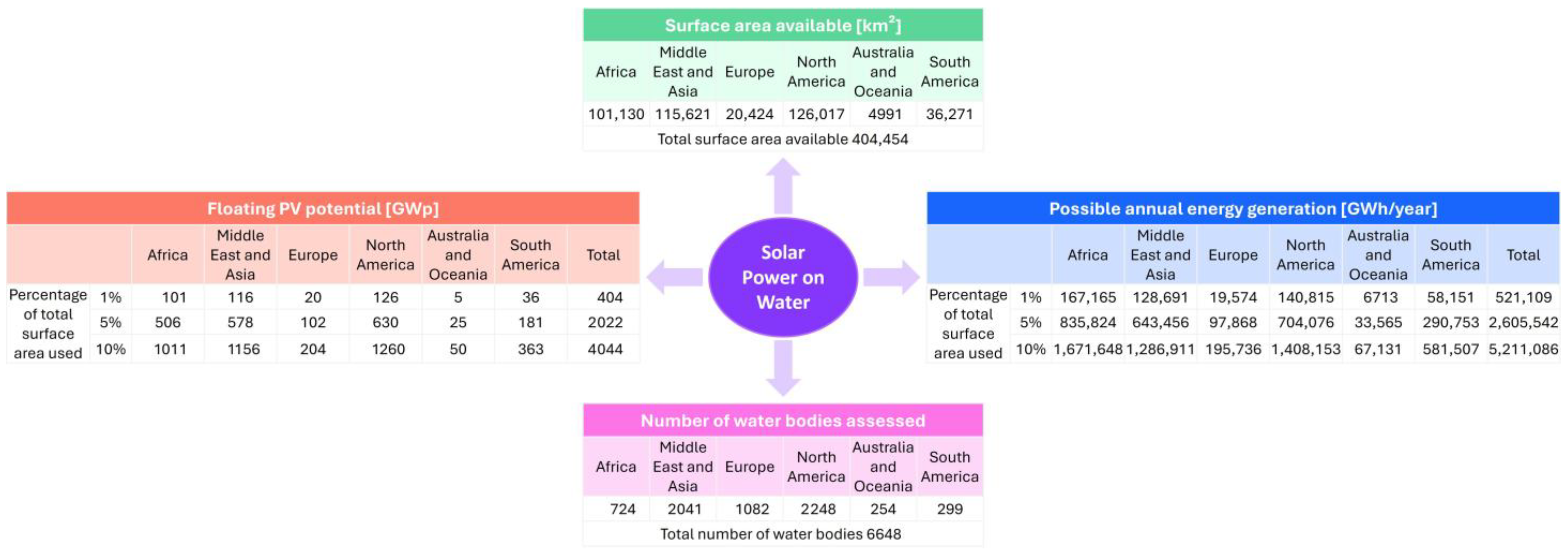

Floating solar installations present a remarkable opportunity to harness the untapped potential of water surfaces for renewable energy. Human-made water reservoirs alone, if partially utilized (just 1% from the total surface available), could generate approximately 404 GW [87], equivalent to 20% of the global solar capacity of 2024 [88]. These initiatives are already in progress in several places, proving their viability while guaranteeing little ecological disturbance through appropriate environmental evaluations. Exploiting even 1% of the surface area of artificial reservoirs may provide roughly 521,106 GWh/year, with potential generation increasing to 5,211,086 GWh/year if the coverage percentage escalates to 10%, as seen in Figure 4. Human-made water reservoir surfaces were extracted from [89] to create the data shown in Figure 4, and irradiation data from the Global Solar Atlas [90] was used to calculate the annual energy generated.

Figure 4.

Peak power from FPV systems placed on human-made freshwater reservoirs globally [91,92,93].

With offshore floating solar systems, the scope greatly expands beyond reservoirs. According to the data obtained from a recent study [94] and a meteorological reanalysis, floating solar farms could generate an estimated 220,000 TWh/year in areas with waves under 4 m and winds under 15 m/s. This would be sufficient to meet the energy needs of 11 billion people. Furthermore, this potential could increase to one million TWh as a result of developments that allow structures to withstand waves as high as six meters, making offshore floating solar a vital component of global renewable energy plans [94].

Some tropical locations, including the Gulf of Guinea and the Indonesian archipelago, are suitable for these systems due to their low wind energy potential, low wave heights, and growing energy demand [95,96,97].

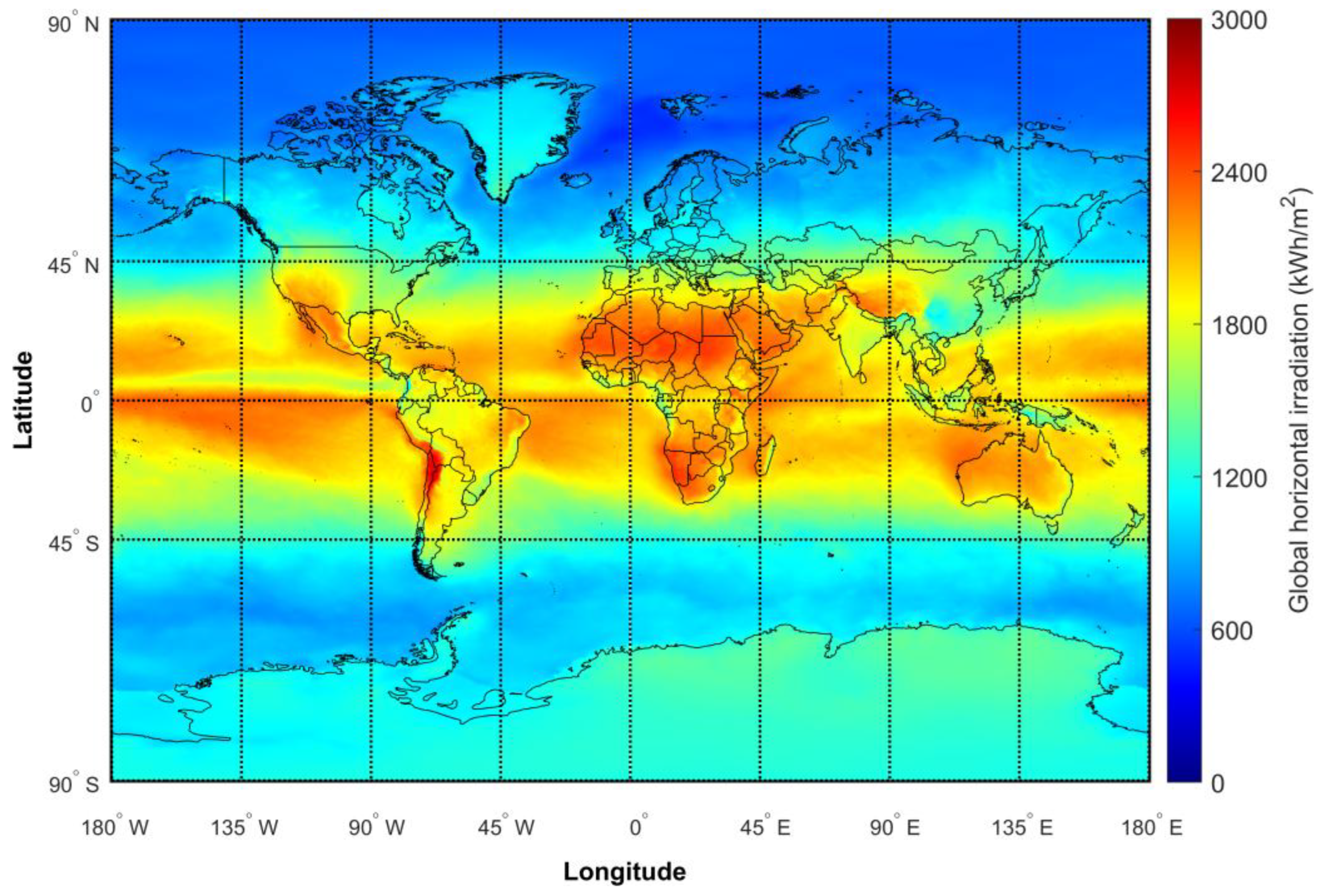

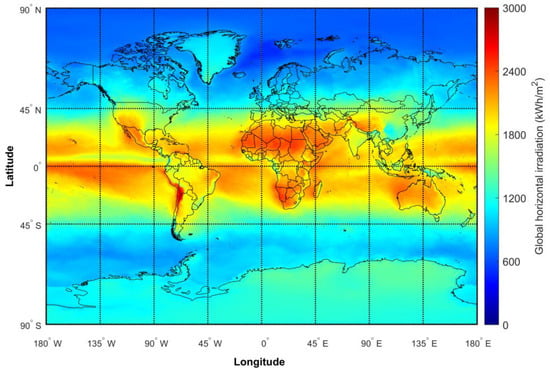

Solar energy potential varies significantly across the globe, influenced by geographical, climatic, and environmental factors. To accurately assess and compare the availability of solar resources in various locations, annual solar irradiation is expressed in a standardized unit—kilowatt-hours per square meter (kWh/m2). By converting all values to this common metric, a clearer understanding of the solar energy landscape emerges, revealing opportunities for renewable energy development in diverse regions worldwide.

One remarkable area of focus lies in lake regions, where solar energy potential is substantial. For instance, Lake Tana in Ethiopia, situated near Bahir Dar in the Amhara region, receives an impressive annual solar irradiation of 2241.1 , emphasizing its strong suitability for renewable energy projects [98]. Similarly, Ethiopia’s Great Ethiopian Renaissance Dam (GERD) benefits from an annual solar irradiation of 2171.75 , reinforcing its role as a cornerstone of the nation’s renewable energy ambitions [99].

In Zambia, the solar potential across key locations is equally significant. Regions such as Kafue Gorge and Itezhi-Tezhi receive approximately 2164.45 , while Kariba North Bank and Mulungushi follow closely with values ranging from 2139.90 to 2153.50 [100]. These values underline Zambia’s abundant solar energy resources, offering substantial opportunities for solar project development to meet the nation’s growing energy needs.

India’s Rajghat Dam in Uttar Pradesh demonstrates a similarly high solar potential, with an annual solar irradiation of 1883.8 [8]. In Turkey, the Demirköprü Dam, located in the Aegean region, achieves a value of 1733.75 , further cementing its viability as a site for renewable energy projects [101]. Brazil’s Balbina Dam also showcases notable solar energy potential with 1795 , while better values are observed in Almeria, Spain, with 1923 , and Barrow Gurney, U.K., which receives only 1083 , reflecting the influence of latitude and local climatic conditions [102].

Offshore regions also offer substantial solar energy potential, often rivaling or exceeding land-based locations. The Indian Exclusive Economic Zone (EEZ) boasts annual solar irradiation values ranging from 1763.95 to 2175.40 , making it a leading global region for offshore solar energy development [103]. The South China Sea demonstrates comparable potential, with annual irradiation levels exceeding 1927.2 , though areas between Taiwan Island and Jiangsu exhibit lower values of 1401.6 to 1489.2 , reflecting regional variations [104].

In the Caspian Sea, solar resources show a clear north-to-south gradient. The southern basin receives the highest annual solar irradiation at 1550 , while the middle and northern basins record 1465 and 1429 , respectively, indicating a gradual decline in solar energy potential moving northward [105]. Similarly, the western part of the Black Sea receives 1390.68 , highlighting moderate solar resources in this area [106].

Other notable offshore regions exhibit diverse solar energy availability. The North Sea demonstrates relatively low annual solar irradiation of 715 , reflecting its high-latitude position and limited sunlight. By contrast, the Gulf of Mexico (GOM) achieves 1756 , while the West Coast of Africa leads with 1865 , showcasing the region’s superior solar energy potential [107]. Along the Brazilian coastline, the northeast coast emerges as a standout solar resource, with values ranging from 2190 to 2628 , surpassing other coastal regions that range between 1314 and 2190 kWh/m2 [4].

This comprehensive analysis reveals the remarkable diversity in solar energy potential across both inland and offshore locations. Regions like the South China Sea, Indian EEZ, and Ethiopia’s lake systems emerge as global leaders, offering extraordinary opportunities for renewable energy projects. In contrast, areas like the North Sea and Barrow Gurney, U.K., illustrate the challenges posed by high latitudes and less favorable climatic conditions.

The findings previously discussed are visually depicted in Figure 5, which displays a global map of solar irradiation for the year 2024, as derived from ERA5 data. Although the values in the figure do not precisely correspond to those in the studies cited, the map emphasizes the same general trends of solar potential across a variety of regions. By offering a distinct visual representation of the global solar radiation distribution, the figure serves to reinforce the solar energy potential identified in the studies, confirming the patterns observed in the previous analyses and providing an additional layer of validation to the results.

Figure 5.

Global solar irradiation distribution map.

In addition to solar irradiation, the average annual yield () is another important parameter in evaluating solar energy potential. It indicates the efficiency of photovoltaic systems in converting solar energy into electricity throughout the year.

A study presented in reference [108] provides a comprehensive analysis of these yields across various offshore locations using hourly solar radiation data from NASA-POWER (2008–2018) and adjusting for offshore ambient and surface water temperatures. An irradiance-dependent temperature correction was used to figure out how well the modules worked. The monocrystalline PV modules had an STC efficiency of 19.35%. For system losses, a fixed loss of 10% was used. These numbers are based on models of floating offshore systems and not direct measurements in the field. According to this study, Puerto La Cruz (Venezuela) and Puerto Colombia (Colombia) exhibit high yields of 1943.69 and 1932.02 , respectively, showing strong solar energy potential. Similarly, Ciudad del Carmen (Mexico) and Tanzania Port (Tanzania) demonstrate yields of approximately 1889 , further highlighting favorable conditions for solar power generation. Other sites such as Port Antonio (Jamaica), Ras Laffan (Qatar), and New Limassol Port (Cyprus) show yields between 1750 and 1818 , suggesting significant opportunities for solar energy development in these regions.

On the other hand, locations like the Port of Rotterdam (Netherlands) and Hengsha Island (China) yield lower values of 1117.90 and 1259.64 , respectively, reflecting more moderate solar potential.

This average annual yield determines the annual energy production (AEP) mentioned in Section 1. This AEP is one of the factors that influence the LCOE, and as noted above, it differs greatly depending on location and, more precisely, on latitude. A study that well illustrates the influence of annual energy production is that in Ref. [102]. In this study, two FPV technologies, C&T with a farm capacity of 319 MW and Solaris Synergy with a farm capacity of 1 MW, were analyzed across three locations, Balbina Dam, Almería, and Barrow Gurney, each with the same CAPEX values—1600 EUR/kW for C&T and 1530 EUR/kW for Solaris Synergy. Despite having identical capital costs, the LCOE varies significantly between sites due to differences in energy yield. For instance, in Almería, where AEP reaches 1739 MWh/MWp for C&T and 1777 MWh/MWp for Solaris Synergy, the LCOE is lowest, at 53.7 EUR/MWh and 50.3 EUR/MWh, respectively. Conversely, in Barrow Gurney, where AEP is substantially lower—969 MWh/MWp for C&T and 984 MWh/MWp for Solaris Synergy—the LCOE rises to 96.2 EUR/MWh and 90.6 EUR/MWh, respectively. A similar trend is observed at Balbina Dam, with an AEP of 1467–1497 MWh/MWp, leading to an LCOE of 67.9 EUR/MWh for C&T and 63.7 EUR/MWh for Solaris Synergy.

3. Components

In FPV projects, the main costs that affect the LCOE are the base structure, electrical systems, anchoring, installation, and regular maintenance, which all depend on the specific environmental and working conditions of offshore locations. For a better understanding of the costs, all prices have been converted into 2025 euros and are presented in Table 2.

Table 2.

Financial overview of key FVP system components.

The substructure, for example, consists of the mast and pontoons that support the solar modules. These floating structures need to be resilient to harsh marine conditions, such as waves and wind. The materials, like high-density polyethylene (HDPE) for floats and structural steel for masts, contribute significantly to the CAPEX. The costs for these materials are variable: the mast is priced between 3.52 and 5.03 EUR/kg, and pontoons range from 3.02 to 4.03 EUR/kg. Alternatively, high-density polyethylene (HDPE) floaters and supports are lightweight and corrosion-resistant, priced at EUR 53.49 and EUR 64.37 per module, respectively. Structural costs vary significantly; while some FPV structures, like Solaris Synergy, cost 0.12 EUR/Wp, others, such as Ciel et Terre, reach 0.23 EUR/Wp. These differences reflect the diverse designs required to adapt to varied aquatic conditions. Furthermore, FPV systems that are composed of steel structures need additional attention since they must be treated against corrosion and are more challenging to transport. Consequently, HDPE structures are the preferred choice.

Currently, in FPV systems, there are both monofacial and bifacial solar modules, but bifacial ones are more recommended due to the significant evolution of solar modules over the years. In terms of costs, it is evident that the two are competitive and priced similarly. The reported price for PV LR5 in 2023 is 0.49 USD/Wp (0.45 EUR/Wp), while the reported price for 2025 is 0.13 EUR/Wp. This decrease in solar module prices is indicative of the maturation of technology. It is also important to mention that some solar module manufacturers have designed certain models specifically for FPV systems. Among them is JA Solar, which has created a selection with powers ranging from 445 W to 620 W. The 565 W module model from PERC and the 720 W module model from Huasun are both module models that have been specifically designed for the FPV technology industry. All of these modules have efficiencies ranging from 21.4 to 23.2 percent.

Essential to FPV technology, tracking systems can optimize energy production; however, farms that use these technologies also have a higher CAPEX. One example of a tracking system is the horizontal single-axis model, which is also the most affordable. In addition to being more difficult to install and more costly than horizontal single-axis systems, vertical ones have additional installation requirements, such as the need to mount the modules at a specific tilt angle and the ability to track the sun’s azimuth angle, which changes throughout the year. Instead, systems with two axes can cost up to 2171.11 EUR/kWp, making them the priciest option. In terms of tracking system maintenance costs, fixed systems are the most cost-effective since they do not use any power and require little to no upkeep. Energy consumption appears during their movement, and they also require regular maintenance, which can significantly drive up the price of OPEX when tracking systems are installed. Expenditure on purchasing tracking systems typically rises by 10% for single-axis systems and 20% for dual-axis systems. However, energy production remains constant despite the price increase.

Our review of the literature on FPV technology led us to the conclusion that tracking systems are useful for higher-tech FPV systems like the HelioSea idea, which has a high CAPEX but can reduce overall expenses. The energy input from less expensive technologies, like conventional pontoons for FPV systems, is insufficient to warrant the implementation of tracking systems as the expenses of capital and maintenance are not justified.

Another important thing to note is the floating tracking system. This time, the tracking system uses bow thrusters. The tracking system is made up of the structure, the anchorage (which is located in the middle of the platform), the solar tracker controller, and four thrusters. We can conclude that this construction is efficient and quite competitive in terms of costs compared with other systems.

For the mooring and anchorage system, which ensures the FPV system remains in place despite wave and wind forces, the installation of tension-leg systems and gravity anchors is essential. Mooring lines cost between 14.40 and 64.79 EUR/m depending on the breaking load, while concrete gravity anchors cost between 36.24 and 52.35 EUR/t. These components are designed to provide the necessary stability for the floating platform in deep water environments, especially given the site-specific conditions, such as water depth, which typically ranges from 30 to 1000 m in the studies researched. While water depth has a negligible impact on the CAPEX, the anchoring lines and the type of anchor are more significantly influenced. Saline environments are also a factor influencing anchoring systems.

Electrical infrastructure, including inter-array cables, export cables, and onshore sub-stations, forms another critical cost category in FPV projects. The inter-array cable, which connects the floating units, has an estimated cost of 362,435 EUR/km, while the export cable that transmits power to shore expenses about 2194.75 EUR/MW/km. The onshore substation, which converts DC to AC power, costs 158,424 EUR/MW, reflecting both the complexity and scale of the electrical setup required.

The distance from the shore influences the costs associated with electrical infrastructure and installation. As the length of export cables and the amount of fuel consumed increase, these costs surpass those associated with mooring and anchoring.

The development and consenting (D&C) phase of a renewable energy project is underestimated but crucial. It transforms theoretical concepts into legally, technically, and socio-politically achievable objectives. The two studies, one on an inland lake PV project in Nigeria and the other on offshore PV development in Northern and Western Europe, reflect differing prices and opinions on “permission to build” in an energy and administrative system.

The Nigerian study puts D&C costs at 973,730 EUR/MW, 12% of project costs. This is a great bargain compared to a 1 MW system. Permits, topographic, engineering, and environmental assessments and project management require time and money in developing countries. A lack of standards, regulatory framework, and automated bureaucratic infrastructure for FPV makes D&C unpredictable and unsafe. The prices reflect objective needs and the extra work needed to handle administrative issues and the lack of a floating solar energy institutional culture. The European analysis estimates D&C costs to be 300,918 EUR/MW. Well-established procedures, transnational legislation, integrated public consultations, and a growing maritime planning framework for European licensing demonstrate efficiency and institutional maturity. However, this framework exhibits rigidity. Europe restricts distances from the beach, biodiversity zones, naval traffic, and compatibility with other maritime uses, unlike Nigeria, which is more flexible but more expensive.

The two studies show different methods of evaluating costs for D&C; the one in Europe focuses on the exploitation of already mature offshore wind farm projects, while in the case of the one in Nigeria, the analysis is conducted based on direct calculations by detailing specific activities and associated local costs. Despite its low percentage value, D&C is crucial strategically. D&Cs that are poorly organized weaken all phases. Despite high costs, this stage does not guarantee investment security.

A close examination of the data reveals significant differences in cost estimates for key components, particularly for mooring systems, where price variations are explained by different technical requirements like the breaking load. The expenses of tracking systems and support structures also differ noticeably, which suggests that different calculation methods were used or that specific project conditions were not considered. These differences underscore the need for a more consistent approach to cost estimation and a thorough assessment of the technical aspects influencing the initial investment and long-term viability.

Refer to the following sections for a thorough understanding of the component technical specifications and cost-influencing factors.

Installation costs are another significant portion of the LCOE for FPV systems. These costs can range from EUR 2 million to EUR 12.08 million per megawatt, depending on the distance from shore, with longer distances naturally leading to higher transportation and installation expenses. The use of jack-up vessels, mooring line installation, and the positioning of electrical components add to this cost.

OPEX is a recurring cost that includes maintenance, cleaning, and inspections, which are generally lower than offshore wind but still essential for ensuring the system’s reliability. OPEX typically ranges from EUR 0.01 to EUR 0.0149 million per megawatt per year, with higher costs incurred for more remote sites due to logistics and access challenges. An important aspect that influences the performance and total costs of photovoltaic farms is the accumulation of dust and biofilms (fouling) on the surface of solar modules. These deposits reduce the light absorption capacity, leading to yield losses depending on the location and environmental conditions, and accelerate mechanical and electrical degradation [124]. In marine environments, fouling is aggravated by colonization with aquatic organisms, such as algae or crustaceans, which not only affect light transmission but can also influence the cooling of components or the mechanical integrity of structures. For example, the weight of bioaccumulations can exceed 2 kg/m2, affecting buoyancy, generating structural stress and requiring specialized maintenance. These problems involve direct costs through frequent cleaning interventions and indirect costs through decreased efficiency and equipment lifespan. All of these are included in the OPEX. To combat these effects, technological solutions such as anti-corrosive materials, antifouling coatings, optimized module tilt angles (≥10°), and automatic or semi-automatic cleaning systems are needed [78].

3.1. Solar Modules

Consider large solar module installations on land or calm sea. The solar plant’s primary converters are PV modules. Each module includes a grid of solar cells that generate power.

Monocrystalline and polycrystalline silicon cells feature tiny semiconductor layers. Solar energy charges silicon electrons, creating a direct current. Monocrystalline silicon cells work effectively in densely packed arrangements due to their highly organized atomic structure, which is important for floating solar farms’ restricted surface area. While polycrystalline cells are cheaper for large-scale land installations, these cells convert solar light into power in tiny places.

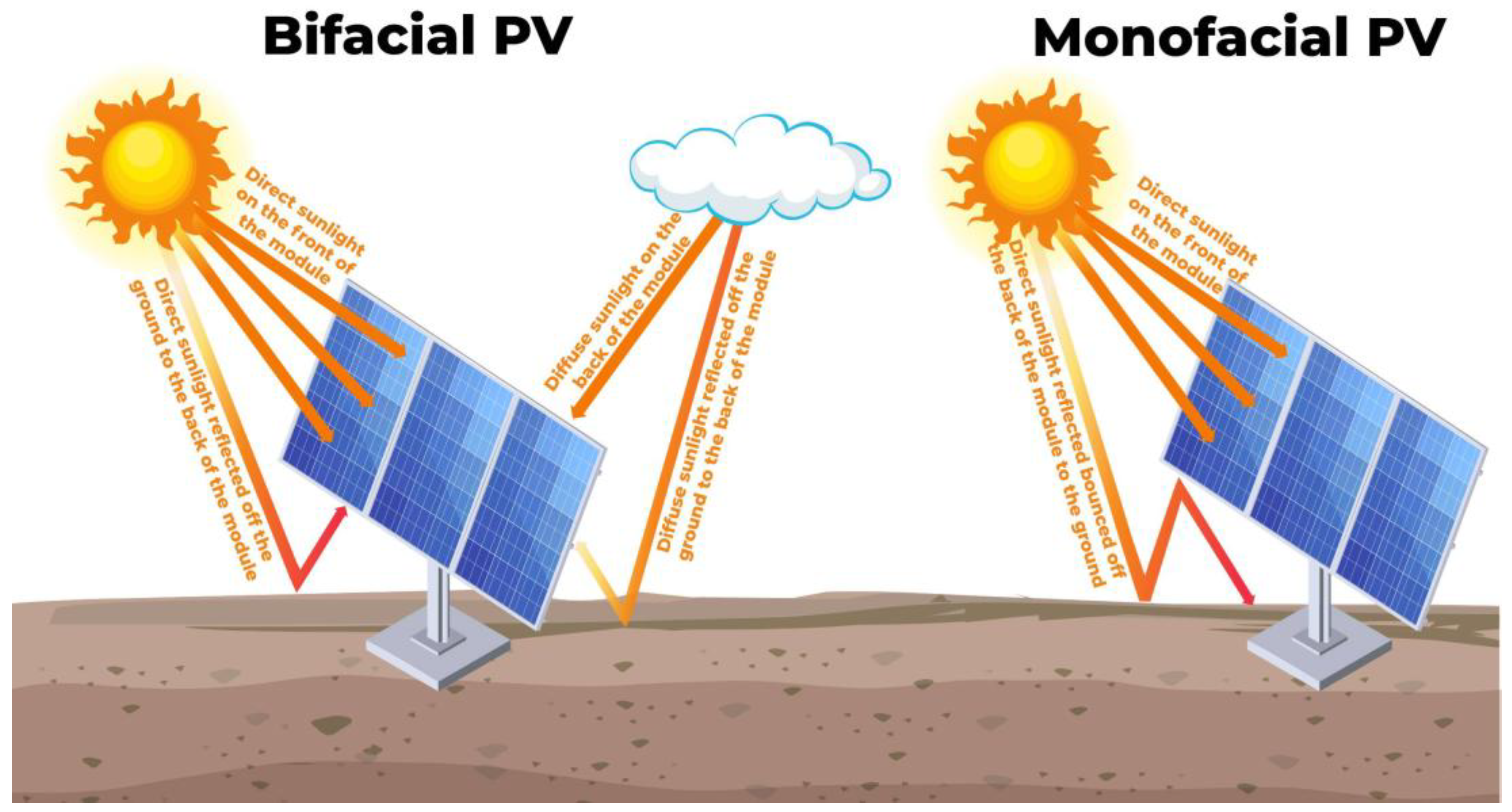

The albedo effect [125,126] generated by sun–water interaction affects floating farm solar modules. This phenomenon helps the water reflect sunlight onto the modules, improving their efficiency. According to experimental data for a 1 MW farm, the albedo impact on water is 0.05–0.07, while on rooftop surfaces, it is more than 0.13 [127]. Experimental data [128] from Yangzhong City, Jiangsu Province, show that the average water surface albedo value is 0.101 (for an FPV of 10 MW). Solar modules lower it to 0.082. For increasing tilt degrees, the albedo impact rises [129], although the sun’s position is the most important factor [130].

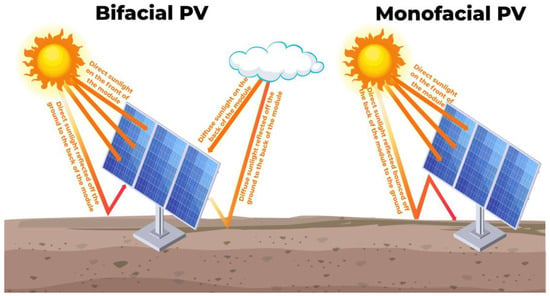

Figure 6 shows monofacial and bifacial solar modules. The monofacial module only gathers solar energy from the front; hence, it only works on the sun-exposed side. In contrast, the bifacial module collects energy reflected from the ground or other surfaces using solar cells on both sides. This makes the bifacial module more efficient. However, bifacial solar modules may use the albedo effect to boost output, as illustrated in [131], which raised production by 12.4%. However, PVsyst simulations may limit the study’s real-world utility. A combination of a hybrid mathematical Perez model and a 2D view factor model effectively represented the albedo effect, but real-life factors such as weather, water clarity, and seasonal changes might affect how well bifacial PV modules work more than the study indicates. Reference [132] compared monofacial and bifacial modules on a white surface. The yield increased by 15–17%, while moss and mold growth caused a 10% drop after one year. Continuing in this vein, the authors of reference [133] assessed the feasibility of situating the bifacial module on CWS and PFS. The research found that the PFS increased energy production by 4.3–4.86% and cooling system performance by 3.19% under different irradiation levels. For floating solar module farms, glass–glass bifacial solar modules are best [134,135]

Figure 6.

The energy capture mode that differentiates bifacial modules from monofacial ones.

Refer to ref. [136] to comprehend all the characteristics stated above. It presents the performance of ten types of monocrystalline and polycrystalline PV modules in an aquatic environment. The research uses weather data to evaluate PV modules by looking at their yearly efficiency, energy density, temperature coefficients, and performance ratio (PR) to see how they work in real-life situations.

The research found that monocrystalline technology outperformed polycrystalline technology in aquatic conditions, particularly for PV modules with advanced technologies. The best monocrystalline PV modules were monocrystalline silicon double-glass double-sided P-type PERC, with an annual performance ratio of 88.95%, a capacity factor of 15.04%, and an annual efficiency of 1339.28 kWh/kWp, 11.26% higher than standard monocrystalline silicon PV modules. At 244.72 kWh/m2, heterojunction with intrinsic thin layer (HIT) technology excels in energy density, making it excellent for restricted aquatic surfaces. Polycrystalline PV modules were functional but had lower yearly efficiency and were more temperature sensitive.

Due to strong solar irradiation, all PV modules perform better in summer, according to a seasonal study. High temperatures impair PV module efficiency, dropping June’s performance ratio to 76.53%. Interestingly, PV modules regained 9% of ambient temperature-induced performance losses during July’s wet periods. Monocrystalline silicon double-glass double-sided P-type PERC technology outperformed nominal power in the winter season because of low temperatures that minimize thermal losses. Advanced monocrystalline PV modules outperform polycrystalline and mono-Si PV modules under these situations.

Heterojunction with intrinsic thin layer (HIT) PV modules have higher energy density, making them ideal for small installations. Monocrystalline silicon double-glass double-sided P-type PERC technology balances efficiency, thermal stability, and cost. The temperature coefficients showed that HIT PV modules had the lowest losses (−0.258%/K) compared to polycrystalline and monocrystalline PV modules, which have a coefficient of −0.41%/K.

The susceptibility to high temperatures and reduced efficiency of typical polycrystalline and monocrystalline PV modules make them less efficient in aquatic situations. Ambient temperature has a greater impact on PV module performance in aquatic situations than water temperature. GDPPEmono-Si and HIT are also more thermally stable, making them better for summer heat.

3.2. Floating Structures

Any FPV system relies on its floating structure. FPV systems differ from GPVs in this way. The floating framework is made of buoyant units made of strong, lightweight materials to support solar modules on water.

Fiber-reinforced plastic (FRP), high-density polyethylene (HDPE), medium-density polyethylene (MDPE), or ferrocement are used for making floating constructions. These materials are chosen for their ability to withstand harsh sunlight and various water conditions. The installation location, environmental impact, cost, and maintenance affect material and design choices.

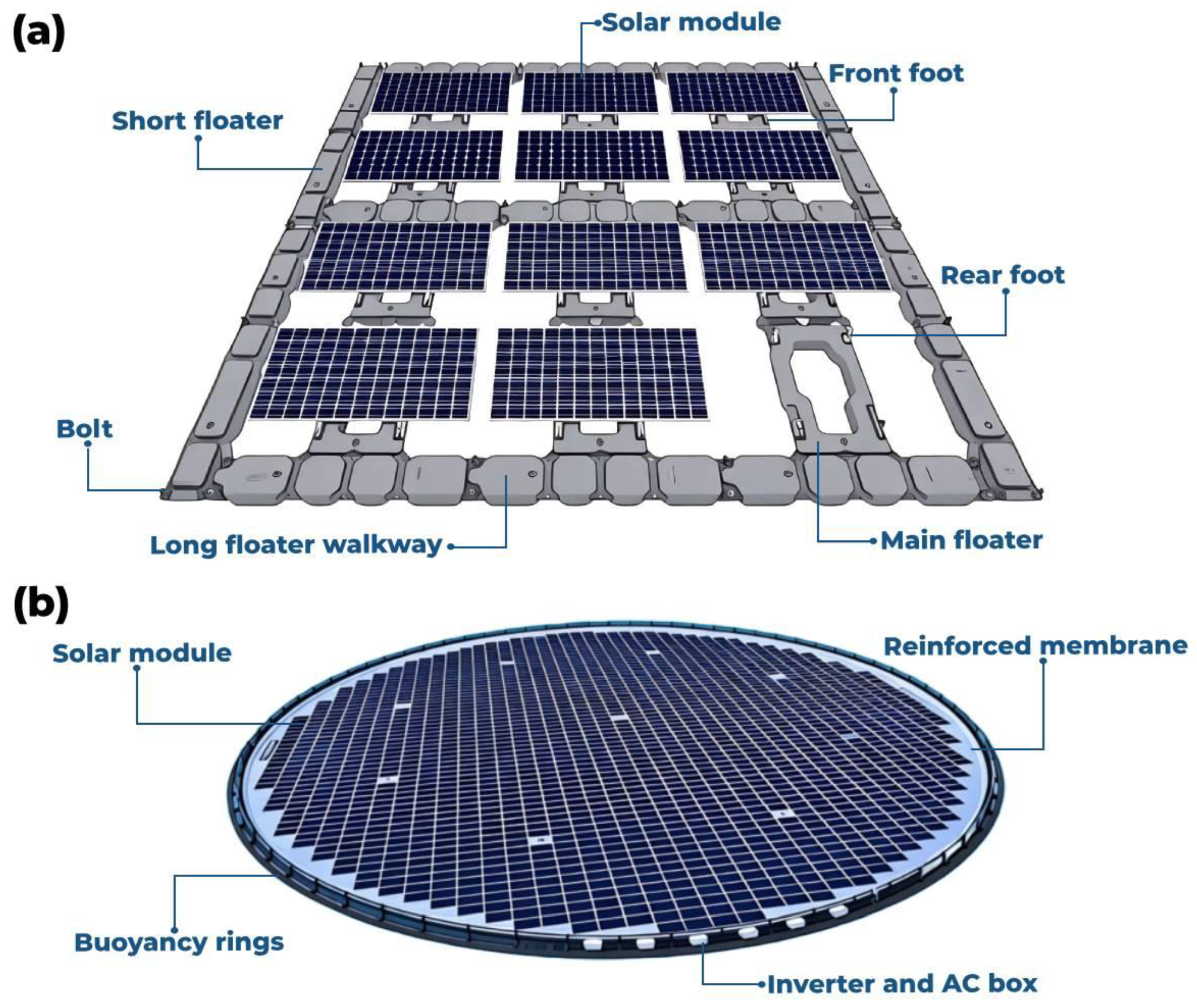

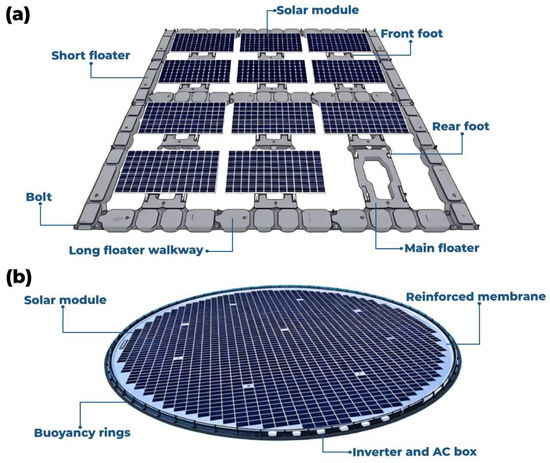

In general, FPV constructions fall into two categories [137]:

- Pontoon-type structures (Figure 7a) provide dependable support for solar modules on a floating platform. Pontoons fall into three categories based on their design and construction [92,138,139]:

Figure 7. Classification of FPV systems. (a) Pontoon-type structures (based on SOEASY). (b) Superficial structures (based on Ocean Sun AS).

Figure 7. Classification of FPV systems. (a) Pontoon-type structures (based on SOEASY). (b) Superficial structures (based on Ocean Sun AS).

Class 1 has a simple construction procedure and uses HDPE rafts as floating devices with steel, aluminum, or reinforced polymer (FRP) frames [137]. These buoyant surfaces are suitable for moderate conditions but may struggle with larger waves [140]. This category includes projects located at Hapcheon Dam [141], Buksin Bay [140], and Dangjin City [142], all situated in Korea.

Class 2 integrates the solar modules directly into the floating structure, thus eliminating the need for additional frames [143]. While these alternatives present an economical choice [144], they often lack customization options and might be more prone to deterioration in humid or windy environments as they are more suited for freshwater [145]. These types of structures are found in projects such as those by Ciel and Terre’s, France [146], Kalpong Hydroelectric Project Dam, North Andaman, and Cecep [147], located in Zhuxianzhuang, China [148].

Class 3 structures were carefully designed to improve prior models [139]. They have larger, robust designs that include a bigger space for walkways and electrical components. Though more expensive, they provide more stability and versatility [144]. Class 3 technologies are found in FPV systems, such as the 500 kW FPV plant at Wayanad in Kerala, India [149], or those built by BayWa r.e. in the Netherlands [150].

- Superficial structures (Figure 7b): These partly submerged systems use water’s cooling properties to keep modules cold. Lowering module temperatures improves efficiency and protects against wind and wave damage [151,152]. Two types of superficial structures exist [153]:

Reservoirs may employ rigid systems since they can handle moderate wave conditions and shallow water [46,154].

Flexible systems use lightweight, adjustable materials like foam-supported PV modules for easy installation and maintenance [155]. The process of water immersion provides cooling advantages and helps to minimize module degradation as time progresses [30,156,157].

3.3. Anchoring and Mooring System

A mooring system connects the floating solar platform to a seabed, coastline, or both anchor points. The plant’s location, water depth, soil type, and environmental conditions like wind and wave activity affect its configuration [158,159,160,161].

Steel chains, cable ropes, and synthetic ropes are used to build mooring lines [162]. Elastic rubber ropes are used to provide flexibility in places with fluctuating water levels or strong currents [163].

FSPV systems use several mooring mechanisms to meet their demands [85,144]: Massive chains or cables bend and hold the structure in catenary mooring. This technology is flexible to water level fluctuations, but its cable length renders it ineffective in deep oceans. Floats and weights improve the catenary system’s mooring line arrangement in compliant mooring. Stability and tension control minimize waves and currents for renewable energy projects. Taut mooring uses buoyancy to hold lines. This architecture reduces vertical and water level changes. Elastic or adjustable-length systems like Seaflex can manage high anchoring component stress. Rigid mooring limits horizontal displacement and allows vertical movement using a seabed-anchored structural part. This is stable in shallow waters but costly in deep oceans [164,165].

Marine installations utilize drag anchors, embedded anchors, or suction foundations, whereas dead weights or helical anchors are used in freshwater. Mooring system selection depends on the water depth, hydrodynamics, seabed characteristics, and cost.

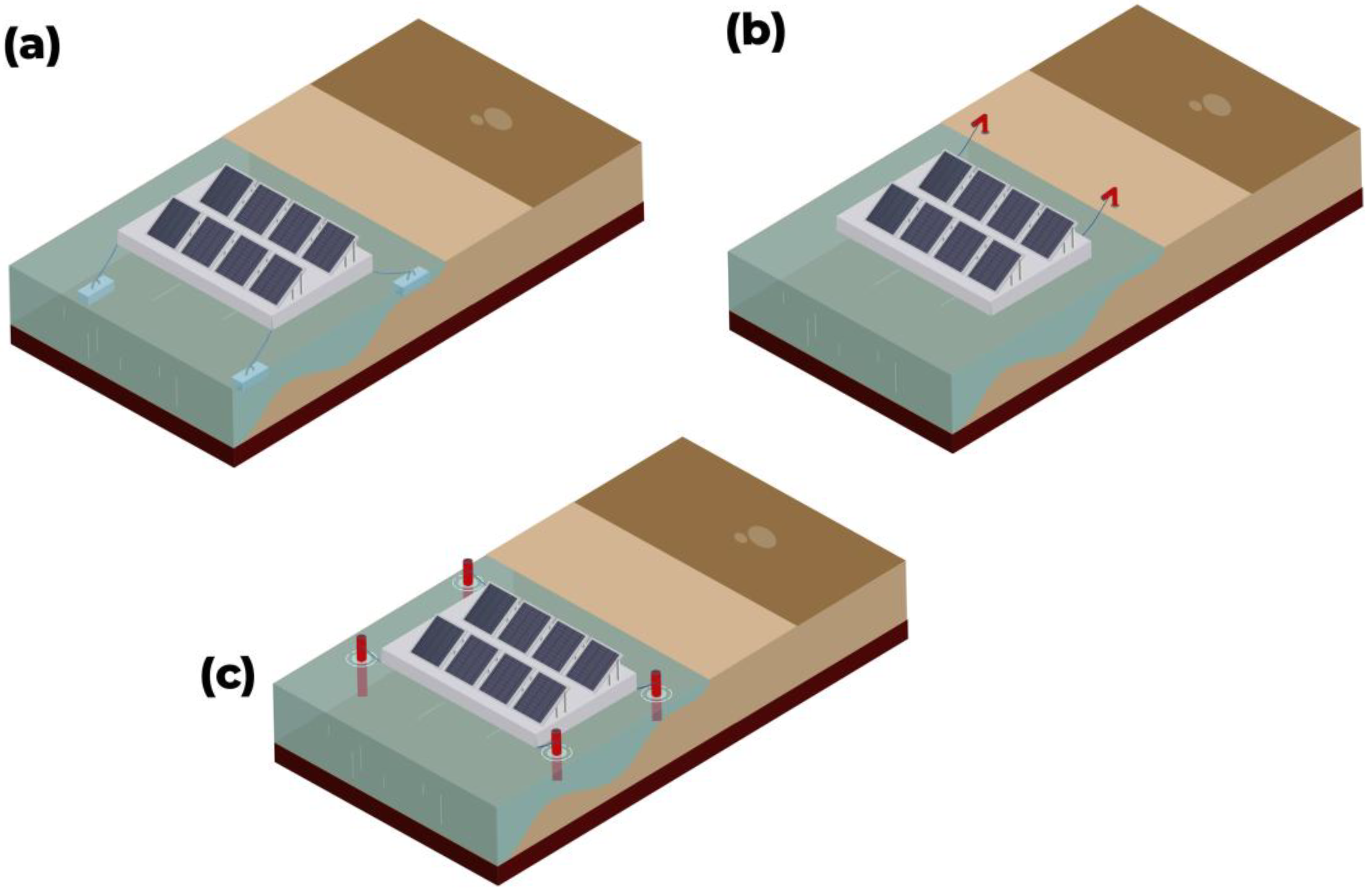

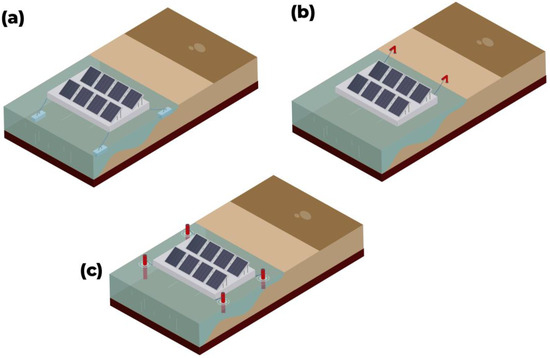

The platform is anchored depending on the water body and topography. Figure 8 depicts three anchoring methods. As seen, bank anchoring secures the system to the shore. Small, shallow water bodies along the bank are ideal. This strategy is cost-effective. Bottom anchoring secures the platform to the seabed. It is well-suited for freshwater environments with consistent soil conditions. It offers robust support and mitigates the pressure on the framework. Despite the higher cost, the durability is significantly improved [144].

Figure 8.

An overview of the anchoring methods for FPV systems: (a) bank anchoring; (b) bottom anchoring; and (c) piling anchoring.

3.4. Inverters

Every solar power system involves a technological conversion process to provide usable energy. PV modules produce DC electricity, while inverters continuously convert this energy into alternating current (AC), which is the type of electricity utilized by homes, businesses, and the power grid. Within these power stations, central inverters operate, converting energy from numerous solar modules and directing it into the grid. In floating systems, the balance between efficiency and redundancy is critical. String inverters and microinverters, which are smaller in size, manage energy across distributed PV modules [166,167]. The decentralization of energy conversion provides a significant benefit in water-based installations: if one part of the array fails, the whole system remains operational. Energy keeps flowing from the surrounding modules managed by the microinverter.

3.5. Grid Connection and Storage

These farms can manage their generated energy in various ways to ensure a dependable energy supply. Direct connection to the grid is a cost-effective and straightforward method for sending energy for instant consumption without storage systems. This method is best suited for areas with consistent use, allowing for synchronization between energy output and usage. However, weather conditions and diurnal cycles may cause output variation, requiring an energy storage system. In the context of FPV systems integrated into shrimp farming [119], the on-grid connection helps the farm manage solar energy production fluctuations by balancing excess production and shortfalls with the public grid, reducing the need for extensive storage. Off-grid energy autonomy allows shrimp farms to fulfill up to 40% of their energy demand from renewable sources and reduces dependency on expensive grid expansion in remote regions according to this research. We found that on-grid floating PV technology provides economic and energy stability advantages in grid-connected regions.

Due to their high energy density and long lifetime, floating farms use batteries to store energy during peak demand periods. Nickel–cadmium (durable but self-discharges), lithium-ion (high energy density, long lifetime, and minimal self-discharge), and lead–acid are common types of batteries [168]. Flow batteries, suitable for large farms, have a high storage capacity and many charge–discharge cycles, making them stable and efficient in long-term applications, but they demand more space. Vanadium-based (VRB) and zinc–bromine flow batteries are common. Zinc–bromine systems reach 1.7 V, whereas vanadium batteries reach 1.6 V [169]. These durable systems may be fully discharged repeatedly without deterioration and have little self-discharge [168].

A unique long-term storage method uses energy to generate green hydrogen by electrolysis and stores it for power production or industrial applications. If solar farms are near a water source and topography allows, hydroelectric pumps may use extra energy to lift water into a reservoir and release it to produce electricity during peak demand.

Another effective large-scale storage method is compressed air energy storage (CAES), which utilizes excess energy to compress air in subterranean caves or specialized tanks. Compressed air is released when power is needed, quickly expanding and activating turbines. Although it requires specific locations for the storage of compressed air, CAES is a reliable long-term storage option that is suitable for large solar farms.

Supercapacitors are efficient in mitigating fluctuations and stabilizing the network for short-term energy storage and discharge. FPV farms must have a range of energy storage and management methods to meet demand and maintain grid stability, maximizing solar resource use regardless of the position on internal or outside waterways.

4. Economic Indicators for Solar or Hybrid Energy Projects

The LCOE for FPV systems, particularly offshore, is a crucial metric for evaluating their economic viability compared to GPV farms and other renewable energy technologies. The LCOE provides a standardized way to express the average cost of producing electricity from a particular technology, factoring in both the CAPEX and OPEX over the project’s lifespan. While GPV has a more established cost structure due to its maturity, floating offshore solar is still a developing technology, meaning there is greater variability in cost estimates. Floating solar, however, holds significant promise due to its potential to exploit underused water surfaces, particularly in coastal or offshore areas where land availability is constrained.

Assessing the economic viability of offshore FPV systems is essential for potential extensive maritime implementations. The LCOE is the principal measure for this purpose [170,171,172,173]. The LCOE is defined as the ratio of overall project costs during its lifespan to the energy generated, so it indicates the cost of generating one unit of energy averaged across the project’s duration. The LCOE is essential for assessing the economic feasibility of various renewable technologies from different domains [122,174,175,176]. The LCOE can be expressed as follows [177]:

where CAPEX represents the capital expenditure [81,102], OPEX is the operational expenditure [178], AEP is the annual energy production, T is the life of the project, and r is the discount rate.

In 2023, the global weighted average LCOE of new renewable energy projects for the vast majority decreased. For onshore wind projects, the LCOE reached 0.033 USD/kWh (€20250.03/kWh), and for offshore ones, it was 0.075 USD/kWh (€20250.069/kWh). The LCOE of solar photovoltaics also decreased to 0.044 USD/kWh (€20250.04/kWh). Bioenergy, on the other hand, experienced an increase in the LCOE from 0.063 USD/kWh (€20250.058/kWh) to 0.072 USD/kWh (€20250.066/kWh). Similarly, geothermal energy projects increased to 0.071 USD/kWh (€20250.065/kWh). Hydrogen projects remain the most expensive at 2806 USD/kWh (€20252,578/kWh) [179].

4.1. LCOE for Onshore and Offshore FPV Systems

In the following studies, we will examine the LCOE for various FVP systems with distinct properties. To provide a better overview, all LCOE values have been converted to €/MWh for the year 2025, with the prices taken from the references mentioned in Table 3.

A comparative analysis of the LCOE across FPV systems reveals significant variations between offshore and inland deployments, driven by factors such as installation complexity, environmental conditions, and cost structures. Offshore FPV systems, while promising in terms of scalability and integration with existing marine infrastructure, exhibit considerably higher LCOE values due to elevated CAPEX and OPEX values, as well as the technical challenges associated with mooring, maintenance, and exposure to extreme marine conditions. The HelioSea concept [109], utilizing a tension leg platform (TLP) with dual-axis tracking, achieves an LCOE of 163–276 EUR/MWh, competitively positioning it within the marine renewables sector but still requiring cost optimizations in platform design and mooring efficiency. A broader study mapping FPV system potential across European coastal waters [120] reports LCOE values ranging from 255 EUR/MWh in southern regions like Spain and Portugal to as high as 664 EUR/MWh (650 EUR/MWh) in Northern Norway, largely influenced by variations in solar resource availability and proximity to shore. Pontoon-based platforms, instead of TLP structures, could lower costs, with estimates around 184 EUR/MWh in the best locations, highlighting how important platform design is for making it affordable. However, offshore FPV technology remains financially unviable without subsidies or further technological advancements to drive cost reductions through supply chain improvements and economies of scale.

In contrast, inland FPV systems demonstrate significantly lower LCOE values, attributed to reduced installation complexities, stable water conditions, and lower CAPEX requirements. A 50 MW FPV system installation in Bangladesh’s Hakaluki Marsh [110] achieves an LCOE of 47 EUR/MWh, substantially below the national fossil fuel average (87 EUR/MWh), benefiting from lower land costs, a high performance ratio (78.9%), and enhanced cooling effects from water. Similarly, an FPV project in Nigeria’s Ikang River [123] reports an LCOE of 827 EUR/MWh, constrained by high initial investment costs but supported by favorable solar irradiance, environmental benefits such as evaporation reduction, and potential for biodiversity conservation. A separate feasibility study [180] analyzing a 10 MW FPV system found a 10.2% higher energy output than GPV, resulting in an LCOE of 28.47 EUR/MWh, marking a 39% cost reduction compared to land-based alternatives, along with significant environmental benefits, including 340,801.74 tons of CO2 emissions avoided. Additionally, another study [102] evaluating FPV systems through PVsyst® simulations across three locations found lower-than-expected performance gains, with energy production increases between 0.31% and 2.59%, significantly below the 10% improvement suggested in the literature. Critical challenges identified include limitation of the simulation tools, uncertainty in cooling effects, and lack of standardization; all of these affect investment confidence and the bankability of FPV systems. The LCOE values in this study range from 118.16 EUR/MWh to 61.78 EUR/MWh depending on the technology used and solar resource availability.

A separate study examining the LCOE across various farm configurations [181], including some with bifacial modules and others employing single-axis or dual-axis tracking systems, revealed that the CAPEX for a monofacial PV dual-axis tracking system exceeds twice that of a system utilizing solely fixed monofacial PV systems. The LCOE for these systems ranges from 51.45 EUR/MWh to 58.81 EUR/MWh, with the research concluding that the most cost-effective system is the one using a fixed bifacial PV system.

Table 3.

List of studies on LCOE for sector of FPV systems.

Table 3.

List of studies on LCOE for sector of FPV systems.

| Title of Study and Year | LCOE from Study | LCOE | Location | Capacity | Type of Structure | Ref. |

|---|---|---|---|---|---|---|

| Advancing offshore solar energy generation: The HelioSea concept (2024) | 160–270 EUR/MWh | 163–276 EUR/MWh | Port of Vigo, Spain | 75 kW | Tension leg platform made of steel | [109] |

| Mapping of the levelised cost of energy from floating solar PV in coastal waters of the European Atlantic, North Sea and Baltic Sea (2024) | 250–1700 EUR/MWh | 255–1737 EUR/MWh | European Atlantic, North Sea and Baltic Sea | 6.762 MW | Tension leg platform made of steel | [120] |

| 180–1200 EUR/MWh | 184–1226 EUR/MWh | Pontoon-type floating structures | ||||

| Optimization and techno-economic assessment of 50 MW floating solar power plant on Hakaluki marsh land in Bangladesh (2023) | 0.051 USD/kWh | 47 EUR/MWh | Hakaluki Marshland–Bangladesh | 50 MW | Pontoon-type floating structures | [110] |

| Feasibility of floating solar photovoltaic systems (FSPVs) development in Nigeria: an economic cost appraisal case study (2023) | 0.9 USD/kWh | 827 EUR/MWh | Ikang River, Nigeria | 1.161 MW | Pontoon or independent floats | [123] |

| Floating solar power plant for sustainable development: A techno-economic analysis (2019) | 0.026 USD/kWh | 28.47 EUR/MWh | Neel-Nirjan Dam of Bakreswar Thermal Power Plant, India | 10 MW | Foundation for PV module mounting with underwater lines | [180] |

| Assessment of the potential of different floating solar technologies–Overview and analysis of different case studies (2020) | 96.2 EUR/MWh | 118.16 EUR/MWh | Barrow Gurney, U.K. | 319 MW | Individual modular HDPE floaters | [102] |

| 90.6 EUR/MWh | 111.28 EUR/MWh | 1 MW | Floating perimeter platform with interior web of stainless-steel cables | |||

| 53.7 EUR/MWh | 65.96 EUR/MWh | Almeria, Spain | 319 MW | Individual modular HDPE floaters | ||

| 50.3 EUR/MWh | 61.78 EUR/MWh | 1 MW | Floating perimeter platform with interior web of stainless-steel cables | |||

| Economic comparison of floating photovoltaic systems with tracking systems and active cooling in a Mediterranean water basin (2023) | 0.056–0.064 USD/kWh | 51.45–58.81 EUR/MWh | Anapo, Italy | 18 MW | Pontoon-type floating structures | [181] |

These studies highlight the key differentiators in the LCOE between offshore and inland FPV system applications, with offshore systems facing higher economic and technical barriers but holding long-term potential for integration with existing maritime infrastructure and large-scale energy production. Inland FPV technology, by contrast, offers immediate cost advantages and environmental co-benefits, making it a more financially attractive option in the short term. Future cost reductions across both domains will depend on advancements in floating platform design, improved mooring solutions for offshore applications, and further optimization of cooling effects for inland installations. Additionally, the standardization of LCOE assessment methodologies will be critical to enhancing investment confidence and ensuring the scalability of FPV technology across diverse geographical and environmental conditions.

By comparing the extreme values obtained, we can conclude that the LCOE with the highest value (1737 EUR/MWh) is linked to a new project that utilizes more expensive technologies in its components, which also leads to a high CAPEX. The LCOE’s high value is also attributable to the location as it is obtained in a less favorable position from a production perspective, but it is also located 100 km from the coast in an offshore area. Therefore, the same study demonstrates that the LCOE decreases to 255 EUR/MWh for a more favorable location using the same construction, such as the Iberian Peninsula. The lowest LCOE (28.47 EUR/MWh) was achieved for an FPV system situated near the shore on the Neel-Nirjan dam, which did not necessitate equally expensive technologies. This is evident in the significantly lower CAPEX compared to the study with the highest LCOE.

Technical, economic, and political factors explain the difference in LCOEs between India and Nigeria, 28.47 EUR/MWh and 827 EUR/MWh, respectively. First, operational efficiency is important: the Indian project has a capacity of 10 MW, which spreads fixed costs over a much larger energy output, while the Nigerian project has 1.161 MW. Due to logistical issues and the corrosive environment, OPEX costs are higher in Nigeria. In India, government support can reduce the CAPEX by 30–50%, but in Nigeria, it covers all costs. Different calculation methods (discount rates, tax treatments, and depreciation) strongly affect the result. Thus, high operational costs, a lack of government support, and poor financial conditions in Nigeria account for the remaining 827 EUR/MWh.

4.2. Hybrid FPV LCOE

Similarly to the studies analyzed above, the following studies that will be analyzed will be converted to euros from 2025, and the prices taken from the references will be presented in Table 4.

The integration of solar photovoltaic (PV) systems into aquaculture has gained increasing attention due to its potential to reduce energy costs and improve sustainability. Various approaches have been explored, from floating PV installations to hybrid PV and battery energy storage (PV/BES) systems, each with distinct economic and operational implications. While some studies emphasize efficiency gains through system design optimizations, others focus on the trade-offs between reliability, cost, and energy surplus utilization [182].

Recent research has examined the incorporation of floating–tracking systems into shrimp farming in Thailand [119], revealing that the LCOE for fixed FPV systems (Scenario S3) and floating–tracking systems (Scenario S4) varies from 383 EUR/MWh to 1205 EUR/MWh, taking into account the reliability of the system. Although their LCOEs are similar, floating–tracking systems surpass fixed systems by enhancing energy production by 5%, providing long-term economic benefits, especially for high-reliability applications, despite their greater initial expenditure being mitigated by reduced storage requirements. Moreover, research has progressed to include FPV systems in offshore wind farms, particularly in the North Sea. Another study that proposes the integration of solar modules in fish farms is the one presented in Ref. [183], since the location is a remote one that would be a considerably better option than diesel generators (DGs). These will be used for the fish feeding system, which is the principal energy consumer. Following the analysis, an LCOE of 411 EUR/MWh was estimated for the favorable case, and 455 EUR/MWh was estimated for the least favorable case.

Other studies have focused on paddlewheel aerators in aquaculture that help increase dissolved oxygen (DO) in pond water. These devices are generally powered by diesel generators (DGs), especially in remote areas where the electricity grid is not available. One such study that approached the integration of a solar module system with battery energy storage integrated directly into the platform is the one presented in Ref. [184], with an LCOE ranging from 138.74 EUR/MWh to 257.28 EUR/MWh depending on the reliability index (RI). The floating PV/BES aerator improved dissolved oxygen levels by 10.91% compared to a PV-only aerator, demonstrating its effectiveness in maintaining optimal water conditions. A comparative analysis of the LCOE for DG or PV/DG and PV/BES hybrid systems was conducted in another study [185]. The LCOE for the PV/BES is approximated at 153.07 EUR/MWh, and the PV/DG system exhibited an even higher LCOE, ranging from 1789 EUR/MWh (1.87 USD/kWh) to 2306 EUR/MWh, making it the least cost-effective option. Comparing the results from both studies with the reference system with DG, whose LCOE is approximately 3386.7 EUR/MWh (3.54 USD/kWh), we can observe a significant decrease in the LCOE for both hybrid systems. PV/BES integration is economically beneficial, especially in cost- and reliability-optimized scenarios. This study shows that higher reliability must be balanced against rising energy costs, with an RI of 97% offering the best cost–performance trade-off.

Another intriguing example of PV integration is found in a study on optimizing solar energy for open-field aquaponic systems in drylands [186], where the LCOE for the standalone photovoltaic system (PVS) was determined to be 473.83 EUR/MWh. Even though this LCOE is greater than Mexico’s current electricity rate, it is still more cost-effective than building transmission lines or depending on diesel generators in isolated locations. Additionally, the study discovered that excess energy production took place in the afternoon, which could be further optimized to reduce the LCOE. This is applicable to PV/BES systems for aerators: optimizing excess energy could reduce costs and improve the overall efficiency of the systems.

Apart from the incorporation of FPV systems in aquaculture, there is a tendency to combine multiple renewable resource types in one area. Studies on the estimation of the LCOE in connection with this aspect have thus been conducted. The integration of solar energy with offshore wind energy is noteworthy as research is focused on utilizing the available space between wind turbines, with solar energy potentially serving as a viable solution. According to a study on the Borssele Wind Farm Zone (BWFZ) [187], combining floating solar with offshore wind can increase overall energy production, but as more modules are added, profits will decrease. The anti-correlation between wind and solar generation makes the integration process beneficial and improves the efficiency of the existing transmission infrastructure. Without subsidies, the project’s economic viability is negligible; however, the LCOE can significantly drop with increased government assistance, especially through the SDE (Stimulation of Sustainable Energy) program. Pricing ranges from 12 to 60 EUR/MWh without subsidies, but with SDE support, it drops to a range of 3.6–27.45 EUR/MWh, and with a doubled SDE, costs drop even further to a range of 3.6–14.32 EUR/MWh. These results demonstrate how crucial policy is in determining whether hybrid offshore wind and solar systems are economically viable. On the contrary, research on Istanbul’s integration of renewable energy [188], which combines offshore and onshore wind and solar systems, offers a compelling viewpoint on energy system architecture. A study employed Geographic Information Systems (GIS) and Multi-Criteria Decision Making (MCDM) to identify the best sites for renewable energy infrastructure. The study revealed that although Istanbul had considerable renewable potential, its current solar and wind energy resources are inadequate to satisfy the city’s overall energy requirements. The capital cost study indicated a cheaper LCOE for the European side of Istanbul at 9.4 EUR/MWh in contrast to the Anatolian side’s LCOE of 13.4 EUR/MWh, with payback periods of 8.55 years and 5.61 years, respectively. Another study [16] examined the integration of solar and wind energy using various structural arrangements, focusing on several factors, including the LCOE. Among the three FPV schemes that were examined, Scheme 1 from [16] had the longest payback period (25 years) and the highest energy production (26.29 million kWh/year), but it also had a higher LCOE (71.5 EUR/MWh). Despite having slightly lower energy outputs, Scheme 2 and Scheme 3 from [16], which used shared mooring systems, had lower LCOEs (63.5 EUR/MWh) and shorter payback periods (14 years).

Probably the most researched hybrid solutions are still those that combine solar and hydropower, where FPV systems are installed on dams that are already used to produce hydropower energy, potentially lowering land costs.

The study presented in Ref. [189] looks at an FPV system on the Rajghat Dam in India and reports an exceptionally low LCOE of 32.79 EUR/MWh with an IRR of 8.55%. Despite its economic feasibility, the study focuses more on theoretical potential than on implementation problems like floating platform stability and transmission limitations. An additional FPV analysis [190] indicates a reduction in LCOE to 29.68 EUR/MWh when integrating FPV with hydropower. This hybridization results in an 8.7% reduction in the LCOE compared to independent hydropower (40 EUR/MWh), highlighting the economic benefit of co-locating these technologies. Nonetheless, the long-term resilience of floating modules and the heightened intricacy of overseeing dual generation sources within a singular reservoir present operational issues that require additional investigation. According to the Balbina Dam study [102], the LCOE of FPV system integration depends on platform design, with a floating perimeter platform costing 78.24 EUR/MWh and modular HDPE floaters costing 83.4 EUR/MWh. This variance shows that structural material costs and design decisions affect FPV economics.

A hybrid pumped storage hydropower (PSH) and FPV system study [191] shows that when FPV coverage rises from 10% to 50%, the LCOE decreases from 175.48 EUR/MWh to 173.12 EUR/MWh. This slight decrease highlights the diminishing returns of FPV integration at higher coverage ratios, which are probably caused by the difficulties in managing large-scale floating arrays and the higher capital costs associated with adding more floating structures. PSH is still a costly storage option when compared to battery storage and other grid-balancing technologies, even though hybridization reduces costs, as evidenced by the LCOE of 240.5.48 EUR/MWh (261.74 USD/MWh) for standalone PSH.

A separate study assessing the LOC focuses on the integration of three forms of renewable energy: solar, wind, and wave energy [192]. The research evaluates both on-grid and off-grid configurations, optimizing various energy combinations for cost-effectiveness and performance. In off-grid situations, the PV/WT/DG/WS system in Royan (Caspian Sea Coast) functions at an LCOE of 196.89 EUR/MWh, whereas the PV/WT/DG system in Shirinoo (Persian-Gulf Coast) attains a reduced LCOE of 177.42 EUR/MWh (0.164 USD/kWh). While hybridization enhances reliability, the elevated LCOE indicates a financial compromise. Conversely, on-grid systems exhibit lower costs, with the Grid/PV/WT system attaining 104.94 EUR/MW (0.097 USD/kWh) in Royan and 100.6 EUR/MWh in Shirinoo. Nonetheless, global electricity tariffs may elevate these expenses by as much as 43.3%. Sensitivity analysis indicates LCOE fluctuations ranging from 151.45 EUR/MWh to 216.36 EUR/MWh (0.140 USD/kWh to 0.200 USD/kWh) in off-grid scenarios and from 97.36 EUR/MW to 165.51 EUR/MW (0.09 to 0.153 USD/kWh) in on-grid configurations, highlighting the reliance on equipment expenses and the availability of renewable resources. Although wave energy enhances the stability of power generation and diminishes dependence on wind and solar resources, its cost-effectiveness is significantly influenced by local wave potential. The study emphasizes that off-grid systems are financially unfeasible for large-scale demands exceeding a breakeven distance of 400 km, yet they are viable for smaller communities with consumption below 1000 kWh/d. The research highlights that hybridizing renewable energy sources improves resilience yet does not ensure reduced energy costs, necessitating a location-specific financial analysis. Ref. [193] analyzes the LCOE for off-grid hybrid energy systems located at River Oshin, Nigeria, reporting values that range from 123.79 EUR/MWh to 315.33 EUR/MWh for capacities between 92.5 kW and 150 kW.

Table 4.

List of studies on LCOE for FPV farms integrating renewable energy sources and aquaculture.

Table 4.

List of studies on LCOE for FPV farms integrating renewable energy sources and aquaculture.

| Title of Study and Year | LCOE from Study | LCOE | Location | Capacity | Utilization of Marine Space | Hybrid Systems | Ref. |

|---|---|---|---|---|---|---|---|

| Optimization and assessment of floating and floating-tracking PV systems integrated in on- and off-grid hybrid energy systems (2019) | 0.35–1.1 USD/kWh | 383–1205 EUR/MWh | Nakhon Si Thammarat, Thailand | – | 3600 m2 | Solar and aquaculture | [119] |

| Design and analysis of a hybrid power system for an offshore aquaculture site in Newfoundland, Canada (2024) | 0.46–0.51 USD/kWh | 411–455 EUR/MWh | Red Island, Placentia Bay, North of the Atlantic Ocean | 366 kW | 1077 PV–1.95 m2 area each | Solar and aquaculture | [183] |

| Design and performance analysis of a standalone floating photovoltaic/battery energy-powered paddlewheel aerator (2023) | 0.15–0.28 USD/kWh | 138.74–257.28 EUR/MWh | Rayong, Thailand | 450 W | 1 PV–2.17 m2 area each | Solar and aquaculture | [184] |

| Optimal techno-economic sizing of a standalone floating photovoltaic/battery energy storage system to power an aquaculture aeration and monitoring system (2022) | 0.16–2.41 USD/kWh | 153.07–2306 EUR/MWh | Rayong, Thailand | 450 W | 1 PV–2.17 m2 area each | Solar and aquaculture | [185] |

| Techno-Economic Feasibility Analysis of a Stand-Alone Photovoltaic System for Combined Aquaponics on Drylands (2020) | 0.438 USD/kWh | 473.83 EUR/MWh | La Paz, Mexico | 12.5 kW | 47 PV–1.55 m2 area each | Solar and aquaculture | [186] |

| A Techno-Economic Feasibility Study of Integrating Offshore Floating Photovoltaic Solar Technology within an Offshore Wind Park (2021) | 10–50 EUR/MWh no subsidies | 12–60 EUR/MWh | North Sea | 0.1–1.8 GW | PV 1.6 m2 area each—different scenarios | Solar and wind | [187] |

| 3–23 EUR/MWh SDE | 3.6–27.45 EUR/MWh | ||||||

| 3–12 EUR/MWh doubled SDE | 3.6–14.32 EUR/MWh | ||||||

| Offshore and Onshore Renewable Energy System Modelling to Meet the Energy Demand of Megacity Istanbul (2024) | 0.0105 USD/kWh | 9.4 EUR/MWh | Istanbul, both onshore and offshore | 690 MW | – | Solar and wind | [188] |

| 0.015 USD/kWh | 13.4 EUR/MWh | 54.2 MW | |||||

| Floating body motion coupling study and economic evaluation of different floating photovoltaic arrangement schemes under hybrid solar-wind power generation (2024) | 0.48–0.54 CNY/kWh | 63.5–71.5 EUR/MWh | Bohai Sea | – | 77.04 m2 25.68 m2 25.6 m2 | Solar and wind | [16] |

| Assessment of floating solar PV (FSPV) potential and water conservation: Case study on Rajghat Dam in Uttar Pradesh, India (2022) | 2.61 INR/kWh | 32.79 EUR/MWh | Rajghat Dam in Uttar Pradesh, India | 6513 MW | Coverage of 25% (6352 ha) of which 3450 ha is PV power | Solar and hydroelectric | [189] |

| Energy economics and environmental assessment of hybrid hydel-floating solar photovoltaic systems for cost-effective low-carbon clean energy generation (2023) | 0.0323 USD/kWh FPV | 29.68 EUR/MWh | Maithon Dam, India | 96 MW | 1.14% dam area covered with PV technology (0.42 km2) | Solar and hydroelectric | [190] |

| 0.0435 USD/kWh hybrid | 40 EUR/MWh | ||||||

| Sustainable and cost-effective hybrid energy solution for arid regions: Floating solar photovoltaic with integrated pumped storage and conventional hydropower (2023) | 190.97–188.41 USD/MWh | 175.48–173.12 EUR/MWh | Kunhar River, Pakistan | 6.04–30.2 MW | 66,940 m2–334,700 m2 (10–50%) | Solar and hydroelectric | [191] |

| Assessment of the potential of different floating solar technologies–Overview and analysis of different case studies (2020) | 63.7 EUR/MWh | 78.24 EUR/MWh | Balbina Dam, Brazil | 1 MW | – | Solar and hydroelectric | [102] |

| 67.9 EUR/MWh | 83.4 EUR/MWh | 319 MW | |||||

| Feasibility study of on/off grid large-scale PV/WT/WEC hybrid energy system in coastal cities: A case-based research (2020) | 0.093–0.139 USD/kWh on-grid | 100.6–150.37 EUR/MWh | Caspian Sea Coast | 20 MW | PV 1.63 m2 area each—different scenarios | Solar, wind, and waves | [192] |

| 0.136–0.182 USD/kWh off-grid | 147.13–196.89 EUR/MWh | Persian-Gulf Coast | |||||

| 20-Design and performance analysis of off-grid hybrid renewable energy systems (2022) | 0.2587 USD/kWh 0.3296 USD/kWh 0.2662 USD/kWh 0.1294 USD/kWh | 247.49 EUR/MWh 315.33 EUR/MWh 254.67 EUR/MWh 123.79 EUR/MWh | River Oshin, Nigeria | 101.5 kW 92.5 kW 150 kW 129 kW | – | Solar, wind, and hydroelectric | [193] |

When comparing FPV systems to GPV systems, the LCOE for floating solar systems is expected to be higher due to the more complex and higher CAPEX required for offshore installations. GPV systems benefit from lower installation and maintenance costs due to their simpler site requirements. However, floating solar offers the potential for greater deployment in areas that would otherwise be unsuitable for land-based systems, which can justify the higher initial costs. Furthermore, as floating solar technology matures and economies of scale are achieved, costs are expected to decrease, which will improve the LCOE over time.

While floating solar technology remains a relatively new and high-cost technology, it offers significant long-term potential for contributing to the global energy transition, especially as technologies improve and regulatory frameworks evolve to support such projects.

It is important to note that not all of the above components are required for every FPV farm. The inclusion of specific elements depends on the complexity of the farm’s design and site conditions. For instance,

- Farms in shallow inland reservoirs may have simpler mooring and anchorage systems compared to offshore installations exposed to stronger currents and deeper waters.