1. Introduction

Throughout history, shipping has been regarded as an international business. Ships travel between different ports, crossing various national and international waters, most of the time beyond the reach of nation states and their regulations. In addition, some shipping organizations have allowed their ships to sail under flags of convenience (FOCs). These decisions have allowed them to choose between different regulatory regimes in order to minimize costs and maximize profits [

1]. This arrangement has contributed to numerous accidents, incidents and environmental disasters at sea throughout history [

2], with human and organizational factors being the main causes [

3].

In order to improve maritime safety, the International Maritime Organization (IMO) has created a series of measures and regulations. Particularly noteworthy are the International Convention on Standards of Training, Certification and Watchkeeping for Seafarers (STCW), with its amendments and revisions, and the International Safety Management (ISM) Code [

4]. The STCW aims to provide an international standard for the training of seafarers and the ISM aims to provide organizations with a uniform international standard for the development and implementation of a Safety Management System (SMS) for their ships. The SMS serves as a structured and documented framework through which organizations can systematically manage safety and environmental protection. Its core components include the identification of risks, the establishment of appropriate safeguards, and strict adherence to safety rules and procedures [

5]. Over time, the living and working conditions of seafarers in the industry have proved to be problematic. The impetus for improvement came from the International Labor Organization (ILO) in the form of the Maritime Labor Convention (MLC) in 2006 [

6]. Among the numerous requirements relating to living and working conditions, particular emphasis was placed on the implementation of and compliance with occupational health and safety measures to ensure a safe working environment on board, i.e., the development of a safety culture [

7]. At the same time, the ILO emphasized that the implementation of the MLC, 2006, should be consistent with all relevant IMO instruments, including the ISM [

7]. In addition to the technical requirements for ships contained in the SOLAS, the above measures should strengthen the human factor by improving the safety culture and competence of seafarers. In other words, the above measures should be sufficient to create a resilient barrier system on board ships. A barrier system refers to a multi-layered set of technical and organizational protective measures designed to prevent accidents or mitigate their consequences. In this context, barriers are not limited to physical protective measures, but also include human and procedural elements such as operational practices, decision-making under pressure, and compliance with safety protocols, which together contribute to the ship’s resilience by ensuring system integrity.

After the introduction of ISM in the initial phase, the number of maritime accidents caused by human error on ships decreased (e.g., [

8]). However, another study found the paradox that the period after the introduction of ISM was associated with a decrease in personal injuries and an increase in ship accidents [

9]. However, previous research has shown that most incidents or accidents in the industry are due to the following causes or a combination thereof: inadequate training and experience, lack of competence, poor communication, lack of safety culture, poor situational awareness and decision-making errors, inadequate system monitoring and maintenance, and/or unlearning from previous accidents [

10,

11,

12,

13].

To gain an insight into the current state of the industry, the statistical data published by the European Maritime Safety Agency (EMSA) on reported accidents and incidents was examined. The data presented relate to accidents and incidents that occurred on ships flying one of the EU flags, operating in EU waters or in which EU Member States were significantly involved. Between 2014 and 2023, 58.4% of reported accidents were attributed to human factors. In addition, ship operations emerged as the most significant contributing factor in 70.1% of the recorded events [

14]. These findings are consistent with the findings of previous studies showing that maritime regulations lead to relatively successful safety outcomes [

15,

16] and underline the findings of Schröder-Hinrichs et al. [

17], who conclude that the impact of safety regulations on a true, proactive approach to maritime safety is questionable.

In practice, the performance of ship operation is an important factor related to accidents and incidents, and the basic elements affecting the ship’s barrier system have not been sufficiently studied. In practice, both problems are related to the human factor in practice. Therefore, the question arises as to whether the implementation of the provisions of the maritime regulatory framework can affect the elements related to the ship’s barrier systems, and the aim of this study is to fill this gap. The approach used in this study is based on the assessment of system functionality. In the literature, system functionality is described as reliability. Thus, system reliability reflects the actual performance of a system, i.e., the ability to maintain the desired performance under working conditions [

18,

19].

The objectives of the study are, therefore, as follows: (1) to investigate and determine the regulatory safety requirements; (2) to investigate and determine the essential factors associated with the shipboard barrier system; (3) to investigate the influence of regulatory safety requirements and seafarer characteristics (age, seagoing service, and tenure) on the elements associated with the shipboard barrier system. The purpose of introducing the age variable is highlighted in the literature, and the purpose of introducing the seagoing service time and tenure variables is to investigate the logical assumptions that working for the same organization for an extended period of time and/or seagoing service time may lead to specific work patterns/habits that could affect the elements associated with shipboard operations.

The paper is organized as follows:

Section 2 provides a literature review on the topic;

Section 3, Methodology, describes the dataset and methodological approach;

Section 4, Results, provides the results of the exploratory analyses used, the modeling approach and the main findings of each model;

Section 5 provides a discussion and the implications of the findings, followed by a conclusion in

Section 6.

2. Literature Review

The requirements established by the IMO [

5] and the ILO [

7] are of particular relevance to this study. The basic requirement is that shipping organizations should establish and implement safety management systems (SMSs) for the ships they manage in order to support and promote the development of safe operations [

20,

21] and a safety culture in shipping [

5]. The purpose of maritime regulations can be seen as a method to reduce the impact of market- and workplace-related risks and/or to prevent maritime accidents and marine pollution [

22]. Furthermore, Størkersen et al. [

9] state that “cost efficiency” is the most important factor for shipping companies and that ISM is a balance to a competitive global market. Theoretically, it should be functional to increase maritime safety, reduce the risks associated with ship operations, and improve human performance. At the same time, the ISM only provides general guidelines to achieve the set goals [

23,

24]. According to the same sources, these guidelines can be interpreted differently depending on the organization’s commitment, values, and beliefs.

Consequently, numerous studies have pointed out a paradox with SMSs. They have identified three main issues that can affect daily tasks and activities on board and create a gap between SMS requirements and actual work practice: the application phase [

25,

26], the standardization of SMS leading to an increase in paperwork and bureaucracy [

16,

27], and the lack of a well-developed safety culture [

15,

28].

The importance of a good safety culture has been highlighted in numerous studies and recognized as a leading indicator of safety outcomes in similar industries (e.g., [

29]). Previous studies on safety culture have found that a good safety culture is based primarily on perceptions of senior managers’ commitment to safety [

22,

30]. Such perceptions are reflected in management’s safety practices and can lead to compliance behavior and good performance [

31]. Similar studies conducted in the maritime environment suggest that the shipboard safety culture is distinctly different from commitment in shipping organizations and should be considered separately (e.g., [

28,

32,

33]).

According to [

34], management delivery is an essential component of SMSs. In addition, Li et al. [

35] state that an appropriate management delivery system should improve the management of safety barriers. Schmitz et al. [

36] define a barrier system as a set of measures designed to prevent causes from becoming consequences. Barriers can be organizational, technical, non-technical, human, or a combination thereof [

37,

38]. The management of safety barriers is a crucial activity for maintaining the process safety of any operating facility [

39]. Furthermore, Schmitz et al. [

36] state that barrier-supportive management systems are indeed non-technical, as they are based on work processes and procedures that emphasize human actions and decisions. Nevertheless, studies have shown that inadequate procedures can be an additional factor contributing to accidents and that the quality of safety rules and procedures should minimize the potential for hazards [

40,

41]. In addition, previous studies have shown that management practices in companies and on board ships are different, as are management delivery systems. The flowchart of maritime regulatory requirements and shipboard safety systems is shown in

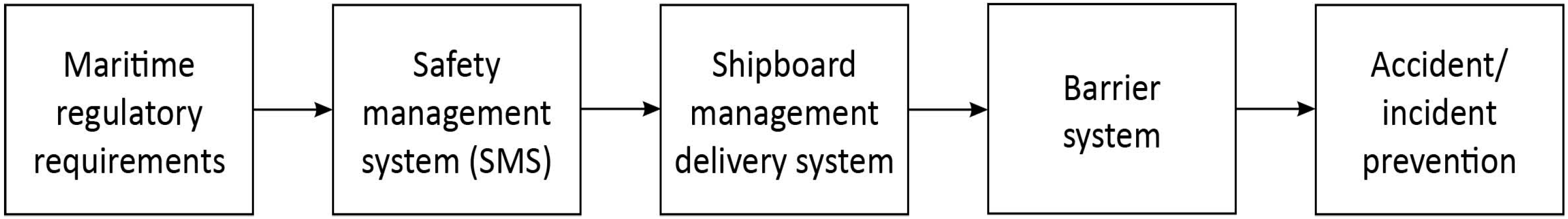

Figure 1.

An early study by Bhattacharya [

16] examined the effectiveness of ISM. According to the results, the use of ISM was perceived differently by shore-based managers and crew members in terms of its intent and associated work practices. In particular, crew members criticized the use of standardized SMS and generic work procedures. In addition, poor communication and a lack of trust between ship and shore management resulted in “formal” compliance by crewmembers. The above comments are confirmed by the results of a similar study [

15]. Their findings show that ship operating plans and a “vast amount of deviation” from safety management systems have a significant impact on “very serious accidents”.

At the beginning of the last decade, a new direction for improvement was taken, based on the human-centered approach of the Health, Safety, Environment, and Quality (HSEQ) management system [

42]. The focus is on establishing common standards for the ship and its systems, ensuring safe working and living conditions, and implementing effective operating procedures. According to the same source, the new management systems should be based on common sense. In practice, the previous SMSs have been expanded to facilitate compliance with the relevant requirements.

In turn, the standardization of SMSs has proven to be important. Numerous studies have addressed the issue of standardization of SMSs. According to [

43], there is an industry that offers a prefabricated SMS as a standard commodity. In addition, organizations typically include all regulatory requirements and expectations instead of focusing on safety issues. Instead of being concise and practical, the systems have become too extensive and bureaucratic; the focus has shifted to documentation, creating additional risks that compromise safety [

27,

44]. Numerous studies emphasize that safety procedures should be flexible and practicable to support safe work practices [

43,

45] and that minimum standards for written procedures should be introduced in the maritime industry [

46]. While many organizations have attempted to simplify their SMS, studies show that these efforts usually end up with the number of rules and procedures remaining almost the same [

32,

47]. Størkersen et al. [

9] state that safety management systems created using this method can also contribute to over-regulation.

A recent study has shown that such an approach leads to numerous violations despite a proper SMS [

48]. According to the results, two-thirds of the seafarers surveyed openly admitted that they do not always comply with the procedures. The reasons given by respondents were that the procedures were either too complicated and/or not applicable in practice, that there were too many of them and/or that the efficiency requirements of the company influenced their decisions.

In addition, previous studies indicate that the age of seafarers is an important risk factor for shipboard accidents [

30,

49,

50,

51]. According to the same sources and available statistics, most accidents occurred while the ships were underway [

14].

3. Methodology

3.1. Data Collection

As part of the study, it was necessary to assess the current situation in the shipping industry. In practice, ship officers are responsible for the conduct of ship operations and, as such, have the best insight into the advantages and disadvantages of the regulatory safety requirements and associated safety management systems that form the basis for this study. For this purpose, accredited maritime training institutions in Croatia were contacted and permissions were obtained to conduct the survey. The survey was conducted from June to September 2022. The research instrument was a questionnaire, which was available in paper form. The distribution and collection of the questionnaires was carried out by the first author. Respondents were introduced to the purpose of the survey, i.e., “what should be done” as per regulatory requirements and “how it is done in practice” as the end result. Participation was voluntary, provided the respondent had completed a period of service as an officer (deck/engine). In addition, the survey was anonymous and confidential to avoid biased participation. No incentives were offered, as this could result in speed runs of participants.

3.2. Survey Measures

The process of defining the measures of the questionnaire is crucial for ensuring content validity [

52]. Therefore, the content validity of the questionnaire statements used was confirmed, i.e., the items and scales were adopted from the literature [

21,

24,

53,

54,

55,

56,

57,

58]. In accordance with the objectives of the study, the questionnaire consisted of three parts: the background of the respondents, regulatory requirements, and the elements related to the barrier system of ship operation.

To determine the regulatory factors for shipboard safety, the requirements for functional safety management systems contained in the regulatory requirements were examined [

5,

6,

7]. One of the requirements relates to the duty of companies to establish and enable effective communication on board. In addition, companies should ensure that crew members are prepared for emergency situations. Companies should also develop and implement rules and procedures for the safe operation of ships. Previous studies have shown that work procedures and checklists are often poorly written. Therefore, it is necessary to gain insight into their quality and availability. According to the studies mentioned in the previous chapter, the ship management’s commitment to safety should be considered separately from organizational management commitment. The following points were considered in the review of ship management commitment: ensuring that safety policies are effectively implemented and maintained, that the responsibilities and authority of personnel performing and supervising the work are defined, and that those performing their duties are supported at all times. A total of 21 statements were selected to gain insight into the enforcement of regulations.

In order to investigate and determine the key elements related to the barrier system for ship operations, 12 statements were used. The statements focused on the perceived commitment of the shipboard safety officer(s), effective implementation and enforcement of safety policies and regulations, adequate familiarization with ship systems, perception of economic/commercial pressures on the ship’s management structure, and the ability of respondents to deal with the hazards present. Based on the author’s expert opinion, two additional measures were included in the questionnaire: “I think that the safety officer (e.g., chief officer) is often in a conflict of interest between the deadlines set and the safety issues” and “I think it is better to delegate the safety supervision job to other officers (e.g., another deck officer/engineer) who are not in a conflict of interest”. The English language was used for all statements in the questionnaire.

All statements were rated on a five-point Likert scale (1: strongly disagree; 2: disagree; 3: neither; 4: agree; 5: strongly agree) so that respondents could indicate their level of agreement. All statements were worded as neutrally as possible so as not to influence or bias participants’ responses. Furthermore, the order of the statements was randomized to mitigate the risk of acquiescence bias. Additionally, to facilitate the screening process, six statements were worded negatively.

3.3. Survey Sample

A total of 315 questionnaires were collected. All questionnaires collected were checked for inconsistencies in the responses. Response bias was found in 19 responses, i.e., respondents indicated the same level of agreement for all statements, so these were discarded and n = 296 responses were accepted.

The seven questions of the questionnaire included background information: nationality, age, occupation, total time at sea, type of ship they worked on, company tenure, and a question about the ship’s flag (Croatian or foreign). All respondents indicated Croatian nationality and foreign ship flag. The majority of respondents (63.9%) reported being deck officers and 36.1% engineers. Regarding total time at sea, the largest percentage (32.8%) indicated >15 years, followed by “1–5 years” (23.0%), “6–10 years” (19.9%), “<1 year” (12.5%), and “11–15 years” (11.8%). When asked what type of vessel they work on, the largest percentage (36.1%) indicated tankers (all types), container ships (23.0%), cruise ships (16.2%), bulk or general cargo ships (15.2%), and other types of ships (9.5%). Additional demographic variables can be found in

Table 1.

3.4. Data Analysis

All statements with negative wording were recoded, e.g., statements with a value of 1 (strongly disagree) were recoded to a value of 5 (strongly agree). The next step was to examine the collected data for possible common method variance (CMV). Given the nature of the data and the need to explore it, i.e., to define the underlying factor structure, exploratory factor analysis (EFA) together with principal component analysis (PCA) was used as the extraction method. Among the available rotation methods, Varimax rotation was chosen as it tends to preserve the “original factor structure” and allows for easier interpretation [

59]. Thus, to achieve the objectives of the study, two exploratory factor analyses (EFA) were conducted for each set of statements. Factor loadings of less than 0.6 were suppressed to ensure the practical significance of the results [

60,

61]. The suppression of factor loadings <0.6 in EFA contributes to a clearer, more meaningful, and more reliable interpretation of the factor structure by focusing on significant associations between variables and factors. Kaiser’s rule, eigenvalues greater than 1, was used as a threshold to determine an acceptable number of factors [

59]. The internal reliability of the factors was then tested using Cronbach’s alpha (>0.70) [

60]. In the next step, three models were constructed; the factors obtained from the first EFA were used as predictors in each model, and the factors obtained from the second EFA were used separately as a dependent variable. A confirmatory factor analysis (CFA) was then conducted to assess the model fit and construct validity of each specified model, i.e., convergent and discriminant validity was confirmed. The factors were formed according to the EFA and CFA results using the sum (average) score method [

60,

62,

63]. The assumptions on which the multiple regression analysis was based were also tested. Finally, three hierarchical multiple regression analyses were performed to examine the influence of maritime safety regulatory requirements as independent factors on the elements of the ship barrier system as dependent factors. The other exploratory variables (age, sea time, and tenure) were entered first, followed by the independent variables in successive steps. At each step, the impact of the newly added block of predictors was evaluated, taking into account the predictors already included. This stepwise approach makes it possible to evaluate the unique contribution of each set of variables while controlling for the influence of the previously entered variables. The IBM SPSS and AMOS programs (Version 26.0), were used for all statistical analyses.

5. Discussion

Considering the study aims, it can be concluded that the objectives of the study have been achieved considering the identified factors. The empirical data used in this study shows the influence of maritime regulatory requirements and seafarers’ characteristics on the ship’s barrier system. Adequate communication, safety training, safety procedures, and management commitment were identified as the most important objectives and correspond to the stated regulatory requirements (e.g., [

5,

6,

7,

9,

15,

16,

56,

70]). In addition, elements related to the barrier system for ship operations were also identified in this study. According to the results of the study, these are shipboard work practices, risk management, and safety competence, which correspond to a ship barrier system consisting of elements that prevent, control, and mitigate consequences.

Several important findings were made in this study, which have both theoretical and practical implications and further underscore the importance of the provisions contained in the current maritime regulations.

5.1. Implications of Regulatory Requirements on Shipboard Work Practices

The results of previous studies indicate that poor communication is the main cause of poor safety performance, increased workplace hazards, and unsafe work (e.g., [

10,

71]). The result confirms previous findings that communication is the most important variable in predicting shipboard work practices (

Table 7). From a practical point of view, the ship’s crew should be a team, and there should be an open and constructive communication atmosphere so that all parties can discuss any work-related problems and find appropriate solutions [

56]. If communication is interrupted, it is likely that important messages will not be passed on to the last person acting, which may ultimately affect the work process. Such a scenario can also occur when the commitment of the ship management structure is low.

In addition to the mandatory requirements for the training of seafarers, the provisions of the ISM [

5] and chapters 6 and 8 of the MLC [

7] provide for additional measures for specific safety training to prepare seafarers for safe work. Consistent with the intent of the requirements, safety training was found to be a significant predictor of the shipboard work practices model. The relationship was positive, suggesting that higher levels of shipboard safety training are associated with higher levels of shipboard work practices. In addition, the study results suggest that shipboard management commitment was a predictor of secondary importance in the model of shipboard work practices. The relationship was positive, suggesting that higher levels of shipboard management commitment were associated with higher levels of work practices. This result is consistent with previous findings and was to be expected.

According to the stated regulations, the purpose of safety procedures is to preventively ensure safe working practices on board ships. Contrary to regulatory intentions, the results of similar studies, and expectations, this result suggests that the perceived safety procedures have not achieved their goal of establishing safe work practices and controlling seafarers’ behavior. To interpret this discrepancy, it is appropriate to draw on the framework provided by contemporary safety science, in particular the distinction between the principles of work-as-imagined (WAI) and work-as-done (WAD). As Ham [

72] notes, safety procedures are often developed by safety practitioners based on the WAI perspective, i.e., an idealized representation of the way work should be done. However, such procedures are often characterized by limited quality and insufficient adaptation to the practical realities of the operational environment [

27,

44].

At sea, seafarers are routinely exposed to complex and demanding environments that require reliance on procedural instructions, situational awareness, and accumulated experiential knowledge. When existing procedures are perceived as too complex, ambiguous, or not aligned with the actual requirements of the task or environment, seafarers tend to rely on professional judgment and adaptive behavior. Consequently, work is performed from a WAD perspective, which can lead to deviations from prescribed procedures or “formal” compliance. Although these adaptations are often essential for successful task performance, they highlight the inherent limitations of procedures based solely on the WAI model and illustrate the persistent mismatch between formalized safety expectations and actual work practice [

48].

5.2. Implications of Regulatory Requirements on Risk Management

The results show that perceived safety procedures were the strongest predictor of the risk management model (

Table 8). The relationship was positive, suggesting that lower levels of inapplicability and/or quality are associated with better risk management. However, this result also points to the undesirable impact of safety procedures on the decision-making process; officers rely heavily on these procedures to manage risk. According to the literature and the authors’ expert opinion, these are sometimes poorly formulated and seafarers have to use their own judgment when making decisions. Furthermore, Doherty [

46] states that sole reliance on written rules and procedures is an undesirable strategy for controlling hazards; seafarers need to be able to fully understand the author’s intentions. If management fails to properly communicate these intentions, the ship’s barrier system may break down. However, the ISM requires the organization to conduct internal safety audits to assess the effectiveness of the SMS, which is an additional safeguard.

Secondly, management commitment was found to be statistically important only when safety procedures were in place. This result also has an important practical implication. The purpose of the safety procedures included in the SMS is to minimize the risks associated with ship operations. Therefore, officer commitment to safety, together with safety procedures, can be seen as the last line of defense against undesirable outcomes associated with risk management.

At the same time, these findings could represent a significant weakness in the ship’s barrier system. Over-reliance on procedural frameworks may limit the ability of experienced officers to make adaptive, contextualized decisions. Furthermore, this can contribute to a false sense of security in ship management and lead to the misconception that the existence of documented procedures alone is sufficient for the management of operational risks, regardless of their relevance, quality, or applicability in a dynamic maritime environment. In addition, it should be noted that there are, to a certain extent, efficiency requirements from management structures (ashore) in the industry that may impact on shipboard risk management, i.e., seafarers may be tempted to exceed safety limits (e.g., [

32,

70]).

Interestingly, the regression coefficients for communication were no longer significant after the introduction of other regulatory requirements. This result is difficult to explain. Under normal circumstances, officers work as a team and communication is an essential part of the decision-making process. One possible explanation could be the hierarchical structure of ship management, where the captain or department heads are responsible for certain operations, meaning that the final decision rests with them.

5.3. Implications of Regulatory Requirements on Safety Competence

A competent officer is essential to the conduct of any operation, and adequate training and experience should enhance his or her skills [

73]. Consistent with previous findings, safety training was found to be a significant predictor of the safety competency model (

Table 9). The relationship was positive, suggesting that higher levels of shipboard safety training are associated with higher levels of officer competence. This result further emphasizes the importance of the ISM and MLC requirements. However, Stracke [

74] (p. 35), describes competence as “the ability that cannot be observed directly but only by activities to adequately and successfully combine and perform necessary activities in any context to achieve specific tasks or objectives”. Thus, it should be noted that officers are often under the influence of organizational factors (e.g., time/commercial pressures) that may affect their decision-making process and cause them to neglect their competence. On the other hand, individuals should be aware of the gaps in their competence and training should minimize the consequences [

75].

5.4. Implications of Seafarer’s Characteristics on Barrier System

The literature identifies characteristics of seafarers such as age and sea service time as risk factors that can have an impact on the safety of ship operations. According to the literature, there is a relationship between age and compliance with safety regulations [

30,

51], safety awareness [

70], and accidents on board [

30,

49]. Similar studies found a relationship between sea service and compliance [

9], safe working skills and knowledge [

16], and safety awareness and risk acceptance [

70].

According to the results obtained, the age variable had no significant influence on the shipboard work practices model. However, it showed a positive influence on the risk management and safety competence models. After the introduction of other variables, the regression coefficients in both models decreased to non-significant, indicating full mediation. With regard to the sea service variable, the results show that the regression coefficients dropped to a lower significance level after the introduction of regulatory variables, indicating partial mediation in risk management and safety competence models.

5.5. Limitations and Future Research

The limitations of the study should also be noted. Firstly, only the responses of the officers/engineers on board were considered in this study. Therefore, the perceptions of lower-ranking crew members are not known. Secondly, only officers of Croatian nationality were included in the study. However, the officers’ responses likely have some multinational and/or cross-cultural influence, as all of them reported working and living under a foreign ship’s flag. Studies that have looked at these issues have found cultural differences between nationalities (e.g., [

30,

76]). In addition, possible differences between ships with different flags and/or owners were not considered in this study.

Furthermore, the influence of perceived safety procedures on shipboard work practices was found to be insignificant, albeit only statistically. Possible explanations for this result may lie in numerous factors, such as the number of items used, their content, and/or the number of respondents in the study. Therefore, these issues should be further investigated in future studies. In addition, the models presented can be used in future studies, regardless of the industrial context, by introducing additional statements and/or exploratory variables to further investigate the models presented.

6. Conclusions

This paper proposes a coherent approach to identify the regulatory safety requirements and associated barrier system for ship operations. It is recognized that a ship is a complex socio-technical system and that human and organizational factors are critical to the safe conduct of ship operations. The results of three models revealed that shipboard work practices, risk management, and safety competence are closely related to the barrier system for ship operations which consist of elements that prevent, control, and mitigate consequences. The models presented can be used in day-to-day ship operations, particularly in critical activities such as confined space entry, bunkering, electrical work, and/or “hot” work. Although the survey included responses from officers working in a broad shipping context and this could be considered a limitation of the study, it should be emphasized that both sets of factors are related to current maritime safety requirements and the ship’s barrier system, regardless of ship type. Although the results of the study show that regulatory safety requirements play an important role in maintaining ship safety, two findings stand out: shipping organizations should try to retain experienced officers and continue to work on the quality of safety rules and procedures and make them practicable, otherwise negative consequences may occur. Throughout history, some of these have had devastating consequences for people and the environment. In this context, it is important for organizations to go beyond the basic requirements of the Maritime Labor Convention (MLC) and the International Safety Management (ISM) Code. Efforts to retain experienced personnel should also take into account living and working conditions, fair compensation, and other supportive measures. Furthermore, the development of safety procedures should not be in the hands of safety experts alone. Rather, shipboard personnel should be actively involved by contributing their operational experience and encouraging continuous feedback in line with the principles of the ISM code.

Considering the current maritime safety requirements, the statistical data on the number of accidents, and the results of this study, the industry should consider developing additional safeguards for the safety of ship operations.