Investigation of Implantable Capsule Grouting Technology and Its Bearing Characteristics in Soft Soil Areas

Abstract

1. Introduction

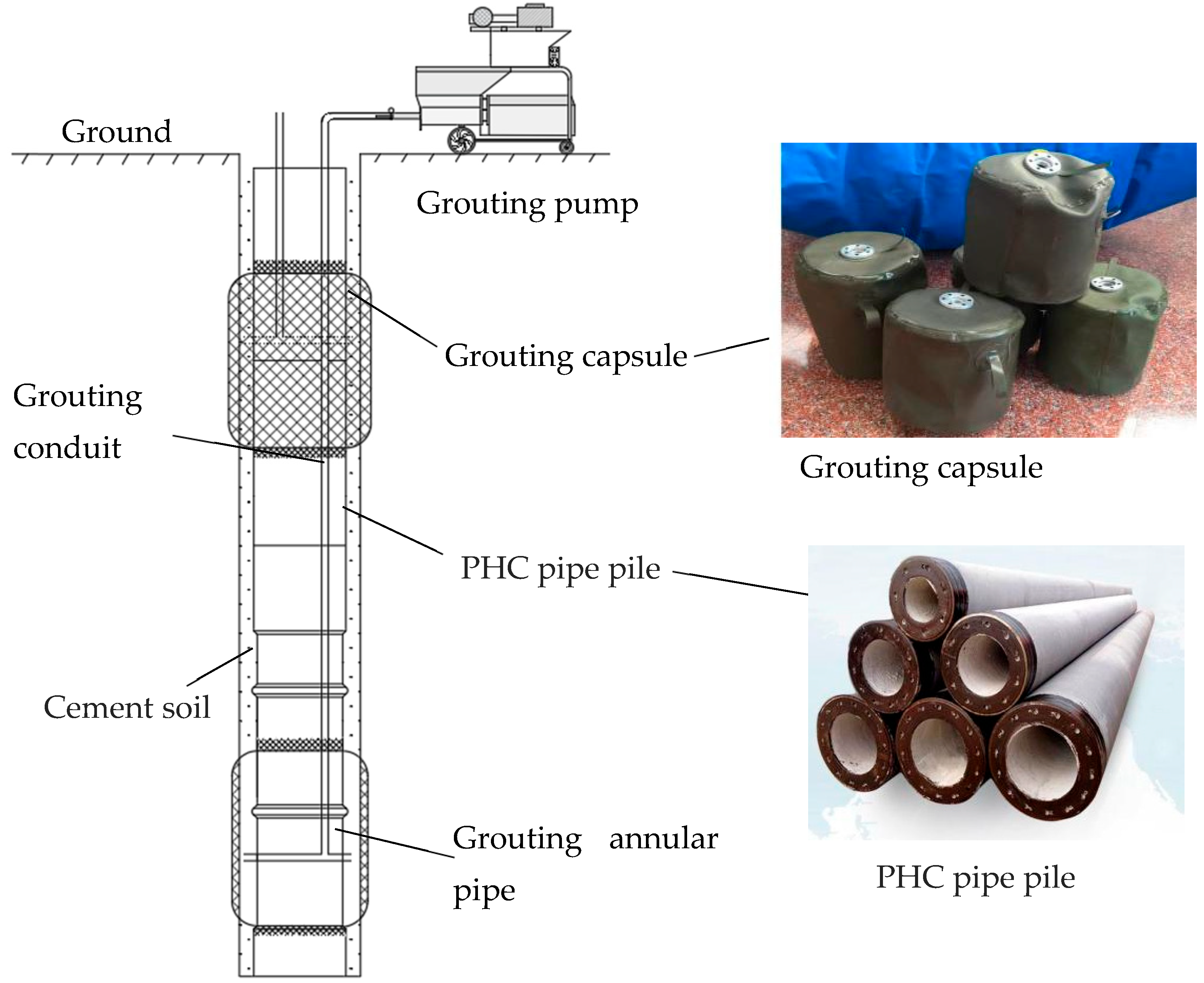

2. ICGP

2.1. Principle of Technical Composition

2.2. Grouting Capsule

2.3. Grouting System

2.4. Construction Steps

3. Model Test

3.1. Test Scheme

3.2. Test Process

3.2.1. Preparation of Model Foundation and Piles

3.2.2. Sensor Layout

3.2.3. Construction of Model Piles

3.2.4. Comparative Detection of Pile Bearing Capacity

4. Analysis of Test Results

4.1. Soil Pressure Around the Piles

4.2. Pile Bearing Capacity

4.3. Pile Shaft Axial Force

4.4. Lateral Frictional Resistance of the Piles

4.5. Resistance at Pile Ends

5. Theoretical Analysis and Discussion on Practical Application

5.1. Theoretical Calculation and Analysis

5.2. Discussion and Analysis of Practical Applications

6. Conclusions

- (1)

- During the construction of implanted piles, drilling, grouting, and pile planting compressed the soil around the piles, resulting in a slow and limited increase in soil pressure around the piles. In contrast, post-grouting significantly increased earth pressure around the piles, with deeper capsules producing greater increases.

- (2)

- Compared with ordinary piles, the ICGP technology improved bearing capacity, with variations based on grouting depths and soil type. In silty clay foundations, the ultimate bearing capacity of the post-grouting piles at different positions increased by 6.8%, 10.9%, and 20.5% compared with the ordinary piles. In clayey silt foundations, the ultimate bearing capacity of the post-grouting piles at different positions increased by 9.5%, 15.3%, and 22.3% compared with the ordinary piles.

- (3)

- The axial force of the pile body at the capsule position decreased significantly, with significant reductions at greater depths. The lateral frictional resistance at the capsule position increased significantly, and the increase was more pronounced with depth. The end resistance of ICGP technology was less than that of ordinary piles, particularly when the capsule was located closer to the pile end.

- (4)

- Through theoretical analysis, the test results satisfied the calculation formula of the bearing capacity of a single pile. The calculated values of the ultimate bearing capacity of the piles were slightly lower than the measured values. By comparing lateral friction resistance under two working conditions, the values of ηs were determined. When ηs was applied to actual engineering cases, the bearing capacity of grouting piles with a capsule length of 1/10 L increased by 1.49%, 4.12%, 4.66%, and 3.83%, while the bearing capacity of grouting piles with a capsule length of 1/5 L increased by 2.99%, 8.24%, 9.32%, and 7.45%. Using 1/5 L capsule grouting piles reduced total project cost by 4.68%, while 1/10 L capsule grouting piles achieved a 1.57% cost reduction. ICGP technology offers substantial practical value in improving the accuracy and economy of pile foundation design, optimizing construction processes, and enhancing project safety and durability in real-world applications.

- (5)

- In laboratory tests, the reduced scale (lower stress levels) leads to a corresponding decrease in grouting pressure. This scaling effect may cause discrepancies compared to real-world conditions. Therefore, it is necessary to further investigate the actual performance of the technology through theoretical analysis, finite element simulations, and field tests.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huynh, V.H.; Nguyen, T.; Nguyen, D.P.; Nguyen, T.S.; Huynh, T.M.D.; Nguyen, T.C. A novel direct SPT method to accurately estimate ultimate axial bearing capacity of bored PHC nodular piles with 81 case studies in Vietnam. Soils Found. 2022, 62, 101163. [Google Scholar] [CrossRef]

- Zhang, R.H.; Wu, L.L.; Kong, Q.H. Research and practice of JZGZ pile foundation. Chin. J. Geotec Hnical Eng. 2013, 35, 1200–1203. [Google Scholar]

- Gong, X.N.; Luo, Z.A.; Zhou, J.J.; Zhang, R.H. Research on calculation method for pre-bored grouted planted pile under compression in soft soil area. Chin. J. Geotech. Eng. 2025, 1–10. [Google Scholar]

- Zhou, J.J.; Yu, J.L.; Gong, X.N.; Yan, T.L. Field tests on behavior of pre-bored grouted planted pile and bored pile embedded in deep soft clay. Soils Found. 2020, 60, 551–561. [Google Scholar] [CrossRef]

- Zhou, J.J.; Yu, J.L.; Gong, X.N.; Zhang, R.H. Field study on installation effects of pre-bored grouted planted pile in deep clayey soil. Can. Geotech. J. 2023, 61, 748–762. [Google Scholar] [CrossRef]

- Ling, Z.; Wang, W.D.; Wu, J.B.; Mengxiong, T. Laboratory Test on Mechanical Properties of Cement Soil in Pre-Bored Precast Pile with an Enlarged Base. Chin. J. Undergr. Space Eng. 2022, 18, 106–113. [Google Scholar]

- Zhou, J.J.; Gong, X.N.; Wang, K.H.; Zhang, R.H.; Xu, G.L. Effect of cemented soil properties on the behavior of pre-bored grouted planted nodular piles under compression. J. Zhejiang Univ.-Sci. A (Appl. Phys. Eng.) 2018, 19, 534–543. [Google Scholar] [CrossRef]

- Zhou, J.; Zhou, S.; Zhang, R.; Yu, J.; Gong, X. Experimental Study on Friction Capacity of Pile-Stabilized Soil Interface. In International Conference on Construction Resources for Environmentally Sustainable Technologies; Springer Nature Singapore: Singapore, 2023; pp. 137–144. [Google Scholar]

- Yu, J.L.; Zhou, J.J.; Gong, X.N.; Zhang, R.H. The frictional capacity of smooth concrete pipe pile-cemented soil interface for pre-bored grouted planted pile. Acta Geotech. 2023, 18, 4207–4218. [Google Scholar] [CrossRef]

- Deng, Y.B.; Zhang, R.H.; Sun, J.F.; Chen, Z.Q.; Chen, K.W.; Yan, T.L. Novel technology of statical-drill and rooted drainage pile and its large-scale model test. J. Build. Struct. 2022, 43, 293–302. [Google Scholar] [CrossRef]

- Wan, Z.H.; Dai, G.L.; Gong, W.M. Field study on post-grouting effects of cast-in-place bored piles in extra-thick fine sand layers. Acta Geotech. 2019, 14, 1357–1377. [Google Scholar] [CrossRef]

- Wang, Z.; Qiu, R.D. Horizontal Static Load Test Research for Pile Lateral friction and Tip Resistance of Grouting Technique. Chin. J. Rock Mech. Eng. 2015, 34, 3588–3596. [Google Scholar] [CrossRef]

- Salem, T.N.; El-Basset, O.H.A.; Hassan, R. 3D Numerical Analysis of Post-Grouted Piles. Indian Geotech. J. 2024, 54, 1562–1583. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, C.; Wu, Y. Experimental Study on Post-Grouting Pile Vertical Bearing Performance Considering Different Grouting Methods and Parameters in Cohesive Soil. Appl. Sci. 2023, 13, 12175. [Google Scholar] [CrossRef]

- Wang, Z.H.; Dai, G.L.; Zhou, F.; Xu, Y.F.; Gao, L.C.; Hu, T. Experimental study on lateral bearing mechanism of distributed post-grouted pile in cohesive soil. China Civ. Eng. J. 2023, 56, 80–91. [Google Scholar] [CrossRef]

- Wang, W.D.; Wu, J.B.; Wang, X.J. Full-scale tests and application of side-grouting uplift piles. Chin. J. Geotech. Eng. 2010, 32, 284–289. [Google Scholar]

- Hu, H.S.; Tang, M.X.; Liu, C.L.; Chen, H.; Zhang, S.; Ling, Z. Vertical bearing capacity characteristics of large-diameter DPC pipe piles based on field tests. China Civ. Eng. J. 2022, 55, 92–99. [Google Scholar] [CrossRef]

- Gao, Q. Application of Post Grouting Technique of Prestressed Pipe Pile in Engineering. Constr. Technol. 2017, 46, 393–395. [Google Scholar]

- Yoo, M.T.; Lee, S.H.; Kim, S.J.; Choi, Y.T.; Park, J. A Study on Bearing Capacity Reinforcement for PHC Pile Foundation Using Post-grouting. J. Korean Geotech. Soc. 2017, 33, 17–25. [Google Scholar]

- Karimi, A.H.; Eslami, A. Physical modelling for pile performance combined with ground improvement using frustum confining vessel. Int. J. Phys. Model. Geotech. 2018, 18, 162–174. [Google Scholar] [CrossRef]

- GB/T 50123–2019; Standard for Geotechnical Testing Method. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

- T/CECS 738-2020; Technical Specification for Prebored Precast Concrete Pile. China Planning Publishing House: Beijing, China, 2020.

- JGJ 94-2008; Technical Code for Building Pile Foundation. China Architecture & Building Press: Beijing, China, 2008.

- Wang, Z.H.; Dai, G.L.; Gao, L.C.; Gong, W.M. A practical method of calculation of bearing capacity and settlement of large-diameter post-grouting piles. Rock Soil Mech. 2020, 41, 2746–2755. [Google Scholar] [CrossRef]

- GB 50021-2023; Code for Investigation of Geotechnical Engineering. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2023.

| Material Performance | ρ (g/cm3) | σt (MPa) | εb (%) | Tr (kN/m) | Ha (Shore A) | T (°C) | Ar | Alr |

|---|---|---|---|---|---|---|---|---|

| Material properties | 0.92–0.98 | 17–25 | 500–800 | 30–50 | 40–90 | −50 to +80 | Ordinary | Preferable |

| Soil Conditions | Pile Types | Grouting Bladder Positions | Earth Pressure Gauges | d (m) | r (m) | |

|---|---|---|---|---|---|---|

| Silty clay | P1 | Ordinary pile | / | T1-1 | 0.11 | 0.1 |

| T1-2 | 0.11 | 0.35 | ||||

| T1-3 | 0.11 | 0.7 | ||||

| P2 | Post-grouting pile | zg = 10 cm | T2-1 | 0.11 | 0.1 | |

| P3 | Post-grouting pile | zg = 35 cm | T3-1 | 0.11 | 0.35 | |

| P4 | Post-grouting pile | zg = 70 cm | T4-1 | 0.11 | 0.7 | |

| Clayey silt | P5 | Ordinary pile | / | T5-1 | 0.11 | 0.1 |

| T5-2 | 0.11 | 0.35 | ||||

| T5-3 | 0.11 | 0.7 | ||||

| P6 | Post-grouting pile | zg = 10 cm | T6-1 | 0.11 | 0.1 | |

| P7 | Post-grouting pile | zg = 35 cm | T7-1 | 0.11 | 0.35 | |

| P8 | Post-grouting pile | zg = 70 cm | T8-1 | 0.11 | 0.7 | |

| Soil Parameters | w (%) | γ (kN/m3) | e | wL (%) | wP (%) | c (kPa) | φ (°) |

|---|---|---|---|---|---|---|---|

| Silty clay | 40.66 | 17.82 | 1.298 | 41.2 | 23.7 | 11.2 | 8.6 |

| Clayey silt | 33.12 | 18.40 | 0.865 | 34.5 | 20.8 | 13.5 | 10.7 |

| Experimental/Theoretical | Working Condition 1 (Silty Clay Foundation) | Working Condition 2 (Clayey Silt Foundation) | ||||||

|---|---|---|---|---|---|---|---|---|

| P1 | P2 | P3 | P4 | P5 | P6 | P7 | P8 | |

| Measured value (kN) | 3.933 | 4.199 | 4.361 | 4.739 | 4.012 | 4.395 | 4.627 | 4.908 |

| Calculated value (kN) | 3.919 | 4.172 | 4.312 | 4.525 | 4.024 | 4.421 | 4.715 | 5.094 |

| Measured value/Calculated value | 1.004 | 1.006 | 1.011 | 1.047 | 1.003 | 1.006 | 1.019 | 1.038 |

| Pile | Working Condition 1 (Silty Clay Foundation) | Working Condition 2 (Clayey Silt Foundation) | ||||||

|---|---|---|---|---|---|---|---|---|

| P1 | P2 | P3 | P4 | P5 | P6 | P7 | P8 | |

| ηs | 1 | 1.097 | 1.156 | 1.294 | 1 | 1.136 | 1.218 | 1.318 |

| Soil Layer | Soil Name | Thickness (m) | γ (kN/m3) | w (%) | e | IP | IL | c (kPa) | φ (°) | ηs |

|---|---|---|---|---|---|---|---|---|---|---|

| 1-2 | Clayey silt | 3.1 | 18.68 | 30.4 | 0.854 | 9.3 | 0.62 | 12.7 | 17.8 | 1.224 |

| 1-3 | Silty clay | 3.1 | 17.44 | 42.1 | 1.179 | 15.9 | 1.28 | 11.3 | 10.2 | 1.182 |

| 3-1 | Clayey silt | 12 | 18.86 | 29.3 | 0.820 | 9.3 | 0.50 | 12.6 | 20.5 | 1.224 |

| 3-2 | Silty clay | 3.9 | 18.60 | 31.0 | 0.870 | 9.3 | 0.69 | 12.6 | 20.0 | 1.203 |

| 4-1 | Silty clay | 9.2 | 17.64 | 40.4 | 1.130 | 15.2 | 1.24 | 11.7 | 10.4 | 1.203 |

| 4-2 | Clayey silt | 9.9 | 17.95 | 37.4 | 1.055 | 17.9 | 0.85 | 26.0 | 12.7 | 1.224 |

| Station | Pile Length (m) | Q1 (kPa) | Q2 (kPa) | Q3 (kPa) | P1 (%) | P2 (%) |

|---|---|---|---|---|---|---|

| Z1 | 10 | 289.70 | 294.039 | 298.375 | 1.49 | 2.99 |

| Z2 | 20 | 511.11 | 532.156 | 553.206 | 4.12 | 8.24 |

| Z3 | 30 | 677.42 | 708.991 | 740.566 | 4.66 | 9.32 |

| Z4 | 40 | 968.07 | 1005.109 | 1040.179 | 3.83 | 7.45 |

| Project | Calculation Method | Cost of Option 1 | Cost of Option 2 | Cost of Option 3 |

|---|---|---|---|---|

| Piles Cost | Pile length × Unit price × Number of piles | The pile quantity was 100 units, with a total cost of CNY 1.5525 million. | The pile quantity was 92 units, with a total cost of CNY 1.4798 million. | The pile quantity was 96 units, with a total cost of CNY 1.5281 million. |

| Added material Cost | Pouches + Grouting pipes | |||

| Equipment Cost | Number of machine shifts × Unit price per machine shift | |||

| Labor Cost | Number of workers × Daily wage × Construction days | |||

| Measure Cost | Site leveling + Pile foundation testing | |||

| Management Cost | 15% of direct costs |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Deng, Y.; Zheng, W.; Zhang, R. Investigation of Implantable Capsule Grouting Technology and Its Bearing Characteristics in Soft Soil Areas. J. Mar. Sci. Eng. 2025, 13, 1362. https://doi.org/10.3390/jmse13071362

Li X, Deng Y, Zheng W, Zhang R. Investigation of Implantable Capsule Grouting Technology and Its Bearing Characteristics in Soft Soil Areas. Journal of Marine Science and Engineering. 2025; 13(7):1362. https://doi.org/10.3390/jmse13071362

Chicago/Turabian StyleLi, Xinran, Yuebao Deng, Wenxi Zheng, and Rihong Zhang. 2025. "Investigation of Implantable Capsule Grouting Technology and Its Bearing Characteristics in Soft Soil Areas" Journal of Marine Science and Engineering 13, no. 7: 1362. https://doi.org/10.3390/jmse13071362

APA StyleLi, X., Deng, Y., Zheng, W., & Zhang, R. (2025). Investigation of Implantable Capsule Grouting Technology and Its Bearing Characteristics in Soft Soil Areas. Journal of Marine Science and Engineering, 13(7), 1362. https://doi.org/10.3390/jmse13071362