Remote Non-Destructive Testing of Port Cranes: A Review of Vibration and Acoustic Sensors with IoT Integration

Abstract

1. Introduction

2. Port Cranes Overview

2.1. Types of Port Cranes

- Ship-to-Shore Cranes (STSCs)—the largest and most iconic port cranes, serving as the primary interface between ships and the shore. These rail-mounted cranes feature telescopic or hinged booms, enabling them to reach container ships with lifting capacities exceeding 100 tons. High-profile STS cranes dominate major ports because of their ability to handle 24,000-TEU vessels with lifting heights exceeding 50 m and reach 25 container rows [4]. Their design has evolved to accommodate Panamax, Neo-Panamax, and Post-Panamax ships with critical advancements in structural integrity and energy efficiency [5,6].

- Rail-Mounted Gantry Cranes (RMGCs)—operate on fixed rails in container yards, stacking containers with precision. These electrically powered cranes are energy-efficient and widely used in automated terminals with lifting capacities of up to 50 tons [7]. Their rail-mounted design ensures stability during high-speed container transfers, rendering them ideal for intermodal terminals [8,9].

- Rubber-Tyred Gantry Cranes (RTGCs)—combine mobility with container stacking capabilities. Equipped with rubber tires, they can move freely across port yards, thereby offering flexibility in congested areas. Traditionally, diesel-powered, fully electric variants have gained traction, reducing emissions by 36% [10]. These cranes are critical for ports requiring dynamic cargo handling [11,12,13].

2.2. Evolution Timeline of Port Cranes

2.2.1. Ancient to Medieval Periods (Pre-18th Century)

- Early Manual Lifting Devices (Pre-530 BC)—Long before the first written records, civilizations such as the Ancient Greeks, Egyptians, and those of the Mycenaean era had already employed basic pulley systems and winches. These simple yet effective mechanisms were crucial for constructing monumental structures and facilitating early port operation. For instance, the construction of massive structures in Tiryns, Mycenae, and the megalithic monuments of Mane in ancient Greece relied on such lifting techniques, although the exact crane-like devices used remain somewhat speculative [1].

- Written Records and Early Cranes (530 BC)—The first known written records of hoisting mechanisms in ports date back to 530 BC in Ephesus, Greece, in relation to the construction of the first Temple of Artemis. Although details are scarce, these records mark an important milestone in the documented history of port-related lifting technologies [1].

- Treadwheel Cranes (12th–18th Centuries)—By the 12th century, Europe saw the emergence of wooden wheel cranes. These cranes, operated by humans walking on a large wheel, can lift up to five tons. They became staples in medieval ports, enabling the loading and unloading of goods, although their operations were labor-intensive and relatively slow. Their design, with wooden gears and ropes, was a significant technological step forward at the time but was limited in terms of mobility and the weight they could handle [2].

2.2.2. Industrial Revolution Era (Late 18th to Mid-19th Century)

- Steam-powered crane introduction (Late 18th Century)—During the Industrial Revolution, the late eighteenth century saw the emergence of steam-powered cranes, which triggered a paradigm shift in port crane technology. Steam engines were introduced to replace the manual and animal power. In 1785, James Watt developed the first practical steam engine, not long before this technology was adapted for crane use. The introduction of steam-powered cranes increased the lifting capacity to approximately 20 tons, thereby significantly improving the efficiency of port operations. However, these cranes require stationary boilers, which limits their mobility, and their complex maintenance requirements are a drawback [2].

- Advancements in Structural Materials (1830s–1850s)—In 1834, the first cast iron crane was constructed. Cast iron offers greater strength than wood, thereby enhancing the durability of cranes. Subsequently, in 1851, more advanced steam-powered designs emerged, and iron and steel began to be widely used in crane structures. This further increases the load capacity and stability of the cranes [3].

2.2.3. Early 20th Century (1900–1950s)

- Electric Crane Adoption (early 1900s)—At the dawn of the 20th century, electric motors began to replace steam engines in cranes. This transition offers numerous advantages including smoother operation, higher reliability, and easier control. Electric cranes reduce the maintenance costs associated with steam engines such as boiler maintenance and coal handling. By 1910, many major ports in developed countries had started to incorporate electric-powered cranes into their operations, leading to increased productivity and a more stable power source for lifting heavy loads [2].

- Bulk Handling Innovations (1920s–1940s)—The 1920s–1940s saw significant advancements in bulk cargo handling. Hydraulic systems and grab buckets were introduced, and revolutionizing materials such as coal, ores, and grains were loaded and unloaded. These innovations increased the throughput of bulk cargo at ports, as hydraulic systems provided more precise control over the lifting and dumping of materials. For example, hydraulically operated grab buckets can be adjusted to pick up different amounts of bulk materials and improve the efficiency of handling various types of cargo [2].

2.2.4. Containerization Revolution (1950s–1970s)

- PACECO Container Crane Invention (1959)—In 1959, a game-changing event occurred in the port crane world. The Pacific Coast Engineering Company (PACECO) introduced the first high-speed container crane for Matson Navigation. This crane was a revolutionary design featuring all-welded box girders that provided enhanced structural integrity. With a lifting capacity of 27.5 tons, it can handle containers at a much faster rate than previously used cranes. The introduction of this crane reduced ship turnaround times from weeks to hours, setting a new standard for container handling globally and paving the way for the containerization revolution [24].

- Widespread Containerization Adoption (1960s–1970s)—By 1966, 16 PACECO cranes were operational in various ports, and containerization had begun to gain widespread acceptance. The standardization of containers has led to the development of specialized port cranes designed specifically for container handling. These cranes, including STS cranes, are essential for efficient port operations. The growth of container shipping has also spurred the development of larger container ships, which in turn require cranes with greater reach and lifting capacities [24].

2.2.5. Specialized Cranes for Larger Vessels (1970s–1990s)

- Panamax/Post-Panamax STSCs Development (1970s–1980s)—As container ships continued to grow, the cranes had to adapt. In the 1970s, Panamax cranes were developed to handle ships passing through the original Panama Canal. These cranes had a reach of 13 container rows and lifting height of approximately 38 m. In the 1980s, post-Panamax cranes were introduced for even wider vessels, extending their reach to 16 rows and increasing lifting capacity to 40–50 tons. Seismic design innovations were also incorporated to ensure the stability of large cranes in regions prone to high winds and earthquakes [25].

- RTGCs Introduction (1987)—In 1987, Valmet (later known as Kalmar) delivered the first batch of RTGCs to the Tanzanian port of Dar es Salaam. RTGCs have several significant advantages over their predecessors such as mobile gantry cranes. They have eight wheels, allowing them to stack containers in a 1 over 3 configurations, which increases the storage density in the container yards. With a lifting capacity of up to 41 tons and 400 horsepower, compared to the 22–30-ton capacity and 130-horsepower of mobile gantry cranes, RTGCs were better equipped to meet the high-productivity demands of modern ports [26].

2.2.6. Automation and Sustainability (1990s–2020s)

- ASCs debut (1990s)—In the 1990s, fully automated rail-mounted ASCs were debuted in European terminals, such as Rotterdam’s ECT Delta Terminal. These cranes eliminate the need for human operators for certain container-handling tasks, enhance safety, and significantly increase the throughput of large terminals. The use of sensors, computer-controlled systems, and automated guidance systems allows ASCs to move containers with high precision and speed [8].

- Electric/Hybrid RTGCs Developments (1997–2005)—In 1997, Kalmar introduced the next generation of AC electric-powered RTGCs along with its own PLC software, which provided in-house electrical engineering capabilities. This shift towards electric power has reduced emissions and noise pollution. In 2005, Kalmar launched the E-One RTGCs, the first fully electric RTGCs without hydraulics. These electric and hybrid RTGs not only improve environmental performance, but also offer better energy efficiency, with some models reducing energy consumption by 30–50% compared to diesel-powered RTGCs [11,27].

- Energy-Saving RTGCs Retrofits (2007–2008)—In 2007, the Ministry of Transport issued Guidance on Energy Conservation and Emission Reduction in Ports. In response, the Water Transport Science Research Institute of the Ministry of Transport, Guangzhou Port Group Co., Ltd. (Guangzhou, China), and Shenzhen Jingsheng Textile Co., Ltd. (Shenzhen, China), initiated a project to retrofit RTGCs for energy efficiency. Through months of laboratory and field testing from 2007 to 2008, the retrofitted RTGCs achieved significant fuel savings of up to 40–65%. For instance, the Shanghai International Port Group retrofitted its RTGCs into hybrid diesel-battery RTGCs, reducing the fuel consumption by 65%. Additionally, in a Shanghai terminal, replacing diesel-powered RTGCs with electric RTGCs reduced the energy consumption by 54.9% and total energy costs by 29.7%. These results demonstrate the potential of retrofitted RTGCs to enhance the energy efficiency of existing port crane fleets [27]. Driven by green port initiatives, container terminal operators have replaced the environmentally and economically inefficient diesel-powered rubber-tyred gantry cranes with new or retrofitted electric cranes. For example, 57 RTGCs in Tianjin Port were converted to electric RTGCs over two years, reducing the unit energy consumption of yard cranes by nearly 80% [28].

- Hydrogen Fuel Cell RTGCs Testing (2025)—In April 2025, DP World completed the initial testing of a hydrogen fuel cell RTGCs at the Port of Vancouver. This marks a significant milestone in decarbonizing port operations. RTGCs, traditionally powered by diesel, are crucial for cargo handling but are major contributors to greenhouse gas emissions. At the DP World’s Vancouver terminal, 19 RTGCs account for 50% of diesel consumption and generate over 4200 tonnes of CO2 annually. The adoption of hydrogen technology promises to drastically reduce or eliminate this environmental impact. The tested RTGCs are currently undergoing field trials, as the DP World evaluates the feasibility of electrifying its global fleet of 1500 RTGCs. If the trials are successful, the DP World may convert its 25 diesel-powered RTGCs to Vancouver and Prince Rupert to meet its zero-emission goals [29].

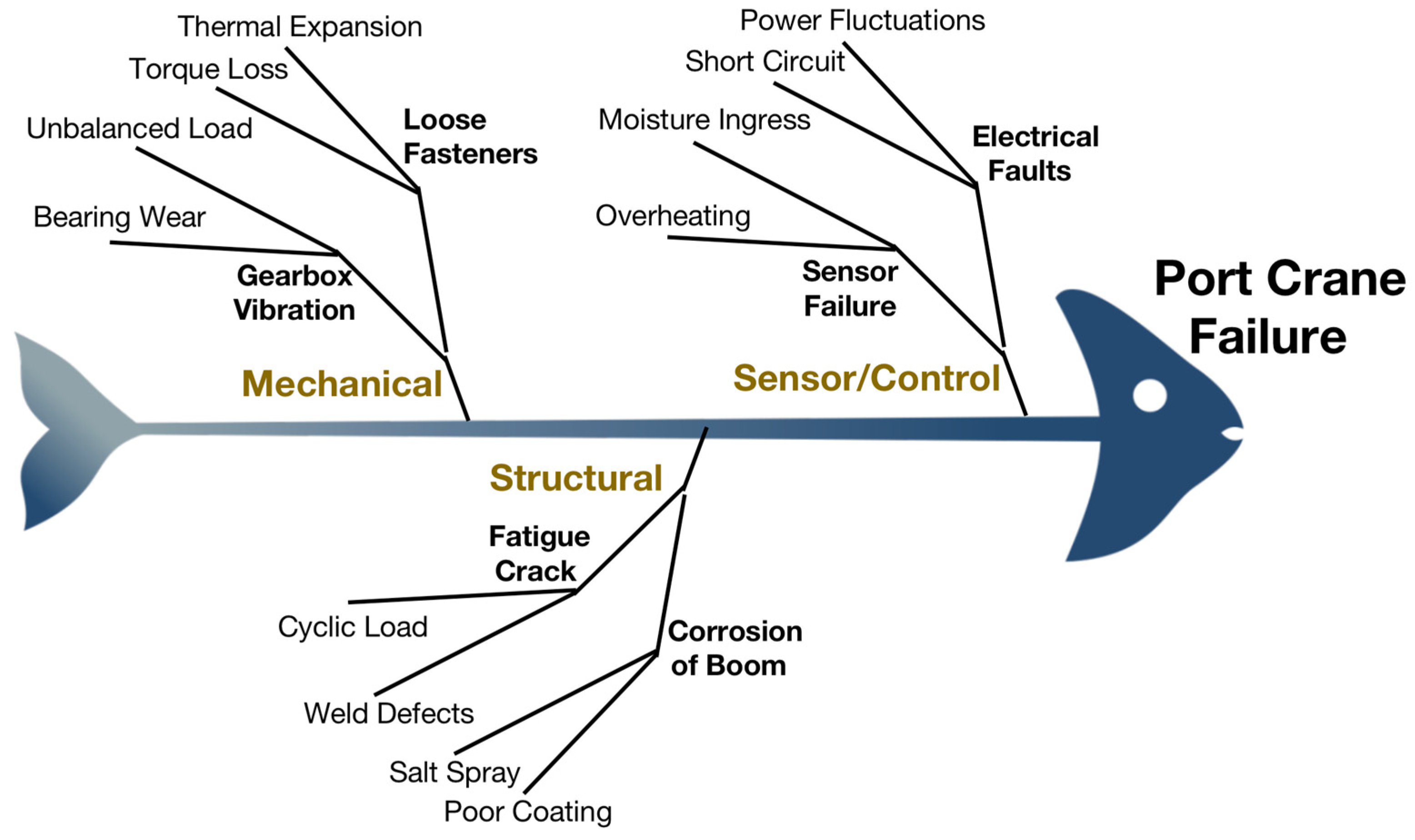

2.3. Mechanical and Structural Defects and Failures of Port Cranes

2.3.1. Mechanical Defects

2.3.2. Structural Defects

2.3.3. Impact of Defects and Failures

3. Current Non-Destructive Testing Practices for Port Cranes and Their Drawbacks

3.1. Common Non-Destructive Testing Methods

- Visual inspection (VI)—the most basic NDT method, in which inspectors visually examine a crane for signs of wear, corrosion, or damage. Although VI is simple and cost-effective, it is subjective and can detect only surface-visible defects. This requires the inspectors to have extensive experience and expertise. Liu et al. [49] highlighted that inspectors with years of experience are better equipped to identify signs of cracks or rust that may lead to damage in complex steel structures. Damage to container cranes often appears in critical structural areas, which are regions that are most prone to structural weaknesses owing to high loads, stress, and environmental factors. Gantry cranes, for instance, operate 24/7, 365 days a year and load and unload containers next to the sea. These working conditions accelerate material deterioration and necessitate more frequent inspections without prolonged downtime for maintenance because such downtime requires significant resources, time, and costs.

- Ultrasonic testing (UT)—uses high-frequency sound waves to detect internal flaws in a material [50]. It is commonly employed to inspect critical components such as welds, pins, and slewing ring bolts [51]. UT can detect subsurface defects and measure the thickness of a material [52]. However, skilled technicians are required to operate the equipment and interpret the results. In conventional UT, the tested component must typically be cleaned and prepared, and direct contact between the probe and the component is necessary, making the process time consuming. Chen et al. [53] indicated that UT is a widely used NDT method for detecting internal defects in steel structures but noted its limitations, such as the need for specialized personnel and component preparation [54].

- Magnetic particle testing (MPT)—used to detect surface and near-surface defects in ferromagnetic materials [55]. It is often applied to inspect components, such as crane hooks and pins. MPT can identify fine cracks but is limited to ferromagnetic materials. The tested component must be magnetized, and the testing environment should avoid magnetic interference [56]. Fonte et al. [57] pointed out that MPT is effective for detecting surface and near-surface defects in ferromagnetic materials but does not apply to non-ferromagnetic materials [58].

- Radiographic testing (RT)—uses X-rays or gamma rays to inspect internal structures and can detect internal defects, such as cracks and porosity, in components such as welds [63,64,65]. RT provides intuitive image results but involves radiation safety hazards. The testing process is complex and time-consuming, and requires strict safety precautions [66,67].

3.2. Drawbacks of Current NDT Practices

- Subjectivity and Human Factors—VI is highly subjective and depends on the inspector’s experience and skills. Human factors can lead to missed detections or misjudgements. Liu et al. [49] pointed out that the subjectivity of VI results in significant variability in defect detection outcomes, influenced by the inspector’s experience and skills.

- Limited Detection Capabilities—Some NDT methods can only detect surface or near-surface defects but cannot identify internal defects. For example, MPT and ECT are only effective for specific material types and defect locations.

- High Requirements for Component Preparation—Certain conventional UT and RT often require the tested component to be cleaned, paints removed, and surface prepared, thereby increasing inspection time and labor costs. Stanić et al. [68] indicated that the preparation of components for UT and RT is time-consuming and labor-intensive, impacting inspection efficiency [69].

- Safety Risks—RT involves radiation hazards, necessitating strict safety measures to protect inspectors and nearby personnel. The operation of the NDT equipment may also pose safety risks. Majumder et al. [70] emphasized the radiation hazards associated with RT and the need for stringent safety protocols during testing [71].

- Inconvenience and Low Efficiency—Traditional NDT methods often require inspectors to access hard-to-reach or elevated areas of the crane, increasing inspection difficulty and risk. Typically performed during scheduled shutdowns, these methods interrupt operations and reduce port efficiency [72].

- Lack of Real-Time Monitoring—Most current NDT methods are periodic inspections that cannot provide real-time information on the structural health of port cranes. Defects that develop between inspections may go undetected, potentially leading to sudden failures [73].

4. Vibration and Acoustic Sensors in Non-Destructive Testing of Port Cranes

4.1. Vibration Sensors in Port Crane Monitoring

4.1.1. Working Principle of Vibration Sensors

4.1.2. Types of Vibration Sensors

4.1.3. Performance Characteristics of Vibration Sensors

4.1.4. Application of Vibration Sensors in Port Cranes

4.2. Acoustic Emission Sensors in Port Crane Maintenance

4.2.1. Working Principle of Acoustic Emission Sensors

4.2.2. Types of Acoustic Emission Sensors

4.2.3. Performance Characteristics of Acoustic Emission Sensors

4.2.4. Applications of Acoustic Emission Sensors in Port Cranes

4.3. Integration with IoT for Remote Monitoring of Port Cranes

4.3.1. Vibration Sensors in IoT-Based Remote Monitoring of Port Cranes

- Data collection and transmission—Vibration sensors, such as accelerometers and strain gauges, are strategically placed on critical components of port cranes. These sensors convert mechanical vibrations into electrical signals that are then amplified and conditioned. The data is collected by IoT-enabled data acquisition systems, which can be located on the crane itself or at a nearby monitoring station. The data is transmitted over wireless or wired networks to a central IoT platform. Wireless networks, such as Wi-Fi, Bluetooth, and cellular networks, are often preferred in marine environments because of their flexibility and ease of installation.

- Data Processing and Analysis—Once the vibration data reaches the IoT platform, it undergoes processing and analysis. Cloud and edge computing can also be used for data processing. Cloud computing offers virtually unlimited storage and computational resources but may introduce latency issues. Edge computing processes data closer to the source, reduces latency, and enables faster response times. The processed data is analyzed using various algorithms and techniques to detect patterns, anomalies, and trends. Machine learning algorithms can be trained to identify the early signs of structural damage or mechanical failure based on historical data and predefined thresholds.

- Automated Monitoring and Alerts—IoT platforms enable the implementation of automated monitoring systems that trigger alerts when abnormal conditions are detected. For example, if the vibration levels exceed predefined thresholds, the system can automatically send alerts to engineers and technicians via email, SMS, or mobile applications. These alerts provide valuable time to investigate and address potential issues before they escalate to catastrophic failure. Automated monitoring systems can also generate reports and dashboards, thereby providing a comprehensive overview of the structural health of the port cranes.

4.3.2. Acoustic Emission Sensors in IoT-Based Remote Monitoring of Port Cranes

- Data Collection and Transmission—AE sensors, such as piezoelectric transducers and fiber-optic sensors, are placed on or near monitored structures. These sensors detect high-frequency acoustic emissions generated by microstructural changes within a material, such as crack propagation or dislocation movement. The detected signals are converted into electrical signals and transmitted to IoT-enabled data acquisition systems. Like vibration sensors, data is transmitted over wireless or wired networks to a central IoT platform.

- Data Processing and Analysis—AE data collected by the AE sensors is processed and analyzed on the IoT platform. Cloud and edge computing can be used for data processing. The analysis of AE data involves the identification and classification of emission sources. Signal processing techniques, such as time-frequency analysis and wavelet transform, are used to extract features from the AE signals. Machine learning algorithms can then be applied to classify signals and determine whether they are indicative of structural damage or other issues.

- Automated Monitoring and Alerts—IoT platforms also enable automated monitoring of systems for AE sensors. When abnormal AE activity is detected, the system can trigger alerts to notify engineers and technicians. These alerts can help prioritize inspections and maintenance activities, ensuring the timely identification and resolution of potential issues. Automated monitoring systems can also integrate data from multiple sensors, including vibration and AE sensors, to provide a more comprehensive assessment of the structural health of the port cranes.

5. Summary and Discussion

5.1. Summary

5.2. Challenges and Limitations

5.2.1. Vibration Sensor Challenges

- Environmental vulnerability: Marine environments present high humidity, salinity, and temperature fluctuations, all of which can impair sensor accuracy and durability. Sensor corrosion is a major concern, necessitating the use of protective housing and robust sealing strategies.

- Installation and calibration complexity: Appropriate sensor placement is crucial for accurate signal acquisition. However, installation on large, geometrically complex structures, such as STSCs or RTGCs, is logistically demanding. Calibration procedures are equally labor-intensive and require periodic readjustments to maintain the measurement integrity.

- Data management constraints: Vibration sensors produce voluminous time-series data, posing challenges for data transmission, especially in areas with limited wireless coverage, and require efficient preprocessing and filtering algorithms to extract actionable insights.

5.2.2. Acoustic Emission Sensor Challenges

- Signal-to-noise ratio—AE sensors are highly sensitive to environmental and mechanical noises. Differentiating genuine acoustic emissions from background noise is nontrivial and requires advanced filtering and denoising algorithms.

- Localization accuracy and sensor placement—The diagnostic effectiveness of the AE testing is influenced by sensor positioning relative to the emission source. Incorrect placement can lead to signal attenuation or misclassification, particularly in multi-material or composite components.

- Interpretation complexity—The acoustic signals generated by microstructural changes can be difficult to interpret without advanced pattern recognition or machine learning tools. False positives and negatives remain a concern in early-stage deployment.

5.2.3. IoT Integration Challenges

- Data security and privacy—Port cranes are often critical for national security and economic interests. Ensuring the security and privacy of the data collected from the sensors is paramount. The implementation of robust encryption protocols, secure authentication mechanisms, and access control measures can help protect data from unauthorized access and cyber threats.

- Data management and storage—The large volume of data generated by vibration and AE sensors requires efficient data management and storage solutions. Cloud storage offers scalable and cost-effective storage options; however, it is essential to implement proper data organization and retrieval mechanisms to ensure quick access to relevant data.

- Network connectivity and reliability—Port environments pose challenges to network connectivity. Ensuring reliable and consistent network connectivity is crucial for transmitting sensor data. Using redundant network connections, satellite communication, and edge computing can help mitigate connectivity issues.

- Sensor calibration and maintenance—Vibration and AE sensors require regular calibration and maintenance to ensure accurate and reliable data collection. Developing automated calibration procedures and implementing remote maintenance capabilities can help reduce the need for manual intervention and minimize downtime.

- Data analysis and interpretation—The analysis and interpretation of data from vibration and AE sensors can be complex because of the high volume and variability of the data. Advanced data analysis techniques, such as machine learning and artificial intelligence, can help automate the analysis process and improve the accuracy of structural issues detection.

5.3. Comparison of Traditional and IoT-Based Non-Destructive Testing

5.4. Future Research Directions for Port Crane Monitoring

- Development of next-generation sensors—Research on nano-enabled, self-powered, or bioinspired sensor materials could yield devices with enhanced sensitivity, environmental resistance, and energy efficiency.

- Hybrid NDT frameworks—Integrating vibration and AE sensors with complementary NDT techniques (e.g., thermal imaging and guided wave testing) may provide a holistic and redundant diagnostic framework for critical crane components.

- AI-driven predictive maintenance—Continued exploration of AI models for anomaly detection, pattern recognition, and lifecycle prediction enhances system autonomy and decision accuracy.

- Self-sustaining monitoring systems—The incorporation of energy harvesting technologies, such as piezoelectric or thermoelectric generators, could eliminate the need for manual sensor recharging or replacement, thereby improving system sustainability.

- Standardization and interoperability—Establishing international standards for RNDT sensor calibration, data formats, and IoT communication protocols would accelerate technology adoption and cross-system integration in global port operations.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AE | Acoustic emission |

| AI | Artificial intelligence |

| ASCs | Automated Stacking Cranes |

| CNC | Computerized Numerical Control |

| ECT | Eddy current testing |

| EMI | Electromagnetic interference |

| FBGs | Fiber Bragg gratings |

| FCs | Floating Cranes |

| IoT | Internet of Things |

| MEMS | Micro Electro-Mechanical Systems |

| MHCs | Mobile Harbor Cranes |

| MPT | Magnetic particle testing |

| NDT | Non-destructive testing |

| PACECO | Pacific Coast Engineering Company |

| RMGCs | Rail-Mounted Gantry Cranes |

| RNDT | Remote non-destructive testing |

| RT | Radiographic testing |

| RTGCs | Rubber-Tyred Gantry (RTG) Cranes |

| SCADA | Supervisory Control and Data Acquisition |

| SHM | Structural health monitoring |

| STSCs | Ship-to-Shore Cranes |

| UAVs | Unmanned aerial vehicles |

| UT | Ultrasonic testing |

| VI | Visual inspection |

References

- Zrni, N.; Hoffmann, K.; Bošnjak, S. A Note on the History of Handling in Ports: From Ancient to Medieval Cranes. In Proceedings of the 12th International Federation for the Theory of Mechanisms and Machines World Congress, Besançon, France, 18–21 June 2007; pp. 1–6. [Google Scholar]

- History of Cranes—Lee Industrial Contracting. Available online: https://www.leecontracting.com/history-of-cranes/ (accessed on 30 April 2025).

- Kumar, S.S. Design and fabrication of hydraulic and mechanical crane lift. Int. J. Sci. Res. Eng. Trends 2019, 5, 721–725. [Google Scholar]

- Tran, Q.H.; Huh, J.; Nguyen, V.B.; Haldar, A.; Kang, C.; Hwang, K.M. Comparative study of nonlinear static and time-history analyses of typical Korean STS container cranes. Adv. Civ. Eng. 2018, 2018, 2176894. [Google Scholar] [CrossRef]

- Tran, Q.H.; Huh, J.; Nguyen, V.B.; Kang, C.; Ahn, J.-H.; Park, I.-J. Sensitivity analysis for ship-to-shore container crane design. Appl. Sci. 2018, 8, 1667. [Google Scholar] [CrossRef]

- Jo, J.-H.; Kim, S. Key performance indicator development for ship-to-shore crane performance assessment in container terminal operations. J. Mar. Sci. Eng. 2020, 8, 6. [Google Scholar] [CrossRef]

- Kim, J.; Hong, E.J.; Yang, Y.; Ryu, K.R.; Kim, J.; Hong, E.J.; Yang, Y.; Ryu, K.R. Noisy optimization of dispatching policy for the cranes at the storage yard in an automated container terminal. Appl. Sci. 2021, 11, 6922. [Google Scholar] [CrossRef]

- Krstić, M.; Tadić, S.; Elia, V.; Massari, S.; Farooq, M.U. Intermodal terminal subsystem technology selection using integrated fuzzy MCDM model. Sustainability 2023, 15, 3427. [Google Scholar] [CrossRef]

- Kermani, M.; Parise, G.; Chavdarian, B.; Martirano, L. Ultracapacitors for port crane applications: Sizing and techno-economic analysis. Energies 2020, 13, 2091. [Google Scholar] [CrossRef]

- Soni, B.P.; Sharma, K.C.; Lutendo, R.; Takalani, E.; Masisi, L. Development of an optimal port crane trajectory for reduced energy consumption. Energies 2023, 16, 7172. [Google Scholar] [CrossRef]

- Antonelli, M.; Ceraolo, M.; Desideri, U.; Lutzemberger, G.; Sani, L. Hybridization of rubber tired gantry (RTG) cranes. J. Energy Storage 2017, 12, 186–195. [Google Scholar] [CrossRef]

- Alasali, F.; Luque, A.; Mayer, R.; Holderbaum, W. A comparative study of energy storage systems and active front ends for networks of two electrified RTG cranes. Energies 2019, 12, 1771. [Google Scholar] [CrossRef]

- Chen, D.; Niu, W.; Gu, W.; Schofield, N. Game-based energy management method for hybrid RTG Cranes. Energies 2019, 12, 3589. [Google Scholar] [CrossRef]

- Gharehgozli, A.H.; Vernooij, F.G.; Zaerpour, N. A Simulation study of the performance of twin automated stacking cranes at a seaport container terminal. Eur. J. Oper. Res. 2017, 261, 108–128. [Google Scholar] [CrossRef]

- Zhou, T.; Lu, X.; Wang, W.; Jin, X.; Mi, N.; Song, W.; Li, Q. Deep reinforcement learning for dynamic twin automated stacking cranes scheduling problem. Electronics 2023, 12, 3288. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhu, Y.; Qin, J.; Duan, J.; Zhou, Y.; Shi, H.; Nie, L. Study on the multi-equipment integrated scheduling problem of a u-shaped automated container terminal based on graph neural network and deep reinforcement learning. J. Mar. Sci. Eng. 2025, 13, 197. [Google Scholar] [CrossRef]

- Hong, K.-S.; Ngo, Q.H. Dynamics of the container crane on a mobile harbor. Ocean Eng. 2012, 53, 16–24. [Google Scholar] [CrossRef]

- Kim, W.-S.; Kim, J. Simulation models for offshore port service concepts. Appl. Sci. 2019, 9, 584. [Google Scholar] [CrossRef]

- Đelović, D. Criticality analysis of a sea port`s shore cranes using analytic hierarchy process method. Open Transp. J. 2024, 18, e26671212293095. [Google Scholar] [CrossRef]

- Lee, M.-W.; Lee, J.-H.; Lee, Y.-S.; Park, H.-J.; Lee, T.-K. Safety assessment for upper part of floating crane considering minimum luffing angle. Appl. Sci. 2021, 11, 5104. [Google Scholar] [CrossRef]

- Zou, H.; Chen, S.; Sun, G.; Gong, Y. Dynamic analysis and safety assessment of ships and cables during salvage operations. Appl. Sci. 2023, 13, 9420. [Google Scholar] [CrossRef]

- Liu, Q.; Lu, Z.; Liu, Z.; Lin, P.; Wang, X. Ballast water dynamic allocation optimization for revolving floating cranes based on a hybrid algorithm of fuzzy-particle swarm optimization with domain knowledge. J. Mar. Sci. Eng. 2022, 10, 1454. [Google Scholar] [CrossRef]

- Wang, X.; Yu, Y.; Li, S.; Zhang, J.; Liu, Z.; Wang, X.; Yu, Y.; Li, S.; Zhang, J.; Liu, Z. Point-to-point-based optimization method of ballast water allocation for revolving floating cranes with experimental verification. J. Mar. Sci. Eng. 2024, 12, 437. [Google Scholar] [CrossRef]

- PACECO Container Crane—ASME. Available online: https://www.asme.org/about-asme/engineering-history/landmarks/85-paceco-container-crane (accessed on 30 April 2025).

- Zrni, N.; Hoffmann, K. Development of design of ship-to-shore container cranes: 1959–2004. In International Symposium on History of Machines and Mechanisms; Ceccarelli, M., Ed.; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2004; pp. 229–242. [Google Scholar]

- Half a Century of RTG History. Available online: https://www.kalmarglobal.com/news--insights/articles/2017/half-a-century-of-rtg-history/ (accessed on 30 April 2025).

- Luque, A.; Harrison, I.; Pietrosanti, S.; Alasali, F.M.M.; Holderbaum, W.; Mayer, R.M.; Becerra, V.M. Energy Reduction on ERTG. In Proceedings of the EEEIC 2016—International Conference on Environment and Electrical Engineering, Florence, Italy, 7–10 June 2016. [Google Scholar]

- Ding, Y.; Yang, Y.; Heilig, L.; Lalla-Ruiz, E.; Voss, S. Deployment and retrofit strategy for rubber-tyred gantry cranes considering carbon emissions. Comput. Ind. Eng. 2021, 161, 107645. [Google Scholar] [CrossRef]

- DP World Pilots Hydrogen Fuel Cell Crane at Vancouver Port. Available online: https://www.dpworld.com/en/canada/news/latest-news/initial-testing-of-hydrogen-fuel-cell-rtg-crane (accessed on 1 May 2025).

- Sawalhi, N.; Wang, W.; Becker, A. Vibration signal processing using cepstrum editing technique to enhance spall-related vibration features in rolling element bearings. Int. J. Mech. Eng. Robot. Res. 2019, 8, 65–68. [Google Scholar] [CrossRef]

- Zmarzły, P. Multi-dimensional mathematical wear models of vibration generated by rolling ball bearings made of AISI 52100 bearing steel. Materials 2020, 13, 5440. [Google Scholar] [CrossRef] [PubMed]

- Wojnar, G.; Burdzik, R.; Wieczorek, A.N.; Konieczny, Ł. Multidimensional data interpretation of vibration signals registered in different locations for system condition monitoring of a three-stage gear transmission operating under difficult conditions. Sensors 2021, 21, 7808. [Google Scholar] [CrossRef]

- Patel, S.; Shah, U.; Khatri, B.; Patel, U. Research progress on bearing fault diagnosis with localized defects and distributed defects for rolling element bearings. Noise Vib. Worldw. 2022, 53, 352–365. [Google Scholar] [CrossRef]

- Feng, K.; Ji, J.C.; Ni, Q.; Beer, M. A review of vibration-based gear wear monitoring and prediction techniques. Mech. Syst. Signal Process. 2023, 182, 109605. [Google Scholar] [CrossRef]

- Sharma, G.; Kaur, T.; Mangal, S.K.; Kohli, A. Investigating bearing and gear vibrations with a Micro-Electro-Mechanical Systems (MEMS) and machine learning approach. Results Eng. 2024, 24, 103499. [Google Scholar] [CrossRef]

- Wodecki, J.; Stefaniak, P.; Obuchowski, J.; Wylomanska, A.; Zimroz, R. Combination of principal component analysis and time-frequency representations of multichannel vibration data for gearbox fault detection. J. Vibroeng. 2016, 18, 2167–2175. [Google Scholar] [CrossRef]

- Hidle, E.L.; Hestmo, R.H.; Adsen, O.S.; Lange, H.; Vinogradov, A. Early detection of subsurface fatigue cracks in rolling element bearings by the knowledge-based analysis of acoustic emission. Sensors 2022, 22, 5187. [Google Scholar] [CrossRef]

- Goswami, P.; Rai, R.N. Principal Component Analysis Based Vibration Sensor Selection for Fault Diagnosis of an Industrial Gearbox. In Proceedings of the IEEE Instrumentation and Measurement Technology Conference, Glasgow, UK, 20–23 May 2024. [Google Scholar]

- Silva, R.L.A.; Alves, K.G.B.; da Costa, J.Â.P.; Ochoa, A.A.V.; Michima, P.S.A.; Leite, G.d.N.P.; Caldas, A.M.A. Dynamics of vibration in crane operation: An elementary modal and harmonic analysis. Processes 2025, 13, 610. [Google Scholar] [CrossRef]

- Grzejda, R. Modelling Nonlinear Multi-Bolted Connections: A Case of the Assembly Condition. In Proceedings of the 15th International Scientific Conference “Engineering for Rural Development 2016”, Jelgava, Latvia, 25–27 May 2016; pp. 329–335. [Google Scholar]

- Grzejda, R. Impact of nonlinearity of the contact layer between elements joined in a multi-bolted system on its preload. Int. J. Appl. Mech. Eng. 2017, 22, 921–930. [Google Scholar] [CrossRef]

- Grzejda, R. Finite element modelling of a pair of flexible elements contact preloaded and externally loaded with an arbitrary force. Adv. Sci. Technol. Res. J. 2020, 14, 118–124. [Google Scholar] [CrossRef]

- Grzejda, R.; Parus, A. Health assessment of a multi-bolted connection due to removing selected bolts. FME Trans. 2021, 49, 634–642. [Google Scholar] [CrossRef]

- Deschanel, S.; Ben Rhouma, W.; Weiss, J. Acoustic emission multiplets as early warnings of fatigue failure in metallic materials. Sci. Rep. 2017, 7, 13680. [Google Scholar] [CrossRef] [PubMed]

- Bhuiyan, M.Y.; Giurgiutiu, V. The signatures of acoustic emission waveforms from fatigue crack advancing in thin metallic plates. Smart Mater. Struct. 2018, 27, 015019. [Google Scholar] [CrossRef]

- Okorn, I.; Nagode, M.; Klemenc, J.; Oman, S. Analysis of additional load and fatigue life of preloaded bolts in a flange joint considering a bolt bending load. Metals 2021, 11, 449. [Google Scholar] [CrossRef]

- Dzioba, I.; Zvirko, O.; Pała, R.; Oliynyk, O. Assessment of the structural integrity of the portal crane elements after long-term operation. Materials 2024, 17, 6133. [Google Scholar] [CrossRef] [PubMed]

- Wong, Y.J.; Hashim, M.S.M.; Shahriman, A.B.; Rahman, A.; Aziz, I.A.; Saad, M.A.M.; Nasirudin, M.A.; Razlan, Z.M.; Kamarrudin, N.S.; Ibrahim, I.; et al. Study on modal and harmonic response analysis by modifying motorcycle chassis using finite element method. J. Phys. Conf. Ser. 2021, 2051, 012004. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.; Ke, Y. Detection and analysis of a quay crane surface based on the images captured by a UAV. Remote Sens. Lett. 2020, 11, 76–85. [Google Scholar] [CrossRef]

- Tai, J.L.; Sultan, M.T.H.; Shahar, F.S. Comparative analysis of ultrasonic inspection techniques for corrosion monitoring in petrochemical plants using Analytic Hierarchy Process (AHP). Pertanika J. Sci. Technol. 2025, 33, 1439–1457. [Google Scholar]

- Kim, Y.L.; Cho, S.; Park, I.K. Analysis of flaw detection sensitivity of phased array ultrasonics in austenitic steel welds according to inspection conditions. Sensors 2021, 21, 242. [Google Scholar] [CrossRef]

- Tai, J.L.; Sultan, M.T.H.; Tarasiuk, W.; Napiórkowski, J.; Łukaszewicz, A.; Shahar, F.S. Ultrasonic velocity and attenuation of low-carbon steel at high temperatures. Materials 2023, 16, 5123. [Google Scholar] [CrossRef]

- Chen, S.; Laefer, D.F.; Mangina, E.; Zolanvari, S.M.I.; Byrne, J. UAV bridge inspection through evaluated 3D reconstructions. J. Bridge Eng. 2019, 24, 05019001. [Google Scholar] [CrossRef]

- Azimi, M.; Eslamlou, A.D.; Pekcan, G. Data-driven structural health monitoring and damage detection through deep learning: State-of-the-art review. Sensors 2020, 20, 2778. [Google Scholar] [CrossRef]

- Azzura, I.; Farhana, M.S.N.; Lokman, M.N.; Mahzan, S.; Ahmad, S.; Rahman, H.A.; Salleh, S.M. Identification corrosion hydrogen attack on carbon steel using Magnetic Particle Inspection (MPI). IOP Conf. Ser. Mater. Sci. Eng. 2019, 494, 012059. [Google Scholar] [CrossRef]

- Jarvis, R.; Cawley, P.; Nagy, P.B. Performance evaluation of a magnetic field measurement NDE technique using a model assisted probability of detection framework. NDT E Int. 2017, 91, 61–70. [Google Scholar] [CrossRef]

- Fonte, M.; Freitas, M.; Li, B.; Duarte, P.; Reis, L. Welding assessment of a damaged crane pedestal of a container ship. Ciênc. Tecnol. Mater. 2015, 27, 10–14. [Google Scholar] [CrossRef]

- Bajauri, M.S.; Alamouri, A.; Gerke, M. Developing a geodatabase for efficient UAV-based automatic container crane inspection. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2022, 43, 335–342. [Google Scholar] [CrossRef]

- Yusa, N.; Tomizawa, T.; Song, H.; Hashizume, H. Probability of detection analyses of eddy current data for the detection of corrosion. Nondestruct. Test. Diagn. 2018, 4, 3–7. [Google Scholar]

- Pelkner, M.; Casperson, R.; Pohl, R.; Munzke, D.; Becker, B. Eddy current testing of composite pressure vessels. Int. J. Appl. Electromagn. Mech. 2019, 59, 1221–1226. [Google Scholar] [CrossRef]

- Santos, D.; Machado, M.A.; Monteiro, J.; Sousa, J.P.; Proença, C.S.; Crivellaro, F.S.; Rosado, L.S.; Santos, T.G. Non-destructive inspection of high temperature piping combining ultrasound and eddy current testing. Sensors 2023, 23, 3348. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Zhou, Z.; Chen, H.; Qu, Z.; Liu, J. Effects of the Wire Mesh on Pulsed Eddy Current Detection of Corrosion Under Insulation. Nondestruct. Test. Eval. 2023, 38, 233–253. [Google Scholar] [CrossRef]

- Boaretto, N.; Centeno, T.M. Automated detection of welding defects in pipelines from radiographic images DWDI. NDT E Int. 2016, 115, 60–66. [Google Scholar] [CrossRef]

- Kumar, S.; Menaka, M.; Venkatraman, B. Radiographic simulation and validation studies on weld joints of annular tanks and cylindrical tanks. IOP Conf. Ser. Mater. Sci. Eng. 2019, 554, 012008. [Google Scholar] [CrossRef]

- Malarvel, M.; Singh, H. An autonomous technique for weld defects detection and classification using multi-class support vector machine in X-radiography image. Optik 2021, 231, 166342. [Google Scholar] [CrossRef]

- Kengyelics, S.M.; Treadgold, L.A.; Davies, A.G. X-ray system simulation software tools for radiology and radiography education. Comput. Biol. Med. 2018, 93, 175–183. [Google Scholar] [CrossRef]

- Marques, L.; Vale, A.; Vaz, P. State-of-the-art mobile radiation detection systems for different scenarios. Sensors 2021, 21, 1051. [Google Scholar] [CrossRef]

- Stanić, N.; Lepot, M.; Catieau, M.; Langeveld, J.; Clemens, F.H.L.R. A technology for sewer pipe inspection (Part 1): Design, calibration, corrections and potential application of a laser profiler. Autom. Constr. 2017, 75, 91–107. [Google Scholar] [CrossRef]

- Feroz, S.; Dabous, S.A. UAV-based remote sensing applications for bridge condition assessment. Remote Sens. 2021, 13, 1809. [Google Scholar] [CrossRef]

- Majumder, S.; Mondal, T.; Deen, M.J. Wearable sensors for remote health monitoring. Sensors 2017, 17, 130. [Google Scholar] [CrossRef]

- Flah, M.; Nunez, I.; Chaabene, W.B.; Nehdi, M.L. Machine learning algorithms in civil structural health monitoring: A systematic review. Arch. Comput. Methods Eng. 2021, 28, 2621–2643. [Google Scholar] [CrossRef]

- Rice, J.A.; Mechitov, K.; Sim, S.-H.; Nagayama, T.; Jang, S.; Kim, R.; Spencer, B.F.; Agha, G.; Fujino, Y. Flexible smart sensor framework for autonomous structural health monitoring. Smart Struct. Syst. 2010, 6, 423–438. [Google Scholar] [CrossRef]

- Guan, S.; Zhu, Z.; Wang, G. A review on UAV-based remote sensing technologies for construction and civil applications. Drones 2022, 6, 117. [Google Scholar] [CrossRef]

- Hackmann, G.; Guo, W.; Yan, G.; Lu, C.; Dyke, S. Cyber-Physical Codesign of Distributed Structural Health Monitoring with Wireless Sensor Networks. In Proceedings of the 1st ACM/IEEE International Conference on Cyber-Physical Systems, Stockholm, Sweden, 13–15 April 2010; pp. 119–128. [Google Scholar]

- Adik, A.K.; Wang, W. An intelligent system for real-time condition monitoring of tower cranes. Intell. Control Autom. 2019, 10, 155–167. [Google Scholar] [CrossRef][Green Version]

- Eager, D.; Hossain, M.I.; Lindqvist, A.L.; Zhou, S. City bus seat vibration analysis using 6-axis accelerometer and gyroscope sensors. Sci. Rep. 2024, 14, 29865. [Google Scholar] [CrossRef]

- Zhao, H.; Machado, L.Q.; Fu, Y.; Ouyang, H.; Mo, J. A self-powered accelerometer with over-range detection for vibration and shock based on triboelectric-electromagnetic mechanism. Nano Energy 2024, 128, 109788. [Google Scholar] [CrossRef]

- Sun, S.; Liu, Y.; Eldean, M.A.S. Design and implementation of an optical fiber sensing based vibration monitoring system. J. Vibroeng. 2021, 23, 496–511. [Google Scholar] [CrossRef]

- Novotný, V.; Sysel, P.; Prokeš, A.; Hanák, P.; Slavíček, K.; Přinosil, J. Fiber optic based distributed mechanical vibration sensing. Sensors 2021, 21, 4779. [Google Scholar] [CrossRef]

- Lin, Z.; Sun, C.; Liu, W.; Fan, E.; Zhang, G.; Tan, X.; Shen, Z.; Qiu, J.; Yang, J. A self-powered and high-frequency vibration sensor with layer-powder-layer structure for structural health monitoring. Nano Energy 2021, 90, 106366. [Google Scholar] [CrossRef]

- Luo, H.; Lu, Y.; Xu, Y.; Yang, G.; Cui, S.; Han, D.; Zhou, Q.; Ouyang, X.; Yang, H.; Cheng, T.; et al. A fully soft, self-powered vibration sensor by laser direct writing. Nano Energy 2022, 103, 107803. [Google Scholar] [CrossRef]

- Wei, H.; Geng, W.; Bi, K.; Li, T.; Li, X.; Qiao, X.; Shi, Y.; Zhang, H.; Zhao, C.; Xue, G.; et al. High-performance piezoelectric-type MEMS vibration sensor based on LiNbO3 single-crystal cantilever beams. Micromachines 2022, 13, 329. [Google Scholar] [CrossRef]

- Wu, T.; You, D.; Gao, H.; Lian, P.; Ma, W.; Zhou, X.; Wang, C.; Luo, J.; Zhang, H.; Tan, H. Research status and development trend of piezoelectric accelerometer. Crystals 2023, 13, 1363. [Google Scholar] [CrossRef]

- Liang, H.; Hao, G.; Olszewski, O.Z. A review on vibration-based piezoelectric energy harvesting from the aspect of compliant mechanisms. Sens. Actuators A Phys. 2021, 331, 112743. [Google Scholar] [CrossRef]

- Mangi, M.A.; Elahi, H.; Ali, A.; Jabbar, H.; Aqeel, A.B.; Farrukh, A.; Bibi, S.; Altabey, W.A.; Kouritem, S.A.; Noori, M. Applications of piezoelectric-based sensors, actuators, and energy harvesters. Sens. Actuators Rep. 2025, 9, 100302. [Google Scholar] [CrossRef]

- Jiao, P.; Egbe, K.J.I.; Xie, Y.; Nazar, A.M.; Alavi, A.H. Piezoelectric sensing techniques in structural health monitoring: A state-of-the-art review. Sensors 2020, 20, 3730. [Google Scholar] [CrossRef] [PubMed]

- Hong, W.; Guo, X.; Zhang, T.; Zhang, A.; Yan, Z.; Zhang, X.; Li, X.; Guan, Y.; Liao, D.; Lu, H.; et al. Flexible capacitive pressure sensor with high sensitivity and wide range based on a cheetah leg structure via 3D printing. ACS Appl. Mater. Interfaces 2023, 15, 46347–46356. [Google Scholar] [CrossRef]

- Utz, A.; Walk, C.; Stanitzki, A.; Mokhtari, M.; Kraft, M.; Kokozinski, R. A high-precision and high-bandwidth MEMS-based capacitive accelerometer. IEEE Sens. J. 2018, 18, 6533–6539. [Google Scholar] [CrossRef]

- Ozioko, O.; Navaraj, W.; Hersh, M.; Dahiya, R. Tacsac: A wearable haptic device with capacitive touch-sensing capability for tactile display. Sensors 2020, 20, 4780. [Google Scholar] [CrossRef]

- Li, M.; Kang, X.; Zhong, X. Process Optimization for CMOS Compatible MEMS Capacitive Acoustic Sensor. In Proceedings of the 2021 IEEE 14th International Conference on ASIC, Kunming, China, 26–29 October 2021. [Google Scholar]

- Dong, T.; Gao, B.; Liu, X.; Wang, Y.; Jiang, C.; Wang, X.; Yan, W.; Zhang, Y. Highly sensitive strain and vibration sensors based on the microfiber sagnac interferometer. IEEE Sens. J. 2023, 23, 24568–24574. [Google Scholar] [CrossRef]

- Biessikirski, A.; Jakóbczyk, J. Application of strain gauge and geophone based integrated monitoring system in the measurements of the blast induced low-frequency vibrations. Sci. Rep. 2025, 15, 9544. [Google Scholar] [CrossRef] [PubMed]

- dos Santos, F.L.M.; Peeters, B.; Lau, J.; Desmet, W.; Goes, L.C.S. The use of strain gauges in vibration-based damage detection. J. Phys. Conf. Ser. 2015, 628, 012119. [Google Scholar] [CrossRef]

- Hadidi, S.; Hassanzadeh, A. A novel self-powered, high-sensitivity piezoelectric vibration sensor based on piezoelectric combo effect. IEEE Sens. J. 2023, 23, 25797–25803. [Google Scholar] [CrossRef]

- Mousavi, M.; Alzgool, M.; Davaji, B.; Towfighian, S. Event-driven MEMS vibration sensor: Integration of triboelectric nanogenerator and low-frequency switch. Mech. Syst. Signal Process. 2023, 187, 109921. [Google Scholar] [CrossRef]

- Kumar, R.; Anand, R.S. Statistical analysis of vibration signal frequency during inner race fault of rolling ball bearings. J. Fail. Anal. Prev. 2023, 23, 2260–2274. [Google Scholar] [CrossRef]

- Ma, P.; Liu, K.; Sun, Z.; Jiang, J.; Wang, S.; Xu, T.; Xu, Z.; Liu, T. Distributed single fiber optic vibration sensing with high frequency response and multi-points accurate location. Opt. Lasers Eng. 2020, 129, 106060. [Google Scholar] [CrossRef]

- Khan, M.A.; Sun, J.; Li, B.; Przybysz, A.; Kosel, J. Magnetic sensors—A review and recent technologies. Eng. Res. Express 2021, 3, 022005. [Google Scholar] [CrossRef]

- Okda, S.; Nampally, S.R.; Fonta, M.; Herold, S.; Nordmann, R.; Rinderknecht, S.; Melz, T. Active Vibration control of gearbox housing using inertial mass actuators. Smart Mater. Struct. 2024, 33, 095008. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; He, B.; Xu, J.; Wei, Y.; Wang, Y. MEMS Acceleration Sensor Vibration Detection System with LoRa Communication. In Proceedings of the 2021 5th International Conference on Electronic Information Technology and Computer Engineering, Xiamen, China, 22–24 October 2021; pp. 282–286. [Google Scholar]

- Soleimanian, S.; Petrone, G.; Franco, F.; De Rosa, S.; Kołakowski, P. Application of metal rubber for semi-active vibration control of mechanical transmission systems. J. Vib. Control 2023, 30, 3319–3334. [Google Scholar] [CrossRef]

- Feng, K.; Ji, J.C.; Ni, Q.; Li, Y.; Mao, W.; Liu, L. A novel vibration-based prognostic scheme for gear health management in surface wear progression of the intelligent manufacturing system. Wear 2023, 522, 204697. [Google Scholar] [CrossRef]

- Li, W.; Zhu, C. Non-contact rotor vibration velocity sensor and its application to vibration control of a flexible rotor on active magnetic bearings. IEEE Sens. J. 2024, 21, 34151–34161. [Google Scholar] [CrossRef]

- García, Y.R.; Corres, J.M.; Goicoechea, J. Vibration detection using optical fiber sensors. J. Sens. 2010, 2010, 936487. [Google Scholar] [CrossRef]

- Güemes, A.; Fernandez-Lopez, A.; Pozo, A.R.; Sierra-Pérez, J. Structural health monitoring for advanced composite structures: A review. J. Compos. Sci. 2020, 4, 13. [Google Scholar] [CrossRef]

- Hong, X.; Liu, Y.; Lin, X.; Luo, Z.; He, Z. Nonlinear ultrasonic detection method for delamination damage of lined anti-corrosion pipes using PZT transducers. Appl.Sci. 2018, 8, 2240. [Google Scholar] [CrossRef]

- Zhao, N.; Huo, L.; Song, G. A nonlinear ultrasonic method for real-time bolt looseness monitoring using PZT transducer–enabled vibro-acoustic modulation. J. Intell. Mater. Syst. Struct. 2019, 31, 364–376. [Google Scholar] [CrossRef]

- Sahota, J.K.; Gupta, N.; Dhawan, D. Fiber Bragg grating sensors for monitoring of physical parameters: A comprehensive review. Opt. Eng. 2020, 59, 060901. [Google Scholar] [CrossRef]

- Hu, D.; Lv, S.; Guo, Y.; He, H.; Liu, J. A fiber Bragg grating force sensor with sensitization structure. IEEE Sens. J. 2021, 21, 3042–3048. [Google Scholar] [CrossRef]

- Flores-Bravo, J.A.; Madrigal, J.; Zubia, J.; Sales, S.; Villatoro, J. Coupled-core fiber Bragg gratings for low-cost sensing. Sci. Rep. 2022, 12, 1280. [Google Scholar] [CrossRef]

- Cai, L.; Wang, B.-Y.; Xiang, F.-C.; Liu, J.; Zhao, Y. A positioning-functionalized force sensor for two-dimensional planes based on a sparse fiber Bragg grating array. Measurement 2023, 216, 112933. [Google Scholar] [CrossRef]

- Yassin, M.H.; Farhat, M.H.; Soleimanpour, R.; Nahas, M. Fiber Bragg grating (FBG)-based sensors: A review of technology and recent applications in structural health monitoring (SHM) of civil engineering structures. Discov. Civ. Eng. 2024, 1, 151. [Google Scholar] [CrossRef]

- Calabrese, L.; Proverbio, E. A review on the applications of acoustic emission technique in the study of stress corrosion cracking. Corros. Mater. Degrad. 2021, 2, 1–30. [Google Scholar] [CrossRef]

- Hassani, S.; Dackermann, U. A systematic review of advanced sensor technologies for non-destructive testing and structural health monitoring. Sensors 2023, 23, 2204. [Google Scholar] [CrossRef] [PubMed]

- Vanniamparambil, P.A.; Guclu, U.; Kontsos, A. Identification of crack initiation in aluminum alloys using acoustic emission. Exp. Mech. 2015, 55, 837–850. [Google Scholar] [CrossRef]

- Yanbing, Z.; Li, Y. The acoustic emission testing technology on large crane structure damage. Eng. Appl. Sci. 2020, 5, 9–14. [Google Scholar] [CrossRef]

- Kietov, V.; Mandel, M.; Krüger, L. Combination of electrochemical noise and acoustic emission for analysis of the pitting corrosion behavior of an austenitic stainless cast steel. Adv. Eng. Mater. 2019, 21, 1800682. [Google Scholar] [CrossRef]

- Saeedifar, M.; Fotouhi, M.; Najafabadi, M.A.; Toudeshky, H.H.; Minak, G. Prediction of quasi-static delamination onset and growth in laminated composites by acoustic emission. Compos. Part. B Eng. 2016, 85, 113–122. [Google Scholar] [CrossRef]

- Saeedifar, M.; Najafabadi, M.A.; Mohammadi, K.; Fotouhi, M.; Toudeshky, H.H.; Mohammadi, R. Acoustic emission-based methodology to evaluate delamination crack growth under quasi-static and fatigue loading conditions. J. Nondestr. Eval. 2018, 37, 1. [Google Scholar]

- Predictive Maintenance of Cranes Red Sea Gateway Terminal—SenseGrow. Available online: https://www.sensegrow.com/blog/customer-stories/case-study-ai-driven-predictive-maintenance-cranes-rsgt (accessed on 2 May 2025).

- Chu, T.; Nguyen, T.; Yoo, H.; Wang, J. A review of vibration analysis and its applications. Heliyon 2024, 10, e26282. [Google Scholar] [CrossRef]

- Muir, C.; Swaminathan, B.; Fields, K.; Almansour, A.S.; Sevener, K.; Smith, C.; Presby, M.; Kiser, J.D.; Pollock, T.M.; Daly, S. A machine learning framework for damage mechanism identification from acoustic emissions in unidirectional SiC/SiC composites. NPJ Comput. Mater. 2021, 7, 146. [Google Scholar] [CrossRef]

- Šofer, M.; Cienciala, J.; Fusek, M.; Pavliček, P.; Moravec, R. Damage analysis of composite CFRP tubes using acoustic emission monitoring. Materials 2021, 14, 786. [Google Scholar] [CrossRef]

- Wang, T.; Han, Q.; Chu, F.; Feng, Z. Vibration based condition monitoring and fault diagnosis of wind turbine planetary gearbox: A review. Mech. Syst. Signal Process. 2019, 126, 662–685. [Google Scholar] [CrossRef]

| Technique | Detection Depth | Material Limitation | Strengths | Inspection Limitations |

|---|---|---|---|---|

| VI | Surface | None | Quick, low cost | Subjective, surface only |

| UT | Subsurface | All metals | Accurate, deep flaw detection | Needs coupling medium |

| RT | Deep | Most metals | High detail imagery | Radiation hazard, costly |

| MPT | Near surface | Ferromagnetic only | Quick for surface cracks | Limited to surface and magnetic materials |

| Metric | Piezoelectric | Capacitive | Strain Gauge |

|---|---|---|---|

| Sensitivity | High | Medium | Medium |

| Frequency Response | Excellent | Good | Fair |

| Environmental Adaptability | Moderate | Poor | Weak |

| Cost | Moderate | High | Low |

| Sensor Type | Sensing Principle | Frequency Range | Sensitivity | Power Source | IoT Compatibility | Application Notes |

|---|---|---|---|---|---|---|

| MEMS Accelerometer | Capacitive/ Piezoelectric | 0.1–5000 Hz | Low to Moderate | Low Power/ Battery | High | Compact, ideal for mobile crane arms |

| Piezoelectric Sensor | Piezoelectric effect | 1–10,000 Hz | High | Wired/Passive | Moderate | Good for high-frequency mechanical faults |

| Triboelectric Sensor | Contact electrification | 1–2000 Hz | Moderate to High | Self-powered | High | Energy harvesting with vibration data |

| Strain Gauge | Resistance change | Static–500 Hz | Moderate | Wired | Low | Best for structural stress monitoring |

| Sensor Type | Peak Frequency Range | Operating Bandwidth | Application Suitability | IoT Integration Capability |

|---|---|---|---|---|

| Narrowband Piezoelectric | 100–300 kHz | Narrow | Crack initiation, fatigue detection | Moderate (wired systems) |

| Broadband Piezoelectric | 100–1000 kHz | Wide | Corrosion, weld defect, delamination detection | High (supports edge analytics) |

| Wireless AE Node | 100–500 kHz | Configurable | Remote real-time SHM | Very High (BLE/Wi-Fi enabled) |

| Parameter | Traditional NDT | IoT-Based NDT | Reference |

|---|---|---|---|

| Inspection Mode | Periodic, manual | Continuous, remote | [73,114] |

| Coverage Scope | Localized, point-based | Wide area, sensor-networked | [104,121] |

| Detection Accuracy | Operator-dependent, variable | Algorithm-enhanced, consistent | [105,122] |

| Personnel Dependency | High (skilled inspectors needed) | Low (remote monitoring and AI-assisted) | [70,102] |

| Cost Efficiency | High labor and equipment costs | Higher setup cost, but reduced long-term O&M costs | [120,123] |

| Safety | Risky for inspectors (e.g., heights) | Safer (less need for physical access) | [72,113] |

| Real-Time Capability | No | Yes | [119,124] |

| Category | Current Limitation/Gap | Future Research Direction |

|---|---|---|

| Sensor Integration | Lack of harmonized multi-sensor data fusion | Develop unified platforms integrating AE, vibration, and thermal sensors |

| Real-Time Data Processing | High latency and poor edge processing in harsh marine environments | Use AI-driven edge computing and real-time analytics platforms |

| Energy Sustainability | Battery-dependent wireless sensor nodes for cranes | Implement self-powered sensors (e.g., piezoelectric, triboelectric) |

| Environmental Durability | Sensor degradation due to salt spray, humidity, and vibration | Develop corrosion-resistant, encapsulated sensor casings |

| Standardization | Absence of unified IoT protocols or NDT communication standards in port environments | Create standardized, ISO-aligned frameworks for IoT-based crane monitoring |

| Predictive Maintenance | Current systems reactive; minimal use of predictive analytics | Integrate machine learning for early damage prediction and remaining life estimation |

| UAV and Mobile Platforms | Limited use in automated crane inspections | Expand UAV-assisted visual/NDT inspection with AI-based defect detection |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tai, J.L.; Hameed Sultan, M.T.; Grzejda, R.; Shahar, F.S. Remote Non-Destructive Testing of Port Cranes: A Review of Vibration and Acoustic Sensors with IoT Integration. J. Mar. Sci. Eng. 2025, 13, 1338. https://doi.org/10.3390/jmse13071338

Tai JL, Hameed Sultan MT, Grzejda R, Shahar FS. Remote Non-Destructive Testing of Port Cranes: A Review of Vibration and Acoustic Sensors with IoT Integration. Journal of Marine Science and Engineering. 2025; 13(7):1338. https://doi.org/10.3390/jmse13071338

Chicago/Turabian StyleTai, Jan Lean, Mohamed Thariq Hameed Sultan, Rafał Grzejda, and Farah Syazwani Shahar. 2025. "Remote Non-Destructive Testing of Port Cranes: A Review of Vibration and Acoustic Sensors with IoT Integration" Journal of Marine Science and Engineering 13, no. 7: 1338. https://doi.org/10.3390/jmse13071338

APA StyleTai, J. L., Hameed Sultan, M. T., Grzejda, R., & Shahar, F. S. (2025). Remote Non-Destructive Testing of Port Cranes: A Review of Vibration and Acoustic Sensors with IoT Integration. Journal of Marine Science and Engineering, 13(7), 1338. https://doi.org/10.3390/jmse13071338